#biocoal

Explore tagged Tumblr posts

Text

IT'S MOTHERFUCKING MALLARD DAY

I BROUGHT CAKE TO WORK AND WE'RE GOING TO HONOR HER SPEED RECORD AND I'M GOING TO CRY A LOT

People may have noticed that Mallard is my blog header and that my locomotive, Nasty Majesty, is numbered 7338, aka 7/3/38. This is not a coincidence - Mallard is why I'm here and why I do what I do and why I'm motivated to go faster and faster and push the limits of what steam can do and achieve.

Nasty Majesty runs on torrefied biomass, aka biocoal. She's designed to be carbon neutral. I hope she and I can continue to carry Mallard's legacy into a cleaner, faster future together.

(Sketch I did from a photo someone took of me and Conductor in the cab.)

4 notes

·

View notes

Text

Can Coal be Replaced with Biomass Briquettes?

India’s natural coal reserves are estimated to last another century and yet, coal shortage and fluctuating prices pose a threat to our country’s energy security. According to an article published by Business Standard, India is likely to face a supply shortage of about 42 million tons of coal in the third quarter of 2022. This is due to higher power demand and lower mine output this year. India is an agricultural country with huge untapped potential for using agricultural waste as biomass for producing Biofuels to replace conventional fuels such as coal and petroleum. Solid Biofuels, such as briquettes and pellets, are considered carbon-neutral and used in industrial boilers, which typically run on coal. Can Biofuels produced from agricultural waste be the new coal? How do they compare in terms of efficiency and cost? Read the article to find out.

How are Biofuels Produced from Agri-waste Briquetting?

Briquettes and pellets are made by compressing biomass material under high pressure and converting them into blocks of various uniform sizes and shapes. These are energy-dense and burn with little or no smoke depending upon the type of biomass used in making them.

The process of briquetting converts loose biomass sourced from various crop residues, agro-waste, and industrial raw biowaste into dense energy-rich bricks of uniform shape and sizes. Briquettes burn without emitting smoke, so they are also known as white coal or biocoal.

The calorific value of solid Biofuels, such as briquettes, varies depending upon the type of biomass used in the manufacturing process. The various type of raw organic waste used in briquette and pellet making include (but are not limited to):

Sugarcane Bagasse

Wood chips, shavings, sawdust

Groundnut and Cashew Seed shells

Rice husk and paddy straw

Coir dust

Wheat straw

Sunflower waste

The calorific value of quality briquettes is substantially higher than loose biomass and is slightly lower in comparison to coal. However, there may be exceptions.

How do Briquettes and Pellets Compare with Coal?

1. Calorific Value Calorific value is a measure of the amount of heat generated from the combustion of a specific quantity of a substance. The calorific value of coal ranges between 25–35 MJ/kg. Anthracite has the highest calorific value among different types of coal. The calorific value of high-quality briquettes ranges between 18 and 24 MJ/kg.

2. Pricing The price of biomass briquettes depends on the burning efficiency, quality, and availability in a particular location and time of the year. Briquettes with higher GCV than coal are likely to be priced higher than coal when the demand is high, and supplies are short. The ongoing surge in coal prices has fueled the demand for locally manufactured briquettes and pellets at competitive prices.

3. Availability:

India’s domestic coal production in financial 2021–22 was at a record high of 780 million tons and is projected to grow in FY 2022–23. And yet, each year, India depends on imported coal to meet its domestic requirements. This has been attributed to the boost in the economy after the pandemic which has led to surplus energy demands. It is estimated that if the current installed capacity for biomass-based power plants is fully utilized, it could bring down the demand for coal by close to 230 million tons. India being an agricultural country, there is immense scope for creating a solid Biofuel reserve from agricultural waste and biowaste generated from industries to ensure a continuous supply of fuels such as briquettes and pellets in place of coal. Currently, there are limitations such as the lack of a steady supply of agricultural waste and quality suppliers of Biofuels, which can create challenges in terms of Biofuel availability throughout the year. A scattered marketplace is a major challenge that needs to be addressed to accelerate the sourcing of biomass to make solid Biofuels for replacing coal.

4. Emissions

It is a well-known fact that coal and other fossil fuels are major sources of greenhouse gas emissions, such as CO2, affecting climate change on a massive scale. Co-firing coal with briquettes and pellets is an effective way to cut down emissions from thermal plants. The debate on whether or not briquettes and pellets are an eco-friendly alternative is still ongoing. However, burning fossil fuels has a negative impact on the environment whereas emissions from briquettes and pellets are comparatively lower.

Is Replacing Coal with Briquettes Economical?

The transition from coal to Biofuels for industrial boilers depends on various factors. This needs careful consideration of certain parameters such as

Gross calorific value

Availability and ease of handling

User’s readiness to modify their boilers

Adapting to changes in boiler equipment

Cost considerations

Co-firing is a viable option implemented by industries, where coal and an additional fuel source such as briquettes are used to power a boiler. This process results in lower emission of greenhouse gases, which is an advantage over burning coal.

Can Briquettes and Pellets Replace Coals?

Our massive dependency on coal to generate electricity makes it highly unlikely that a complete transition to solid Biofuels will be immediate. But the fact that coal reserves are depleting but the energy requirements continue to rise makes it necessary that we move towards cleaner fuels. In developing countries, the use of briquettes and pellets to fire industrial boilers has seen an upward trend. Rising coal prices and limited fossil fuel reserves are likely to further contribute to this shift in the coming years. A positive environmental impact works in favour of using Biofuels as a substitute for coal. The Ministry of New and Renewable Energy is set to achieve 500 GW of electricity from non-fossil fuels by the year 2030. A total of 152.90 GW of renewable energy projects have been installed as of January 2022, of which 10.63 GW is from Bio-power. This presents a great opportunity for use of Biofuels in place of coal.

The attributes of briquettes and pellets such as calorific values and energy efficiency make them an ideal fuel source to power industrial boilers. Although there are several bottlenecks in realizing their full potential as a replacement for coal, the shift in this direction is evident. The need for economical and eco-friendly alternative fuels is likely to drive this shift in the near future.

For More Information Click On : https://www.biofuelcircle.com/contact-us/

#biofuel companies in india#biomass briquettes#biofuels manufacturers in india#biomass pellets#biomass in india

0 notes

Text

NTPC Ltd sets up agri-waste based integrated torrefaction and pelletization plant at NETRA

Representational image Team News Riveting New Delhi, October 30 NETRA, the R&D wing of NTPC Ltd, and LWP Biocoal LLP, a Startup registered under GoI, have developed and setup a 10 TPD Integrated Torrefaction and Pelletization Plant for demonstration of indigenous technology and promotion of manufacturing of torrefied pellets in the country. It may be mentioned that agricultural residue-based…

0 notes

Link

1 note

·

View note

Link

CoalShastra is a B2B online marketplace for coal buyers & sellers. We were founded on the values of T.R.U.S.T (Transparency, Reliability, Unbiased, Service, Thorough), that form our core. In us, our clients TRUST as a partner to help source the best quality materials & help them understand market dynamics.

#coalshastra#coal#coaltraders#coalsuppplier#coalseller#coalimporter#importedcoalsupplier#koyla#koylasupplier#indonesiancoal#indonesiancoalsupplier#metcoke#petcoke#coalimporterinindia#coalexporter#cokingcoal#biocoal#coaltradingcompanies#coalbuy#buycoal#koylabuy#buykoyla#thermalcoal#thermalcoalsupplier#steamcoalsupplier

1 note

·

View note

Text

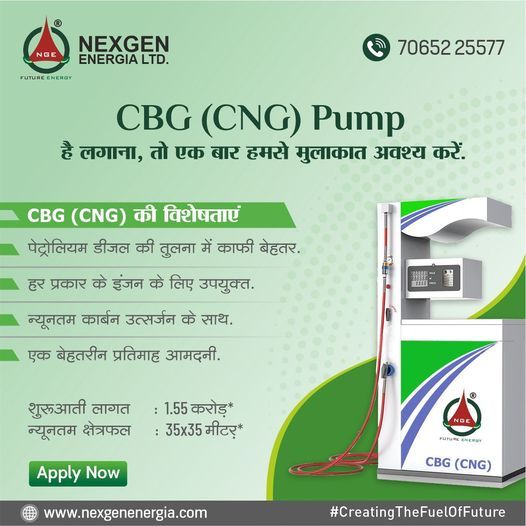

Apply Now- Nexgen Energia is providing CBG(CNG) Pump dealership

Apply now for CNG/CBG Pump Dealership. Nexgen Energia is helping entrepreneurs, business aspirants, to provide dealerships BioCNG retail outlets pan India. NexGen Energeia’s business projects are diversified to CNG/CBG production, CBG retail outlets, green diesel production, green diesel retail outlets, bio-coal, EV charging, etc. Nexgen Energia is providing CNG/CBG Pump dealership in India.The business project Based on Government’s SATAT scheme.

For any Information/Querry please Contact us [email protected]

CONTACT NO- 7065225577

#Nexgenenergia#biocng#cbg#creatingthefueloffuture#futureenergy#nge#NX100#cngpump#cngretailoutlet#cbgplant#biogas#biocngplant#cbgmanufacturingplant#biocoal#ethanol

0 notes

Photo

Making coal from food waste, garden cuttings – and even human sewage

Describes the process of High Temperature Carbonization (HTC), and potential advantages. Some economics but limited. Any want to start a 20000 Euro Kickstarter?

#high temperature carbonization#htc#biochar#biocoal#climate change#sewage management#carbon capture#horizon magazine#rex merrifield

0 notes

Text

Inktober 4. Experiment for a commission for Biocoal. Started out as just a study of his character Karma, but decided to do a quick finish. Spent 5 or 6 hours in the car today, so nothing too complex.

11 notes

·

View notes

Text

Biomass Secure Power Inc. signs Letter of Intent with Japanese trading company

Biomass Secure Power Inc. signs Letter of Intent with Japanese trading company

Biomass Secure Power Inc. signs letter of Intent with Japanese trading company to purchase Biocoal Biomass Secure Power Inc. (OTCMKTS:BMSPF) CHILLIWACK, BRITISH COLUMBIA, CANADA, September 8, 2022 /EINPresswire.com/ — Biomass Secure Power Inc. Signs Letter of Intent Biomass Secure Power Inc. (BSP) (OTC Market Pinksheets: BMSPF) has signed a Letter of Intent, (LOI) with a Japanese trading company…

View On WordPress

0 notes

Text

What is Feedstock in Garden waste and what are their characteristics

Setting up the process for biochar from the garden waste designing process starts with the choice of the right feedstock for the process. During this stage, a key characteristic of the feedstock for garden waste are described, such as:

Carbon content: carbon content which represents the amount of carbon available that will be eventually transferred to the biocoal (fixed carbon) or released into syngas by pyrolysis.

Volatile matter: This volatile matter represents the part of biomass that will be released during the pyrolysis and carbonisation process.

Fixed carbon: It demonstrates the carbon that will be directly represented in the bio coal produced.

Ash content: which describes the mineral residue of compost that is expected to be found in solid product. Higher ash contents in raw material (feedstock) will result in the increase of the ash content of bio coal and optimum ash content in feedstock is needed to control the burning process of the biocoal

Calorific value: that will determine the amount of energy released during the biocoal production and determine the full plant configuration and target business model, often allowing to benefit thanks to the additional heat and power production

Moisture content: higher contents may increase the production cost due to more energy demand to evaporate the water content in the process of biomass conversion in the composting process. Since the moisture content will impact the efficiency and costs of the operation, it is important to maintain relatively less moisture contents at the inlet to the Biogreen bio coal production kiln. Optimum moisture content for the production between 5% to 15%.

Mastering the production: Quality biochar production from garden waste and garden compost is related to both, adequate feedstock characteristics as well as the precise operating temperature control.

Including the feedstock all garden waste can be formed by composting process with help of this vertical garden tower it has two parts planter and composter.

A vertical gardening systems that works in an efficient way in process of planting and composting fertilizer Sadabahar (Our Portable Vertical garden) will works effectively. It helps in fertilizer of each Grab the deal with in budget at Urban plants

0 notes

Text

What is briquette machine?

Briquette machine is a Machine used to recycle Biomass waste into High Calorific Fuel Briquettes. Briquetting can be done to agricultural and Forest Waste with a maximum moisture content of 8-12%. The Biomass waste with higher moisture is dried and moisture is reduced up to 25% in Flash Dryer and above 25-50% is in Rotary Drum dryer and is than pulverized to small particles with hammer mill Grinder and fed to Briquetting Press with the help of Hopper. Yuke briquette machine manufacturers's machine feature a sturdy construction, which guarantees constant briquette-quality in continuous operation.

Briquette Press Machine Features:

Briquetting Press is die and punch type mechanical press with two Ry wheels. One Ry wheel is driven by belts with Motor. Filtered & cooled lubrication oil is supplied by pump through p.pipes. Material is continuously fed through a hopper by means of a vertical feeder with its own gearbox and a motor. Regulated feed to the press is provided by independently driven screw through Rexible pulley/drive on motor. From feeding chamber material is compressed by ram through taper bore die. Briquettes comes out from cooling line. Total process is Continuous & Controlled by panel. Charcoal maker machine is used for binder less production of high density fuel briquettes i.e. “biocoal” from all types of degradeable biomass. Residues & wastes such as groundnut shell, wood waste, baggasse (sugar cane stalk), cotton shell/stalk, mustard husk/straw, coQee husk, pine needle, saw dust etc. Acceptable moisture in raw material of briquetting is 8-12%.

Why Briquetting :

Today every country wants to preserve their fossil fuel such as oil, natural gas, coal & wood. Briquette is not only a good fuel but is also good for nature, as it only emits that mush of CO2 which is required by the environment for Plants & trees. Beside Energy various governments offers huge incentives and promotional tax benefits to install coal briquette machine.

0 notes

Text

Lots of wips! Ych of Penelope & Mike for Biocoal, Aztecca belly bust for him as well, and 2 other anthros for him as well..... names have escaped me currently, but also a piece of Jess the naga for @AveryHillpeak cuz I wanted to finish an old piece I found of her~ better late than never lol.

10 notes

·

View notes

Text

Soil Wetting Agents Market by Growth, Shares, Driving Factors, Key Segments and Regional Analysis 2021

Soil Wetting Agents Market is expected to show magnificent CAGR according to latest study Published by Profshare Market Research. The percentage splits, market shares, growth rate and breakdowns of the product markets are determined through using secondary sources and verified through the primary sources. The study also provides key market indicators affecting the growth of the market.

Research report includes in depth competitive analysis with shares of each player inside market, growth rate and market attractiveness in different end users/regions. Study used very precise top-down and bottom-up approach in order to validate market revenue, volume, manufacturers, regional analysis, product segments and end users/applications.

Major players in the market are identified through secondary research and their market revenues determined through primary and secondary research. Secondary research included the research of the annual and financial reports of the top manufacturers; whereas, primary research included key opinion of leaders and industry experts.

Seamless product delivery to consumer has become more important than it ever were, proper value chain analysis exactly delivers the same. Supplier analysis delivers very clear picture supply- demand scenario in the market. Opportunities and threat analysis has gain significant importance in recent years primarily due to dynamic nature of industry. Analytical tools used while developing research studies includes SWOT analysis, market sizing, Porter’s 5 Forces model, PESTAL analysis.

Access Full Report @ https://www.profsharemarketresearch.com/soil-wetting-agents-market/

Market Segmentation

Product Types:

Granular

Liquid

Application/ End User Analysis

Agriculture

Turf Care

Company Analysis

BASF SE

easol International Pty Ltd

Brett-Young Seeds Limited

MD Biocoals Pvt. Ltd.

Geoponics Corp

Wilbur-Ellis Company

Nufarm Limited

Grow More

Regional analysis

North America : USA, Mexico, Canada

Europe: UK, Germany, France, Spain, Italy, Netherlands & Rest of Europe

Asia Pacific : China, India, Japan, Singapore, South Korea & Oceania

Latin America : Brazil & Argentina

Middle East : UAE, Qatar, Israel.

Rest of the World.

Research report includes below primary reasons that makes it very useful as one stop information point for various market scenarios.

Market estimation

Forecast 2020-28

Growth drivers

Raw material & Supply analysis

End User & Application insight

Key player’s analysis

Import & Export scenario

Challenges & Opportunities

Current & emerging market trends.

Tenders & Pricing scenario.

Key Questions answered by the Soil Wetting Agents Market Report:

What is the Base Year for Soil Wetting Agents Market report?

What historical data is included in Soil Wetting Agents Market Report?

Are Top companies in Soil Wetting Agents Market are analysed in this report?

What are the regions analysed in Soil Wetting Agents Market Report?

What are the main topics covered in the Soil Wetting Agents Market Report ?

Is COVID 19 impact on the Soil Wetting Agents Market included in the report ?

About Profshare:

Profshare Market Research is a full service market research company that delivers in depth market research globally. We operate within consumer and business to business markets offering both qualitative and quantitative research services. We work for private sector clients, along with public sector and voluntary organizations. Profshare Market Research publishes high quality, in-depth market research studies, to help clients obtain granular level clarity on current business trends and expected future developments. We are committed to our client’s needs, providing custom solutions best fit for strategy development and implementation to extract tangible results.

To Know More About Us Visit :https://www.profsharemarketresearch.com/

Contact :

Kalyani D

Profshare Market Research

0 notes