#paddy dryer manufacturer in india

Explore tagged Tumblr posts

Text

Are you seeking to enhance the effectiveness of rice manufacturing? Photons, a renowned of paddy parboiling plants manufacturer in India, offers customized solutions tailored to the scale of your operations and specific needs. Our aim is to contribute to the production of healthier and higher-quality rice, helping to sustainably feed the nation.

#Paddy Parboiling And Dryer Plant Manufacturers#Paddy Parboiling Plant Manufacturers#Paddy Dryer Manufacturer In India#Paddy Dryer Machine#Parboiled Paddy Dryer

0 notes

Text

With its high-quality materials and advanced technology, Photon’s Paddy Storage Bunker is designed to keep your grains safe and secure. They ensure optimal storage conditions and maximum protection of your paddy against pets, moisture, and other factors. Contact us to learn more.

#paddy dryer machine#paddy cleaner#food processing machinery manufacturers in india#food processing machinery manufacturers#food processing machinery#paddy dryer manufacturer in india#industrial food machinery

0 notes

Text

Food India Expo 2023 Elevates Rice Export Dialogue with IREF's Dr. Prem Garg as Chief Guest

The Food India Expo 2023 is a major event in India's food industry, serving as the country's largest international platform for bringing together food machinery manufacturers, traders, dealers, and exporters from both India and other countries. This event is set to take place from December 28-30, 2023, at Biswa Bangla Mela Prangan, near ITC Sonar in Kolkata, India.

This expo focuses on a wide array of sectors within the food industry, including rice, pulses, wheat, flour, spices, sugar, fortified products, tea, coffee, and various types of food processing machinery. Notably, the expo also showcases products and technologies like Paddy/Grain Dryers, Parboiling Plants, Color Sorters, Air Compressors, Grain Storage and Material Handling, Packaging Solutions, Dairy Equipment, Poultry/Cattle Feed Technology, Waste Water Treatment, Grain Chillers, and more.

The event is not just an exhibition but also a platform for training the younger generation and promoting well-established businesses. It facilitates networking and brand promotion for these businesses both in India and internationally. Additionally, the expo includes seminars and conferences conducted by professionals, offering insights into the latest trends and technologies in food processing.

The Food India Expo 2023 aims to cater to a diverse range of visitors, including CEOs, managing directors, business heads, owners, employees, managers, brokers, mediators, distributors, researchers, processing experts, scientists, and technologists, among others. It's an excellent opportunity for professionals in these areas to explore new technologies, network with industry experts, and gain insights into the latest market trends.

In terms of exhibitors, the expo welcomes a wide range of participants from various sectors such as rice mills, flour mills, pulse mills, and those involved in processing, distribution, and technology related to the food industry. The event also garners interest from government officials and representatives from industry associations.

The Food India Expo is more than just a trade show; it's a comprehensive platform for learning, networking, and exploring the latest innovations in the food processing industry.

For more detailed information about the Food India Expo 2023, you can visit their official websites at Food India Expo and Food India.

Chief Guest Dr. Prem Garg

Dr. Prem Garg is a notable figure in the Indian rice export industry and is associated with the Indian Rice Exporters Federation (IREF). He is recognized for his innovative approaches and leadership in the rice export sector, contributing significantly to positioning India as a global leader in rice exports. The IREF operates with the motto "One Nation, One Trade, One Policy," striving to foster unity and coherence in India’s rice export sector. The federation plays a key role in policy advocacy, trade negotiations, and ensuring the interests of a wide range of stakeholders in the rice export industry are represented.

However, there's no specific information available linking Dr. Prem Garg directly to the Food India Expo 2023 as a chief guest or in a similar capacity. For the most current information about the expo, including details about guests and speakers, it's recommended to regularly check the official websites of the Food India Expo here and the Indian Rice Exporters Federation here.

Facebook

Instagram

Twitter

Youtube

Pinterest

Website :- https://iref.net/

Address:- Office at 73 LGF World Trade Centre, Hotel Lalit, Connaught Place, New Delhi 110001

Phone no- +918383810826

0 notes

Text

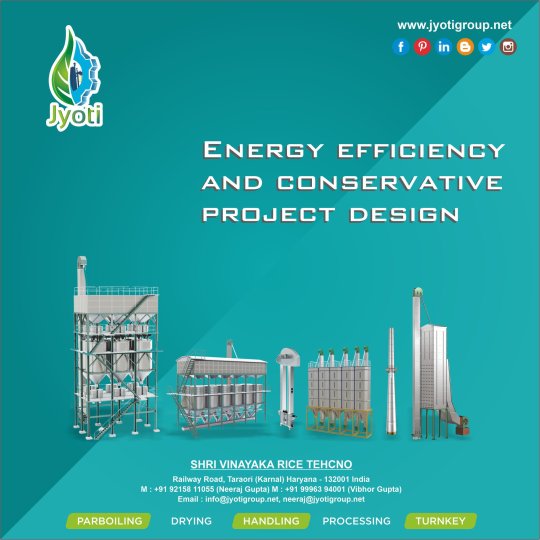

Jyoti group is Best Paddy Dryer Manufacturer

The paddy dryer machine is equipped with all of the necessary equipment to make the entire operation better, easier, and more convenient. It is equipped with stainless steel bucket conveyors and elevators that facilitate the transportation of grains to higher levels without loss or damage. There are various types of dryers like the LSU dryer which can also be used to fulfil any particular requirement. One can compare paddy dryer machine price in India and ensure that they buy from the best only. Jyoti group is a great paddy dryer manufacturer in India that offers various types of dryers-

· Suits all kinds of paddy

· Construction is made of stainless steel

· There are also customised designs that make use of boiler steam.

· Civil works are minimal, and maintenance is minimal.

For more info: https://jyotigroup.net/Paddy-Drying-Solutions.html

#paddy dryer machine#paddy dryer manufacturer in india#paddy dryer machine price in india#bucket conveyors#LSU dryer

0 notes

Text

Stemtech Engineers, is a established machinery manufacturing and exporting unit located at Rajkot, Gujarat, India. We are popularly known as drying expert. We made dryers like agarbatti dryer, agarbatti heat dryer, cottonseed dryer (continuous), maize dryer (continuous), paddy dryer (continuous), sambrani dhoop cup dryer, sambrani dhoop stick dryer, incense stick dryer, sambrani cone dryer, soybean dryer (soyabean), Peanut seed dryer, dal dryer, pulses dryer.

1 note

·

View note

Video

youtube

Moisture Meter, Seed Grain Testing Lab Equipment, Fruit Sizer - Green Agritech Equipment in Haryana We are a well reputed company, consistently engaged in designing and manufacturing wide range of testing equipment. Quality for us is the prime objective, and we always focus on offering flawless products at competitive rate. We are known as one of the noted manufacturers, exporters, traders and suppliers of the domain. Established in 2007, we are engaged in manufacturing superior quality testing devices. The offered range comprises Grain Moisture Meter, Sample Divider, Rice Polisher, Rice Miller, Paddy De-husker, Seed Analysis Kit, Seed Germinator, and more. These are appreciated for their high performance, durability and accurate results.Factory Manufacturing:-• Machinery - 6 Machinery• Production Capacity - 300Moisture meter in one month.• Raw Material Used - MS Sheet, rod, brass sheet,rod stainless steel sheet, rod, wire, switch, light, wooden plate, etc.Clients • Agriculture college• Agriculture research center• food corporation of india• center warehouse• state warehouse• rice mill• corporate department mandi • Prisad.• PatanjaliPackaging Material• Wooden crate• wooden box• thermocol sheet• cardbod boxesCustomized Packaging Facility - Strip Packing Machine Deals In: Moisture Meter, Advance Digital Moisture Meter, Advance Handy Digital Moisture Meter, Chlorophyll Meter, Digital Grain Moisture Meter, Digital Moisture Meter, Halogen Moisture Meter, Handy Digital Moisture Meter, Portable Grain Moisture Meter, Universal Digital Moisture Meter, Seed Grain Testing Lab Equipment, Grain Testing Dryer, Lab Willy Grinder, Riffle Grain Divider, Seed Counter, Seed Dryer, Seed Germinator Double Chamber, Seed Germinator Single Chamber, Soil Moisture Meter, Rice And Grain Testing Lab Equipments, Broken Rice Separator, Grain Analyser, Grain Sample Divider, Grain Size Vernier Calliper, Mini Lab Husker, Paddy Cleaner Seed Grader, Palm Husker, Rice Aspirator, Rice Emasculator, Rice Polisher, White Enamel Plate, Fruit Testing Equipment, Digital Fruit Penetrometer, Fruit Penetrometer, Fruit Sizer Contact Detail: Contact Person: Mr. Vijay VermaAddress: 34 Hari Nagar Behind B.D Flour Mill., Ambala Cantt, Haryana, India, 133001.Mobile No: +91-9896118188 / 7056788567Email ID: [email protected]: https://www.agriculturelabindia.comCatalog: https://www.tradekeyindia.com/green-agritech-equipment/ #GreenAgritechEquipment #MoistureMeter #TradeKeyIndia #MoistureMeter #AdvanceDigitalMoistureMeter #AdvanceHandyDigitalMoistureMeter #ChlorophyllMeter #DigitalGrainMoistureMeter #DigitalMoistureMeter #HalogenMoistureMeter #HandyDigitalMoistureMeter #PortableGrainMoistureMeter #UniversalDigitalMoistureMeter #SeedGrainTestingLabEquipment #GrainTestingDryer #LabWillyGrinder #RiffleGrainDivider #SeedCounter #SeedDryer #SeedGerminatorDoubleChamber #SeedGerminatorSingleChamber #SoilMoistureMeter #RiceAndGrainTestingLabEquipments #BrokenRiceSeparator #GrainAnalyser #GrainSampleDivider #GrainSizeVernierCalliper #MiniLabHusker #PaddyCleanerSeedGrader #PalmHusker #RiceAspirator #RiceEmasculator #RicePolisher #WhiteEnamelPlate #FruitTestingEquipment #DigitalFruitPenetrometer #FruitPenetrometer #FruitSizer

1 note

·

View note

Text

How to Start a Rice Milling Business?

As the highest source of nourishment for over half the world's population, rice is by far one of the most essential commercial food crops. Its yearly yield worldwide is approximately 535 million tons. Fifty countries yield rice, with China and India they are supportive 50% of total production. Southeast Asian countries independently support an annual production rate of 9-23 million metric tons of which they export very little. Collectively, they are categorizing the Rice Bowl. Over 300 million acres of Asian land is cast-off for growing rice. Rice production is so main essential to Asian cultures that oftentimes the word for rice in a specific Asian language also means food itself.

Do you live in one of the countries where rice is widely consumed? Are you looking for profitable business to do? Are you interested in starting a rice milling business? Do you need a rice milling business plan? If you answered YES to any of the questions above, please read this article and the steps discuss will help you put your rice milling business plan into reality.

What is rice milling?

Rice milling is a step in the post production of rice that involves the removal of husk and bran layers, which produce white rice that can be edible free of impurities.

The rice paddy comprises of about 20% of husk and 11% bran layers, which leaves you with about 69% edible white rice free from impurities.

It Include:

Paddy Cleaing

Paddy Drying (if needed)

Rice Hulling

Paddy Separating

Rice Milling

Rice Grading

Rice Polishing

Rice Color Sorting

Rice Packing

What is The Process of Starting a Rice Milling Business

1. Acquire the required knowledge

Before you start a rice milling business, it is important that you need to have a good knowledge of the rice milling business and you should find any rice mill around you and have a feel of the processes involved in rice milling. Apart from the general entrepreneurial skills that you will need to operate the business, you need to acquire other skills that may be specifically related to rice mill business. You may not get this kind of skills from schools. The best way to acquire the skills is to work directly with somebody who is successful in rice mill business. You should also find out the costs of starting the business as well the costs of running the business after launch. Find out the equipment and manpower required. Find out about the pitfalls and challenges that new entrants into the business will most likely face. And find out how to avoid the pitfalls and overcome the challenges.

2.Write a rice milling business plan

By now, you should have known a lot about rice mill and the things you need to run the business. It’s now the stage where you need to put everything into a business plan.

Developing a business plan for your rice milling business is very important, as it will guide you through the process of starting the business successfully and running it effectively afterwards. Your business plan will also come in handy when you approach investors or lenders to fund your business.

Your business plan will detail your business’s goals and objectives, required startup and running costs, projected earnings over the first few years, required staff, your target market and a thorough analysis of that market, the competition, your marketing strategy and unique selling point, and your exit strategy. The rice milling business plan is what will keep you on track when you want to deviate from the business goals. It also is another document that you can use to attract investors.

3. Obtain the necessary licenses and permits

In virtually all parts of the world, obtaining licenses and business permits is a requirement for starting any business. However, the required licenses and permits vary between states and countries.

So I advice that you visit the appropriate agency in your state or country to inquire about the licenses and permits you will need to obtain before you can start your rice milling business. Better yet, visit the agency’s website or contact a seasoned attorney to find out.

4.Find a good location

Choice of location has a big role to plan in the success of a rice mill business. Essentially, a rice mill business should be located very close to where rice is grown. You need a place that is easily accessible to farmers. They should be able to transport the rice produce to your place without much trouble. You need a large space where the farmers can drop their harvests. Also, you need storage place where the milled rice can be kept. The layout of the rice mill should allow free movement of people and should be very ventilated.

5. Buy the equipment

According to the size of the rice mill processing plant, there is the different type of machinery available in the market; you need to choose the right machinery for your rice mill plant

.The important factor is cone slider while selecting the machinery are production rate, efficiency, capacity, and power equipment; also consider the execution, whether the machine is a single stage or multi-stage.

·Grain Storage Silos

·Grain Dryer

· Rice Cleaner Machine

·Rice Destoner Machine

· Rice Color Sorter

·Rice Huller Machine

· Rice Milling Machine

· Rice Separating Machine

· Rice Polishing Machine

· Rice Grading Machine

· Rice Packing Machine

Most of the equipment are durable and stands the test of time.

Some of the equipment can be fabricated. The fabricated one will be less expensive compared to the real one.

Note that you’ll need to be sure that the fabricated machine will do the work it was meant to be else, you’ll only waste your money.

7.Install the equipment

By now your rice milling machines have arrived. It’s time to start installing them. The services of an expert will be required in other for the installation to be successful.

Most often the company that sells the machines will always have an expert that will do the work for you. You’ll only need to ask them.

8.Hire employees and start operations

It’s time to hire people who will help in running the business. In rice milling business one important factor to consider when hiring people is their experience. Each person you hired can be given a defined role that will ensure the process of rice mill works in an effective way.

This will ease the stress going through the process of training before kicking the work.

It’s important to hire both technicians and administrators. The technicians are responsible for operating and maintenance of the machines. While the administrators do the paperwork on a daily basis.

9. Find Buyers

It is supreme important part in any export business that how to find potential buyers in the international market? Some guidelines for discovery potential buyers are through communicating your relatives in that country, export trade fairs and expos, through online portal, etc.

Zhengzhou VOS Machinery Equipment Co., Ltd. Was established in the year 2000, it is a professional manufacturer and exporter of rice mill machine, rice processing machines, rice mill plant, rice mill production line, and parboiled rice mill plant. We can provide unique overall layout design of rice milling machine production line, customized rice milling machine products and installation services according to different needs of customers and site conditions. It integrates technology, manufacturing and sales together.

If You Are Ready to Start a Rice Milling Business, please contact us for the Rice Milling Machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Zhengzhou VOS Machinery Equipment Co., Ltd.

Email:[email protected]

Phone/Whatsapp: 008615736756203

0 notes

Text

Are you seeking ways to enhance rice production efficiency? Photons, renowned as one of India's leading manufacturers of paddy parboiling plants, offers customized solutions to suit your industry's scale and specific needs, ensuring the delivery of healthier, high-quality rice to contribute to the nation's food supply.

#Paddy Dryer Manufacturer In India#Paddy Dryer Machine#Parboiling Plant Manufacturer India#Paddy Parboiling And Dryer Plant Manufacturers

0 notes

Text

Photon Foods is a Paddy Dryer Manufacturer in India which is one of the smartest systems to accelerate rice yield and match the requirements of modern millers. To satisfy higher cleanliness requirements and processes our parboilers and paddy dryer machines are equipped with stainless steel. +91 86010167937 to know more about paddy dryer equipment.

1 note

·

View note

Text

Photons are trusted Paddy Dryer Manufacturer in India, providing efficient and reliable solutions for businesses in the rice processing industry. Our advanced paddy parboiling and dryer plants are designed to meet the highest quality standards so you can achieve higher efficiency.

#photons food processing engineers#food processing machinery manufacturers in india#industrial food machinery#food processing machinery#Paddy Dryer Manufacturer in India

0 notes

Text

We at photons, one of the top Rice Mill Machinery Manufacturers in India, offer to develop smarter and more creative solutions to deliver the best goods by utilizing the power of science and technology. Our goal is to raise production consistency while lowering broken and lost produce and raising produce quality.

#Paddy Dryer Machine#industrial food machinery#photons food processing engineers#Industrial Food Machinery#Food Machinery Manufacturers In India#Paddy Dryer Manufacturer In India

0 notes

Text

Where To Find The Ideal Food Processing Machinery Manufacturers In India?

In a world where food security and quality are major concerns, manufacturers of food processing machinery play a significant role. It has a direct bearing on public health, social stability, and economic prosperity in the contemporary world.

With the recognition of the food processing industry in India as a high priority industry, the equipment business is growing in importance.

From this blog, we shall examine the role of Innovative firms such as Photons Food aims to revolutionize the production and consumption of food.

Why Is Photons Food Among The Leading Food Processing Machinery Manufacturers In India?

Photons Food is revolutionising the food processing industry with cutting edge technology, cutting edge research, and innovative thinking.

Established in 1985 in Thanjavur, Tamil Nadu, Photons Food has long been known for its quality and reliability. With time, the business has grown into a full-service provider of solutions, offering an extensive range of fully automated food processing machinery. Photons Food offers solutions for all stages of food processing, including storage bins, parboiling units, dryers, and cleaners.

Among otherfood processing machinery manufacturers in India, one thing that sets Photons Food apart is its unwavering dedication to innovation. This organisation is known for constantly pushing the boundaries of what is deemed possible. This can be attributed to its one of a kind equipment and knowledgeable team leading to the creation of ingenious devices such as theDryer Machine for paddy. Moreover, In an effort to maintain its solutions at the cutting edge of technology, Photons Food is continuously creating new products while improving its previous ones.

How Is Photons Food Able To Preserve Quality Of Grains?

Photons Food has established itself within the realm of leading food processing units for a variety of reasons. Out of which, it excels in one key area which is the handling and preservation of grains such as rice and paddy. Photons Food truly believes in the value of each and every grain, from the farm to your plate and the role they play in nutrition and health. Owing to their quality control and efficiency, these grains are able to last a long time without affecting its composition and nutritional integrity.

This is made possible by their ongoing innovation, which has resulted in advanced, large-scale, continuous/batch processing units for rice and other grains such as the Dryer machine for paddy. These are ultimately used for a variety of services such as parboiling, drying, steaming, storage and more .

In conclusion, Photons Food has emerged as a leader within the food processing industry of India largely because of its consistency, efficiency and innovation. Its value for health and nutrition is reflected through the principles reflected within their enterprise.

Contact Us:

Photons Food

Visit Us: https://photonsfood.com/

Call: +918610167937, +65-91684326

Email: [email protected]

0 notes

Text

Understanding The Process of Paddy Pre-Cleaning in Rice Production

Rice cultivation has been part of our civilization for many years. The rice harvested is also known as paddy or rough, which is usually enfolded by husk or hull. The process of rice production is usually accompanied by cleaning, drying, and packaging.

Paddy Cleaning is a vital step in rice production that helps to separate contamination such as straw, dust, clay, and hefty flecks from the paddy before the process of rice production.

This is where Paddy Pre-cleaner machinery has simplified the whole process. Let us dig in and understand how Paddy Dryer works.

The age-old tradition of pre-cleaning of rice

Earlier the process of rice cleaning involved manual labor work. The rice grains were cleaned from their impurities through wind or fan. However, this process was time-consuming and does not assure complete removal of impurities.

The Modern Paddy Pre-cleaner process

With technology upgrading various aspects of the rice production process. Modern Paddy Pre-cleaners can easily separate rice grains from contaminated ones on the basis of colors. The Paddy pre-cleaner process improves the overall quality and quantity of the grains.

These methods have proven to show much better output than the age-old tradition of cleaning.

Importance of Paddy pre-cleaner in rice production

When paddy is deposited in the mill, it contains lots of unwanted material which is necessary to sieve out. The pre-cleaning process helps in improving the quality through hull and milling recovery.

The foreign material present in the paddy does not damage or block the machinery. The rice grains are disparate according to their size with the help of separators that are installed in the Paddy Pre-cleaner machinery.

Role Of Paddy Cleaners in the process

The Paddy pre-cleaner can easily improve the quality of rice grains by properly separating the impurities from it.

1-the first level includes separation and detaching the hefty foreign impurities from pure grains. The pre-cleaners then separate the grains on the basis of size.

2-straws and weed seeds are able to pass through, that is where the blower installed removes the particles and light grains.

3- After that, paddy pre-cleaner machinery further sends grains to a sheller that completely cleans the rice from its impurities.

The benefit of Paddy pre-cleaner

The most essential benefit of investing in and installing a Paddy pre-cleaner is that it improves quality, increases the longevity of grains, and adds the percentage of essential oil required in bran.

Conclusion

If you are worried about improving the quality of the yield, then the process of cleaning and pre-cleaning is an essential step that you should not miss. The equipment allows you to smoothen the process. It is recommended to research your requirements for the Paddy Dryer Manufacturer In India while investing in Pre-cleaner and Paddy dryer machinery.

#industrial food machinery#food processing machinery#paddy cleaner#food machinery manufacturers in india#paddy dryer machine

0 notes

Text

Advancing Food Industry Efficiency with Photons Food's Industrial Measurement Equipment and Rice Mill Dryer

The ever-evolving food business has made innovation and technology essential. The leading supplier of cutting-edge industrial measurement tools and solutions for rice mill dryer is Photons Food, a pioneering business. In this article, we look at how Photons Food modernizes the food processing industry by reducing processes and improving product quality.

Industrial measurement technology is revolutionizing efficiency:

The industrial measurement equipment from Photons Food delivers a paradigm shift in the way the food processing industries track and regulate numerous crucial parameters. These high-tech devices combine cutting-edge sensors and data analytics to deliver in-the-moment information on important variables, including temperature, humidity, moisture content, and grain quality. With this level of accuracy, food producers can streamline their operations, cut waste, and preserve a constant level of product quality.

Industrial measurement equipment benefits include:

Precision Monitoring: The equipment's accurate measurements guarantee that food processing activities uphold the strictest quality requirements, leaving no space for speculation or mistakes.

Process optimization: Food producers can spot bottlenecks and inefficiencies and improve productivity and cost-effectiveness by continuously monitoring and analyzing data.

Quality Control: Regular monitoring allows for the early identification of any irregularities, ensuring that only top-notch products are sent onto the market and enhancing the brand's reputation.

Using a rice mill dryer to increase rice drying efficiency:

Effective drying is essential for preserving the quality and shelf life of the finished product in the rice processing sector. In this regard, Photons Food's Rice Mill Dryer is a game-changer, utilizing cutting-edge drying technology to guarantee uniform and quick moisture removal from freshly harvested rice.

Rice mill dryer's main characteristics:

Uniform Dying: The rice mill drier uses cutting-edge temperature and airflow controls to produce consistent drying, lowering the danger of spoiling by uneven moisture distribution.

Energy Efficiency: By minimizing energy usage throughout the drying process, the rice mill dryer offers rice processors a practical option that is also low-cost.

Maintaining Nutritional Value: Rice's nutritional value is maintained during gentle drying, giving consumers access to tastier and healthier foods.

Utilizing Photons Food in Sustainable Ways:

Sustainability is a fundamental concept that underpins all of Photons Food's offerings in terms of both goods and services. The Rice Mill Dryer and Industrial Measurement Equipment's energy-saving features help lessen the food processing's environmental impact. By implementing these strategies, businesses can support sustainability initiatives and encourage environmentally friendly practices in the food sector.

Conclusion:

The Industrial Measurement Equipment and Rice Mill Dryer from Photons Food are innovative leaders in the food processing sector, providing strong instruments to improve productivity, product quality, and sustainability. Photons Food is dedicated to providing food makers with cutting-edge solutions that will help define the future of the global food business. As technology advances, the company remains at the forefront of this field.

Company Name:- Photons Food

Visit our Website:- https://photonsfood.com/

Call:- +91-8610167937, +65-91684326

Email:- [email protected]

Address:- Brahmanagudem Village, Nidadavole, 534 302, East Godavari District, Andhra Pradesh 534301 India.

#industrial food machinery#food processing machinery#paddy dryer machine#paddy cleaner#photons food#food machinery manufacturers in india

0 notes

Text

Looking for reliable paddy parboiling and dryer machine manufacturers? Look no further than Photons Food. Our high-quality and efficient dryer machines for paddy ensure optimal drying for your crops. Contact us now to learn more!

#Paddy Parboiling Plant Manufacturers#industrial food machinery#photons food processing engineers#food processing machinery manufacturers in india#food processing machinery#paddy dryer machine#food processing machinery manufacturers#paddy cleaner#photons food#parboiled paddy dryer

0 notes

Text

Photons is known as the expert Paddy Parboiling Plant Manufacturers in India. Our parboiling plant solutions are efficient, reliable, and the best in the industry for your rice mills. We are dedicated to providing high-quality products and services that exceed customer expectations.

#Industrial Food Machinery#photons food processing engineers#food processing machinery manufacturers in india#food processing machinery#paddy dryer machine#food processing machinery manufacturers#paddy cleaner#parboiled paddy dryer#photons food

0 notes