#boron nitride

Explore tagged Tumblr posts

Text

Hexagons of hexagonal boron nitride join up to form 2D insulator for next-gen electronic devices

A method that can grow a useful insulating material into exceptionally high-quality films that are just one atom thick and are suitable for industrial-scale production has been developed by an international team led by Xixiang Zhang from KAUST. The work is published in the journal Nature Communications. The material, called hexagonal boron nitride (hBN), is used in semiconductor devices and can also enhance the performance of other two-dimensional (2D) materials such as graphene and transition metal dichalcogenides (TMDs). Researchers can combine 2D materials to build tiny electronic components for quantum computing, electronic communications, and other applications. While most 2D materials conduct electricity, hBN is one of the few that is an insulator, making it an indispensable component within many of these devices.

Read more.

#Materials Science#Science#Boron nitride#2D materials#Electronics#Semiconductors#Materials synthesis#KAUST

16 notes

·

View notes

Text

New transistor’s superlative properties could have broad electronics applications

New Post has been published on https://thedigitalinsider.com/new-transistors-superlative-properties-could-have-broad-electronics-applications/

New transistor’s superlative properties could have broad electronics applications

In 2021, a team led by MIT physicists reported creating a new ultrathin ferroelectric material, or one where positive and negative charges separate into different layers. At the time they noted the material’s potential for applications in computer memory and much more. Now the same core team and colleagues — including two from the lab next door — have built a transistor with that material and shown that its properties are so useful that it could change the world of electronics.

Although the team’s results are based on a single transistor in the lab, “in several aspects its properties already meet or exceed industry standards” for the ferroelectric transistors produced today, says Pablo Jarillo-Herrero, the Cecil and Ida Green Professor of Physics, who led the work with professor of physics Raymond Ashoori. Both are also affiliated with the Materials Research Laboratory.

“In my lab we primarily do fundamental physics. This is one of the first, and perhaps most dramatic, examples of how very basic science has led to something that could have a major impact on applications,” Jarillo-Herrero says.

Says Ashoori, “When I think of my whole career in physics, this is the work that I think 10 to 20 years from now could change the world.”

Among the new transistor’s superlative properties:

It can switch between positive and negative charges — essentially the ones and zeros of digital information — at very high speeds, on nanosecond time scales. (A nanosecond is a billionth of a second.)

It is extremely tough. After 100 billion switches it still worked with no signs of degradation.

The material behind the magic is only billionths of a meter thick, one of the thinnest of its kind in the world. That, in turn, could allow for much denser computer memory storage. It could also lead to much more energy-efficient transistors because the voltage required for switching scales with material thickness. (Ultrathin equals ultralow voltages.)

The work is reported in a recent issue of Science. The co-first authors of the paper are Kenji Yasuda, now an assistant professor at Cornell University, and Evan Zalys-Geller, now at Atom Computing. Additional authors are Xirui Wang, an MIT graduate student in physics; Daniel Bennett and Efthimios Kaxiras of Harvard University; Suraj S. Cheema, an assistant professor in MIT’s Department of Electrical Engineering and Computer Science and an affiliate of the Research Laboratory of Electronics; and Kenji Watanabe and Takashi Taniguchi of the National Institute for Materials Science in Japan.

What they did

In a ferroelectric material, positive and negative charges spontaneously head to different sides, or poles. Upon the application of an external electric field, those charges switch sides, reversing the polarization. Switching the polarization can be used to encode digital information, and that information will be nonvolatile, or stable over time. It won’t change unless an electric field is applied. For a ferroelectric to have broad application to electronics, all of this needs to happen at room temperature.

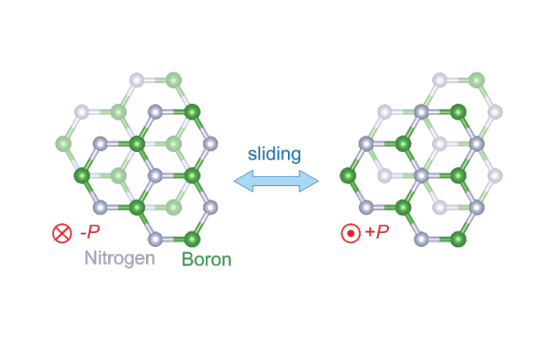

The new ferroelectric material reported in Science in 2021 is based on atomically thin sheets of boron nitride that are stacked parallel to each other, a configuration that doesn’t exist in nature. In bulk boron nitride, the individual layers of boron nitride are instead rotated by 180 degrees.

It turns out that when an electric field is applied to this parallel stacked configuration, one layer of the new boron nitride material slides over the other, slightly changing the positions of the boron and nitrogen atoms. For example, imagine that each of your hands is composed of only one layer of cells. The new phenomenon is akin to pressing your hands together then slightly shifting one above the other.

“So the miracle is that by sliding the two layers a few angstroms, you end up with radically different electronics,” says Ashoori. The diameter of an atom is about 1 angstrom.

Another miracle: “nothing wears out in the sliding,” Ashoori continues. That’s why the new transistor could be switched 100 billion times without degrading. Compare that to the memory in a flash drive made with conventional materials. “Each time you write and erase a flash memory, you get some degradation,” says Ashoori. “Over time, it wears out, which means that you have to use some very sophisticated methods for distributing where you’re reading and writing on the chip.” The new material could make those steps obsolete.

A collaborative effort

Yasuda, the co-first author of the current Science paper, applauds the collaborations involved in the work. Among them, “we [Jarillo-Herrero’s team] made the material and, together with Ray [Ashoori] and [co-first author] Evan [Zalys-Geller], we measured its characteristics in detail. That was very exciting.” Says Ashoori, “many of the techniques in my lab just naturally applied to work that was going on in the lab next door. It’s been a lot of fun.”

Ashoori notes that “there’s a lot of interesting physics behind this” that could be explored. For example, “if you think about the two layers sliding past each other, where does that sliding start?” In addition, says Yasuda, could the ferroelectricity be triggered with something other than electricity, like an optical pulse? And is there a fundamental limit to the amount of switches the material can make?

Challenges remain. For example, the current way of producing the new ferroelectrics is difficult and not conducive to mass manufacturing. “We made a single transistor as a demonstration. If people could grow these materials on the wafer scale, we could create many, many more,” says Yasuda. He notes that different groups are already working to that end.

Concludes Ashoori, “There are a few problems. But if you solve them, this material fits in so many ways into potential future electronics. It’s very exciting.”

This work was supported by the U.S. Army Research Office, the MIT/Microsystems Technology Laboratories Samsung Semiconductor Research Fund, the U.S. National Science Foundation, the Gordon and Betty Moore Foundation, the Ramon Areces Foundation, the Basic Energy Sciences program of the U.S. Department of Energy, the Japan Society for the Promotion of Science, and the Ministry of Education, Culture, Sports, Science and Technology (MEXT) of Japan.

#2-D#affiliate#applications#atom#atoms#author#billion#boron nitride#career#Cells#change#chip#collaborative#computer#computer memory#Computer Science#Computer science and technology#computing#education#electric field#Electrical Engineering&Computer Science (eecs)#electricity#Electronics#energy#engineering#flash#Foundation#Fundamental#Future#green

2 notes

·

View notes

Text

Boron Nitride Electroless Nickel || Advanced Surface Technologies

Our Boron Nitride Electroless Nickel (BNEN) plating service provides a composite deposition of Electroless Nickel and Boron Nitride particles. This advanced composite plating operation is ideal for parts that require both hardness and lubricity. The benefits of this deposit include the exceptionally low coefficient of friction, superior release, and excellent wear resistance. BNEN can be coated to thicknesses ranging from .00005-.002 inches. Unlike EN-PTFE, EN Boron Nitride deposits can be heat-treated to attain maximum hardness for severe wear applications. Our team at Advanced Surface Technologies can deposit the Electroless Nickel with Boron Nitride on various materials, including Aluminum, Copper, Brass, Magnesium, Stainless Steel, and Steel.

Contact Us today for the best nickel boron coating service. We are the only expert in plating in the USA

1 note

·

View note

Text

Properties and synthesis of hexagonal boron nitride

Hexagonal boron nitride is a kind of synthetic inorganic material with many excellent properties, which is more and more widely used in a variety of new technologies and products, improving the technical level of modern industry and promoting the development of new material industry to deeper and wider fields.

Properties of hexagonal boron nitride

(1) High heat resistance. Hexagonal boron nitride (h-BN) in 0.1Mpa nitrogen heated to more than 3000 ℃ will sublimate, at 1800 ℃ when the strength of the room temperature for twice, so has excellent thermal shock resistance, in 1500 ℃ air-cooled to room temperature dozens of times will not rupture.

(2) High thermal conductivity. The thermal conductivity of hexagonal boron nitride products is about 34W/m-k, which is similar to that of stainless steel, and the thermal conductivity is larger.

(3) Low expansion coefficient. The expansion coefficient of hexagonal boron nitride is (2.0~6.5)*10-6/℃, second only to quartz glass, coupled with its high coefficient of thermal conductivity, so have excellent thermal shock resistance.

(4) Excellent electrical insulation. Hexagonal boron nitride has good high-temperature insulation, high purity hexagonal boron nitride maximum volume resistivity up to 1016 ~ 1018Ω-m, even at 1000 ℃ high temperature, there is still 104 ~ 106Ω-m.

(5) Good corrosion resistance. Hexagonal boron nitride has good chemical stability and is not wetted by most molten metals, glass, and salt, so it has strong resistance to acid, alkali, molten metal, and glass erosion, and good chemical inertia.

(6) Low coefficient of friction. Hexagonal boron nitride has excellent lubricating properties, the coefficient of friction is 0.16, which does not increase at high temperatures and is more resistant to high temperatures and oxidation than molybdenum disulfide and graphite.

(7) Machinability. Hexagonal boron nitride is very easy to use conventional metal cutting technology for product finishing, with a turning accuracy of up to 0.05mm, so the hexagonal boron nitride blanks can be processed to get the complex shape of the product.

Synthesis of hexagonal boron nitride

There are various methods to prepare hexagonal boron nitride, such as the elemental boron method, boric acid method, borate method, boron halide method, and so on. The basic principle is that boron compounds (such as boric acid, elemental boron, boron halide, and other borates) and nitrogen-containing compounds (such as ammonia, urea, ammonia chloride, melamine, etc.) together with the heating reaction can be obtained after chemical treatment of hexagonal boron nitride of different purities.

0 notes

Text

Scientists have solved a decades-long puzzle and unveiled a near unbreakable substance that could rival diamond as the hardest material on Earth.

Researchers found that when carbon and nitrogen precursors were subjected to extreme heat and pressure, the resulting materials—known as carbon nitrides—were tougher than cubic boron nitride, the second hardest material after diamond.

0 notes

Text

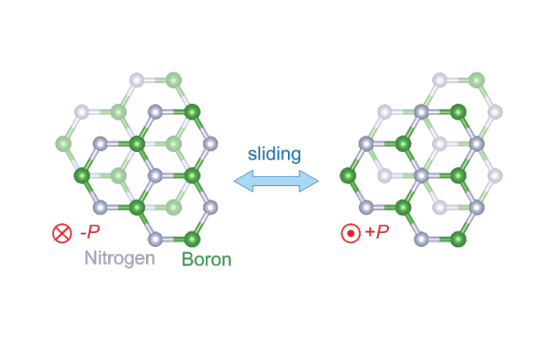

Table 7.3 contains a list of some advanced ceramic materials and they're properties, along with the properties of some metals in common use. (...) Table 7.3 shows that ceramics generally contain metals in relatively high positive oxidation states, combined with small nonmetals (e.g. O, N and C) with high negative oxidation states. (...) Actually, the ceramic compounds listed in table 7.3 possess substantial covalent bonding between the atoms.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#ceramics#carbon#oxygen#nitrogen#diamond#boron nitride#titanium carbide#silicon carbide#zirconium carbide#tungsten carbide#titanium nitride#alumina#aluminum oxide#beryllia#beryllium oxide#zirconia#zirconium oxide#aluminum nitride#titania#titanium dioxide#stainless steel#steel#aluminum

0 notes

Text

Cubic Boron Nitride (CBN) Wheels Market Industry Report | Analysis Report | 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Cubic Boron Nitride (CBN) Wheels Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Cubic Boron Nitride (CBN) Wheels Market Share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Cubic Boron Nitride (CBN) Wheels Market?

The Cubic Boron Nitride (CBN) wheels market is expected to grow at a CAGR of 5.3% during the forecast period of 2024 to 2032.

What are Cubic Boron Nitride (CBN) Wheels?

Cubic boron nitride (CBN) wheels are advanced grinding tools made from cubic boron nitride, one of the hardest known materials, just behind diamond. These wheels are specifically designed for precision grinding and finishing of tough materials such as high-speed steel, tool steels, and superalloys. Renowned for their exceptional hardness, thermal stability, and resistance to wear, CBN wheels excel in high-speed machining and offer extended tool life. Their superior properties facilitate efficient material removal and high-quality surface finishes, making them essential in industries like aerospace, automotive, and manufacturing where precision and durability are paramount.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1932

What are the growth prospects and trends in the Cubic Boron Nitride (CBN) Wheels industry?

The cubic boron nitride (CBN) wheels market growth is driven by various factors and trends. The market for Cubic Boron Nitride (CBN) wheels is expanding due to the growing need for high-performance grinding tools in sectors such as aerospace, automotive, and manufacturing. CBN wheels are highly sought after for their exceptional hardness, thermal stability, and long-lasting durability, making them ideal for precision grinding of hard materials like tool steels and superalloys. As industries demand greater efficiency, extended tool life, and superior surface finishes, the use of CBN wheels is increasing. The market is also benefiting from technological advancements and the broader application of CBN wheels in high-speed machining, driving investment in these advanced tools to meet rigorous production and quality demands. Hence, all these factors contribute to cubic boron nitride (CBN) wheels market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Resin CBN Wheels

Metal CBN Wheels

Ceramic CBN Wheels

Electroplated CBN Wheels

By Application:

Automotive Parts

Metal Grinding

Industrial

Others

Market Segmentation By Region:

North America

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

3M Company

Saint-Gobain Abrasives Inc.

ILJIN Diamond Co., Ltd.

Noritake Co., Ltd.

Asahi Diamond Industrial Co., Ltd.

Carborundum Universal Limited

Ehwa Diamond Industrial Co., Ltd.

Diametal AG

Tokyo Diamond Tools Mfg. Co., Ltd.

Zhengzhou Hongtuo Superabrasive Products Co., Ltd.

Sandvik AB

Engis Corporation

Karnasch Professional Tools GmbH

Nanjing Sanchao Advanced Materials Co., Ltd.

SuperAbrasives, Inc.

View Full Report: https://www.reportsandinsights.com/report/Cubic Boron Nitride (CBN) Wheels-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Cubic Boron Nitride (CBN) Wheels Market share#Cubic Boron Nitride (CBN) Wheels Market size#Cubic Boron Nitride (CBN) Wheels Market trends

0 notes

Text

Hexagonal Boron Nitride Powder Market Size, Share, Trends, Opportunities, Key Drivers and Growth Prospectus

"Global Hexagonal Boron Nitride Powder Market – Industry Trends and Forecast to 2029

Global Hexagonal Boron Nitride Powder Market, By Application (Coatings/Mold Release/Spray, Electrical Insulation, Composites, Industrial Lubricants, Thermal Spray, Personal Care, Others), Type (Tubes, Rods, Powder, Gaskets, Plates and Sheets, Others), Classification (Premium Grade, Standard Grade, Custom Grade), End-User (Aerospace, Automotive, Semiconductors and Electronics, Others) – Industry Trends and Forecast to 2029

Access Full 350 Pages PDF Report @

**Segments**

- **Application** - Ceramics - Cosmetics - Lubricants - Thermal Spray Coatings - Paints - Others

- **Grade** - Superior Grade Hexagonal Boron Nitride Powder - Standard Grade Hexagonal Boron Nitride Powder

- **End-Use Industry** - Electrical Insulation - Composites - Personal Care - Lubrication Industrial - Paints & Coatings - Thermal Spray - Others

Hexagonal Boron Nitride (hBN) powder is segmented based on application, grade, and end-use industry. In terms of applications, hBN powder finds uses in ceramics, cosmetics, lubricants, thermal spray coatings, paints, and other industrial applications. The grade segment includes superior grade hBN powder and standard grade hBN powder, each catering to specific quality requirements of end users. Furthermore, the end-use industry segment covers electrical insulation, composites, personal care, industrial lubrication, paints and coatings, thermal spray applications, and other sectors that leverage the unique properties of hBN powder for various purposes.

**Market Players**

- 3M - Saint-Gobain - Momentive Performance Materials Inc. - ZYP Coatings Inc. - Showa Denko K.K. - Denka Company Limited - Henze BNP AG - H.C. Stark GmbH - UK Abrasives Inc. - 3A Composites

Key market players in the hexagonal boron nitride powder market are actively involved in research and development activities to enhance product quality and expand their product portfolios. Companies such as 3M, Saint-Gobain, Momentive Performance Materials Inc., ZYP Coatings Inc., and Showa Denko K.K. are prominent players driving innovation in the sector. Other players like Denka Company Limited, Henze BNP AG, H.C. Stark GmbHThe global hexagonal boron nitride (hBN) powder market is witnessing significant growth, driven by the diverse applications and rising demand across various industries. The versatility of hBN powder in applications such as ceramics, cosmetics, lubricants, thermal spray coatings, and paints among others, has propelled its adoption in different sectors. The ceramics industry, in particular, is a major consumer of hBN powder due to its high thermal conductivity, lubricating properties, and chemical inertness, which enhance the performance of ceramic products. Additionally, the use of hBN powder in cosmetics for its light-diffusing and texturizing properties has gained traction in the personal care industry.

In terms of grades, the market offers superior grade and standard grade hBN powder to cater to the specific quality requirements of end-users. Superior grade hBN powder is characterized by its high purity and exceptional thermal conductivity, making it suitable for advanced applications that demand top-notch performance. On the other hand, standard grade hBN powder provides a cost-effective solution for applications where high purity is not a critical factor. This segmentation based on grade allows manufacturers to meet the diverse needs of customers across different industries, further driving market growth.

The end-use industry segment of the hBN powder market encompasses a wide range of sectors such as electrical insulation, composites, personal care, industrial lubrication, paints and coatings, and thermal spray applications, among others. The electrical insulation industry utilizes hBN powder for its excellent dielectric properties, thermal stability, and chemical resistance, making it an ideal material for insulating components in electrical systems. In composites, hBN powder enhances the mechanical properties and thermal conductivity of composite materials, leading to improved performance in various applications.

Market players such as 3M, Saint-Gobain, Momentive Performance Materials Inc., ZYP Coatings Inc., and Showa Denko K.K. are at the forefront of driving innovation in the hBN powder market. These key players are investing heavily in research and development**Global Hexagonal Boron Nitride Powder Market**

- **Application** - Coatings/Mold Release/Spray - Electrical Insulation - Composites - Industrial Lubricants - Thermal Spray - Personal Care - Others

- **Type** - Tubes - Rods - Powder - Gaskets - Plates and Sheets - Others

- **Classification** - Premium Grade - Standard Grade - Custom Grade

- **End-User** - Aerospace - Automotive - Semiconductors and Electronics - Others

The global hexagonal boron nitride powder market is witnessing substantial growth and is driven by a combination of factors, including the diverse applications of hBN powder and the increasing demand across various industries. The versatility of hBN powder in applications such as coatings, electrical insulation, composites, industrial lubricants, thermal spray, personal care, and other sectors has fueled its adoption in different industrial segments. Among these, the ceramics industry stands out as a major consumer of hBN powder due to its exceptional properties such as high thermal conductivity, lubrication, and chemical inertness, which significantly enhance the performance of ceramic products. Additionally, the personal care industry has embraced hBN powder for its light-diffusing and texturizing characteristics, contributing to the market growth.

Within the market, the segmentation based on grade is crucial in meeting

Highlights of TOC:

Chapter 1: Market overview

Chapter 2: Global Hexagonal Boron Nitride Powder Market

Chapter 3: Regional analysis of the Global Hexagonal Boron Nitride Powder Market industry

Chapter 4: Hexagonal Boron Nitride Powder Market segmentation based on types and applications

Chapter 5: Revenue analysis based on types and applications

Chapter 6: Market share

Chapter 7: Competitive Landscape

Chapter 8: Drivers, Restraints, Challenges, and Opportunities

Chapter 9: Gross Margin and Price Analysis

Key takeaways from the Hexagonal Boron Nitride Powder Market report:

Detailed considerate of Hexagonal Boron Nitride Powder Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the Hexagonal Boron Nitride Powder Market-leading players.

Hexagonal Boron Nitride Powder Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of Hexagonal Boron Nitride Powder Market for forthcoming years.

Browse Trending Reports:

Smart Agriculture Market Instant Noodles Market Ai In Fashion Market Infantile Hemangioma Market Waste To Diesel Market Contactless Payment Market Necrotizing Enterocolitis Treatment Market Metalized Flexible Packaging Market Customer Analytics Market Plastic Bags Sacks Market Sports Energy Drinks Market Vacuum Packaging Market Pneumococcal Vaccine Market Micro And Nano Plc Market Wireless Medical Device Connectivity Market Herbal Beverages Market Plastic Surgery Devices Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Spherical Boron Nitride (BN), The Top 8 Largest Companies in World Ranked by Revenue in 2023 (2023)

Spherical Boron Nitride (BN) Market Summary

Spherical boron nitride particles are polycrystalline spheres composed of micron-sized single crystals of boron nitride. They have good fluidity and can improve the anisotropic performance of thermal conductivity. Spherical boron nitride particles have a small surface area, which allows a higher amount of boron nitride to be added to the polymer, thereby obtaining higher thermal conductivity performance.

According to the new market research report "Global Spherical Boron Nitride (BN) Market Report 2024-2030", published by QYResearch, the global Spherical Boron Nitride (BN) market size is projected to grow from USD 7.2 million in 2023 to USD 11.7 million by 2030, at a CAGR of 7.55% during the forecast period.

Figure. Global Spherical Boron Nitride (BN) Market Size (US$ Million), 2019-2030

Figure. Global Spherical Boron Nitride (BN) Top 8 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

According to QYResearch Top Players Research Center, the global key manufacturers of Spherical Boron Nitride (BN) include Saint-Gobain, 3M, xtra GmbH, Bestry Performance Materials, Suzhou Ginet New Material, etc. In 2023, the global top four players had a share approximately 75.0% in terms of revenue.

Figure. Spherical Boron Nitride (BN), Global Market Size, Split by Product Segment

In terms of product type, 50-100μm is the largest segment, hold a share of 48%,

Figure. Spherical Boron Nitride (BN), Global Market Size, Split by Application Segment

In terms of product application, Thermal Interface Materials is the largest application, hold a share of 83%,

Figure. Spherical Boron Nitride (BN), Global Market Size, Split by Region (Production)

Figure. Spherical Boron Nitride (BN), Global Market Size, Split by Region

Market Drivers:

1. Growth in applications in the field of electronic devices: With the rapid development of microelectronics technology, the demand for high-performance heat dissipation materials is increasing. Spherical boron nitride has become an ideal material for semiconductor packaging, integrated circuit heat dissipation and other fields due to its high thermal conductivity, electrical insulation and chemical stability.

2. Technological innovation and cost reduction: Advances in production technology, such as the application of advanced methods such as chemical vapor deposition (CVD) and plasma enhanced chemical vapor deposition (PECVD), have improved the preparation efficiency and product quality of spherical boron nitride, while also gradually reducing production costs, allowing this high-performance material to be more widely used in commercial products.

3. Increased demand for advanced composite materials: In industries such as aerospace and automotive manufacturing, lightweight and high strength are important criteria for material selection. Spherical boron nitride is added as a reinforcing phase to a resin, ceramic or metal matrix, which can significantly improve the thermal stability and mechanical properties of the composite material while maintaining a low density, meeting the needs of these industries for high-performance composite materials.

4. Advances in energy storage and conversion technology: In lithium-ion batteries, supercapacitors and other energy storage devices, spherical boron nitride can be used as a thermally conductive filler or isolation layer to improve the thermal management of the battery and increase its safety and cycle life.

Restraint:

Production technology barriers: The preparation technology of high-quality spherical boron nitride is relatively complex, including chemical vapor deposition (CVD), combustion synthesis, etc. These technologies have high requirements for equipment and require precise control of reaction conditions. Technical bottlenecks restrict new entrants and also increase the difficulty of upgrading and expanding production for existing companies.

About The Authors

Jiashi Dong

Lead Author

Email: [email protected]

QYResearch Nanning Branch Analyst, as a member of the QYResearch Semiconductor Equipment and Materials Department, his main research areas include automotive electronics, semiconductor equipment, materials and thermally conductive powders. Some subdivided research topics include automotive diodes, automotive inductors, automotive lidar, radio frequency power supplies, plastic sealing machines, high-purity non-ferrous metals, battery materials, precursors, electroplating equipment, thermal conductive ball aluminum, semiconductor chemical plating solutions, semiconductor coating devices, etc. At the same time, he is also engaged in the development of market segment reports and participates in the writing of customized projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

The global hexagonal boron nitride (HBN) market size reached US$ 801.8 Million in 2023. Looking forward, IMARC Group expects the market to reach US$ 1,115.2 Million by 2032, exhibiting a growth rate (CAGR) of 3.62% during 2024-2032.

#Hexagonal Boron Nitride HBN Market#Hexagonal Boron Nitride HBN#Hexagonal Boron Nitride#Hexagonal Boron Nitride Market#Hexagonal Boron

0 notes

Text

Powering the future—ultrathin films enhance electrical conductivity in flexible electronics

What if your electronic devices could adapt on the fly to temperature, pressure, or impact? Thanks to a new breakthrough in downsizing quantum materials, that idea is becoming a reality. In an article published this month in Applied Physics Express, a multi-institutional research team led by Osaka University announced that they have successfully synthesized an ultrathin vanadium dioxide film on a flexible substrate, in a way that preserves the film's electrical properties. Vanadium dioxide is well known in the scientific community for its ability to transition between conductor and insulator phases at nearly room temperature. This phase transition underpins smart and adaptable electronics that can adjust to their environment in real time. But there is a limit to how thin vanadium dioxide films can be, because making a material too small affects its ability to conduct or insulate electricity.

Read more.

#Materials Science#Science#Thin films#Electrical conductivity#Electronics#Flexible electronics#Vanadium dioxide#Vanadium#Oxides#2D materials#Boron nitride#Osaka University

10 notes

·

View notes

Text

How can electrons can split into fractions of themselves?

New Post has been published on https://thedigitalinsider.com/how-can-electrons-can-split-into-fractions-of-themselves/

How can electrons can split into fractions of themselves?

MIT physicists have taken a key step toward solving the puzzle of what leads electrons to split into fractions of themselves. Their solution sheds light on the conditions that give rise to exotic electronic states in graphene and other two-dimensional systems.

The new work is an effort to make sense of a discovery that was reported earlier this year by a different group of physicists at MIT, led by Assistant Professor Long Ju. Ju’s team found that electrons appear to exhibit “fractional charge” in pentalayer graphene — a configuration of five graphene layers that are stacked atop a similarly structured sheet of boron nitride.

Ju discovered that when he sent an electric current through the pentalayer structure, the electrons seemed to pass through as fractions of their total charge, even in the absence of a magnetic field. Scientists had already shown that electrons can split into fractions under a very strong magnetic field, in what is known as the fractional quantum Hall effect. Ju’s work was the first to find that this effect was possible in graphene without a magnetic field — which until recently was not expected to exhibit such an effect.

The phenemonon was coined the “fractional quantum anomalous Hall effect,” and theorists have been keen to find an explanation for how fractional charge can emerge from pentalayer graphene.

The new study, led by MIT professor of physics Senthil Todadri, provides a crucial piece of the answer. Through calculations of quantum mechanical interactions, he and his colleagues show that the electrons form a sort of crystal structure, the properties of which are ideal for fractions of electrons to emerge.

“This is a completely new mechanism, meaning in the decades-long history, people have never had a system go toward these kinds of fractional electron phenomena,” Todadri says. “It’s really exciting because it makes possible all kinds of new experiments that previously one could only dream about.”

The team’s study appeared last week in the journal Physical Review Letters. Two other research teams — one from Johns Hopkins University, and the other from Harvard University, the University of California at Berkeley, and Lawrence Berkeley National Laboratory — have each published similar results in the same issue. The MIT team includes Zhihuan Dong PhD ’24 and former postdoc Adarsh Patri.

“Fractional phenomena”

In 2018, MIT professor of physics Pablo Jarillo-Herrero and his colleagues were the first to observe that new electronic behavior could emerge from stacking and twisting two sheets of graphene. Each layer of graphene is as thin as a single atom and structured in a chicken-wire lattice of hexagonal carbon atoms. By stacking two sheets at a very specific angle to each other, he found that the resulting interference, or moiré pattern, induced unexpected phenomena such as both superconducting and insulating properties in the same material. This “magic-angle graphene,” as it was soon coined, ignited a new field known as twistronics, the study of electronic behavior in twisted, two-dimensional materials.

“Shortly after his experiments, we realized these moiré systems would be ideal platforms in general to find the kinds of conditions that enable these fractional electron phases to emerge,” says Todadri, who collaborated with Jarillo-Herrero on a study that same year to show that, in theory, such twisted systems could exhibit fractional charge without a magnetic field. “We were advocating these as the best systems to look for these kinds of fractional phenomena,” he says.

Then, in September of 2023, Todadri hopped on a Zoom call with Ju, who was familiar with Todari’s theoretical work and had kept in touch with him through Ju’s own experimental work.

“He called me on a Saturday and showed me the data in which he saw these [electron] fractions in pentalayer graphene,” Todadri recalls. “And that was a big surprise because it didn’t play out the way we thought.”

In his 2018 paper, Todadri predicted that fractional charge should emerge from a precursor phase characterized by a particular twisting of the electron wavefunction. Broadly speaking, he theorized that an electron’s quantum properties should have a certain twisting, or degree to which it can be manipulated without changing its inherent structure. This winding, he predicted, should increase with the number of graphene layers added to a given moiré structure.

“For pentalayer graphene, we thought the wavefunction would wind around five times, and that would be a precursor for electron fractions,” Todadri says. “But he did his experiments and discovered that it does wind around, but only once. That then raised this big question: How should we think about whatever we are seeing?”

Extraordinary crystal

In the team’s new study, Todadri went back to work out how electron fractions could emerge from pentalayer graphene if not through the path he initially predicted. The physicists looked through their original hypothesis and realized they may have missed a key ingredient.

“The standard strategy in the field when figuring out what’s happening in any electronic system is to treat electrons as independent actors, and from that, figure out their topology, or winding,” Todadri explains. “But from Long’s experiments, we knew this approximation must be incorrect.”

While in most materials, electrons have plenty of space to repel each other and zing about as independent agents, the particles are much more confined in two-dimensional structures such as pentalayer graphene. In such tight quarters, the team realized that electrons should also be forced to interact, behaving according to their quantum correlations in addition to their natural repulsion. When the physicists added interelectron interactions to their theory, they found it correctly predicted the winding that Ju observed for pentalayer graphene.

Once they had a theoretical prediction that matched with observations, the team could work from this prediction to identify a mechanism by which pentalayer graphene gave rise to fractional charge.

They found that the moiré arrangement of pentalayer graphene, in which each lattice-like layer of carbon atoms is arranged atop the other and on top of the boron-nitride, induces a weak electrical potential. When electrons pass through this potential, they form a sort of crystal, or a periodic formation, that confines the electrons and forces them to interact through their quantum correlations. This electron tug-of-war creates a sort of cloud of possible physical states for each electron, which interacts with every other electron cloud in the crystal, in a wavefunction, or a pattern of quantum correlations, that gives the winding that should set the stage for electrons to split into fractions of themselves.

“This crystal has a whole set of unusual properties that are different from ordinary crystals, and leads to many fascinating questions for future research,” Todadri says. “For the short term, this mechanism provides the theoretical foundation for understanding the observations of fractions of electrons in pentalayer graphene and for predicting other systems with similar physics.”

This work was supported, in part, by the National Science Foundation and the Simons Foundation.

#2023#agents#arrangement#atom#atoms#Behavior#boron nitride#california#carbon#carbon atoms#Carbon materials#chicken#Cloud#crystal#crystal structure#crystals#data#electron#electronic#electrons#experimental#explanation#form#Foundation#Future#graphene#harvard#History#how#interference

0 notes

Text

Hexagonal Boron Nitride Market Size, Share, Forecast-2030

0 notes

Text

Hexagonal boron nitride (h-BN) Overview

Hexagonal boron nitride (h-BN) is a kind of synthetic inorganic material with many excellent properties, which is more and more widely used in a variety of new technologies and products, improving the technical level of modern industry and promoting the development of new material industry to deeper and wider fields.

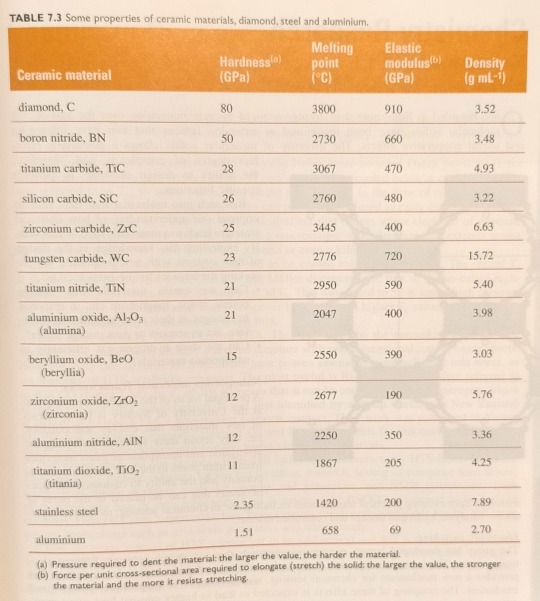

Definition of hexagonal boron nitride

Hexagonal boron nitride (h-BN) is a hexagonal network of layer structure crystals composed of nitrogen and boron atoms, and it is the only boron nitride physical phase structure that exists in all the physical phases in nature. Its appearance is a white powder with a soft texture, which is loose, smooth, and easy to absorb moisture, and it has a layer structure similar to that of graphene, and thus it is also known as "white graphite".

Structure of hexagonal boron nitride

From the molecular structure diagram, hexagonal boron nitride belongs to the hexagonal crystal system and has the same hexagonal crystal structure as graphene, consisting of multiple layers stacked together, with the different layers connected B-N-B by van der Waals forces, with lattice constants a=0.2506±0.0002 nm and c=0.667±0.0004 nm, and a density ρ=2.25 g/cm³.

Hexagonal boron nitride is very stable in air, has a wide band gap (5.1 eV), can withstand high temperatures up to 2270°C, and sublimes only at about 3000°C. Hexagonal boron nitride also has good insulation, thermal conductivity, and chemical stability, low thermal expansion/shrinkage, and is non-reactive with both weak acids and strong bases at room temperature.

0 notes

Text

HBN tube by Edgetech Industries, advanced ceramics division. Other Hot-pressed boron nitride parts can be customized, Pyrolytic Boron Nitride (PBN) Parts are also available on request.

0 notes