#automatic spices processing plant

Explore tagged Tumblr posts

Text

How do you cleanse?

How do you cleanse?

Cleansing is one of the major parts of witchcraft, and often one of the first things a new witch will learn on their path. There are many different ways to cleanse; I will describe some methods here, as well as answer some common questions I see about cleansing. What is the purpose of cleansing? Cleansing is used to clear out any negative or stale energy that may be affecting a person or space. Cleansing does not automatically bring in positive energy, that is something that needs to be done alongside the cleansing process. I see a lot of newer witches cleanse, and then get confused as to why negative energy keeps filling the space. This can often be because they are not bringing positive energy in after cleansing. Essentially, you leave the area open for any energy to come in, rather than bringing specific energies in. Cleansing can help to get rid of old energies that no longer serve you, and any negative energy that may be holding you back. You can cleanse yourself, your space (wherever you live/perform your craft) and the tools you use in your craft.

Will cleansing get rid of all energy?

Cleansing is meant to only cleanse away negative and stale energy that is no longer serving you, it will not get rid of any positive energies you are wanting to keep around you. How do you cleanse? There are tons of methods you can use to cleanse. I'll be listing some common methods, as well as some of my favorite methods to do cleansing. This is not an exhaustive list, you can even make up your own ways to cleanse (I have an example of a method of cleansing I do that I made up on my own). Common Cleansing Methods

Florida Water

Rose Water

Rosemary/herb water

Salt

Sound cleansing

Smoke cleansing

Candles

Some of my favorite ways to cleanse are sound cleansing and using candles to cleanse. With sound cleansing, you can get a bell, a sound bowl, or simply play some music and dance around your room; you can get really creative with sound cleansing. Same goes for candles, using candles alongside color magic and even scent associations can be a wonderful way to cleanse and bring in positive energies. What is Florida Water? Florida Water is a mixture of alcohol, perfume, and herbs/spices. You can actually make Florida Water at home with the right materials! Please be careful with it; while it is great for cleansing, you'll want to check what types of chemicals it may have in it and if it is safe for human skin if you've bought it from online/in-store.

How do you smoke cleanse?

Smoke cleansing can look different for everyone; some people burn bundles of herbs, some people will use incense, and some may use candles. Please always be fire-safe is you are using smoke to cleanse your area.

For smoke cleansing, you can walk around your house with your smoke of choice lite, or just allow it to sit and burn in the same room as you. I also want to mention at this point that white sage is from a closed practice; it is also endangered. The use of white sage is very controversial in the witchcraft community. I personally have found that there are plenty of alternatives (such as black sage, or even incense) that work better for me than white sage has. I also generally don't like the smell of white sage.

I also want to bring up salt; salt can be used both for cleansing and protections. Please only use salt indoors, as it can be damaging to the dirt and plants. You can make salt water and spray it around your house to cleanse; you can put salt in your doorways and on your windowsills as a form of protection (this will be covered more in a different post). You can also cleanse your crystals and divination tools in a bowl of salt. Please be careful when cleansing crystals using this method, as some crystals may be disintegrated by salt.

How often should I cleanse? The answer for this will vary from person to person; however there are several points I want to touch on where I personally recommend cleansing. If you are feeling a lot of negativity around you, or just generally feeling 'off', that may be a good sign and opportunity to do some cleansing.

In terms of tools, if your tools are acting funky (divination not giving consistent answers, for example) that could be a sign they may need to be cleansed. I personally cleanse my decks after every reading I do; the way I do this is also incredibly simple. I put my cards away with the intention that the reading I have just done is over, and the energies from that reading are being released. If I need them for another reading, I simply take them back out, and use them, putting them away between each reading I do. Cleanse while bathing. This is a great opportunity for you to cleanse yourself, you don't even need anything extra except for your regular body wash/shampoos etc. You can cleanse yourself while you are cleaning your body by bathing/showering with the intention that you are cleaning not only physically, but spiritually as well. Washing away any negativity you have picked up throughout the day.

Similarly, you can cleanse your house while you clean it as well. I will often put some Florida water into my mop water when I'm mopping the floors; and again cleansing can be about intentions as well. Cleaning your house with the intention of getting rid of that old, stale, and negative energy can be a wonderful way to cleanse (this is also a great tip for if you are in the broom closet).

Cleansing after you've gotten over an illness is also something I recommend. Shaking off sickness by cleansing it away has sometimes helped me feel better after I'm recovering. I highly recommend using bathing to cleanse after being sick; its a low energy, low effort way to cleanse, and I know at least for me personally after I've been sick, I generally want to take a bath/shower anyway so my physical body doesn't feel so yucky. Cleansing during transitional periods of the seasons (springtime cleaning, but you can also do this for other seasonal changes as well), can often be good too. This helps the energies around you to stay fresh, and works well with the earth's natural cycles.

What are some cheap, easy ways to cleanse, especially without smoke?

I find a really cheap and easy way to cleanse without smoke is using water and herbs. Most families keep at least some herbs in their kitchen; you can use rosemary as it is very easily accessible. Other herbs that are used for cleansing can be lavender (many cleaning products also come with lavender scents in them too), basil, and bay leaves. Any of these can be soaked or boiled in water and made into a cleansing spray/solution you can use to clean your house with!

Sound cleansing can be another easy, and often free, way to cleanse. Using music, singing, and even dancing to cleanse your space and bring in positive energy is very accessible to a lot of people (youtube is free!), and it can be a very fun and creative way to cleanse your space. It’s also very broom closet friendly.

Someone in my household gets headaches when I use incense/candles. Are they a negative person?

No, this does not automatically mean that this person is negative or has bad energy. I know many people who have sensitivities to certain scents, and especially with incense and candles, they can have very strong scents at times. If this is the case, I recommend looking into alternatives to smoke cleansing. In terms of candles, I’ve found that some people have sensitivity to wax candles specifically, so looking into beeswax or soy alternatives may be worth it.

Disclaimer! PLEASE make sure that any cleansing method you use will be safe for you, and any animals you may have in the household. I know a lot of people dislike smoke cleansing in particular because it can be bad for pets. Please make sure that you are checking to make sure any herbs and scents you are using will also be pet-friendly!

63 notes

·

View notes

Text

Just A Little Spice - Dean x Reader

“Just A Little Spice” - Dean x Reader

Rating Teen

Dean x Reader

Tags: Language, Dean Makes Bad Decisions, Dean in Mild Peril, Dean is Infuriating but We Still Love Him

Word Count: 1500

Dean likes to spice things up, but it would be nice if he didn’t have to put his life in danger in the process.

I'm participating in @jacklesversebingo and this part will fill my "I would burn down the world for you." dialogue square.

A/N: Something Short and Kinda Cute. I ended up finding a way to tie this to my other Bingo Square “Ice Play.”

Image created in Canva (photo used/found through Google Image Search)

You’d gotten back to the bunker a day later. Exhausted from the heat, satiated by the relief from the iceman. You’d found Sam organizing and labeling ingredients in his witchcraft cabinet. He was going to try a few new spells from Rowen’s bequeathed library. Realizing he needed some specialty items, he had to head up Nebraska way to meet with an herbalist who sourced supernatural spices.

Dean hovered near the cabinet, picking up jars, and mumbling pronunciations to himself. Sitting on a nearby stool beside a podium meant to support hefty grimoires for spellbook incantations, you chuckled at Sam’s constant swatting of Dean’s hands with each new inspection. You stared at Dean with your best telepathic “stop playing with your brother’s toys” look.

He frowned, relented, and placed a tincture back on a shelf. “That dude, Elijah?”

“Yep,” Sam huffed.

“What’s so important you gotta get right now?” Dean shrugged.

“Nothing important. I found a couple of spells that can change atmospheric pressure and manipulate temperature shifts. Was thinking those could come in handy in the greenhouse. Planning some experiments with out-of-season fruits and vegetables or plants that usually can’t grow in our area.”

You smiled. Sam had become quite the gardener the past year.

Sam eyed Dean in a way that cued me in on the fact that they had something private to discuss. Dean shot you a gentle “get the fuck out” request with raised brows and a head tilt.

“Alright, I’m gonna get unpacked.” You slapped your thighs and gave Sam a forearm squeeze as you passed. Dean tapped your ass on your way out.

You closed the door but lingered long enough to hear Sam, “I figured you were still planning something for-”

“Keep it movin’, sweetheart!” Dean bellowed.

You sighed and smiled to yourself. Dean had a surprise in mind for your anniversary.

~

You’d gone along with Dean’s ask for you to head out solo and grab beers and other supplies later that afternoon. Sam was well on his way to Nebraska by then. And, even if you didn’t play dumb well, you could give Dean time to do whatever it was he was doing for you.

Neither one of you was terribly romantic, but Dean could on occasion whip up the softest, cuddliest little moments.

So, two hours later, as Dean had nonchalantly yet specifically detailed for you to return, you stood outside the bunker door and readied for an anniversary celebration for the books.

Instead, after a hefty pull and the rattle and creak of the iron cell-like door, a plume of smoke released and assaulted your senses. Your eyes watered and you began to cough.

Beer and supplies dropped outside the threshold, you covered your mouth and nose with the collar of your T-shirt and darted inside. You crab walked down the stairs, below the cloud of smoke that hovered at the ceiling. Emergency flood lights flickered over the war room, washing it in an eerie red glow.

The bunker door slammed shut when your boots hit the ground floor, but that never happened. Some sort of automatic electrical protocol engaged for a lockdown scenario?

“Dean!” You tried your best shout to carry through the cavernous levels. He wasn’t in the library and the source of the smoke wasn’t anywhere near your current location. You dashed to the kitchen to what you assumed held the source.

You rounded the kitchen entrance. The contents of a heavy stock pot flicked with flames and churned out thick puffs of smoke on the stovetop. Your heart stopped, finding Dean splayed on the floor by the oven. Your eyes widened. Your coughing worsened at the acidic, burning taste filling your nose and mouth.

“Dean!” you called out again between wheezes. In the hazy film of smoke you spotted his head roll at your voice. You surveyed the area in seconds. You dropped to your knees and crawled over to him. You nestled by his side, grabbed his face by the jaw and jiggled. “Dean?”

“Hm?”

“Are you alright?”

His lids flitted open. Upon a deep inhale, his coughing fit began.

You’d freak out and try to figure out what irritant or poison was in the smoke later. For the moment he was alive.

After shielding him from further smoke inhalation, you dragged him by his ankles out of the kitchen unceremoniously up and over a step. The back of his head cracked onto the granite with one of your sharp tugs. He cursed into a terry kitchen towel you’d wrapped around his mouth and nose. About 20 yards into the shit show of a rescue he had enough awareness to flip onto his stomach and urge you that he could manage.

You hopped up, lungs on fire, and ran back into the kitchen despite his yelling and a failed attempt to hook his hand around one of your shins. You grabbed the fire extinguisher in the kitchen corner, pointed the nozzle at the pot, and, from a safe distance, sprayed the flame retardant all over the stove.

The fire was finally out and with it the smoke production.

A familiar smell wafted through the heat now that the flames had dissipated. Roasted Pork? Barbecue?

Arms dropped to your side. They were heavy and searing from the exertion. Tears poured from your eyes. Through blurry blinks as the scene cleared, you spotted a tiny glass jar a few feet from where you’d found Dean.

The extinguisher clattered to the floor. You picked up the jar, examined it with a sigh, accompanied by many more coughs, and trudged your way back to Dean.

He was sat on the floor, back against one of the hall walls. He clutched the towel that had been wrapped around his face. He looked up at you with tear-streaked cheeks beneath the flashing red floodlights. “Thank Christ,” he wheezed out.

“You alright?” you asked and fell to your knees beside him. One hand steadied yourself on his thigh.

He nodded.

You waited a few agonizing minutes with him, gaze steady on each other. The air cleared as each second ticked by, enough for you to both begin to breathe with some regularity. The coughs subsided. His hand clutched yours and squeezed.

You pulled your phone out and dialed Sam.

“Hello?”

“Hey, Sam.” You swallowed, throat dry. “Got a question for you,” you rasped.

“Yeah, sure. You okay?”

“Just peachy.”

You watched Dean’s face begin to redden for another reason.

“Curious, what’s this firecracker pepper do from your stash?”

Sam’s silence on the other end didn't bode well. “Why?”

“I’m guessing it’s not an herb you’d use for culinary experiments.”

After three more beats. “He didn’t?”

“Yep, he did.”

“Holy shit! That stuff is highly combustible! It’s meant to oxygenate a fire and sustain it for a prolonged period.”

“Gathered that. Anything we should worry about with substantial smoke inhalation?”

“Nothing more than the usual. I can be back in a few hours.”

“No, no, we’re good. He’ll clean up his own mess.”

Dean frowned.

“You sure?”

“Absolutely. You enjoy your time away from us.”

Sam sighed. “For fuck’s sake. Never a dull moment.”

“Not with your brother it isn’t. Talk soon.”

You ended the call and stared at Dean. Hard. “Dean?” you prodded.

“We were out of pepper!” His shoulders lifted and met his ears.

“I was out getting supplies!”

“If I’d asked you to get pepper you’d have known I was cooking!”

“I already knew you were cooking for our anniversary, Mr. Not Subtle!”

“I wanted to surprise you,” he murmured. “We missed celebrating the way I’d planned because of the hunt. I was making those spicy pulled pork sandwiches you love with all the extra chiles. I tossed some of the pepper in and this fucking flash bomb happened. I jumped back and lost my footing. Hit my head and that was all she wrote.”

You leaned in to feel the knot on the back of his head. “You probably have a concussion.”

He shrugged. “Nothing new there. I’ll be fine.”

You fumed, nostrils flared. “How can you be so, so-” you tossed your hands in his direction, “-this!”

He dared to toss you a cheeky grin.

“Dean, it’s not funny! You could have burned the bunker down and who knows what could’ve happened to-”

He grabbed your face with both hands. Quietly, he stated, “I would burn down the world for you.”

“Don’t do that.” You whispered. “You aren’t gonna get out of me being mad at you.”

He smiled. “Good. That means we can finally have angry make-up sex.”

You pursed your lips together and swallowed down a laugh.

His expression turned serious. “I made a mistake. It happens. I’ll clean up the mess in the kitchen.”

The thunder in your chest faded away. “You can be so careless sometimes.”

He nodded.

“You just act first, think later.”

He nodded.

“Well, you're right that you’re cleaning up all that mess and whatever the hell you did to the bunker.” You pointed down the hall to the kitchen and up at the lights.

He nodded. “Absolutely, sweetheart.”

You rolled your eyes. “Fine! You can kiss me now!”

He repeated. “Absolutely, sweetheart.”

#jacklesversebingo23#dean winchester fan fiction#dean x reader#dean x you#dean winchester#dean winchester x reader#dean winchester x you#dean winchester x female!reader#supernatural#spn#dean winchester fanfiction#supernatural fanfiction#spn fanfic#dean winchester fanfic#dean winchester fic

119 notes

·

View notes

Text

the isekai thing where,

Hey this post is too long and i'm not fuckin editing down my stream of consciousness tumblr post because it's dumb anyway.

, because of weird inscrutable genre stuff, the protagonist often can't just be The Strongest Person In The World or like recruit all the strongest people into their party or learn magic or something, or use modern medicine to save lives or whatever, they need to also like. Be a business owner. and they can't just like- like, they always Invent Soap (Note: Soap existed already) or whatever, and to be fair, inventing the bessemer process is often a pretty good one.

but no they also need to be like, importing japanese cultural products (sometimes korean! when it's a korean one. duh.) to the fantasy world, which are universally beloved because obviously japanese cultural products are great and applicable everywhere. like, every medieval noble wants to wear a yukata. and like, they can never just have one business either, they have to do like 20 things and each member of their cast has their own subsidiary business (which lets you get rid of some of the cast members because theyre successfully doing their own thing, i guess). but like okay yknow. one of the ones they *always* want to do, because food is such a big thing for culture, is open a restaurant. and it's like, guys, the economics on this are insane.

(First off, this was prompted by the summer 'when a book is set in year A and written in year B and the author refers to X dollars, do they mean X dollars in year A or are they automatically translating to the equivalent year B monetary value' which presumably is talking about real life stuff)

but like dude, when these fuckin isekai protagonists open a fast food restaurant and they bill it as 'the genius idea is that we'll sell to the lower class and get a bigger market' like. first off, they had restaurants or similar equivalents back then. like, thats part of what the tavern was for. and the wealthy people could afford to just have chefs on retainer. but secondly, those peasants are not paying extra for your insanely expensive spices on your Japanese Ramen or Korean Fried Chicken In Medieval Europe. like the protagonist always has to find how some rare plant or monster part tastes exactly like the right ingredient they were missing and they're like, oh FINALLY i can eat some of the cuisine i've been missing. and then they open a restaurant.

and it's like no go back a second this shit was rare as hell you can't sell that to poor people. like dude that medieval milk soup (btw. Whats up with that. Max Miller made a video on one that was like, essentially the milk from your bowl of cereal where it was full of cinnamon and sugar. but he mentioned that there were actually savory milk soups with meat and vegetables in it, and he just isnt doing one of those. And that's like, obviously the more interesting one, and is the one you see in some of those isekai that makes you go What The Fuck Is That? Like for real what was in that. Whats up with the milk soup) was cheap as fuck. like the cows just make the milk. and like bread is bread. like the food isnt gonna be total dog shit, it's still fresh food, they have some herbs and spices just not *all* of the ones we have, the maillaird reaction still works the same. you got eggs, mushrooms, butter or animal fat. missing some veggies because you havent made contact with south america (although. i mean it's fantasy you can make it up. but they never make the thing they use to make the pseudo-japanese/korean food a super common ingredient because then it would already be in use and the protagonist wouldnt be like craving for a taste of home and then inventing a new cuisine and being super smart and innovative)

Anyway thats that but the other thing is it's insane when a story forgets to do the copper-silver-gold thing and peasants are spending like 20 gold pieces on some Fantasy Meat Skewers or w/e. like you find a treasure chest full of golden ingots and you're like holy shit we're rich but each ingot is only like a hundred sandwiches. (although admittedly i feel like copper still had to be like. pretty expensive back then right? like silver for sure, it seems insane for 10 copper coins to be worth a silver coin, but it also feels insane that you would buy a beer for multiple pieces of like metal that was taken out of the earth and refined from ore and melted into a coin. I guess they didnt have wiring so the value was probably lower)

the main thing though is why the hell are all the isekai protagonists opening like 7 small businesses. thats weird man. they should just be stabbing dragons or whatever why are they like opening a massage parlor. anyone can do that. the comparative advantage is horrible

3 notes

·

View notes

Text

Water also destroys computers, and anything that runs off electricity, so the odds that this cooling process involves dumping the water straight up directly onto the machines seems really, really unlikely. I would assume that water heat sinks involve pumping cold water through pipes in the machines, not literally dumping water on computers.

The ocean is very, very, very, very big. Also rising. If you consumed as much ocean water as there is drinkable water on the planet, you'd see an effect, sure, but you could literally remove billions of gallons of water from the ocean and have it be a proverbial "drop in the bucket". Since the tides are constantly sloshing the water in the ocean around, there will be no local "we drained a lot of water in this one coastal region so now the water is low there" effects; drain water in one region and the tide will fill it back in more or less instantly. It's the ocean, not a lake.

What you'd have to be careful about is the impact on fish and other sea life so they don't get sucked into the pipeline. Fine grates, maybe pumping in pulses so if a fish gets sucked against the grate the suction will be gone in a second so they can get out of there... maybe there are sounds or colors that could be employed underwater that would drive most sea life away. Don't put the entrance to the pipeline on the beach or directly on the sea bed; it should probably sit inside the water at a reasonably deep coastal level but with plenty of clearance, so as to not suck in sessile creatures who live on the bottom.

The pipeline itself would consume electricity -- the ocean's at the bottom of the gravity well of the planet's surface, you can't use gravity to passively pull the water back out. But by employing wave turbines, you can recapture a lot of the energy you put into pumping back out as power you can reuse. No such thing as a perpetual motion machine, but if by using seawater to fuel solar steam plants in places like deserts you can make back more energy than you had before, you've got a net positive outcome in terms of energy.

Issues to consider:

A salt water pipe breaking would be almost as toxic as an oil pipe breaking. And salt's corrosive to metal. You'd have to be careful what you made it out of, be constantly checking, and have baffles that will drop the moment there's a loss of local water pressure anywhere in the pipe, and a means of instantly and automatically stopping the pump if that happens. And protection of the pipeline to stop bad actors from deliberate sabotage.

Solar power plants can have an impact on the local environment if they block sun that plants and animals need. On the other hand, global warming suggests that what plants and animals need right now is a lot less sun overall, so creating areas of shade in places that don't have them might actually be good for the life in those places.

The whole system requires a lot of industries to cooperate. If solar steam plants or data centers dump their salt in giant piles in the desert rather than letting spice companies sell it as sea salt, this could be very bad for the environment. If rich people are allowed to fill their swimming pools with it, this has enormous political benefits for the pipeline because as soon as the rich feel entitled to it, they will make sure it stays working and stable, but then what happens if the data centers need more and more?

I don't pretend to have all the answers but I don't think any of the difficulties are insurmountable. Humans are using very, very little of the resource of ocean water, on a planetary basis... a resource we're getting more and more of as the seas rise, and as the heat dries up freshwater sources on land, we're going to need desalinization on a massive scale. Integrate that desalinization with industries that need to use water but it doesn't have to be fresh water, especially industries that could turn moving water or heated water into power in a way that's clean, and we could build a system that helps to solve multiple problems at once.

(BTW, this is not an issue of AI. This is an issue of data centers. The whole goddamn internet is to blame, not just AI, and even if AI collapsed and burned tomorrow we would still need to do something about cooling our data centers without using up drinkable water.)

64K notes

·

View notes

Text

Food Coating Market Report: Competitive Landscape & Future Trends

United States of America – The Insight Partners is delighted to release its latest market report, "FOOD COATING Market: An In-depth Analysis of Opportunities and Trends". A comprehensive report, this offers a complete picture of the market and examines current trends, important challenges, growth opportunities, and future prospects.

Overview

The FOOD COATING industry has undergone drastic transformation in the last few years due to the demand for improved food aesthetics, texture, and shelf life by consumers. Although certain market sectors have witnessed high growth rates, other sectors have been hampered by sustainability and regulatory pressures. This report explores the drivers behind these changes technological innovation, updating regulations, and changing consumer behavior all of which are transforming the future.

Key Findings and Insights

Market Size and Growth

Historical Data & Forecast: Food coating market is anticipated to record a CAGR of 6% through forecast period.

Key Growth Drivers:

Growing demand for convenience and ready-to-eat food.

Expansion in the bakery, confectionery, and processed meat industries.

Growing emphasis on clean-label and functional ingredients.

Use of automated coating technologies in food processing facilities.

Get Sample Report: https://www.theinsightpartners.com/sample/TIPRE00004454

Market Segmentation

By Type

Fats and Oils

Cocoa and Chocolates

Spices

Flours

Starches

Syrups and Sugar

Salts

Hydrocolloids

By Application

Confectioneries

RTE Cereals

Dairy Products

Bakery Products

Nutritional Snacks and Bars

Meat and Poultry Products

Fruits and Vegetables

Based on Mode of Operation

Automatic

Semi-Automatic

Identifying Emerging Trends

Technology Advances

Establishment of automatic and continuous coating lines to boost efficiency and lower labor expenses.

Application of nanoencapsulation in coatings to increase nutritional value and stability.

Creation of sustainable and plant-based coating materials to address environmental and vegan demands.

Evolution of Consumer Preferences

Consumers are turning to natural, organic, and clean-label coating ingredients.

Rising interest in gluten-free and allergen-free coatings.

Preference for coatings with health-enhancing benefits like protein or fiber addition.

Regulatory Changes

Strict food safety and labeling rules by organizations like the FDA, EFSA, and FSSAI are forcing manufacturers to rethink and revalidate coating ingredients.

Increased attention on the addition of artificial additives and trans fats in coatings is forcing the industry to seek out natural alternatives.

Growth Opportunities

Plant-based and allergen-free coating innovation presents opportunities to new consumer bases.

Asia-Pacific and Latin American emerging markets offer high growth opportunities based on accelerating urbanization and consumption of processed foods.

Partnerships with QSR chains and foodservice companies for tailored coating applications.

Expansion of e-commerce and online food delivery sites, which enhances demand for longer shelf-life products and improved visual appeal.

Conclusion

The FOOD COATING Industry: Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast Period report offers valuable insights for entrepreneurs, investors, and companies aiming to start or extend a business in the sector. With comprehensive analysis of market trends, competitive environment, technological advancements, and regulatory factors, the report facilitates data-driven decision-making to drive business prosperity and capture new opportunities.

About The Insight Partners

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

0 notes

Text

Spice Processing Plant - Leading Manufacturer of Spice Milling Machines

Flourtech offers spice processing plants equipped with fully automatic machinery for grinding and processing a variety of spices with precision.

#spicemakingmachine#spiceprocessingmachine#spiceprocessingplant#spicemakingmachineprice#fullyautomaticspiceprocessingplant

0 notes

Text

Pour, Pack, Preserve: Nichrome’s Packaging Powerhouse Arrives at ProPak East Africa

Packaging is experiencing a significant shift in Africa. Manufacturers in the Africa region are seeking smart, scalable solutions due to rising consumer interest, growing agro and dairy industry. ProPak East Africa 2025, the region's most significant and influential processing and packaging exhibition, is at the heart of this evolution. And, Nichrome is once again at the forefront.

With a rich legacy of experience, Nichrome has transformed the way brands package milk, grains, pulses, powders and liquids in India. Our focus at ProPak East Africa is not solely on machines, but also on facilitating new possibilities. Our show floor will showcase a powerful combination of state-of-the-art technology, application-specific engineering, and deep understanding of African market dynamics.

We're offering end-to-end packaging solutions for your business at an advanced level, so take a look at what Nichrome is exhibiting at ProPak East Africa 2025.

Liquid Packaging Solutions: Edible Oils, Detergents & Beyond

Handling liquids and ensuring their seals are free of any contamination. Filpack Servo 6K, FilPack Servo 12K and Filpack CMS 5L are Nichrome's VFFS and High Fidelity Flavors (HFFS) liquid packaging machines that can process edible oil sack or detergent pod fillings.

Edible Oils

Edible Oil Packaging Machine solutions come in the form of multi-layer, nitrogen-flushed pouches that retain freshness.

With servo-driven accuracy, our Bottle Filling Capping Machine lines, including the Filpack Universal bottle filler, can safely fill up to 6,000 bottles/hr.

Detergents & Powders

Our detergent packaging machine integrates an auger filler for powders and a volumetric cup filler for granules, ideal for washing powder and detergent sachets.

Washing Powder Packaging Machine setups feature quick‑change feed screws to switch between coarse and fine powders in minutes.

Mini Dairy Plant & Milk Packaging:

Hygiene and consistency are essential aspects of any dairy production. Our mini dairy plant puts pasteurization, homogenization, and pouch‑packing under one roof—ideal for small to medium cooperatives and private dairies.

We pioneered India’s first milk pouch packing machine in 1977, and today our milk filling machine range includes:Filpack Universal, Excel 400 and Filling lines.

Why settle for generic when you can get application‑specific? Our automatic powder packaging machine and bottle filling capping machine keep your line flexible, moving from edible oil pouches to detergent sachets with ease. We guarantee our products will never break.

Powder & Granular Packaging: Speed, Accuracy & Versatility

From sugar to spices, our powder and granule systems are built to scale. At ProPak East Africa, we’ll demo:

Powder sachet packaging machine for milk powder, RTE mixes, and spices

Volumetric cup filler units for rice, pulses, maize, and wheat

Auger filler packing machine modules for fine powders like flour and detergent

Key machines on display:

Excel 400 with Servo Auger Filler: Packs up to 400 sachets/min with ±1 % precision.

Sprint 250: Compact, high‑speed VFFS for small‑batch runs of spices and coffee.

Flexible 450: Multi‑lane powder sachet packaging machine—perfect for RTE coffee mixes.

Our solutions are suitable for center, threeside, gusseted, and zipper pouches, which can be used with rice packaging machines, maize packaging machinery, or wheat packaging equipment. Changeovers are now simple, meaning you can easily switch from sugar to coffee packaging machine formats.

Agrochemical & Seed Packaging: Precision Under Pressure

Agribusinesses require machines that handle corrosive chemicals and bulk seeds with extreme care. Enter our seed packaging machine and Pulses Packaging machine lines:

Anti-corrosive contact parts and dust-tight enclosure design are hallmarks of our seed packaging machine units.

Various pulses packaging machines are equipped with nitrogen flushing to prevent rancidity.

Our automatic powder packaging machine can control the dosage of powdered pesticides and fertilizer, while our powder packaging machines with multitrack heads achieve rates up to 1,200 packs/min. The ability to customize powder sachet packaging machine configurations for 5 g–50 ml is essential for small dose agrochemicals.

Our agro line is built with safety in mind: emergency‑stop interlocks, ATEX‑rated motors, and full CE certification. When you need a seed packaging machine that won’t quit halfway through planting season, you know who to call.

Tea, Coffee & Snack Packaging: Freshness You Can Taste

The scent of freshly ground coffee or crunch of your favourite snack is omnipresent almost everywhere, making it imperative that your packaging machine maintains that aroma and taste.

Coffee & Tea

Our Coffee packaging machines are equipped with features such as nitrogen flushing, vacuum sealing, and tamper‑evident sachets for singleserve and bulk configurations. Our cup filling sealing machine can divide leaf tea into individual cups with the lid applied automatically for tea delivery.

Snacks & Yogurt

The cup filling lines deliver up to 240 cups/min for pudding, yogurt, and RTE noodles. Coupled with our cup filling sealing machine, you get leak‑proof seals—crucial for chilled snacks. And yes, our Yogurt Packaging Machine ensures creamy consistency every time.

Whether you’re in the chai business or snack aisle, Nichrome has you covered: from Sugar Packaging machine sachets for traditional tea to multi‑serve coffee canisters.

Why Nichrome is Africa‑Ready

To cope with the exceptional conditions in Africa, machines must be robust enough to handle humidity levels, voltage fluctuations, and dust. We've invested in:

Local service hubs in Kenya, Uganda, Tanzania, Rwanda, and Nigeria

Tech‑savvy field engineers who speak Swahili, English, and French

Customized voltage stabilizers & heat‑resistant components

Our ROI calculators show payback in 12–18 months for mid‑range lines—thanks to reduced labour, lower scrap rates, and 24/7 reliability. We calibrate each rice packaging machine, maize packaging machine, and milk filling machine for local SKUs, ensuring your line doesn’t hiccup when you switch from 500 ml milk pouches to 50 g coffee sachets.

We’re not just here to be at booth C5, we’re to be your long‑term partner. From training your team on the mini dairy plant to stocking spares for your Detergent Packaging machine, we stand behind every solution with genuine, end‑to‑end support.

Ready to Package Smarter? Join Us at ProPak East Africa 2025

At Nichrome, we don’t just sell machines—we build packaging ecosystems designed to grow with you. Every solution we showcased at ProPak East Africa 2025—from the versatile Filpack CMD Alpha and compact mini dairy plant, to our advanced powder sachet packaging machines and bottle filling capping lines—is engineered with purpose. Whether it’s a milk pouch or a detergent sachet, a spice pack or an agrochemical dose, we customize and deliver with precision, speed, and scalability. Join us at:

Date: May 20–22, 2025

Venue: Sarit Expo Centre, Nairobi

Stall No.: Booth C5

Swing by to see live demos of our Filpack CMD Alpha, Excel 400, Sprint 250, and integrated mini dairy plant in action. Chat one‑on‑one with our experts, get tailored proposals, and pick up show‑only deals. We can’t wait to help you scale up, streamline, and dominate your category.

FAQs

1. Can Nichrome customize packaging machines for my specific product or pouch format? Ans: Absolutely! Whether you need a powder sachet packaging machine, rice packaging machine, bottle filling capping machine, or a cup filling sealing machine, Nichrome offers modular configurations with flexible fillers (auger, cup, weighers) and pouch styles (3-side seal, gusseted, zipper). We even help with product trials and format changeover support for smooth commissioning.

2. How do Nichrome machines handle sensitive products like dairy, detergent, or seeds? Ans: Our machines are engineered with product-specific technologies—like nitrogen flushing for milk and seeds, anti-corrosive components for chemicals, and hygiene-first designs for dairy. For example, the Yogurt Packaging Machine ensures cold-chain integrity, and the Automatic Powder Packaging Machine features dust-free enclosures for fine detergents or agrochemicals.

3. Does Nichrome provide after-sales support in East Africa? Ans: Yes! Nichrome has established service hubs across Kenya, Uganda, Tanzania, Nigeria, and Rwanda, with multilingual engineers and ready access to critical spares. We offer training, remote diagnostics, AMC packages, and performance optimization to ensure that every sugar packaging machine, seed packaging machine, or pulses packaging machine runs at peak efficiency.

4. What’s the ROI on investing in Nichrome’s packaging automation? Ans: Our packaging systems deliver ROI within 12 to 18 months, thanks to higher OEE, reduced wastage, and lower labor dependency. For instance, our mini dairy plant can reduce manual operations by 30% while increasing output with consistent quality. We also provide ROI calculators tailored to your product and throughput goals.

5. Why should I visit Nichrome at Propak East Africa 2025?

Visiting Nichrome at Propak East Africa 2025 means experiencing packaging innovation firsthand. You'll get to know more about our innovations across sectors like dairy, edible oils, detergents, seeds, and coffee. It’s your chance to meet our experts, explore tailor-made packaging systems, and get business-specific consultations that can future-proof your packaging line.

#Edible Oil Packaging Machine#liquid packaging machines#Bottle Filling Capping Machine#detergent packaging machine#Washing Powder Packaging Machine#mini dairy plant#milk filling machine#automatic powder packaging machine#Powder sachet packaging machine#rice packaging machines#maize packaging machinery#wheat packaging equipment#seed packaging machine#Pulses Packaging machine#Coffee packaging machines#cup filling lines#Yogurt Packaging Machine#Sugar Packaging machine#bottle filling capping lines

0 notes

Text

Top-Notch Blower Pulverizer Machine for Grinding Spices at the Lowest Price

Investing in high-quality machinery is a must if you want to make spices. The Blower Pulverizer Machine is a top-notch spice grinder because it blends cutting-edge technology with affordable price. We'll go over the many uses for this machine and how to save money on it so you can add it to your spice processing arsenal.

What is a Blower Pulverizer Machine?

To make fine powder from grains, spices, herbs, and other food items, an industrial-grade grinder called a blower pulverizer machine is utilized. Importantly, the blower function sends the tiny particles to a cyclone separator automatically, which guarantees a uniform texture and reduces waste.

This type of machine is perfect for spice producers who want to:

Produce consistent, fine powder from a variety of spices.

Ensure minimal wastage during processing.

Increase productivity with a high-speed, efficient system.

Key Features of the Blower Pulverizer Machine

High Grinding Capacity : Medium- to large-scale spice production plants will find this machine to be ideal because to its ability to handle massive volumes of spices. From cumin and chili seeds to turmeric and coriander, it grinds it all.

Efficient Blower System : For effective and clog-free delivery of ground material to the storage area or packing unit, the integrated blower system is in place. Additionally, it aids in cooling down the equipment, which in turn reduces wear and tear.

Fine and Uniform Grinding : For consistent flavor and product quality, use this pulverizer with an adjustable mesh system to grind all spices to a uniform particle size.

Energy-Efficient Design : The blower pulverizer machine is designed to preserve energy while operating at high speeds, which is great for your bottom line because it decreases electricity use.

Low Maintenance and Easy Cleaning : This machine's long-lasting construction means it won't break down or cost you a fortune in repairs. As an essential component of any food production setup, it is also simple to dismantle and clean.

Benefits of Using a Blower Pulverizer for Spices

Boosts Efficiency: You can process big batches with ease, meeting market demand.

The quality of your finished goods will always be higher if you grind your spices finely and consistently so that they have a stronger scent and flavor.

Reasonably Priced: This machine provides excellent value for the money thanks to its energy-efficient performance and minimal maintenance requirements.

Multipurpose: This adaptable addition to your production line can be used for a wide range of spices.

Finding the Best Price for a Blower Pulverizer Machine

Purchasing a blower pulverizer machine can be somewhat costly; however, by employing the most effective approach, you can secure the most favorable bargain. Make sure you're receiving the best deal on a high-quality machine by following these steps:

Research and Compare : Try to find manufacturers and suppliers that you can trust. Evaluate many models side by side in terms of pricing and features. Buying in bulk or signing a long-term contract can sometimes result in a discount from many manufacturers.

Look for Warranty and After-Sales Service : When purchasing a machine, it's important to consider the warranty and support options before settling on the lowest price. Choose devices with an easily available after-sale support system and a guarantee of at least one year.

Buy Directly from Manufacturers : Cut out the middleman and buy straight from the source. As a result, markups are reduced, and in many cases, manufacturers even provide better deals for direct sales.

Consider Used or Refurbished Machines : Consider used models if your budget is limited. For a fraction of the price, you may get machines that are restored to almost new condition that work just fine.

Final Thoughts

When it comes to preparing spices, a blower pulverizer machine is revolutionary. When it comes to powdering spices, it's an indispensable instrument due to its efficiency, adaptability, and longevity. You can discover high-quality models at reasonable prices if you do your homework and buy from reputable vendors directly.

Investing in high-quality equipment is crucial for the success of any spice business, whether you're just starting out or looking to expand. Your output and revenue will skyrocket once you include the blower pulverizer in your fleet.

#Spice Processing Machine Manufacturers#Masala Processing Machines#Spice Processing Machine Suppliers#Spice Machine#Masala Machines#pulverizer machine#pulverizer machine manufacturers#pulverizer machine suppliers#spice#machines

0 notes

Text

Creature Industry: India’s Largest Food Machinery Suppliers

When it comes to food processing machinery in India, Creature Industry stands as a beacon of quality and innovation. As the largest supplier of food machinery in the country, Creature Industry offers a comprehensive range of equipment designed to meet the diverse needs of food processing businesses. From oil expellers to pulverizers, their products are known for their reliability, efficiency, and superior performance. Here’s a closer look at why Creature Industry is the leading name in food machinery supply and how they can help elevate your food processing operations.

Extensive Range of Food Machinery

1. Oil Expeller Machines

Creature Industry specializes in various types of oil expellers, including:

4 Bolt Oil Expeller

6 Bolt Oil Expeller

9 Bolt Oil Expeller

Mini Oil Expeller

Multi Seed Oil Expeller

Mustard Oil Expeller Machine

These machines are designed for efficient oil extraction from a wide variety of seeds and nuts, ensuring high yield and quality.

2. Packaging Machines

Packaging is crucial in the food industry, and Creature Industry offers state-of-the-art solutions:

Automatic Pouch Packing Machine

Box Strapping Machine

Double Chamber Vacuum Packing Machine

Food Vacuum Sealer

These machines ensure that food products are safely and hygienically packaged, maintaining their freshness and extending shelf life.

3. Pulverizer Machines

For grinding and processing spices, grains, and other food items, Creature Industry provides:

2 In 1 Pulverizer

Blower Pulverizer

Dhaniya Pisne Ki Machine

Domestic Pulverizer

Double Chamber Pulverizer

Grain Destoner

Gravy Machine

Haldi Pisne Ki Machine

Impact Pulverizer

Masala Kandap Machine

Mirchi Pisne Ki Machine

Wet Grinder Machine

These machines are essential for achieving fine, consistent textures in a variety of food products.

4. Grain Processing Equipment

Creature Industry also excels in providing machinery for grain processing:

Fully Automatic Industrial Atta Chakki Plant

Domestic Atta Chakki

Grain Destoner

These machines ensure efficient and high-quality processing of grains, making them ideal for both small-scale and large-scale operations.

Commitment to Quality and Innovation

Creature Industry is dedicated to incorporating the latest technological advancements into their machinery. This commitment to innovation ensures that their equipment not only meets but exceeds industry standards. Each machine undergoes rigorous quality control tests to guarantee durability and performance.

Customer-Centric Approach

Creature Industry understands that each business has unique needs. Their team of experts works closely with clients to recommend the best machinery for their specific requirements. This personalized approach ensures maximum efficiency and satisfaction. Additionally, they offer comprehensive after-sales support, including installation, maintenance, and troubleshooting services.

Benefits of Choosing Creature Industry

Cost-Effective Solutions: Competitive pricing makes their machinery accessible to businesses of all sizes.

Scalability: Whether you are a small startup or a large-scale operation, Creature Industry provides scalable solutions.

Reliability: With a proven track record, Creature Industry is a trusted partner for food processing businesses across India.

Sustainability: Eco-friendly machinery options help reduce environmental impact.

Conclusion

Creature Industry has established itself as India’s largest supplier of food machinery by consistently delivering high-quality, innovative, and customer-focused solutions. Their extensive product range, commitment to quality, and exceptional customer service make them the ideal partner for any business in the food processing industry. By choosing Creature Industry, businesses can enhance their production capabilities, ensure quality, and achieve long-term success.

#atta chakki machine#domestic pulverizer#haldi pisne ki machine#creatureindustry#pulverizer#foodindustry#kitchen equipment#kitchen setup#businessgrowth#foodprocessing

0 notes

Text

Kolkata's AB Polypacks adds a new rotogravure press

AB Polypacks, a West Bengal-headquartered one-stop shop for a wide range of flexible packaging solutions, recently added a 9-color Solomark ELS 6450 rotogravure press from Pelican Rotoflex to its portfolio. The company had earlier added a turret slitter from Pelican.

With its manufacturing facility spread over 1.5 lakh square feet of land in Howrah near Kolkata, the company, which started its journey in 2006, provides a wide range of flexible packaging solutions, including collation shrink films, shrink labels, wrap-around labels, laminates, and all kinds of pouches, under one roof.

The Solomark 6450 has a maximum web width of up to 1300 mm, with a web tension range of 60 to 400N and a reel diameter of 1000 mm. Chinmay Kumar, co-founder of AB Polypacks, emphasized its high energy efficiency with lower power consumption and less waste. “It is user-friendly with better operational ease with better print quality and higher productivity,” he said.

According to Kumar, the machines present in the plant's arsenal for printing, lamination, blown films, shrink labels, and pouching are what set the company apart from its counterparts.

The printing unit, apart from the new Solomark 6450, is equipped with four more high-speed rotogravure printing presses. It has expertise in a diverse range of materials, ranging from polyester and PVC to PET-G, shrink film, BOPP film, foil, and paper.

The blown polyethylene film unit at the plant has a production capacity of 10,000 metric tonnes per annum. The company says it takes pride in manufacturing the best quality three-layer collation shrink film and poly films of a wide variety for lamination.

Speaking about the blown film unit, Kumar said, “Our W&H Optimex extruder provides excellent mechanical strength, and a completely automated machine provides precise operations. The thickness controller ensures easy downgauging and reduces micron variation with minimum wastage.” The major suppliers of plastic granules to the plant are HPL, IOCL, Dow Chemicals, and Borouge.

To provide high-quality packaging material, the manufacturing unit is equipped with fully automatic corona treatment machines such as Nordmeccanica. It is a combi line in which simultaneously solventless and base facility can be utilized.

The pouching unit manufactures various types such as three-sided sealed pouches, central seal pouches, stand-up pouches, pillow pouches, spout pouches, shaped pouches, and various customized pouches as per requirements.

With the entire gamut of flexible packaging solutions under one roof, the company offers its products to the food packaging, liquid packaging, healthcare, and agriculture sectors, the household and personal care sectors, and the spices industry as well.

“High barrier properties along with high aroma retention properties of our packaging material make us the supplier of choice to most of the spices brands in the country,” he said. Multinational brands such as Coca-Cola, Pepsico, Hindustan Unilever, Britannia, Parle Agro, Haldiram’s, Pidilite Industries, etc., form part of the company's key client portfolio.

On the sustainability front, Kumar aims to make solar power the primary renewable source of energy for AB Polypacks by the year 2025. “Through the integration of new technology and machinery, we are wholeheartedly embracing sustainability.” According to Kumar, the company works to reduce waste and energy consumption in the manufacturing process, thereby doing its bit to produce more responsible packaging solutions.

0 notes

Text

Are You Looking for Namkeen Making Machine Manufacturers in India? Gulab Singh and Company

We are leading Namkeen Making Machine Manufacturers in Ghaziabad, Uttar Pradesh, India. We provide snacks like sev, chakli, and bhujia. It typically comprises a mixer, extruder, fryer, seasoning unit, and packaging component. Initially, ingredients like besan and spices are mixed to form dough, then extruded into various shapes, fried until crispy, seasoned for flavor, cooled, and finally packaged. These machines range from small-scale units for home businesses to industrial setups for commercial production. By streamlining processes, ensuring consistency, and offering easy maintenance, Namkeen Making Machines play a crucial role in efficiently meeting the demand for these popular snacks in the food industry.

Product details

Air Pressure: 6 Kg

Machine Dimension: 110 X 164 X 175 Cm (L X W X H)

Oil Capacity: 60 to 100 Ltr

Weight: 350 kg, Approx

Power: 750 W

Voltage: 220 V

Power Source: Electric

Brand: Gulab Singh and Co.

Machine Type: Automatic

Type Of Namkeen: Nylon Sev/Ratlami Sev/Ompudi/Aloo Sev, etc.

Capacity: 50-100 Kg Per Hour.

Best Namkeen Processing Plant Manufacturers in India

Gulab Singh and Company stands as one of the premier Namkeen Processing Plant manufacturers in India. With a commitment to excellence and innovation, we offer state-of-the-art processing plants designed to meet the diverse needs of the snack industry. Our plants are engineered with cutting-edge technology to ensure efficiency, reliability, and superior quality output. From raw material handling to packaging, our solutions streamline the entire production process, enabling clients to achieve optimal productivity and profitability. Trust Gulab Singh and Company for top-notch Namkeen Processing Plants that elevate your production capabilities and set new standards in the snack manufacturing industry.

Contact us right away, if you want to learn more about our wide range of namkeen making machine products. Call us at +91–9953108079 or send an email to [email protected], we are India’s largest namkeen making machine manufacturers and suppliers.

#Namkeen Making Machine#Namkeen Making Machine Manufacturers#Namkeen Making Machine Manufacturer in India#Namkeen Making Machine Supplier in India#Namkeen Making Machine Suppliers in Delhi/NCR

0 notes

Text

Commercial Meat Mixer Machine in India

A meat mixer machine is a device used in the food industry for mixing and blending different types of meat together. It is commonly used in meat processing plants, butcher shops, and restaurants to efficiently combine different types of meat to create various products such as sausages, meatballs, and ground meat.

The machine consists of a large mixing chamber, typically made of stainless steel, where the meat is placed. The chamber is equipped with blades or paddles that rotate to mix the meat together. Some meat mixer machines also have adjustable speeds and timers to control the mixing process.

To use the meat mixer machine, the operator first loads the desired types of meat into the chamber. The machine is then turned on, and the blades or paddles begin to rotate, mixing the meat together. The operator can adjust the speed and time of the mixing process depending on the desired consistency and texture of the meat.

Meat mixer machines come in different sizes and capacities, ranging from small countertop models to large industrial ones. They can also be manual or electric, with some models requiring manual cranking while others are powered by electricity.

In addition to mixing meat, some meat mixer machines also have the capability to mix in other ingredients such as spices, herbs, and seasonings to enhance the flavor of the final product. This makes the machine a versatile tool in the food industry, allowing for the creation of unique and customized meat blends.

Regular maintenance and cleaning of a meat mixer machine is essential to ensure its proper functioning and to prevent cross-contamination between different types of meat. The machine should be thoroughly cleaned and sanitized after each use, and all removable parts should be washed separately.

In conclusion, a meat mixer machine is a valuable piece of equipment in the food industry, providing an efficient and effective way to mix different types of meat and create a variety of products. Its versatility and capability to mix in other ingredients make it a must-have for any meat processing company or restaurant.

Main construction features of meat mixer machine

Two full-metal, shafts with polished mixing paddles Grinded outer surface (not sandblasted) - less rough/easier to clean Grinded interior of the mixing bowl Smooth speed control (inverter) Clockwise and anticlockwise rotations Top lid and unlodaing flap opened/closed manually Manual or automatic (option) control of mixing, automatic unloading programm Kit of safety switches/sensors Heavy, solid contruction 100% stainless steel Total capacity: 300 L Max. filling capacity: 240 kg Power of engine: 4 kW Smooth speed control [r/min] 1-40, inverter Manually opened loading/unloading flaps Safety switches and trolley presence sensor Power supply: 3x400V/50Hz Weight: ~600 kg

0 notes

Text

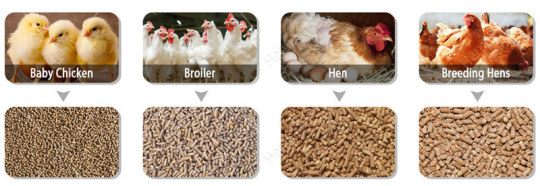

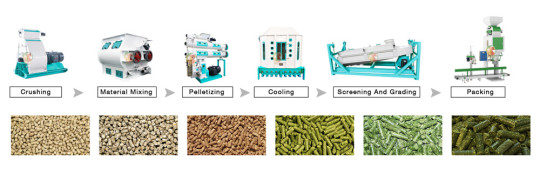

8-10 T/H Chicken Feed Pellet Line Project in Mexico

Mexico will continue to be a major importer of basic grains. Imports of basic grains are expected to continue growing modestly in 2019-20 to meet the growing demand for livestock feed.

youtube

A Mexican customer ordered an 8-10T/H chicken feed pellet machine production line from Herm Machinery, which is mainly used to produce 2-12mm animal feed pellets, such as poultry feed, cattle, sheep feed, pig feed, etc. The best-priced high-performance feed pellet machines from Herm Machinery are of good quality, long life, and low failure rate. Our animal feed production line has become a favorite of many farm users.

With higher consumer incomes, spending on cereals and basic crops tends to decrease, while consumer spending on poultry, pork and beef, milk, and eggs increases. For feed consumption, corn kernels are fed to livestock and poultry in raw form alone or with supplements in compound feed. The animal feed industry is expected to grow slightly in 2020, and the poultry industry remains the main user of feed grains in Mexico, mainly corn.

How To Make Chicken Feed?

1. Raw Material Crushing Section:

The feed grinder can grind the raw material ingredients to the required size. The grind fitness is different for different grinders. We supply four types of feed grinders. The hammer mills are suitable for small-sized or medium-sized feed pelletizing plants. The wide chamber fine grinders and water drop hammer mills are usually used in large-sized and medium-sized feed pelletizing factories. The ultra-fine feed grinder is designed for grinding raw materials of special aquatic feed.

2. Feed Material Mixing Section:

3. Feed Pelletizing Section:

The feed pellet mill is the main equipment of the whole production line. There are two common kinds of feed pellet mills: ring die feed pellet mills and flat die feed pellet mills. If you want to produce feed pellets in large quantities, the ring dies feed pellet mill is the ideal choice. If your demanded quantity is small, you can choose the flat die feed pellet mill. Also, we supply the aquatic feed pellet mill for pressing fish feed pellets and shrimp feed pellets, etc. If you have more questions about customized feed pellet production requirements, please feel free to leave a message or send an email for more support.

4. Feed Pellet Cooling Section:

The feed pellets pressed out by the feed pellet mill are hot and moist. They can't be crushed, screened, or packed immediately. A counterflow feed pellet cooler is designed to cool or dry the feed pellets. It can decrease the temperature and moisture of the feed pellets, preparing for the following sections.

5. Feed Pellet Crushing Section:

Different poultry, livestock, or aquatic feed pellets are of different sizes. Some big ones should be crushed into small ones. Roll-type feed pellet crumbler is just the equipment for feed pellet crushing. Double-roll feed pellet crumbler is suitable for crushing poultry feed, such as chicken feed, duck feed, goose feed, etc. Three-roll feed pellet crumbler is suitable to crush aquatic feed including fish feed and shrimp feed etc.

6. Feed Pellet Screening And Grading Section:

The crushed feed pellets are of different sizes, and there may be some powder. The rotary grading sieve can be used to screen and grade the feed pellets. After processing, you can get the qualified feed pellets without fine powder.

7. Feed Pellet Packing Section:

The feed pellets should be packed for transporting, storing, or selling. Automatic weighing and packing machines can weigh and pack the pellets automatically with high accuracy.

8. Automatic PLC Control System:

With the automatic PLC control system, the production line is with high efficiency and convenient operation.

Raw Material

Cereals: con, wheat bran, soybean, rice bran, sorghum, millet, vinasse, etc.

Proteins and fat: fishmeal, bone meal, soybean meal, peanut cake, cottonseed cake, rapeseed cake, etc.

Additive: spices, sweeteners, molasses, fat, mineral elements.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10-year experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: [email protected]

Whatsapp: 0086 18037508651

0 notes

Text

Revolutionize Your Production Process with a Spices Processing Plant

Can revolutionize your production process with our Spices Processing Plant. Shree Viratra Engineering is a leading Manufacturer of Spices Processing Plant in India. We provide a centralized and efficient facility for cleaning, processing, and packaging your spices. By investing in our Spices Processing Plant, you can improve the quality and consistency of your products, increase production capacity, reduce waste, labor costs, and less manpower required, and expand your market reach.

The Automatic Spices Processing Plant can be customized to meet your specific needs and requirements, with a range of machinery available for sorting, grading, cleaning, and grinding your spices. Depending on the size and scope of your operation, you can choose from a variety of processing technologies, such as mechanical, optical, and electromagnetic sorting systems, and various types of grinders and mills for grinding and milling your spices. In addition to processing, the plant can also provide storage and packaging facilities for your spices, ensuring that they are stored in optimal conditions and packaged in a manner that preserves their freshness, flavor, and aroma. The packaging can be tailored to your specific needs, with options ranging from bulk bags and boxes to retail-ready packaging for consumer sales.

By investing in our spices processing plant, you can take advantage of economies of scale and reduce your production costs, while also improving the quality and consistency of your products. You can also benefit from the expertise and support of a team of professionals who can help you optimize your production process and ensure that your products meet the highest quality standards.

Overall, Our spices processing plant can be a game-changer for your business, enabling you to produce high-quality spices at scale and expand your market reach. If you're looking to take your production process to the next level, consider investing in a spices processing plant today.

0 notes

Text

Elevate Your Grain Packaging Game: Discover Nichrome’s Innovative Solutions

Cereals, the delightful fruits of domestically cultivated grasses, are essential players in the global food scene. Key players include wheat, barley, oats, rye, rice, maize, sorghum, and millets. These staples have fed civilizations since prehistoric times, and their production, storage, and utilization have been pivotal in shaping modern society. With a growing range of cereal-based products on the market, informed consumers are constantly on the lookout for quality offerings.

Each year, over two billion tonnes of grains are produced worldwide, stored at various points along the grain distribution chain—from producer to consumer. These grains are packed into defined Stock Keeping Units (SKUs) like bags, silos, warehouses, containers, and even stacks on the ground, ensuring they maintain their quality and flavor.

Why Store Grains?

Grains need proper storage for several reasons:

Processing is often done away from production sites

Seasonal production requires year-round availability

Emergency reserves are crucial during crises like famines

Seeds must be stored for the next planting season

Nichrome’s Grain Packaging Solutions

At Nichrome, we take grain packaging to the next level. Our automated packaging machines, filling systems, and integrated packaging solutions are designed to meet your grain and seed packaging needs with precision and flair. Our Excel Plus series of food packaging machines combines cutting-edge technology with stringent quality standards to deliver exceptional results for a wide array of products.

Excel 400 Plus Intelligent Electronic Weigh Filler

This VFFS (Vertical Form Fill Seal) packaging machine is a true all-rounder, adept at packaging grains, pulses, sugar, seeds, spices, and tea. The Excel 400 can produce pouches of up to 10 kg at a rapid pace of 80 packs per minute. It offers a variety of pouch formats, including Pentaseal, Pentaseal with D cut, Gusset Pouch, CSPP, and 4 Line Seal pouch.

Key Features:

Print mark scanners for precise alignment

Servo motor-driven bag length control for accuracy

Adjustable cross-sealing jaws for optimal sealing quality

Compliance with stringent quality standards

Seamless integration into upstream and downstream systems

Versatile compatibility with various fillers

Sprint 250 Plus Intelligent Electronic Weigh Filler

The Sprint 250 Plus series is your go-to for speed, accuracy, and efficiency in flexible packaging. Operating with a CE-marked PLC and touchscreen HMI, this automated machine features a servo motor-driven sealing system that ensures packs are sealed to perfection. It precisely pulls the right length of film and includes a perforation system for delivering chains of small pouches.

Specifications:

Packs up to 2 kg pouches at an impressive rate of 120 packs per minute

Supports pouch formats like CSPP and Gusset pouch

Conclusion: Pack a Punch with Nichrome

Packaging is not just a necessity; it’s the backbone of grain storage, processing, protection, and presentation. As staples in the diets of countless individuals, grains deserve packaging that is both functional and cost-effective, maximizing profits while minimizing costs.

Nichrome is not just a packaging machine manufacturer; we’re your partners in understanding the unique challenges and requirements of your products. Our extensive portfolio of Automatic Packing Machines includes solutions for milk, rice, powders, liquids, and more. Our commitment to innovative in-house R&D and robust manufacturing capabilities has helped us establish a strong global presence.

Ready to take your grain packaging to the next level? Let Nichrome be your guide in Africa, where quality meets creativity in every pack. Reach out to us today and transform how you package grains for the better! Learn More: https://africa.nichrome.com/blog/elevate-grain-packaging-game-with-innovative-solutions/

#vffs packaging machine#seed packaging machine#packing machine for food products#grain packing machine price

0 notes

Text

Unexpected surprise

Crush x reader (you guys like each other, a lot)

Genre: fluff & spice. mostly spice

Warnings: suggestive

Key: B/B/F: Boy bestfriend

-----

‘Riiinnngg‘

The bell rang as you quickly packed your bag and went to your locker.

“Y/N.“ Your B/B/F said as he walked towards you and placed his bag in his locker.

“Hi, math was so hard today I am going to fail my test.“ You said, as you pulled your hoodie off and shoved it in your locker, then slamming the door shut.

“Yeah, what are you gonna get for lunch?“

“Hmm, I’m not sure, I plan to go down for a walk first.“

B/B/F nodded and closed his locker door. “I’ll go and take a walk with you.”

“Really? Okay.“

You both walked down the halls and once you reached the staircase, you quickly turned, pulled your eye down and stuck out your tongue, “Race you down!!!”

B/B/F sighed and did not increase in his pace.

You knew he wasn’t going to chase after you, but you still happily skipped down the stairs, and turned around the corner just to open the door-

‘Bam’

You felt as something slammed in front of you, and before you knew it your back was up against the wall.

You opened your eyes to see C/N, with his left hand on the wall right next to your head, pinning you down.

“C-C/N?“ Your face was red, not expecting to see your crush today, especially not with him this close to you.

His breath was tingling your skin as he panted, his dark pupils staring right into you, face pink.

“I can’t do this anymore,“ he muttered, and his lips planted on yours.

His rosy, soft lips were on yours, stealing your first kiss. After processing what happened you fluttered your eyes, and slowly, but surely kissed him back. You felt as his lips were pushed against yours, not once letting you go.

His other hand slowly moved towards your hips, sliding from your shoulders, chest and finally to your waist, planting his firm grip on your side. Your hands automatically went to his hair, ruffling his fluffy dark locks.

You felt his body pushing onto you, placing more force onto your body. His hand sneakily lifted your shirt up, his cold fingers leaving a touch you’ll never forget. Your mouth opened slightly, by surprise and his hot, wet tongue slithered into your mouth, exploring every inch. Your tongue happily swirled around his, both of you getting hotter and hotter by the second.

You felt yourself sweating, due to the steaminess this situation has gotten. His hand moved from the wall to your face, gently cupping your cheek, your face heating up even more. His knee pushed in between your legs, while his hands explored further up your shirt, his whole hand squeezing your waist.

“C-C/N. A-hh Mmm-“

You whimpered under him, who had full control over you.

“I didn’t know you liked me this much Y/N~“ He panted,

“I didn’t know you liked me at all.“ You whispered, pushing your head in his chest.

“I love you.“

You looked up to him, your eyes getting wet.

“I love you too.“

“Damn.“ You hear someone say.

You and C/N quickly turned your heads towards the voice, and you see B/B/F holding his phone, recording the two of you.

“That was cute.“ He commented.

“H- how long were you h- here?“ You panted, running out of breath.

“Since you two started touching each other. Let me show this to everyone- haha~“

-----

Hoped you liked it!! It wasn’t a long one, but it’s pretty cute imo <3 It’s been a while hahahaa follow for more~

~ Lily

37 notes

·

View notes