#anti-monel

Explore tagged Tumblr posts

Text

Deep Dive Update

I've been working on a Part 2 for the Chris Wood deep dive. If there is anything you think should be added, DM me with receipts.

Also, I'll be doing more exposes in the near future. While I do have some people in mind, let me know if there are celebrities you'd like to see featured here. You can send in suggestions via DM or just drop them in the ask box.

Thanks!

#anti chris wood#anti karamel#anti melwood#anti karamelwood#anti kai parker#cw deep dive#deep dive#deep dives#supergirl#the vampire diaries#containment#almost famous#broadway#motu#masters of the universe#the carrie diaries#deuxmoi#cdan#anti monel#anti mon-el#anti supervalor#anti christopher wood

13 notes

·

View notes

Text

Monel 400 Pipes Suppliers

Chhajed Steel Limited Manufacturers and Exports high-quality Monel 400 Pipes and Tubes. These tubes are Fabricated from High-Quality Raw Materials. As monel is stress resistant, anti-corrosive & anti-cracking in fresh waters. These Monel 400 pipes and tubes are used widely in the marine industries and various other industries across the globe.

Our product includes tubes and pipes, Monel 400 Tubes, Monel 400 Pipes, Monel Alloy 400 Seamless Pipes & Tubes etc. They are available in the rectangular, square, coil, round, ‘U’ shape. Others are available in horn tube, IBR tube, capillary tube, precision tube, boiler tube and hydraulic tube. Monel 400 Pipes and Tubes are available in different grades and forms. They are at ease with the customization.

#Monel 400 Pipes Manufacturers in India#Monel 400 Pipes Suppliers in India#Monel UNS N04400 ERW Pipes#Monel 400 Pipes Exporters in India#Monel 400 Pipes Importers in India.

0 notes

Text

Ananka

1: Introduction to Monel Fastener Manufacturing

Introduction

Monel fasteners are crucial components in industries that demand high corrosion resistance and strength, such as marine, chemical processing, and oil and gas. Monel, a nickel-copper alloy, is celebrated for its durability and performance in harsh environments. This series of s will provide a detailed look into the manufacturing process of Monel fasteners, beginning with an overview of the entire process.

Material Selection

The manufacturing journey starts with selecting the appropriate Monel alloy. The most commonly used grades are Monel 400 and Monel K-500, each offering distinct properties suited to different applications. Monel 400 is known for its excellent corrosion resistance and high strength, while Monel K-500 offers greater hardness and strength due to its age-hardenable properties.

Forming

Once the material is selected, the next step is forming the raw Monel into the desired fastener shape. This is typically achieved through hot forging, which involves heating the material to make it malleable and then pressing it into shape using a die.

Heat Treatment

Heat treatment is crucial to enhance the mechanical properties of Monel fasteners. This process involves heating the fasteners to a specific temperature and then rapidly cooling them to increase their strength and hardness.

Machining

Following heat treatment, the fasteners undergo machining to achieve precise dimensions and threading. This step requires high-precision equipment and skilled operators to ensure the fasteners meet stringent tolerances.

Surface Finishing

The final step in the manufacturing process is surface finishing. This provides additional protection against corrosion and enhances the appearance of the fasteners. Common techniques include passivation, plating, and coating with anti-corrosive materials.

Conclusion

The manufacturing process of Monel fasteners involves several critical steps, each contributing to the final product's strength, durability, and performance. In the following s, we will delve deeper into each of these steps, starting with material selection and its impact on fastener quality.

Monel Manufacturer in India

2: Material Selection in Monel Fastener Manufacturing

Introduction

The foundation of a high-quality Monel fastener lies in the selection of the right material. Different applications require fasteners with specific characteristics, which are largely determined by the grade of Monel used. This explores the various grades of Monel used in fastener manufacturing and their properties.

Monel 400

Monel 400 is a nickel-copper alloy known for its excellent resistance to corrosion in a wide range of environments, including seawater, acids, and alkaline solutions. It is commonly used in marine and chemical processing applications. Fasteners made from Monel 400 offer reliable performance and durability.

Monel K-500

Monel K-500 is a precipitation-hardenable alloy that offers higher strength and hardness compared to Monel 400, while retaining similar corrosion resistance. This grade is ideal for applications requiring high mechanical properties and resistance to corrosive environments, such as oil and gas exploration. Monel K-500 fasteners are known for their toughness and durability.

Conclusion

Selecting the right grade of Monel is crucial in fastener manufacturing as it directly affects the fastener's performance and suitability for specific applications. Each grade offers unique properties, and understanding these can help in choosing the right fastener for the job. The next will focus on the forming process and how it shapes the Monel material into fasteners.

Monel Bolt Supplier

3: The Forming Process in Monel Fastener Manufacturing

Introduction

Forming is a pivotal stage in Monel fastener manufacturing, where the raw material is shaped into the desired fastener. This delves into the hot forging process, explaining how it creates fasteners that meet stringent standards for strength and precision.

Hot Forging

Hot forging involves shaping the Monel material at high temperatures, making it malleable and easier to form. This method is preferred for Monel fastener manufacturing because it enhances the metal's grain structure, resulting in stronger and more durable fasteners. The process begins with heating the Monel material to a specific temperature.

Heating

The Monel material is heated in a furnace to temperatures ranging from 1800°F to 2200°F (980°C to 1200°C). This heating process is critical as it makes the material pliable and ready for forging.

Forging

Once the material reaches the desired temperature, it is placed in a die and subjected to high-pressure deformation. This step requires precise control to ensure the shape and size meet the specifications. The forged fasteners are then cooled slowly to maintain their structural integrity.

Precision and Consistency

Hot forging ensures that the fasteners have a uniform grain structure, which enhances their mechanical properties. The process also allows for the production of complex shapes with high precision and consistency.

Conclusion

The forming process is a critical step in Monel fastener manufacturing, setting the foundation for the fastener's strength and durability. Hot forging, heating, and precision control all contribute to creating a fastener that meets precise specifications. The next will explore the heat treatment process, which enhances the fastener's mechanical properties.

Monel Fasteners Manufacturer in India

4: Heat Treatment in Monel Fastener Manufacturing

Introduction

Heat treatment is a crucial step in Monel fastener manufacturing that enhances the mechanical properties of the fasteners, such as hardness, strength, and resistance to creep. This explores the heat treatment process, its various stages, and its importance in producing high-quality Monel fasteners.

Purpose of Heat Treatment

Heat treatment involves heating and cooling the fasteners to alter their physical and mechanical properties. The primary goals are to increase hardness, improve strength, and enhance resistance to wear and fatigue.

Stages of Heat Treatment

The heat treatment process typically involves three stages: solution annealing, quenching, and aging.

Solution Annealing

The first stage is solution annealing, where the fasteners are heated to a high temperature to dissolve any precipitated phases and create a homogeneous structure. This process improves the material's ductility and prepares it for the next stage.

Quenching

After solution annealing, the fasteners are rapidly cooled, usually by immersion in water or oil. This process, known as quenching, locks the dissolved elements in place, creating a uniform microstructure. Quenching enhances the fastener's strength but can also make it brittle, so it is often followed by aging.

Aging

Aging involves reheating the fasteners to a lower temperature and then cooling them slowly. This process precipitates secondary phases, which strengthen the material and reduce brittleness. The result is a fastener with a balanced combination of strength and toughness.

Conclusion

Heat treatment is essential for producing Monel fasteners with the desired mechanical properties. The solution annealing, quenching, and aging stages work together to enhance the fastener's hardness, strength, and durability. The next will discuss the machining process, which achieves precise dimensions and threads.

Monel Fasteners suppliers

5: Machining in Monel Fastener Manufacturing

Introduction

Machining is a critical step in Monel fastener manufacturing, where the fasteners are shaped to precise dimensions and threads are created. This delves into the machining process, explaining how it ensures the high precision and quality required for Monel fasteners.

Challenges of Machining Monel

Monel is a difficult material to machine due to its high strength, work hardening properties, and tendency to generate heat during cutting. These challenges require specialized techniques and equipment to achieve the desired precision and finish.

Cutting Tools

Machining Monel requires cutting tools made from high-speed steel, carbide, or ceramic materials, which can withstand the high temperatures and stresses involved. These tools are designed to maintain sharp edges and resist wear.

Coolant and Lubrication

Using appropriate coolants and lubricants is essential to control the heat generated during machining. These fluids help dissipate heat, reduce friction, and prevent the cutting tools from overheating and wearing out prematurely.

Precision Machining

Precision machining involves several steps to ensure the fasteners meet exact specifications:

- Turning: This process shapes the fastener by rotating it against a cutting tool. It is used to create the basic cylindrical shape and remove excess material.

- Milling: Milling involves moving a rotating cutting tool across the fastener to create flat surfaces, grooves, and other features.

- Threading: Threads are created using taps or thread rolling techniques. Thread rolling is preferred for Monel fasteners as it enhances the material's strength by displacing rather than cutting the material.

Quality Control

After machining, the fasteners undergo rigorous inspection to ensure they meet the required dimensions and tolerances. This includes checking the thread pitch, diameter, and surface finish.

Conclusion

Machining is a critical step in Monel fastener manufacturing, requiring specialized techniques and equipment to achieve high precision and quality. The use of appropriate cutting tools, coolants, and precision machining processes ensures that the fasteners meet exact specifications. The next will focus on surface finishing, the final step in the manufacturing process.

Monel Manufacturer in Mumbai

6: Surface Finishing in Monel Fastener Manufacturing

Introduction

Surface finishing is the final step in Monel fastener manufacturing, providing additional protection against corrosion and improving the fastener's appearance. This examines the various surface finishing techniques used to produce high-quality Monel fasteners.

Purpose of Surface Finishing

Surface finishing enhances the fastener's resistance to environmental factors, such as moisture, chemicals, and heat. It also improves the fastener's aesthetic appeal and can provide additional functional benefits, such as reduced friction.

Common Surface Finishing Techniques

Several surface finishing techniques are used for Monel fasteners, each offering unique benefits:

Passivation

Passivation involves treating the fasteners with an acid solution to remove surface contaminants and enhance the natural oxide layer. This process improves the fastener's corrosion resistance without altering its appearance.

Plating

Plating involves coating the fasteners with a thin layer of another metal, such as zinc, cadmium, or chromium. This additional layer provides extra protection against corrosion and can also improve the fastener's wear resistance.

Coating

Coating involves applying a layer of protective material, such as paint or a polymer, to the fastener's surface. This technique offers excellent corrosion protection and can be customized to meet specific environmental or aesthetic requirements.

Quality Inspection

After surface finishing, the fasteners undergo thorough inspection to ensure the coating or treatment is uniform and defect-free. This step is essential to guarantee the fasteners' performance and longevity in their intended applications.

Conclusion

Surface finishing is the final, yet critical, step in Monel fastener manufacturing. Techniques such as passivation, plating, and coating enhance the fasteners' corrosion resistance and appearance, ensuring they perform well in harsh environments. This series has provided an in-depth look into the manufacturing process of Monel fasteners, highlighting the importance of each step in producing high-quality, durable products.

Monel Fasteners

0 notes

Text

High-Performance Alloys in Piping Systems: Monel 400, Hastelloy C276, Copper Nickel, and the Role of Titanium Pipe Manufacturers in India

Titanium is a relatively sought-after steel in several industries, and bicycle producers are no exception. Because of its light weight and extraordinary sturdiness, a titanium motorcycle frame can offer riders of all talent tiers with a remarkable revel in. Furthermore, the highest caliber and accuracy of titanium tube are required at the same time as constructing a titanium bike’s body.

Sealed grade 9 titanium tube is the first-class material to make use of whilst constructing a titanium motorcycle body. Your frame’s resistance to corrosion and wear will ensure that it lasts for a completely lengthy length. Additionally, the seamless creation guarantees that the frame has no possible vulnerable points.

One of the principle benefits of the usage of seamless Grade nine titanium tubing is its first-rate power-to-weight ratio. Consequently, you may create a body that is sturdy and sturdy without sacrificing weight or power. For professional riders, who need a motorcycle that may navigate all terrains speedy and easily, that is crucial.

The seamless grade nine titanium tubing used to make bicycle frames also has the introduced advantage of being suitable with lots of welding strategies. It’s smooth to weld this fabric into a strong, elegant seamless body the usage of TIG or MIG welding strategies.

Building a titanium bike frame with seamless grade 9 titanium tubing ensures a long lasting, stylish, and practical ride. Therefore, in case you’re wanting to improve your motorcycle, consider buying a titanium body made completely of seamless grade nine titanium tubing. It has several benefits to offer.

Monel 400 Alloy

Pipes are unrivaled in terms of typical performance and resistance to corrosion. When exposed to gaseous fluorine, hydrochloric acid, sulfuric acid, hydrofluoric acid, and their derivatives, the Monel 400 pipes reveal notable resistance to corrosion. The alloy finds application in numerous industries, such as the chemical and maritime ones. General uses include pipelines, boiler feed water warmers, substitute warmers, drive-shafts, chemical apparatus, water and fuel storage tanks, crude oil distillation vessels, processing vessels, pipelines, and naval tools.

Hastelloy C276 metal

This Hastelloy C276 wrought nickel-chromium-molybdenum alloy happens to be the most pliable anti-corrosion alloy available. Because it does not readily form grain boundary precipitates in the heat-affected weld zone, this alloy is perfect for use in the majority of chemical processes in its welded state. Furthermore, in temperatures as high as 1900°F, Hastelloy C276 pipes exhibit exceptional resistance to oxidation, stress-corrosion cracking, and coring. Alloy C-276 keeps its exceptional resistance even when subjected to a wide variety of substances.

Copper-Nickel Pipe

The technique used to manufacture Nickel 200 flanges is vital to the final product’s efficacy and fine. Copper-nickel alloy pipes have many commercial uses due to their energy, resistance to corrosion, and warmth conductivity. We’ll talk about making copper-nickel alloy pipes here.

Titanium pipe manufacturers in India

Products made with titanium tubes are renowned for their outstanding mechanical properties, great strength, and light weight. Many heat exchange devices, such as transportation pipes, condensers, evaporators, coil heat exchangers, serpentine tube heat exchangers, and tube and tube heat exchangers, use it extensively. The industry standard for many nuclear power reactors is titanium tubes.

As a producer and supplier of premium titanium tubes, ASTM B564 UNS N06625 handle skinning on all tube surfaces, even if it lowers the rate of completed products and raises costs.

0 notes

Text

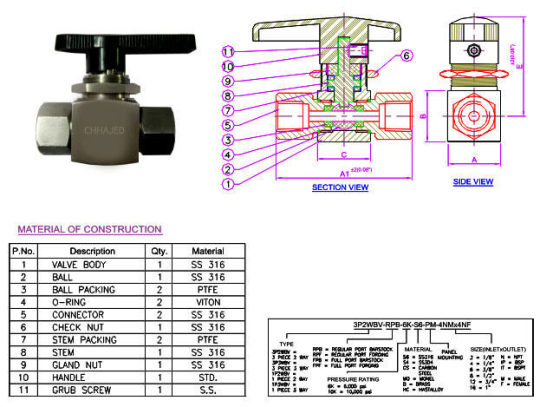

Ball Valve Suppliers in India

2 WAY BALL VALVE F X F (PANEL MOUNTING)

Features : 1. SS 316 construction for corrossion resistance, full or reduced bore for excellent flow.3 piece design.peek/delrin seat for better performance. 2. Ball hard chrome plated for smooth operation. Physical Features : Pressure rating 400 kg/cm2 Material Options : 1. Brass, SS 316, carbon steel, bronze, hastalloy, monel, etc. 2. Optional kel-f, viton packing available with high pressure valves Standards : BS 5750; ISO 9001-2000; MSS SP-99 Testing : 1. For seat and seal leakage with a leakage rate of 0.1 std. Cm3. 2. Working pressure : 6000 psi (431 bar) Hydro Tests : 1. Performed with pure water at 1-1/2 times of the working pressure. 2. Other tests like helium, seismic are availbale upon request. End Connections : End connections available in NPT / BSPP / BSPT / JIC / SAE

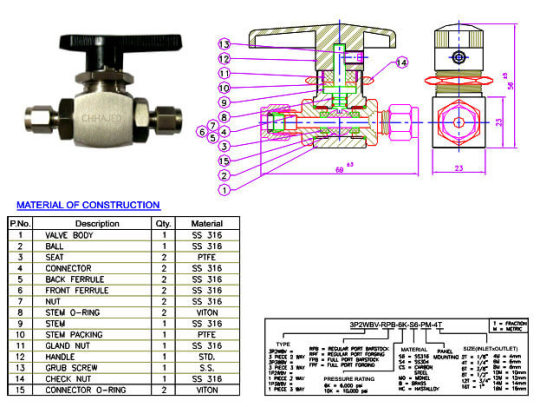

2 BALL WAY PANEL MOUNTING TUBE X TUBE

Features : 1. SS 316 construction for corrossion resistance, full or reduced bore for excellent flow.flexible 3 piece design. Anti blow out internally 2. Ball hard chrome plated for smooth operation. 3. Loaded stem for safety. 90° Smooth operation. Physical Features : Pressure rating 400 kg/cm2 Material Options : 1. Brass, SS 316, carbon steel, bronze, hastalloy, monel, etc. 2. Optional kel-f, packing available with high pressure valves Standards : BS 5750 Testing : 1. Each valve is tested with nitrogen at 1000 psi 2. For seat and seal leakage with a leakage rate of 0.1 std. Cm3/min. Hydro Tests : 1. Performed with pure water at 1-1/2 times of the working pressure. 2. Other tests like helium, seismic are availbale upon request. End Connections : Variety of end connections 1/4" to 1" npt, bsp male or female threaded or 1/4", 3/8", 1/2" powerlok single or twin ferrule tube fitting ends.

0 notes

Text

What is it about stainless steel that you need to know?

Manufacturing relies on a wide variety of metals, but stainless steel is among the most significant of these. Because of the strong demand for it, it is one of the metals that is among the most expensive on the market. As a result of this, a significant number of engineers do not make use of the advantages that it provides. On the other hand, many engineers are of the opinion that the expense of purchasing stainless steel is justified due to the material's long-term durability and adaptability.

Many in the industrial world consider stainless steel to be the most impressive metal available. Inconel pipe fittings manufacturer in India are outstanding. Stainless steel that has been made is not only very useful, but also highly sought after because of the variety of uses it can be put to. That's why they have their very own stainless steel fabrication shop: the fabricators. This is fantastic news, as it solidifies their position as Nickel alloy suppliers.

Manufactured stainless steel offers a number of benefits when used in manufacturing. Some instances are shown below.

100% Recyclable

Stainless steel may be damaging to the environment, yet few companies realize this. Consequently, Monel suppliers in India produce a great deal of stainless steel waste, such as steel scraps and the like. However, there are others who are aware of their surroundings and act accordingly. The firm asserts that eliminating garbage altogether through recycling will reduce harmful by-products. Inconel suppliers in India are of the highest grade.

Simple Fabrication

It would appear that stainless steel is an excellent metal. Unlike aluminum conductor, this metal may be used in many different contexts. Depending on the use and context, it may be processed in a variety of ways, including chopping, melting, or welding. The greatest Inconel tube suppliers in India is available on the web.

Anti-corrosion and rust properties

Stainless steel's resistance to corrosion is one of the main reasons it's used in so many different kinds of manufacturing. Inconel flanges manufacturer in India will help you out. Multiple alloys are often used in the fabrication of stainless steel. The element chromium plays a crucial role in preventing steel from corroding. Other alloys, however, are also used. In general, the setting in which the steel will be used is reflected in the specific ratios of these alloys. When it comes to damp parts Monel tube manufacturers in India, for instance, lower-grade alloys tend to win out. High-quality alloys are recommended for use with alkaline or acidic solutions. The outcomes from Inconel plate suppliers in India are rather good.

Resistance to High Temperatures

Stainless steel's resistance to fire and high temperatures is well-established. This boosts its practicality and elevates it to the ranks of the world's most significant metals. Valve bodies, heat exchangers, boilers, and water heaters are just some of the many products that can benefit from using stainless steel that has been alloyed with nickel and chromium. Aluminium costs from Inconel round bar manufacturer in India are competitive.

It's worth it in the long run.

Stainless steel often receives criticism due to its high price. However, the metal significantly improves the infrastructure's value and performance by boosting its resilience and longevity. These intangible gains are often overlooked, yet they end up being crucial. Inconel fasteners manufacturer in India are the best.

1 note

·

View note

Text

Stainless Steel Vs Aluminum high Pressure Pipe Clamps

Features of stainless steel clamps:

Stainless steel clamp not only has a beautiful shape, and the use of the process is very convenient, with a strong clamp function, outstanding sealing. Therefore, the stainless steel clamp in the machine tool manufacturing, diesel engine equipment, a variety of vehicle equipment, chemical equipment and pipes have been excellent performance, for our life has brought a lot of lunch.

Therefore, people are particularly fond of stainless steel clamps, the parties have been well received. In addition, stainless steel clamp also has strong corrosion resistance and wear resistance, long service life. For us to save a lot of manpower and to a certain extent also save us a lot of costs. In addition, stainless steel clamp also has many categories, such as double-wire stainless steel clamp, stainless steel brass clamp, galvanized stainless steel clamp, and so on. Clamp is used for gas, liquid and other things linked in the industrial production widely used. Then the use of the clamp process is how? Then let’s give an introduction.

At the time, the clamp had become the devaluation skill of liquid and gas pipeline connection. Although this skill was later developed in China than abroad, it was quickly accepted by the domestic market due to its advanced skill. From the beginning of research and development in 1998 to now, through just a few years of development and use, the two traditional pipe joining methods of flange and welding have been gradually replaced.

Pipes of Steel, Stainless Steel, Exotic Materials like Monel, Hastelloy, Inconel, Titanium can be used.Designed according to DIN 3015 – Part -2 Even Heavy Series Clamps Pipe – Tube clamps are available in Multilayer, Welding Plates, Rail Nuts, Construction Types, Rubber inlay types and many other designs. Steel Components undergo trivalent coating for anti-corrosive measure, better performance and Smooth Finishing.Further we have Full details of high pressure Pipe – Tube clamp in our catalogue. Catalogue contains proper Selection Guide, Dimensions and Part Numbers

Features of Aluminum steel clamps:

Designed in accordance with the standards of DIN 3015 – Part 2

The clamp bodies are made up of aluminum pipe with steel / stainless steel plates & bolts.

It is constructed through the use of aluminum extrusions of high tensile strength

The product is available along with Multilayer, Welding plates, Rail Nuts, etc.

Can be availed in different construction types including Rubber Inlay Types & many more

Tap here to read more about:

1 note

·

View note

Text

I'm sticking to my guns here. Monel was fucking annoying cuz he took away from Kara's narrative and was just plain rude and annoying. Lena also sucks for the same reasons on top of being a whiny rich white brat who thinks it's ok to assault and steal from her friend and violate the free will all of humanity bc waaaahhh her friend didn't come out to her waaaahhh.

Mon-el vs. Lena: They Both Suck Edition

83 notes

·

View notes

Text

The show actually called mon-el abusive!!!

2 notes

·

View notes

Text

WATCHING THE EPISODE AND THEYRE SETTING MON-EL UP TO LEAVE ITS TRUE ITS TRUE ITS HAPPENING

13 notes

·

View notes

Text

Hating the male half of a popular or canon ship does not automatically mean we want the female half to be single, celibate, or paired with another female because of gurl power, or yay feminism sexism and heterophobia. Especially when there are better male dating options for her. Even if neither would cause stupid drama or light horny shippers on fire, they would still be better boyfriends. Nobody except the most densest people are calling out this male character and this ship because he’s cramping her style as a feminist icon simply by being her boyfriend. It takes a lot of specifically chosen bad characterization and backstory choices and continued bad choices to make a character despised.

#Anti-Monel#Anti-Karamel#lowkey anti-supercorp fandom for dropping the ball further legitimizing this fandoms persecution complex#your behavior basically shields this character from criticism now#because people with valid points beyond liking a cute femslash ship look like psychos condoning your toxic behavior#because we both hate the same male character we get lumped in with your behavior that goes beyond criticizing a character

27 notes

·

View notes

Text

The CW going from an amazing Danvers sisters episode to shoving Mon-el down our throats again is abso-fucking-lutely disgusting.

The Danvers episode was perfect, everything I’ve wanted for 2 seasons, and yet they still ruined it by following it up with Mon-El impossible return.

They’re trying to show us Kara finally grieving, understanding that she’s just as much human as she is alien, and yet they’re bringing back the Daxam asshole.

If they really bring Mon-El back to reunite with Kara, after breaking up Alex and Maggie for something so stupid (MAGGIE HAS A DAUGHTER IN THE COMICS) I think all hope is lost of the CW’s Supergirl.

I’m disappointed, furious, but not shocked by the CW’s blatant disrespect.

#Supergirl#anti-karamel#Anti-Monel#anti-everything Karamel stands for#Alex Danvers#Maggie Sawyer#Kara Danvers

36 notes

·

View notes

Text

Monel 400 Pipes Exporters in India

Chhajed Steel Limited Manufacturers and Exports high-quality Monel 400 Pipes and Tubes. These tubes are Fabricated from High-Quality Raw Materials. As monel is stress resistant, anti-corrosive & anti-cracking in fresh waters. These Monel 400 pipes and tubes are used widely in the marine industries and various other industries across the globe.

Our product includes tubes and pipes, Monel 400 Tubes, Monel 400 Pipes, Monel Alloy 400 Seamless Pipes & Tubes etc. They are available in the rectangular, square, coil, round, ‘U’ shape. Others are available in horn tube, IBR tube, capillary tube, precision tube, boiler tube and hydraulic tube. Monel 400 Pipes and Tubes are available in different grades and forms. They are at ease with the customization.

#Monel 400 Pipes Manufacturers in India#Monel 400 Pipes Suppliers in India#Monel UNS N04400 ERW Pipes#Monel 400 Pipes Exporters in India#Monel 400 Pipes Importers in India.

0 notes

Text

Shouldn’t be Surprised

But I was anyway.

I rarely DNF books. I’m a reader, and I’ve read some very badly written stuff all the way to the end.

But, Supergirl: Age of Atlantis.

It’s fucking swimming in Mon-El, and, from what I could see, has absolutely no Alex is a lesbian in it at all (although, maybe it’s farther in, but, my guess is not. If anyone has read it an knows differently let me know, I might reconsider reading it)

So, yeah... screw you DC, I’ll keep reading Barry Lyga’s awesome Flash series, but, this one is going down the tubes for sure. Gag, Mon-El... way to ruin a book.

1 note

·

View note

Text

watching seasons 2 and 3 of supergirl like

4 notes

·

View notes

Text

the amount of times that other people have to talk kara into forgiving/getting back with monel, like hmm maybe if she has to be talked into it so much it’s not what she wants to happen

96 notes

·

View notes