#biomanufacturing market

Explore tagged Tumblr posts

Text

Advanced Biomanufacturing Solutions: How Biofabrication is Meeting the Need for Complex Biologics in the Biotechnology Industry

Biofabrication Market: A Growing Industry with Promising Future

Biofabrication is an emerging technological field that focuses on manufacturing structures for tissue engineering and regenerative medicine. This field has gained significant attention in recent years due to its potential to revolutionize the healthcare industry. In this article, we will explore the biofabrication market, its size, growth projections, and the key factors driving its growth.

Market Size and Growth Projections

The biofabrication market is expected to grow significantly in the coming years. According to a report by Intent Market Research, the global biofabrication market size is anticipated to reach USD 80 Billion by the end of 2036, growing at a CAGR of 10% during the forecast period, i.e., 2024-2036. Another report estimates the market size to be USD 22.76 Billion in 2023 and predicts it to reach USD 48.27 Billion by 2031, with a CAGR of 10.2% from 2024 to 2031.

Key Factors Driving Growth

Several factors are driving the growth of the biofabrication market. One of the primary factors is the increasing demand for biologics and biosimilars. The development of biologics accounts for around 40% of all pharmaceutical R&D spending, making it essential for advancing healthcare. Additionally, biomanufacturing accelerates scientific research, boosts economic growth, and provides jobs, making it a vital industry for the future.

Another key factor driving growth is the advancements in biofabrication techniques. Recent advancements in volumetric bioprinting, scaffold-free bioassembly, and hybrid biofabrication strategies have improved the scale, rate, and intricacy at which tissues can be fabricated. These advancements have the potential to recapitulate the structure and complexity of native tissues, making them suitable for various applications such as biomimetically engineered models for drug discovery, cosmetics testing, tissue regeneration, and medical devices.

Regional Analysis

The biofabrication market is expected to grow significantly in various regions. North America is expected to hold the largest share of 36% during the forecast period due to the robust presence of large biopharmaceutical businesses and the improved infrastructure in biological research. The Asia-Pacific region is expected to witness the fastest growth due to the rapid adoption of advanced technologies and the high prevalence of chronic diseases.

Competitive Landscape

The biofabrication market is highly competitive, with several key players operating in the market. Some of the major players include Applikon Biotechnology BV, bbi-biotech GmbH, Danaher Corporation, Eppendorf AG, Esco Group of Companies, GEA Group Aktiengesellschaft, Meissner Filtration Products, Inc., Merck KGaA, PBS Biotech, Inc., Pierre Guérin, Sartorius AG, Shanghai Bailun Biotechnology Co. Ltd., Solaris Biotechnology Srl., Thermo Fisher Scientific Inc., and ZETA GmbH.

Conclusion

In conclusion, the biofabrication market is expected to grow significantly in the coming years due to the increasing demand for biologics and biosimilars, advancements in biofabrication techniques, and the growing demand for advanced biomanufacturing solutions. The market is expected to be driven by key players operating in the market, and regional growth is expected to vary. As the industry continues to evolve, it is essential to stay updated on the latest advancements and trends to capitalize on the growth opportunities in the biofabrication market.

#Biofabrication#biomanufacturing#biologics#biosimilars#regenerative medicine#tissue engineering#biomimetic engineering#biotechnology#biopharmaceutical industry#advanced biomanufacturing solutions#volumetric bioprinting#scaffold-free bioassembly#hybrid biofabrication strategies#biomanufacturing techniques#biomanufacturing market

0 notes

Text

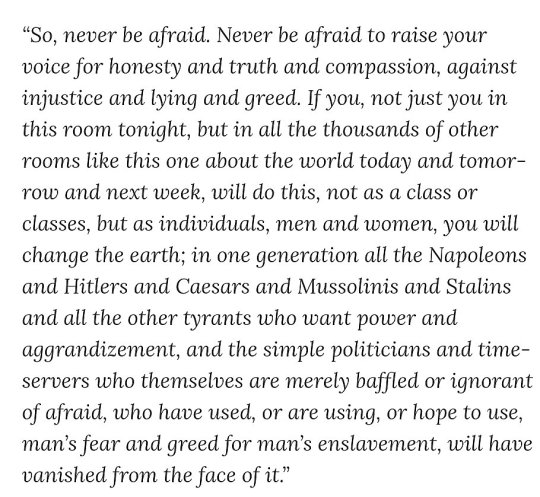

William Faulkner, "Never be afraid" :: [(From a speech delivered May 28, 1951 at Fulton Chapel, University of Mississippi)]

* * * *

LETTERS FROM AN AMERICAN

September 25, 2024

Heather Cox Richardson

Sep 26, 2024

In 2004 a senior advisor to President George W. Bush famously told journalist Ron Suskind that people like Suskind lived in “the reality-based community.” They believed people could find solutions to problems through careful study of discernible reality. But, the aide continued, Suskind’s worldview was obsolete. “That’s not the way the world really works anymore,” the aide said. “We are an empire now, and when we act, we create our own reality. And while you’re studying that reality— judiciously, as you will—we’ll act again, creating other new realities, which you can study too, and that’s how things will sort out. We’re history’s actors…and you, all of you, will be left to just study what we do.”

We appear to be in a moment when the reality-based community is challenging the ability of the MAGA Republicans to create their own reality.

Central to the worldview of MAGA Republicans is that Democrats are socialists who have destroyed the American economy. Trump calls Harris a “radical-left. Marxist, communist, fascist” and insists the economy is failing.

In Pittsburgh, Pennsylvania, today, Harris laid out her three-pillar plan for an “opportunity economy.” She explained that she would lower costs by cutting taxes for the middle class, cutting the red tape that stops housing construction, take on corporate landlords who are hiking rental prices, work with builders and developers to construct 3 million new homes and rentals, and help first-time homebuyers with $25,000 down payment assistance. She also promised to enact a federal ban on corporate price gouging on groceries and to cap prescription drug prices by negotiating with pharmaceutical companies.

Harris said she plans to invest in innovation by raising the deduction for startup businesses from its current $5,000 to $50,000 and providing low- or no-interest loans to small businesses that want to expand. Her goal is to open the way for 25 million new small businesses in her first four years, noting that small businesses create nearly 50% of private sector jobs in the U.S.

Harris plans to create manufacturing jobs of the future by investing in biomanufacturing and aerospace, remaining “dominant in AI, quantum computing, blockchain, and other emerging technologies, and expand[ing] our lead in clean energy innovation and manufacturing.” She vowed to see that the next generation of breakthroughs—“from advanced batteries to geothermal to advanced nuclear—are not just invented, but built here in America by American workers.” Investing in these industries means strengthening factory towns, retooling existing factories, hiring locally, and working with unions. She vowed to make jobs available for skilled workers without college degrees and to cut red tape to reform permitting for innovation.

“I am a capitalist,” she said. “I believe in free and fair markets. I believe in consistent and transparent rules of the road to create a stable business environment. And I know the power of American innovation.” She said she would be pragmatic in her approach to the economy, seeking practical solutions to problems and taking good ideas from wherever they come.

“Kamala Harris, Reagan Democrat!” conservative pundit Bill Kristol posted on social media after her speech.

For his part, Trump has promised an across-the-board tariff of 10% to 20% that billionaire Mark Cuban on the Fox News Channel called “insane” and Quin Hillyer of the Washington Examiner warned “would almost certainly cause immense price hikes domestically, goad other countries into retaliating, and perhaps set off an international trade war” that could “wreck the economy.” Cuban then told Jake Tapper of CNN that Trump’s promise to impose 10% price controls on credit card interest rates and price caps is “Socialism 101.”

Yesterday, more than 400 economists and high-ranking U.S. policymakers endorsed Harris, and today, the members of former South Carolina governor Nikki Haley’s presidential leadership teams in Michigan, Iowa, and Vermont announced they would be supporting Harris, in part because of Trump’s economic policies.

While Trump insisted yet again today that “the economy is doing really, really badly,” the stock market closed at a record high today for the fourth day in a row.

In other economic news, for nine years, Trump has said he will find a cheaper and better way to provide healthcare to Americans than the Affordable Care Act, although on September 10 he admitted he has only the “concepts of a plan.” Today the Treasury Department released statistics showing that 4.2 million small business owners have coverage through the ACA. Losing that protection would impact 618,590 small business owners in Florida, 450,010 in California, 423,790 in Texas, and 168,070 in Georgia.

Trump has made a claim that crime has risen dramatically under President Joe Biden and Vice President Kamala Harris central to his campaign rhetoric. The opposite is true. Two days ago, on September 23, the Federal Bureau of Investigation released its official report on crime statistics from 2023 compared with 2022. Those statistics showed that murder and non-negligent manslaughter fell by 11.6%. Rape fell by 9.4%. Aggravated assault fell by 2.8%. Robbery fell by 0.3%. Hate crimes fell by 0.6%.

Central to the worldview of MAGA Republicans is that immigration weakens a nation and that immigrants increase crime and disease. First Republican vice presidential nominee Ohio senator J.D. Vance and then Trump himself repeatedly advanced the lie that Haitian immigrants in Springfield, Ohio, are eating their neighbors’ pets and bringing disease.

Clergy members from multiple faiths have asked politicians to stop their lies about Haitian immigrants, and today the leader of Haitian Bridge Alliance, a nonprofit organization that represents the Haitian community, filed a charges against Trump and Vance for disrupting public services, making false alarms, telecommunications harassment, and aggravated menacing and complicity.

Immediately, Representative Clay Higgins (R-LA), who in the past supported Ku Klux Klan leader David Duke and filmed a selfie inside a gas chamber at Auschwitz, posted on social media: “Lol. These Haitians are wild. Eating pets, vudu, nastiest country in the western hemisphere, cults, slapstick gangsters…but damned if they don’t feel all sophisticated now, filing charges against our President and VP. All these thugs better get their mind right and their *ss out of our country before January 20th.”

After an outcry, Higgins took the post down. According to House speaker and fellow Louisiana Republican Mike Johnson, who called Higgins a “very principled man,” Higgins took it down after he “prayed about it.” Johnson seemed unconcerned about his colleague’s racism, saying, “we believe in redemption around here.”

But in a statement, House minority leader Hakeem Jeffries (D-NY) called Higgins’s statement “vile, racist and beneath the dignity of the United States House of Representatives. He must be held accountable for dishonorable conduct that is unbecoming of a Member of Congress. Clay Higgins is an election-denying, conspiracy-peddling racial arsonist who is a disgrace to the People’s House. This is who they have become. Republicans are the party of Donald Trump, Mark Robinson, Marjorie Taylor Greene, Clay Higgins and Project 2025. The extreme MAGA Republicans in the House are unfit to govern.”

On Monday, Dan Gooding of Newsweek reported that although Trump said on September 18 he would go to Springfield, he will not. Republican Ohio governor Mike DeWine had warned that the local community would not welcome a visit from the former president.

Republican politicians and candidates, including Trump, embraced North Carolina gubernatorial candidate and current lieutenant governor Mark Robinson, who trumpeted the extremists’ MAGA narrative. The September 19 revelation by CNN reporters Andrew Kaczynski and Em Steck that Robinson had boasted on a pornography website that he considers himself a “black NAZI!”, would like to reinstate slavery, and would like to own some people himself, and shared the sexual kinks in which he engaged with his wife’s sister prompted most of his campaign staff to resign.

Andrew Egger of The Bulwark reported today that on a different online forum, Robinson called for a political assassination as well as making racist attacks on entertainer Oprah Winfrey and former president Barack Obama. Robinson has called all the information released about him “false smears” and has said “[n]ow is not the time for intra-party squabbling and nonsense,” but declined help tracking down those he claims falsified his online comments. Today, multiple media outlets reported that top staff in Robinson’s government office are stepping down.

Reality hit hard this week in Texas, too, where U.S. Bankruptcy Judge Christopher Lopez yesterday approved the auctioning off of conspiracy theorist Alex Jones’s media business, the aptly-named InfoWars. Jones insisted that the 2012 Sandy Hook Elementary School shooting was a “hoax” designed to whip up support for gun restrictions, and that the grieving parents were played by “crisis actors.” Juries found Jones guilty of defaming the families of the murdered children and causing them emotional distress.

The auction of his property will enable the families to begin to collect on the more than $1 billion the jurors determined Jones owed them for his reprehensible and harmful behavior.

LETTERS FROM AN AMERICAN

HEATHER COX RICHARDSON

#Letters From An American#Heather Cox Richardson#election 2024#William Faulkner#quotes#MAGA poison#racism#Mark Robinson#Clay Higgins#the economy#the middle class

21 notes

·

View notes

Text

Crew-8 Astronauts Return to Earth

After seven months of living and working onboard the International Space Station (ISSInternational Space Station), astronauts of NASA’s eighth rotational SpaceX crew mission (Crew-8) splashed down safely off the coast of Florida. The mission, which is part of NASA’s Commercial Crew Program, included NASANational Aeronautics and Space Administration astronauts Matthew Dominick, Michael Barratt, and Jeanette Epps, as well as Roscosmos cosmonaut Alexander Grebenkin. During their mission on station, the three NASA astronauts supported dozens of research investigations sponsored by the ISS National Laboratory®.

These investigations spanned many areas, including in-space production applications(Abbreviation: InSPA) InSPA is an applied research and development program sponsored by NASA and the ISS National Lab aimed at demonstrating space-based manufacturing and production activities by using the unique space environment to develop, test, or mature products and processes that could have an economic impact., life and physical sciences, and technology development, all aimed at bringing value to humanity and enabling a robust market in low Earth orbit(Abbreviation: LEO) The orbit around the Earth that extends up to an altitude of 2,000 km (1,200 miles) from Earth’s surface. The International Space Station’s orbit is in LEO, at an altitude of approximately 250 miles. (LEO).

Below highlights a few of the ISS National Lab-sponsored projects the Crew-8 NASA astronauts worked on during their mission.

Several investigations focused on in-space production applications, an increasingly important area of emphasis for the ISS National Lab and NASA.

A project from Cedars Sinai Medical Center aims to establish methods to support the in-space manufacturing of stem cells, which can be matured into a wide variety of tissues. These methods will be used for future large-scale in-space biomanufacturing of stem cell-derived products, which could lead to new treatments for heart disease, neurodegenerative diseases, and many other conditions.

Redwire Corporation partnered with Eli Lilly and Company and Butler University on a series of investigations leveraging Redwire’s Pharmaceutical In-space Laboratory (PIL-BOX), a platform to crystallize organic molecules in microgravityThe condition of perceived weightlessness created when an object is in free fall, for example when an object is in orbital motion. Microgravity alters many observable phenomena within the physical and life sciences, allowing scientists to study things in ways not possible on Earth. The International Space Station provides access to a persistent microgravity environment.. Results from this research could lead to improved therapeutics to treat an array of conditions. These projects continue Eli Lilly’s space journey, as the company has launched multiple investigations to the orbiting laboratory over the years for the benefit of patient care on Earth.

The astronauts supported the third experiment in a series of projects from the University of Notre Dame to improve ultra-sensitive biosensors. The biosensors can detect trace substances in liquids, including early cancer biomarkers. By using laser heating to control bubble formation in microgravity, the team improved particle collection—a key step in boosting sensor sensitivity. This research, funded by the U.S. National Science Foundation, could transform early and asymptomatic cancer detection and other medical diagnostics.

The crew conducted phase two of a technology development project from Sphere Entertainment to test Big Sky—the company’s new ultra-high-resolution, single-sensor camera—on the space station. In the first phase of the project, which launched in November 2022, astronauts tested a commercial off-the-shelf camera on the ISS to collect baseline information. During the second phase, the astronauts tested Big Sky to validate the camera’s function, operations, and video downlink capabilities in microgravity. Big Sky is being developed by Sphere Entertainment to capture content for Sphere, the next-generation entertainment medium in Las Vegas.

In the final days before their departure from the space station, the Crew-8 astronauts supported projects that recently launched on NASA’s ninth rotational crew mission (Crew-9).

One is a student-led project from Isabel Jiang, a recent high school graduate from Hillsborough, CA, who is now in her first year at Yale. Jiang is the winner of the 2023 Genes in Space student research competition, founded by Boeing and miniPCR bio and supported by the ISS National Lab and New England Biolabs. Jiang’s experiment investigates the effect of radiation and the space environment on mechanisms for gene editing. Results could help develop methods to better protect astronauts and shed light on genetic risks for certain diseases during spaceflight.

Another is an investigation from the U.S. Air Force Academy and Rhodium Scientific to compare the root growth of Arabidopsis plants, a member of the mustard family, at two different orbital altitudes. Plants grown on the space station in LEO for four to six days will be compared with similar plants grown on the recent Polaris Dawn mission, which flew in the same type of vehicle at a higher orbit for approximately the same amount of time. Results could provide insights into the production of crops for long-duration space missions and in high-radiation environments.

IMAGE: SpaceX Crew-8 astronauts (top to bottom) NASA's Jeanette Epps, Mike Barratt & Matthew Dominick, and Roscosmos cosmonaut Alexander Grebenkin onboard the ISS. Credit NASA

5 notes

·

View notes

Text

Biotechnology Market- Trends Shaping the Future

The modern biotech realm provides cutting-edge technologies to tackle rare diseases and minimize environmental impact. From companies leveraging human genetics to possibilities of personalized medicine, biotech influence spans a profound spectrum. This technology is capable of feeding the hungry and offering them a cure. It is a cleaner, safer, and efficient technology for the future.

Biotech holds significant promises for companies. The approach to precision medicine allows pharmaceutical companies to reduce the risk of human complications. The biomanufacturing trend is transforming the ways to produce chemicals and materials that are conventionally produced through synthetic processes. Biotechnology in manufacturing is foreseen to improve productivity and innovation.

Biotechnology is expanding in additive manufacturing processes such as 3D printing. Bioprinters print organ-like structures to benefit the healthcare sector. The potential of biotech is widespread from drug discovery to the creation of personalized medicines. Recent bioprinting innovation is foreseen to be a breakthrough in the coming years.

The biotechnology market is anticipated to hold promising growth potential in coming years driven by trends that engineer new biological systems and aim to redesign existing ones. Although there are challenges in the biotechnology market ahead, its potential outweighs the hurdles. Biotechnology is capable of delivering new solutions in agriculture, medicine, and industrial sectors foreseen to increase biotechnology market share.

2 notes

·

View notes

Text

Biologics and Biosimilars Market Size, Trends, and Growth Forecast 2025–2032

Global Biologics and Biosimilars Market: Industry Analysis, Trends, and Forecast (2024-2031)

Introduction

The Global Biologics and Biosimilars Market is experiencing rapid expansion, driven by advancements in biotechnology, increasing prevalence of chronic diseases, and rising demand for cost-effective treatment options. Biologics, derived from living organisms, are playing a transformative role in treating cancer, autoimmune diseases, and rare disorders, offering targeted and highly effective therapies.

The introduction of biosimilars—which are highly similar versions of already approved biologics—is further enhancing market accessibility, reducing healthcare costs, and expanding patient reach. As regulatory frameworks become more supportive and manufacturing technologies advance, both biologics and biosimilars are expected to see significant growth.

In 2023, the market was valued at approximately USD 23,960 million and is projected to reach USD 73,030 million by 2031, reflecting a compound annual growth rate (CAGR) of 17.3%. The market is driven by:

Growing adoption of personalized medicine, leveraging biologics for targeted therapies.

Increased government support for biosimilars, promoting affordable treatment alternatives.

Technological advancements in bioprocessing, enhancing efficiency and scalability in drug development.

Expanding healthcare access in emerging markets, improving biopharmaceutical adoption.

However, challenges such as complex manufacturing processes, stringent regulatory requirements, and intellectual property barriers pose potential growth constraints. Nonetheless, with strong industry collaborations and ongoing R&D, the biologics and biosimilars market is expected to witness continued expansion and innovation.

Get free sample copy @ https://www.statsandresearch.com/request-sample/40532-global-biologics-and-biosimilars-market

Market Dynamics

Market Drivers

Rising Prevalence of Chronic Diseases

Cancer, autoimmune disorders, and diabetes are driving demand for biologic treatments.

Monoclonal antibodies, therapeutic proteins, and gene therapies are being widely used for targeted disease management.

Growing Demand for Cost-Effective Biosimilars

Biosimilars offer affordable alternatives to high-cost biologics, increasing patient accessibility.

Governments and healthcare agencies are supporting biosimilar adoption to lower drug costs.

Advancements in Biomanufacturing Technologies

Recombinant DNA technology, monoclonal antibody production, and cell culture techniques are improving drug development efficiency.

Automation and AI-driven analytics are enhancing yield optimization and bioprocessing scalability.

Regulatory Support and Expanding Approval Pathways

The FDA, EMA, and regulatory bodies are creating clearer guidelines for biosimilars, facilitating faster approvals.

Patent expirations of major biologic drugs are opening opportunities for biosimilar market entry.

Increasing Investment in Personalized Medicine and Biopharmaceutical R&D

Precision therapies tailored to genetic profiles are becoming a key focus in oncology and autoimmune treatments.

Pharmaceutical companies are investing in next-generation biologics, such as gene therapy and cell-based treatments.

Market Challenges

High Development and Manufacturing Costs

Biologic drug production requires complex cell culture and purification processes, leading to high R&D expenses.

Biosimilar production demands strict quality control measures, increasing overall costs.

Regulatory and Intellectual Property Barriers

Stringent biosimilar approval requirements can slow down market entry.

Patent litigations and exclusivity extensions delay biosimilar commercialization.

Market Competition from Established Biologics

Biologics manufacturers are implementing pricing strategies and patient assistance programs to retain market share.

Physician and patient skepticism about switching to biosimilars remains a challenge.

Supply Chain and Production Scalability Issues

Cold chain logistics are required for biologics, increasing distribution complexity.

Limited biosimilar manufacturing capacity may hinder large-scale adoption.

Get full report @ https://www.statsandresearch.com/report/40532-global-biologics-and-biosimilars-market/

Market Segmentation

The Biologics and Biosimilars Market is segmented based on product type, source, and manufacturing process.

By Product Type:

1. Biologics

Includes monoclonal antibodies (mAbs), vaccines, and recombinant proteins.

Used in treating cancer, rheumatoid arthritis, and neurological diseases.

Largest market segment, driven by targeted therapy advancements.

2. Biosimilars

Highly similar to approved biologics, offering lower-cost alternatives.

Includes biosimilar monoclonal antibodies, insulin, and growth hormones.

Growth driven by patent expirations of blockbuster biologics.

3. Others

Includes emerging biologic drug classes such as gene therapy and cell-based therapies.

By Source:

1. Human-Derived

Includes monoclonal antibodies and therapeutic proteins.

Dominates the market due to its high specificity and efficacy.

2. Animal-Derived

Includes vaccines and insulin derived from animal sources.

Ethical and regulatory concerns may limit usage.

3. Microbial-Derived

Includes recombinant proteins produced in bacteria and yeast.

Growing adoption due to genetic engineering advancements.

4. Plant-Derived

Includes plant-based biologics and vaccine candidates.

Still in early development stages, but gaining research attention.

By Manufacturing Process:

1. Recombinant DNA Technology

Most widely used method for producing therapeutic proteins and monoclonal antibodies.

2. Monoclonal Antibody Production

Rapidly growing segment, with applications in cancer immunotherapy.

3. Cell Culture Techniques

Utilized for complex biologic drug development.

4. Others

Includes novel bioprocessing methods, such as cell-free protein synthesis.

Regional Analysis

1. North America

Largest market, driven by strong biotech infrastructure and high healthcare spending.

FDA approvals of biosimilars accelerating market growth.

2. Europe

Second-largest market, with strong government support for biosimilar adoption.

Germany, UK, and France leading in biosimilar regulations and patient access.

3. Asia-Pacific

Fastest-growing market, driven by rising healthcare investments in China, India, and Japan.

Expanding biopharmaceutical R&D and biosimilar production capacity.

4. Middle East & Africa

Increasing demand for affordable biosimilars due to rising chronic disease burden.

5. South America

Brazil and Argentina emerging as biosimilar manufacturing hubs.

Competitive Landscape

Key Players in the Biologics and Biosimilars Market:

Amgen (Leading biologics manufacturer)

Roche (Strong in monoclonal antibodies and oncology biologics)

AbbVie (Known for blockbuster biologic Humira)

Bristol-Myers Squibb (Expanding into immuno-oncology biologics)

Sandoz (Biosimilar leader)

Pfizer (Developing biosimilars for rheumatoid arthritis and cancer)

Mylan (now part of Viatris) (Strong biosimilar portfolio)

Samsung Bioepis (Advancing biosimilar R&D)

Celltrion (Developing biosimilars for autoimmune diseases)

Teva Pharmaceutical Industries (Investing in biosimilar manufacturing)

Recent Developments:

Amgen launched new biosimilars for oncology treatments.

Pfizer expanded biosimilar manufacturing capacity to meet global demand.

Samsung Bioepis entered strategic partnerships for biosimilar commercialization.

Get enquiry before buying @ https://www.statsandresearch.com/enquire-before/40532-global-biologics-and-biosimilars-market

0 notes

Text

Microcarrier Market: Innovations in Cell Culture Technologies for Biomanufacturing up to 2033

Market Definition

The microcarrier market involves the use of small, solid or semi-solid beads called microcarriers, which provide a surface for cells to grow in bioreactors. These microcarriers are important in cell culture processes, especially for the large-scale production of cells used in research, therapy, and industrial applications. They offer a large surface area for cells to attach and grow, making it easier to produce cell-based products like vaccines, biologic drugs, and regenerative therapies.

To Know More @ https://www.globalinsightservices.com/reports/Microcarrier-Market

The microcarrier market is anticipated to expand from $1.8 billion in 2023 to $4.2 billion by 2033, with a robust CAGR of 8.7%, reflecting industry growth trends.

Market Outlook

The microcarrier market is growing quickly, driven by the increasing demand for cell-based therapies, advancements in regenerative medicine, and the expansion of biopharmaceutical production. As the development of biologics and biosimilars rises, and with a greater focus on personalized medicine, there is a growing need for efficient and scalable cell culture systems, where microcarriers are key.

Technological advances are a major factor driving market growth. New innovations in microcarrier materials, such as biodegradable and functionalized microcarriers, are improving cell growth and productivity. The integration of advanced technologies like automated cell culture systems and real-time monitoring tools is making microcarrier-based cell culture processes more efficient and scalable. Additionally, microcarriers are being used in three-dimensional (3D) cell culture systems, which is expanding their role in tissue engineering and regenerative medicine.

The market is also benefiting from increased research and development investments by pharmaceutical and biotechnology companies. The growth of the biopharmaceutical industry, fueled by the rising number of chronic diseases and the demand for new therapies, is driving the need for microcarriers. Collaborations between industry leaders and research institutions are helping to push forward the development of new microcarrier technologies and their applications.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS20943

0 notes

Text

Bioprocess Bags Market: Innovations Driving Growth in Biopharmaceutical Production- UnivDatos

According to a new report by UnivDatos Market Insights, the Bioprocess Bags Market was valued at approximately USD 3.85 Billion in 2023 and is expected to grow at a substantial CAGR of around 17.5% during the forecast period (2024-2032) owing to the increased demand for biologics and biosimilars. The growth of the bioprocess bags market reflects the global trend towards the usage of single-use technologies in biopharmaceutical production. These industries avail themselves by minimized lead time, decreased probability of contamination, and improved production. The bioprocess bags market expansion is fueled by the increasing need for biologics, biosimilars, and vaccines. In October 2022, Austrian solution provider Single Use Support GmbH expanded its product portfolio with new single-use bioprocess containers under the brand name IRIS. The pioneering company leverages its know-how to provide reliable process solutions in the field of biopharmaceutical fluid management, continuing to pursue its vendor-agnostic approach.

Request To Download Sample of This Strategic Report - https://univdatos.com/get-a-free-sample-form-php/?product_id=68909&utm_source=LinkSJ&utm_medium=Snehal&utm_campaign=Snehal&utm_id=snehal

Segments that transform the industry

· Based on product type, the market is segmented into single-use bioprocessing bags and multi-use bioprocessing bags. Single-use bioprocessing bags held a significant share of the market in 2023 owing to enhanced growth by facilitating rapid production scaling, the need to clean them less often, and possessing lower risk of cross-contamination. Adding to this, companies use these bags in bioprocessing due to their adaptability to bioprocesses such as media preparation, mixing, and product storage. Their adaptability to automated bioreactors and closed systems makes them fundamental to the current biomanufacturing industry. For instance, on March 28, 2022 — ILC Dover LP (“ILC Dover” or the “Company”), specializing in innovative single-use solutions for biotherapeutics and pharmaceutical processing, announced its launch of liquid single-use bioprocessing bags, representing the first of many new products for handling and supply of sterile liquids for the biotherapeutics market. This expansion is a continuation of ILC Dover’s solution set across the entire biotherapeutic and pharmaceutical manufacturing workflow, from powder containment and handling, through sterile liquid handling and pre-filled liquid and powder bags.

According to the report, the impact of Bioprocess Bags has been identified to be high for the Asia-Pacific area.

For More Informative Information, Please Visit Us- https://univdatos.com/get-a-free-sample-form-php/?product_id=68909&utm_source=LinkSJ&utm_medium=Snehal&utm_campaign=Snehal&utm_id=snehal

Some of how this impact has been felt include:

Asia-Pacific is expected to grow with a significant CAGR during the forecast period (2024-2032). This is due to the booming biotechnology industry and rapidly growing consumption of biopharma products in the region’s emerging giants such as China and India. It is one of the most important bioprocessing locations because government policies support the production of local goods along with cheaper manufacturing expenses. Increased spending on single-use technologies and increasing outsourcing of CMC services through more CMOs/CROs are critical drivers. There are several reasons companies opt for bioprocess bags compliance with international quality standards and the need to scale up biosimilars and vaccine production. The region’s emphasis on new technologies and export-oriented biomanufacturing also drives adoption even more.

On June 1, 2021, Avantor, Inc. (NYSE: AVTR), a leading global provider of mission-critical products and services to customers in the life sciences, advanced technologies and applied materials industries, announced that it has acquired RIM Bio, a leading China-based manufacturer of single-use bioprocess bags and assemblies for biopharmaceutical manufacturing applications.

0 notes

Text

Global Single-Use Bioprocessing Market: Trends, Challenges, and Strategic Forecasts

The global single-use bioprocessing market size is projected to reach USD 80.13 billion by 2030, registering a compound annual growth rate (CAGR) of 16.24% over the forecast period, according to a new report by Grand View Research, Inc. The demand for single-use bioprocessing offerings is driven by the commercial advantages offered, including a reduction in costs and time required for bioprocessing operations. Originally used for monoclonal antibody production, single-use technologies are also gaining traction for cell and gene therapy manufacturing. As a result, broadening the scope of applications in biomanufacturing operations is likely to drive industry growth.

Furthermore, strategic initiatives from key players are expanding the industry's growth prospects. For instance, in July 2021, Cytiva and Pall Corp. announced investment plans for capacity expansion over two years. Among other key products, more than USD 300 million were invested in single-use technologies, such as bioreactor bags for cell expansion, used to make personalized therapies and syringe filters for scientific research. Similarly, the growing adoption of single-use equipment for in-house and contract manufacturing has opened new avenues for the flow of investments in this space. The industry is witnessing significant advancements in several product portfolios, including disposable probes and sensors, stirring systems, bioreactor designs, and filtration technologies, which are expected to contribute to strong revenue growth.

The benefits offered by single-use bioprocessing systems have enabled biopharmaceutical manufacturers to offer their products faster to the market by introducing multi-product facilities, entering into partnerships, or outsourcing pipeline products for contract development and manufacturing. For instance, in January 2021, Sartorius AG partnered with RoosterBio, a leading supplier of human Mesenchymal Stem/Stromal Cells (hMSC). This collaboration aimed at advancing cell & gene therapy manufacturing by leveraging the single-use manufacturing technologies from Sartorius AG. The COVID-19 pandemic has generated new growth opportunities for key stakeholders in the industry.

Key biopharmaceutical players can leverage the opportunity by expanding their COVID-19-related product offerings by scaling up their production facilities with the implementation of single-use bioprocessing equipment. A significant number of biopharmaceutical companies are actively involved in the development and production of COVID-19 vaccines. These programs are majorly based on single-use technologies as these systems are flexible, cost-effective, and reduce the risk of cross-contamination. Such an ongoing and continuous increase in the adoption of bioprocessing systems due to the COVID-19 pandemic is anticipated to drive industry growth.

Single-use Bioprocessing Market Report Highlights

The simple & peripheral elements segment held the largest share in 2023 due to the significant adoption of these products as a result of a variety of customizable options available for bioprocessing applications

The upstream bioprocessing workflow segment accounted for the largest share in 2023. Continuous developments and betterment in technologies for upstream bioprocessing are driving the segment growth

North America was the leading region in 2023 due to the high R&D spending and growth of the biopharmaceutical manufacturing sector in the region

Furthermore, the presence of key players, such as Thermo Fisher Scientific, Inc. and Danaher Corp., is driving the regional market

The biopharmaceutical manufacturers end-use segment dominated the industry in 2023 and accounted for the maximum revenue share. This was due to the high demand for biologics and heavy investments in cell & gene therapy manufacturing

Single-use Bioprocessing Market Segmentation

Grand View Research has segmented the global single-use bioprocessing market based on product, workflow, end-use, and region:

Single-use Bioprocessing By Product Outlook (Revenue, USD Million, 2018 - 2030)

Simple & Peripheral Elements

Tubing, Filters, Connectors, & Transfer Systems

Bags

Sampling Systems

Probes & Sensors

pH Sensor

Oxygen Sensor

Pressure Sensors

Temperature Sensors

Conductivity Sensors

Flow Sensors

Others

Others

Apparatus & Plants

Bioreactors

Upto 1000L

Above 1000L to 2000L

Above 2000L

Mixing, Storage, & Filling Systems

Filtration System

Chromatography Systems

Pumps

Others

Work Equipment

Cell Culture System

Syringes

Others

Single-use Bioprocessing By Workflow Outlook (Revenue, USD Million, 2018 - 2030)

Upstream Bioprocessing

Fermentation

Downstream Bioprocessing

Single-use Bioprocessing By End-use Outlook (Revenue, USD Million, 2018 - 2030)

Biopharmaceutical Manufacturers

CMOs & CROs

In-house Manufacturers

Academic & Clinical Research Institutes

Single-use Bioprocessing Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Europe

UK

Germany

France

Italy

Spain

Denmark

Sweden

Norway

Asia Pacific

Japan

China

India

South Korea

Australia

Thailand

Latin America

Brazil

Mexico

Argentina

Middle East and Africa (MEA)

South Africa

Saudi Arabia

UAE

Kuwait

List of key players

Sartorius AG

Danaher

Thermo Fisher Scientific, Inc.

Merck KGaA

Avantor, Inc.

Eppendorf SE

Corning Incorporated

Lonza

PBS Biotech, Inc.

Meissner Filtration Products, Inc.

Order a free sample PDF of the Single-use Bioprocessing Market Intelligence Study, published by Grand View Research.

0 notes

Text

Advancements and Opportunities in Cell and Gene Therapy Biomanufacturing: A Comprehensive Market Report

In recent years, the field of biomanufacturing has witnessed remarkable growth, driven by breakthroughs in cell and gene therapy. These cutting-edge technologies hold immense promise for treating a wide array of diseases, ranging from genetic disorders to certain types of cancers.

The global cell and gene therapy biomanufacturing market was valued at $12.31 billion in 2022 and is anticipated to reach $29.76 billion by 2031, witnessing a CAGR of 10.31% during the forecast period 2022-2031.

Market Overview

The Cell and Gene Therapy Biomanufacturing market has experienced substantial expansion, reflecting the increasing demand for personalized and targeted treatments.

The growth in the global cell and gene therapy biomanufacturing market is expected to be driven by the increased number of approved therapies and growing infrastructure requirements.

Market Segmentation

Segmentation 1: by Product Type

Segmentation 2: by Usage

Segmentation 3: by Application

Segmentation 4: by End User

Segmentation 5: by Region

Key Drivers

Rising Incidence of Genetic Disorders

Supportive Regulatory Environment

Download the free sample @ Cell and Gene Therapy Biomanufacturing Market Report

Challenges and Opportunities

While the Cell and Gene Therapy Biomanufacturing market shows great promise, it also faces several challenges. These include the complexity of manufacturing processes, high costs, and the need for skilled personnel. However, these challenges present opportunities for further research, innovation, and collaboration to overcome these barriers and drive market growth.

Grab a better look and understand better @ precision medicine

Future Outlook

The future of the Cell and Gene Therapy Biomanufacturing market looks promising, with ongoing research and development, technological advancements, and a favorable regulatory landscape. As the industry continues to evolve, collaborations between biopharmaceutical companies, academic institutions, and government bodies are likely to accelerate progress and drive further innovations in biomanufacturing.

Conclusion

The Cell and Gene Therapy Biomanufacturing market report highlights the significant strides made in the field, showcasing the potential to revolutionize healthcare. With a robust market outlook, supported by advancements in technology and a favorable regulatory environment, the industry is well-positioned for sustained growth.

As bio manufacturing capabilities continue to expand, the promise of more accessible and effective cell and gene therapies draws closer to reality, offering hope for patients and transforming the landscape of modern medicine.

#Cell and Gene Therapy Biomanufacturing Market#Cell and Gene Therapy Biomanufacturing Market Report#Cell and Gene Therapy Biomanufacturing Industry#Cell and Gene Therapy Biomanufacturing Key Players#Cell and Gene Therapy Biomanufacturing Market Trends

0 notes

Text

Exploring the Single-Use Bioprocessing Market: Trends, Benefits, and Future Opportunities

The Single-Use Bioprocessing Market has emerged as a transformative segment in the biopharmaceutical industry. With increasing demand for flexible, efficient, and cost-effective bioprocessing solutions, single-use systems (SUS) are becoming the cornerstone of modern biomanufacturing. This blog delves into the key aspects of the single-use bioprocessing market, its benefits, trends, and future opportunities.

Download PDF Brochure

What is Single-Use Bioprocessing?

Single-use bioprocessing refers to the use of disposable bioprocessing equipment and components made from polymers or plastics. These systems are designed for single-use, eliminating the need for cleaning and sterilization. Typical single-use bioprocessing components include:

Bioreactors

Mixing systems

Filtration assemblies

Storage bags

Tubing and connectors

These disposable technologies cater to small-scale and large-scale biopharmaceutical production.

Market Drivers for Single-Use Bioprocessing

The increasing adoption of single-use systems is driven by several factors:

1. Cost-Effectiveness

Single-use systems significantly reduce costs associated with cleaning, sterilization, and validation. Traditional stainless-steel equipment requires extensive maintenance and validation, which SUS eliminate.

2. Flexibility

Single-use systems offer unmatched flexibility. They allow manufacturers to switch between products quickly, enabling faster production of biologics and reducing time-to-market.

3. Scalability

Single-use technologies are ideal for clinical and commercial-scale production, particularly for biologics, cell therapies, and vaccines.

4. Reduced Contamination Risk

Since SUS are pre-sterilized and disposable, they minimize contamination risks, ensuring product integrity and compliance with stringent regulatory requirements.

Request Sample Pages

Applications of Single-Use Bioprocessing

Single-use systems are widely used across various stages of biomanufacturing:

1. Upstream Processing

Single-use bioreactors dominate upstream processing due to their scalability and ease of use. They are commonly used for culturing cells and producing biologics.

2. Downstream Processing

Single-use systems for downstream processing include filtration units and chromatography columns, streamlining purification processes.

3. Vaccine Production

The COVID-19 pandemic highlighted the need for rapid vaccine development. Single-use technologies played a critical role in scaling up vaccine production.

4. Cell and Gene Therapies

The precision and flexibility of SUS make them indispensable in the manufacture of personalized cell and gene therapies.

Emerging Trends in the Single-Use Bioprocessing Market

The single-use bioprocessing market is continuously evolving, driven by technological innovations and changing industry demands. Key trends include:

1. Automation and Digitalization

The integration of sensors, IoT, and AI into single-use systems enhances process monitoring, data collection, and analytics, improving efficiency and quality control.

2. Sustainability Initiatives

With increasing focus on sustainability, manufacturers are developing recyclable or biodegradable single-use components to address environmental concerns.

3. Expansion in Emerging Markets

The adoption of single-use systems is gaining traction in emerging markets like Asia-Pacific, driven by the region's growing biopharmaceutical manufacturing capabilities.

4. Modular Bioprocessing

Modular bioprocessing facilities, equipped with single-use technologies, are being designed to meet diverse production needs and enable rapid deployment.

Challenges in the Single-Use Bioprocessing Market

While single-use systems offer numerous benefits, they also face certain challenges:

1. Plastic Waste Management

The disposable nature of single-use systems generates significant plastic waste, raising concerns about environmental impact.

2. Supply Chain Constraints

The growing demand for SUS has led to supply chain bottlenecks, impacting timely availability of components.

3. Compatibility Issues

Ensuring compatibility between different single-use components and systems remains a technical challenge.

Future Opportunities

The future of the single-use bioprocessing market is bright, with ample opportunities for growth:

1. Advancements in Materials

Innovations in biocompatible and sustainable materials will address concerns related to waste and environmental impact.

2. Integration with Continuous Manufacturing

Single-use systems are being integrated into continuous manufacturing processes, enhancing productivity and reducing costs.

3. Expansion in Biosimilars

As the biosimilars market grows, single-use technologies will play a crucial role in cost-efficient production.

Market Insights

Key Players

Leading companies in the single-use bioprocessing market include:

Thermo Fisher Scientific

Sartorius AG

Merck KGaA

Danaher Corporation

GE Healthcare

Market Size and Growth

The global single-use bioprocessing market is expected to witness robust growth, driven by increasing biopharmaceutical R&D investments and demand for biologics.

Conclusion

The Single-Use Bioprocessing Market is revolutionizing biopharmaceutical manufacturing. Its ability to enhance efficiency, reduce costs, and ensure product safety positions it as a vital technology for the future of biologics production. As the industry evolves, innovations in materials, digitalization, and sustainable practices will further bolster the adoption of single-use systems. Biomanufacturers and stakeholders must navigate challenges while leveraging the immense opportunities this market presents.

By embracing single-use bioprocessing, the biopharmaceutical industry can continue to meet the growing global demand for biologics, vaccines, and advanced therapies efficiently and sustainably.

Content Source:

0 notes

Text

Why Choose Dubai for Your Biotechnology Job Career?

Dubai has emerged as a top destination for professionals seeking a promising career in biotechnology. With its rapid development, favourable economic environment, and ambitious focus on innovation, the city has become a magnet for talent in high-tech industries, especially biotech. A wealth of resources, strategic location, and commitment to research and development make Dubai an attractive choice for those looking to advance their biotech careers. For job seekers, finding opportunities through a reliable biotech recruitment agency can provide a crucial bridge to thriving in this dynamic sector.

A Growing Biotech Hub

Dubai’s vision for the future includes significant investment in biotechnology and related life sciences. This growth is fueled by public and private sector initiatives prioritizing research, health, and bioengineering. Dubai Science Park, for example, is a dedicated area supporting life sciences, attracting biotech firms and research centres to establish their presence. Such projects encourage professionals from around the globe to contribute to a thriving ecosystem that bridges medical research, biomanufacturing, and healthcare services.

Innovation and Research Incentives

Dubai’s commitment to innovation extends into biotech with various incentives to attract skilled professionals. The UAE government actively supports initiatives such as the Mohammed Bin Rashid Al Maktoum Knowledge Foundation and Dubai Future Foundation, which foster a culture of scientific discovery. These programs create an environment that values and rewards innovation, providing fertile ground for biotechnology professionals. Tax benefits, free zones with specialized biotech facilities, and grants for research projects further enhance Dubai’s appeal, making it a place where new ideas can take root and flourish.

World-Class Infrastructure

One of Dubai’s hallmarks is its world-class infrastructure, which benefits traditional industries and supports emerging fields like biotechnology. From high-tech laboratories to modern research facilities, Dubai’s infrastructure is designed to meet the needs of a global scientific community. Its excellent transport network, strong digital infrastructure, and access to well-equipped research parks give biotech professionals the tools they need to succeed. Furthermore, Dubai’s connectivity with other global innovation hubs ensures access to the latest developments in biotechnology and fosters collaboration across borders.

Diverse and Collaborative Environment

Dubai is a melting pot of cultures, making it a perfect setting for biotech professionals who value collaboration and diversity. Working in such an inclusive environment enriches perspectives and can lead to breakthroughs and innovations in biotech. Many professionals find that Dubai’s mix of cultures fosters a unique exchange of ideas and problem-solving approaches, essential for a dynamic, research-intensive field like biotechnology. Collaboration is encouraged within companies and across research institutions, universities, and healthcare facilities, all contributing to a rich, multidisciplinary environment. For those seeking biotechnology jobs in Dubai, the city’s diverse culture and emphasis on collaboration create unparalleled opportunities for career advancement and meaningful work.

High Quality of Life

Dubai’s appeal is not limited to career opportunities; the city also offers an exceptional quality of life. With world-class amenities, safety, and a cosmopolitan lifestyle, Dubai ensures professionals enjoy a balanced work-life experience. Its excellent healthcare, diverse entertainment options, and year-round sunshine make it an attractive place to live. For those in biotech, a city that supports professional ambitions while offering a high quality of life is an invaluable combination.

Strategic Location and Access to Emerging Markets

At the crossroads of Europe, Asia, and Africa, Dubai is a strategic gateway for biotech companies aiming to tap into emerging markets. This advantage makes it easier for professionals working in Dubai to interact with colleagues and clients in different regions, promoting a global outlook. The city’s access to these markets provides a unique edge for biotech specialists and companies, enabling faster exchange of ideas, goods, and services across continents.

Dubai is quickly establishing itself as a premier biotech hub thanks to its well-rounded infrastructure, government support, and strategic vision. Professionals in biotechnology here benefit from a highly collaborative ecosystem designed to foster innovation and career growth. With state-of-the-art laboratories, research facilities, and specialized biotech recruitment agencies like Real Staffing, Dubai makes finding the right opportunities streamlined and efficient for top talent. Beyond professional advancement, Dubai’s multicultural lifestyle and forward-thinking approach make it a unique destination for those eager to shape the future of biotechnology. Combining career potential with lifestyle allure, Dubai is an unmatched choice for biotech professionals aiming to make a global impact.

0 notes

Text

Sustainability's Secret Revolution in Bioprocessing

Rising Demand for Sustainable Bioprocessing

The quest for sustainability is reshaping industries worldwide, and bioprocessing is leading the charge. At the forefront of this movement are companies seeking to minimize environmental impact while maximizing efficiency and profitability. According to experts at the World Biomanufacturing Forum, the market for next-generation biomanufacturing is expected to double by 2033, reaching a staggering $40 billion. This growth indicates not only the economic potential but also the urgent need for sustainable practices to meet global demands.

What Drives Sustainability in Bioprocessing?

Several factors drive the push toward sustainability in bioprocessing. First is the increasing regulatory pressure to reduce carbon footprints and manage waste responsibly. Companies face mounting expectations from consumers and stakeholders to commit to sustainability. Furthermore, innovations in technology provide the tools necessary to implement green solutions effectively, making sustainability both feasible and advantageous.

A Closer Look at Bioprocessing Stages

Bioprocessing can be divided into two main stages—upstream and downstream processing. Each plays a critical role in the overall sustainability of operations. Upstream processing involves the cultivation of biological materials, while downstream processing encompasses the purification and packaging of the final product. Addressing sustainability in both stages is essential for comprehensive eco-friendly practices.

The implementation of eco-friendly practices in bioprocessing involves using renewable materials, improving energy efficiency, and reducing water usage to minimize environmental impact. In upstream processing, sustainable techniques help optimize resource use, while in downstream processing, methods like anaerobic digestion, composting, and advanced filtration reduce waste and resource demands. Employing green chemistry principles in both upstream and downstream processing minimizes chemical use, promoting ecological balance and regulatory compliance.

Case Study Spotlight: Eco-Innovation in Action

Leading Bioprocessing Giant Sets New Standards

A notable case study from the World Biomanufacturing Forum showcased a leading bioprocessing company's commitment to sustainability. By investing in cutting-edge technology and sustainable practices, they achieved a 30% reduction in carbon emissions and a 25% decrease in water usage across their facilities. This initiative not only positioned them as industry leaders but also significantly boosted their market competitiveness.

Collaborative Efforts Yield Impressive Results

Collaboration played a crucial role in this company's success. By partnering with technology providers, academic institutions, and regulatory bodies, they fostered an environment conducive to innovation and sustainable growth. This cooperative approach underscores the importance of synergy in achieving sustainability goals.

The Role of Technology in Advancing Sustainability

Automation and robotics in bioprocessing improve sustainability by reducing errors and resource consumption. Real-time monitoring and data analytics optimize processes and anticipate issues, enhancing efficiency and sustainability. AI and machine learning drive innovation by enabling predictive analytics and intelligent decision-making, supporting sustainable and high-quality production.

FAQs on Sustainability in Bioprocessing

What are the primary benefits of adopting sustainable bioprocessing practices?

Sustainable bioprocessing provides a wealth of advantages, such as minimizing environmental impact, boosting resource efficiency, ensuring regulatory compliance, and enhancing market competitiveness. By adopting sustainable practices, companies can also achieve significant cost savings and boost their brand reputation.

What methods can companies use to evaluate the success of their sustainability initiatives?

Success in sustainability can be measured through various metrics, such as reductions in carbon emissions, water usage, and waste generation. Additionally, companies can assess the economic impact of their initiatives by evaluating cost savings and return on investment.

Is sustainable bioprocessing financially viable for small and medium-sized enterprises (SMEs)?

Yes, sustainable bioprocessing can be financially viable for SMEs. By focusing on incremental improvements and leveraging available technologies, SMEs can achieve meaningful sustainability outcomes without significant financial burdens.

0 notes

Text

India Charts a Sustainable Future with BioE3 Policy

India Charts a Sustainable Future with BioE3 Policy A Dive into High-Performance Biomanufacturing @neosciencehub #neosciencehub #science #research #BioE3 #Modi #BioTechnology #biomanufacturing #market #bioproducts #proteins #chemicals #polymers #NSH

A Dive into High-Performance Biomanufacturing In an ambitious stride toward green growth, the Union Cabinet, led by Prime Minister Narendra Modi, has approved the pioneering BioE3 (Biotechnology for Economy, Environment, and Employment) Policy. This comprehensive framework is set to redefine the contours of India’s biotechnology sector, aiming to elevate the bioeconomy from its current valuation…

0 notes