#automotive spray paint service

Explore tagged Tumblr posts

Text

Car Smash Repair Near Tarneit

Seeking reliable car smash repair near Tarneit? Look no further than AP Smash Repair. Our proficient team delivers swift and effective collision solutions, ensuring your vehicle receives the care it deserves. Experience hassle-free and professional automotive restoration services with us.

#Collision repairs near me#car smash repair near me#smash repairs service near me#car body repair near me#panel beaters near me#collision repairs centre Tarneit#car smash repairs Tarneit#smash repairs Tarneit#auto body repair Tarneit#car paint shops Tarneit#auto body repair centre Tarneit#auto body painting Tarneit#car scratch repair Tarneit#car body repair Tarneit#car panel beaters Tarneit#car panel beater repair Tarneit#car spray painting Tarneit#automotive spray paint service#car spray painters Tarneit#car insurance recovery#car accident insurance claims

0 notes

Text

High-Quality Car Spray Painting Services in Australia

Rising Sun Automotive offers premium car spray painting services in Australia, using top-grade paints and equipment to ensure a flawless finish. From minor touch-ups to full resprays, we've got you covered.

0 notes

Text

What're Mobile Car Coating Repair Services?

To review the premium of mobile phone automotive paint fixing solutions in Brisbane, look at the following elements: look for customer assessments as well as endorsements for comments on their job. Determine the certifications as well as knowledge of the service technicians. Ensure they use high-grade components and progressed methods. Confirm their guarantee and assurance policies. Furthermore, contrast quotes and also solutions along with various other service providers to make certain reasonable pricing and complete company. Quality assurance, reliability, and also client satisfaction are actually key indications of a reputable company.

3 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

A comprehensive guide to eco-friendly auto paint supply options in Miami

As environmental awareness grows, more vehicle owners and professionals are prioritizing eco-friendly options when choosing auto paint supplies. Miami, with its vibrant car culture and commitment to sustainability, offers a variety of solutions for those seeking environmentally responsible products. Whether you're an auto body shop owner, a professional painter, or a DIY enthusiast, this guide will help you navigate eco-friendly auto paint supply options in Miami.

Why Choose Eco-Friendly Auto Paint?

Traditional automotive paints often contain high levels of volatile organic compounds (VOCs), which can harm both the environment and human health. Eco-friendly paints are designed to minimize these risks while still delivering exceptional performance. Here’s why you should consider making the switch:

Reduced Environmental Impact: Low-VOC and water-based paints release fewer pollutants into the atmosphere.

Improved Air Quality: Eco-friendly paints help minimize indoor and outdoor air pollution.

Safer Work Environment: With reduced toxic fumes, painters and technicians are exposed to fewer health hazards.

Compliance with Regulations: Many jurisdictions, including parts of Florida, have stricter guidelines on VOC emissions.

Eco-Friendly Paint Types

Before diving into Miami’s supply options, it’s essential to understand the types of eco-friendly paints available:

Water-Based Paints: These replace harmful solvents with water, resulting in lower VOC emissions without compromising quality.

Low-VOC Paints: These contain reduced levels of volatile organic compounds, making them less toxic and more environmentally friendly.

Powder Coatings: Applied as a dry powder, these coatings emit zero VOCs and provide a durable, high-quality finish.

Bio-Based Paints: Derived from renewable resources, such as plant-based oils, these are a sustainable alternative to traditional paints.

Top Stores for Eco-Friendly Auto Paint Supplies in Miami

Miami is home to several suppliers of Auto Paint Supply Miami that cater to environmentally conscious customers. Here are the top options:

Superior Exotic Color & Paint

One of Miami’s most trusted names in auto paint supplies, Superior Exotic Color & Paint is a leader in offering eco-friendly solutions.

Eco-Friendly Options: The store stocks water-based and low-VOC paints from top brands, ensuring high performance and sustainability.

Custom Services: Their team can create custom blends using eco-friendly products to match any vehicle.

Technical Support: They provide expert advice on applying environmentally safe paints and coatings.

Tropical Paint Depot

A family-owned business with a focus on sustainability, Tropical Paint Depot has a wide selection of green products.

Specialty Coatings: They offer powder coatings and water-based primers ideal for eco-conscious projects.

Recycling Programs: Customers can bring back unused or expired paints for proper disposal.

Workshops: The store occasionally hosts training sessions on sustainable painting practices.

Miami Green Coatings

Dedicated to environmentally friendly solutions, Miami Green Coatings is a one-stop shop for green automotive painting supplies.

Bio-Based Paints: This store carries innovative products made from renewable materials.

Low-Waste Packaging: Their products come in recyclable or biodegradable containers.

Bulk Discounts: They offer discounts on bulk purchases, encouraging sustainable practices for auto body shops.

PaintMasters Miami

Known for its advanced technology, PaintMasters Miami provides state-of-the-art eco-friendly products.

Water-Based Systems: They specialize in high-performance water-based paints and clear coats.

Advanced Tools: The store also stocks eco-friendly painting tools and spray equipment.

Color-Matching Technology: PaintMasters ensures precise color matching while using environmentally responsible materials.

ProFinish Auto Paint & Accessories

ProFinish combines quality and sustainability to cater to Miami’s environmentally conscious automotive community.

Low-VOC Solutions: Their inventory includes a range of low-VOC paints and finishes.

Eco-Friendly Accessories: From biodegradable masking tapes to energy-efficient spray guns, they provide tools to complement green practices.

Educational Resources: ProFinish offers brochures and guides on sustainable auto painting techniques.

Factors to Consider When Choosing Eco-Friendly Auto Paint Supplies

When shopping for eco-friendly auto paint, keep these factors in mind to ensure you’re making the right choice:

VOC Levels: Look for paints labeled as “low-VOC” or “zero-VOC” to minimize environmental and health risks.

Durability: Eco-friendly products should still provide long-lasting results to reduce the need for frequent repaints.

Brand Reputation: Opt for trusted brands that have a proven track record of quality and sustainability.

Application Ease: Choose products that are easy to work with, especially if you’re a DIY enthusiast.

Cost: While eco-friendly paints can be slightly more expensive, they offer better long-term value by reducing health and environmental costs.

Tips for Using Eco-Friendly Auto Paint

Using eco-friendly products effectively requires proper techniques and tools. Here are some tips to maximize results:

Surface Preparation: Ensure the vehicle surface is clean and properly primed to enhance paint adhesion.

Use Appropriate Equipment: Eco-friendly paints often require specific spray guns or airbrushes for optimal application.

Follow Manufacturer Instructions: Always adhere to the recommended drying times and application methods.

Dispose of Leftovers Responsibly: Take advantage of recycling programs offered by suppliers to reduce waste.

Ventilation is Key: While eco-friendly paints emit fewer fumes, working in a well-ventilated area is still important.

Why Superior Exotic Color & Paint is a Top Choice

Among suppliers of Auto Paint Supply Miami, Superior Exotic Color & Paint stands out for its commitment to quality and sustainability. With a wide range of eco-friendly options, expert staff, and custom services, they cater to professionals and hobbyists alike. Whether you need water-based paints, low-VOC products, or eco-friendly tools, Superior Exotic Color & Paint ensures you can complete your project responsibly without compromising on results.

Conclusion

Switching to eco-friendly auto paint supplies is a smart choice for vehicle owners and professionals who care about sustainability. Miami’s diverse range of suppliers makes it easy to find high-quality, environmentally responsible products. By considering factors like VOC levels, brand reputation, and customization services, you can select the best options for your needs.

For a reliable partner in eco-friendly automotive painting, look no further than Superior Exotic Color & Paint. Their extensive inventory, expert guidance, and dedication to green practices make them the go-to supplier for environmentally conscious car enthusiasts in Miami. Visit them today to explore their range of sustainable solutions and elevate your auto painting projects while protecting the planet.

0 notes

Text

From Air to Action: Supporting Industry Everywhere from Gajjar Compressor

Introduction

Industries worldwide are evolving rapidly, requiring cutting-edge technology to meet growing demands for efficiency, reliability, and sustainability. At the heart of this transformation are industrial air compressors—critical tools powering operations across diverse sectors. Gajjar Compressor, a trusted name in the industry, is leading this revolution with innovative solutions that cater to a wide range of industrial applications.

Understanding the Importance of Air Compressors

Air compressors are integral to various industries, converting power into potential energy stored in pressurized air. This stored energy powers tools, machinery, and processes that form the backbone of industrial production. From manufacturing to healthcare, food processing to automotive, the applications are vast and indispensable.

Key Benefits of Industrial Air Compressors

Versatility: Suitable for various applications, from assembly lines to pneumatic tools.

Cost-Effectiveness: Reduces operational costs by optimizing energy usage.

Enhanced Productivity: Improves workflow efficiency and minimizes downtime.

Environmental Benefits: Modern compressors focus on energy efficiency, reducing carbon footprints.

Gajjar Compressor recognizes these benefits and incorporates them into its product designs, ensuring clients receive maximum value and performance.

Gajjar Compressor: A Legacy of Excellence

With decades of experience, Gajjar Compressor has built a reputation for delivering reliable and innovative air compressor solutions. The company’s commitment to quality, affordability, and customer satisfaction sets it apart in the competitive market.

Why Choose Gajjar Compressor?

Wide Range of Products: From oil-free compressors to high-pressure systems, Gajjar Compressor offers solutions tailored to industry-specific needs.

Innovative Technology: Integrating the latest advancements in energy efficiency and performance.

Global Reach: Trusted by clients worldwide, showcasing its credibility and expertise.

After-Sales Support: Comprehensive maintenance services and spare parts availability ensure uninterrupted operations.

Supporting Industries Across the Spectrum

Gajjar Compressor’s versatile products cater to various industries, ensuring seamless operations and enhanced productivity.

1. Manufacturing and Assembly Lines

In the manufacturing sector, precision and consistency are paramount. Gajjar Compressor provides solutions that power pneumatic tools, conveyor systems, and automation technologies, ensuring high-quality output with minimal downtime.

Applications in Manufacturing:

Operating robotic arms and CNC machines.

Spray painting and coating systems.

Assembly and packaging lines.

2. Healthcare and Pharmaceuticals

Air purity is critical in healthcare and pharmaceutical industries. Gajjar’s oil-free compressors ensure contamination-free air supply, meeting stringent safety and hygiene standards.

Key Benefits for Healthcare:

Reliable operation of ventilators and other medical devices.

Sterile air for pharmaceutical production.

Quiet and efficient systems ideal for hospital environments.

3. Food and Beverage Processing

Food safety regulations demand clean and reliable air systems. Gajjar Compressor delivers compressors that maintain product integrity and quality during food processing, packaging, and storage.

Food Industry Applications:

Packaging and bottling lines.

Mixing and blending systems.

Air-driven cleaning and drying processes.

4. Automotive Industry

From car manufacturing plants to service centers, the automotive industry relies on air compressors for a range of applications, including powering tools and inflating tires.

Automotive Uses:

Painting and finishing.

Operating air tools like wrenches and drills.

Vehicle assembly processes.

5. Energy and Power Generation

Energy-intensive industries require robust and efficient compressors. Gajjar Compressor’s high-pressure systems are designed to withstand demanding environments, ensuring optimal performance.

Examples of Use:

Gas and oil extraction processes.

Power plant maintenance.

Operating turbines and pneumatic systems.

Sustainability: A Core Focus of Gajjar Compressor

As industries shift towards sustainable practices, Gajjar Compressor remains at the forefront, developing energy-efficient compressors that reduce carbon emissions and operational costs.

Green Initiatives by Gajjar Compressor:

Energy-Efficient Designs: Compressors that consume less energy without compromising performance.

Eco-Friendly Manufacturing: Minimizing waste and using sustainable materials in production.

Recycling Programs: Encouraging clients to adopt responsible disposal and recycling of old equipment.

Customer-Centric Approach

Gajjar Compressor’s success stems from its unwavering commitment to customer satisfaction. The company goes beyond selling products by providing tailored solutions, technical support, and training to clients.

Highlights of Gajjar’s Customer Service:

Customizable Solutions: Understanding unique requirements and delivering customized compressors.

24/7 Support: Ensuring clients receive assistance whenever needed.

Comprehensive Training: Educating clients on the proper use and maintenance of equipment.

Future Innovations from Gajjar Compressor

The company’s focus on research and development ensures it stays ahead of industry trends. From IoT-enabled compressors to AI-driven predictive maintenance systems, Gajjar Compressor is pioneering the future of industrial air solutions.

Upcoming Advancements:

Smart compressors with remote monitoring capabilities.

Advanced filtration systems for ultra-clean air.

Enhanced durability for extreme operating conditions.

Conclusion

Gajjar Compressor continues to redefine industry standards by delivering innovative, efficient, and sustainable air compressor solutions. By empowering industries with reliable technology, Gajjar is not just providing compressors but enabling growth, efficiency, and success.

From air to action, Gajjar Compressor is a trusted partner in powering industries worldwide, ensuring they thrive in an ever-evolving landscape.

Explore the possibilities with Gajjar Compressor today and experience the difference in quality, performance, and support!

0 notes

Text

Best Way to Remove Graffiti from Cars Without Damaging the Paint

Graffiti on vehicles can be a frustrating and challenging issue, especially for car owners who take pride in maintaining their vehicles' appearance. The presence of spray paint or other graffiti on a car not only diminishes its aesthetic value but can also potentially harm its paint job. A specialized graffiti remover for cars can be a lifesaver in such situations, providing a safe and effective way to restore your car to its original state.

This guide offers practical insights into understanding graffiti removers, choosing the right product, and using it effectively while preserving the integrity of your car’s paint.

Understanding the Impact of Graffiti on Cars

Graffiti on cars is more than just an eyesore. Depending on the material used for the graffiti, such as spray paint or marker ink, it can penetrate the clear coat layer of the vehicle’s paint. If not addressed promptly, this damage may require extensive repairs. Using a dedicated graffiti remover is an effective first step to minimizing damage and saving on costly professional services.

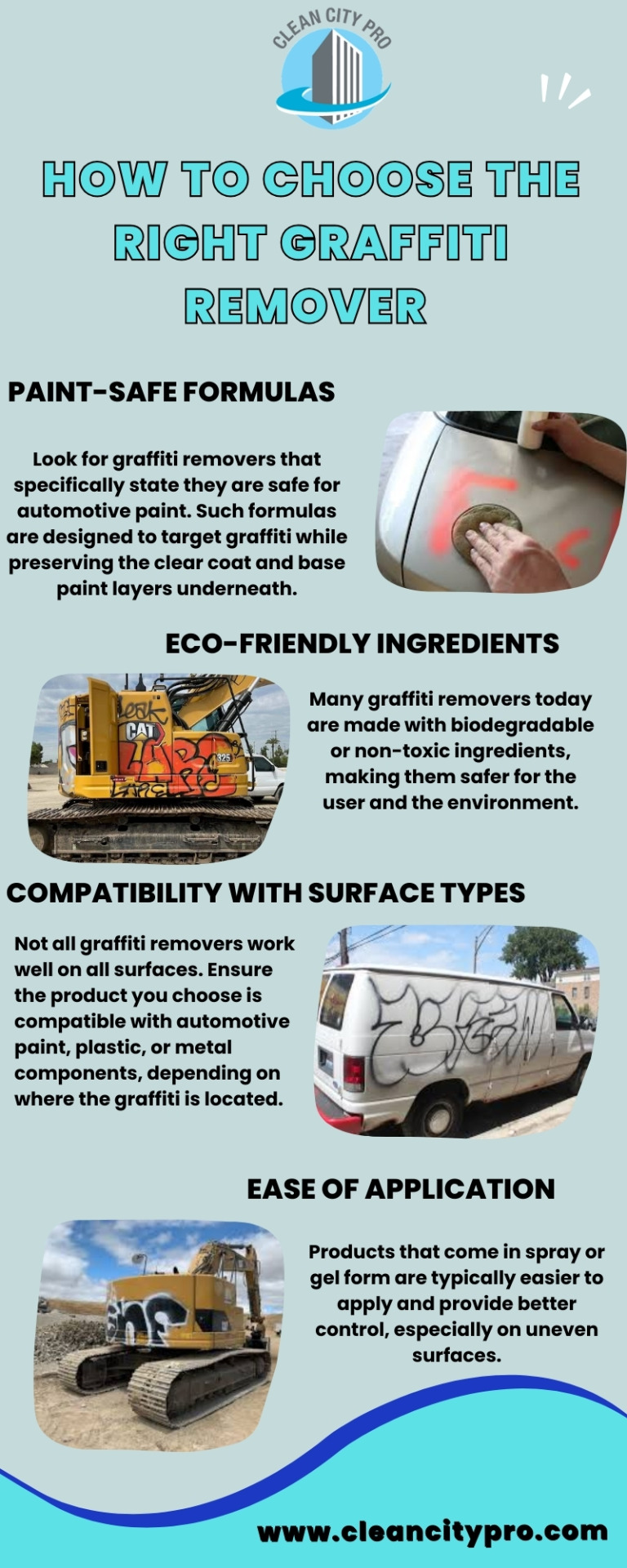

How to Choose the Right Graffiti Remover

When selecting a graffiti remover, it’s essential to consider the following factors:

1. Paint-Safe Formulas

Look for graffiti removers that specifically state they are safe for automotive paint. Such formulas are designed to target graffiti while preserving the clear coat and base paint layers underneath.

2. Eco-Friendly Ingredients

Many graffiti removers today are made with biodegradable or non-toxic ingredients, making them safer for the user and the environment.

3. Compatibility with Surface Types

Not all graffiti removers work well on all surfaces. Ensure the product you choose is compatible with automotive paint, plastic, or metal components, depending on where the graffiti is located.

4. Ease of Application

Products that come in spray or gel form are typically easier to apply and provide better control, especially on uneven surfaces.

Step-by-Step Guide to Removing Graffiti from Cars

Using a graffiti remover involves a systematic approach to ensure that the graffiti is effectively eliminated without damaging the car's surface. Follow these steps for optimal results:

Step 1: Gather Supplies

You’ll need:

A graffiti remover designed for cars

Microfiber cloths or soft sponges

A bucket of clean water

Gloves and protective eyewear

Step 2: Test in a Small Area

Before applying the remover across the graffiti, test it in an inconspicuous spot. This ensures the product won’t harm your car’s paint.

Step 3: Apply the Remover

Spray or apply the graffiti remover directly onto the graffiti. Allow it to sit for the recommended time specified by the manufacturer. This helps the product break down the paint or ink.

Step 4: Gently Wipe Away

Using a microfiber cloth or sponge, gently wipe away the graffiti. Avoid scrubbing too hard, as excessive pressure may damage the underlying paint.

Step 5: Rinse Thoroughly

Rinse the area with clean water to remove any residue. Dry the surface with a clean microfiber cloth.

Step 6: Inspect and Repeat if Necessary

If traces of graffiti remain, repeat the process. Persistent stains might require multiple applications.

Preventing Graffiti on Cars

While graffiti is often unpredictable, there are steps you can take to reduce the likelihood of it occurring:

1. Park in Safe Areas

Whenever possible, park your car in a secure location, such as a garage or monitored parking lot.

2. Install a Car Cover

A protective car cover acts as a physical barrier against spray paint and other forms of graffiti.

3. Use Anti-Graffiti Coatings

Anti-graffiti coatings create a protective layer over your car's paint, making it harder for graffiti to adhere and easier to remove.

Myths About Graffiti Removal

Myth 1: Any Solvent Can Be Used

Many believe that household solvents like acetone or nail polish remover are sufficient to tackle graffiti. However, these products can severely damage automotive paint, making a professional remover for cars the safer option.

Myth 2: Pressure Washing Removes Graffiti

While pressure washing might seem effective, it can chip away at your car’s paint and worsen the problem.

Myth 3: All Graffiti Is Permanent

With the right tools and timely action, most graffiti can be successfully removed without permanent damage.

Common Mistakes to Avoid

1. Delaying Removal

The longer graffiti sits on your car, the harder it becomes to remove. Address the issue as soon as possible to prevent permanent damage.

2. Using Abrasive Tools

Steel wool or rough sponges might seem like quick fixes, but they can scratch the paint, causing more harm than good.

3. Overlooking Protective Measures

Skipping gloves or eyewear while using chemical removers can pose health risks. Always prioritize safety.

When to Seek Professional Help

While DIY methods can be effective, some cases may require professional intervention, especially when:

The graffiti has penetrated the paint layers.

The car’s surface has sustained scratches during removal attempts.

Specialized tools or expertise are needed for restoration.

The Importance of Timely Action

Prompt action not only preserves your car’s appearance but also protects its resale value. Even minor blemishes can impact potential buyers' perceptions, making it crucial to maintain a pristine exterior.

Environmental Considerations in Graffiti Removal

Choosing eco-friendly graffiti removers ensures that harmful chemicals don’t end up polluting the environment. Proper disposal of cleaning materials, such as used cloths and empty containers, also minimizes ecological impact.

Dealing with graffiti on your car can be a daunting experience, but the right tools and techniques can make the process manageable and stress-free. By investing in a reliable graffiti remover and following proper removal practices, you can restore your vehicle’s pristine look without compromising its paint job.

Maintaining your car’s appearance doesn’t just enhance its visual appeal—it’s a reflection of care and attention that preserves its long-term value. With preventative measures and informed choices, you can safeguard your vehicle from graffiti-related damage in the future.

0 notes

Text

Professional Spray Painting Services

Spray painting has revolutionized the way we approach home improvement and commercial projects. Whether it’s revitalizing a worn-out wall, giving furniture a modern touch, or achieving a flawless finish for large-scale industrial applications, spray painting provides precision, speed, and quality unmatched by traditional brush-and-roller techniques.

What Is Professional Spray Painting?

Professional spray painting is a technique that uses specialized equipment to apply paint or coatings in a fine, even mist. The process relies on compressed air or high-pressure systems to deliver a smooth and uniform finish, making it ideal for both residential and commercial projects.

Unlike conventional painting methods, spray painting covers surfaces efficiently and ensures minimal waste, producing superior results in less time.

Applications of Spray Painting Services

Spray painting is incredibly versatile, catering to a wide range of projects and surfaces, including:

1. Residential Spaces

Walls and ceilings

Doors, cabinets, and furniture

Outdoor fencing and decking

Decorative finishes and accents

2. Commercial Spaces

Office interiors and exteriors

Retail store fronts

Restaurants and cafes

Parking lots and signage

3. Industrial Projects

Metal structures and machinery

Automotive refinishing

Equipment and tool coatings

Warehouses and factory interiors

Advantages of Professional Spray Painting

1. Superior Finish

Spray painting creates a flawless, streak-free surface. Its even application is perfect for achieving a polished, professional look.

2. Time-Efficient

With spray painting, large surfaces can be covered in a fraction of the time compared to traditional methods. This efficiency is especially beneficial for commercial and industrial projects.

3. Versatility

Spray painting works on a variety of surfaces, including wood, metal, plastic, and concrete. This flexibility makes it suitable for diverse applications.

4. Cost-Effective

By reducing the time and materials needed for a project, spray painting often proves to be more economical in the long run.

5. Minimal Waste

Professional spray painters use advanced equipment that minimizes overspray and waste, ensuring a sustainable and efficient process.

6. Customization Options

With endless color choices and finishes — matte, gloss, satin, or textured — spray painting can bring your creative vision to life.

Why Choose Professional Spray Painting Services?

While DIY spray painting kits are available, hiring professionals ensures the best results. Here’s why:

1. Expertise

Professional painters have the experience and skills needed to handle various surfaces and challenges.

2. High-Quality Equipment

From airless sprayers to HVLP (High Volume Low Pressure) systems, professionals use advanced tools for precision and efficiency.

3. Proper Surface Preparation

Experts ensure that surfaces are clean, smooth, and primed before painting, guaranteeing long-lasting results.

4. Safety Compliance

Spray painting involves chemicals and fumes. Professionals adhere to safety protocols to protect both workers and the environment.

5. Guaranteed Results

Most professional services provide warranties, giving you peace of mind and ensuring satisfaction.

Step-by-Step Process of Professional Spray Painting

1. Initial Consultation and Assessment

The process begins with understanding your needs, inspecting the surfaces, and discussing color choices and finishes.

2. Surface Preparation

Cleaning to remove dirt, grease, and old paint

Sanding or stripping to create a smooth base

Applying primer for better adhesion and durability

3. Masking and Protection

Non-paintable areas are masked off, and protective coverings are applied to safeguard surrounding spaces.

4. Painting

Using the appropriate spray painting technique, professionals apply multiple coats evenly for a flawless finish.

5. Drying and Curing

The painted surface is allowed to dry and cure fully, ensuring a durable and long-lasting result.

6. Final Inspection and Cleanup

After completion, the work is inspected for quality, and the area is cleaned thoroughly, leaving no trace of the process.

Types of Spray Painting Techniques

1. Airless Spray Painting

Uses high pressure to atomize paint

Ideal for large surfaces and thick coatings

2. HVLP (High Volume Low Pressure)

Delivers precision with minimal overspray

Suitable for detailed work like furniture and trim

3. Electrostatic Spray Painting

Uses charged particles for even coverage

Commonly used for metal objects and machinery

4. Automotive Spray Painting

Specialized for cars and vehicles

Provides a factory-grade finish

Common Challenges in Spray Painting and How Professionals Handle Them

Overspray: Professionals use advanced equipment and masking techniques to control overspray.

Uneven Coverage: Proper surface preparation and multiple coats ensure uniform application.

Drips and Runs: Expert painters adjust spray pressure and technique to prevent imperfections.

Fume Safety: Professionals use proper ventilation systems and protective gear to manage paint fumes.

Creative Uses of Spray Painting Services

Revamp Old Furniture: Transform outdated furniture with a fresh coat of spray paint in trendy colors.

Accent Walls: Create eye-catching focal points with bold, textured finishes.

Metal Restoration: Rejuvenate rusted gates, railings, or industrial machinery.

Custom Artwork: Spray painting can be used to create murals or decorative patterns on walls and ceilings.

Cost of Professional Spray Painting Services

The cost of spray painting services depends on several factors:

Surface Area: Larger projects require more paint and time.

Surface Type: Complex surfaces like furniture or machinery may incur higher costs.

Paint Type: Premium paints and finishes may increase expenses.

Labor: Prices vary based on expertise and location.

On average:

Residential Projects: $2–$6 per square foot

Commercial Projects: $5–$10 per square foot

Automotive Projects: $300–$2,000 (depending on the vehicle size and customization)

Why Choose No Need To Paint?

At No Need To Paint, we bring decades of experience and cutting-edge technology to deliver exceptional spray painting services. Here’s what sets us apart:

Highly Skilled Team: Our professionals are trained to handle diverse projects with precision.

Eco-Friendly Practices: We use low-VOC paints and sustainable methods.

Custom Solutions: From residential to industrial needs, we tailor our services to meet your expectations.

Guaranteed Satisfaction: Quality is at the heart of everything we do.

Tips for Maintaining Spray-Painted Surfaces

Regular Cleaning: Use a soft cloth and mild detergent to keep surfaces clean.

Avoid Abrasives: Stay away from harsh chemicals or scrubbers that can damage the paint.

Touch-Up Repairs: Address chips or scratches promptly to maintain the finish.

Protect Against Elements: Use protective coatings for outdoor surfaces to shield them from weather damage.

Conclusion: Elevate Your Space with Spray Painting

Professional spray painting services offer a seamless way to enhance and protect your surfaces, delivering outstanding results that stand the test of time. Whether you’re looking to refresh your home, revitalize your office, or upgrade industrial equipment, spray painting is the ultimate solution for a flawless, cost-effective finish.

Choose No Need To Paint for all your spray painting needs and experience the transformative power of professional craftsmanship. Let us help you bring your vision to life!

0 notes

Text

Phosphating Tank Manufacturers in India

What is a Phosphating Tank?

Phosphating is a vital surface treatment process used to enhance the durability and performance of metal surfaces. It improves corrosion resistance and provides an excellent base for paint adhesion. A Phosphating Tank is an essential component in this process, serving as a container for chemical solutions where metal parts undergo phosphating. Industries such as automotive, construction, and manufacturing rely heavily on these tanks for efficient surface treatment.

Phosphating Tank manufacturers in India

STEP® Techno Solutions LLP is a prominent Phosphating Tank Manufacturer in Gujarat, India, offering innovative solutions for a variety of industrial needs.

Understanding Phosphating

Phosphating involves applying a protective phosphate coating to metal surfaces. This process creates a stable layer that shields metals from corrosion and enhances their ability to hold paint or other coatings. Common applications include treating automobile parts, machinery components, and construction materials.

Phosphating is critical for industries aiming to extend the life of their metal products and improve overall performance. A phosphating tank is essential to the process's efficiency and reliability.

The Role of Phosphating Tanks

A Phosphating Tank is specifically designed to hold the chemical solutions used in phosphating. These tanks are integral to phosphating plants, enabling controlled and efficient surface treatment processes.

There are various types of Phosphating Tanks, each tailored for specific needs:

Immersion Tanks: For dipping metal parts entirely into the solution.

Spray Tanks: For targeted surface treatments.

Multi-stage Tanks: For sequential treatments like cleaning, phosphating, and rinsing.

Choosing the right tank type is essential for achieving the desired treatment results.

Key Features of Quality Phosphating Tanks

A high-quality Phosphating Tank should include:

Durable Material: Resistant to chemical corrosion and high temperatures.

Precision Design: Ensures uniform chemical distribution and efficient treatment.

Customizability: Adaptable to specific industry needs, such as size, shape, and operational features.

Customization allows industries to optimize their phosphating processes for better outcomes.

Overview of STEP® Techno Solutions LLP

STEP® Techno Solutions LLP is a trusted name in phosphating tank manufacturers in India. The company specializes in designing and manufacturing high-performance phosphating tanks for various industries.

Known for their innovation and attention to quality, STEP® Techno Solutions LLP delivers solutions tailored to customer requirements. Their products are durable, efficient, and aligned with industry standards, making them a top choice for businesses across India.

Advantages of Choosing a Top Phosphating Tank

Partnering with a reputable Phosphating Tank Manufacturer like STEP® Techno Solutions LLP offers several benefits:

Enhanced Efficiency: Advanced tank designs ensure optimal chemical usage and faster processing times.

Reliability: High-quality materials and robust construction ensure long-lasting performance.

Excellent Support: Comprehensive after-sales services and technical support help maintain operational efficiency.

For industries seeking reliable surface treatment solutions, choosing a top manufacturer ensures seamless operations.

Customization Options for Phosphating Tanks

Customization is a game-changer for industries with unique requirements. STEP® Techno Solutions LLP offers tailored solutions, including:

Size Adjustments: Tanks designed to fit specific production lines.

Operational Features: Automated systems for improved efficiency.

Material Choices: Selection of materials based on chemical compatibility and durability.

These options enable businesses to maximize productivity and reduce operational costs.

Industry Trends and Innovations

Phosphating technology is constantly evolving. Modern trends include:

Eco-friendly Solutions: Use of non-toxic chemicals for sustainable processing.

Automation: Integration of smart controls for precise treatment.

Compact Designs: Space-saving tanks for small-scale industries.

As one of the leading Phosphating Tank manufacturers in India, STEP® Techno Solutions LLP stays ahead by incorporating these innovations into its products.

Conclusion

A phosphating tank is an essential part of the surface treatment process, assuring durability and efficiency in metal finishing. Industries looking to improve corrosion resistance and coating adhesion can benefit greatly from advanced phosphating tanks.

For reliable and customized solutions, STEP® Techno Solutions LLP stands out as a top Phosphating Tank Manufacturer in India. With their focus on quality and innovation, they deliver products that meet the highest industry standards.

For more information or to inquire about Phosphating Plants, visit our website, call +919898875757, or email at [email protected].

#Phosphating Tank#Phosphating Tank in India#Phosphating Tank Manufacturer#Phosphating Tank manufacturers in India

0 notes

Text

Essential Garage Tools and Equipment for Every DIY Enthusiast

Whether you're a DIY enthusiast or a professional mechanic, having the right garage tools and equipment can make all the difference in achieving quality results with ease. A well-stocked garage not only enhances efficiency but also opens up new possibilities for repairs, maintenance, and creative projects. Here’s a guide to some of the essential tools and equipment that every garage should have.

Basic Hand Tools

Starting with the basics, hand tools are the foundation of any well-equipped garage. Screwdrivers, wrenches, pliers, and hammers should be readily accessible. These tools cover a wide range of everyday tasks, from assembling furniture to fixing loose bolts. A socket set with various socket sizes is also essential for tackling automotive and mechanical tasks. Quality hand tools are typically built to last, providing reliable service for years.

Power Tools

Power tools make work faster and easier, especially for larger projects. Drills, impact drivers, and rotary tools are key power tools for drilling holes, tightening screws, and performing a variety of tasks. A cordless drill, in particular, adds convenience and flexibility. For cutting materials like wood, metal, or plastic, a jigsaw or circular saw can be incredibly useful. Angle grinders and sanders are also handy for smoothing surfaces and polishing metal parts.

Air Compressor and Pneumatic Tools

An air compressor is a versatile piece of garage equipment that powers various pneumatic tools like air wrenches, spray guns, and air blowers. Air compressors come in different sizes and capacities, so choose one that fits your needs. Having a compressor and pneumatic tools can significantly increase productivity, especially for tasks like inflating tires, painting, or loosening tough bolts.

Lifting Equipment

When it comes to working on vehicles, lifting equipment is essential. Floor jacks, jack stands, and ramps allow safe access to the underside of a car for repairs and maintenance. A hydraulic floor jack with a high lifting capacity is ideal for most home garages, and sturdy jack stands add an extra layer of security. For more advanced needs, a car lift may also be worth considering if space allows.

Workbench and Storage Solutions

A solid workbench is a must-have for any garage. It provides a stable surface for working on projects, whether you're cutting, drilling, or assembling. To keep your tools organized and accessible, invest in tool cabinets, pegboards, and shelves. Good storage solutions help prevent clutter and make it easy to locate tools when needed, ultimately saving time and frustration.

Safety Gear and Lighting

Safety should always be a priority in any garage workspace. Safety glasses, gloves, and ear protection help shield you from potential hazards. Additionally, a well-lit workspace reduces the risk of mistakes and accidents. Consider installing overhead lights, task lights, or portable work lights to keep your workspace adequately illuminated.

Specialty Tools for Specific Needs

Depending on your projects, you might need specialty tools like a torque wrench for precise tightening, a multimeter for electrical diagnostics, or even a welding machine. These tools may not be necessary for everyone, but they’re invaluable for specialised tasks, especially in automotive work and metal fabrication.

Bottom-line

Having a well-rounded collection of garage tools and equipment is an investment that pays off over time. With these essentials, you'll be equipped to handle a range of projects and repairs efficiently, ensuring your garage becomes a true hub for productivity and creativity.

0 notes

Text

Clear PPF: The Invisible Shield for Your Car's Paint

In the world of automotive protection, Paint Protection Film (PPF) has emerged as a game-changing solution for vehicle owners who want to preserve their car's pristine appearance. This innovative technology, often called Clear PPF, offers an invisible yet powerful shield that keeps your vehicle looking showroom-fresh for years to come.

Understanding Paint Protection Film

Paint Protection Film is a thermoplastic urethane film that acts as a transparent armor for your car's paint. Unlike traditional paint protection methods, Clear PPF provides a self-healing layer that can withstand the daily assault of road debris, stone chips, bug splatter, and environmental contaminants. This revolutionary material works alongside other protective measures like Window Tint to create a comprehensive defense system for your vehicle.

The Science Behind Clear PPF

The magic of Clear PPF lies in its multi-layer construction. The outer layer features advanced self-healing properties that can repair minor scratches and swirl marks when exposed to heat. Beneath this, a clear coat layer provides UV protection, while the adhesive layer ensures a perfect bond with your car's paint. This sophisticated engineering makes Paint Protection Film an investment that pays dividends in maintaining your vehicle's value.

Benefits Beyond Basic Protection

While the primary purpose of Paint Protection Film is to shield your car's paint, its advantages extend far beyond basic protection:

Preserves Resale Value: A well-maintained exterior protected by Clear PPF can significantly increase your car's resale value

Self-Healing Properties: Minor scratches disappear with heat application

UV Protection: Works alongside Window Tint to prevent paint oxidation and interior fading

Minimal Maintenance: Requires less frequent washing and waxing

Invisible Protection: Unlike bulky car bras or covers, Clear PPF is virtually invisible

Professional Installation Matters

While Paint Protection Film is a remarkable product, proper installation is crucial. Professional installers use computer-cut patterns specific to your vehicle model, ensuring precise coverage of vulnerable areas. They work in controlled environments to prevent dust contamination and utilize specialized techniques to achieve a seamless application that's virtually undetectable.

Strategic Coverage Areas

Most professionals recommend strategic application of Clear PPF to high-impact areas:

Front bumper and hood

Side mirrors

Door edges and handle cups

Rear wheel arches

Full front-end coverage

Complete vehicle coverage for ultimate protection

The Perfect Pair: PPF and Window Tint

Many car enthusiasts combine Paint Protection Film with Window Tint for comprehensive vehicle protection. While Clear PPF shields the exterior, quality Window Tint protects your car's interior from UV damage, heat, and glare. This dynamic duo creates a protective ecosystem that maintains your vehicle's aesthetic and functional integrity.

Long-Term Value Proposition

Though the initial investment in Paint Protection Film might seem significant, the long-term benefits far outweigh the costs. Consider the expenses you'll avoid:

Frequent paint touch-ups

Major paint correction services

Depreciation due to exterior damage

Potential repainting costs

Maintaining Your Invisible Shield

Once installed, Clear PPF requires minimal maintenance. Regular washing with pH-neutral car shampoo and occasional spray waxing is usually sufficient. Avoid aggressive polishing compounds and always follow manufacturer guidelines for optimal performance and longevity.

Future-Proofing Your Investment

In today's automotive market, where vehicles represent significant investments, protecting your car's finish with Paint Protection Film is a smart decision. Combined with quality Window Tint, it creates a comprehensive protection system that maintains your vehicle's value and appearance for years to come. Whether you're protecting a daily driver or a luxury vehicle, Clear PPF offers peace of mind knowing your car's paint is shielded by the most advanced protection technology available. It's an invisible guardian that works tirelessly to keep your vehicle looking its best, mile after mile.

#paint protection film#ultraguardindia#ppf coating#car paint protection#ppf on car#ppf coating for car#paint protection film price#ppf coating price#paint protection film (ppf)#ppf cost

0 notes

Text

Get Your Car Resprayed to Perfection | Rising Sun Automotive

Don't settle for mediocre results! Rising Sun Automotive offers expert car spray painting services that guarantee a flawless finish. Our team uses state-of-the-art equipment and premium paints for a superior outcome.

0 notes

Text

Car coating fixing in Brisbane includes correcting any sort of problems to the automobile's paintwork. This can feature blemishes, potato chips, fading, or various other infirmities. The method generally features sanding down the destroyed place, applying guide and also matching coating colour, at that point ending up with a clear coat for defense. Specialist automotive body system shops in Brisbane give professional automobile coating repair services to recover your car's look and secure it from more damage.

2 notes

·

View notes

Text

Car Denting and Painting Costs in Noida and Delhi

Owning a car in a bustling city like Delhi means dealing with frequent bumps, scratches, and dents, which are part of the city's high-paced, traffic-heavy environment. Whether it's a minor scratch or a significant dent from a collision, getting professional denting and painting services is essential to restore your car's original look and maintain its resale value. Detailing Machines, a leading provider of automotive detailing and restoration services, offers high-quality car denting and painting solutions across Delhi, ensuring every vehicle looks as good as new. Here’s a detailed guide on what goes into the cost of these services and why choosing us in Delhi can be a smart investment.

Key Factors Influencing Car Denting and Painting Costs

Extent of Damage: The cost of denting and painting largely depends on the damage's severity. Minor dents and scratches usually require less time and materials, costing significantly less than extensive damages that affect the car’s body structure. For smaller dents, the cost generally remains moderate, whereas severe or extensive dents increase labor and material requirements, pushing up the overall price.

Type of Paint Used: Paint quality is crucial for long-lasting and high-quality results. We uses premium automotive paint options that offer durability, UV protection, and an exact color match to the car’s original shade. While quality paints may slightly increase the cost, they provide better resilience against Delhi’s weather, pollution, and road conditions, ensuring a lasting, vibrant finish.

Painting Method: Advanced techniques such as spray painting and multi-layer coating are available for a flawless finish. Our employs advanced spray painting methods, ensuring an even, factory-finish look that doesn’t fade or chip easily. This precision in technique can impact the cost but guarantees a high-quality outcome.

Labor and Expertise: Skilled labor and professional expertise directly affect the quality and cost of denting and painting services. Technicians at our office bring years of experience to every job, ensuring that each panel is carefully repaired and painted. This expertise is especially vital for matching colors accurately and restoring the original contour of the car's body. Higher skill levels may reflect in the cost but ensure that the restoration is seamless and long-lasting.

Additional Coating Options: For those looking to enhance the durability and aesthetics further, we offers options like ceramic coating and paint protection films (PPF) after the denting and painting process. These add-ons provide an extra layer of protection, keeping the paint fresh and protected from scratches, fading, and pollutants. Although these add-ons increase the cost, they are excellent for long-term maintenance, especially in Delhi’s harsh environment.

Why Choose Detailing Machines for Denting and Painting in Delhi?

1. State-of-the-Art Facilities: Detailing Machines has advanced equipment and facilities to handle all types of denting and painting jobs, from minor scratches to major collision damage. With premium paints and high-quality spray guns, each job promises a flawless finish.

2. Expertise with a Personal Touch: Technicians understand that every car is unique, treating each vehicle with care and precision. Our experts offer tailored solutions, ensuring that the denting and painting job fits your car’s specific needs and aesthetic requirements.

3. Affordable and Transparent Pricing: We believes in transparent pricing, offering competitive rates without compromising on quality. Customers receive a detailed cost breakdown, making it easy to understand what they are paying for, from labor to materials.

4. Up to 20% Off on All Services: As a special offer, We are providing up to 20% off on all denting and painting services, making it an ideal time to restore your vehicle’s beauty without stretching your budget. (Terms and conditions apply.)

Car Denting and Painting Costs in Delhi: A General Guide

While the actual cost varies depending on the vehicle type, extent of damage, and materials used, here’s a rough price guide for denting and painting services:

Minor Dents and Scratches

Moderate Damage

Major Dents or Collision Repair

To get an accurate estimate, we offers an in-person inspection, allowing our experts to assess the damage and provide a transparent, customized quote.

Ensuring Your Car’s Value with Quality Restoration

Car denting and painting not only restore the appearance but also help maintain your car's resale value. Poor-quality repairs can decrease the car's overall worth, while high-quality restoration enhances its appeal and keeps it looking newer for longer. Investing in quality denting and painting services by Detailing Machines in Delhi ensures that each repair and paint job meets the highest standards, extending your vehicle's longevity and aesthetic appeal.

#cardentingpaintingnoida#cardentingpaintingnearme#cardentingpaintingdelhi#cardentingpaintingshopnearme#cardentingpaintingprice#cardentingpaintingcost#cardentingpaintingcostnearme

0 notes

Text

The benefits of professional services at a car paint shop in Fort Lauderdale FL

Maintaining your vehicle’s appearance is as important as ensuring its mechanical performance. Over time, exposure to sunlight, road debris, weather conditions, and other environmental factors can damage your car’s paint, diminishing its value and appeal. Whether you’re looking to restore your car’s finish, repair scratches, or explore custom designs, professional services at a car paint shop in Fort Lauderdale FL offer unparalleled advantages.

At Superior Exotic Color & Paint, we specialize in providing top-tier automotive painting services that enhance the look, durability, and value of your vehicle. Here, we’ll explore the numerous benefits of entrusting your car to professionals for painting and finishing services.

Expertise and Skill

One of the most significant benefits of choosing a professional Car Paint Shop Fort Lauderdale FL is the expertise and skill that experienced technicians bring to the job. Automotive painting requires a deep understanding of surface preparation, paint application techniques, and the use of specialized equipment.

At Superior Exotic Color & Paint, our team has years of experience handling vehicles of all makes and models. From luxury sedans to rugged SUVs, we ensure every vehicle receives meticulous attention and a flawless finish. Our expertise guarantees superior results that far surpass DIY attempts or low-cost services.

Use of High-Quality Materials

Professional car paint shops use premium-quality paints, primers, and clear coats that ensure a durable and long-lasting finish. These materials are often designed to withstand harsh environmental conditions, including UV rays, humidity, and salt exposure, which are common in Fort Lauderdale FL.

At Superior Exotic Color & Paint, we use only the best products from trusted brands to deliver results that stand the test of time. Our materials not only enhance the appearance of your vehicle but also provide a protective layer against external damage.

Advanced Equipment and Techniques

Professional car paint shops are equipped with advanced tools and facilities that ensure precision and efficiency. For example, high-tech spray booths with controlled environments prevent contaminants like dust and debris from affecting the paint job. Modern tools, such as computerized color-matching systems, ensure that the paint perfectly matches your vehicle’s original shade or your desired custom color.

At Superior Exotic Color & Paint, we invest in state-of-the-art equipment to provide seamless, factory-quality finishes. Our cutting-edge techniques and meticulous processes guarantee your vehicle looks as good as new.

Customization Options

A professional Car Paint Shop Fort Lauderdale FL offers extensive customization options to meet your unique style preferences. Whether you want a custom color, intricate design, or personalized graphics, professionals can bring your vision to life. Customization not only enhances your vehicle’s aesthetic appeal but also makes it stand out on the road.

Our team at Superior Exotic Color & Paint specializes in crafting bespoke designs tailored to your personality. From sleek racing stripes to bold multi-color patterns, we turn your creative ideas into reality.

Restoration of Damaged Surfaces

Scratches, dents, and fading paint can significantly impact the appearance of your vehicle. Professional car paint shops have the expertise to repair damaged surfaces before applying new paint. This ensures that the final finish is smooth and flawless, without imperfections.

At Superior Exotic Color & Paint, we perform thorough surface preparation, including sanding, dent repair, and priming, to create the perfect base for your new paint. This attention to detail ensures a high-quality, professional result every time.

Increased Resale Value

A fresh, professionally applied paint job can dramatically increase your vehicle’s resale value. A well-maintained exterior is one of the first things potential buyers notice, and a polished, attractive appearance can make your car more appealing in the competitive used car market.

In Fort Lauderdale’s thriving automotive scene, Superior Exotic Color & Paint helps you maximize your vehicle’s value with premium painting services that restore its original luster or add a unique, eye-catching touch.

Time Efficiency

While DIY painting might seem cost-effective initially, it often takes much longer and leads to subpar results. Professional car paint shops have the experience and tools to complete the job efficiently without compromising on quality.

At Superior Exotic Color & Paint, we provide accurate timelines for each project and work diligently to meet deadlines, so you can get back on the road quickly with a vehicle that looks its best.

Warranty and Assurance

Reputable car paint shops stand behind their work with warranties, providing peace of mind and confidence in the quality of their services. A warranty demonstrates the shop’s commitment to excellence and ensures you’re covered in case of any issues.

At Superior Exotic Color & Paint, we offer industry-leading warranties on all our painting services. Our commitment to customer satisfaction means you can trust us to deliver results that last.

Eco-Friendly Practices

Many professional car paint shops now prioritize environmentally friendly practices. From using low-VOC (volatile organic compound) paints to implementing responsible waste disposal methods, these efforts minimize the environmental impact of automotive painting.

Superior Exotic Color & Paint is proud to embrace sustainable practices. We use eco-friendly materials and techniques to deliver outstanding results while protecting the environment.

Personalized Customer Service

Professional car paint shops provide personalized service tailored to your specific needs. From color selection to design consultations, the team works closely with you to ensure the final result aligns with your vision.

At Superior Exotic Color & Paint, customer satisfaction is our top priority. Our friendly, knowledgeable staff takes the time to understand your requirements and guide you through every step of the process.

Protection Against the Elements

Florida’s climate can be tough on vehicles, with intense sunlight, humidity, and salt air causing paint to fade, peel, or corrode over time. Professional paint shops use advanced coatings and finishes that provide extra protection against these elements, ensuring your car maintains its appearance for longer.

At Superior Exotic Color & Paint, we specialize in UV-resistant and weatherproof finishes that are perfect for Fort Lauderdale’s coastal conditions.

Long-Term Cost Savings

While professional painting services may seem like a significant upfront investment, they can save you money in the long run. High-quality materials and expert application reduce the need for frequent touch-ups or repainting, making it a cost-effective choice over time.

By choosing Superior Exotic Color & Paint, you’re investing in durability and excellence, ensuring your car’s paint remains vibrant and intact for years to come.

Confidence and Pride

Driving a car with a stunning, professional paint job boosts your confidence and pride in your vehicle. Whether you’re commuting to work, heading to the beach, or attending a car show, a polished, eye-catching exterior ensures your car turns heads wherever you go.

Superior Exotic Color & Paint helps you feel proud of your vehicle by delivering exceptional results that showcase its beauty and uniqueness.

The benefits of professional services at a car paint shop in Fort Lauderdale FL are clear. From expert craftsmanship to increased resale value, a professional paint job is an investment that enhances your vehicle’s appearance and longevity. At Superior Exotic Color & Paint, we’re dedicated to providing top-notch services that exceed your expectations. Visit us today to experience the difference of working with true professionals.

0 notes

Text

Metal Finishing: A Comprehensive Guide to Coating and Plating Techniques

Metal finishing is the process of treating metal surfaces to enhance their appearance, durability, and functionality. Various techniques are employed to achieve different desired outcomes, such as corrosion resistance, conductivity, or aesthetic appeal. Here's a look at some of the most common metal finishing methods:

1. CED Coating (Cathodic Electrodeposition Coating)

CED coating is an electrochemical process used to apply a uniform coating of paint or other materials to metal surfaces. An electric current is passed through a bath containing the coating material, causing it to deposit onto the metal. This technique is widely used in the automotive industry for its efficiency and ability to produce high-quality finishes.

2. ED Coating (Electrophoretic Deposition Coating)

Similar to CED, ED coating involves the application of a coating material using an electric current. However, ED coating is more commonly used for applying primer coatings to metal surfaces. It offers excellent corrosion resistance and adhesion properties.

3. Zinc Plating

Zinc plating is a process of applying a zinc coating to metal surfaces to protect them from corrosion. Zinc is a sacrificial metal, meaning it corrodes preferentially to the base metal, protecting it from damage. Zinc plating is commonly used in industries such as automotive, construction, and electronics.

4. Electroplating

Electroplating is a broad term that encompasses various processes for applying a metal coating to another metal surface using an electric current. Different metals can be used for electroplating, such as nickel, chromium, copper, and gold. Electroplating service is used for a variety of purposes, including decorative finishes, corrosion protection, and improved conductivity.

5. Liquid Spray Painting

Liquid spray painting is a traditional method of applying a coating to a metal surface using a spray gun. The coating material is sprayed onto the surface in a fine mist, allowing for a uniform and even finish. Liquid painting is widely used in various industries, including automotive, aerospace, and furniture manufacturing.

Choosing the Right Metal Finishing Technique

The best metal finishing technique for a particular application depends on several factors, including:

Desired properties: What properties do you want the coating to provide, such as corrosion resistance, conductivity, or aesthetic appeal?

Metal type: Different metals require different finishing techniques.

Application: The specific application will influence the choice of technique.

Cost: The cost of different metal finishing techniques can vary significantly.

In conclusion, metal finishing is vital for enhancing the durability, appearance, and performance of metal products. Techniques like CED, ED coating, zinc plating, electroplating, and spray painting each offer unique advantages. Choosing the right technique ensures optimal performance and longevity, making it essential to align the process with the specific application and budgetary constraints.

For any clarifications or queries, please feel free to contact us:

Mobile: +91–9311813406

Email ID: [email protected]

Website: www.sarcoatings.com

#zinc plating#zinc plating service#liquid painting#metal finishing#electroplating#ced coating#sarcoatingsllp

0 notes