#best grain dryer manufacturers in india

Explore tagged Tumblr posts

Text

Revolutionizing Rice Production: India's Leading Rice Mill Machinery Manufacturers

In the coronary heart of India's agricultural panorama, a silent revolution is taking vicinity. Rice production, a staple in Indian delicacies, is a process of transformation way to the innovation and determination of rice mill equipment producers inside the USA. With a focal point on best, performance, and sustainability, those manufacturers are paving the way for a brighter destiny in rice processing.

Key Players in the Industry:

Suri Engineers: A call synonymous with modern rice milling generation.

Mill Master Machinery: Delivering excellence in rice mill machinery for many years.

Perfect Equipment: Committed to raising rice milling standards.

Fowler Westrup: An international leader in put-up-harvest agricultural machinery.

Bühler India: Combining Swiss precision with Indian understanding.

The Rice Mill Machinery Advantage:

Rice Mill Machinery Manufacturers in India are at the forefront of innovation, providing ultra-modern solutions that are revolutionizing the rice milling enterprise. Here's how:

Enhanced Productivity: Modern rice mill machinery ensures higher output with minimum wastage, boosting ordinary productiveness for farmers and mill owners.

Quality Assurance: Precise milling tactics bring about advanced-quality rice, assembly worldwide standards, and increasing market competitiveness.

Energy Efficiency: Energy-efficient machinery reduces operational charges and environmental impact.

Customization: Manufacturers provide tailor-made answers to meet the particular needs of various areas and rice types.

User-Friendly Design: Intuitive interfaces make operations less complicated, decreasing the need for widespread education.

Low Maintenance: Robust equipment requires minimum protection, minimizing downtime and maximizing efficiency.

Introducing the Rice Dryer Machine

One of the most critical factors of rice processing is drying. Proper drying is crucial to ensure the toughness and excellence of rice grains. Rice Dryer Machines have emerged as a game-changer in this component.

Advantages of Rice Dryer Machines

Faster Drying: Rice dryer machines drastically lessen drying time, allowing for faster processing and packaging.

Uniform Drying: These machines ensure uniform drying, removing the danger of moisture-associated troubles.

Preservation of Quality: Proper drying enables the preservation of the flavor, aroma, and nutritional fee of the rice.

Why Choose Indian Rice Dryer Machines?

India isn't always the best hub for rice production but is additionally a main producer of Rice Dryer Machines. Here's why you have to recollect Indian-made dryers:

Proven Expertise: Indian producers have a large enjoy in rice processing, making sure that their rice dryer machines are tailor-made for neighborhood situations.

Innovation: Manufacturers in India constantly innovate to live inside the marketplace, integrating the modern era into their machines.

Global Presence: Indian Rice Dryer Machines have received recognition and agreed with globally, making them a preferred desire for rice millers globally.

Sustainable Practices

Rice mill equipment producers in India are also taking large steps toward sustainability:

Reduced Water Consumption: Advanced machinery makes use of less water at some stage in the milling procedure, preserving this valuable aid.

Energy Efficiency: Many producers prioritize strength-green designs, lowering the carbon footprint of rice turbines.

In Conclusion:

Rice Mill Machinery Manufacturers in India and their contemporary rice dryer machines are shaping the future of rice processing. With their commitment to pleasant, innovation, and sustainability, they're not handiest meeting the desires of the present but additionally making sure a higher day after today for the rice enterprise in India and beyond.

So, the next time you revel in a plate of fragrant, perfectly cooked rice, keep in mind the silent heroes behind the scenes, the rice mill equipment producers of India, making all of it viable.

0 notes

Text

Screw Conveyors Supply in Cairo

- Screw Conveyors Supply in Cairo“R Mech Machines LLP” were established in 2008 in Ahmedabad, Gujarat, India. - We manufacture and supplier of a comprehensive range of Bale Opener Machines, Grinder Machines, Industrial Dryers, Conveyor Belt, Dewatering Machine, Floating Tank, Force Feeder Machines, Friction Washer Machine, Bottle Recycling Plant, Granulator Machines, Label Removing Machine. - Our goods are made using the highest quality components and advanced technology under the supervision of our experienced employees and in accordance with international quality standards. What Is the Use of Screw Conveyors? - Screw conveyors, also known as auger conveyors, are pieces of industrial machinery used to move large quantities of granular solids (such as powder, grains, or granules), semi-solids, liquids, and even non-flowing materials. By removing the need for the employees to manually move loads, they maintain great operating efficiency. - The main component of a screw conveyor is a revolving screw shaft that is mounted inside a trough. - The material is linearly moved by the screw shaft as it revolves. They can be made to offer straight, angled, and vertical movement pathways. Features - Simple and trouble-free functioning. - Very little investment and very little power use. - Rigid construction, manufactured with top-notch materials and cutting-edge production techniques. - According to the needs of the process, we can offer screw conveyors that are horizontal, inclined, or vertical. - We can provide screw conveyors in various sizes, pitches, and materials. Benefit of Screw Conveyors - Screw conveyors can handle a wide range of bulk materials, from slow-moving to freely flowing. - Numerous inlet and outflow points are possible with screw conveyors. Bulk supplies can be transported and dispersed as needed to different places. - You can add slide gates or valves to a screw conveyor to regulate the flow into and out of the conveyor.A screw conveyor is referred to as a screw feeder when it is employed as a metering tool. Screw feeders are used to take items from a bin or hopper to start a material operation. - Screw conveyors are incredibly small and flexible in crowded spaces. Unlike a belt or drag conveyor, a screw conveyor does not have a return. R Mech Machine LLP is a Supplier of Screw Conveyors Supply in Cairo. If you are interested then contact us. we will offer you our best quality product. Call: Email: Read the full article

#Cairo#ConveyorBelt#GranulatorMachines#LabelRemoving#RMechMachinesLLP#Screwconveyors#ScrewConveyorsSupply#ScrewConveyorsSupplyinCairo

0 notes

Text

The Importance of Rice Mill Machinery Manufacturers In India

The Value of Different Rice Mill Machinery

Before producing rice for the retail market, a variety of adjustments and processing operations are carried out using different types of rice mill machinery. According to makers of rice mill machinery, the most important of these kinds of machinery are those that clean the product of contaminants. The rice mill machinery manufacturers in India guarantee superiority in the product's texture, and coloring is considered to be the best in India.

Paddy Cooker

The paddy cooker guarantees entirely consistent steaming of every paddy grain, producing rice of superior quality. It assists in reducing human error while steaming. Reducing the number of tanks can simplify plant operations.

Paddy Drier

In order to make the rice safe for storage, a paddy dryer device is employed. The most crucial step following harvesting a rice crop is drying, which reduces the grain moisture content to a level where it is safe to store. They come with technologies to assist customers in controlling and monitoring the drying temperature.

Paddy Hoppers

A grain hopper efficiently keeps the goods at the right temperature and in the finest quality possible, away from moisture intrusion and dew drop impact. In order to get the greatest paddy hopper, you must contact one of the best providers.

The automated plant is sure to progress quickly with fewer repairs and a perfect yield because the processing equipment is simple to operate, and there is a high demand for rice around the world. After doing the entire project, you can obtain complete information about the rice mill and its setup of industrial food machinery from rice mill consultant firms and machinery providers. Before putting up the mill and locating the raw materials, careful planning, space, and financial resources are needed.

Paddy Silo

Due to its propensity to sprout and sensitivity to high temperatures, the rice must be stored cautiously. In a paddy storage silo, rice is frequently vulnerable to germination during condensation, dampness, or rain. The grain surface of the rice is prone to cracking when it is exposed to light or when it unexpectedly becomes chilly after exposure. Therefore, a paddy storage silo is the best option for grain storage and quality assurance.

Parboiling Equipment

A sound design, an easy process, a potent process effect, and low energy consumption characterize equipment for paddy parboiling. The parboiling process typically uses pre-cleaning, soaking, steaming, casting, rice milling, etc. Rice that has been parboiled is abundant in nutrients, quickly absorbed, produces a lot of rice, cooks in a short amount of time, and is resistant to storage.

Conclusion!

This concludes our discussion of the significance of the various rice milling equipment. One of the top rice mill machinery manufacturers in India, Photon Foods offers a full range of handling, boiling, and drying options. The pricing of their contemporary and traditional rice mill equipment in India is quite reasonable.

Company Name: Photons Food

Email: [email protected]

Visit Us: https://photonsfood.com/

Phone No.: +91-8610167937, +65-91684326

Address: Brahmnagudem Village, Nidadavole, 534 302, East Godavari District, Andhra Pradesh 534301 India

#Food Processing Machinery Manufacturers In India#Photons Food Processing Engineers#Paddy Parboiling Plant Manufacturers#Parboiled Paddy Dryer#Paddy Cleaner#Rice Mill Paddy Cleaner#Food Processing Machinery

0 notes

Photo

Seed Coating Machine, Centrifugal Fans at affordable prices!!!! Request a quotation: [email protected], +91- 98665 83700 Website: https://goo.gl/TQKsae

#seed coating machine manufacturers#best grain dryer manufacturers in india#mobile maize dryer#seed coating machines and dryers manufacturers

0 notes

Text

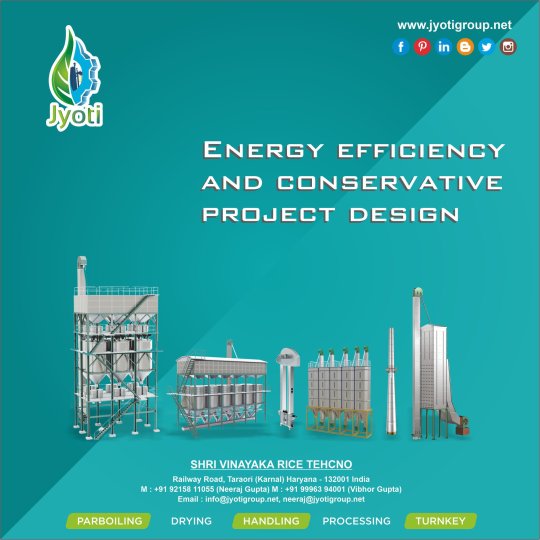

Jyoti group is Best Paddy Dryer Manufacturer

The paddy dryer machine is equipped with all of the necessary equipment to make the entire operation better, easier, and more convenient. It is equipped with stainless steel bucket conveyors and elevators that facilitate the transportation of grains to higher levels without loss or damage. There are various types of dryers like the LSU dryer which can also be used to fulfil any particular requirement. One can compare paddy dryer machine price in India and ensure that they buy from the best only. Jyoti group is a great paddy dryer manufacturer in India that offers various types of dryers-

· Suits all kinds of paddy

· Construction is made of stainless steel

· There are also customised designs that make use of boiler steam.

· Civil works are minimal, and maintenance is minimal.

For more info: https://jyotigroup.net/Paddy-Drying-Solutions.html

#paddy dryer machine#paddy dryer manufacturer in india#paddy dryer machine price in india#bucket conveyors#LSU dryer

0 notes

Text

How to Start a Rice Milling Business?

As the highest source of nourishment for over half the world's population, rice is by far one of the most essential commercial food crops. Its yearly yield worldwide is approximately 535 million tons. Fifty countries yield rice, with China and India they are supportive 50% of total production. Southeast Asian countries independently support an annual production rate of 9-23 million metric tons of which they export very little. Collectively, they are categorizing the Rice Bowl. Over 300 million acres of Asian land is cast-off for growing rice. Rice production is so main essential to Asian cultures that oftentimes the word for rice in a specific Asian language also means food itself.

Do you live in one of the countries where rice is widely consumed? Are you looking for profitable business to do? Are you interested in starting a rice milling business? Do you need a rice milling business plan? If you answered YES to any of the questions above, please read this article and the steps discuss will help you put your rice milling business plan into reality.

What is rice milling?

Rice milling is a step in the post production of rice that involves the removal of husk and bran layers, which produce white rice that can be edible free of impurities.

The rice paddy comprises of about 20% of husk and 11% bran layers, which leaves you with about 69% edible white rice free from impurities.

It Include:

Paddy Cleaing

Paddy Drying (if needed)

Rice Hulling

Paddy Separating

Rice Milling

Rice Grading

Rice Polishing

Rice Color Sorting

Rice Packing

What is The Process of Starting a Rice Milling Business

1. Acquire the required knowledge

Before you start a rice milling business, it is important that you need to have a good knowledge of the rice milling business and you should find any rice mill around you and have a feel of the processes involved in rice milling. Apart from the general entrepreneurial skills that you will need to operate the business, you need to acquire other skills that may be specifically related to rice mill business. You may not get this kind of skills from schools. The best way to acquire the skills is to work directly with somebody who is successful in rice mill business. You should also find out the costs of starting the business as well the costs of running the business after launch. Find out the equipment and manpower required. Find out about the pitfalls and challenges that new entrants into the business will most likely face. And find out how to avoid the pitfalls and overcome the challenges.

2.Write a rice milling business plan

By now, you should have known a lot about rice mill and the things you need to run the business. It’s now the stage where you need to put everything into a business plan.

Developing a business plan for your rice milling business is very important, as it will guide you through the process of starting the business successfully and running it effectively afterwards. Your business plan will also come in handy when you approach investors or lenders to fund your business.

Your business plan will detail your business’s goals and objectives, required startup and running costs, projected earnings over the first few years, required staff, your target market and a thorough analysis of that market, the competition, your marketing strategy and unique selling point, and your exit strategy. The rice milling business plan is what will keep you on track when you want to deviate from the business goals. It also is another document that you can use to attract investors.

3. Obtain the necessary licenses and permits

In virtually all parts of the world, obtaining licenses and business permits is a requirement for starting any business. However, the required licenses and permits vary between states and countries.

So I advice that you visit the appropriate agency in your state or country to inquire about the licenses and permits you will need to obtain before you can start your rice milling business. Better yet, visit the agency’s website or contact a seasoned attorney to find out.

4.Find a good location

Choice of location has a big role to plan in the success of a rice mill business. Essentially, a rice mill business should be located very close to where rice is grown. You need a place that is easily accessible to farmers. They should be able to transport the rice produce to your place without much trouble. You need a large space where the farmers can drop their harvests. Also, you need storage place where the milled rice can be kept. The layout of the rice mill should allow free movement of people and should be very ventilated.

5. Buy the equipment

According to the size of the rice mill processing plant, there is the different type of machinery available in the market; you need to choose the right machinery for your rice mill plant

.The important factor is cone slider while selecting the machinery are production rate, efficiency, capacity, and power equipment; also consider the execution, whether the machine is a single stage or multi-stage.

·Grain Storage Silos

·Grain Dryer

· Rice Cleaner Machine

·Rice Destoner Machine

· Rice Color Sorter

·Rice Huller Machine

· Rice Milling Machine

· Rice Separating Machine

· Rice Polishing Machine

· Rice Grading Machine

· Rice Packing Machine

Most of the equipment are durable and stands the test of time.

Some of the equipment can be fabricated. The fabricated one will be less expensive compared to the real one.

Note that you’ll need to be sure that the fabricated machine will do the work it was meant to be else, you’ll only waste your money.

7.Install the equipment

By now your rice milling machines have arrived. It’s time to start installing them. The services of an expert will be required in other for the installation to be successful.

Most often the company that sells the machines will always have an expert that will do the work for you. You’ll only need to ask them.

8.Hire employees and start operations

It’s time to hire people who will help in running the business. In rice milling business one important factor to consider when hiring people is their experience. Each person you hired can be given a defined role that will ensure the process of rice mill works in an effective way.

This will ease the stress going through the process of training before kicking the work.

It’s important to hire both technicians and administrators. The technicians are responsible for operating and maintenance of the machines. While the administrators do the paperwork on a daily basis.

9. Find Buyers

It is supreme important part in any export business that how to find potential buyers in the international market? Some guidelines for discovery potential buyers are through communicating your relatives in that country, export trade fairs and expos, through online portal, etc.

Zhengzhou VOS Machinery Equipment Co., Ltd. Was established in the year 2000, it is a professional manufacturer and exporter of rice mill machine, rice processing machines, rice mill plant, rice mill production line, and parboiled rice mill plant. We can provide unique overall layout design of rice milling machine production line, customized rice milling machine products and installation services according to different needs of customers and site conditions. It integrates technology, manufacturing and sales together.

If You Are Ready to Start a Rice Milling Business, please contact us for the Rice Milling Machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Zhengzhou VOS Machinery Equipment Co., Ltd.

Email:[email protected]

Phone/Whatsapp: 008615736756203

0 notes

Photo

About 85-90% of our energy needs today are met using fossil fuels. Fossil fuels have a limited supply, driving a rise in fuel prices all over the world. Renewable energy sources are the solution to this energy and economy crisis. These energy sources are in focus today owing to the potential they hold to replace fossil fuels. Solar energy is a very valuable source of renewable energy along with being one of the most accessible ones. This energy source finds wide use in a number of industries including agriculture, and is a pollution-free source of energy.

The use of solar energy will help meet the rising need for agriculture products that come from the increasing population. Solar energy can be used for a variety of agriculture activities such as irrigation, ventilation niches, keeping livestock, and drying products.

Solar energy can be converted to electrical energy in two ways:

1)Using photovoltaic technology

2)Using solar capture heating systems

Photovoltaic technology works by collecting sun rays via small semi-conductor plates that convert this energy to electricity.

PV cells are of two types: concentrator and flat panel. In flat panel cells light is immediately brought to the semiconductor and converted to electricity. In concentrator cells, sunlight is guided via reflectors, concentrated, and then the solar cell connects together.

Drying food is one of the oldest and most common methods of preservation in agriculture. When moisture from food is removed products can be stored for a long time with a reduced risk of damage from microbes. The weight and volume of materials are also reduced in this process, which makes for easier transportation and storage of food. Before solar energy was harnessed by technology the way it is done today, crops were dried under the sun. Now we have solar dryers which protect grains, fruits, and vegetables from losses. They help food products dry faster and in a more uniform manner, resulting in better quality products for users. With solar dryers, food can be processed in sanitary conditions. Solar technology in drying saves time, energy, enhances product quality, improves the efficiency of the process, and is better for the environment.

Agricultural facilities that have adopted the use of solar dryers report high levels of satisfaction from this technology due to the low operations and maintenance costs, durability, and high economical nature of these dryers compared to conventional dryers.

If you are in search of the best solar dryer for your facility, make sure to check out https://www.thermaxglobal.com/. Thermax is a solar power plant manufacturer in India of international repute.

0 notes

Text

What are the applications of various level sensors?

Level sensors are a tool that finds extensive application in various industries. Level sensors help in detecting the exact level of solids and liquids stored inside a container. Plenty of industries use a variety of machinery that require different types of level sensors to display the right amount of stored material inside it at any point in time. Therefore, level sensors are of different types, as well. Here are some of the widely used applications of level sensors that most of the manufacturing and processing units used to maintain smooth operation.

Brewer production firms

Processing beer from malt involves several levels of processing methods that require different level sensors to keep track of the materials. While manufacturing beer, hygienic and strict environment is maintained. From malting the barley grains to mashing every level of beer production involved separate sets of level sensors like SLA series, SLC series, and the Elixir-T-Uni with smoother fork are some of the varieties of level sensors used for brewery production units.

Cement manufacturing units

Level sensors are widely used for the cement manufacturing units. The stacker machine, limestone silo, additive silo, clinker cooler, ESP filter hoppers, and bag filters, cement storage silo, gearboxes, water tanks, bucket elevators, etc use different varieties of level sensors according to requirements. However, the SLA series level sensors are the best choice for cement manufacturing units.

Chemical plant

Level sensors are also used for chemical plants. There are several instruments and machinery used in these industries, such as storage tanks, glass line HCL reactors, etc for which level sensors are used extensively. All of these machines use a different type of level sensing and level sensor. Elixir-T Uni, SLC level sensors, are some of the commonly used varieties for chemical industries.

Dairy processing plants

Level sensors are critical for every dairy processing firm. Dairy firms deal with liquid, and maintaining the level is important. In raw milk storage tanks, pasteurized milk storage tanks, CIP processing units, butter storage tanks, and jaw cooling balance tank level sensors are a must. Capvel ICT, Elixir-T-Uni, and the SLC level sensors are some of the commonly used varieties of level sensors in dairy processing plants.

Fertilizers and pesticide industry

Different types of machinery in the fertilizer and pesticide producing units use variety of level sensors. The raw feed hopper, buffer tank, dryer, recycle bin hopper, product bin hopper, coal bunker use level sensors like calibration-free SLP, SLA dot display, SLA series, SLA bar display, etc. depending on the application and the requirement, these varieties of level sensors are used in the relevant industries.

Foundry and casting

Foundry and casting is another domain of industry that uses level sensors extensively. New sand hopper, additive hopper, return sand hopper, and molding sand hopper is some of the units that use level sensors of different types. Coat endure level sensor and SLA series level sensor are the two most used options.

There are plenty of level sensor manufacturers in India that produce a range of level sensors. You can choose the best one, depending on the specific requirement of the industry.

0 notes

Text

Things to Know About Industrial Dryer Supplier

Industrial dryers are the machines that remove moisture or liquid from the bulk food materials. Apart from the food processing industry, other industries that rely on industrial dryers include pharmaceuticals, agriculture, paper and pulp, air and pollution control, and other industries. The processed food materials, dairy products, sludge, plastics, grain, refuse, chemicals, and fertilizers, among other material, can be dried by using the industrial dryers. A leading industrial dryer supplier helps his clients meet the demands easily by providing to the company’s new-age dryers at a reasonable cost.

There are many different industrial drying manufacturers and industrial dryer supplier firms today in the market that can provide you the equipment and industrial dryers easily. But to ensure that the products and machines are reliable, and you are offered prompt after-sales support as well, you need to choose a reputed and leading supplier.

Does the Supplier Offer a Comprehensive Variety?

The industrial dryers have evolved and use many new technologies including multistage drying, freeze drying, and infrared drying among others. These technologies and the exclusive industrial drying equipment are targeted at the drying of particular and specific materials. Therefore your supplier should offer you the comprehensive range of drying equipment including the fluidized bed dryer, convection dryers, vibratory fluid bed dryer, rotary dryer, batch dryers, freeze dryers, and others so that you can invest the money in the right area. The variety also helps you choose the best and most advanced technology and equipment.

After Sales Support

The supplier should provide you the dryers from world-class and the most reputed brands. The leading suppliers and brands ensure that you get a prompt and efficient after-sales service/maintenance support at any time you wish. Effective support ensures that you get the right advice regarding the use of material and the downtime is also the least.

Certified

An industrial dryer supplier should provide you industrial dryers manufactured by ISO certified companies only. This will ensure that your products possess good quality, and are flawless machines that are built according to world standards.

Research the internet, read the business/industrial magazines and also check on the references, including your friends, colleagues, and others to get to know about the best in suppliers of industrial equipment and air dryers in India.

0 notes

Photo

#MobileMaizeDryer: The high quality & cost-effective solution to On-Floor #Crop Drying!!! Contact us, https://goo.gl/XSRdXn, +91-98665 83700, [email protected]

#id fan manufacturers india#id fd fan manufacturer#seed coating machine manufacturers#best grain dryer manufacturers in india#mobile maize dryer#pulse jet bag filter manufacturers

1 note

·

View note

Photo

Essar Enviro Air Systems engaged in offering a wide range of #CentrifugalFans for #WetScrubber which is designed in order to fulfil the requirement of various #chemical industries!!!

https://goo.gl/DqLQpM, (+91 ) 98665 83700, [email protected]

#best grain dryer manufacturers in india#mobile maize dryer#wet scrubber#centrifugal fans#id fan manufacturers india#id fd fan manufacturer#pulse jet bag filter manufacturers

1 note

·

View note

Link

Industrial Draft Fan Solutions from Essar Air Systems!!!! http://bit.ly/2tOs29Q, [email protected]

#id fan manufacturers india#id fd fan manufacturer#boiler id fan manufacturer#seed coating machine manufacturers#best grain dryer manufacturers in india#mobile maize dryer#pulse jet bag filter manufacturers

0 notes

Photo

Dust collection solutions designed for your operation!!!! Send an enquiry - http://www.essarairsystems.com/, [email protected]

#pulse jet bag filter#mobile maize dryer#id fan manufacturers india#id fd fan manufacturer#boiler id fan manufacturer#seed coating machine manufacturers#best grain dryer manufacturers in india

0 notes

Photo

ID(Induced Draft), FD(Forced Draft), #CentrifugalFans manufacturers in #India!!! View details http://www.essarairsystems.com/id-fd-fan-manufacturer.php

#id fan manufacturers india#id fd fan manufacturer#seed coating machine manufacturers#best grain dryer manufacturers in india#mobile maize dryer#pulse jet bag filter manufacturers

0 notes

Photo

#Centrifugal Blower is indispensable equipment for air pollution systems. More details, https://goo.gl/yKJvPe

#id fan manufacturers india#id fd fan manufacturer#boiler id fan manufacturer#seed coating machine manufacturers#best grain dryer manufacturers in india#mobile maize dryer#pulse jet bag filter manufacturers

0 notes

Photo

High efficiency with low maintenance!!!

https://goo.gl/zGejgc

+91-98665 83700

#id fd fan manufacturer#id fan manufacturers india#boiler id fan manufacturer#best grain dryer manufacturers in india#mobile maize dryer

0 notes