#automatedpackaging

Explore tagged Tumblr posts

Text

Pharma Packaging with Cutting-Edge

Explore our advanced machines for pharma packaging, designed to elevate your production line. From blister packing to labeling, our solutions ensure efficiency, accuracy, and compliance with industry standards.

#PharmaPackagingMachines#PharmaceuticalPackaging#PackagingSolutions#PharmaManufacturing#AutomatedPackaging

0 notes

Text

Packaging Perfection: Nichrome’s Integrated Solutions for the Food Industry

When it comes to the food industry, there is a high-stakes environment involved where efficiency, hygiene and product integrity are extremely crucial to the success of the brand. We at Nichrome understand this and have dedicated over four decades to designing the most efficient cutting-edge packaging systems that are able to cater to your every need, straight from product handling to warehousing and dispatching.

Nichrome’s Integrated Solutions are here to simplify the complexities that arrive when it comes to food packaging and deliver reliable solutions at every stage.

Innovating for the Future

At Nichrome, Innovation and Solutions constantly tend to go hand-in-hand. We have consistently pushed the boundaries of packaging technology and its achievements. From single pack machines to comprehensive turnkey solutions, our portfolio of wide range solutions reflect a deep understanding of the food industry and its ever evolving demands.

Nichrome’s Comprehensive Packaging Solutions for Every Segment

Our extensive range of packaging systems serves a wide array of food industry sectors, such as:

Snacks & Namkeen: To ensure that your favourite munch always has that perfect crunch, our packaging solutions constantly work on delivering precision portioning and airtight sealing. This also helps in enhancing the product’s shelf life.

Dairy Products: In order to keep your dairy delights safe and fresh, our packaging solutions adhere to the highest hygienic standards.

Ready-to-eat Meals: The demand of convenience in the food segment is ever growing, and constantly meeting this demand are the ready-to-eat meals. When it comes to these meals, efficiency and quality play an important role. Our systems always ensure that the meals reach the consumers in the perfect condition.

Powdered Foods and Granular Products: The reliable solutions that our systems provide is thanks to the precision-engineering that they come equipped with. Because ensuring minimal wastage with maximum efficiency is a key factor when packaging flours, spices, sugar, or any other powdered/granular food.

End-to-end Efficiency ensured with Integrated Solutions

At Nichrome, we are committed to taking care of the complete production and distribution span. This helps in offering an unmatched inconvenience through our reliable packaging systems. From product handling to warehousing and distribution, our systems provide a seamless flow that not only minimizes the manual intervention but also optimises the operations.

Key features of our Integrated Systems:

Automated Filling Machines: These high-speed and accurate filling systems reduce product wastage and maintain consistency across every package.

Advanced Sealing Technology: Our systems offer flexible sealing options for a variety of packaging styles, ensuring airtight and tamper-proof packaging.

Automated Filling Machines: These high-speed and accurate filling systems reduce product wastage and maintain consistency across every package.

Cartoning & Secondary Packaging: These systems simplify secondary packaging processes, offering a wide variety of cartoning solutions tailored to meet any and all customer requirements.

Turnkey Project Management: Our end-to-end solutions take care of the packaging process straight from planning and customization to installation and commissioning. This ensures smooth integration of systems with the existing workflows with minimal transition downtime.

Commitment to Quality & Customer Success

Quality isn’t just a buzzword for us, it is our promise. Every single machine, system, and service is designed to constantly exceed customer expectations.

This is why our support never stops at installation, it also spans to “Aftersales Support.” We have a dedicated team that ensures that every operation is running smoothly, providing timely maintenance along with troubleshooting and required spare parts.

Partnering for a Better Tomorrow

Nichrome’s vision extends beyond packaging. Their solutions are designed with sustainability in mind, reducing material wastage and energy consumption. By choosing Nichrome, businesses not only benefit from superior technology but also contribute to a greener future.

For food manufacturers ready to revolutionize their packaging processes, Nichrome offers more than machines—they offer a partnership built on trust, innovation, and excellence.

Discover the difference Nichrome can make for your business. Visit https://www.nichrome.com to learn more.

#packagingsolutions#efficientpackaging#nichrome#nichromepackaging#foodpackaging#packagingmachines#automatedpackaging#nichromesolutions#automaticbottlefillingmachine

0 notes

Text

#strappingmachine#industrial packaging#box packaging#packagingsolutions#industrialautomation#efficiency#warehousesolutions#supplychain#automatedpackaging#logistics#GlobalPackagingAutomation

0 notes

Text

The Benefits of BOPP Bags for Industrial Packaging

Introduction

In today’s competitive market, industrial packaging is crucial for product safety, brand visibility, and operational efficiency. Among various options, BOPP bags (Biaxially Oriented Polypropylene bags) stand out due to their superior qualities and versatility.

Overview of BOPP Bags

BOPP bags are made from biaxially oriented polypropylene, known for its strength and clarity. The manufacturing process enhances their mechanical and barrier properties. Key benefits include:

High durability and tear resistance

Excellent moisture resistance

Enhanced printability for high-quality graphics

Lightweight nature for reduced shipping costs

What Are the Benefits of Utilizing BOPP Bags?

BOPP bags (Biaxially Oriented Polypropylene bags) offer numerous advantages for industrial packaging. These benefits make them a popular choice across various industries, ensuring that products are stored and transported securely and efficiently. Let’s explore the key benefits of utilizing BOPP bags.

Are BOPP Bags Water-Resistant? Yes, BOPP bags are water-resistant, which is a crucial feature for many industrial applications.

How Stable Are BOPP Bags? BOPP bags are known for their high stability and durability.

Are BOPP Bags Recyclable? Sustainability is a growing concern in industrial packaging, and BOPP bags are recyclable.

Are BOPP Bags Compatible with Automated Bagging Processes? Yes, BOPP bags are highly compatible with automated bagging processes.

How Customizable Are BOPP Bags? BOPP bags offer a high degree of customizability, allowing businesses to tailor the packaging to their specific needs.

Can BOPP Bags Help Your Company Save Money? BOPP bags can help your company save money in several ways.

By understanding and leveraging these benefits, businesses can enhance their packaging strategies, ensuring product safety, cost-effectiveness, and sustainability with the use of BOPP bags.

Finding a Quotation from Formosa Synthetics Pvt. Ltd. for Your Company’s BOPP Bags

To acquire a quotation from Formosa Synthetics Pvt. Ltd. for your company’s BOPP bags, simply visit their website to access detailed product information and then reach out via their contact form or customer service number. Ensure to specify your BOPP bag requirements clearly, including size, quantity, and any customization needs. Requesting samples for quality assessment is advisable, and discussing lead times and delivery schedules will help in planning. Upon receiving the quotation, compare it with other suppliers to ensure competitiveness, and negotiate terms where necessary to optimize your purchasing agreement. This process ensures that you obtain tailored and high-quality BOPP bags from Formosa Synthetics Pvt. Ltd. for your industrial packaging needs.

Conclusion

In today’s competitive market, BOPP bags (Biaxially Oriented Polypropylene bags) emerge as the preferred choice for industrial packaging. Offering exceptional strength, moisture resistance, and enhanced printability, they ensure product safety and brand visibility. Their lightweight nature reduces shipping costs and improves operational efficiency, while their recyclability aligns with sustainability goals. By adopting BOPP bags, businesses can achieve a harmonious balance between product protection, brand enhancement, and cost optimization, driving long-term success and growth.

Read More

#IndustrialPackaging#BOPPBags#ProductSafety#BrandVisibility#Sustainability#RecyclablePackaging#CustomizablePackaging#CostSavings#FormosaSynthetics#Quotation#AutomatedPackaging#MoistureResistance

0 notes

Text

Stick Pack Machine - VGA Automation

VGA Automation stick pack machine is a type of packaging equipment designed to package small quantities of products into long, narrow, and sealed packages called "stick packs." These machines are commonly used in the food, beverage, pharmaceutical, and cosmetic industries for products like instant coffee, sugar, drink mixes, nutritional supplements, energy drinks, powders, liquids, gels, and more.

#VGAAutomation#VGApackingmachine#VGA#vgaautomationStickPackMachine#StickPackMachine#AutomatedPackaging#PackagingMachin#FoodPackaging#BeveragePackaging#stickpacks#instantcoffeepack#sugarpack#energydrinks#liquidpack#powderpack#gelpack#drinkmixes#vgapackingmachine#packingautomation

1 note

·

View note

Text

Dry Fruit Cashew Nut Granule Snack Sachet Packing Machine

Introducing our innovative Dry Fruit Cashew Nut Granule Snack Sachet Packing Machine! Designed for efficiency and precision, it flawlessly packs crunchy cashew nut granules into convenient sachets. With user-friendly controls and high-speed operation, it ensures seamless packaging, maintaining freshness and quality. Ideal for snack manufacturers aiming for streamlined production and superior packaging standards. Elevate your snack packaging with our advanced solution today!

#DryFruit#CashewNut#GranuleSnack#SachetPacking#Machine#PackagingEquipment#FoodProcessing#AutomatedPackaging#SnackPackaging#NutritionTechnology

0 notes

Text

🚀 VidePak FFS Tubular Woven Bags – Efficiency Meets Durability! 🚀

Looking for a packaging solution that maximizes efficiency while ensuring product protection? VidePak's FFS (Form-Fill-Seal) Tubular Woven Bags are the perfect choice for high-speed packaging lines in industries such as construction, agriculture, and chemicals.

✨ Key Benefits of FFS Tubular Woven Bags: ✅ Optimized for Automation: Designed for seamless operation with automated FFS machines, speeding up your packaging process. ✅ Extra Strength: Woven polypropylene ensures these bags can handle heavy loads with ease. ✅ Enhanced Sealing: Reliable sealing properties keep products safe from contamination and moisture. ✅ Space-Saving Design: Tubular construction eliminates side seams, providing better stacking and storage efficiency. ✅ Customizable Options: Available in various sizes, colors, and printing options to fit your brand and product needs.

🌍 Why Choose VidePak?

Advanced technology ensures every bag is crafted to perfection.

Trusted by global clients for high-quality, durable packaging solutions.

A commitment to efficiency, quality, and sustainability.

📌 Explore More: Ready to elevate your packaging? Visit www.pp-wovenbags.com/ffs-tubular-bags/ to learn more about our FFS Tubular Woven Bags.

📩 Let’s Collaborate: Contact us today for customized solutions to meet your unique business needs.

#VidePak #FFSTubularBags #AutomatedPackaging #DurableSolutions

0 notes

Text

How to Fill 20 mm Chocolate Balls into Bottles with King Dispenser Rx Benchtop Tablet Counter

Watch as the King Dispenser Rx, a state-of-the-art semi-automatic dual station tablet and capsule counting and filling machine, effortlessly handles the counting and filling of 20mm blue chocolate balls into bottles with impeccable accuracy and speed. Perfectly suited for a myriad of oral dose and tabletted products, this GMP countertop machine demonstrates its versatility and modern design by managing products up to 25mm in diameter, in counts ranging from 1 to 10,000, ensuring your production needs are met with precision and reliability.

The transparent conical product hopper gently delivers the chocolate balls to the vibratory bowl feeder, where they are meticulously separated, aligned, and counted by a sensing head, before being directed into waiting containers via a divider flap mechanism. With an easily adjustable feed rate via its touchscreen interface, the King Dispenser Rx not only exemplifies accuracy but also user-friendly operation, making it a stellar choice for various industries.

Dive into this video to witness the King Dispenser Rx in action, as it seamlessly counts and fills bottles with blue chocolate balls, showcasing its unparalleled precision and efficiency in every cycle. Explore more about how the King Dispenser Rx can elevate your production capabilities and ensure every count and fill is flawless.

Your journey towards enhanced packaging precision starts here with C.E.King Limited! Contact us at [email protected] for more information!

youtube

#chocolateballs #foodcounter #foodpackaging #confectionery #tabletcountingmachine #capsulefillingmachine #packagingmachinery #pharmaceuticalpackaging #automatedpackaging #PrecisionCounting

0 notes

Link

#Automatedproductpackaging#automatedpackagingsystems#Automatedpackaging#Automatedpackagingmethods#automatedpackagingsystem#foodpackaging#Packagingindustry#ManufacturingIndustry

0 notes

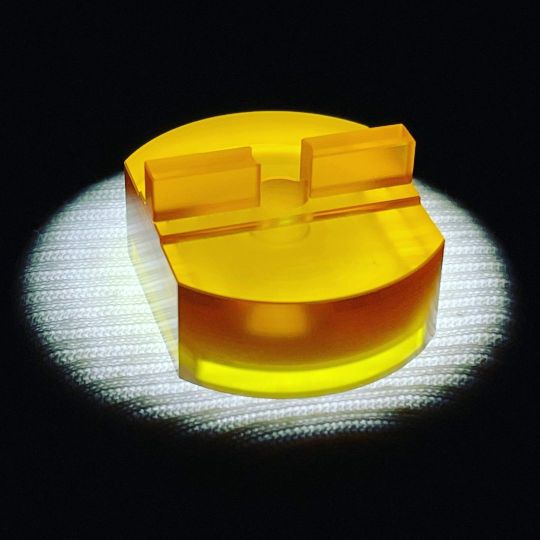

Photo

Did a job for a local company here in Modesto called SunOpta, Inc. They are a leading global company focused on natural food, indredient sourcing, organic food, and specialty foods. I was provided the opportunity and introduced to Senior Plant Engineer, Patrick Fischer via @sonnygirlcnc with Rexel Automation Solutions. There are many OEM parts that cannot be sourced because of global supply chain issues for their automated palletizing systems. Even if all OEM parts were available for them to order, most don’t last long from the 24-7 production stress and environmental factors. So @rpmcorporation is stepping in to help reverse engineer them with a more robust goal and better choice of materials for the different environments they are in. The part in my post is a steam regulating valve key, machined from Ultem 1000 that is part of a bigger housing assembly for their CIP process. Patrick has waited over 2 months for the original OEM manufacturer to get him replacements of this exact part or an ETA on delivery with zero luck. So with the introduction from @sonnygirlcnc, we were able to get our foot in the door and after today’s delivery of parts/plant tour, their go to shop is officially @rpmcorporation. We also did a Teflon version so they could test which material will hold up better though both are rated well for such high temps from something like steam. Appreciation to both Sonny and Patrick for the opportunity to earn the business of such a huge company, SunOpta, Inc. . . . . #automation #rexel #cip #automatedpackaging #cipsolutions #tertrapak #automationsolutions #palletizer #systemintegration #cleaninprogress #sunopta #modestofoodproduction #localsourcing #americanmade #ultem #teflon #reverseengineering #cncmachining #cncdesign #cncparts #chemicalenvironments (at Sunopta Aseptic) https://www.instagram.com/p/CVReoC5FXgM/?utm_medium=tumblr

#automation#rexel#cip#automatedpackaging#cipsolutions#tertrapak#automationsolutions#palletizer#systemintegration#cleaninprogress#sunopta#modestofoodproduction#localsourcing#americanmade#ultem#teflon#reverseengineering#cncmachining#cncdesign#cncparts#chemicalenvironments

0 notes

Text

#packagingsolutions#nichrome#efficientpackaging#nichromepackaging#foodpackaging#packagingmachines#automatedpackaging#nichromesolutions#automaticbottlefillingmachine

0 notes

Text

PPS Water Engineers has been your trusted partner in providing top-notch Shrink Packing Machines and related equipment. Our machines ensure durability, efficiency, and precision for all your packaging needs.

Discover the Ultimate Shrink Packing Solutions with PPS Water Engineers!

From compact machines for small businesses to industrial-grade equipment for large-scale operations, we have it all. Check out our range of Shrink Packing Machines designed to meet your unique packaging needs.

#ShrinkPacking#ShrinkPackingMachine#PackagingSolutions#PackagingEquipment#ShrinkWrap#ShrinkWrapping#PackagingTechnology#EfficientPackaging#IndustrialPackaging#PackagingMachinery#PackagingInnovation#ShrinkWrapMachine#PackingMachine#PackagingEfficiency#ShrinkWrapEquipment#PackingSolutions#ShrinkFilm#AutomatedPackaging#PackagingIndustry#ShrinkPack#MachineManufacturing#PackagingMachines#SmartPackaging#InnovativePackaging#PackingEquipment#PackagingExperts#ShrinkWrappingSolutions#ReliablePackaging#PackagingEngineering#PPSWaterEngineers

0 notes

Text

Range and Reliability in Powder Packaging: Nichrome

Powder packaging is not easy. Different powders come with their own challenges. Some are free flowing, others are not. Some, like flour, cause a dusty environment. Certain powders like agro-chemicals can turn explosive with certain gases and an electrical spark. Product changeovers can cause cross-contamination issues.

Then, different customers have different expectations. Some have limited floor space; some want multiple types of pouch formats and package quantities. Many demand versatility so the same machine can be used for varied products. Some plants do only small sachet packaging; others do bulk packaging. Few prefer Horizontal-Form-Fill-Seal (HFFS) machines while others like Vertical-Form-Fill-Seal (VFFS) technology.

Nichrome has an automated powder packaging solution to suit every need and challenge. As a reputed automatic filling machine manufacturer and experienced provider of integrated packaging solutions, Nichrome's technology expertise and indepth knowledge of different industries and applications. Nichrome offers a wide range of spice packaging machines, coffee packaging machines, tea packaging machines, pharmaceutical packaging machines and other powder filling machines. Nichrome can also customise and adapt solutions for specific requirements.

The Nichrome range for powder packaging includes:

Vertical-Form-Fill-Seal (VFFS) Machines

Excel 400 Plus Servo Auger: Easily integrated to upstream or downstream machines/systems this versatile machine offers many pouch formats and has an optimum bagger speed of 80 pouches per minute, depending on the pack size and product bulk density.

Sprint 250 Plus Servo Auger: Sprint 250 Plus Servo Auger: For pouch quantities up to 2 Kgs, Nichrome’s Sprint 250 Plus offers speed (up to 120 pouches per minute), accuracy and efficiency for flexible packaging of a wide variety of powders besides snacks & grains.

Maxima 200/400: With a compact design, Maxima 200/400 has a small footprint and produces single or perforated chain of pouches. A PLC-based control system and optional interface with PC & data processors make the Maxima 200/400 a favourite with powder manufacturers.

Horizontal-Form-Fill-Seal (VFFS) Machines

T Series: Nichrome offers HFFS packaging machines from Totpack, Spain. T110, T140 and T170 offer new generation linear technology with compact design. They offer a range of pouch formats with superior pouch aesthetics. Well designed duplex modules are available for higher outputs.

Multilane Machines

Multilane Stickpack with Multi Head Servo Auger: Packs free-flowing powders such as milk powder, coffee powder, salt, sugar, tea/coffee premixes in single-serve stick packs - popular among food chains, travel and hospitality industries.

Conclusion For a comprehensive range of automated powder packaging machines, few can match the portfolio of Nichrome. Nichrome's powder filling machines are high speed, high performance machines providing accuracy, durability and dependable performance for years. They are easy to clean and maintain, offering versatility with easy changeover. So if you need a packaging machine manufacturer with proven expertise in powder packaging, contact Nichrome today.

#powder filling machine#powder packaging machine#powderpackaging#integrated packaging solutions#AutomatedPackaging#automaticPackagingMachine

0 notes

Text

Four Big Benefits of Utilizing Packaging Machinery

One of the primary musings to enter a packagers mind when talking about bundling apparatus identifies with speed. What number of jugs every moment can that filling machine, topping machine, labeler or other bit of hardware produce? Will it have the option to deal with my day by day, week after week or month to month yield? In any case, programmed and self-loader hardware offer a bigger number of advantages than just added speed to a bundling procedure.

CONSISTENCY:

One huge objective of bundling an item for any business is to make that item appealing to clients and potential clients. Appearance does make a difference. For example, hand filling a refreshment can bring about conflicting fluid levels from container to bottle, while the utilization of a flood filler can guarantee that each jug arrives at a similar level, adding to the stylish estimation of the item when it arrives at the rack. The equivalent is valid for setting marks with logos or wholesome data in a reliable way. Hand marking can bring about wrinkled names or lost names, while utilizing a naming machine can guarantee each name is applied in a similar way.

Unwavering quality:

Utilizing bundling apparatus can likewise make the procedure more dependable than utilizing a hand bundling process. For instance, regardless of whether the start of the generation day or the end, the topping machine will seal bottles or different holders in a similar way, evacuating the danger of free tops coming about in spilled item. Regardless of whether a capper didn't accelerate the procedure, utilizing bundling hardware for such tasks can lessen cross-stringing, over-fixing, dreary movement wounds and different issues that can result from physically fixing tops. Coming back to the fluid filler, not all packagers will need to fill to a level. Various item packagers are hoping to arrive at a particular volume of item in every holder. Hardware, for example, gravity fillers and cylinder fillers offer a dependable way of arriving at a similar volume with each cycle, an errand substantially more troublesome when filling by hand.

Effectiveness:

Bundling gear essentially doesn't get worn out following six hours of generation. From fillers and cappers to transports, labelers and that's just the beginning, the gear will perform at a similar rate for the duration of the day. While physical work might be important to give mass item, tops, marks and different parts to the bundling line, the decrease of difficult work implies less slip-ups and less oversight. By always running the bundling procedure at a similar pace, packagers can all the more likely measure day by day creation, loaning to expanded effectiveness in the general procedure.

Yield:

As implied in the opening section, speed can be imperative to a packager. Here and there generation request just surpasses what can be put out regularly utilizing a hand bundling process. Mechanization through bundling gear takes into consideration more prominent paces in the case of utilizing self-loader or programmed apparatus. While only one out of every odd organization may totally robotize their framework, as creation develops apparatus may trade hand bundling for the slowest forms until complete robotization can be come to.

While only one out of every odd bundling procedure will require bundling hardware, there are benefits well beyond included speed. Hardware can run from straightforward handheld gear that can add consistency and unwavering quality to finish bundling lines that can build yield many occasions over when contrasted and hand bundling forms. The key for any business when picking bundling hardware is to examine the necessities of the particular undertaking to achieve the particular objectives, regardless of whether it be one or those spread out above.

1 note

·

View note

Link

Columbia's FL1000SW Floor Level Palletizer with Integrated Stretch Wrapper Stacking bottles of water packaged in trays and film with pad. Columbia's FL1000SW can palletize up to 10 cases per minute depending on case size and pallet pattern.

#Palletizer#ColumbiaMachineIndia#Automatedpackaging#MaterialHandling#FMCG#Packagingmachine#Boxpalletizer

0 notes

Photo

Fab-Ron is one of the leading automated packaging equipment distributors that provides suitable automation solutions to all clients after identifying their problems.- https://bit.ly/2GAVEOg

0 notes