#astm a182 f321

Explore tagged Tumblr posts

Text

ASTM A182 F321 Flanges, Fittings & Pipe Suppliers | Om Export India

Explore premium ASTM A182 F321 stainless steel flanges, fittings, and pipe products at Om Export India. Our high-quality F321 materials offer superior resistance to corrosion and high temperatures. Visit us for top-notch ASTM A182 F321 products and services.

#f321#sa182 f321#astm a182 f321#alloy steel a182 f1 forged fittings#alloy steel a182 f1 flanges#alloy steel a182 f1 flanges exporter#alloy steel a182 f1 flanges supplier

0 notes

Text

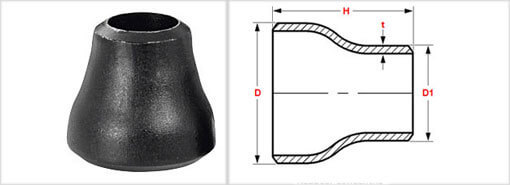

Concentric Reducers Exporters in India

CONCENTRIC REDUCERS

The Concentric Reducers are accessible in assortment of shapes and measurements to suit real pipeline establishment necessities in commercial ventures. This is a standout amongst the most generally utilized modern funnel fitting for adjusting distinctive channel sizes in a pipeline framework. It is fundamentally used to associate two funnels with various widths.

Produced using best grades of stainless steel, these reducers are accessible in an extensive variety of sizes, divider thicknesses and weight evaluations to look over as indicated by the pipeline. Guaranteeing an in-line funnel shaped move between various widths of pressurized channels, these concentric reducers join the pipelines on the same axis.The development of these reducers is finished by joining the little breadths and expansive distances across on inverse closures of cone formed move area. Discover application in petrochemicals, sugar factories and refineries, steel plants and bond and development commercial ventures, the reducer has separate gulf and outlet closes.TECHNICAL SPECIFICATIONSSTANDARD MATERIAL GRADES OF BUTTWELD SS REDUCER

Stainless steel grades:

ASTM A403 Grade WP304, WP304L, WP304H, WP304N, WP304LN, WP309, WP310S, WPS31254, WP316, WP316L, WP316H, WP316N, WP316LN, WP317, WP317L, WP321H, WP321, ASTM A815 S31803, S32750, S32760, S32205

Standard material grades in stainless steel:

ASTM A182 F304, F304H, F304L, F304N, F304LN, F309H, F310, F310H, F316, F316H, F316L, F316N, F316LN, F317, F317L, F347, F347H, F321, F321H, FXM-19, F50, F51, F53, F55, F60, F904L

Application Areas:

Oil and gas industry

Petrochemical industry

Power stations

Shipbuilding industry

10 notes

·

View notes

Text

Socket Weld Flanges Manufacturer in Mumbai

About the product

Socket weld flanges, also simply called SW flanges, have a recess (shoulder-like part) in the flange hole. This shoulder serves as a guide for determining the depth of the pipe inserted into the flange. A socket weld type flange was originally designed for small diameter high pressure piping systems. Socket weld pipe flanges are typically useful for smaller, high pressure pipe sizes.

Specifications

Our socket weld flanges boast a comprehensive range of specifications tailored to meet diverse piping requirements. These flanges are available in sizes from 1/2″ (15 NB) to 48″ (1200 NB) Compliant with industry standards. Our flanges ensure compatibility and reliability, and as well as PN6 to PN64, our products cater to a wide spectrum of operational pressures. Crafted from premium materials.

and liquid within the pipe. This allows for smooth drilling and improves the flow of gas The pipe is attached to the outside of the hub with a flange by filet welding. The main disadvantage of this type of flange is that it is not a highly integrated connection, as the weld is difficult to detect. Socket weld flanges have poor integrity and are not suitable for use at high pressures, so they most often have flat or raised surfaces.

including carbon steel (ASTM A105/A105N, A350, 70, etc.), stainless steel (ASTM A182 F202, F304/304L/304H, F316/316L, F316H, F316TI, F310, F321, F904L).

0 notes

Photo

Nufit Piping Solutions - Manufacturer, exporter & supplier of Stainless Steel Flanges, Carbon Steel Flanges, Alloy Steel Flanges, Duplex Steel Flanges according to ASME B16.5. Stainless Steel Flanges - ASTM A182 / ASME SA182 F304, F304L, F310, F310S, F316, F316L, F316Ti, F317L, F321, F347, F20 (N08020), F904L (N08904) Carbon Steel Flanges - ASTM A105 / ASME SA105, ASTM A350 / ASME SA350 LF2, LF3, ASTM A516 / ASME SA516 Grade 60, 70 Alloy Steel Flanges - ASTM A182 / ASME SA182 F1, F5, F9, F11, F12, F22, F91 Duplex Steel Flanges - ASTM A182 / ASME SA182 F44 (S31254), F51 (S31803), F52 (S32950), F53 (S32750), F55 (S32760), F60 (S32205) Flange types: Slip-on, Socketweld, Weld Neck, Blind, Threaded, Long Weld Neck Flange Face: Flat Face, Raised Face, Ring Type Joint Face, Male/Female Face, Tongue and Groove Face For more details, visit us at Https://flanges-manufacturer.com For your requirement, mail us at [email protected] #ssflange #csflange#sliponflange #socketweldflange #weldneckflange #blindflange #threadedflange #longweldneckflange #forgedflange #nace #flange #rtjflange #texas #rotterdam #miami #milan #canada #manufacturer #exporter #flangemanufacturer #flangeexporter #astmflange #asmeflange #nufit #nufitpipingsolutions #india #instagood #instadaily #instalike #newpost (at Berkel en Rodenrijs, Zuid-Holland, Netherlands) https://www.instagram.com/p/Cj3dilfLEul/?igshid=NGJjMDIxMWI=

#ssflange#csflange#sliponflange#socketweldflange#weldneckflange#blindflange#threadedflange#longweldneckflange#forgedflange#nace#flange#rtjflange#texas#rotterdam#miami#milan#canada#manufacturer#exporter#flangemanufacturer#flangeexporter#astmflange#asmeflange#nufit#nufitpipingsolutions#india#instagood#instadaily#instalike#newpost

0 notes

Text

Lap Joint Flanges Suppliers

ASME B16.5 Lap joint rib can be refined by two systems. Right when the line material is incredible the "lap" is laid out by technicality the line material later the free spine has been fitted. On the off chance that the getting sorted out material is rapidly weld able a "lap" end can be butt welded to the line. A105 Lap joint Flange are essential for non-metallic getting sorted out and regions. Most materials are hugely dealt with in pressure than in strain. The Stainless Steel Lap joint Flange is held in pressure by the free rib which is in strain because of the stun load.

Treated Steel Lap joint Flange producers in India. We are giving Lap Joint Pipe Flange, ASME B16.47 Lap Joint Flange, 2 inch lap joint spine and Lap Joint Backing Flange at moderate expense thinking about sensible virtuoso hours in India and tremendous wellspring of amazing Lap Joint Pipe Flanges, most ideal circumstance, cost open in Mumbai, India. Are you searching for Lap Joint Flange With Stub End reach us for same, Check Lap Joint Flange Dimensions and Lap Joint Flange Weight Chart to purchase Lap Joint Flange Welding. We have clear Lap Joint Flange Types and they are essential for Installation Also. View Lap Joint Flange Stub End Dimensions.

Material of Lap Joint Flange

Carbon Steel Lap Joint Stub End Flanges

Alloy Steel High-Temp RF Lap Joint Flange

Alloy Steel Low-Temp Lap Joint Ring Flange

Austenitic Stainless Steel Lap Joint Flange

Nickel Alloy RTJ Lap Joint Flange

Titanium Lap Joint Ring Flange

A105 Lap Joint Flange

A182 Gr F1 Lap Joint Pipe Flanges

A182 Gr F11 RTJ Lap Joint Flange

A182 Gr F12 Lap Joint Stub End Flanges

A182 Gr F22 Lap Joint Flange

A182 Gr F5 Lap Joint Weld Flange

A182 Gr F9 RF Lap Joint Flange

A350 Gr LF2 RTJ Lap Joint Flange

A350 Gr LF3 Lap Joint Flange

A182 Gr F304 Lap Joint Ring Flange

A182 Gr F316 RF Lap Joint Flange

A182 Gr F321 RTJ Lap Joint Flange

A182 Gr F347 Lap Joint Flange

A182 Gr F304L Lap Joint Pipe Flanges

A182 Gr F316L Lap Joint Stub End Flanges

A182 Gr F317 RF Lap Joint Flange

A182 Gr F317L RTJ Lap Joint Flange

A182 Gr F321 Lap Joint Pipe Flanges

A182 Gr F310 Lap Joint Weld Flange

A182 Gr 347 Lap Joint Flange

ASTM B564 Lap Joint Weld Flange

astm b564 uns n06600 RTJ Lap Joint Flange

astm b564 uns n06625 Lap Joint Ring Flange

astm b564 uns no4400 RF Lap Joint Flange

astm b564 uns n08810 RTJ Lap Joint Flange

astm b564 uns n08811 Lap Joint Pipe Flanges

astm b564 uns n08825 Lap Joint Flange

astm b564 uns n04400 RF Lap Joint Flange

astm b564 uns n10276 Lap Joint Stub End Flanges

astm b564 uns n10665 Lap Joint Weld Flange

astm b381 grade f2 Lap Joint Weld Flange

astm b381 f5 Lap Joint Stub End Flanges

astm b381 f3 Lap Joint Flange

astm b381 f12 RF Lap Joint Flange

astm b381 f7 RTJ Lap Joint Flange

0 notes

Photo

Socket Weld Pipe Fittings Manufacturers, Socket Weld Fittings Exporters, Socket Weld Fittings Suppliers, Socket Weld Fittings Importers.

Socket Weld Fittings Manufacturers in India, Socket Weld Fittings Exporters in India, Socket Weld Fittings Suppliers in India, Socket Weld Fittings Importers in India.

Socket Weld Pipe Fittings Manufacturers in Mumbai, Socket Weld Pipe Fittings Exporters in Mumbai, Socket Weld Pipe Fittings Suppliers in Mumbai, Socket Weld Pipe Fittings Importers in Mumbai.

Dipti Metal Industries is driving Manufacturer of stainless steel pipe fittings and stainless steel ribs in INDIA since Five Decades,Dipti Metal Industries positions in Top Ten organization in INDIA occupied with assembling of produced pipe fittings, at Dipti Metal Industries we offers the total scope of fashioned fittings including Socket Weld Fittings, Threaded Fittings, Nipple, Branch Outlet Fittings , Bosses, Union Joint and the sky is the limit from there. we would exporter be able to and provider of fashioned attachment weld fittings fabricated in understanding to ASME B16.11. Produced attachment weld fittings are accessible ex-stock in all real stainless steel grades (ASTM A182 F316L, F304L), carbon steel and combination steel grades. We offer different sorts of attachment weld fittings including attachment weld elbow, attachment weld tees, attachment weld cross, and the sky is the limit from there. Attachment weld fittings are broadly utilized as a part of channeling frameworks crosswise over real ventures, for example, petrochemicals, control age, send building, journal industry, distilleries, squander water treatment, compound, pharmaceuticals and others.

SPECIFICATIONS

Material

Stainless Steel ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L ASTM A312/A403 TP304, TP304L, TP316, TP316L Carbon Steel ASTM A105, A350 LF2, A106 Gr.B, A234 WPB

Dimension

ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Pressure

3000LBS, 6000LBS, 9000LBS

Size

1/8"~4" (DN6~DN100)

FORGED PIPE FITTINGS MANUFACTURING STANDARDS

· ASTM A182 – ASME SA182 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

· ASME B16.9 – Factory-Made Wrought Buttwelding Fittings

· ASME B16.11 – Socket Welding and Threaded Forged Fittings

· MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications

· MSS SP-95 – Swage(d) Nipples and Bull Plugs

· BS3799 – Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry

Stainless Steel Threaded SS 304 Threaded Fittings SS 304L Threaded Fittings SS 304H Threaded Fittings SS 316 Threaded Fittings SS 316L Threaded Fittings SS 316Ti Threaded Fittings SS 310 Threaded Fittings SS 310S Threaded Fittings SS 321 Threaded Fittings SS 321H Threaded Fittings SS 317 Threaded Fittings SS 347 Threaded Fittings SS 347H Threaded Fittings

Alloy Steel Threaded Fittings Nickel Alloys Threaded Nickel 200 Threaded Fittings Nickel 201 Threaded Fittings Monel 400 Threaded Fittings Monel 500 Threaded Fittings Inconel 800 Threaded Fittings Inconel 825 Threaded Fittings Inconel 600 Threaded Fittings Inconel 625 Threaded Fittings Inconel 601 Threaded Fittings

Carbon Steel ASTM A 234 Threaded Hastelloy C 276 Threaded Fittings Alloy 20 Threaded Fittings Titanium Threaded Fittings Duplex Steel 2205 Threaded Fittings Copper Alloys Threaded Fittings Aluminium Threaded Fittings Copper Threaded Fittings Brass Threaded Fittings Gunmetal Threaded Fittings

OUR SUMMARY:

Reviewer

Dipti Metal Industries.

Review Date

6-06-2017

Reviewed Product

Socket Weld Pipe Fittings

Author Rating

Domestic Area

Mumbai

Ahmedabad

Bhopal

Bikaner

Pune

Delhi

Chennai

Visakhapatnam

Mangalore

Nagpur

Bangalore

Kolkata

Siliguri

Assam

Indore

Hyderabad

Surat

Nashik

Cochin

Thane

Faridabad

Rajkot

Aurangabad

Bhavnagar

Ranchi

Coimbatore

Mysore

Salem

Tirupur

Bikaner

Raipur

Bhubaneswar

Bhilai

Ankleshwar

Bhiwandi

Our Export

Eastern Europe

Asia

North America

Western Europe

Mid East/Africa

Australasia

Central/South

UAE

America

Portugal

Spain

Indonesia

Italy

Angola

Poland

Brazil

Sri Lanka

Russia

Chile

Singapore

Oman

Venezuela

Costa Rica

USA

Qatar

Thailand

Canada

Saudi Arabia

Bahrain

Egypt

Malaysia

Turkey

Mexico

Chine

Peru

United States

Nigeria

Jordan

Kuwait

Dubai

Bangkok

Iran

Germany

UK

New Zealand

Vietnam

South Africa

Mexico

Kazakhstan

http://www.diptimetals.com/socket-weld-and-threaded-pipe-fittings-manufacturers-exporters-suppliers-importers.html

0 notes

Text

Socket Weld Flanges

Socket weld flanges are counter-bored to receive the pipe earlier than being fillet welded. The bore of the pipe and flange are both the equal to grant exact float characteristics. Stainless steel socket weld flanges are oxidation resistant and promote better weldability and fabricability. WENZHOU HUASHANG STEEL CO.,LTD is manufacturer ,trader, supplier and exporter for socket weld flange.

Socket Welding Flanges Forming:

Forged

Socket Welding Flanges Material

Stainless Steel:

OCr18Ni9, 0Cr18Ni9Ti, 1Cr18Ni9Ti, 0Cr18Ni12Mo2Ti, 00Cr19Ni10, 00Cr17Ni14Mo2, ASTM A182-F304, F304L, F304H, F316, F316L, F321, F321H, F347H, F317,

Super Stainless Steel:

ASTM A182-904L, 317, 317L

Duplex Steel:

ASTM A182-F51, F53, F44

Special steel:

N06600, N08800, N08811

Alloy Steel:

16Mn, 12CrMo, 15Cr5Mo, Cr5Mo, 12Cr1MoV, ASTM A182-F11, F22, F91 F9 F5

Pipe Line:

ASTM A694-F42, F46, F48, F50, F52, F56, F60, F65, F70, F80

Carbon Steel:

ASTM A350-LF2, LF3 Q235A, 20#, ASTM A105

http://www.sstubecn.com/forged-flanges/socket-weld-flanges.html

0 notes

Text

How Flanges Suppliers In Uae Maintain Quality Service?

Flanges are basic pieces of equipment used to connect the various pipes, valves, pumps and other pieces of equipment that are installed in an oil & gas plant. By acting as a connecting medium, they make it easier to connect and disconnect various pieces while also making the cleaning and maintenance tasks a lot easier.

In a flourishing oil and gas industry such as that in the UAE, there is always a huge demand for high-quality flanges. Even though the oil and gas industry is the primary and foremost user of these flanges, they can also be used in various other manufacturing and production activities.

Flanges Supplies By NWH

Being the market leader in this area, New World Horizon is one of the leading flanges suppliers in Dubai. We have a wide range of flanges available which can be readily employed in your manufacturing or production plant.

No matter which type of flange you want: weld neck, slip on, blind, socket weld, threaded, long weld neck or even anchor flange, you name it, we have it. Not only are we one of the most trusted flanges suppliers in UAE but also the most available one. Our flanges come in the size range of 1/2″ to 72″ which can cover almost all applications.

Besides this, we supply the flanges in various material grades which are listed below:

Carbon Steel: ASTM A105N/A694 F52. These are the most common types of flanges that are used for ambient and higher temperature service in pressure conditions. This is because they are made up of highly durable carbon steel which is difficult to break.

Carbon Steel Alloy Low Temp: ASTM A350 LF2/LF3. These are generally used in non-corrosive applications such as underwater and in the oil and gas industries.

Carbon Steel Alloy High Temp: ASTM A182 F1/F2/F5. These offer good oxidation and scaling resistance. They are also easy to weld and hence can be used in a variety of applications.

Austenitic Stainless Steel: ASTM A182 F304/304L, A182 F316/316L, A182 F321/347. These flanges have a good anti-corrosion effect and can hence easily be used for underwater applications.

Duplex & Super Duplex: F51/F53. Apart from the oil & gas industry, they are used in various other industries such as petrochemical, transportation, pharmaceuticals, etc.

New World Horizon is an enthusiastic and professional company that can enable you to procure world class products for your industrial plant. Besides providing high-quality flanges, we also provide high-quality maintenance services and are there for our customers 24/7.

0 notes

Text

Different materials which are used for flanges manufacturing

With our day to day life surrounded by machines all around us, it is impossible not to notice flanges all around us. A flange is an external or internal ridge or rim provided for support andattachment to another object that it gets attached to. Some of the most common example of flanges are iron beams in the form of I-beam or T-beam, on the lens mount of a camera, ski shoes with rim on the toes and heel part of shoes, rail cart wheel with flange on one side of wheel, microwave, piping system where pipes are joined. Flanges can be combined with other flanges to form a flange. Flanges not only provide easy access for cleaning but also for inspection and modification.

Generally screwed together, flange joints are created by bolting two flanges together creating a seal. There are different types of flanges available depending on their usage and industry they are used for. Some of the most common used flanges are welding neck flange, slip on flange, lap joint flange, blind flange, reducing flange etc. Flanges are not recommended in underground piping where they have to be buried.

Since the work of flange is to keep the system in place and together without any leakage or failure, it is very important to identify the usage and material for manufacturing the flanges. The flange is generally manufactured in the same material as the material of connecting machines as different material can compromise on stability. Some of the most common flange materials are stainless steel, carbon steel, aluminium, nickel alloy, plastic etc and are listed below:

· Stainless Steel – Known for its corrosion resistant property, sanitation and durability, it is perfect for the drinking water application or any system that needs to remain clean throughout its service life. Stainless steel flanges are higher in cost and have a long service life. They should also be replaced at the appropriate time, even if the flange is still in good working order.

· Carbon Steel – Carbon steel flanges are used where toughness is required and sanitation is low on priority. Carbon steel is used in the fuel lines and on a shipping vessel as they can bear the vibrations and heat very well. Carbon steel flanges require a monitoring on tight connection during installation.

· Aluminium – Aluminium flanges are used when a light weight option is required. Aluminium is a good option for lighter weight options and less pressure on the structure option. It is also used as a face of stainless steel flanges.

· Nickel Alloy – Nickel Alloy shares many characteristics as stainless steel. It adds strength to the construction of the flange and offers resistance to corrosion. Being an alloy and premium material at par with stainless steel, it is expensive and will be costly for a large system.

The manufacturing of the flanges follows the international standard ASTM. These ASTM standards, define the specific manufacturing process of the material by determining the exact chemical composition of pipes, fittings and flanges, through percentages of the permitted quantities of carbon, magnesium, nickel, etc., which are specified by "Grade". ASTM examples are mentioned below:

· ASTM A105 specification chalks out the standards for forged steel piping components made of carbon which are flanges, fittings, valves to be used in pressure system at high temperature service conditions.

· ASTM A182 defines the specification for forged/rolled alloy and stainless steel pipe flanges, forged fittings and valves and parts of high temperature service.

· ASTM A350 informs about the several grades of carbon and low alloy steel that are used to manufacture forged or ring rolled flanges, forged fittings and valves for low temperature service.

There are other ASTM standards available that defines the different material specifications.

Some of the examples for Grade are:

· A carbon steel flange can be identified with Grade F9 or F11.

· A stainless-steel flange with Grade F316 or Grade F321

After welding, the flange is considered as the most widely used joining method in case of requirement of dismantling of the joints and requires continuous maintenance. Though it is widely used and manufactured using the ASTM standards, it is globally accepted providing the same specifications flanges across the world.

0 notes

Link

JIS B2220 SUS304 SOP Flange FF 2-1/2 Inch 5K

FOB Price USD 1 - 1,900/Piece

Port Ningbo or Shanghai Port

MOQ 1 Piece

Supply Ability 1000 Pieces Per Day

Payment Terms L/C,T/T,Western Union,MoneyGram

Packaging Seaworthy plywood cases or pallets

Delivery 2 - 10 days

Quick Details

Material: SUS304, etc

Size: 2-1/2" (DN65)

Type: SUS304 SOP Flange Place of Origin: Zhejiang, China (Mainland)

Connection: Welding

Brand Name: Yaang Standard: JIS B2220

Shape: Round

Standard or Nonstandard: Standard Technics: Forged

Packaging & Delivery

Packaging Details:Seaworthy plywood case or as customer requests Delivery Detail:2 - 10 days after receiving the deposit

Specifications

4. Pressure: 5K (5kg/cm2)

There are two types of JIS B2220 slip on flange products,which can distinguish from the products’ neck.The JIS B2220 slip on plate flange(JIS B2220 SOP Flange) just looks like the plate flange,the JIS B2220 slip on hubbed flange(JIS B2220 SOH flange) have a neck.

China Slip On Plate Flange Manufacturer yaang supplies JIS B2220 SUS304 SOP Flange FF, 2-1/2 Inch, 5K.

Chemical Composition and Mechanical Property for 304/304L

Steel Grade

Chemical Composition

Mechanical Performance

C(Max)

Si(Max)

Mn(Max)

P(Max)

S(Max)

Ni

Cr

N

Mo

Tensile Strength (Min)

Yield Strength (Min)

Mpa

Mpa

304

0.08

0.75

2.00

0.045

0.03

8.0–10.5

18.0–20.0

0.1

/

515

205

304L

0.03

0.75

2.00

0.045

0.03

8.0–12.0

18.0–20.0

0.1

/

485

170

Type

SUS304 Slip On Plate Flange FF

Size

1/2" to 80"

Standards

SO, WN, SW, TH, LJ, BL, PL, etc

Material

Carbon Steel Plate Flanges: ASTM A105/A105N, etc

Stainless Steel Plate Flanges: ASTM A182 F304/304L/304H, F316/316L, F310, F321, F904L, etc

Alloy Steel Plate Flanges: ASTM A182 F1, F5, F9, F11, F22, F91, etc

Nickel Alloys Plate Flanges: Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II).

Duplex, Super Duplex Plate Flanges: ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61, 2205 (UNS No. S31803), 2507 (UNS No.S32750), etc

Copper Alloy Plate Flanges: UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C71500 (Cu -Ni- 70/30), etc

Surface treatment

Applications

Petroleum,chemical,power,gas,metallurgy, shipbuilding, construction, etc

JIS 5K

LTB

DRILLING DATA

JIS 5K

NOMINAL PIPE SIZE

OUTSIDE DIAMETER OF FLANGE

THICKNESS OF FLANGE

THINKNESS BLIND

BOSSES LENGTH SOH,SWLJ

WELD NECK LENGTH

PITCH CIRCLE DIAMETER

NUMBER OF BOLT HOLES

BOLT HOLE DIAMETER

NOMINAL PIPE SIZE

MM

INCH

C

T

T1

L

L1

PCD

#

H

MM

INCH

10

3/8

75

9

9

13

24

55

4

12

10

3/8

15

1/2

80

9

9

13

25

60

4

12

15

1/2

20

3/4

85

10

10

15

28

65

4

12

20

3/4

25

1

95

10

10

17

30

75

4

12

25

1

32

1 1/4

115

12

12

19

33

90

4

15

32

1 1/4

40

1 1/2

120

12

12

20

34

95

4

15

40

1 1/2

50

2

130

14

14

24

36

105

4

15

50

2

65

2 1/2

155

14

14

27

39

130

4

15

65

2 1/2

80

3

180

14

14

30

41

145

4

19

80

3

90

3 1/2

190

14

14

41

155

4

19

90

3 1/2

100

4

200

16

16

36

41

165

8

19

100

4

125

5

235

16

16

40

43

200

8

19

125

5

150

6

265

18

18

40

49

230

8

19

150

6

175

7

300

18

18

N/A

49

260

8

23

175

7

200

8

320

20

20

N/A

53

280

8

23

200

8

225

9

345

20

20

N/A

54

305

12

23

225

9

250

10

385

22

22

N/A

61

345

12

23

250

10

300

12

430

22

22

N/A

62

390

12

23

300

12

350

14

480

24

24

N/A

73

435

12

25

350

14

400

16

540

24

24

N/A

76

495

16

25

400

16

450

18

605

24

24

40

79

555

16

25

450

18

500

20

655

24

24

40

79

605

20

25

500

20

550

22

720

26

26

42

81

665

20

27

550

22

600

24

770

26

26

44

81

715

20

27

600

24

650

26

825

26

28

48

85

770

24

27

650

26

700

28

875

26

30

48

94

820

24

27

700

28

750

30

945

28

32

52

100

880

24

33

750

30

800

32

995

28

34

52

100

930

24

33

800

32

850

34

1045

28

36

54

108

980

24

33

850

34

900

36

1095

30

36

56

108

1030

24

33

900

36

1000

40

1195

32

40

60

116

1130

28

33

1000

40

APPLICATIONS:

1. Petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

JIS B2220 SUS304 SORF Flange's Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps , pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request.

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality JIS B2220 SUS304 SOP Flange FF, 2-1/2 Inch, 5K.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited is a China Plate Flange Manufacturer).

If any inquiry about products, please feel free to contact us [email protected]

Related products:

More>>

ASME B16.47 Series B Class 75 Weld Neck Flanges

EN1092-1/01/B1 304L Plate Flange RF DN250 PN16

ASME B16.5 A182 F904L WNRF Flange DN80 SCH10S CL150

ASME B16.5 A182 F304 SORF Flange 2-1/2 Inch CL15

0 notes

Text

Forged 3000lb stainless steel screw /socket weld pipe fitting

1. Forged Fittings Type: Elbow, cross, street elbow, tee, coupling, half coupling, cap, plug, bushing, union, outlet, sage nipple, bull plug, reducer insert, pipe nipple etc.

2. Connection: Socket Welded, Threaded

3. Size Range: 1/8" - 4"(6mm - 100mm)

4. Pressure Rating:

Threaded Forged Pipe Fittings: 2000LBS, 3000LBS, 6000LBS

Socket welding Wog 3000, 6000, 9000 LBS

5. Specifications:

1) Standard: ASME B 16.11, MSS-SP-79\ 83\ 95\97

2) Material: F304, F304L, F316, F316L, F304H, F316H, F317L, F321, F11, F22, F91,ASTM A105, ASTM A182(

3) Size of raw material: Dia. 19-85mm round bar.

6. Technology: Forged

7. Packing: Wooden cases or wooden pallet or as per customers requirement

8. Delivery Time: 25 days after order conformed

9. Payment: By T/T or L/C

10. Applications range: Petroleum, chemical, machinery, electric power, shipbuilding,

Papermaking, construction etc

http://www.icmhoseind.com/c473.html

0 notes

Video

youtube

http://www.fittechind.com/

ASTM A105 Flange Manufacturers, Carbon Steel Flanges Manufacturers In India ASTM A105 Forged Flange, ASTM A105 Blind Flange, ASTM A105 Plate Flange, ASTM A105 Weld Neck Flange, ASTM A105 Slip On Flange, ASTM A105 Threaded Flange

Exporter of Carbon Steel Flanges, ASTM A105 FLANGES As Per ANSI B16.5, BS10 TABLE D, TABLE E, DIN Standard Flanges, A105 Carbon Steel Flanges Supplier – Slip On, Weld Neck, Blind Flanges, Plate Flanges Exporter, Manufacturer of CS Flanges

FitTech Industries Pvt. Ltd. was established in 1985 and have 3 decades of experience in manufacturing carbon steel pipe fittings and flanges in accordance to ASME B16.9/ B16.11 with commitment to provide world class quality to our customers at competitive price by using innovative production system and process.

We are manufacturer & exporters of A105 Flanges, ASTM A350 Carbon Steel Flanges, A694 Carbon Steel Flanges, Alloy Steel Pipe Fittings, ASTM A182 Alloy Steel Flanges, ASTM A182 F5, ASTM A182 F9, ASTM A182 F11, ASTM A182 F12, ASTM A182 F22, ASTM A182 F91, ASTM A105 Flange, ASTM A350 Flanges, ASTM A694 Flanges, A182 F304 Flange, A182 F 304L Flange, A182 F316 Flange, A182 F316L Flange, A182 F316Ti Flange, A182 F321 Flange, A182 F321H Flange, A182 F347 Flange, A182 F347H Flange, A182 F317 Flange, A182 F 317L Flange for the Oil, Gas, Nuclear, Petro-Chemical and Process Industries.

Contact Us : Address : FitTech Industries Pvt. Ltd, Unit No. 12, JD Industrial Estate, Near Dahisar Check naka, Opp Prasad Hotel, Mira Village, Mira Road(East), Distric Thane-401104, Maharashtra, India Email: [email protected] Telephone: +91-22-29451270/71/71 Fax No.: +91-22-29451269 Visit us: http://www.fittechind.com/ssflange-csflange-steelflange-flanges/a105steelflanges-norm-astma105-carbonsteel-flanges-manufacturers-in-india/

0 notes

Text

Olets Exporters in India

THREADOLETS

We supply Threadolets (3000#, 6000 #) in pressure grade of 3000LBSCH40, SCH80, STD, XS, 6000LBSCH160, XXS etc., and carbon steel of A182 A105 and in stainless steel of A182 F304, A182 F304L, A182 F316, A182 F316L, A182 F321 respectively. These Threadolet Fittings are available in sizes ranging from 1/8" ~ 20".

SPECIFICATIONOutlet SizeABC3000 #6000 #3000 #6000#3000#6000#½25.431.834.944.523.819.1¾27.036.544.550.830.225.4133.339.754.061.936.533.31 1/433.341.365.169.944.538.11 1/234.942.973.082.650.849.2238.152.488.9103.265.169.92 1/246.0-103.2-76.2-350.8-122.2-93.7-457.2-152.4-120.7-Nickel AlloyASTM / ASME SB 564 UNS 2200 ( NICKEL 200 ), UNS 4400 (MONEL 400 ), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) ASTM / ASME SB 160 UNS 2201 (NICKEL 201 ) ASTM / ASME SB 472 UNS 8020 ( ALLOY 20 / 20 CB 3 )Copper AlloyASTM / ASME SB 61 UNS NO. C 92200 & ASTM / ASME SB 62 UNS NO. C 83600. ASTM / ASME SB 151 UNS NO. 70600, 71500, C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30), ASTM / ASME SB 152 UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200.Stainless SteelASTM / ASME SA 182 F 304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316 LN, 317, 317L, 321, 321H, 347, 347 H.Duplex SteelASTM / ASME SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61.Carbon SteelASTM / ASME A 105. ASTM / ASME A 350 LF 2.Alloy SteelASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91.

#Threadolets in India#Threadolets Manufacturers in India#Threadolets Suppliers in India#Threadolets Exporters in India#Threadolets Stockists in India.

0 notes

Text

Nufit Piping Solutions - Manufacturer, exporter & supplier of Stainless Steel Flanges according to ASTM A182 / ASME SA182 F304 F304L F316 F316L F321 F347

Above flange size 12" (DN 300) x 1500# x SCH 80 according to ASME B16.5 exported to our overseas client

For more details, visit us at Https://flanges-manufacturer.com

For your requirement, mail us at [email protected]

#ssflanges#flanges#rtjflange#astma182#oilngas#manufacturer#supplier#exporter#flangemanufacturer#flangeexporter#asmeflange#industrialflanges#nufit#nufitpipingsolutions#nufitbrand#india#newpost

1 note

·

View note

Text

Lap Joint Flanges Exporters

ASME B16.5 Lap joint rib can be refined by two systems. Right when the line material is incredible the "lap" is laid out by technicality the line material later the free spine has been fitted. On the off chance that the getting sorted out material is rapidly weld able a "lap" end can be butt welded to the line. A105 Lap joint Flange are essential for non-metallic getting sorted out and regions. Most materials are hugely dealt with in pressure than in strain. The Stainless Steel Lap joint Flange is held in pressure by the free rib which is in strain because of the stun load.

Treated Steel Lap joint Flange producers in India. We are giving Lap Joint Pipe Flange, ASME B16.47 Lap Joint Flange, 2 inch lap joint spine and Lap Joint Backing Flange at moderate expense thinking about sensible virtuoso hours in India and tremendous wellspring of amazing Lap Joint Pipe Flanges, most ideal circumstance, cost open in Mumbai, India. Are you searching for Lap Joint Flange With Stub End reach us for same, Check Lap Joint Flange Dimensions and Lap Joint Flange Weight Chart to purchase Lap Joint Flange Welding. We have clear Lap Joint Flange Types and they are essential for Installation Also. View Lap Joint Flange Stub End Dimensions.

Material of Lap Joint Flange

Carbon Steel Lap Joint Stub End Flanges

Alloy Steel High-Temp RF Lap Joint Flange

Alloy Steel Low-Temp Lap Joint Ring Flange

Austenitic Stainless Steel Lap Joint Flange

Nickel Alloy RTJ Lap Joint Flange

Titanium Lap Joint Ring Flange

A105 Lap Joint Flange

A182 Gr F1 Lap Joint Pipe Flanges

A182 Gr F11 RTJ Lap Joint Flange

A182 Gr F12 Lap Joint Stub End Flanges

A182 Gr F22 Lap Joint Flange

A182 Gr F5 Lap Joint Weld Flange

A182 Gr F9 RF Lap Joint Flange

A350 Gr LF2 RTJ Lap Joint Flange

A350 Gr LF3 Lap Joint Flange

A182 Gr F304 Lap Joint Ring Flange

A182 Gr F316 RF Lap Joint Flange

A182 Gr F321 RTJ Lap Joint Flange

A182 Gr F347 Lap Joint Flange

A182 Gr F304L Lap Joint Pipe Flanges

A182 Gr F316L Lap Joint Stub End Flanges

A182 Gr F317 RF Lap Joint Flange

A182 Gr F317L RTJ Lap Joint Flange

A182 Gr F321 Lap Joint Pipe Flanges

A182 Gr F310 Lap Joint Weld Flange

A182 Gr 347 Lap Joint Flange

ASTM B564 Lap Joint Weld Flange

astm b564 uns n06600 RTJ Lap Joint Flange

astm b564 uns n06625 Lap Joint Ring Flange

astm b564 uns no4400 RF Lap Joint Flange

astm b564 uns n08810 RTJ Lap Joint Flange

astm b564 uns n08811 Lap Joint Pipe Flanges

astm b564 uns n08825 Lap Joint Flange

astm b564 uns n04400 RF Lap Joint Flange

astm b564 uns n10276 Lap Joint Stub End Flanges

astm b564 uns n10665 Lap Joint Weld Flange

0 notes

Text

SLIP ON FLANGES MANUFACTURERS IN MUMBAI

The relationship with the line is done with 2 filet welds, too at the outside as other than at inside the Raised Faced Slip-On Flanges. Level Faced Slip-On Flanges have a lower material cost than weld neck spine and are everything viewed as the more accommodatingly changed. Our Carbon Steel Slip On Flange Manufacturers workplaces can complete any level of courses of action. Slip on pipe spine may what's more be used a lap joint ribs expecting Type B or Type C stub closes are used.

Omaa Metal Sources,We are Leading creator of Stainless Steel Slip On Flange, We all around have a pre-arranged pile of 6 inch Stainless Steel Slip On Flange, Stainless Steel Reducing Slip On Flange and Stainless Steel Slip Ring Flange to fulfill any need climate its epic or little, We had given Stainless Steel Slip-on Pipe Flanges, 8 inch Stainless Steel Slip On Flange in Many beach front and toward the ocean attempts the world over.

Material of Slip On Weld Flange

Carbon Steel Slip on pipe flange

Alloy Steel High-Temp Slip On Weld Flange

Alloy Steel Low-Temp Flat Faced Slip-On Flanges

Austenitic Stainless Steel Raised Faced Slip-On Flanges

Nickel Alloy SORF Flanges

A105 Slip On Flange

A182 Gr F1 Slip on threaded flange

A182 Gr F11 SORF Flanges

A182 Gr F12 Slip on pipe flange

A182 Gr F22 Slip On Flange

A182 Gr F5 Raised Faced Slip-On Flanges

A182 Gr F9 Slip On Weld Flange

A350 Gr LF2 SORF Flanges

A350 Gr LF3 Slip On Flange

A182 Gr F304 Flat Faced Slip-On Flanges

A182 Gr F316 Slip On Weld Flange

A182 Gr F321 SORF Flanges

A182 Gr F347 Slip On Flange

A182 Gr F304L Slip on threaded flange

A182 Gr F316L Slip on pipe flange

A182 Gr F317 Slip On Weld Flange

A182 Gr F317L SORF Flanges

A182 Gr F321 Slip on threaded flange

A182 Gr F310 Raised Faced Slip-On Flanges

A182 Gr 347 Slip On Flange

ASTM B564 Raised Faced Slip-On Flanges

astm b564 uns n06600 SORF Flanges

astm b564 uns n06625 Flat Faced Slip-On Flanges

astm b564 uns no4400 Slip On Weld Flange

astm b564 uns n08810 SORF Flanges

astm b564 uns n08811 Slip on threaded flange

astm b564 uns n08825 Slip On Flange

astm b564 uns n04400 Slip On Weld Flange

0 notes