#automotive wheel bearing

Explore tagged Tumblr posts

Text

I had to replace the front wheel bearing and cv axle on my Denali the other day. The wheel bearing was breaking apart and making a loud grinding noise. Glad this one is done. Now on to the other side...

Video of the work on my YouTube:

youtube

#gmc#denali#gmc sierra#chevy#suspension work#cv axle#axle#wheel bearing#bearings#cars#dodge#ford#2008#mechanic#automobile#automotive#auto mechanic#weekend project#weekend warrior#new part#upgrade#new#toyota#nissan#mopar#american muscle#chrome#22s son#awd#v8

5 notes

·

View notes

Text

Onwo products have been tested and confirmed to work in abrasive environments where conventional industrial lubricants have failed to lubricate. A whole spectrum of greases and oils are included in the performance plus products, which are made to withstand the harsh lubrication conditions seen in the steel, cement, mining, building, power, and automotive industries.

#petroleum lubricating oil#petroleum-based grease#automotive wheel bearing grease#industrial lubricant company#petroleum products#industrial oil suppliers#machinery grease#textile lubricants#onwo#rajpetro#raj petro

0 notes

Photo

New Post has been published on https://www.vividracing.com/blog/top-8-best-mods-for-a-800-hp-c7-z06-corvette/

Top 8 Best Mods for a 800+ HP C7 Z06 Corvette

If you’re looking to take your Corvette’s power and presence to the next level, you’ve come to the right place. In this guide, we’ll explore the top 8 best mods that can transform your Z06 into an 800+ horsepower beast, unleashing its full potential on the track or the street.

From enhancing exhaust notes to optimizing engine performance and improving traction, each of these mods plays a crucial role in elevating your driving experience. Whether you’re a seasoned enthusiast or just diving into the world of automotive upgrades, these carefully selected parts and accessories are sure to make a significant impact on your Corvette’s performance and aesthetics.

So buckle up, rev your engines, and let’s dive into the details of the Kooks Headers, Kooks X-Pipe, Borla ATAK Axleback exhaust, Cordes Performance upgrades including the 2.30″ LT4 Upper Pulley Kit and Engine Bay Ice Tank, the Low Side Fuel System for optimal fuel delivery, the traction-boosting Mickey Thompson Et Street SS Tires, and the stylish yet functional Forgestar D5 Drag Wheels. Get ready to experience the thrill of pushing your C7 Z06 Corvette to new heights!

youtube

https://www.vividracing.com/blog/wp-content/uploads/img-c7z06_forgestard5_mickeythompsonetstreet-3-scaled.jpg

1.) Kooks 1-7/8″ x 2″ x 3″ Stainless Steel Headers Chevrolet Corvette C7 2014-2019

When it comes to elevating your Corvette’s performance, few names carry as much weight as Kooks Headers and Exhaust. With a legacy spanning over 50 years, Kooks has solidified its position as a leader in the High Performance Exhaust Industry since 1962. What sets Kooks apart is not just their reputation but their unwavering commitment to delivering top-notch headers and exhaust systems for street, race, and off-road applications.

The accolades speak for themselves – Kooks has secured hundreds of championships and set numerous records across renowned racing organizations like NHRA, IHRA, NMCA, NMRA, NASCAR, NASA, SCCA, and many others. This level of success is a testament to the quality and performance of Kooks products.

What makes Kooks truly special is their dedication to craftsmanship and American manufacturing. With three generations of family leadership at the helm, every Kooks product is handcrafted right here in the USA. This commitment to quality control and precision ensures that every header and exhaust system that bears the Kooks name meets the highest standards of excellence.

The Kooks Headers and Exhaust kit for the C7 Corvette includes a 1-7/8″ x 2″ x 3″ Stainless Steel Long Tube Header, Cometic Multi-Layer Gaskets, Stage 8 Header Bolts, O2 Extensions, and Torca Clamps. Crafted from premium 304 Stainless Steel, these components not only offer exceptional durability but also add a touch of aesthetic appeal with their stainless steel finish.

Fitment is seamless for various Corvette models, including the Chevrolet Corvette C7 LT1 6.2L (2014-2019), Chevrolet Corvette C7 Z06/Z07 LT4 6.2L (2015-2019), and Chevrolet Corvette C7 ZR1 LT5 6.2L (2019).

So, if you’re ready to “Get Kookin with KOOKS!” and experience a performance boost like never before, the Kooks Headers and Exhaust system is a must-have addition to your C7 Corvette.

2.) Kooks OEM X 3 X 2 3/4 (OEM) C7 X Pipe Chevrolet Corvette C7 6.2L -All models 2014-2019

Upgrade your Chevrolet Corvette C7’s exhaust system with the high-performance Kooks X-Pipe. Crafted from T-304 Aircraft Quality Steel, this 3″ x 3″ X-Pipe optimizes exhaust gas flow for maximum power and a thrilling exhaust note.

Features:

OEM x 3″ Front connections to factory catalytic converter

3″ x 3″ X-Pipe

3″ x 2 3/4″ Mid-Pipes. Connects to 2 3/4″ OEM Style Exhaust.

Benefits:

Enhanced engine efficiency with reduced back pressure

Dyno and race-tested for optimal performance

Direct fitment for Chevrolet Corvette C7 6.2L models 2014-2019

Limited lifetime warranty to the original purchaser

Note: Designed for off-road use only and not CARB compliant for California.

Experience over fifty years of exhaust system craftsmanship with the Kooks X-Pipe, delivering power and performance for your Corvette C7.

3.) Borla ATAK Axleback Exhaust System Chevrolet 6.2L V8

The Borla ATAK Axleback exhaust system is the ideal companion to your Kooks X-Pipe and Headers upgrade for the Chevrolet Corvette C7, offering a seamless integration that results in a host of performance benefits. Together, these high-performance exhaust components optimize exhaust flow, reduce back pressure, and improve engine efficiency, translating into a noticeable increase in horsepower and torque for exhilarating acceleration. What truly sets this combination apart is the distinctive Borla Sound of Power, delivering an aggressive yet refined exhaust note that not only enhances driving excitement but also sets your Corvette apart from the crowd. Crafted from polished T-304 stainless steel, the Borla exhaust system not only ensures premium quality and durability but also adds a touch of visual appeal to your Corvette’s rear end. With precision CNC manufacturing and Borla’s Million-Mile Warranty backing, you can trust that your exhaust system will fit perfectly and be covered for the long haul. Together, the Kooks X-Pipe and Headers with the Borla ATAK Axleback exhaust unleash the full potential of your Corvette C7, offering an unmatched driving experience that’s as thrilling as it is refined.

4.) Cordes Performance 2.30″ LT4 Upper Pulley Kit Chevrolet Corvette 2014-2021

Upgrade your Chevrolet Corvette’s performance with the Cordes Performance 2.30″ LT4 Upper Pulley Kit, designed specifically for models from 2014 to 2021. This kit offers a significant improvement by reducing the pulley size from the OEM 2.5 inches to a 2.3-inch diameter, resulting in a boost of 2-3 psi over stock levels. Included in the kit are essential components such as a press-on hub, 10 titanium torx bolts for secure installation, and the pulley itself featuring the newest griptec finish for enhanced traction and durability. Notably, the OEM belt can be reused if you have a stock-size lower, ensuring compatibility and ease of installation. This kit is compatible with all LT4 superchargers, making it a versatile and effective upgrade for unlocking additional power and performance from your Corvette’s engine. Experience improved boost levels and overall driving excitement with the Cordes Performance 2.30″ LT4 Upper Pulley Kit, tailored to elevate your Corvette’s performance to new heights.

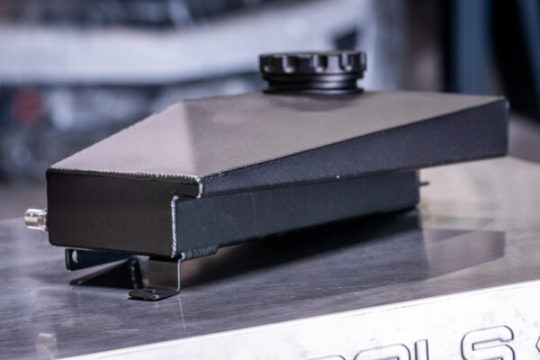

5.) Cordes Performance Engine Bay Ice Tank Chevrolet Corvette 2014-2021

Elevate your Chevrolet Corvette’s cooling capabilities with the Cordes Performance Engine Bay Ice Tank designed for models from 2014 to 2021. Cordes Performance Racing, renowned as the premier GM LTX/LTX motorsports company in Arizona, brings a wealth of expertise and passion to every product they offer. As a family-run business deeply committed to performance excellence, Cordes Performance Racing not only focuses on building high-level performing vehicles but also prioritizes the overall presentation, ensuring that you’re proud to showcase your Corvette. The Engine Bay Ice Tank is no exception, crafted using the highest-quality components to deliver optimal cooling efficiency and performance reliability. By maintaining lower engine temperatures, especially during high-performance driving or track sessions, this ice tank ensures that your Corvette operates at the peak of its performance, providing consistent power delivery and reliability. Trust Cordes Performance Racing to go above and beyond in enhancing your Corvette’s cooling system, enabling you to push the limits with confidence and enjoy an exhilarating driving experience every time you hit the road or track.

6.) Cordes Performance Low Side Fuel System Chevrolet Corvette 2014-2021

(Image may differ from actual product)

Enhance the fuel delivery and performance of your Chevrolet Corvette from 2014 to 2021 with the Cordes Performance Low Side Fuel System. Cordes Performance Racing stands as the premier GM LTX/LTX motorsports company in Arizona, driven by a deep passion for excellence in automotive performance. As a family-run business, Cordes Performance Racing not only focuses on building high-level performing vehicles but also emphasizes an overall presentation that you’ll be proud to showcase. The Low Side Fuel System exemplifies this commitment, utilizing only the highest-quality components to ensure optimal fuel delivery and engine performance. Compatible with Chevrolet Corvette C7 models from 2014 to 2021, including the C7ZO6 and C7ZR1 variants, this fuel system upgrade is designed to keep your vehicle at the peak of its performance, providing consistent fuel delivery and power output. Trust Cordes Performance Racing to go the extra mile in upgrading your Corvette’s fuel system, delivering reliability and performance that you can count on for every drive.

7.) Forgestar D5 Drag Wheel 18×12 5×120.65 50mm Gloss Black w/ Machined Lip

The Forgestar D5 Drag Wheel in 18×12 size with a 5×120.65 bolt pattern and 50mm offset is a game-changer for high-performance builds like the 800hp C7 Z06 Corvette. Forgestar performance wheels are renowned for bridging the gap between forged and cast wheels, delivering exceptional strength and lightweight characteristics crucial for demanding applications. Using an innovative rotary formed production process, Forgestar creates a lightweight cast wheel with strength and impact values comparable to forged wheels, making them ideal for street, racing, and drag racing applications. The Drag Wheel variant is drag strip approved with SFI 15.1 and 15.2 ratings, ensuring top-notch safety and performance standards. The wheel features a rotary forged flow-formed barrel, monoblock construction, and a Gloss Black finish with a machined lip, combining aesthetics with functionality. Its lightweight design not only enhances acceleration and handling but also clears big brake kits for improved stopping power. The raised center cap adds axle clearance convenience, while bead knurling ensures secure tire fitment. With a load rating of 1600 lbs and meticulous attention to detail in construction, the Forgestar D5 Drag Wheel is a must-have for high-performance enthusiasts looking to maximize their C7 Z06 Corvette’s potential on the drag strip and beyond.

Mickey Thompson ET Street S/S Tire – P345/35R18

The Mickey Thompson ET Street S/S Tire in P345/35R18 size is a high-performance street-to-strip tire designed for enthusiasts seeking exceptional traction on both the street and the drag strip. Featuring radial construction and the renowned R2 compound, this tire delivers superior performance in 15- to 20-inch fitments. It is D.O.T. approved for street use, making it a versatile choice for daily driving and track days alike. The ET Street S/S tire boasts an equivalent tread void as the ET Street Radial II but with improved hydroplane resistance, ensuring excellent dry traction while maintaining safety in wet conditions. The proven R2 compound, also used in top “drag radials,” provides superior traction at the strip, often requiring minimal or no burnout for optimal performance. Tubeless construction adds convenience with a leak-free seal, eliminating the need for tubes. With specifications like a centerline tread depth of 6.0/32″, an inflated overall diameter of 27.8 inches, and a maximum rim width of 13.5 inches, this tire offers a perfect balance of performance and durability. Whether you’re hitting the drag strip or cruising the streets, the Mickey Thompson ET Street S/S Tire is the ideal choice for enthusiasts seeking exceptional traction and performance in a street-legal package.

By combining top-notch performance upgrades from industry leaders, the Chevrolet Corvette C7 Z06 transforms into an 800hp powerhouse ready to dominate the streets and the track. The Kooks Headers and Exhaust system, along with the Borla ATAK Axleback exhaust, not only optimize exhaust flow but also enhance the aggressive exhaust note, while the Cordes Performance 2.30″ LT4 Upper Pulley Kit and Engine Bay Ice Tank ensure optimal engine cooling and power delivery. The Cordes Performance Low Side Fuel System keeps fuel delivery consistent, while the Forgestar D5 Drag Wheels and Mickey Thompson ET Street S/S Tires provide traction and stability necessary for harnessing the massive power output. Together, these meticulously selected upgrades create a harmonious synergy, elevating the Corvette C7 Z06 to 800hp and delivering an exhilarating driving experience that’s as thrilling as it is refined.

As always, if you need any assistance with selecting the right parts for your car, feel free to shoot us an email at [email protected] or give us a call at (480) 966-3040. Whether it’s helping you pick the best parts, or being a shoulder to cry on, we’ll be here!

#800hp C7 Z06 Corvette#Borla ATAK#c7 z06#Chevrolet#Cordes Performance#Corvette#Engine Bay Ice Tank#exhaust#Forgestar Drag Wheels#Headers#kooks#Low Side Fuel System#Mickey Thompson

7 notes

·

View notes

Note

i am coming to you seeking automotive advice. toyota wants $1,900 of my hard earned us american dollars to replace my car’s rear wheel bearings…but they sell them on amazon for $40. do you have any knowledge on if it’s something that can be fixed by someone with no mechanical experience besides changing a headlight? i have a jack and a socket wrench. i just need the courage

my first piece of advice is never go to the dealer for auto repairs. they are fucked up and insane extortionists. they always charge the highest prices it's craaaaaazy. try to find a place where only one person speaks english and she seems like probably the mechanics high schooler niece. $1,900 for a wheel bearing replacement is fucking highway robbery

but second of all yeah i think you could probably pull this repair off yourself. the only caveats being you'd need tools, not just the kit, which could be an investment. whether you need more than just the tools you already have depends on the model and how old and fucked up your car is. for instance you might need a bearing puller. and things might go very smoothly, or things might possibly get hairy, and then you'd need a tow to the shop (but don't go to the dealer cause wtf)

tldr definitely get a second opinion on that price, have fun and get the proper tools if u decide to diy.

p.s. what model and year???? please tell me

4 notes

·

View notes

Text

1958 Porsche 356 A Coupe

The Porsche 356A (T2) Speedster September 1957 to August 1958 (Carrerra Speedsters continued into 1959)

The last of the 356A Speedsters are probably the most attractive and the most desirable. The 356A (T2) Speedster was introduced in September 1957 and continued until the basic Speedster was replaced by the Convertible D in August 1958 although a number of Carrera, GS and GT Speedsters were produced in 1959.

History:

Ferdinand Porsche and the foundation of the Porsche Company

Ferdinand Porsche was born on September 3rd 1875, in the Bohemian village of Maffersdor. After attending grammar school and Staatsgewerbeschule (State Vocational School) in Reichenberg, he entered his father's metalworking business. The young and imaginative Ferdinand pursued a fascination with electricity working on the design of an electric car and in 1900 The Lohner-Porsche electric car is presented at the World Fair in Paris. Porsche's wheel hub engines brought the young engineer international attention. In the same year, he developed an all-wheel-drive racecar, as well as a hybrid petrol/electric vehicle.

In 1906 Ferdinand Porsche became Technical Director at Austro-Daimler in Wiener Neustadt. At the age of only 31, he became responsible for the model range of one of Europe's largest automotive concerns.

In September1909 Ferdinand's first son, Ferdinand Anton Ernst Porsche, later known as 'Ferry', was born. In 1910 The Austro-Daimler touring car designed by Ferdinand Porsche scores a triple victory in the Prince Henry Trials.

In 1923 as Technical Director and Board Member of the Daimler-Motoren-Gesellschaft in Stuttgart, Ferdinand Porsche was responsible for the design of the legendary Mercedes Compressor Sports Car and in the following year, he led the development of the 2-litre racecar won the Targa Florio. The Mercedes-Benz S-Type models dominate international motorsport from 1927.

Professor Ferdinand Porsche 1875-1951

In 1931 Ferdinand Porsche founded the company that bears his name "Dr. Ing. h. c. F. Porsche GmbH" to provide 'engineering and consultation on engine and vehicle design'. Based in Stuttgart the company carried out projects for manufacturers such as as Wanderer, Zündapp and NSU. In 1933 Porsche developed a Grand Prix mid-engined 16-cylinder racecar for Auto Union. He also developed a rear engined compact vehicle concept for NSU.

One year later the Porsche company received an official order for the design and construction of a German 'Peoples Car' or Volkswagen. The prototype was developed and assembled in the garage of the Porsche villa in Stuttgart and was road tested within 12 months At the same time production facilities were being set up for the Volkswagen which was officially called the 'KdF-Wagen'.

In December 1935 Ferdinand Alexander Porsche the first son of Ferry Porsche (and later known as 'Butzi') was born in Stuttgart.

During 1939 Porsche developed 3 racing coupés for long-distance endurance competition. These 'BerlinRome-Wagens' could be considered the forerunners of later Porsche sports cars.

He also designed the Mercedes T-80 in1939 to conquer the world land speed record. It was reputed to have a 3000 hp aircraft engine.

Because of the outbreak of the second world war Volkswagen production was diverted towards the military version of the Beetle, the Kübelwagen and Schwimmwagen. Only 1207 Volkswagen KdFs were built between 1941 and 1944

Porsche also designed several heavy tanks but did not get the production contract. Towards the end of the war the Porsche Engineering office moved to the relative safety of Gmünd in the Austrian province of Carinthia.

After the war the Volkswagen factory at Wolfsburg was taken over by the British and Ferdinand Porsche was arrested and imprisoned in France for 20 months.

In 1946 under the direction of Ferdinand Porsche's son Ferry, the Porsche Engineering office became involved in the design of an all-wheeldrive Grand Prix racecar for an Italian industrialist, Piero Dusio.

Ferry Porsche saw a market for a small, light two seater roadster and was unable to find a car in the market that matched his preference. He decided to build a car which became the first 356 and the first sportscar to bear the Porsche name.

4 notes

·

View notes

Text

Car Tuning – An Ultimate Guide

Nowadays car tuning has gained popularity among automotive enthusiasts. This is not surprising, in the era of modern technology, people are constantly craving for reaching the highest level of performance in every aspect of life. Hence, the automotive industry is not an exception. From the very first moment of car invention, it was a subject of modification. Here comes auto tuning –one of the most favorite topics for discussion. It is more than just maintenance, it implies all kinds of enhancement starting from the visual change to the engine boosting. You may wonder why I need it? The simple response is that the manufacturers tend to limit the capabilities of your automobile. They aim to find the balance and somehow insure themselves because unlocking the full potential of vehicles may be an inefficient decision.

So let’s take a closer look at what it means in a wide sense and learn more about its types. Keep on reading to learn everything you need to know if you think about boosting your automobile.

WHAT IS CAR TUNING?

Tuning auto is known as a wide range of vehicle modifications. It incorporates various kinds of changes to provide improved performance, functionality and better visual effect. It can be understood in many ways. However, the aim is the same – to improve automobile capabilities. There are certain areas of modification including audio system, interior, motor, suspension, body, tires and brakes. Below I will provide you with a comprehensive explanation of every one of them.

WAYS TO UPGRADE YOUR AUTO IN AND OUT

Let’s start with visual improvement. Personalizing an automobile is always a subject of excitement among motorists. Does this sound like you? I’m sure it does. We all share this feeling. Improving the aesthetics is very tempting for all. For some people, it’s a kind of obsession. When it comes to visual upgrading, it is easier to take control of the situation if you are one of those DIYers. Here are two areas where you can transform your automobile.

Body

Transforming your vehicle exterior is a big move, so you should carefully consider every detail. You need to bear in mind, the aim is to improve the exterior significantly. Hence, you should find the proper body kit that is a set of modified parts or additional components for the car. It contains front and rear bumpers, side skirts, spoilers, bonnets (bonnet scoop), sometimes roof and side scoops. There is a wide range of companies that offer this hardware. Firstly, find the one that works for you. Do not hesitate to search for photos that are inspiring and buy them. Next, think twice before you start doing it yourself, if you are good at following the instructions here is a step-by-step guide on how to install.

Interior

Another form of a car tune-up is interior styling. This type of transformation is best-loved among those who love to emphasize individuality. There are several options for personalizing the interior. For example, cockpit improvement, which implies coating plastic with wood or leather. In addition to that, automobile seats and steering wheels are also subject to upgrading. It’s pretty obvious once you think about it, so let me tell you that you don’t need to go to the workshop. Just search for and shop for accessories on internet retail shopping websites at an affordable price.

WHY IS SUSPENSION TUNING NECESSARY?

The Suspension system is what ensures road holding and ride quality. Hence, it supports a comfortable ride. Suspension is a system of tires, tire air, springs, shock absorbers and linkages that connect an automobile to its wheels. The main function of struts and shock absorbers is to control stability. The spring is what holds the car up in the air. Hence, the rocking, bouncing and shaking of an automobile is an indicator that those components need replacement.

Auto tune-up improves speed and pick up. Hence cars need an enhanced suspension system for better handling on the road. Here comes the necessity and importance of suspension tuning. suspension tuning implies the modification of springs, struts and, shock absorbers to affect how a vehicle accelerates, brakes and corners.

The most common type of suspension tuning is so-called – lowering. The closer an automobile is to the surface, the better you can develop high speed. Lowering is done through springs. Tuning implies shortening the existing springs or replacing them with a new one.

Believe it or not, an innovative device is for sale at Super Kilometer Filter. It allows you to do suspension tuning independently.

The best DIY tool for suspension tuning

Lowering device is an innovative and user-friendly tool for Mercedes owners. Manufacturers designed specifically for airmatic suspension. You get various benefits from using this tool.it allows lowering and increasing options, improved responsiveness, faster acceleration, quicker stops, less rollover risk. The module also serves a practical purpose, a lowered automobile is comfortable for a person with a disability. The tool offers three different modes: factory, low and custom.

CHIP TUNING

It is the most popular type of car tuning. ECU is responsible for controlling the fuel supply, airflow, fuel injection and ignition. It implies overwriting the manufacturer’s existing setting with new software. The main benefits that drivers get are improved horsepower and torque, better control and drivability, enhanced rev range. This type of auto tuning is significantly beneficial for diesel cars.

There are recommended programs that support live, 2D and 3D tuning. As a mechanic, all you have to do is search for the one which will be compatible with the automobile. Make sure that you own the laptop that serves you well.

Despite the above mentioned, here’s another way to think about the issue. Boosted functioning and efficiency can be related to some risks. It is worth considering everything before you make a final decision.

What to consider

Remember, I don’t want you to become the victim of common biases related to tuning auto. how to avoid it? – get comprehensive information and be ready for the possible consequences. there is a list of things to consider before:

Increased maintenance cost. When you enjoy all the benefits from boosting automobiles, you should know that there will be the necessity to replace components such as the ignition coils more often. So consider your budget.

Insurance costs. Besides, consider insurance premiums. This type of tuning can have a potential impact on insurance costs. Trust me, they know that you don’t miss a chance to use the full potential of your automobile. Hence it makes you a high-risk driver.

Forget fuel economy. Don’t believe that fuel efficiency will be possible, you will need high-quality fuel at any rate.

Harmful to the environment. The factory settings provide the lowest emissions and therefore stock automobiles are environmentally friendly. The changes in the manufacturer’s setting may result in increased emissions.

Choose the mechanic. Make sure that everything will be done correctly. Your automobile should be in the hand of a qualified specialist if you want the best possible outcome.

Mind the warranty. If tuning is not approved by the manufacturer, you should expect to void the warranty. Let’s be realistic, you change the factory settings, so they refuse to take responsibility for the safety and reliability.

CAR TUNE-UP IS FINISHED – WHAT’S NEXT?

So, you have a tuned automobile. It would be interesting if you could test it and see the results. However, something holds you back. I guess it is a danger of adding miles on your odometer. What if, I can tell you that testing is possible without the risk of adding mileage on your automobile. For this purpose manufacturers designed a special tool. It allows you to carefully examine all the benefits you get from tuning. This device is known as a mileage blocker.

Mileage blocker

This extraordinary and premium quality product from Germany is specially for stopping the mileage recording process from all control units untraceably. This is a user-friendly module that is easily installed behind the dashboard. The tool is superior to its counterfeits. Mileage blocker is available online and you can purchase mileage blocker from superkilometerfilter. Consider avoiding illegal usage, some people use it for deceiving potential buyers. Remember, it is only created for testing and tuning purposes. In case of any further questions, please feel free to contact us anytime.

CONCLUSION

Now you have read through the blog and you know what is auto tune-up, why it is beneficial, what to consider and how much you risk. By now you have realized that it is a very controversial topic, but the good news is that you can weigh all options and think twice before you make a final decision. There are some areas where you don’t need careful examination of every detail. For instance, interior refinement of your automobile, it just takes your creativity and budget. As for internal changes, it is worth discussing and exchanging opinions. All in all, it’s up to you. Good luck!

2 notes

·

View notes

Text

CNC Grinding Overview: Understanding the Basics

CNC grinding is a manufacturing process involving computer-controlled grinding machines to produce precise and high-quality components. These machines are used in a wide range of industries, including aerospace, automotive, medical, and more. In this article, we will discuss an overview of CNC grinding and its benefits.

What is CNC Grinding?

CNC grinding is a machining process that uses computer-controlled grinding machines to remove material from a workpiece. The process involves using an abrasive wheel to grind away material and create the desired shape or surface finish. CNC grinding machine is programmed using a computer-aided design (CAD) file that specifies the geometry and tolerances of the part to be machined.

Benefits of CNC Grinding

CNC grinding offers several benefits over traditional grinding methods. One of the most significant advantage is the ability to produce exact and repeatable components. In addition, CNC machines can hold very tight tolerances, often within a few microns, which is vital for industries such as aerospace and medical, where precision is critical.

Another benefit of CNC grinding is the ability to automate the process. As a result, CNC machines can run for long periods with minimal operator intervention, leading to increased productivity and lower costs. Additionally, CNC grinding machines can be programmed to produce a wide range of components, making them a versatile and efficient solution for manufacturers.

Common Types of CNC Grinding Machines

Several types of CNC grinding machines are designed for specific applications. Some of the most common types include:

Surface Grinding Machines: Surface grinding machines produce a smooth finish on flat surfaces. They use a rotating abrasive wheel to remove material from the surface of the workpiece. Surface grinding machines can be manual or CNC-controlled and can be used to grind a wide variety of materials, including metal, plastics, and ceramics.

Cylindrical Grinding Machines: Cylindrical grinding machines are mainly used to grind the outside diameter of cylindrical workpieces. They use a rotating grinding wheel to remove material from the workpiece and can produce very precise and accurate results. Cylindrical grinding machines can be manual or CNC-controlled and are commonly used in the automotive and aerospace industries.

Centerless Grinding Machines: Centerless grinding machines are used to grind cylindrical workpieces without a centre. They use a regulating wheel to control the speed and rotation of the workpiece and a grinding wheel to remove material. Centerless grinding machines are often used to produce high-volume, precision parts such as bearings and shafts.

Tool and Cutter Grinding Machines: These machines are used to sharpen and recondition cutting tools such as drills, milling cutters, and end mills. They use a variety of grinding wheels to produce the desired shape and finish on the device. Tool and cutter grinding machines can be manual or CNC-controlled and are used in a wide range of industries.

By understanding the different types of CNC grinding machines, manufacturers can choose the suitable machine for their specific application and achieve the desired results.

Special Purpose Machines for CNC Grinding

In addition to standard CNC grinding machines, there are special-purpose machines designed for specific applications. One such example is deep hole drilling machines, which are used to drill deep, narrow holes with high precision. These machines are commonly used in the aerospace and defence industries.

Conclusion

CNC grinding is an exact and efficient machining process that offers several benefits over traditional grinding methods. In addition, special-purpose machines, such as deep-hole drilling machines, can further enhance the capabilities of CNC grinding. If you are in the market for a CNC grinding machine or special-purpose machine, consider Widma for its expertise and high-quality products.

2 notes

·

View notes

Text

Automotive Bearing Market Financial Health: Challenges in Demand, Supply Chains, and Technological Innovations Ahead for 2025

The automotive bearing market has witnessed considerable growth in the past few decades. Bearings are essential components in automotive applications, ensuring smooth rotational movement while reducing friction and wear. These components are found in almost every part of the vehicle, including the engine, wheels, and steering system. With the automotive industry's rapid advancement and innovation, the demand for high-quality bearings has grown immensely, impacting the market’s financial health. This article explores the financial outlook of the automotive bearing market and the factors shaping its future.

1. Market Demand and Financial Impact

The increasing demand for vehicles worldwide is one of the most prominent drivers of the automotive bearing market's financial health. As global vehicle production continues to rise, the demand for bearings has expanded. Innovations such as electric vehicles (EVs) and autonomous vehicles (AVs) are expected to further boost market growth. Bearings' role in EVs and AVs—helping optimize energy efficiency and vehicle stability—has placed them at the forefront of future automotive trends. The flourishing demand for electric and hybrid vehicles, alongside the need for highly efficient, lightweight components, has shown positive financial impacts.

2. Supply Chain Challenges and Financial Risks

However, the financial health of the automotive bearing market is not without its challenges. The global supply chain disruptions, especially those caused by the COVID-19 pandemic, have hindered production and delivery schedules. Manufacturing delays, labor shortages, and rising material costs have resulted in price hikes for bearings, which put pressure on the financial stability of both manufacturers and suppliers. The ongoing issues of raw material cost increases have forced businesses to reassess their pricing models and distribution strategies to retain profitability.

3. Technological Innovations and Cost Efficiency

Despite the challenges, advancements in manufacturing technologies have allowed businesses to optimize their processes and reduce production costs. Automation in the bearing manufacturing process has streamlined production, improving efficiency while lowering overhead costs. Additionally, 3D printing technology has begun to revolutionize prototype designs, allowing faster testing and less resource consumption. While technology has introduced its share of investment challenges, in the long run, it plays a vital role in driving the financial health of the market by lowering operational costs.

4. Regional Financial Trends

The geographical market variations also impact the financial health of the automotive bearing industry. In North America and Europe, there is a focus on high-quality, performance-oriented bearings, particularly for luxury and high-performance vehicles. These markets tend to have stable growth but are more sensitive to changes in market demand and raw material prices. In contrast, the Asia-Pacific region has exhibited robust growth in recent years, led by burgeoning automotive production in China, India, and Japan. Cost-effective manufacturing in these regions helps cushion the impact of global supply chain instability and drives overall market growth. This regional difference in supply chains, consumer behavior, and market demand has led to varied financial outcomes for bearing manufacturers and suppliers.

5. Key Players and Investment Prospects

Major automotive bearing manufacturers such as SKF, NSK, Timken, and Schaeffler dominate the market, leveraging strong investment in R&D, operational efficiency, and capacity expansion. These players are taking advantage of global expansion opportunities to secure a competitive edge, ensuring long-term financial health through diversification and technological development. Investors continue to explore the automotive bearing sector, anticipating continued expansion due to increased vehicle production, technological innovations, and more stringent environmental standards. Consequently, automotive bearing companies have generally maintained a healthy financial outlook, backed by consistent revenue streams from top-tier vehicle manufacturers and innovative partnerships in the market.

Conclusion

The automotive bearing market's financial health is characterized by a strong growth trajectory, tempered by global challenges. While demand for bearings in the automotive industry is buoyed by trends in electrification, vehicle production, and innovation, the market faces pressures from supply chain issues, rising costs, and regional differences. Technological advancements in bearing manufacturing processes and investment from key industry players are expected to keep the market resilient, ensuring its continued financial growth. As we move forward into the future of automotive design, the health of the automotive bearing market will likely continue to improve, albeit with attention to maintaining balance between cost, quality, and production efficiency.

0 notes

Text

KG Bearings Near Me: Your Trusted Partner for Premium Bearings

When it comes to high-quality bearings, KG Bearings stands out as a global leader. Known for their exceptional durability, performance, and reliability, KG Bearings are the top choice for a wide range of industries, including automotive, industrial, and manufacturing sectors. If you’re searching for KG Bearings near me, Bearings and Tools Syndicate (BTS Bearings) is your one-stop solution. As the largest distributor of KG Bearings in India, we are here to meet all your bearing needs with unmatched quality and service.

Why Choose KG Bearings?

KG Bearings has earned a stellar reputation for delivering world-class bearings that excel in performance and longevity. Here are some reasons why KG Bearings are highly preferred:

Unmatched Quality: Manufactured with precision, KG Bearings meet international standards, ensuring top-notch performance and reliability.

Wide Range: From deep groove ball bearings to angular contact bearings, KG offers a comprehensive range of products to suit diverse applications.

Cost-Effective: KG Bearings provide excellent value for money without compromising on quality.

Global Reach: With a strong presence in over 50 countries, KG Bearings are trusted worldwide.

Bearings and Tools Syndicate: Your Source for KG Bearings Near Me

At BTS Bearings, we have been in a strategic partnership with KG International for over 15 years, making us the largest distributor of KG Bearings in India. Our commitment to quality and customer satisfaction has made us a trusted name in the industry. Here’s why you should choose us for KG Bearings near me:

Extensive Inventory: We maintain a large stock of KG Bearings to ensure quick availability for our customers.

Competitive Pricing: Our strong relationship with KG International enables us to offer competitive prices, providing excellent value for your investment.

Technical Expertise: Our experienced team provides technical guidance to help you select the right bearing for your specific application.

Prompt Deliveries: With a robust distribution network, we ensure timely deliveries to meet your operational needs.

Customer Support: We are dedicated to offering exceptional customer service, ensuring a seamless experience from selection to delivery.

Industries We Serve

KG Bearings are widely used across various industries. At BTS Bearings, we cater to a diverse clientele, including:

Automotive Industry: Bearings for engines, gearboxes, and wheels ensure smooth performance and longevity.

Textile Industry: High-precision bearings for spinning, weaving, and other textile machinery.

Pump and Motor Industry: Bearings designed for efficient and durable performance in pumps and motors.

Wet Grinder Industry: Essential for ensuring the smooth operation of wet grinders, a staple in Indian households.

Industrial Applications: Bearings for heavy machinery, conveyors, and other industrial equipment.

Finding KG Bearings Near Me: Our Product Range

At BTS Bearings, we offer a comprehensive range of KG Bearings to meet the diverse needs of our customers. Our product lineup includes:

Deep Groove Ball Bearings: Ideal for high-speed applications, capable of handling both radial and axial loads.

Angular Contact Ball Bearings: Designed for applications requiring high precision and efficiency.

Self-Aligning Ball Bearings: Suitable for applications with misalignment issues, ensuring smooth operation.

Thrust Ball Bearings: Specifically engineered to handle axial loads in low-speed applications.

Customized Bearings: Tailored solutions for unique industrial requirements.

Advantages of Choosing BTS Bearings for KG Bearings Near Me

1. Proximity and Accessibility

With our widespread presence in South India, including Coimbatore and other major industrial hubs, finding KG Bearings near me has never been easier. Our strategic location ensures quick and hassle-free access to premium bearings.

2. Reliable Stock Availability

We understand the importance of minimizing downtime in industrial operations. That’s why we maintain a robust inventory to ensure that your required bearings are always in stock.

3. Trusted Partnerships

Our long-standing collaboration with KG International reflects our commitment to quality and reliability. We are proud to bring their world-class products closer to you.

4. Expert Guidance

Choosing the right bearing can be challenging. Our team of experts is here to assist you with product selection, ensuring optimal performance and cost-effectiveness.

5. Customer-Centric Approach

At BTS Bearings, customer satisfaction is at the heart of everything we do. From prompt responses to post-sales support, we are committed to exceeding your expectations.

How to Choose the Right KG Bearings Near Me

Selecting the appropriate bearing for your application is crucial for achieving optimal performance. Here are some tips to help you make the right choice:

Understand Your Requirements: Identify the load type, speed, and environmental conditions for your application.

Consider Material and Quality: Opt for bearings made from high-quality materials to ensure durability.

Check Compatibility: Ensure the bearing dimensions and specifications match your machinery.

Consult Experts: Seek advice from trusted suppliers like BTS Bearings for tailored recommendations.

Verify Authenticity: Always purchase bearings from authorized distributors to guarantee genuine products.

Why BTS Bearings is the Best Choice for KG Bearings Near Me

Over the years, BTS Bearings has earned the trust of countless clients across industries. Here’s what sets us apart:

Experience and Expertise: With decades of experience in the bearing industry, we have the knowledge and expertise to meet your needs.

Quality Assurance: Our partnership with KG International ensures that you receive only the highest-quality bearings.

Customer Satisfaction: We go the extra mile to provide a seamless and positive experience for our clients.

Partner with Bearings and Tools Syndicate for all your KG Bearing needs. Reach out to us today and experience the difference in quality, service, and reliability!

0 notes

Text

0 notes

Text

Diesel Engine Oils and Greases – A Perfect Partnership for Machinery Efficiency

IntroductionEfficient machinery relies heavily on proper lubrication, making diesel engine oils and greases essential components. While diesel engine oils ensure the smooth operation of engines, greases provide targeted protection for specific parts. This article explores how these lubricants form a perfect partnership in machinery maintenance.

Diesel Engine Oils: The Backbone of Engine Performance

1. Purpose and Composition:Diesel engine oils are designed to handle the intense demands of diesel engines. They consist of a base oil mixed with additives like detergents, anti-wear agents, and viscosity improvers.

2. Benefits of Diesel Engine Oils:

Friction Reduction: Minimizes wear and tear between moving parts.

Thermal Management: Dissipates heat to prevent overheating.

Contaminant Control: Keeps engines clean by preventing sludge and soot buildup.

Longevity: Extends the life of engine components.

3. Applications Across Industries:

Used in transportation (trucks, buses), construction machinery (excavators, loaders), and agriculture (tractors, harvesters).

The Critical Role of Greases

1. What Makes Greases Unique?Unlike oils, Greases are semi-solid and remain in place, even under extreme pressure or environmental conditions. This makes them ideal for components that experience heavy loads or limited motion.

2. Key Properties of Greases:

Adhesiveness: Stays on surfaces, providing long-lasting protection.

Water Resistance: Prevents rust and corrosion in wet conditions.

Shock Absorption: Cushions parts from sudden impacts.

3. Common Applications:

Bearings, gears, and linkages in industrial machinery.

Hinges, pins, and joints in vehicles and equipment.

How Diesel Engine Oils and Greases Work Together

1. Complementary Functions:Diesel engine oils manage dynamic lubrication inside engines, while greases protect stationary or slow-moving parts. Both ensure smooth operations, reducing wear and tear.

2. Enhancing Machinery Efficiency:

Diesel oils improve fuel efficiency by reducing internal resistance.

Greases enhance the longevity of mechanical linkages and bearings, reducing downtime.

3. Case Studies:

Automotive Sector: Diesel oils power truck engines, while greases ensure stability in wheel bearings.

Agriculture: Tractors rely on diesel oils for engines and greases for hitch points and joints.

Maintaining Lubrication Systems

1. Importance of Regular Checks:

Monitor oil levels and change schedules.

Ensure grease is applied correctly and at the right intervals.

2. Using High-Quality Products:

Opt for synthetic diesel engine oils and greases for extreme conditions.

Work with trusted suppliers to ensure the quality and reliability of lubricants.

Future Innovations in Lubricants

1. Synthetic Lubricants:Advanced synthetic diesel engine oils and greases are designed to perform under extreme conditions, providing better efficiency and longevity.

2. Smart Technology:Lubricants integrated with IoT sensors allow for real-time monitoring, optimizing maintenance schedules and reducing downtime.

3. Eco-Friendly Solutions:Bio-based greases and diesel oils offer sustainable alternatives, minimizing environmental impact.

ConclusionThe synergy between Diesel engine oils and greases is critical for the efficient operation of machinery. By understanding their roles and maintaining regular lubrication schedules, industries can maximize productivity, reduce maintenance costs, and ensure long-term equipment reliability. Together, these lubricants form the backbone of industrial success.

0 notes

Text

Grinding Machines - Essential Tools for Precision and Efficiency

Grinding machines are pivotal in various industrial and manufacturing processes. These machines are designed to achieve high levels of precision by removing material from a workpiece, often for shaping, finishing, or improving surface quality. They play an indispensable role in producing parts with tight tolerances, a key factor for industries such as automotive, aerospace, and toolmaking. Their versatility and precision make them a cornerstone of modern manufacturing.

The Role of Grinding in Manufacturing

Grinding is a machining process that utilizes an abrasive wheel to remove material from a workpiece. Unlike cutting or milling, grinding employs friction to shave off material, making it ideal for achieving fine finishes or precise dimensional tolerances. The grinding process is usually used after other machining operations, such as turning or milling, to refine the surface and remove any imperfections that may have resulted. Whether the task involves sharpening tools, smoothing rough surfaces, or shaping complex geometries, grinding machines are equipped to meet the demands.

Types of Grinding Machines

Grinding machines come in various types, each suited to specific tasks. Surface grinders, one of the most common types, are designed to provide a flat finish on a workpiece. They feature a rotating wheel that moves across the surface of the material, removing thin layers to create a smooth, even surface. Cylindrical grinders are another key type, ideal for working on cylindrical parts. They allow the grinding of both the outer diameter and the inner diameter, which is critical in the production of parts such as shafts, bearings, and pistons.

Centerless grinders are used for high-precision grinding of parts without requiring the need for centers or fixtures. These machines work by holding the workpiece between two rotating wheels—one that drives the part and another that performs the grinding. This type of grinding is highly effective for producing parts in large quantities due to its efficient design. Internal grinding machines are specifically designed for grinding the inner surfaces of workpieces, such as holes, bores, or tubes.

Advancements in Grinding Technology

Over time, grinding technology has evolved to meet the increasing demands for precision, speed, and efficiency. Modern grinding machines incorporate advanced features such as computer numerical control (CNC), which allows for greater automation and precision. CNC grinding machines enable manufacturers to input complex geometries directly into the machine, reducing the likelihood of human error and enhancing repeatability. The use of digital controls also allows for faster setup times, shorter production cycles, and the ability to handle more complex tasks.

Additionally, the development of high-performance grinding wheels and abrasive materials has significantly improved the grinding process. Diamond and cubic boron nitride (CBN) wheels, for instance, offer longer tool life and greater cutting efficiency. These materials are especially effective in grinding harder materials like ceramics, hardened steels, and superalloys used in critical applications such as aerospace and automotive engines.

Applications of Grinding Machines

The applications of grinding machines span a wide range of industries. In the automotive sector, grinding is used for parts like camshafts, crankshafts, gears, and other components requiring tight tolerances. Aerospace companies rely heavily on grinding to produce precision components like turbine blades and engine parts, where surface integrity and dimensional accuracy are crucial for safety and performance.

Grinding machines are also essential in tool and die making. The ability to create intricate features and sharp cutting edges on tools, dies, and molds is made possible through grinding. Moreover, medical device manufacturers use grinding to create components such as orthopedic implants and surgical instruments, where precision and surface finish directly impact functionality and patient safety.

Challenges and Future Trends

Despite their advantages, grinding machines face certain challenges. The high heat generated during the grinding process can cause thermal damage to both the workpiece and the grinding wheel. To address this, modern machines are designed with advanced cooling and lubrication systems to manage heat and reduce wear. Additionally, the use of superabrasives, which are more efficient and durable than traditional abrasives, has helped overcome some of these challenges.

Looking ahead, there is a growing focus on increasing the automation and integration of grinding machines with other manufacturing processes. With the rise of Industry 4.0 and smart manufacturing, grinding machines are becoming more connected and capable of exchanging data in real-time. This allows for predictive maintenance, more efficient production scheduling, and improved process monitoring, ensuring that grinding remains a vital tool in precision manufacturing.

In conclusion, grinding machines are crucial to modern manufacturing due to their ability to achieve high levels of precision and quality. As technology continues to advance, these machines are evolving to meet the ever-growing demands of industries that require fine finishes, tight tolerances, and the ability to handle increasingly complex materials. Their continued development will undoubtedly contribute to the future of manufacturing, supporting innovation and efficiency across multiple sectors

0 notes

Text

Local Wheel Bearing Replacement in Queanbeyan – JSG Automotive

Smooth out your ride with professional local wheel bearing replacement in Queanbeyan from JSG Automotive. Call us at 0449 899 202 to book your service today. Trust our experts to keep your vehicle safe and road-ready!

Local Wheel Bearing Replacement In Queanbeyan

0 notes

Text

A roaring noise could be heard when driving a Hyundai Santa Fe.

One of our technicians found that a wheel bearing was the source. He suggested installing a new wheel bearing and hub.

All of the lug nuts should also be replaced, as two are broken and three are loose.

If you notice an abnormal sound coming from your vehicle, ask an automotive expert to look into it.

#roaring noise#wheel bearing#lug nuts#hyundai santa fe#hometowne auto repair and tire#prince william county virginia

0 notes

Text

The Rise of Plastic Bearing Wheels in the U.S. Automotive Industry: Driving Efficiency and Sustainability

The rise of plastic bearing wheels in the U.S. automotive industry marks a revolutionary step toward enhanced efficiency and sustainability. These innovative wheels leverage lightweight, durable materials to reduce vehicle weight, improving fuel efficiency and lowering emissions. Beyond performance, plastic-bearing wheels contribute to sustainability by utilizing recyclable components and reducing reliance on traditional, resource-intensive materials. As automakers increasingly prioritize eco-friendly practices, this cutting-edge technology is steering the industry toward a greener, more efficient future while maintaining the high standards of safety and durability that consumers demand.

0 notes

Link

0 notes