#automobile plastic bumper

Explore tagged Tumblr posts

Text

Introducing China Automotive Plastic Mould: Precision and Innovation in Automotive Manufacturing

China Automotive Plastic Mould is a leading provider of high-quality plastic moulds for the automotive industry. Specializing in the design and production of moulds, China Automotive Plastic Mould has become synonymous with precision engineering and cutting-edge technology. Our China Automotive Plastic Mould products are renowned for their durability, reliability, and the ability to meet the stringent demands of modern automotive manufacturing.

Each China Automotive Plastic Mould is crafted with meticulous attention to detail, ensuring that the end product is not only functional but also aesthetically pleasing. Our commitment to excellence is evident in every China Automotive Plastic Mould we produce, as we continuously strive to push the boundaries of what is possible in plastic mould technology.

China Automotive Plastic Mould is dedicated to providing moulds that can withstand the rigors of high-volume production while maintaining the highest standards of quality. Our China Automotive Plastic Mould products are used in the creation of a variety of automotive components, from interior trim to exterior panels, showcasing the versatility of our moulds.

Investing in a China Automotive Plastic Mould means investing in a future-proof solution for your automotive plastic component needs. Our China Automotive Plastic Mould is designed to adapt to the evolving requirements of the automotive industry, ensuring that your production lines remain at the forefront of innovation.

China Automotive Plastic Mould is not just a product; it's a partnership with a company that values long-term relationships and is dedicated to the success of your projects. We are proud of our China Automotive Plastic Mould and the role it plays in shaping the future of the automotive industry. Choose China Automotive Plastic Mould for your next project, and experience the difference that precision and innovation can make.

#China Automotive Plastic Mould#injection molding automotive#auto bumper mould#automobile mould#automotive injection molding company#automotive injection molding suppliers

0 notes

Text

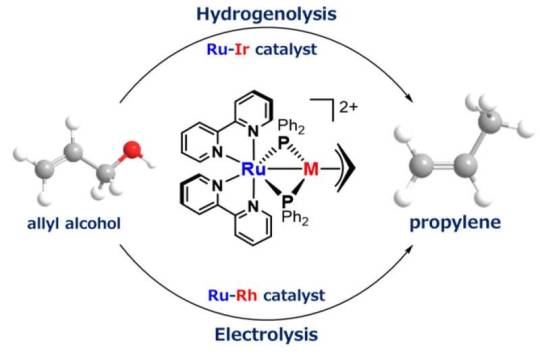

New catalyst developed for sustainable propylene production from biomass

Achieving carbon neutrality requires the effective use of renewable biomass. In the production of biodiesel, for instance, glycerol is generated as a major byproduct. Researchers at Osaka Metropolitan University have developed a new catalyst that efficiently converts a derivative of glycerol into bio-based propylene, contributing to sustainable chemical production. The findings were published in Chemical Communications. Propylene is typically produced from petroleum and is widely used in the manufacture of plastics, such as automobile bumpers and food containers. The research team, led by Associate Professor Shin Takemoto and Professor Hiroyuki Matsuzaka from the Graduate School of Science, developed a catalyst that selectively breaks down the oxygen-carbon bond in allyl alcohol, a derivative of glycerol, to produce bio-based propylene.

Read more.

#Materials Science#Science#Catalysts#Biomaterials#Materials processing#Osaka Metropolitan University

17 notes

·

View notes

Text

Europe Carbon Black Market, Size, Segment and Growth by Forecast Period: (2023-2028)

Europe Carbon Black Market Outlook (2022–2028)

The Europe carbon black market is projected to grow from US$ 2,530.99 million in 2022 to US$ 3,392.58 million by 2028, registering a CAGR of 5.0% during the forecast period. 📚Download Full PDF Sample Copy of Market Report @ https://wwcw.businessmarketinsights.com/sample/BMIRE00028316

Key Growth Driver: Rising Demand for Specialty Carbon Black

The increasing demand for specialty carbon black is a primary factor driving market growth across Europe. Specialty carbon black is a high-purity form of carbon black with minimal ash, sulfur, metals, and other impurities. It is produced through the partial combustion of hydrocarbons such as oil and gas to meet strict quality standards tailored to diverse end-use applications.

This type of carbon black is widely used as a reinforcing agent in a range of rubber and plastic products, including hoses, belts, gaskets, vibration isolation components, diaphragms, bushings, air springs, chassis bumpers, conveyor wheels, and grommets. It also finds applications in industrial packaging materials such as refuse sacks and industrial bags, as well as in photographic containers, stretch films, agricultural mulch films, and thermoplastic molding for sectors like automotive, electronics, and container manufacturing.

One of the most notable trends is the surging use of conductive specialty carbon black in industries such as transportation, construction, and electronics, driven by its versatility in lithium-ion batteries, fuel cells, and polymer systems.

With the accelerating shift toward electric vehicles (EVs), the demand for conductive additives such as specialty carbon black is gaining strong momentum. According to the International Energy Agency (IEA), more than 10 million electric cars were on the roads globally in 2020—a 43% increase from 2019. Of this, Europe recorded the highest annual growth, reaching 3.2 million electric cars. The growing adoption of EVs to curb greenhouse gas emissions and promote energy diversification continues to bolster the specialty carbon black segment.

To capitalize on these trends, many manufacturers are expanding their footprint and investing in emerging economies to address the rising demand for specialty carbon black.

Regional Insights: Europe Carbon Black Market

Europe's major economies—Germany, France, Italy, the UK, and Russia—play a central role in driving demand for carbon black, particularly through the automotive sector, which remains a cornerstone of the regional economy.

According to the European Automobile Manufacturers’ Association (ACEA), approximately 12 million motor vehicles were produced in the region in 2021. The strong growth of the automotive industry continues to fuel demand for tires, one of the largest application areas for carbon black.

Carbon black is essential in tire production, as it enhances processing, strength, durability, and overall performance. With increasing automotive production and a growing focus on performance and sustainability, the demand for carbon black in Europe is expected to remain strong throughout the forecast period.

Europe Carbon Black Strategic Insights

Strategic insights for the Europe Carbon Black provides data-driven analysis of the industry landscape, including current trends, key players, and regional nuances. These insights offer actionable recommendations, enabling readers to differentiate themselves from competitors by identifying untapped segments or developing unique value propositions. Leveraging data analytics, these insights help industry players anticipate the market shifts, whether investors, manufacturers, or other stakeholders. A future-oriented perspective is essential, helping stakeholders anticipate market shifts and position themselves for long-term success in this dynamic region. Ultimately, effective strategic insights empower readers to make informed decisions that drive profitability and achieve their business objectives within the market.

Market leaders and key company profiles HiiROC Ltd

Black Bear Carbon BV

Klean Industries Inc

OMSK Carbon Group Ltd

Imerys SA

Tokai Carbon Co Ltd

Orion Engineered Carbons SA

Cabot Corp Regional Insights – Europe Carbon Black Market

The geographic scope of the Europe Carbon Black market highlights the specific regions where companies operate and compete. Recognizing regional differences—such as varying consumer preferences, economic conditions, and regulatory frameworks—is essential for tailoring market strategies. For instance, demand for certain product specifications may differ by region, influenced by industry focus or environmental regulations. By identifying underserved areas and adapting offerings to meet localized needs, businesses can expand their footprint. A focused regional strategy enables more efficient resource allocation, targeted marketing, and stronger positioning against local competitors—ultimately driving sustainable growth across Europe.

Europe Carbon Black Market Segmentation Overview

The Europe carbon black market is categorized based on type, grade, application, and country.

By Type: The market is segmented into acetylene black, channel black, furnace black, thermal black, and others. Among these, furnace black accounted for the largest market share in 2022.

By Grade: The market is divided into standard grade and specialty grade. In 2022, the standard grade segment held the dominant share.

By Application: The key applications include tires, non-tire rubber, plastics, inks & coatings, and others. The tire segment emerged as the leading application area in 2022.

By Country: The regional analysis includes Germany, France, the UK, Italy, Russia, and the Rest of Europe. Germany led the market in terms of revenue in 2022.

Key Players: Leading companies operating in the Europe carbon black market include: HiiROC Ltd, Black Bear Carbon BV, Klean Industries Inc, OMSK Carbon Group Ltd, Imerys SA, Tokai Carbon Co Ltd, Orion Engineered Carbons SA, and Cabot Corporation. About Us: Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Défense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications Author's Bio Akshay Senior Market Research Expert at Business Market Insights

0 notes

Text

Expanded Polypropylene Foam Market Size, Share and forecast 2034

Expanded polypropylene (EPP) foam is frequently used to give fragile items like circuit boards and computer equipment superior impact protection. Polypropylene is used to produce expanded polypropylene (EPP) foam. Numerous impact resistance, thermal insulation, superior energy absorption, buoyancy, water and chemical resistance, remarkable 100% recyclability, and a high strength-to-weight ratio are just a few of the special attributes of these incredibly flexible closed-cell bead foams. With customers growing more concerned about their physical well-being, it is anticipated that expanded polypropylene (EPP) foam will be used in toys and sporting products.

According to SPER Market Research, ‘Global Expanded Polypropylene Foam Market Size- By Product, By Application- Regional Outlook, Competitive Strategies and Segment Forecast to 2034’ state that the Global Expanded Polypropylene Foam Market is predicted to reach 3621.67 million by 2034 with a CAGR of 11.47%.

Drivers:

Expanded polypropylene (EPP) foam is widely used in the automotive industry for thermal insulation, noise control, and impact absorption in floors, seats, bumpers, and door panels. Furthermore, the increasing use of electric vehicles stimulates the growth of the expanded polypropylene (EPP) foam market since these foams play an essential role in the construction of lightweight and thermally insulated electric vehicles improve the energy absorption capacity of electric vehicles. As a result, rising demand for expanded polypropylene (EPP) foam in the automotive sector is expected to drive market growth. In automotive uses, porous expanded polypropylene (EPP) foam is often black, but it can alternatively be white for packing. Some providers offer it in brilliant hues appropriate for a presentation-grade textured surface. The growing popularity of porous expanded polypropylene (EPP) foam is projected to drive market growth.

Request a Free Sample Report: https://www.sperresearch.com/report-store/expanded-polypropylene-foam-market?sample=1

Restraints:

The biggest issue facing the EPP foam business is the unpredictability of raw material pricing, particularly polypropylene resins manufactured from petrochemicals. Fluctuations in global crude oil prices, supply chain interruptions, and the introduction of legislative restrictions on plastic manufacture can all have a direct impact on commodity pricing and market supply. Low-cost EPP foam production is further hampered by trade restrictions and transportation problems in the polymer supply chain. In addition to reducing supply risk, the companies are focusing on bio-based polypropylene replacements and implementing local production techniques. The Global Expanded Polypropylene Epp Foam Market's revenue was mostly generated by North America, with Europe and Asia Pacific following closely behind. The industry is expanding as a result of the numerous building and automobile businesses that are present in these areas. Over the course of the projected period, the South American and MEA markets are also anticipated to expand significantly. The market in these areas is expanding due to the rising need for insulation products in the building sector. Some significant market players are Armacel, Clark Foam Products Corporation, DONGSHIN INDUSTRY INCORPORATED, and others.

For More Information, refer to below link: –

Expanded Polypropylene Foam Market Share

Related Reports:

Citrus Solvents Market Growth

Concrete Bonding Agents Market Growth

Follow Us –

LinkedIn | Instagram | Facebook | Twitter

Contact Us:

Sara Lopes, Business Consultant — USA

SPER Market Research

+1–347–460–2899

#Expanded Polypropylene Foam Market#Expanded Polypropylene Foam Market Share#Expanded Polypropylene Foam Market Size#Expanded Polypropylene Foam Market Revenue#Expanded Polypropylene Foam Market Analysis#Expanded Polypropylene Foam Market Segmentation#Expanded Polypropylene Foam Market Future Outlook#Expanded Polypropylene Foam Market Competition#Expanded Polypropylene Foam Market forecast

0 notes

Text

Best Use of Melt Flow Index Tester in Industries

Source of Info: https://www.perfectgroupindia.co.in/blog/best-use-of-melt-flow-index-tester-in-industries

Introduction

The Melt Flow Index Tester is a useful tool in plastic manufacturing that measures how easily melted plastic flows, helping industries to guarantee material quality for molding and extrusion processes. Selecting the best plastic for a variety of uses is made simpler by this testing device which provides an understanding of how various plastic types behave when melted. Its daily use helps industries to include packaging, everyday items and the automobile industry. It reduces material waste and increases better manufacturing decisions with its consistent results. Many experts in plastic testing depend on Perfect Group India innovative products for reliable results.

Why Melt Flow Index Tester is Important?

A laboratory tool called a Melt Flow Index Tester is used to measure how quickly thermoplastic materials flow under pressure and heat. Flow rate can be gauged in grams per ten minutes. The amount shown helps to analyze how easily melted plastic flows. The material gets thinner when melted if the melt flow index is higher. This makes it simpler for industries to select the right material for various processes such as film extrusion, blow molding and injection molding.

Why Industries Need the Melt Flow Index Tester

Industries that work with plastic materials must know how the material behaves when melted. Here’s why this equipment is important:

• Material Selection: Different products need different flow features. A bottle needs plastic with different properties than a pipe. The tester helps select the most suitable material.

• Production Efficiency: Knowing the melt flow rate can help set the correct device temperature and pressure settings. This reduces waste and saves time.

• Quality Control: The final product is guaranteed to maintain consistency through regular testing. Any change in the properties of the raw material can be detected early.

• Cost Reduction: Avoid the use of wrong or incompatible materials, avoiding rework or product rejection.

Key Industries Using Melt Flow Index Tester

Many sectors depend on the Melt Flow Index Tester for Simple use. Here are some examples:

1. Plastic Manufacturing Industry

Plastic product makers use the tester to control raw material quality. It guarantees that materials used for making household goods, toys and containers meet required standards.

2. Automotive Industry

Vehicle parts made of plastic must be strong and flexible. The tester helps check if the material has suitable flow properties for manufacturing bumpers, dashboards and panels.

3. Packaging Industry

Flexible films and rigid containers must be tested to maintain durability and strength. This is where melt flow analysis becomes important to avoid packaging failure.

4. Medical Equipment Industry

Plastics are often used in everyday medical products including syringes, tubes and containers. These products must be accurate and reliable. Melt flow testing helps in the manufacturing of better plastics.

5. Construction Industry

Performance and safety requirements must be met by pipes, fittings and insulation materials. The Melt Flow Index Tester helps builders choose plastic with consistent performance.

How the Melt Flow Index Tester Works

The testing process is simple. The equipment barrel has a small amount of plastic. This barrel is heated to a standard temperature and then a weight is placed on top of the molten plastic. The material flows through a narrow die and the amount of plastic that flows out in 10 minutes is measured.

This test is repeated in different manufacturing stages right from raw material to final product guarantee the material quality stays within the desired range.

Features That Make a Quality Melt Flow Index Tester

When industries choose a device they look for:

• Digital Display: Easy to read data and faster decision making.

• Temperature Control: Accurate heating provides reliable results.

• Strong Construction: Strong design for extended use in industrial environments.

• Ease of Work: User friendly design reduces training needs.

Benefits of Using a Melt Flow Index Tester

Using this testing equipment brings several advantages:

• Better Product Quality: Regular melt flow results in better final products.

• Reduced Production Errors: Testing helps identify poor quality batches early.

• Faster Material Approval: Quick analysis leads to faster decisions.

• Improved Storage Control: Make sure that only tested materials are sent to manufacturing.

I• ncreased Customer Satisfaction: Customers are more trusting of high quality products.

Tips for Best Use in Industry Settings

To get the most out of the device from industries should follow these tips:

• Train Staff Properly: Results from trained workers are more trustworthy.

• Test at Multiple Stages: Testing should be done on raw materials in process samples and final products.

• Maintain Equipment Regularly: Test quality is maintained through cleaning and calibration.

• Store Data for Records: Maintain logs for audits and comparisons.

• Use Certified Weights and Dies: Guarantee test accuracy.

Conclusion

The Melt Flow Index Tester makes it simpler for industries to select the best material for various uses by helping them in understanding how plastic materials behave when melted and forced through a tiny opening under pressure and heat. This testing technique improves the quality of plastic products and helps better choices during processing. It is important to maintain manufacturing standards from packaging to auto parts. For trustworthy and accurate outcomes industries choose Perfect Group India to provide advanced testing solutions which offer instruments made to satisfy modern quality standards. Across all industries selecting the right equipment guarantees productive manufacturing and improved product performance.

0 notes

Text

Best Use of Melt Flow Index Tester in Industries

Source of Info: https://www.perfectgroupindia.co.in/blog/best-use-of-melt-flow-index-tester-in-industries

Introduction

The Melt Flow Index Tester is a useful tool in plastic manufacturing that measures how easily melted plastic flows, helping industries to guarantee material quality for molding and extrusion processes. Selecting the best plastic for a variety of uses is made simpler by this testing device which provides an understanding of how various plastic types behave when melted. Its daily use helps industries to include packaging, everyday items and the automobile industry. It reduces material waste and increases better manufacturing decisions with its consistent results. Many experts in plastic testing depend on Perfect Group India innovative products for reliable results.

Why Melt Flow Index Tester is Important? A laboratory tool called a Melt Flow Index Tester is used to measure how quickly thermoplastic materials flow under pressure and heat. Flow rate can be gauged in grams per ten minutes. The amount shown helps to analyze how easily melted plastic flows. The material gets thinner when melted if the melt flow index is higher. This makes it simpler for industries to select the right material for various processes such as film extrusion, blow molding and injection molding.

Why Industries Need the Melt Flow Index Tester Industries that work with plastic materials must know how the material behaves when melted. Here’s why this equipment is important:

Material Selection: Different products need different flow features. A bottle needs plastic with different properties than a pipe. The tester helps select the most suitable material.

Production Efficiency: Knowing the melt flow rate can help set the correct device temperature and pressure settings. This reduces waste and saves time.

Quality Control: The final product is guaranteed to maintain consistency through regular testing. Any change in the properties of the raw material can be detected early.

Cost Reduction: Avoid the use of wrong or incompatible materials, avoiding rework or product rejection.

Key Industries Using Melt Flow Index Tester Many sectors depend on the Melt Flow Index Tester for Simple use. Here are some examples:

Plastic Manufacturing Industry Plastic product makers use the tester to control raw material quality. It guarantees that materials used for making household goods, toys and containers meet required standards.

Automotive Industry Vehicle parts made of plastic must be strong and flexible. The tester helps check if the material has suitable flow properties for manufacturing bumpers, dashboards and panels.

Packaging Industry Flexible films and rigid containers must be tested to maintain durability and strength. This is where melt flow analysis becomes important to avoid packaging failure.

Medical Equipment Industry Plastics are often used in everyday medical products including syringes, tubes and containers. These products must be accurate and reliable. Melt flow testing helps in the manufacturing of better plastics.

Construction Industry Performance and safety requirements must be met by pipes, fittings and insulation materials. The Melt Flow Index Tester helps builders choose plastic with consistent performance.

How the Melt Flow Index Tester Works The testing process is simple. The equipment barrel has a small amount of plastic. This barrel is heated to a standard temperature and then a weight is placed on top of the molten plastic. The material flows through a narrow die and the amount of plastic that flows out in 10 minutes is measured.

This test is repeated in different manufacturing stages right from raw material to final product guarantee the material quality stays within the desired range.

Features That Make a Quality Melt Flow Index Tester When industries choose a device they look for:

Digital Display: Easy to read data and faster decision making.

Temperature Control: Accurate heating provides reliable results.

Strong Construction: Strong design for extended use in industrial environments.

Ease of Work: User friendly design reduces training needs.

Benefits of Using a Melt Flow Index Tester Using this testing equipment brings several advantages:

Better Product Quality: Regular melt flow results in better final products.

Reduced Production Errors: Testing helps identify poor quality batches early.

Faster Material Approval: Quick analysis leads to faster decisions.

Improved Storage Control: Make sure that only tested materials are sent to manufacturing.

I• ncreased Customer Satisfaction: Customers are more trusting of high quality products.

Tips for Best Use in Industry Settings To get the most out of the device from industries should follow these tips:

Train Staff Properly: Results from trained workers are more trustworthy.

Test at Multiple Stages: Testing should be done on raw materials in process samples and final products.

Maintain Equipment Regularly: Test quality is maintained through cleaning and calibration.

Store Data for Records: Maintain logs for audits and comparisons.

Use Certified Weights and Dies: Guarantee test accuracy.

Conclusion The Melt Flow Index Tester makes it simpler for industries to select the best material for various uses by helping them in understanding how plastic materials behave when melted and forced through a tiny opening under pressure and heat. This testing technique improves the quality of plastic products and helps better choices during processing. It is important to maintain manufacturing standards from packaging to auto parts. For trustworthy and accurate outcomes industries choose Perfect Group India to provide advanced testing solutions which offer instruments made to satisfy modern quality standards. Across all industries selecting the right equipment guarantees productive manufacturing and improved product performance.

0 notes

Text

Artist Research

Ant Farm, Cadillac Ranch, 1974

As a part of Ant Farm, Chip Lord, Hudson Marquez and Doug Michels partially buried ten Cadillacs dating between 1949 and 1963 in a row in chronological order from when they were produced. The specific cars were chosen as they document the rise and fall of the tail-fin in car design, a symbol of US manufacturing in the post-war era (Harris 2006). The work is typically read as exploration and critique of consumer culture. As Patrick Maguire writes, “The decayed cars that comprise Cadillac Ranch have indeed reached a kind of terminal state, and their tailfins (marking the terminus of the automobile) read as an epigraph for historical styles caught in the cycle of adoption and abandonment” (2014, p.7). In this context, displaying changes in tail-fin design shows in the relief the ways that consumers buy into arbitrary aesthetic changes in consumer products that have little practical purpose.

What interests me about this work in my art practice is that it presents cars as consumer items with personal and cultural significance rather than simple being functional tools. The work uses cars as readymades, much like I do in my engravings on plastic bumpers. I would also argue that in making mobile objects static, the viewer is better able to think of cars outside of their functional purpose.

Paul Harris, “How the US Fell Out of Love with Its Cars: Tail Fins and Chrome Grilles Were Once the Symbols of a Superpower. Now, with 36,000 Jobs Cut in a Week and Foreign Vehicles Filling the Highways, Paul Harris in New York Surveys the Collapse of an Industry,” The Observer (England),Jan. 29, 2006

Maguire, P. (2014). Terminal structures: Ant farm's cadillac ranch, 1974 (Order No. 1566512).

0 notes

Text

Paint Protection Film vs. Ceramic Coating: The Ultimate Guide

The most famous choices in the industry for keeping your car’s paint showroom finish are Paint Protection Film (PPF) and Ceramic Coating. Both of them are behemoth in the auto paint protection industry, but they dliver different purposes, and each has its pros and cons.

So, how will you choose the best one for your car? That’s why we’re here to assist you in making the correct decisions, whether you are an automobile enthusiast trying to maintain the looks of your daily driver or somebody who wants to protect your precious car.

Paint Protection Film: The Invisible Armor

Paint Protection Film (PPF) is a clear plastic film of thermoplastic urethane, applied to your automobile’s body. Initially developed for the military, now increasingly used by car and bike owners to get the utmost protection against bug splatters, scratches, and road scrapes.

Features:

Self-healing capability against small scratches

Excellent resistance to stone chips and road debris

UV protection to avoid fading

In matte, gloss, or even color finishes

The original paint won't be harmed when removed.

The ideal alternative to a bulletproof vest for the body of your car Paint Protection Film. It forms a barrier that can withstand abrasions and collisions that would otherwise harm the original paint on your car.

Ceramic Coating: The Magic Gloss

Ceramic coating is a liquid polymer that forms a hydrophobic (water-repelling) layer on the car’s factory paint by chemically binding to it. It completely increases gloss and is easy to wipe too, but it doesn’t offer the same level of physical protection as PPF.

At a Glance Features:

Increases shine and color depth

Repels water, dirt, and contaminants

Provides UV and oxidation protection

Easy to wash and keep clean

Lasts 2 to 5 years based on product quality and maintenance

If PPF is armor, Ceramic Coating is the magical cloak that keeps your car stunning and cleaner for longer.

Clash of the Titans: Comparing the Two

Let's compare them head-to-head in important categories and see where each excels.

1. Scratch and Impact Resistance

Paint Protection Film: Here, PPF takes the cake. It can take the impact of little rocks, scratches from branches, and other physical abrasions.

Ceramic Coating: It provides very little protection from physical harm. It may be resistant to light swirls, but nothing more.

Winner: Paint Protection Film

2. Aesthetic Enhancement

PPF: Contemporary PPFs have a glossy appearance and even matte or satin versions, but they're a tad duller than a new ceramic coat.

Ceramic Coating: The clear winner in terms of gloss. It enhances the paint's clarity and depth, making your car look "wet."

Winner: Ceramic Coating

3. Ease of Cleaning

PPF: Does provides some hydrophobic capabilities, but less so than ceramic coating.

Ceramic Coating: With its hydrophobic coating, water, dirt, and grime glides off. Less washing needed and no waxing required.

Winner: Ceramic Coating

4. UV and Chemical Protection

PPF: Shields against damaging UV rays and prevents yellowing and oxidation with age.

Ceramic Coating: Very good at repelling chemical stains from bird droppings, sap, and industrial fallout.

5. Cost of Durability

PPF: Generally lasts up to 5 to 10 years, according to the maintenance and environment.

Ceramic Coating: Typically lasts 2 to 5 years, but professional-quality coatings can push this upto more years.

Winner: Paint Protection Film

6. Cost and Value

PPF: Considerably more costly.

Ceramic Coating: Less expensive.

Winner: Ceramic Coating (for price-sensitive buyers)

Best of Both Worlds: Can You Have Both PPF and Ceramic Coating?

Yes! Numerous car owners choose both for the ultimate protection and looks. Here's the deal:

1. Install PPF in high-wear areas such as the hood, bumper, side mirrors, and rocker panels.

2. Apply Ceramic Coating over the top of the PPF and the rest of the vehicle for additional gloss and simple maintenance.

This combination provides physical protection where you need it most and ensures the whole car remains looking perfect with less work.

Which One is Right for You?

Now that we've contrasted them on several factors, let's consider who the best car owner is for each.

Opt for Paint Protection Film if:

You often commute on highways or dirt roads

You drive a valuable luxury or sports vehicle.

You'd like to safeguard your investment from physical harm.m

You intend to own the vehicle for a long time.

Opt for Ceramic Coating if:

You value a glossy, showroom-quality appearance. nce

You prefer easier upkeep and infrequent was.

You reside in a region with intense sun exposure.

Your budget is modest, but you still desire quality protection.

Busting Myths: Disproven Misconceptions

Ceramic Coating Makes My Car Scratch-Proof

Not true. It's resistant to mild scratches and swirl marks but not rock chips or deep scratches.

PPF Will Peel Off and Look Ugly Over Time!

High-quality car paint protection films are designed to last for years without yellowing, peeling, or cracking (if applied by professionals).

Washing the car regularly is better than protection!

Washing removes dirt, but it cannot protect your paint from UV rays, bird droppings, tree sap, or road debris.

Real-World Scenarios: Choose Smartly

Scenario 1: The Weekend Warrior

You have a Mustang GT that you commute on scenic highways. You adore how it appears and intend to own it for life-long. Choose PPF on the front and ceramic on the whole vehicle.

Scenario 2: The Urban Commuter

You commute every day on city streets with the occasional Saturday afternoon getaway. You want something easy to maintain. Ceramic coating will make your vehicle easy to clean and keep it looking razor-sharp.

Scenario 3: The Showstopper

You frequent car shows and have a strong attachment to looks. Do both PPF and ceramic coating. Your car will get attention and remain perfect.

Final Thoughts: The Protection That Pays Off

Paint Protection Film vs. Ceramic Coating isn't merely a matter of budget—it's a matter of how you drive, how long you keep your car, and what protection is most important to you.

If you're looking for maximum protection, particularly from physical damage, PPF is the hands-down choice. If you're looking for maximum shine and minimal maintenance, Ceramic Coating is the way to go. For the ultimate in solution, do both—cover high-impact zones with PPF and improve the rest with Ceramic Coating. Ceramic coatings and automobile paint protection films are about more than simply looks; they're about protecting the value of your vehicle and assuring you to enjoy every drive.

#paint protection film#car paint protection#ppf coating for car#ppf on car#ppf coating#ultraguardindia#window tint film#window tint#window tint for cars

0 notes

Text

A trunk door handle serves a fundamental role in a vehicle, enabling easy access to the trunk for storing and retrieving items. It’s a simple but essential component that many often take for granted until it’s in need of replacement. These handles are available in various designs, including manual and automatic options, and they are typically constructed from materials like stainless steel, aluminum, or plastic to ensure durability and ease of use.

Taizhou Huangyan Maorong Plastic Mould Co., Ltd. business: design and manufacture of automotive interior and exterior molds, processing pipe molds, and daily necessities molds. As a famous Custom Chevrolet car handle and Wholesale Chevrolet car handle Factory in China, our company's leading products: automobile bumpers, grilles, side steps, door guards, door sill trims, wheel eyebrows, front cabin trim cover moulds and products.High-end processing equipment: CNC machining centers, injection molding machines, electroplating lines, spraying lines, and other advanced automatic mold processing and mold testing equipment, product surface treatment production lines.

0 notes

Text

Buy CAR BUMPER PROTECTORS Online - Call +91 97113 93973

Car bumper protectors help to protect your car from scratches, dents, and damage due to small accidents, parking mishaps, or road wear. Selecting the best of them is subject to various considerations like material, compatibility, durability, and style. Take a glance at these useful tips that will assist you in selecting the best one for your car bumper protector:

1. Know Your Needs

Before buying a bumper protector, know if you require front, rear, or corner protection. If you normally park your vehicle in tight parking spaces or in city streets very often, the best would be a heavy-duty full-coverage protector. In case you are looking for scratch protection from carts or bikes, a light adhesive guard would work.

2. Select the proper material

Bumper protectors employ various materials with diverse advantages: Rubber: Extremely flexible, dents well, and provides good toughness. Plastic (ABS or PVC): Light, rigid, and most suitable for cosmetic repair. Foam: Bubbles well but perhaps not very durable. Stainless Steel: Has a high-end finish and superior scratch resistance.

3. Ensure It Is Compatible with Your Vehicle

Not all bumper protectors are made for all automobile models. Read product size and compatibility list before purchasing. Universal protectors will fit most cars, but custom-fit protectors will have the neatest look and protection.

4. Select Easy Installation

Bumper protectors have various installation styles: Adhesive-based: Easy to install and remove without drilling but less durable. Screw-mounted: Stronger and more permanent but needs drilling, which is not always possible in leased vehicles. Magnetic: Temporary security that is easy to remove but not as secure.

5. Select Design and Aesthetic Appeal

Your bumper guard needs to match your car. Select color finishes and shades to match your vehicle's look. Some guards have a textured finish for additional grip as well as better fashion on the car.

6. Make It Weather-Resistant and Durable

Select a bumper protector that is weather-resistant, resistant to UV, rain, snow, and temperature. Rubber and stainless steel types are weather-resistant compared to foam or plastic types.

7. Read Ratings and Reviews of Customers

Customer reviews are wonderful indications of real-world performance, fitment, and lifespan. Select products with high ratings and reviews for fitment and durability.

8. Verify Brand Reputation and Warranty

Good brands will give you a warranty or a guarantee, and that shows how confident they are about the quality of their product. Use brands like Bumper Bully, BumpShox, and Luv-Tap when you are shopping for something that has a guarantee.

9. Compare Prices and Value for Money

Affordability should always be a demand, but never at the expense of settling for something of low quality under the pretext of being affordable. Compare features, material, and warranty and make a well-informed decision to get the best out of your money.

10. Test for Legal Compliance

There are bumper guards that stick out beyond the model of the automobile, which might be illegal on the roads where you live. Ensure the guard is legal for your area traffic law before you buy. Applying these guidelines, you will be able to buy a car bumper guard that from Carzex, located in Vishnu Garden New Delhi-110018 that is completely protective without changing the appearance of your vehicle.URL: https://carzex.com/product-category/exterior-accessories/car-bumper-protectors/

0 notes

Text

4 Axis CNC Router for Foam, Aluminum, Wood Mold Processing

The 4 axis CNC router has become an indispensable tool in the fields of mold processing and fabrication. Whether working with foam, aluminum, or wood, these machines offer unparalleled precision, versatility, and efficiency.

4 Axis CNC Router

A 4 axis CNC router is a computer-controlled machine that can move along four different axes: X, Y, Z, and an additional rotational axis (A-axis). This additional axis allows for more complex and intricate cuts, making it ideal for mold processing and other detailed fabrication tasks.

The 4 axis machining centre at a good price, provide several configurations to meet different requirement, perfect for several kinds of foam and mould router, the innovation model designed by iGOLDENCNC, combined with a competitive set of configurations. Hot applications include:

>Carving all kinds of non-metal materials processing such as foam, lost foam, automobile foam mold, yacht mold, large ship wooden mold, cast wooden mold, engineering plastic materials, aviation wooden mold, propeller, train wooden mold, etc. >Foam processing of automotive stamping molds, casting wood molds, automotive interiors, processing of engineering plastic materials; >Other industry molds: electrical appliance molds, lighting molds, ceramic sanitary ware, three-dimensional curved surfaces for large musical instruments, instrument molds, home appliance molds, air-conditioning molds, automotive molds, automotive interior molds, automotive bumper molds, automotive instrument table molds, etc.

Benefits of Using a 4 Axis CNC Router for Mold Processing

Precision and Accuracy

4 axis CNC routers offer exceptional precision and accuracy, allowing for the creation of intricate designs and complex shapes. The computer-controlled movements ensure consistent and high-quality cuts.

Versatility

These machines can work with various materials, including foam, aluminum, and wood. This versatility makes them ideal for a wide range of mold processing projects.

Complex Geometries

The additional rotational axis (A-axis) allows for the creation of complex geometries and detailed features that would be difficult or impossible to achieve with traditional 3 axis routers.

Efficiency

4 axis CNC routers can operate at high speeds, significantly reducing production time. The automation of the cutting process allows for continuous operation, increasing overall productivity.

Material Efficiency

CNC routers minimize material waste by producing precise cuts and shapes. This efficiency is particularly beneficial when working with expensive materials like aluminum.

4 Axis CNC Router for Foam Parameter

ModeliGW-MC-2060Working area2000*6000*1100mmSpindleChina HQD 9kw atc air cooling spindle + swing 180 degreeInverterFulingMotorJapan Yaskawa 850W servo motorDriverJapan Yaskawa 1kw servo driverControl SystemSyntec 6MB control system + hand wheelTableVacuum & T-slot table with 7.5kw air vacuum pumpTransmissionXY helical rack, Z Taiwan TBI ball screwGuide railTaiwan linear guideBall screwZ TBI ball screwBodyThick steel tube Welded bodyBeamSteel beamColumnsSteel columnsControl boxIndependent control boxColourCustom madeLubricationAutomatic oilingTool SettingAutomatic Tool Calibration SensorDust collectorDouble bag dust collectorVoltage3 Phase/380V/50HZRotary axisOptional part

Applications of 4 Axis CNC Routers in Mold Processing

4 axis CNC routers are used in various applications within mold processing, including:

Foam Molds: Creating detailed foam molds for casting and prototyping.

Aluminum Molds: Fabricating precise aluminum molds for injection molding and other manufacturing processes.

Wood Molds: Producing custom wood molds for casting, forming, and other applications.

Prototyping: Rapid prototyping of complex designs and geometries.

Custom Tooling: Creating custom tooling and fixtures for specialized manufacturing processes.

Choosing the Right 4 Axis CNC Router for Mold Processing

Consider Your Needs

Identify the specific requirements for your mold processing projects, such as the types of materials you will be working with, the complexity of the designs, and the production volume. Choose a machine that meets these needs.

Machine Size and Capacity

Consider the size of the materials you will be cutting and choose a machine with an appropriate bed size and cutting capacity. Larger machines can handle bigger projects, while smaller machines are suitable for detailed work.

Spindle Power

The spindle power determines the cutting capability of the CNC router. Higher power spindles can cut through thicker and harder materials more efficiently. Choose a spindle power that matches your specific cutting requirements.

Software Compatibility

Ensure the CNC machine is compatible with the CAD and CAM software you plan to use. Compatibility ensures seamless design and toolpath generation.

What is the 4 axis CNC Router?

4 axis CNC router is an automatic computer-controlled machine tool whose spindle rotates 180° along the X-axis or the Y-axis to do 3D arc milling and cutting, which is based on the ordinary 3 axis machine tool. 4th axis CNC router is an automated machine tool kit with computer numerical controller for relief carving and sheet cutting, as well as adding the fourth axis (rotary axis) for 3D cylinders milling.

In addition, the 4-axis CNC machine is divided into four-axis three-linkage and four-linkagel, not to say that the rotation is added, it is a four-axis linkage machine tool, and a computer-controlled system with a rotating axis and a four-axis linkage can be called as a real 4 axis CNC machine. Because of the rotation movement of the 4th rotary axis, 3D machining of cylindrical, arc, and circular surfaces is realized.

CNC FOAM CUTTERHot Wire Foam Cutter

3D CNC ROUTER, CNC FOAM CUTTER, CNC ROUTER2060 3d Foam Milling Machine Carving Eps Foam Polystyrene

3D CNC ROUTER, ATC CNC ROUTER, CNC FOAM CUTTER, CNC ROUTERTop 3d CNC Foam Cutting & Carving Machine

HOT4 AXIS CNC ROUTER, CNC FOAM CUTTER, CNC ROUTER, CNC WOOD ROUTER4 Axis Machining Centre CNC Milling Machine for Foam, Aluminum, Wood Mold Processing5.00 out of 5

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC FOAM CUTTER, CNC ROUTER, CNC WOOD ROUTERDetachable 4 Axis CNC Foam Cutting Machine for EPS, Wood, Metal Carving

HOT4 AXIS CNC ROUTER, CNC FOAM CUTTER, CNC ROUTER, CNC WOOD ROUTER1530 EPS Foam Cutting Machine Mold Making

HOT4 AXIS CNC ROUTER, CNC FOAM CUTTER, CNC ROUTER, CNC WOOD ROUTERDouble Layer 4 Axis CNC Machine for Foam, Aluminum, Wood Mold Making

HOTREAD MOREQUICK VIEWCNC FOAM CUTTER, CNC ROUTERCNC Foam Cutting Machine for EPS, EPP, XPS

A real 4-axis machine tool can cut wood, foam, stone, white marble, human body, Buddha statues, sculptures, handicrafts, furniture. 4-axis is refer to X-Y-Z-A, X-Y-Z-B or X-Y-Z-C, 4 axis are linked, the four axis can work at the same time. If the machine has only three feed axes (X, Y, Z), the Y-axis can be manually replaced with a rotating axis, and it can only be three-axis linkage at most. This is a 4th axis CNC machine, and it is also the usual fake four axis. In terms of use, it can process planes, reliefs, and cylinders. If the machine has four feed axes (X, Y, Z, A), it can be processed with four-axis linkage, and can process planes, reliefs, cylinders, non-standard three-dimensional patterns, and corners of 3D patterns.

1530 CNC Foam Cutter for 3D Foam Mold Carving

3D Carving CNC Router Machine with Three Heads

3D Engraving 5 Axis CNC Machining Center

5 Axis CNC Router Woodworking for Sale

4 Axis CNC Foam Carving Router with Rotary Device

4 Axis EPS/Foam CNC Router Carving Machine

4 Axis Rotary 1325 Wood Carving Cnc Router

CNC 5 Axis Gantry Machining Center

CNC Foam Cutting Machine Hot Wire

Foam Hot Wire Cutter

Customized 1325 CNC Foam Carving&Cutting Machine

Double Work Table 4 Axis CNC Router Machine

0 notes

Text

Melt Flow Index Tester Need In Industry

Source of info: https://www.perfectgroupindia.co.in/melt-flow-index-tester-need-in-industry.php

Melt flow index tester is a useful instrument in many sectors because it lets you perform an analysis of a polymer's flow qualities, which helps in quality control, material selection, and solving issues. Perfect Group India, an industry leader in testing equipment, has been at the top of supplying innovative equipment to sectors as diverse as plastics, packaging, automotive, aerospace, and food. Perfect Group India's melt flow index tester has proven valuable in making sure of product quality and performance, establishing its position as a trustworthy partner for companies aiming for perfection.

Understanding Melt Flow Index A melt flow index tester measures the flow properties of a polymer under specific conditions. It specifies the speed at which a melted polymer flows from a chosen opening. This feature is necessary for several reasons:

Quality Control: The melt flow value of the index is an important measure of the quality of a polymer. It helps manufacturers make sure that their products satisfy the required standards and work properly.

Processing: Melt flow index values change between polymers, and these values affect their processing properties. Understanding the melt flow index may help you choose the best polymer for your use.

Consistency: Maintaining the same in polymer melt flow properties is important for keeping quality of product.

Function of Melt Flow Index tester The instruments provided by Perfect Group India are used to calculate a polymer's melt flow index. They are needed for multiple reasons:

Quality Assurance: A tester for the melt flow index is necessary for quality assurance. By evaluating the melt flow index, manufacturers may confirm that their products meet the necessary requirements and regulations. This is particularly crucial in areas like the automotive and food packaging sectors where material quality may have a significant influence on performance and safety.

Material Selection: Values for the melt flow index help with choosing the right polymer for a specific purpose. Some industries need polymers with certain flow properties. For example, in order to ensure the structural strength of products during injection molding operations, the automobile sector may require polymers with a specific melt flow index.

Troubleshooting: An important tool for identifying production problems is the melt flow index tester. Variations in the melt flow index may help in detecting production-related issues so that manufacturers are able to quickly fix them.

Industries That Rely on Melt Flow Index tester Melt flow index testers are used in many different sectors for material selection and quality control. The products created by the Perfect Group India serve a wide range of sectors, such as but not exclusive to:

Plastics Industry: In the plastics business, where many polymer types have been used for a wide range of purposes, melt flow index analysis is important. Products made of plastic may have the required strength, flexibility, and durability with the use of the melt flow index value.

Automotive Industry: A melt flow index tester is necessary for verifying the quality of different polymer-based components in the automobile industry. These parts include engine parts, interior trim, and bumpers.

Food Industry: Using materials with the right melt flow index values in food packaging is essential to ensure product safety and shelf life. Staleness or infection might result from selecting the incorrect material.

Perfect Group India's Contribution For many years, companies have been receiving top-notch equipment from Perfect Group India, a well-known brand in the testing equipment market. They are now a leader in the business because of their attention to accuracy and quality.

Advanced Technology: The melt flow index tester from Perfect Group India has been equipped with modern technology that offers accurate and trustworthy results. By using this technology, companies are able to choose resources and processes with information.

Service and Support: Perfect Group India offers more than just equipment for sale. They guarantee that their clients can depend on their products for a long amount of time by offering first-rate after-sales service and support.

Training and Education: The business goes above and above by offering instruction and training on how to make use of its tools properly. By doing it, industries are able to optimize the advantages of melt flow index testing in their quality control methods. Real-World Applications In order to gain more knowledge of the importance of melt flow index testers all over multiple industries, let us examine a few practical uses.

Automotive Industry: Melt flow index tester are used in the automobile industry to check the flow qualities of polymers used in interior parts. For example, high-impact polystyrene is commonly used to make automotive dashboards. With the help of this machinery, manufacturers can guarantee that the material has the required flow properties for injection molding, enabling the creation of durable and attractive dashboards.

Packaging Industry: Melt flow index testing is used by the packaging industry to figure out which materials are most suited for certain packaging tasks. For example, to achieve the proper balance between flexibility and strength in the manufacturing of thin plastic films used in food packaging, materials with accurate melt flow index values are required. Food Industry: Melt flow index testing is used in the food business to guarantee the quality and security of packaging materials. For example, in order to preserve product freshness and avoid damage, packing materials used for fresh products must have the right melt flow index values.

Conclusion In many different industries, the melt flow index tester is a necessary instrument. In the process of helping with material selection and performance, they also support research and development and troubleshooting. In order to assist companies in maintaining their standards and fulfilling the changing demands of their respective industries, Perfect Group India has shown a dedication to offering advanced technology together with great service and support. The importance of melt flow index testing cannot be pointed out in a world where material quality directly affects product performance and safety.

0 notes

Text

Automotive Interior Materials Market - Forecast(2025 - 2031)

The automotive interior materials market signifies the utility of various materials for the designing of the interior materials in an automobile. There are various parts of an automotive where many materials play a key role in their manufacturing.

Request Sample The increasing automobile demand and changing customer preferences with regards to comfort, every automotive OEM is differentiating the interiors of their vehicles and this has been driving the automotive interior materials market. The major factor that which every automotive OEM is focusing is to reduce the weight of the vehicle because the less weight vehicles can accelerate more with optimal utilization of fuel when compared to heavy weight vehicles. Hence, reducing weight by the use of lighter materials is the most driving factor. Moreover, with the reduction in weight, the vehicles can carry additional advanced emission control systems, safety devices and integrated electronic systems without increasing its overall weight. The market for the automotive interior materials is found to be increasing year by year. Asia Pacific and Rest of the World are the key markets for the future and are expected to provide huge opportunities to the global automotive interior materials manufacturers because of the growth in the automotive sector and increasing demand for passenger vehicles in the regions. The forecast of this market is going to be $XX bn by the end of 2021.

Inquiry Before Buying

The segmentation of automotive interior materials market can be done based on the type of materials such as fabrics, thermo plastics, polymers, vinyl compounds, synthetic and natural fibers, wood, glass, composite materials and also based on the type of the application such as the high or medium commercial vehicles and also passenger vehicles, and also on the criteria of the products which we obtain by the use of these materials such as seat belts, seat covers, door trims, scuff plates, floor carpets, dash boards, bumpers, filters and reservoirs and so on.

Schedule a Call The geographical information of this automotive interior materials market has been varying with respect to the span of time. Asia pacific occupies the largest share of the automotive interior materials suppliers and the majority of suppliers are from the countries such as India, China, Japan, South Korea and others, the demand for the automobile materials manufacturers is at an all time high in these areas and the emergence of new technologies is the major reason for the increase of demand and vast development in supplying the automotive materials.

Buy Now

The European region occupies the next major share and most of the European countries are developed so their major concentration is on the safety of the passengers. So, most of the European countries will target on the appropriate selection of materials which provide safety for the passengers during the times of accidents or crashes. The next major share is of the US market mostly supplemented by countries such as Canada, but some of the major key countries for the supplying of the automotive interior materials market are Mexico, Canada, Germany, France, Spain, China, India, Japan, South Korea, and Brazil on a global level.

#"automotive interior materials market#automotive interior materials market size#automotive interior materials market forecast#automotive interior materials market shape#automotive interior materials market report#automotive interior materials market research#advanced emission control systems#integrated electronic systems#safety devices

0 notes

Text

Paint Protection Film for Cars: A Simple Guide

Car ownership is not just an advantage; it is a great way of making a good investment. Regardless of the kind of car you own, a small personal car or a flashy brand car you need to protect its looks. Paint Protection Film, more widely referred to as PPF, is probably one of the best methods that can be used to ensure your car’s external appearance does not fade quickly.

What is a Paint Protection Film?

Paint Protection Film as the name suggests is a highly flexible layer of clear material that can be applied directly over your car. It’s most crucial function is to take the brunt of abrasion, small dents, staining, and minor damage.

Made from flexible and transparent material, PPF is often formed out of polyurethane or a similar type of plastic. They also have the function of a body armor shielding your cars paint from things like gravel, dust, stones and in effect the harsh rays of the sun.

See also: Getting Started with WebdriverIO: A Modern Approach to Web Automation

How Does PPF Work?

When applied on the surface of your car, it forms a layer that reduces the chances of your paint coming into contact with harmful elements. This layer also absorbs most of the minor impacts from scratching or chipping the paint on the car.

The majority of contemporary PPFs have the property of auto healing. This implies that, if the film experiences a minor damage, it can repair itself when exposed to some heat, like sun, or warm water. This makes your car stays smooth and shiny for longer compared to using other polishes.

It is also hydrophobic so it also helps in the repelling of water and dirt, and so your car will be easier to clean and less effort.

1. Protects Against Everyday Damage

Driving exposes your car to the small stones, gravel, and other materials on the roads. These can leave little scratch or dents on the surface of the paint coat. PPF thus serve to protect against this damage.

2. Prevents Fading

Exposure to the sun’s UV rays can cause your car’s paint to fade, losing its original brightness and shine. PPF shields your car’s from the sun’s UV rays and helps maintain the vehicle’s colour bright and new.

3. Maintains Your Car’s Value

If a car’s paint has no scratches, it is a more attractive sight for potential buyers. Since PPF will help in preventing the paint of your car from fading you will be in a position to retain its value in case you decide to sell the car in future or trading it with another car.

4. Easy Maintenance

Known as PPF, your car becomes more resistant to dirt and stains. Cleaning your car is less time consuming and less demanding because the film minimises the possibility of stains.

5. Long Lasting Protection

PPF is a material that has a very long-life span, with high quality material on average used for about several years. This makes it to be an investment on the side of ensuring that your car is well taken to have a polished look.

Is PPF Suitable for All Cars?

Yes, Paint Protection Film can be applied on any type of automobile, or say on a new as well as old car. Nevertheless, it is especially loved by people interested in automotive and car lovers who possess expensive and luxurious cars and would like to maintain their cars in the most optimum manner.

PPF is most commonly applied to high impact areas of the car, such as:

The front bumper

Bonnet (hood)

Side mirrors

Door edges

Headlights

If one wants to go for the entire car coverage, to ensure maximum protection is offered, then they opt for the PPF. Contact us for more information on PPF for cars.

Source URL By: https://abdellatifturf.com/paint-protection-film-for-cars-a-simple-guide/

1 note

·

View note

Text

Best Melt Flow Index Tester for Plastic Testing

Source of Info: https://www.perfectgroupindia.co.in/blog/best-melt-flow-index-tester-for-plastic-testing

Introduction

The Melt Flow Index Tester is a reliable device to help industries select the best material for molding by measuring how easily molten plastic flows through a small opening when pressure and heat are applied. The purpose of this lab and manufacturing equipment is to give better control over the performance and quality of plastics. It helps plastics businesses with daily quality checks and is simple to use with accurate results. This tool makes testing polymers for packaging or auto parts easier and creates accurate results every time. For trustworthy plastic testing solutions, Perfect Group India provides equipment that is specific to your manufacturing and testing needs.

What is a Melt Flow Index Tester?

A Melt Flow Index Tester is a laboratory device to measure the flow rate of molten plastic through a small die under a standard weight and temperature. This flow rate, expressed in grams per 10 minutes, is called Melt Flow Rate. The MFI value tells how easily a plastic melts and flows important information for manufacturing and processing.

Why Melt Flow Index Matters in Plastic Testing

The MFI value directly impacts the processing method of plastic products. High melt flow index materials are suitable for injection molding, while lower index materials can perform better in extrusion processes. This one test guarantees product quality, consistency, and following to industry standards by showing information about the molecular weight and processing behavior of the polymer.

Using a this device helps in:

• Selecting the right material for a specific uses

• Identifying batch to batch variations

• Guarantee following ISO 1133 or ASTM D1238.

• Quality control and product development

How a Melt Flow Index Tester Works

The testing process is simple and consistent. A barrel that has been heated is filled with a plastic sample. A fixed weight, usually 2.16 kg or 5 kg is applied to force the molten polymer through a die. After extrusion the material is collected and weighed. The amount given in within ten minutes shows the MFI.

The tester usually includes:

• A heating barrel to reach desired temperature

• A piston and weight mechanism

• A accurate die

• A digital display or timer

• An automated or manual cutting system

For a variety of thermoplastics, users can provide consistent and trustworthy MFI values by accurately performing the testing steps.

Important Qualities of the Best Melt Flow Index Tester

When investing in a Melt Flow Index Tester it's important to look for features that support quality, safety and ease of use. Here are some of the top features that define a high-quality instrument:

• Digital Temperature Control – Guarantee accurate heating with Few modifications.

• Touchscreen Interface – Makes work simple and user-friendly.

• Quick Heat-Up Time – Reduces waiting and speeds up testing cycles.

• Sturdy Construction – Durable build for durability use in lab conditions.

• Multiple Load Options – Offers flexibility for testing under various conditions.

• Die Cleaning Tools – Simplifies maintenance between tests.

• Auto Sample Cutting – Provides hands-free use for better accuracy.

• RealTime Data Display – Shows ongoing test data for better tracking.

• Compact Design – Saves bench space in laboratories.

• Safety Shields and Alarms – Protect users during uses.

Applications in Various Industries

The Melt Flow Index Tester finds wide usage across industries that best with polymers and plastics:

• Automobile Industry: For plastic items such as bumpers, clips and dashboards

• Packaging Industry: For films, bottles and containers

• Healthcare Equipment: For trustworthy and secure plastic products

• Consumer Goods: For everyday items like toys, appliances and more

• Construction: For insulating materials, fittings and pipes

Choosing the Right Melt Flow Index Tester

Your unique testing requirements will impact which tester is best for you. Before choosing, think about the following:

Type of material you are testing

• Frequency of testing

• Available lab space

• Required standards (ASTM/ISO)

• Manual vs. automatic works

• Budget constraints

A good equipment should provide fast, repeatable and easy-to-understand results while meeting global testing standards.

Why Choose Perfect Group India

Perfect Group India offers a range of advanced testing instruments designed to meet today’s industrial needs. Our Melt Flow Index Tester is engineered for performance, user friendly and l reliability. Whether you are in manufacturing, R&D or quality control our equipment supports you with accuracy and quality.

With solid build quality, smart features and support tailored to your industry our testing solutions help you deliver better products with confidence. When it comes to polymer testing, trust the technology that’s built to perform.

Conclusion

The Melt Flow Index Tester is an important instrument for plastic testing because it gives manufacturers details about how various materials react when melted and forced through a die. Choosing a suitable polymer for manufacturing, extrusion and molding requires knowledge of this information. Industries can improve quality checks and reduce manufacturing issues with a reliable solution like the one provided by Perfect Group India. Better product performance and easy use are guaranteed when the best equipment is chosen. Using advanced testing tools is an important decision for any company dealing with plastics to increase product strength, reliability and customer satisfaction in the competitive industry of today.

0 notes

Text

Melt Flow Index Tester: For Stronger and High-Quality Plastics

Source of Info: https://www.perfectgroupindia.co.in/blog/melt-flow-index-tester-for-stronger-and-high-quality-plastics

Introduction

A test to analyze the quality of plastics with great accuracy and reliability by using the Melt Flow Index Tester. At a given load and temperature, it provides details about the quality of the molten plastic test. This helps manufacturers guarantee their plastic products are strong, solid, and meet industry standards. Whether in packaging, automotive, or products for sale, understanding the Melt Flow Index (MFI) of plastics is important for reliable production. A high or low MFI affects the strength, flexibility, and use of plastic products. Businesses can improve the overall quality of plastic and make better raw material selections by using a flow index device.

Use of Melt Flow Index Tester The Melt Flow Index Tester is required for analyzing how quickly plastic melts. It helps businesses in making sure the plastic is suitable for creating strong, high-performing items. Industries can improve material quality and guarantee the quality to manufacturers who make solid plastic products for a variety of industries by analyzing the MFI.

How Does the Melt Flow Index Tester Work? A Melt Flow Index Tester works on a simple but highly productive concept. It includes the following steps:

Preheating the Plastic Sample: A small amount of plastic material is placed inside a heated barrel.

The temperature is set based on the type of plastic under test.

Applying a Specific Load: A weighted piston is placed on top of the molten plastic.

The weight exerts pressure, forcing melted plastic through a small.

Measuring the Flow Rate: The plastic that flows out in 10 minutes is seized and weighed.

The resulting value is known as the Melt Flow Index (MFI).

Interpreting the Results: A higher MFI value proves that the plastic flows easily and has a low molecular weight.

A lower MFI value indicates that the plastic is more fluid and contains larger particles.

Why is the Melt Flow Index Test Important? The Melt Flow Index Tester is widely used in plastic manufacturing because it helps in:

Material Selection Different plastic uses require different flow qualities.

The MFI value helps manufacturers in selecting the most suitable material for each product.

Quality Control The test guarantees the plastic used in production meets the strength and strength requirements.

It helps to detect variations in raw materials.

Process Optimization For increased productivity and higher-quality results, process improvement boosts performance, reduces waste, and increases productivity.

Sustainability and Recycling For finding out if plastic materials can be recycled, the MFI test is helpful.

It makes sure that recycled plastics have qualities suitable for recycling.

Applications of the Melt Flow Index Tester A Melt Flow Index Tester is widely used in industries where plastic is a primary material. Some of its primary uses are:

Plastic Packaging Industry Guarantees the proper strength and flexibility of plastic films, bottles, and containers.

The automotive Sector supports in selecting plastics for dashboard items, bumpers, and automobile interiors.

Construction and Infrastructure Pipes, fittings, and insulation supplies are tested to guarantee their strength.

Medical and Healthcare Checks that plastics used in medical devices and packaging meet safety requirements.

Electronics and Electrical Industry Helps to create durable cable insulation, switches, and plastic structures.

Factors Affecting Melt Flow Index Values Several factors can influence the Melt Flow Index Tester value of plastic materials, including:

Temperature and Pressure A higher testing temperature may increase the flow rate, resulting in a higher MFI value.

The use of weight influences how quickly the plastic flows.

Additives and Fillers The presence of additions, plasticizers, and support can affect the MFI value.

Moisture Content Moisture in plastic pellets can produce inaccurate MFI results. Drying the material before testing is important.

Choosing the Right Melt Flow Index Tester When selecting an MFI Tester, manufacturers should consider:

Importance of Accurate Flow Measurements Accurate material quality and high standard in manufacturing processes are guaranteed by selecting the right device.

Material Compatibility Considerations For accurate and trustworthy results, make sure the tester is useful with the specific materials you use.

Understanding Test Standards To guarantee smooth and uniform legal testing processes, pick an item that conforms with industry standards.

Cost-Effectiveness in Testing Equipment For long-term value and productivity, buying devices that impacts a balance between performance and financial limitations.

Advanced Features to Look For To increase testing flexibility, look for features like automated data checking and adjustable test parameters.

Conclusion The Melt Flow Index Tester is required to make sure plastic materials fulfill strength and quality requirements. This device helps manufacturers to make long-lasting, high-performing products by checking how easily melted plastic flows. Industries can choose the perfect group India for best materials and retail products, automotive, and packaging by knowing flow features. A trustworthy Index Tester provides waste reduction, increased productivity, and high quality products. Finding these tools guarantees improved product dependability and quality control. Using modern testing equipment is important for industries searching for excellence in plastic manufacturing in order to meet different industry standards and customer expectations.

0 notes