#automatic snacks packing machine

Explore tagged Tumblr posts

Video

youtube

food packaging machine|#automatic dry fruits packing machine#automatic snacks packing machine

Raw material: Snacks, candy, nuts, potato chips, french fries etc. Capacity:50kg/h-500kg/h https://hnjoyshine.com/products/Granule-Packaging-Machine.html Wechat/whatsapp:8613213203466 #automatic dry fruits packing machine #automatic seed packing machine #automatic dal packing machine #automatic vegetable packing machine #automatic snacks packing machine #food packing machine automatic #automatic food packaging machine #automatic candy wrapping machine #automatic popcorn packing machine

#food packaging machine#automatic dry fruits packing machine#automatic snacks packing machine#puff food packaging machine#potato chips packaging machine#french fries packaging machine

0 notes

Text

Namkeen Packing Machine: Start Your Namkeen & Snacks Packaging Business in 2024

Namkeen packing machine is a sophisticated medium that correctly packages namkeen, some other call for snack treats in South Asian cookery. among the snacks that may be included in this order are sev, sweet potato chips like lime, bhujia, and chiwda.

The critical tendencies of a namkeen packing machine may additionally include automated packaging namkeen quilting machines are often automatic to lessen the want for mortal intervention in packaging.

Read More: Namkeen Packing Machine

#Namkeen packing machine#Snacks packing machine#pouch packing machine#food packaging#Automatic packing machine

1 note

·

View note

Text

Leading Packaging Machines, Packaging Systems Manufacturer | Nichrome

In the competitive landscape of salt packaging, ensuring consistent quality is paramount for maintaining customer trust and product integrity. Nichrome, a leading player in the field, has been at the forefront of delivering high-quality, reliable, and efficient integrated packaging solutions. With a range of our packaging machines, Nichrome leverages advanced technology to meet the diverse needs of the industry. Here's how Nichrome ensures consistent quality in salt packaging.

Our salt packaging machines are equipped with advanced automatic packaging technology, designed to maintain high standards of precision and efficiency. These machines reduce human error and ensure uniformity in every pack, crucial for maintaining the brand's reputation and customer satisfaction.

Precision in Vertical Form Fill Seal Machines

Our Vertical Form Fill Seal (VFFS) machines are engineered for precision and reliability. These automatic filling machines play a vital role in salt packaging by creating secure, airtight seals that preserve the product's quality and shelf life. The VFFS machines ensure that each sachet is consistently filled to the exact specific weight, minimizing waste and maximizing efficiency.

VFFS Saltpack Machine by Nichrome

The Saltpack Vertical Form Fill Seal Machine is a high-speed packaging solution for the salt industry. It is a robust machine with open construction, made of special grade material suitable for salt handling.

The Saltpack machine is designed for long-term performance under continuous operations. It involves the lowest running cost through a reputed CE marked PLC housed in a dust tight electrical panel for machine control.

With optional fillers, Saltpack can also be used for packaging other free flow products and viscous products.

Benefits of using our salt packaging machine

Enhanced Efficiency and Speed: Our salt packaging machines are engineered to deliver high-speed performance, significantly boosting your production capacity. Whether you need small sachets or large bags, our automatic packaging machines can handle high volumes with precision, ensuring that you meet market demand without compromising on quality.

Consistent Quality and Precision: Our filling and sealing machines are critical in salt packaging. Our sachet filling machines are equipped with advanced technology to ensure consistent weight and secure seals for each package. This precision helps in maintaining uniformity across all packs, enhancing product quality and customer satisfaction.

Versatility in Packaging: Our salt packaging machines offer versatile solutions for various packaging formats, including sachets, pouches, and bags. This flexibility allows you to cater to different market segments and consumer preferences, expanding your product range and market reach.

Durable and Reliable Performance: Built with high-quality materials and components, our salt packaging machines are designed for durability and long-term reliability. They can withstand the rigors of daily operation, ensuring consistent performance and minimal maintenance.

Cost-Effective Operations: By optimizing the packaging process, our sachet filling machines help reduce waste and increase operational efficiency. This cost-effectiveness translates to savings on raw materials and labor, enhancing your bottom line while maintaining high packaging standards.

User-Friendly Interface: As an we design packaging machines with user-friendly interfaces that simplify operation and control. With intuitive touch screens and easy-to-navigate menus, your operators can quickly learn to use the machines, reducing training time and increasing productivity.

Enhanced Product Safety: Ensuring that salt is packaged in a hygienic environment is crucial. Our machines are designed with features that prevent contamination, ensuring that the packaged salt remains safe and pure for consumers.

Conclusion

Nichrome’s commitment to quality and innovation in salt packaging is evident in its range of advanced packaging machines. From automatic packaging machines to specialized powder filling machines, Nichrome ensures that every package meets the highest standards of consistency and quality. By leveraging cutting-edge technology and customized solutions, Nichrome continues to set the benchmark in the packaging industry, ensuring that salt packaging is efficient, reliable, and of superior quality. For businesses seeking top-tier packaging solutions in India, Nichrome stands out as a trusted partner, delivering excellence through its comprehensive range of packaging machines.

If you're looking to enhance your salt packaging process, Nichrome's state-of-the-art machines and expertise offer the ideal solution. Explore our offerings and see how you can achieve consistent quality in every pack.

#integrated packaging solutions#packaging machines#Vertical Form Fill Seal (VFFS) machines#VFFS machines#Vertical Form Fill Seal Machine#salt packaging machines#automatic packaging machines#filling and sealing machines#sachet filling machines#automatic filling machine manufacturer#salt packaging#packaging machines india#snacks machine manufacturer#food packaging machine#liquid packaging machine#packaging solutions#namkeen packing machine#packaging machine manufacturers

0 notes

Text

0 notes

Video

youtube

automatic bag filling and sealing machine price|automatic packaging machine

Raw material: Snacks, candy, nuts, potato chips, french fries etc. Capacity:50kg/h-500kg/h https://www.cnyazhong.com/products/Snacks-packaging-machine.html Wechat/whatsapp:8613213203466 #automatic dry fruits packing machine #automatic seed packing machine #automatic dal packing machine #automatic vegetable packing machine #automatic snacks packing machine #food packing machine automatic #automatic food packaging machine #automatic candy wrapping machine #automatic popcorn packing machine

#automatic bag filling and sealing machine price#automatic packaging machine#snacks packaging machine#snack packing machine

0 notes

Video

youtube

automatic bag filling and sealing machine for snacks| food packaging machine

Raw material: Snacks, candy, nuts, potato chips, french fries etc. Capacity:50kg/h-500kg/h https://hnjoyshine.com/products/Granule-Packaging-Machine.html Wechat/whatsapp:8613213203466 #automatic dry fruits packing machine #automatic seed packing machine #automatic dal packing machine #automatic vegetable packing machine #automatic snacks packing machine #food packing machine automatic #automatic food packaging machine #automatic candy wrapping machine #automatic popcorn packing machine

#automatic bag filling and sealing machine for snacks#food packaging machine#snacks packaging machine#potato chips packaging machine#french fries packing machine#puff food packaging machine

0 notes

Note

Can you do a fluff of Sam x pregnant reader?

In which it's almost time for the baby to be born, so she’s constantly tired, so Sam takes over the house chores, even cooking for the pack so the reader can get rest.

Thank youuuuu 🩷

Ouuu this is sooo cute! 🥰 thank you for sending this. Send more 💜

Domesticated wolf pack~ Sam x pregnant reader (The Little Princess part 2)

You were on bed rest. Christmas turned out okay with mild complications, but as it neared your due date in late February, the Sue had to put you on full bed rest due to your heart rate and blood pressure. Genetically, the baby looked perfectly healthy as well as during all the checkups. You were the one with the complications. You figured your little girl was simply being the center of attention, but Sam was not taking chances with either of his princesses. That meant the pack house was in his complete control. He had the whole pack over taking care of the house guarding it as well. Sam was on edge taking care of you that his wolf felt better to have a pack member on guard during these last couple of weeks. It wasn’t all bad, sometimes they played a board game with you to keep you occupied. Others they were simply there while Sam was running errands to make sure you were breathing and alive. They would give you snacks etc, as well as running the home perimeter or just being alert from the couch or porch. Sam often chose the younger wolf like Brady or Collin to give them experience, but also so the more experienced wolves could do the pack job of guarding the Rez….but whoever guarded you was off duty when it came to housework so they were the lucky ones.

As for Sam, and the rest of the pack, they were on domestic duties when not full filling their obligations as a tribe protector. Sam has been running things and giving orders since Christmas as an alpha, and now he has cooking and cleaning duties. He was also driving you insane checking on you. At this point, you worked out a system to leave the bedroom door open through the day to simply give a thumbs up as a sign for him to how you are doing. He was at the point where he asked every five seconds that he passed the room. That was the comprise for his need to check on you, but solving your annoyance at answering 20 questions every five minutes. It helped calm his wolf enough, unless you were having a rough day to which he would be with you 24/7. You needed him so you didn’t mind. He was the only thing getting you through these last couple of weeks, but the baby is due anytime. You are in pain with Braxton hicks, but not too bad. You were mostly huge and miserable. Your blood pressure and heart rate at times could drop and you were feeling as bad as when you get an awful stomach virus. Sam made sure you watch it, as was Sue’s instructions. So he took your blood pressure with your cheap, but accurate, home machine every 15-30 minutes. The automatic reading recorded on an app that both you and Sue could see. That’s the way you were able to rest in your own bed until it was delivery time. You were 38 weeks and Sue said your body was showing your princess would come anytime. Sooner rather than later.

Per that news, Sam was putting the finishing touches on the nursery per your instructions. The bassinet with diapers and wipes storage beside your bed were pushed against the wall for when it would be needed. Sam has all baby shower gifts put away, including help from the guys hanging all the little baby clothes on baby hangers. Compared to giant wolves, the image was comical and a great laugh, along with blackmail photos. Although, the guys would be proud to help their honorary niece. As for Leah and Seth, they were excited likely the most as they were blood family. Seth couldn’t wait!

Sam was putting on chili while trying to clean up the kitchen. Paul was out on vacuuming, and cleaning up the living room. Sam knows you hate dust due to your allergies, but this was more of a nervous tick of Sam’s to make it perfect. It helped him not check on you every five seconds. Seth gladly took bathroom duty just so he could help. He always tried to make a good deal out of a bad one. Leah got over the imprinting situation a while ago, and now she often helps you shower or wash your hair. You really couldn’t do much under Sue’s orders.

“Shut up! Y/N is sleeping finally!” Sam warned the rowdy wolves. “She has had a rough time and it looks like the baby is coming any day. Seriously this place needs to be a sanctuary for my girls.” Jared rolled his eyes a little thinking Sam was exaggerating, but one look from Sam quickly proved the opposite.

Jared was responsible for cleaning up dinner and doing dishes now. Sue was coming to check on you today as you were concerned with some blood pressures. Sam cleaned a little harder for his anxiety. Embry and Quil took off all the empty boxes from the crib, changing table, etc as most items needed assembled. Paul came in to relay to Sam that the vacuuming and dusting was completed. As he saw Sam with an anxious look on his face, he wanted to find out what was wrong as as Sam never looked this way.

“I’m just worried man. That’s my girl well now girls. I don’t mind taking care of the home, but I don’t want anything to happen to her. The heart rate spikes and high blood pressure are getting worse. I’m scared something will happen during delivery where she bleeds out. I’ve read books, heard stories, asked questions, but I feel so lost still.” Paul was quick to give Sam a bro hug as they became very close when it was just him, Sam, and Jared he phased. Paul gave words of confidence. He knew everything would work out. These were likely very normal questions for any new dad. Sam relaxed some after getting to let it all out, but he still felt the nerves.

Sue came and went. You were okay right now, but she encouraged you both to pack a hospital bag if you haven’t already. Stay in bed rest but start recording the harder contractions. You should give birth anytime now, but with your blood pressure if you don’t by next week, they would do a c section. Sue hoped you were able to deliver on your own, but that blood pressure and heart rate is nothing to mess with!

Sam carried you out of the shower and into bed wrapped in a huge fluffy towel. You had to sit to do most activities. He didn’t mind doing it for you. He appreciated the closeness with his imprint and wife. Finally dry, you held your stomach for a moment as Sam crouched down to eye level with his imprint. He saw how scared you were so he started rubbing your back and stomach. This action seems to help, so he got you dressed for bed, as Sam thought it would be a helpful idea to continue the massage so you can relax enough to sleep without pain.

“Let me know if you need anything baby okay? Please don’t hurt yourself to even roll over.” You laughed and replied, “Sam, I’m pregnant, not an invalid. However, thank you for everything these past eight months. You are forever my love.” You kissed him sweetly, and snuggled into his side. You knew nights with sleep were soon to be far in between. “I love you too sweetheart. Don’t ever think I won’t be here for you. You are my heart, my light, and my life. Most important, my beautiful wife. Love you so much.”

Some men aren’t there for their women when a baby or pregnancy is involved, but Sam was the opposite. You never truly had to lift a finger the whole pregnancy. You relaxed into sleep, for the first night in months feeling zero contractions. Sam was at peace as well…here’s to the last few days before full on parenthood.

12 notes

·

View notes

Text

PJO FANDOOOOOOOM

Slice of life days where they make, pack and deliver jam.(Headcannons, i guess)

Just, a bunch of demigods that go with Argus bi-weekly to deliver jam and strawberries to the nearby markets ❤️

And the oldest campers always share the first batch of jam to the little newcomers so they can eat and bond with their cabins.

Demeter kids like to do various mixed jams like strawberry with dandelion etc.

Hephaestus kids wanted to build an industrial/automatic machine so it's easier to make all the jam, but the campers realized that it was a bonding activity for them and the hermes kids broke the machine "by accident".

Also they make bread.

When a camper is claimed, they offer the first jam that they ever made to their parents (one jar to the mortal one, one jar to the godly one).

If they aren't claimed, usually the first batch goes to their most appreciated and looked up to adult(s), impressively, Mr.D has quite a lot of jars in a shelf kinda hidden in the Big House. (Empty in general, some of them have little tokens that remind him of the campers that gave him the jam, some are just covered because it was painful to look at them -because we also need angst-, just two campers know of that shelf, one is Annabeth)

Of course Chiron has a shit ton of empty jars. 🤍

When the campers go on quest (usually 3 people, as i remember) their cabins prepare a bit of jam together as a good luck token for them (they also have some made already in case of emergency and hurries).

If they have a funeral they also burn the last jam that they made together in the cabin, so they can "have a snack" in the underworld.

#i will expand this#believe me#omg i just find it so cute#jam and good vibes#just campers being campers even for a brief moment#also the road trips to do deliveries#pjo headcannons#percy jackson#percy jackson and the olympians#riordanverse#camp half blood#chb headcannons#pjo hoo#pjo fandom

15 notes

·

View notes

Text

JapanQuest 2025 Day 3 – From Tokyo to Osaka: A Journey on the Shinkansen and more Snacks

The morning started slow. I spent most of it resting, writing up this log, and packing for Osaka. Sali, on the other hand, ventured out to find breakfast and returned with a selection of treats from a bakery called Mini One.

She also came back raving about the best coffee she has ever had from Sarutahiko Coffee. Supposedly, this place had won the title of Best Coffee in Tokyo. A strong claim, but she was convinced.

Breakfast included:

Melon Pan – Not like the last one. No melon flavor, just sugar. Nice, but a little disappointing.

Curry Pan – Packed with potent curry flavor. Delicious.

Egg & Ham Bread – A solid and filling choice.

Shortly after, we hit a small snag. Sali lost her Suica card. Without it, she needed a paper ticket, which meant getting cash, since the machines wouldn’t accept cards. A quick stop at a Lawson’s ATM, then the ticket machine. Instead of choosing a specific destination, we had to select a fare amount from the map. Once purchased, the tiny paper ticket was punched upon entry and then stolen upon exit. Drat. Kinda wanted that as a souvenir.

We made our way to Tokyo Station, where Sali replaced her Suica, and we picked up our super express bullet train tickets for Osaka. The menu's were a bit confusing even in English. Before boarding, we stopped for a meal at Taishimi, a restaurant known for beef hamburg steak and grilled ribs.

Despite the name, the hamburg steak wasn’t what you might expect. It was like butter melting in my mouth. The steak was cooked to perfection, rich and flavorful, neither too chewy nor too dry. The ginger ale stood out, too. Unlike the harsh artificial stuff back home, it had real slices of ginger and a smooth, mild taste.

Boarding the Shinkansen

We stocked up on snacks and made our way to the Shinkansen. That’s when we realized. We had bought an super express ticket, but not a fare ticket. Both are required to board. A quick fix at the counter, and we were good to go, with 20 minutes to spare. Lucky we tried to enter the gate early otherwise we'd be out quite a bit of money.

At exactly five minutes before departure, a team of cleaners lined up by the train gates. Three per carriage. The train arrived on the dot, and within five minutes, the entire train was cleaned and prepped for boarding. Efficiency at its finest. Like clockwork.

I managed to get a video of the bullet train arriving. The cleaners didn't seem to fond of being caught on camera. Aren't I just an obnoxious 'American' Gaijin (The joke is all foreigners before they speak are assumed American).

We reserved a Green Car, a premium-class cabin. The difference was immediately noticeable. More leg space. Footrests. Automatic reclining seats. A fold-out table hidden in the armrest. It was a thousand times better than any flight on Jetstar or Qantas and a fraction of the price. The train departed so smoothly that we barely noticed we were moving. A cabin attendant came through, handing out moist towelettes to every passenger.

Settling in, we tried some snacks:

Mitarashi Dango – Expected something sweet, but it was savory with a soy sauce glaze. Unexpected but surprisingly good.

Apple juice – Much sweeter here. Big fan.

Banana & Strawberry Cream Sandwiches – Exceeded expectations. Sali had seen them on TikTok, and they turned out better than expected. Might try making these at home.

Crunky Chocolate – Basically a chocolate rice crispy bar.

Sali made sure we sat on the right side of the train. the Mount Fuji side. She did well as we caught a clear view of the iconic peak.

The train cars tilt when taking turns, almost like how a motorbike leans into a curve. It was barely noticeable but cool to observe while going 320 km/h. Before long, the gentle motion lulled us both to sleep.

We woke up just in time to catch snowfields and a massive mountain in the distance. Shortly after, we arrived in Osaka.

Osaka – A Different Energy

The walk to our accommodation was a bit of a trek, but the place was bigger than our apartment in Akihabara.

After settling in, we wasted no time and headed straight for Dotonbori, Osaka’s neon-lit, food-filled heart.

First stop: Takoyaki. Fresh off the grill, these little octopus balls were hot, the octopus was chewy, and the balls crust melted away.

We also tried strawberry ice cream melon pan. The melon pan was toasted, while the ice cream was smooth and sweet. It worked.

Sali couldn’t resist getting an Tanghulu candied strawberry. Sweet and crunchy, just as expected.

Further on, I fell in love with an small octopus plushie. There was no question. I had to buy the biggest one.

Then came the Kobe A5 Wagyu beef on a stick. It was like butter, incredibly rich yet light, melting instantly in the mouth.

Lastly: A mozzarella 10 yen pancake. Gooey with a faint egg taste. Simple but satisfying. It's a pity it didn't cost 10 yen. It costed 500 yen.

Sidenote: As of today's post 100 yen is close to 1 Australian Dollar. Just imagine that the last 2 digits are cents.

As we wandered through backstreets, we spotted a hidden shrine, the thick smell of incense filling the air. Beautiful. Old style.

Osaka vs. Tokyo – A Different Vibe

Right away, Osaka felt different from Tokyo. The contrasts were impossible to miss:

People talk on trains.

There’s litter.

Pleasantries are not a priority.

Fashion is bolder and more expressive.

Where Tokyo felt sterile, robotic, and service-focused, Osaka felt raw, alive, and unfiltered. While we both liked Osaka, Tokyo suited us more.

Even the stair and escalator etiquette was different. In Tokyo, everyone stood on the left side of escalators. Here? Everyone stood on the right.

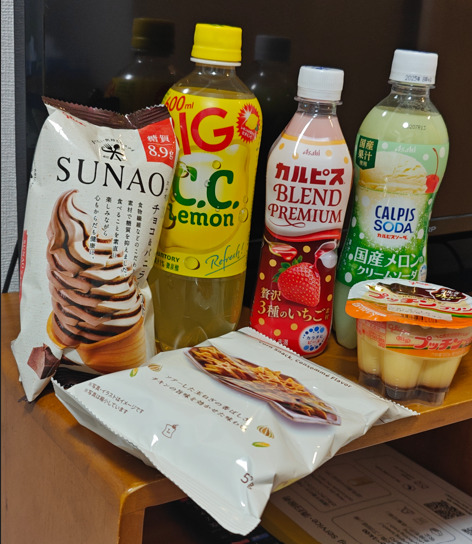

A Final Snack Run and Crashing Hard

Exhausted from the day, we stopped by a Lawson’s for more snacks:

Vanilla & Chocolate Ice Cream – Nothing special. Just okay.

Strawberry Drink – Tasted like strawberry Yakult. Nice.

Calpis Soda – Unexpectedly melon-flavored. Also nice.

With that, we crashed immediately.

While we'll be staying in Osaka one more night, tomorrow morning, we'll be heading over to Kyoto.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] 2 IN 1 SEALER WITH CUTTER: The plastic sealing machine with cutter. COMPACT, LIGHTWEIGHT: Its Compact and Lightweight Sealer easy to carry and use. Type C Charging, Inbuilt Rechargeble Large Battery for longer duration. Recharge with your Type C Mobile Charger. The Vacuum Bag Sealer is suitable for sealing a variety of plastic bag materials, including aluminum foil heat seal bags, plastic snack bags, vacuum food storage bags, food packaging bags, and PVC bags. With its ability to keep chips, snacks, and food fresh and crispy, it can help you reduce food waste and save money. 2-in-1 Heat Sealer with Cutter: This mini bag sealer comes with both heat sealing and blade cutting. Keeping food fresh is much easier with this handheld heat sealer, you can seal food vacuum bags, or chips bags directly to prevent food spoilage. The built-in stainless steel sharp blade helps you open the package quickly and smoothly. Rechargeable Battery: This bag sealer is equipped with a built-in 400 mAh battery. Compared with old-style heat sealer machines, this bag heat sealer is more powerful, and also environmentally friendly since no batteries replacement is required! Normally, a full charge needs 2.5 hours, and it lasts for 10~15 days (depending on the frequency of use). TYPE C cable included. Suitable for Different Plastic Bags: This mini heat sealer machine can reseal various bags to keep food fresh and crispy, such as chips, snacks, sandwiches, candy, pet food vacuum bags, etc, also works for mylar bags, and plastic bags, but is not suitable for a wrap, cellophane bags, kraft paper bags, pure aluminium bags or thin food storage bags. Handheld and Portable Plastic Bag Sealer Mini: This hand held bag sealer mini can be placed on the refrigerator with magnetic on the back, so you can get it very conveniently. Its mini size enables it to be placed anywhere in the house to save space or in bags. Only weighing 0.2 pounds, it's portable to carry out for picnics and camping trips and helps keep food fresh outdoors. No Preheating Needed: Only in 5s, you can regain an airtight bag. This bag sealing machine can be heated very soon, it's a powerful and efficient automatic sealing machine that can quickly heat and seal bags at a stable working temperature. Switch on, and in 1 sec, you can directly seal the package and bag resealed firmly in 5 sec, convenient and time-saving. Power off immediately after use to save battery. Professional Heat Sealer will easily reseal original plastic bags so food will stop being exposed to dust and bacteria. Store food in original packaging help save the Earth. Airtight seal - Create airtight seal and prevent your food from tasting bland and stale and lock in freshness and flavor. Also safely pack cosmetics when traveling. [ad_2]

0 notes

Text

The Evolution of Khakhra Making Machines: From Traditional to Automated

Khakhra, a popular Indian snack made from whole wheat flour, is loved for its crispiness and flavor. Traditionally, khakhra making was a labor-intensive process, requiring a significant amount of manual effort. However, the introduction of the khakhra-making machine has revolutionized this process, making it more efficient and less time-consuming. This article explores the evolution of the khakhra-making machine, from traditional methods to fully automated solutions.

1. Customary Khakhra-making machine

Making khakhra the old-fashioned way required a number of physical procedures. Water, spices, and whole wheat flour were combined to make the dough. The dough was then manually rolled out into thin discs in small pieces. On a heated griddle, these discs were roasted, necessitating continual supervision and hand labor to guarantee uniform cooking and avoid burning. Producing a tiny batch of khakhra was a time-consuming and arduous procedure that frequently took hours.

2. Semi-Automatic Machines' Introduction

The introduction of the semi-automatic khakhra-making machine marked the first notable development in khakhra manufacture. While some steps of the process, including rolling and kneading the dough, were mechanized by these machines, roasting still required human interaction. Machines that khakhra making machines semi-automatically greatly decreased the amount of work required and enhanced output. They enabled small-scale firms to expand their operations and offered a more uniform product quality.

3. Fully Automated Khakhra-making machine

The creation of a completely automated khakhra-making machine marked the next advancement in khakhra production technology. Everything is automated by these machines, including the making of the dough, roasting, and packing. The following are essential components of a fully automated khakhra-making machine:

Dough Kneading: To guarantee consistent quality, the machine automatically kneads the dough to the ideal consistency.

Dough Rolling: The machine rolls out the dough into uniformly thin discs, removing the need for manual rolling.

Roasting: To guarantee uniform cooking and crispiness, the machine roasts the khakhra discs equally on both sides.

Packaging: To maintain freshness, some machines additionally include an automatic packaging function that seals the khakhra in airtight containers.

Benefits of Fully Automatic Khakhra Making Machines

The introduction of the fully automatic khakhra-making machine has brought numerous benefits to the industry:

Increased Efficiency: Fully automatic machines can produce large quantities of khakhra in a fraction of the time required by traditional methods. This allows manufacturers to meet higher demand and increase their market reach.

Consistent Quality: Automation ensures that each khakhra is rolled and roasted to the same standard, resulting in a uniform product that meets quality expectations.

Reduced Labor Costs: With the entire process automated, the need for manual labor is significantly reduced. This lowers production costs and increases profitability for manufacturers.

Hygiene and Safety: Fully automatic khakhra-making machines operate in a controlled environment, minimizing the risk of contamination and ensuring higher hygiene standards.

Scalability: These machines enable small and medium-sized enterprises to scale up their production without a proportional increase in labor costs, making it easier to grow their business.

Technological Innovations

The evolution of the khakhra-making machine continues with ongoing technological innovations. Modern machines are equipped with advanced features such as:

Touchscreen Controls: For easy operation and precise control over the production process.

Energy Efficiency: Machines are designed to consume less energy, reducing operational costs and environmental impact.

Customization: Machines can be customized to produce different types of khakhra, catering to diverse consumer preferences.

The snack industry is undergoing a notable change due to the introduction of fully automatic khakhra-making machines. These machines have transformed the production process, enhancing efficiency, consistency, and scalability to unprecedented heights.

The foremost benefit of utilizing a fully automatic khakhra-making machine is the significant enhancement in production efficiency. These machines streamline the entire operation, encompassing dough preparation, roasting, and packaging. By automating these processes, the reliance on manual labor is diminished, leading to a reduction in production time and an increase in output. Consequently, manufacturers are now able to generate substantial quantities of khakhra in a considerably shorter timeframe compared to conventional methods.

The Khakhra-making machine fully automatic guarantees uniform product quality. By automating the production process, these machines ensure consistency in dough thickness, roasting duration, and overall texture. Such uniformity is essential for upholding a brand reputation and satisfying customer demands. Each batch of khakhra produced by a fully automatic machine adheres to the same elevated standards, providing a dependable product consistently.

The khakhra-making machine fully automatic is transforming the snack production sector by improving efficiency, uniformity, and scalability. These machines provide a variety of advantages, such as heightened production efficiency, consistent quality of products, lower labor expenses, improved hygiene standards, scalability, energy efficiency, and advancements in technology. With the increasing demand for premium khakhra, investing in a khakhra-making machine fully automatic enables manufacturers to maintain a competitive edge and address the changing requirements of their clientele.

0 notes

Text

Comprehensive Guide to Cartoning Machines: An Essential Tool for Packaging

In today’s fast-paced industrial world, packaging has become an integral part of the manufacturing process. Cartoning machines are a cornerstone of the packaging industry, offering efficiency, consistency, and reliability. This blog post will delve into what cartoning machines are, how they work, their types, and why they are indispensable in various industries.

What is a Cartoning Machine?

A cartoning machine is a piece of automated equipment used for forming, filling, and sealing cartons. These machines are commonly found in industries such as food, pharmaceuticals, cosmetics, and consumer goods. Cartoning machines streamline the packaging process, ensuring precision and reducing labor costs.

The primary purpose of these machines is to package products into cartons, which are then prepared for distribution. Depending on the type of machine, the process can include various stages such as erecting the carton, filling it with the product, sealing it, and labeling it.

How Does a Cartoning Machine Work?

Cartoning machines operate through a series of automated steps designed to package products efficiently. Here’s a typical workflow:

Carton Erection: The machine pulls a flat carton from a stack, forming it into a box shape.

Filling: The product, which can be anything from food items to pharmaceuticals, is placed into the erected carton.

Sealing: Once the product is in place, the carton is sealed using adhesive, tape, or other methods.

Labeling: Many machines also include a labeling mechanism to apply barcodes, logos, or other necessary information.

Types of Cartoning Machines

Cartoning machines come in various types, each suited for specific packaging requirements. Below are the most common types:

1. Horizontal Cartoning Machines

These machines are ideal for products that can be slid into a carton horizontally. Examples include soap bars, tubes, and jars. Horizontal cartoning machines are widely used in the food and pharmaceutical industries.

2. Vertical Cartoning Machines

For products that need to be dropped into cartons, vertical cartoning machines are the preferred choice. These machines are commonly used for granular items, bottles, and vials.

3. Wrap-Around Cartoning Machines

Wrap-around machines form cartons around the product, ensuring a snug fit. They are typically used in the beverage and dairy industries.

4. Semi-Automatic Cartoning Machines

Semi-automatic machines require some level of manual intervention. They are suitable for businesses with moderate production volumes.

5. Fully Automatic Cartoning Machines

Fully automatic machines handle every step of the packaging process without manual input. These are ideal for high-speed, large-scale production lines.

Benefits of Using Cartoning Machines

Investing in a cartoning machine offers numerous advantages, including:

Increased Efficiency: Automating the packaging process reduces time and labor costs.

Consistency and Precision: Machines ensure that every carton is packed uniformly.

Flexibility: Modern cartoning machines can handle various carton sizes and product types.

Cost Savings: While the initial investment may be significant, the long-term savings in labor and materials justify the expense.

Enhanced Product Safety: Properly sealed cartons protect products from contamination and damage.

Applications of Cartoning Machines

Cartoning machines are versatile and find applications across multiple industries:

1. Food and Beverage Industry

In this sector, cartoning machines are used to package items such as cereals, snacks, juices, and dairy products. The machines ensure that the products remain fresh and safe for consumption.

2. Pharmaceutical Industry

Pharmaceutical companies use cartoning machines to package medicines, syringes, and other medical supplies. These machines adhere to stringent regulatory standards, ensuring the safety and integrity of the products.

3. Cosmetics Industry

From skincare products to fragrances, cartoning machines help package cosmetics attractively and securely.

4. Consumer Goods

Everyday items such as detergents, soaps, and electronic accessories are packaged using cartoning machines.

Integration with Case Sealers

A critical aspect of modern packaging lines is the integration of cartoning machines with case sealers. Case sealers are machines that close and seal cartons after they have been filled and packed. When paired with a cartoning machine, case sealers provide a seamless and efficient packaging solution. This integration minimizes manual handling, speeds up the process, and ensures the security of the packaged goods.

Key Features to Look for in a Cartoning Machine

When selecting a cartoning machine, consider the following features:

Speed: The machine’s speed should align with your production requirements.

Flexibility: Ensure the machine can handle various carton sizes and product types.

Ease of Use: A user-friendly interface minimizes the learning curve for operators.

Durability: High-quality materials and robust construction ensure longevity.

Integration Capabilities: The ability to integrate with other machines, such as case sealers, is a plus.

Conclusion

Cartoning machines are a vital investment for businesses aiming to optimize their packaging processes. From improving efficiency to ensuring product safety, these machines offer numerous benefits. With the added advantage of integration with case sealers, cartoning machines provide a comprehensive packaging solution for various industries.

As packaging demands evolve, so do the technologies supporting them. By choosing the right cartoning machine for your needs, you can streamline your operations and stay ahead in today’s competitive market. Whether you’re in the food, pharmaceutical, or cosmetics industry, a cartoning machine is a step toward greater efficiency and success.

0 notes

Text

Tanishka Packaging Machines: Leading Pouch Packing Machine Manufacturers in Jaipur, Rajasthan

In today’s fast-paced industrial world, packaging is more than just about enclosing a product. It’s about creating efficiency, ensuring the longevity of products, and maintaining brand integrity. For businesses that require high-quality, reliable packaging solutions, Tanishka Packaging Machines, based in Jaipur, Rajasthan, stands as a prominent name in the industry. As a leading pouch packing machine manufacturer in India, Tanishka is revolutionizing the packaging process with innovative machinery designed to meet the needs of various industries.

Who is Tanishka Packaging Machines?

Tanishka Packaging Machines is a renowned manufacturer of advanced packaging equipment, specializing in pouch packing machines. With years of expertise, the company has become one of the top players in the packaging machine industry in India, particularly in Rajasthan. Tanishka is dedicated to providing businesses with cutting-edge solutions that ensure accurate, efficient, and cost-effective packaging.

Types of Pouch Packing Machines by Tanishka

Tanishka Packaging Machines offers a wide range of pouch packing machines designed to meet the diverse needs of industries such as food and beverages, pharmaceuticals, chemicals, cosmetics, and more. Some of the most popular pouch packing machines manufactured by Tanishka include:

Vertical Form Fill Seal (VFFS) Pouch Packing Machines These machines are perfect for packing granular and powdery products like spices, coffee, snacks, grains, and more. The VFFS machine uses a roll of film to form pouches, fills them with the product, and seals them, all in one continuous process. This is one of the most efficient and cost-effective packaging solutions for high-volume production.

Horizontal Form Fill Seal (HFFS) Pouch Packing Machines For products that need to be packed in horizontal pouches, the HFFS machines from Tanishka offer high-speed, reliable packaging. These machines are ideal for packing products like ready-to-eat meals, powdered food, and other similar items, ensuring minimal waste and maximum efficiency.

Liquid Pouch Packing Machines Tanishka’s liquid pouch packing machines are designed to handle products like oils, beverages, sauces, and other liquid items. The machines are built to fill liquid products accurately without leakage or spillage, making them a preferred choice for businesses in the beverage and food industries.

Multi-Head Weighing Pouch Packing Machines These machines are engineered to handle products that require precise weighing before being packed. Whether it’s grains, pulses, or other similar products, the multi-head weighing system ensures perfect accuracy, reducing product wastage and improving efficiency.

Automatic Pouch Filling Machines Tanishka also manufactures fully automatic pouch filling machines that offer high precision, speed, and consistency. These machines reduce manual intervention and allow businesses to pack large quantities of products quickly and efficiently.

Why Tanishka Packaging Machines Stand Out

When it comes to finding a reliable pouch packing machine in Rajasthan, Tanishka Packaging Machines has built a reputation for quality and reliability. Here’s why businesses choose Tanishka:

Innovative Technology Tanishka Packaging Machines uses the latest technology in designing and manufacturing its machines. With automated features, high-speed packing, and cutting-edge functionality, Tanishka ensures that its customers get the most advanced machinery that boosts productivity.

Customization Options Tanishka understands that each industry has its unique packaging needs. That’s why they offer customizable solutions to tailor machines based on product size, pouch type, production volume, and other specific requirements. Whether you need machines for packing powders, liquids, or solid items, Tanishka can provide a solution that suits your exact needs.

Durability and Performance Tanishka’s pouch packing machines are built to last. Made from high-quality materials and designed for continuous operation, these machines offer long-term durability and minimal maintenance requirements. This makes them a cost-effective choice for businesses aiming for long-term success.

High Efficiency and Speed Tanishka’s machines are designed for high-speed packaging, reducing bottlenecks in the production line. Whether it’s filling, sealing, or labeling, these machines help improve the overall efficiency of the packaging process, saving businesses time and labor costs.

Affordable and Competitive Pricing Despite offering high-quality, state-of-the-art machinery, Tanishka ensures that its packaging machines come at competitive prices. This balance between affordability and quality has made Tanishka a preferred choice for businesses looking for value-driven solutions.

After-Sales Support and Service Tanishka Packaging Machines is committed to customer satisfaction, offering comprehensive after-sales support. Whether you need training on how to operate the machine, troubleshooting assistance, or regular maintenance, Tanishka provides reliable service to ensure smooth machine operations.

Packaging Machines in Rajasthan: A Local Advantage

As a prominent pouch packing machine manufacturer in Rajasthan, Tanishka Packaging Machines provides a significant advantage to businesses in the region. Rajasthan, with its diverse industrial landscape, requires packaging solutions that cater to a wide variety of products. Tanishka has a strong presence in the state, offering local businesses easy access to high-quality packaging machinery.

Being based in Jaipur, Tanishka is strategically positioned to serve not only Rajasthan but also businesses across India. With its local presence, Tanishka can offer quick delivery, on-site consultations, and after-sales services to businesses within the region.

Industries Served by Tanishka Packaging Machines

Tanishka’s pouch packing machines serve a variety of industries, each with its specific packaging requirements:

Food and Beverages: Packaging snacks, spices, powdered foods, liquids, and beverages.

Pharmaceuticals: Packing tablets, syrups, powders, and other medical products.

Cosmetics and Personal Care: Packaging lotions, creams, oils, and more.

Chemicals and Fertilizers: Packaging powders, granules, and other chemical products.

Agriculture: Packaging seeds, pulses, and fertilizers.

Conclusion

For businesses looking for top-notch pouch packing machines in Rajasthan, Tanishka Packaging Machines stands as a trusted manufacturer offering innovative, reliable, and efficient packaging solutions. Whether you’re in the food and beverage, pharmaceutical, or agricultural sector, Tanishka’s advanced machinery can streamline your packaging process, boost efficiency, and reduce operational costs.

With a commitment to quality, customer satisfaction, and long-term success, Tanishka Packaging Machines continues to lead the way in pouch packaging technology across India, especially in Rajasthan. If you’re looking to upgrade your packaging line or invest in advanced pouch packing machines, Tanishka is the partner you can trust to deliver quality and performance.

0 notes

Text

How Nichrome Ensures Consistent Quality in Salt Packaging

In the competitive landscape of salt packaging, ensuring consistent quality is paramount for maintaining customer trust and product integrity. Nichrome, a leading player in the field, has been at the forefront of delivering high-quality, reliable, and efficient integrated packaging solutions. With a range of our packaging machines, Nichrome leverages advanced technology to meet the diverse needs of the industry. Here's how Nichrome ensures consistent quality in salt packaging.

Our salt packaging machines are equipped with advanced automatic packaging technology, designed to maintain high standards of precision and efficiency. These machines reduce human error and ensure uniformity in every pack, crucial for maintaining the brand's reputation and customer satisfaction.

Precision in Vertical Form Fill Seal Machines

Our Vertical Form Fill Seal (VFFS) machines are engineered for precision and reliability. These automatic filling machines play a vital role in salt packaging by creating secure, airtight seals that preserve the product's quality and shelf life. The VFFS machines ensure that each sachet is consistently filled to the exact specific weight, minimizing waste and maximizing efficiency.

#integrated packaging solutions#packaging machines#Vertical Form Fill Seal (VFFS) machines#VFFS machines#Vertical Form Fill Seal Machine#salt packaging machines#automatic packaging machines#filling and sealing machines#sachet filling machines#automatic filling machine manufacturer#salt packaging#packaging machines india#snacks machine manufacturer#food packaging machine#liquid packaging machine#packaging solutions#namkeen packing machine#packaging machine manufacturers

0 notes

Text

#snack machine#automatic packaging machine#food packaging#Snacks packaging machine#Namkeen packing machine#Namkeen packaging machine#Snacks machine manufacturer#packaging machine manufacturers#integrated packaging solutions#innovative packaging solutions#milk packaging machine#packaging machine manufacturer

0 notes

Text

Pillow Filling Machine Maintenance: Tips for Longevity

Many of the small snacks you consume on a daily basis contain confections that are wrapped and produced by a pillow-shaped machine. The packaging design of the automatic pillow packing machine conforms to all relevant national safety and health standards. Automatic pillow packaging machines currently make up a bigger portion of the packaging machinery sector, but as the food market grows, this is anticipated to change.

Although many customers have a basic understanding of what a pillow-type packaging machine is and how it operates, that understanding is limited. Lubricating the mechanical parts, inspecting the electrical components, and replacing the mechanical parts are the three phases involved in maintaining a complete Pillow Filling Machine. Upon closer examination, it becomes evident that these three stages are actually composed of three separate components.

Advice on Keeping Filling Machines in Top Condition through Regular Maintenance

A Typical Cleaning Process:

Establish a daily cleaning schedule. It is to discard any scum. It might have accumulated in the machine. Use the cleaning solutions recommended by the original equipment manufacturer (OEM). It is to lessen product accumulation. It can lead to obstruction contamination and machine failure.

Schedule a Comprehensive Cleaning Appointment:

You should schedule a thorough cleaning for your machine once a week or once a month if it is used frequently. This method entails disassembling any components that come into contact with the product in order to thoroughly clean them. This is a good time to inspect parts like nozzles and seals for wear and tear.

Use the Proper Cleaning Supplies:

The type of cleaning agent to use when filling the product is up to the product itself. For instance, mineral residues benefit from acidic cleaners, while greasy or fatty components are better suited for alkaline solutions. It is possible to get in touch with the manufacturer of the equipment and request guidance on safeguarding sensitive components.

Monitoring Information:

If you keep a thorough log of every cleaning and maintenance activity you do on your filling machine, it will be much easier to identify recurring issues that could require a longer-term solution.

The shelf life of the filler is extended by regular use

Regular cleaning and pillow filling machine maintenance programs should be prioritized with every effort. You may be sure that the filling machine will continue to operate at its best if you incorporate them into your weekly routine. Preventative filling machine maintenance can save a significant amount of time and money in the long run. But it is frequently disregarded or neglected due to the initial expense. Unexpected breakdowns result in downtime. It can affect the bottom line of your business. If your problem is more complicated than what can be resolved by standard maintenance Please get in touch with a qualified Terron India service professional. Maintaining optimal performance from your filling machine is a continuous task that, when executed correctly, significantly enhances your packaging procedures.

Manufacturers must do preventative maintenance on their automatic filling and capping machines. They must do this if they want to preserve superior product quality and minimize downtime. It happens to extend the equipment's lifespan. You can guarantee the smooth and efficient running of your automatic equipment. It can be done by performing routine inspections cleaning lubrication calibration and part replacement. A filling and capping system can result in significant cost savings, higher output, and satisfied consumers over time with the right maintenance.

Last wordsTerron India is the company to call when you need proactive assistance and scheduled preventative Industrial pillow filling machine maintenance. You don't need to search any farther. You can sign up with Terron India to benefit from this. In addition to providing you with priority access to the knowledgeable engineering staff and a single point of contact for direct emergency communication, it will cover parts and labor for many years.

#pillow filling machines#fiber opening and pillow filling machine#Pillow filling machine manufacturers#Pillow filling machine manufacturers in india

0 notes