#best stainless steel fittings India

Text

Top Stainless Steel Fitting Suppliers in India for 2024

India is domestic to some of the location’s most important manufacturers and corporations of chrome steel fittings, which may be important additives in a big form of industries. Whether it’s to be used in production, car, petrochemical, or meals processing, stainless-steel fittings are regarded for their durability, resistance to corrosion, and versatility. In 2024, the selection for for notable chrome steel fittings continues to grow, and organizations in the course of the u . S . Are stepping up to meet this call for. In this weblog, we're capable of discover the pinnacle stainless steel turning into companies in India for 2024, with a focus on what makes them the awesome in the company.

Importance of Stainless Steel Fittings

Before diving into the listing of top companies, it’s essential to recognize why chrome steel fittings are so crucial. These additives, which embody elbows, tees, couplings, flanges, and further, are used to attach pipes, valves, and different equipment in an entire lot of structures. The choice of cloth is essential due to the fact the fittings need to withstand excessive pressures, severe temperatures, and corrosive environments without failing.

Stainless steel is the preferred cloth for fittings due to its superior houses:

Corrosion Resistance: Stainless steel’s chromium content material cloth office paintings a passive layer that stops rust and corrosion.

Strength and Durability: Stainless metal can face up to immoderate strain and temperatures, making it ideal for enterprise programs.

Hygiene: In industries like meals processing and prescribed drugs, stainless-steel’s non-porous floor guarantees that it no longer harbors microorganisms, making it clean to easy and preserve.

Aesthetic Appeal: In architectural programs, chrome steel fittings offer a swish, current-day look.

Given the advantages, the choice for chrome steel fittings stays robust, and finding a dependable dealer is important for companies in India and past.

Top Stainless Steel Fitting Suppliers in India for 2024

Sailesh Metal

Overview: They have mounted itself as one of the main stainless steel companies in India. Known for its commitment to brilliant and purchaser delight, the organization gives a huge type of stainless-steel fittings, which consist of elbows, tees, reducers, and flanges, amongst others.

Strengths: It is diagnosed for its large stock, competitive pricing, and potential to deliver stylish and custom fittings. The business enterprise’s products are made from high-grade stainless-steel, making sure extended-lasting common universal standard performance in even the maximum worrying environments.

Certifications: Sailesh Metal is ISO certified, reflecting its adherence to stringent awesome manage requirements.

Key Markets: The enterprise serves a numerous style of industries, along with oil and gasoline, chemical processing, meals and beverage, and introduction.

Suraj Metal Corporation

Overview: Suraj Metal Corporation is every other top participant inside the Indian stainless-steel fittings marketplace. With a long term of enjoyment, the corporation is thought for its first rate products and splendid customer support.

Strengths: Suraj Metal Corporation offers a complete variety of fittings, which include but no longer restrained to, strong fittings, buttweld fittings, and flanges. The agency is also well-known for its prompt shipping and incredible after-profits aid.

Certifications: The industrial enterprise company employer holds a couple of certifications, such as ISO 9001, ensuring that their products meet international requirements.

Key Markets: Suraj Metal Corporation regularly caters to the auto, petrochemical, and power generation industries.

Bhansali Overseas

Overview: Bhansali Overseas has earned recognition as one of the exceptional stainless steel becoming providers in India through continuously offering brilliant products to its customers. The business business enterprise offers an intensive kind of stainless-steel fittings that meet the numerous desires of diverse industries.

Strengths: Bhansali Overseas is known for its revolutionary solutions and capacity to meet the correct necessities of its customers. The enterprise's products are known for his or her precision, sturdiness, and corrosion resistance.

Certifications: Bhansali Overseas is licensed under several worldwide requirements, which consist of ASTM and ASME, ensuring that their fittings meet international benchmarks for fantastic.

Key Markets: Bhansali Overseas materials to industries which includes pharmaceuticals, dairy, and meals processing, in which hygiene and reliability are paramount.

K. K. Industries

Overview: K. K. Industries is a prominent call in the stainless steel fittings employer, said for its superb merchandise and client-centric technique. The business corporation has a big type of fittings, together with solid fittings, pipe fittings, and flanges, to be had in numerous grades of stainless steel.

Strengths: K. K. Industries’ energy lies in its strong production skills, which allow it to supply fittings that meet the first-rate specifications of its clients. The enterprise moreover gives customized answers to cater to particular enterprise necessities.

Certifications: The organization is ISO 9001 licensed and adheres to strict super manipulate measures at every degree of manufacturing.

Key Markets: K. K. Industries considerably serve the chemical, oil and fuel, and introduction sectors.

Petromet Flange Inc.

Overview: Petromet Flange Inc. Is a number one dealer of stainless steel fittings in India, regarded for its willpower to be extremely good and innovative. The organization gives a huge form of fittings, at the side of buttweld fittings, socket weld fittings, and threaded fittings.

Strengths: Petromet Flanges Inc. Is recognized for its first-rate products, properly timed delivery, and terrific customer service. The company invests within the modern-day production

technologies to make sure that its products meet the very first-rate requirements of super.

Certifications: The organization is certified underneath ISO 9001, and its products examine worldwide necessities alongside ASTM and ASME.

Key Markets: Petromet Flanges Inc. Serves industries collectively with oil and gas, petrochemicals, and marine.

Metal Forge India

Overview: Metal Forge India is every other pinnacle provider of stainless steel fittings, seemed for its complete product range and robust hobby on customer delight. The company offers a large type of fittings, consisting of elbows, tees, reducers, and extra.

Strengths: Metal Forge India is noted for its great merchandise, aggressive pricing, and super customer support. The corporation additionally gives customized fittings to satisfy the appropriate dreams of its clients.

Certifications: Metal Forge India is ISO licensed and follows rigorous exceptional control procedures to make sure the reliability of its merchandise.

Key Markets: The industrial organization business enterprise usually serves the oil and fuel, chemical processing, and power technology industries.

As we circulate into 2024, the choice for best stainless steel fittings India maintains upward thrust, driven through the growth of industries collectively with introduction, automobile, and petrochemicals. The terrific stainless steel fittings India has to offer come from businesses that prioritize excellent, purchaser delight, and innovation. Whether you’re looking for well-known or custom fittings, the agencies listed above have installed themselves as leaders inside the marketplace, providing reliable products that meet the various desires of diverse industries.

At Sailesh Metal, we pride ourselves on being one of the pinnacle stainless steel turning into agencies in India. Our electricity of mind to top notch, large product range, and client-focused method set us other than the competition. Contact us nowadays to have a study more about our products and the manner we're able to benefit from the useful resource your agency desires with the incredible stainless steel fittings in India.

0 notes

Text

Mild Steel Flanges Details

Why MS Flanges Matter

MS flanges, short for Mild Steel flanges, are essential components in the industrial and construction sectors. These flanges, made from mild steel, are prized for their robust strength, cost-efficiency, and versatility. They serve as crucial connectors, fastening pipes, valves, and various machinery, ensuring that everything stays tightly sealed and leak-free.

The Appeal of Mild Steel

Mild steel is a top choice for many due to its durability, ease of use, and affordability. It offers a great balance between performance and cost, making it resistant to moderate corrosion while withstanding significant pressure. Whether you're working on an industrial project or a construction site, mild steel is a reliable material. For the best MS flanges in India, look no further than Udhhyog, a leading manufacturer in the field.

A Closer Look at Different MS Flanges

Slip-On Flanges: Easy and Effective

Slip-on flanges are known for their ease of installation—they slip over the pipe and are welded into place. This makes them perfect for applications where precise fitting is key. They’re commonly used in low-pressure environments and offer an economical solution for various projects.

Weld Neck Flanges: Built for Performance

Weld neck flanges feature a long, tapered neck that smoothly transitions from the pipe to the flange. This design reduces stress concentrations, making these flanges ideal for high-pressure and high-temperature applications. They are often used in critical systems where reliability and strength are crucial.

Blind Flanges: Sealing with Confidence

Blind flanges are designed to close off the end of a pipe or vessel, with no central hole. They are perfect for sealing off pipelines or openings, providing a strong barrier for maintenance or potential expansion in the future.

Socket Weld Flanges: Strong and Reliable

Socket weld flanges have a recessed area where the pipe fits before being welded. This design ensures a smooth bore and a secure connection, making them suitable for high-pressure applications. They’re commonly used in industries where a strong, leak-proof joint is essential.

Real-World Applications of MS Flanges

MS Flanges in Industrial Operations

In industrial environments, MS flanges are critical for connecting various machinery components, such as pumps and valves. They ensure that these parts are securely joined, helping to maintain efficient operations and prevent leaks.

Their Role in the Construction Industry

MS flanges are vital in construction projects, where they link structural steel components. They provide the necessary strength to handle heavy loads and ensure that different parts of a structure are firmly connected.

Crucial for Piping Systems and Equipment

MS flanges play a key role in piping systems, connecting pipes, valves, and other fittings. They help maintain the system's integrity, making it easier to perform maintenance and repairs when needed.

Why Choose MS Flanges?

Cost-Effective and High Value

MS flanges offer a cost-effective alternative to more expensive materials like stainless steel. Despite their lower cost, they do not compromise on quality, making them a popular choice for various applications.

Durability and Robustness

Mild steel flanges are known for their durability and strength. They are built to withstand various pressures and temperatures, making them suitable for a wide range of industrial and construction uses.

Simple Installation and Maintenance

MS flanges are designed for easy installation and maintenance. Their straightforward design makes them easy to assemble and disassemble, which can save both time and effort during installation and upkeep.

How to Select the Right MS Flange

Important Considerations

When selecting an MS flange, it’s essential to consider the type, pressure rating, and compatibility with other materials. Choosing the right flange ensures a secure connection and optimal performance for your specific application.

Sizing and Specification Essentials

Accurate sizing is crucial for a secure and efficient connection. Refer to industry standards and specifications to ensure you select the right size and type of flange for your project.

This version offers another fresh perspective, ensuring the content remains original and engaging while highlighting the key aspects of MS flanges.

2 notes

·

View notes

Text

Concentric Reducers Exporters in India

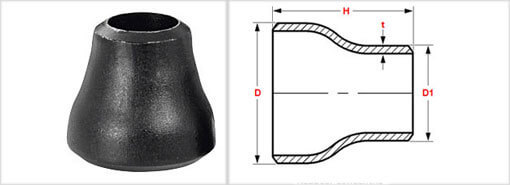

CONCENTRIC REDUCERS

The Concentric Reducers are accessible in assortment of shapes and measurements to suit real pipeline establishment necessities in commercial ventures. This is a standout amongst the most generally utilized modern funnel fitting for adjusting distinctive channel sizes in a pipeline framework. It is fundamentally used to associate two funnels with various widths.

Produced using best grades of stainless steel, these reducers are accessible in an extensive variety of sizes, divider thicknesses and weight evaluations to look over as indicated by the pipeline. Guaranteeing an in-line funnel shaped move between various widths of pressurized channels, these concentric reducers join the pipelines on the same axis.The development of these reducers is finished by joining the little breadths and expansive distances across on inverse closures of cone formed move area. Discover application in petrochemicals, sugar factories and refineries, steel plants and bond and development commercial ventures, the reducer has separate gulf and outlet closes.TECHNICAL SPECIFICATIONSSTANDARD MATERIAL GRADES OF BUTTWELD SS REDUCER

Stainless steel grades:

ASTM A403 Grade WP304, WP304L, WP304H, WP304N, WP304LN, WP309, WP310S, WPS31254, WP316, WP316L, WP316H, WP316N, WP316LN, WP317, WP317L, WP321H, WP321, ASTM A815 S31803, S32750, S32760, S32205

Standard material grades in stainless steel:

ASTM A182 F304, F304H, F304L, F304N, F304LN, F309H, F310, F310H, F316, F316H, F316L, F316N, F316LN, F317, F317L, F347, F347H, F321, F321H, FXM-19, F50, F51, F53, F55, F60, F904L

Application Areas:

Oil and gas industry

Petrochemical industry

Power stations

Shipbuilding industry

10 notes

·

View notes

Text

Super Duplex S32760 Flanges Manufacturers in India

The manufacturer and supplier of Very Duplex Steel Flanges made their products in a variety of sizes and forms for the customer in response to interest. The manufacturer, stockist, and supplier of the entire stainless steel item, including this, is Sankalp Alloys Overseas. They provide everything and deliver the product while maintaining excellent quality and price as well.

Super Duplex Steel Flanges are regarded as the best in the series of steel Flanges based on their characteristics and strong points. The austenitic toughened steel is offered in Very Choice with a few components like copper, zinc, and chromium. The majority of businesses use a lot of Duplex steel products since they provide high strength when they come into touch.

There are many kinds of Flanges accessible, for example, Welding Neck Wall It is by and large utilized in low-temperature and high-pressure applications since they required the unhindered liquid stream conveyed by the line framework. Long welding Neck-They is equivalent to a weld neck just contrast in a lengthy welding neck the tightened center point (neck) is expanded and performs like an exhausting expansion. Slip-on Spine It is appended to the fittings or the line by two filet welds, one external the hole and the other one executed inside the rib. They are handily perceived by their minimal and thin shape.

Strung Rib This is attached by screwing the line into the spine rather than using a crease weld. They are typically used in small, low-temperature, low-stress applications like utility and water management. They are legally required in dangerous areas like petrol stations and industries. Since welding associations could be dangerous in this type of environment. Spine Attachment Weld To connect this type of rib to the lines, a single fillet weld is performed on the exterior of the rib. Joint-joint ribs This spine frequently uses an alloy with a stub end and a component with a level spacing. Dark Spine Due to the necessary catapulting forces and the structure pressure, these Flanges reduce outstanding mechanical forces.

A few other exceptional sorts of rib are Nipo rib, Weldo rib, Turn Rib, Elbo Rib, Lactro Rib, Growing spine, and Lessening Rib.

Specification of Super Duplex Stainless Steel S32750/S32760 Flanges

Super Duplex Stainless Steel Flanges Specification: ASTM A182 / ASME SA182

Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size: 1/2" (15 NB) to 48" (1200NB)

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges: BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

11 notes

·

View notes

Text

Barred Tee Buttweld Fitting Exporters in India

Nutech Overseas, should see the open method to present as a fundamental Stainless Steel Banned Tee Manufacturers in India. ASME B16.9 Banished Tee are stacked or open in the going with level of materials and sizes for the oil, gas, petrochemical and joined endeavors. Pipes & Tubes with Banned Tee can be collected and crushed with no issue. SS Banned Tee can be made or plate. Many Alloy Steel Buttweld Banned Tee Manufacturers in India produce these Carbon Steel Banished Tee from made materials and have machined surfaces. Consider our expense from Banned Tee manufacturers in India or China you will find best rate from our affiliation.

4 notes

·

View notes

Text

Hydraulic Manifold valve manufacturer in india by hydrofittings

In addition, an Air Manifold With Valves allows the set up of more than one solenoid valves in a centralized vicinity. A unmarried air deliver and port are shared by means of numerous valves. Manifold take a look at Valve acts as a primary distribution point for aircraft that have dual dry air pumps. If one pump of Manifold Pneumatic fails it’s miles designed to isolate the failed pump and provide continuous airflow from the operating pump. Water Manifold With Valves is designed to distribute water and has built-in ports in a section of pipe. They act as manage facilities of water distribution within the house. Solenoid Valve Manifold has a most preferred stress of 6000 psi at a hundred ranges F and has a mounting hollow that enables inside the self-supporting software. Hydraulic Valve Manifold Has a stainless steel pin that forestalls the bonnet from detaching itself from the frame due to vibration. Ball Valve Manifold has a burr-loose thread that reduces inner floor leaks accordingly offering accurate transmitter read. No O-ring is used bonnet to body pressure Transmitter Manifold seal. It is a steel-to-metallic seal. Hydraulic Valve Manifold Block has the choice of panel mounting. There are one of a kind sorts of Manifold Valves to be had within the market but the maximum typically used ones are the two valve, three valve, and 5 valve assemblies. Swagelok Manifold is designed mainly for liquid stage, static stress, and differential stress packages. Smc Valve Manifold has a blended isolating and venting in a single valve that eliminates the want for tubing and fitting. Festo Valve Manifold is simple to gather and set up and is dependable. They’ve dirt caps fitted on them that comprise stem lubricant and save you the ingress of contaminants. Rosemount 305 Manifold gets rid of the need for a flange because it suits immediately to the patented Rosemount. Why to choose hydrofittings ? About us – The briefcase of our company consists of numerous additions which include, – clever hydraulics, engineering, and digital answers. With the guide of 80 personnel, our company works like a well-oiled system to deliver most effective the very best fine product to our buyers. Proper from the responsibly sourced product by way of our procurement team to our nice manage team, many agencies have lauded our work. And that they admire the fact that we’re transparent in all our dealings. With a properly-mounted channel of communique, our customers can connect with us anytime. Our control and our body of workers, together form a competent and ambitious crew. The readability and high stage of performance make us one of the most modern but sought after manufacturers. And because we fee initiative behavior, we adore to have our studies and development crew collaborate with the opposite teams to recognize the current requirements of the hour. We frequently have checking out and great exams to maintain brilliant requirements.

An global provider of

TO KNOW MORE ABOUTS US VISITE OUR WEBSITE www.hydrofittings.com

3 notes

·

View notes

Text

Genuine Modular Kitchen in Indian Style

Source of info: https://www.regalokitchens.com/blog/genuine-modular-kitchen-in-indian-style

Introduction

India's homes are being transformed by a modular kitchen in their homes which combine new benefits with the rich culture of the nation. The flexibility, practicality, and attractive appearance of the customized kitchen concept are responsible for its wide popularity. Indian homeowners are accepting flexible kitchen designs more and more, which not only improve performance but also showcase their personal tastes. This blog post will cover the appealing qualities of authentic Indian-style customized kitchens and how Regalo Kitchens can build the perfect kitchen for you. Depending on your demands, a modular cooking area can be placed in a small apartment or a big house.

The Essence of Indian Style Modular Kitchen

The customs of Indian cooking are unique, as are the needs for a practical kitchen area. Indian food has many flavors and often calls for a large variety of ingredients, cookware, and appliances. This means that the most key features of an Indian-style modular kitchen are storage and accessibility. A genuine kitchen with modular design combines trendy design features for user-friendliness with the basic features of traditional Indian kitchens, such natural color palettes, organic materials, and practical storage options. It offers the perfect solution for the stressful lifestyle of today by carefully combining design and functionality.

Key Features of a Modular Kitchen in Indian Style:

Customized Storage Solution

A wide range of spices, pulses, and cookware are used in Indian cuisine, all of which require their own place. Indian-style kitchens that are modular highlight practical storage solutions to keep everything accessible and organized, such as deep drawers, cabinets, pull-out shelves, and corner units. Regalo Kitchens is an expert in creating personalized storage solutions that maximize the amount of space you have available.

Durable Materials

Durability is important since Indian kitchens include a lot of hard cooking. Solid oak cabinets, granite countertops, and stainless steel are common materials. These materials are durable to heat, oil, and spice the exposure, all of which are common in regular cooking. Regalo Kitchens provides a range of long-lasting materials that improve the functionality of your kitchen while also giving it a luxurious feel.

Traditional Aesthetics

A Modern modular kitchen can have a traditional Indian touch in their design even if they work in a modern way. An Indian atmosphere is produced by features like warm color schemes (terracotta, beige, or mustard) combined with decorative backsplashes, wooden cabinets, or brass fittings. Regalo Kitchens develops designs that express a feeling of tradition without giving up on modern effectiveness.

Ventilation and Lighting

Since Indian food can often be fresh, airflow is important. Proper windows, exhaust fans, and chimneys make sure your modular kitchen stays fresh. Warm, bright lighting also adds to the overall attraction, especially when it's used for task lighting, which is ideal above counters for precise work.

Efficient Workflow

An effective workflow is based upon the layout of a modular kitchen. The L- or U-shaped layout is a common characteristic in Indian-style kitchens, providing lots of room for easy access to areas for cooking, cleaning, and preparation work. Regalo Kitchens provides designs that are customized to satisfy the unique requirements of Indian homes.

Indian Modular Kitchen Layouts: Designs for Every Home

For the best possible functioning of your kitchen, the layout you choose is important. Because of their flexibility, flexible kitchen layouts let homeowners choose the style that best fits their requirements.

1. L-Shaped Kitchen

The L-shaped kitchen is a popular choice for Indian homes, as it offers efficient space utilization while keeping everything within easy reach. It is particularly suitable for smaller spaces and allows for a cozy dining nook.

2. U-Shaped Kitchen

For larger kitchens, the U-shaped layout provides ample counter space and storage. It’s ideal for families who love cooking together, as it allows multiple people to work in the kitchen simultaneously without feeling cramped.

3. Island Kitchen

The island kitchen is perfect for open-plan homes, where the kitchen is part of a larger living space. An island counter can serve as both a workspace and a dining area, creating a multifunctional space that’s perfect for modern Indian homes.

Regalo Kitchens: Bringing Authentic Modular Kitchens to Your Home

The kitchen is the main attraction of any Indian house, in our opinion at Regalo Kitchens. Our modular kitchen layouts combine modern usefulness with traditional style, fully suited to the unique needs of Indian homes. Whether you have your choice for a modern design or a kitchen that reflects your cultural background, we have the knowledge and passion for achieving your idea.

Our design staff collaborates directly with you to fully understand your unique needs, making sure that every element of your kitchen—from layout to storage—is customized for your way of life. Regalo Kitchens builds long-lasting kitchens by focusing environmentally friendly practices, fine materials, and expert craftsmanship.

Conclusion

The best way to combine the comforts of modern design with the customs of Indian cuisine is with a genuine modular kitchen. Regalo Kitchens is your partner in designing a kitchen that is as beautiful as it is practical, whether you are building a new house or remodeling your current one. To combine the best features of history and modernity, select a modular kitchen that suits your daily needs and expresses your style.

1 note

·

View note

Text

Top-Quality Pipe Fittings by Pearl Pipe Fittings

Pearl Pipe Fittings is a reputed Pipe Fittings Manufacturer in India specializing in various comprehensive solutions. These products are carbon steel fittings and flanges used in severe service applications. Pearl is also committed to precision engineering, using only the finest materials to lead industries including oil/gas construction.We are also the best Flange Manufacturer in India and CS Flanges Manufacturers in India

Contact us

Website: https://pearlpipefittings.com

Call us at +91 91723 33437

Product Source: Carbon Steel Pipe Fittings Manufacturer in India and Copper Nickel Flange Manufacturer in India

You may also like: Stainless Steel Flanges Manufacturer in India and SS Pipe Fittings Manufacturers in India

#carbon steel pipe fittings manufacturer in india#pipe fittings manufacturer in india#flange manufacturer in india#cs flanges manufacturers in india#cristiano ronaldo#stainless steel flanges manufacturer in india#copper nickel flange manufacturer in india#business#industrial#ss pipe fittings manufacturers in india

0 notes

Text

Importance of Compression Tube Fittings Manufacturer in India

Overview of Compression Tube Fittings

Compression tube fittings are a critical component in various industries, providing a reliable and leak-proof connection for tubing systems. These fittings are essential in applications where precision, durability, and safety are paramount. Whether it's in the oil and gas sector, chemical processing, or power generation, the right choice of compression tube fittings manufacturer in Mumbai, Chennai, Ahmedabad, Rajasthan, Bangalore, Vadodara, Gujarat, Ghaziabad and Delhi, it can make a significant difference in operational efficiency and safety.

Why Choose Compression Tube Fittings?

Compression fittings offer numerous advantages, such as ease of installation, reusability, and resistance to high pressures and temperatures. Unlike welded or soldered joints, compression fittings can be assembled and disassembled without specialized tools, making them a preferred choice for maintenance and repairs.

The Importance of Quality in Fittings Manufacturing

The quality of compression tube fittings is crucial. Poor-quality fittings can lead to leaks, system failures, and even safety hazards. Therefore, selecting a reputable manufacturer like We ensures that you get products that meet stringent quality standards and provide reliable performance over time.

Pedlock's History and Reputation

Pedlock has established itself as a premier manufacturer of compression tube fittings, known for its commitment to quality and innovation. With decades of experience, our company has built a solid reputation in the industry, providing top products to clients worldwide.

Commitment to Quality and Innovation

We dedication to quality is evident in its state of the art manufacturing facilities and rigorous quality control processes. The company continually invests in research and development to innovate and improve its product offerings, ensuring that customers receive the best solutions for their needs.

Global Presence and Clientele

With a global presence, we serves a diverse range of industries and clients, from small businesses to large multinational corporations. This extensive reach is a testament to the trust and confidence that customers place in our products and services.

What Are Compression Tube Fittings?

Compression tube fittings manufacturer in Bangalore, Ahmedabad, Vadodara, Mumbai, Chennai, Delhi, Rajasthan, Ghaziabad and Gujarat is mechanical fittings used to connect tubes in a secure and leak-proof manner. They are commonly used in applications involving fluids and gases, where precision and reliability are essential.

How Do They Work?

Compression fittings work by compressing a ferrule onto the tube as a nut is tightened, creating a tight seal. This mechanism allows for secure connections without the need for welding, threading, or adhesives.

Types of Compression Tube Fittings

Single Ferrule vs. Double Ferrule

Single Ferrule: Consists of one ferrule that compresses onto the tube, providing a seal.

Double Ferrule: Uses two ferrules, offering enhanced sealing and gripping performance, making them ideal for high-pressure applications.

Male vs. Female Connectors

Male Connectors: Feature an external thread, used to connect to female fittings.

Female Connectors: Have an internal thread, designed to receive male connectors.

Raw Material Selection

We carefully select high quality raw materials to ensure the durability and performance of its fittings. Materials like stainless steel, brass, and other corrosion resistant alloys are commonly used.

Precision Engineering and Machining

Advanced CNC machines and precision engineering techniques are employed to manufacture fittings to exact specifications. This precision ensures that each fitting performs reliably, even in demanding conditions.

Quality Control Measures

Every Pedlock fitting undergoes stringent quality control checks, including dimensional inspections, pressure testing, and material verification. This rigorous process ensures that only the highest quality products reach the customer.

Benefits of Using Compression Tube Fittings

Superior Leak-Proof Design

Our fittings are engineered to provide a secure, leak-proof connection, even under high-pressure conditions. This reliability makes them ideal for critical applications where leaks are not an option.

High Pressure and Temperature Resistance

Our fittings are designed to with stand extreme pressures and temperatures, ensuring long lasting performance in challenging environments.

Easy Installation and Maintenance

The design of our compression tube fittings allows for quick and easy installation, reducing downtime and maintenance costs. This user-friendly feature is particularly beneficial in industries where time is of the essence.

Applications of Compression Tube Fittings Manufacturer

Oil and Gas Industry

Pedlock fittings are extensively used in the oil and gas sector, where they provide reliable connections in pipelines and equipment used for extraction, refining, and distribution.

Chemical and Petrochemical Industry

In chemical processing plants, our fittings ensure safe and leak-proof connections in systems handling hazardous materials, maintaining the integrity of the operation.

Power Generation and Utilities

Our compression fittings are crucial in power generation facilities, providing secure connections in systems that require high pressure and temperature resistance.

Other Industrial Applications

From automotive to aerospace, our fittings find applications across various industries, proving their versatility and reliability in diverse environments.

Choosing the Right Compression Tube Fitting

Factors to Consider

When selecting a compression fitting, it's essential to consider factors such as pressure rating, temperature compatibility, and material selection to ensure optimal performance.

Compatibility and Sizing

Choosing the correct size and ensuring compatibility with existing systems is crucial to prevent leaks and maintain the integrity of the connection.

Material Selection and Corrosion Resistance

Selecting the appropriate material for your application is key to preventing corrosion and ensuring the longevity of the fitting. We offer a range of materials to suit different needs.

Pedlock's Competitive Advantage

Cutting Edge Manufacturing Technology

We use of an advanced manufacturing technology ensures the production of high-quality, precision-engineered fittings that meet the stringent demands of various industries.

Exceptional Customer Support

We pride it on providing exceptional customer support, assisting clients with product selection, installation guidance, and technical support.

Certifications and Compliance

Our fittings are certified to meet various international standards, ensuring compliance and quality assurance for customers worldwide.

Conclusion

Pedlock is a trusted name in the field of compression tube fittings manufacturer in Ahmedabad, Chennai, Mumbai, Vadodara, Gujarat, Bangalore, Rajasthan, Delhi, and Ghaziabad in India as known for its quality, innovation, and exceptional customer service. With a wide range of products and a commitment to excellence, we remain the preferred choice for industries seeking reliable and high-performance fittings.

#compression tube fittings manufacturer in Mumbai#compression tube fittings manufacturer in Chennai#compression tube fittings manufacturer in Ahmedabad#compression tube fittings manufacturer in Vadodara#compression tube fittings manufacturer in Gujarat#compression tube fittings manufacturer in Delhi#compression tube fittings manufacturer in Rajasthan#compression tube fittings manufacturer in Ghaziabad#compression tube fittings manufacturer in Bangalore

0 notes

Text

Figuring out Round Bars' Superiority: An All-Inclusive Guide

Introduction:

Nova Steel Corporation is leading Round Bar Manufacturer in India. Round bars, the unsung heroes of the industrial world, have a significant impact on modern infrastructure and innovation. Despite their simple appearance, round bars are essential components in a variety of industries, including construction, manufacturing, automotive, and aerospace. In this comprehensive tutorial, we will look at the fundamentals of round bars, including their applications, properties, and why they are such important components in engineering and design.

Understanding Round Bars:

Round bars, often called rods or solid bars, are cylindrical metal bars with a circular cross section. They are fabricated from different materials, including steel, stainless steel round bar, High Nickel Alloy Round Bars, XM19/Nitronic Round Bar, LF2 Round Bar, and Alloy Steel 4340 Round Bar, each offering unique properties suited for specific applications. Round bars are manufactured through processes such as hot rolling, cold drawing, or machining, ensuring precise dimensions and consistent quality.

Applications Across Industries:

The versatility of round bars renders them indispensable across a myriad of industries:

1. Construction: Round bars are fundamental components of construction projects; they are used to fabricate building and bridge frameworks, create support beams, and reinforce concrete structures.

2. Manufacturing: Round bars are used in the manufacturing industry to make shafts, axles, fasteners, and precision components for machinery, equipment, and tools.

3. Automotive and Aerospace: Because of their strength, endurance, and resistance to corrosion, round bars are widely used in the automotive and aerospace industries for the fabrication of engine parts, chassis components, landing gear, and structural elements.

4. Energy Sector: Round bars are used in the energy industry to manufacture pipelines, drill rods, and components for power production and transmission equipment.

Key Characteristics:

Several key characteristics make round bars indispensable in engineering and construction:

1. Strength and Durability: Round bars provide structural integrity and endurance because of their great tensile strength and resilience, which allows them to handle large loads and harsh environments.

2. Machinability: Round bars are easily machined and built into unique components, allowing for precision shape and dimensional accuracy to fulfill design specifications.

3. Corrosion Resistance: Because of their superior corrosion resistance, materials such as aluminum and stainless steel are a good choice for outdoor and marine applications where exposure to severe conditions and moisture is common.

4. Thermal Conductivity: Round bars conduct heat well, making them ideal for applications that require heat transmission or dissipation, such as heat exchangers and thermal management systems.

Best Round Bar Manufacturer

Nova Steel Corporation is leading Round Bar Supplier in India. We have substantial expertise in the manufacturing and supplying of all sorts of Round Bars. We are Best Round Bar Manufacturers. Personnel with the necessary qualifications and a wealth of experience handling different kinds of Pipe Fittings and other products supervise the whole manufacturing process.

Finally, round bars represent the pinnacle of versatility, strength, and dependability in the field of engineering and building. From towering skyscrapers to precise machinery, round bars are the foundation of modern infrastructure and innovations, representing human ingenuity and perfection. As technology advances and businesses evolve, the importance of round bars will grow, influencing the landscapes of tomorrow and beyond.

0 notes

Text

A Detailed Overview of Pipe Fittings Manufacturers in India

In the industrial world, the seamless operation of fluid and gas transportation systems heavily relies on the quality of the pipe fittings that connect and support these systems. These components, though often overlooked, are critical in ensuring the safety, efficiency, and longevity of industries such as oil and gas, chemical processing, water treatment, pharmaceuticals, and power generation. India, as one of the fastest-growing industrial hubs, has emerged as a global leader in manufacturing high-quality pipe and tube fittings. This blog will explore the roles of pipe fittings manufacturers in India, their connection with tube fittings manufacturers, the significance of double ferrule fittings, and the leading companies in cities like Mumbai.

The Importance of Pipe Fittings in Industrial Systems

Pipe fittings are integral in creating connections within piping systems that transport liquids, gases, and sometimes solids. They allow changes in direction, branch connections, size changes, and even secure closures of systems. Pipe fittings must be engineered to withstand high pressures, extreme temperatures, and corrosion to ensure reliability over long periods. These components come in many forms, including elbows, tees, reducers, couplings, and flanges.

Key qualities of high-performance pipe fittings include:

Leak Prevention: A top priority, as leaks can cause accidents, product loss, and environmental damage.

Durability: Made from materials like stainless steel, carbon steel, and brass, quality pipe fittings withstand harsh environments and high-pressure systems.

Easy Maintenance: Well-designed fittings should allow for quick and easy assembly or disassembly for repairs and replacements.

Corrosion Resistance: Fittings, especially in industries like oil and gas, should be highly resistant to corrosion caused by exposure to chemicals and fluids.

Leading Pipe Fittings Manufacturers in India

India has grown into one of the top markets for pipe fittings production, driven by increasing demand from its industrial sector. Among the best-known pipe fittings manufacturers in India, companies like Expand Engineering have established themselves as pioneers in the production of durable and precision-engineered products.

Expand Engineering specializes in pipe fittings used in industries like oil and gas, chemical processing, and water treatment. Their products meet both domestic and international standards, making them a trusted supplier in the global market. The company’s range of pipe fittings includes stainless steel fittings, carbon steel fittings, and brass fittings, all of which are designed for long-lasting performance under challenging conditions.

Tube Fittings: Another Essential Component

While pipe fittings connect larger sections of piping, tube fittings are used to connect smaller, more delicate tubes, commonly seen in industries like chemical processing, pharmaceuticals, and instrumentation. Tube fittings are essential for ensuring leak-proof connections in systems that transport fluids or gases under precise conditions.

India has emerged as a major producer of tube fittings, with companies like Expand Engineering leading the way in offering a wide range of products. As a top tube fittings manufacturer in India, Expand Engineering provides fittings for a variety of applications, from simple residential installations to complex industrial systems. Their products are designed to meet international safety and performance standards, ensuring they can be used in high-stress environments.

Double Ferrule Fittings: A Step Above

One of the most advanced types of tube fittings is the double ferrule fitting. These fittings are designed to provide secure, leak-proof connections in high-pressure environments. A double ferrule fitting consists of two ferrules—a front ferrule that seals the tube and a back ferrule that grips the tube, providing extra strength and resistance to vibration.

Double ferrule fittings are highly valued in industries where safety and precision are critical, such as in oil and gas plants, chemical processing, and pharmaceutical manufacturing. Expand Engineering, a leading double ferrule fittings manufacturer in India, produces a wide range of double ferrule fittings that meet the stringent requirements of these industries.

Key features of double ferrule fittings include:

Leak-Proof Design: The dual ferrule system creates a reliable seal that prevents leaks even in high-pressure applications.

Vibration Resistance: The back ferrule grips the tube securely, ensuring the fitting remains intact even under high vibration.

Ease of Installation: Double ferrule fittings are designed for easy installation and disassembly, making them a practical choice for industries where quick maintenance is essential.

Corrosion Resistance: Manufactured from materials like stainless steel and brass, these fittings are highly resistant to corrosion, making them suitable for use in harsh environments.

Pipe Fittings Manufacturer in Mumbai

Mumbai, India’s financial capital, has also become a significant hub for the production of pipe and tube fittings. Several companies have established themselves as leaders in the pipe fittings manufacturer in Mumbai segment, leveraging the city’s infrastructure, access to skilled labor, and proximity to international ports.

Expand Engineering is one such company, recognized for its innovation and commitment to quality. As a pipe fittings manufacturer in Mumbai, the company provides a wide array of products that are used across different industries. Their pipe fittings are known for their durability, resistance to corrosion, and ability to perform under high pressures, making them a popular choice for industries that require reliable and long-lasting solutions.

The Role of Tube Fittings in Mumbai’s Industrial Sector

Mumbai’s industrial sector benefits from the availability of high-quality tube fittings, which are essential for various sectors, from pharmaceuticals to instrumentation. With manufacturers like Expand Engineering based in the city, Mumbai has become a key player in the tube fittings manufacturer in India industry. These fittings are crucial for creating precise and reliable connections in systems that transport fluids and gases.

Why Choose Indian Pipe and Tube Fittings Manufacturers?

Indian manufacturers have earned a reputation for producing high-quality products that meet international standards. Here’s why companies around the world choose pipe fittings manufacturers in India:

Advanced Manufacturing Technologies: Indian manufacturers utilize state-of-the-art technologies to produce fittings that are durable and meet the specific requirements of various industries.

Stringent Quality Control: Quality control processes in Indian manufacturing facilities are on par with global standards, ensuring that the products are reliable and long-lasting.

Cost-Effective Solutions: Indian manufacturers are known for offering competitive pricing without compromising on quality, making them a cost-effective option for companies worldwide.

Global Reach: Indian manufacturers export their products to numerous countries, ensuring that their pipe and tube fittings are available in global markets.

Pipe and tube fittings are critical components in any industrial system, and the quality of these fittings can make all the difference in ensuring the safety, efficiency, and longevity of such systems. India has positioned itself as a global leader in the production of pipe and tube fittings, with companies like Expand Engineering setting the standard for quality and reliability.

Whether you are looking for a pipe fittings manufacturer in Mumbai, a tube fittings manufacturer in India, or a trusted provider of double ferrule fittings, Indian manufacturers offer a wide range of high-quality, durable products designed to meet the needs of industries worldwide. Their commitment to innovation and excellence ensures that Indian-made pipe and tube fittings continue to be a crucial part of industrial systems around the globe.

#Double Ferrule Fittings Manufacturer in Mumbai#Tube Fittings Manufacturer in Mumbai#Compression Tube Fittings Manufacturer In mumbai#Double Ferrule Fittings Manufacturer in India#Tube Fittings Manufacturer in India#Pipe Fittings Manufacturer in Mumbai#Closed Die Forging Supplier in Mumbai#Hot Forging Manufacturer in Mumbai#Pipe Fittings Manufacturer in india#Closed Die Forging Supplier in India#Closed Die Forging Manufacturer in mumbai#Closed Die Forging manufacturer In India

0 notes

Text

Stainless Steel 304L Sheets & Plates Exporters In India

In today's fast-paced industrial world, the demand for high-quality, corrosion-resistant stainless steel products is on the rise. Stainless Steel 304L is one of the most popular grades for various applications due to its versatility, excellent corrosion resistance, and ease of fabrication. When it comes to exporting Stainless Steel 304L Sheets & Plates, Padmavati Steel & Engg. Co. is a name that stands out in India. With years of expertise and a reputation for delivering premium products, they are among the top exporters of stainless steel products globally.

What is Stainless Steel 304L?

The Ss 304 L plates and sheets are proposed to meet the particular necessities of the clients. These SSs things are made particularly for high risky and high warmth catch applications. The Stainless Steel 304L Sheets and Plates are enduring and can fit into any length with no burden and it is open in various shapes and sizes.

Key Features of Stainless Steel 304L:

Corrosion Resistance: 304L offers excellent corrosion resistance, particularly in mildly corrosive environments. It resists rusting and pitting, making it ideal for use in chemical processing, marine, and industrial applications.

Low Carbon Content: The “L” in 304L stands for "low carbon," which makes it more resistant to intergranular corrosion, especially after welding.

High Strength & Durability: Like other 300 series stainless steels, 304L exhibits high tensile strength and durability, making it suitable for heavy-duty applications.

Weldability: The low carbon content minimizes carbide precipitation, making 304L easy to weld without compromising corrosion resistance.

Stainless Steel 304L Sheet and Plate Specification

Standard : ASTM / ASME A240 / SA240

Size : 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm

Thickness :0.01 mm to 250 mmThk

Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange)

Finish : Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Hardness : Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

Conclusion

When it comes to Stainless Steel 304L Sheets & Plates, Padmavati Steel & Engg. Co. is a trusted name in India and across the world. With a focus on quality, affordability, and customer satisfaction, they have established themselves as a leading exporter in the stainless steel industry. Whether your project requires high corrosion resistance, weldability, or durability, you can count on Padmavati Steel & Engg. Co. to deliver the best Stainless Steel 304L solutions.

For More Information:

Visit: https://www.padmavatisteel.com/

Contact: +91-9930388308

Email-Id: [email protected]

0 notes

Text

Inside the Manufacturing Process: How Bicycle Brakes Are Made

One of a bike's most important parts for maintaining rider safety and control is the brake system. We at S.K. Aggarwal & CO are proud to be among the top manufacturers of leading bicycle brake parts in India. Situated in Ludhiana, a center for high-quality bicycle production, we are committed to creating brakes that surpass industry standards in terms of functionality, robustness, and security. We show you how we make premium bicycle brakes by taking you inside our manufacturing facility in this blog.

Step 1: Design and Engineering

Careful engineering and design serve as the foundation for the production process. Whether they are disc brakes, V-brakes, or other forms of brakes, our team of professionals is dedicated to designing brake systems that provide the best possible performance. Every component is designed with precision and dependability using sophisticated CAD tools. We take into account elements like heat dissipation, weight distribution, and material choice to create brakes that function superbly in a variety of circumstances.

Step 2: Material Selection

Selecting the proper materials is essential to producing bicycle brakes that are long-lasting and efficient. Being the top producers of bicycle brakes in Ludhiana, we employ premium components like composites, stainless steel, and aluminum alloys. These materials have been selected due to their strength, low weight, and ability to withstand corrosion and wear. To ensure long-lasting performance, our brake rotors, for instance, are made of hardened stainless steel that can tolerate severe friction and heat.

Step 3: Component Fabrication

Once the design and materials are finalized, the next step is component fabrication. This involves various processes, including:

Step 4: Assembly

In the assembly stage, individual components are brought together to form a complete brake system. This requires careful attention to detail to ensure each part fits perfectly. For instance, when assembling disc brakes, the calipers must align precisely with the rotors to provide optimal braking force. As a bicycle brakes manufacturer Ludhiana, our assembly process includes the following steps:

Cutting and Shaping: Raw materials are shaped into the precise pieces required for the brake system using CNC machines and precision cutting tools. This covers brake pads, calipers, rotors, and brake levers.

Machining: To ensure a flawless fit, these components are machined to precise specifications using high-precision CNC equipment. The smooth and responsive braking action that riders depend on is only possible with this level of precision.

Heat Treatment: To improve their hardness and wear resistance, some parts, including rotors, are subjected to heat treatment. To obtain the required mechanical qualities, this method entails heating the metal to a high temperature and quickly cooling it down.

Sub-Assembly: Individual smaller parts, including calipers and brake levers, are constructed first. This entails fastening nuts, springs, and additional tiny components.

Final Assembly: The entire brake unit is then formed by combining the sub-assemblies. Every assembly is examined by our knowledgeable specialists to ensure correct alignment, tension, and movement.

Lubrication: To guarantee smooth operation and stop wear, moving parts are greased. For the brakes to continue working as intended over time, this procedure is essential.

Step 5: Quality Control and Testing

An essential component of our production process is quality control. We follow strict quality standards as one of the top producers of bicycle brake parts in India to make sure every brake system satisfies safety and performance requirements. Our procedure for quality control consists of:

Visual Inspection: Every brake is examined visually to check for flaws such as surface abnormalities, cracks, and misalignments.

Performance Testing: Brake performance is evaluated by measuring stopping power, modulation, and heat dissipation. To make sure the brakes will function dependably in a variety of situations, this testing replicates real-world circumstances.

Testing for Durability: Brakes are put through extensive wear and fatigue tests to make sure they can handle repeated use. This involves conducting repeated brake tests to assess the components' resilience under load.

Step 6: Finishing and Packaging

The final stage is where the brakes go after passing quality control. Protective coatings, like anodizing for aluminum components, are applied to components to improve their resistance to corrosion and give them a sleek look. Lastly, to avoid damage while delivery, the brakes are properly packed. Being the best bicycle brakes manufacturers in Ludhiana, we guarantee that our goods arrive to clients' locations in flawless shape and are prepared for installation.

Conclusion

Bicycle brakes are made using a process that combines precision craftsmanship, premium materials, and cutting-edge engineering. We at S.K. Aggarwal & CO are dedicated to creating brake systems that give riders the performance and safety they require. Every stage of our production process, from design to quality assurance, demonstrates our commitment to being the top producer of bicycle brakes in Ludhiana, India.

We continue to provide brake systems that are the industry standard for performance and safety in the cycling sector by putting an emphasis on innovation and quality. Our brakes are made to provide you with the assurance and control you require on every ride, whatever of your skill level.

#bicycle brakes manufacturer in india#bicycle disc brakes in ludhiana#bicycle brakes manufacturer ludhiana#bicycle v brakes in india#bicycle disc brakes in india#bicycle disc brakes in punjab#bicycle brakes manufacturer in punjab#bicycle v brakes in ludhiana#best bicycle brakes manufacturers in ludhiana#best bicycle brakes manufacturers in punjab

0 notes

Text

Long Stub End Buttweld Fitting Exporters in India

Nutech Overseas areFittings or ANSI B 16.9 Stub End, Stub End Buttweld Fittings close to you with most limited time transport or free instance of Stub End Racket 2642. Call us or mail to [email protected] for Most recent and Refreshed regard Rundown of Stub End Buttweld Fittings and EN 1092-1 Stub End.

Nutech Overseas is most irrefutable Stub End manufacturers in India. We keep up most recognizable store of Stainless Steel Stub End Pipe Fittings. We stock vastest degree of Carbon Steel Stub End Fittings, Stub End Buttweld Fittings in different sizes. We are standard trained professional and suppliers of ANSI B 16.9 Stub End, most very smart arrangement, cost as we are one of the most astonishing suppliers and vendor of Stub End EN 1092-1 Sort 36 in India. We are most huge Manufacturers of Stub End Noise 2642 mentioned by Saudi Aramco. We pass on Stub End Jis 10k, EN 1092-1 Stub End, Stub End 304 and Mss Type B Stub End at humble rate because of sensible virtuoso hours in India and amazing store of top notch Stub End Carbon Steel, most very smart arrangement, cost open in Mumbai, India.

Nutech Overseas are manufacturers of ASME B16.9 Stub End and deftly top notch Stainless Steel Stub End Pipe Fittings offer you the best costs keeping watch. The Stub End Stainless Steel are made in all Stub End Aspects. Our important Stub End Type A, Stub End Buttweld Fittings are endeavored and checked for strength, precision and exactness. ANSI B 16.9 Stub End are incredibly utilized in pipe works and are utilized in joint various kinds of Pipes & Tubes.

Stub End Fittings are mechanical joints that wires two districts: The Stub End, which in a general sense a short length of line, which has one end that is radiated outwards and the far edge made to be welded to line of near Ostensible Line Gauge (NPS), material and of an essentially hazy divider thickness. Laid out Steel Stub End slide direct over the line and are generally regularly used with stub end fittings. A line is normally welded to the Carbon Steel Stub End and the Lap Joint line rib is allowed to turn the stub end. The upside of lap joint stubend fittings is that there won't be any issues with paralyze opening plan.

For More Information:

Visit Our Website - https://nutechoverseas.com/long-stub-end-buttweld-fitting-manufacturers-exporters-suppliers-stockists.html

Call Us: +91-9769056671

E-mail: [email protected]

#Lap Joint Stub End Buttweld Fitting Manufacturers#Lap Joint Stub End Buttweld Fitting Suppliers#Lap Joint Stub End Buttweld Fitting Stockists

10 notes

·

View notes

Text

2 Inch Gate Valves: Best Prices and Quality from Udhhyog in Delhi, India

Udhhyog, a prominent manufacturer and supplier based in Delhi, India, is proud to offer high-quality 2 inch gate valves at the lowest prices and best prices in the market. Our gate valves are engineered for superior performance and durability, making them a reliable choice for various industrial applications.

Discover our 2 inch gate valves here:

2 Inch Gate Valve

Why Choose Udhhyog’s 2 Inch Gate Valves?

Udhhyog stands out for its commitment to delivering exceptional value and quality. Here’s why our 2 inch gate valves are the ideal choice:

Durability: Our valves are crafted to withstand harsh conditions and provide long-lasting performance.

Affordability: We ensure the lowest price and best price without compromising on quality.

Dependability: Designed for accurate flow control and reliable operation.

Variety: A diverse range of options to fit different industrial needs.

Featured Gate Valve Options

1. Atam Investment Casting Stainless Steel (CF-8) Gate Valve Screwed PN-16

Our stainless steel gate valve is an excellent choice for high-pressure applications, offering superior corrosion resistance and a robust screwed PN-16 connection. This valve ensures dependable performance in demanding environments.

Explore this valve here:

Atam Investment Casting Stainless Steel (CF-8) Gate Valve Screwed PN-16

2. Atam Cast Iron Gate Valve Flanged PN-16

Our cast iron gate valve with a flanged PN-16 connection is designed for high-pressure systems. It combines durability with cost-effectiveness, making it a practical choice for a wide range of industrial applications.

Find out more here:

Atam Cast Iron Gate Valve Flanged PN-16

3. Atam Cast Iron Gate Valve Flanged PN-10

For applications requiring a lower pressure rating, our cast iron gate valve flanged PN-10 offers excellent performance and reliability at a more affordable price. It’s perfect for general industrial use.

Check out this valve here:

Atam Cast Iron Gate Valve Flanged PN-10

Selecting the Right 2 Inch Gate Valve

When choosing a 2 inch gate valve, consider these key factors:

Material: Stainless steel for superior corrosion resistance or cast iron for durability and cost-effectiveness.

Pressure Rating: Match the valve’s pressure rating to the requirements of your application.

Connection Type: Ensure the valve’s connection type is compatible with your piping system for a secure fit.

Udhhyog offers a broad selection of 2 inch gate valves tailored to meet your specific needs, backed by our commitment to quality and competitive pricing.

Why Udhhyog?

At Udhhyog, we simplify industrial procurement by offering a range of high-quality products at the best prices. Our dedication to customer satisfaction and quality ensures we are the top choice for your gate valve needs.

For more information and to view our full range of 2 inch gate valves, visit Udhhyog today.

#2InchGateValves#GateValves#IndustrialValves#BestPriceValves#LowestPriceValves#DelhiManufacturers#IndiaSuppliers#StainlessSteelValves#CastIronValves#ValveManufacturers

1 note

·

View note

Text

SS 304 Flange at the Lowest Price – High Quality from Udhhyog

When it comes to reliable and high-quality flanges for industrial applications, the SS 304 flange is a top choice. Known for its excellent durability, resistance to corrosion, and affordability, it’s widely used across various industries. At Udhhyog, we offer SS 304 flanges at the lowest prices without compromising on quality.

Get your SS 304 flanges now and experience the best value in the market!

Why Choose SS 304 Flanges?

SS 304 is a popular grade of stainless steel, known for its exceptional resistance to corrosion and rust, making it perfect for harsh environments. Whether you need it for piping systems or any industrial application, this stainless steel flange offers durability and longevity, reducing maintenance costs over time.

Types of Flanges and Fittings Available

At Udhhyog, we provide a wide range of flanges to meet the needs of different industries. From pipe flange fittings to complex flange fittings, we ensure that you get the right products at competitive prices. Our offerings include a variety of flanges and fittings suitable for various piping systems.

Explore our full range of flanges:

👉 Flanges and Fittings

Why Buy from Udhhyog?

As one of the leading flange manufacturers in India, we take pride in supplying high-quality products at competitive rates. Our flange pipe fittings are designed to withstand high pressure and ensure leak-proof connections, making them ideal for industrial uses.

When you buy from Udhhyog, you’re not just getting products—you’re investing in quality and performance.

Key Features of SS 304 Flanges at Udhhyog:

High corrosion resistance

Available at the lowest price

Durable and long-lasting

Wide range of options

Reliable supplier

Check out our full selection of SS 304 flanges and other flange pipe fittings to find the perfect fit for your industrial needs.

#SS304Flange#Flanges#PipeFlange#StainlessSteelFlange#FlangeFitting#FlangeManufacturers#FlangesAndFittings

1 note

·

View note