#ammonia fermentation

Explore tagged Tumblr posts

Text

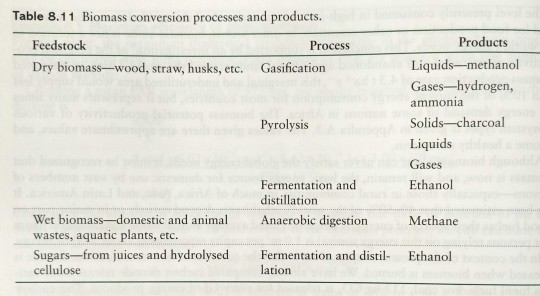

Table 8.11 lists some such feedstocks, processes, and products.

"Environmental Chemistry: A Global Perspective", 4e - Gary W. VanLoon & Stephen J. Duffy

#book quotes#environmental chemistry#nonfiction#textbook#biomass#feedstock#wood#straw#husks#gasification#pyrolysis#fermentation#distillation#liquid#methanol#gas#hydrogen#ammonia#charcoal#ethanol#anaerobic#digestion#waste products#aquatic plants#methane#sugar#hydrolysis#juice#cellulose

0 notes

Text

OC deep dive tag

TY for the open tag @the-golden-comet

Here is Fen:

Phobias: Very slight acrophobia

Other fears: Having his secret discovered, losing those close to him

Pet peeves: arrogance, slander, cockiness

3 items you can find in his bedroom: Music box, bed (obviously), pitcher of water

First thing he notices in a person: Body language

On a scale of 1 to 10, how high is his pain tolerance? A solid 7

Does he go into fight or flight mode when under pressure? Yes, and if push comes to shove, it’s fight all the way.

Does he come from a big family/ are they a family person? No to the first one. His biological family are all dead. Only his adoptive father is still alive. Closest thing to a family are the group of friends he has made.

What animal represents them the best? A crow (literally, that’s what he is)

What is a smell he dislikes? Rotting flesh, sulphur and ammonia

Has he broken any bones? Yes

How would a stranger describe him? Very strange and peculiar looking. You see, Fen conceals himself before going out of doors. As long as no one gets too close or looks for too long, he can pass for a fox, albeit a very unusual looking one.

Is he a night owl or a morning bird? Morning bird

What is a flavor he hates, and a flavor he loves? Hates anything sulfurous or deeply fermented. Likes savory and sweet

Does he have any hobbies? Spear fishing, darts, whittling

Boom,surprise birthday party! How does he react to surprises? Either is happy, or triggers the fight response

Does he like to wear jewelry? No

Does he have neat or messy handwriting? It’s legible, not too fancy

What are the two emotions he feels the most? Determination and restlessness

Does he have a favorite fabric? Hemp cloth

What accent does he have? I’d imagine somewhere between a UP (Upper Peninsula) and Acadian.

Leaving this tag open for anyone interested! Enjoy!

#oc deep dive#tag game#open tag#writer#writers#writers and poets#writing community#writer on tumblr#writeblr

8 notes

·

View notes

Text

I just realized that the Nordic countries are probably just as well-known for their notorious fish dishes as they are for Ikea, skiing, volcanoes, and akvavit.

Surströmming (Swedish sardines; western culture's favorite to rag on right now)

Hàkarl (Icelandic; fermented shark, with a strong ammonia odor)

Inlagd sill (pickled herring; yes, some people absolutely love pickled herring, but just as many people can't stand the stuff)

And of course, lutefisk (Norwegian; whitefish, usually cod, dried and then reconstituted in lye and then rinsed for four to six days; typically very gelatinous in texture)

#Tried to find a Danish-specific dish but couldn't find anything unique to Denmark#Though most of these are eaten across the Nordic countries all the same regardless of origin

4 notes

·

View notes

Text

Like the piss shark, there must be a way to take the ammonium ions out of the meat so you just need more experiments before you can achieve your dreams

just found out that giant squid meat is chock fucking full of ammonium ions to increase buoyancy so they would taste fucking disgusting if you tried to make calamari out of them. i mean i wasn't planning on it but a girl can dream right? nobody talk to me

#they ferment the shark for long so it can become edible#but since its ions#it might be possible to neutralize the meat with a salt bath#not regular salt though#but smth that takes out ammonia

32K notes

·

View notes

Text

Reykjavik Food Walk with Jenny

The Mountain Lady

Pulled duck on traditional Icelandic flatbread from the Westfjords, with carrot purée, pickled red onions, and horseradish sauce.

Lightly cured arctic charr on chickpea blini (a.k.a. the tiny pancake), with horseradish sauce, roe, crispy lentils, and yuzu elderflower dressing.

The Messhall

Arctic char baked in honey, butter and lemon with cherry tomatoes and almonds.

Icelandic “Plokkfiskur” with Bernaise Sauce: Boiled cod mashed with potatoes, onion, garlic, celery, lime, white wine, cream, and butter.

Icelandic rye bread, “rúgbrauð” with butter.

Bæjarins Beztu Pylsur

The Town’s Best Hot Dogs

Traditional Icelandic hot dog with Icelandic ketchup, Icelandic mustard, remoulade sauce (remúlaði), deep fried onions and raw onions.

Íslenski Barinn

The Icelandic Bar - Home of the all the Icelandic Beer and unique cuisine

Traditional Icelandic lamb soup with root vegetables - “Kjötsúpa”

Fermented shark - “Hákarl” with a shot of Brennivín

Einstök Lite White Ale // Appelsín orange soda

Café Loki

Rye bread ice cream with whipped cream and caramelised rhubarb syrup

The Icelandic Twisted Donut = “Kleina”

Some of the best coffee in town!

Everything was so good. The fermented shark smelled worse than it tasted (salty ammonia flavor) which Jenny instructed us to chew 10 times and shout "Viking!" My group liked the hot dogs best. Two of the stops included Arctic char (milder than salmon), something I want to start making at home.

3 notes

·

View notes

Text

Biohydrogen Market to Double by 2034: Key Growth Drivers

The global biohydrogen market, valued at US$ 73.4 Mn in 2023, is forecast to more than double in size, reaching approximately US$ 146.7 Mn by 2034, expanding at a CAGR of 6.5% from 2024 to 2034. This growth is driven by a global shift toward renewable energy sources amid intensifying climate change concerns and dwindling fossil fuel reserves.

A Green Alternative in a Climate-Conscious Era

The mounting impact of fossil fuel consumption on global warming has intensified the search for clean and sustainable energy sources. Biohydrogen has emerged as a promising contender. Unlike conventional hydrogen produced through fossil fuel-based processes, biohydrogen is derived from biological means—making it a low-emission, environmentally safe alternative.

Green hydrogen derived from wind and solar power is gaining attention for its vast potential in reducing greenhouse gas emissions, particularly in hard-to-abate sectors such as refineries, industrial processes, and ammonia production.

Biohydrogen: Understanding the Process

Biohydrogen production involves the utilization of renewable biomass, photosynthetic bacteria, and dark fermentation techniques. It leverages microbial metabolism to convert organic substrates into hydrogen without releasing greenhouse gases. Two key processes dominate the production landscape:

Moreover, biomass gasification—a thermochemical process using heat, steam, and oxygen—has proven to be an efficient method for hydrogen generation, utilizing agricultural and organic waste.

Market Drivers: Climate Policies and Energy Security

Several factors are fueling the rapid adoption of biohydrogen:

Regional Insights: Asia Pacific Leads the Charge

Asia Pacific emerged as the leading region in the global biohydrogen market in 2023. Countries such as Japan, China, India, and South Korea have outlined aggressive hydrogen strategies. These nations are:

Japan’s revised Basic Hydrogen Strategy targets hydrogen supply growth from 3 million tons by 2030 to 20 million tons by 2050, setting a strong precedent for other countries.

Challenges: Infrastructure and Cost Barriers

Despite strong growth projections, the biohydrogen industry faces notable obstacles:

Competitive Landscape: Major Players and Recent Developments

Key companies like ExxonMobil Corporation, Linde Group, Air Products and Chemicals, Inc., BP, Shell Plc, and Chevron Corporation are driving innovation in the biohydrogen value chain. These firms are actively pursuing:

In April 2024, H2Carrier proposed two offshore wind farms in Norway to produce green hydrogen aboard floating vessels. Likewise, White Martins, a Linde subsidiary, announced a new 5MW electrolyzer in Brazil to serve the local glass industry—signaling industrial-scale applications of biohydrogen.

Outlook: The Road Ahead for Biohydrogen

As climate action intensifies and petroleum dependency declines, biohydrogen stands at the forefront of the next energy revolution. Its potential to serve multiple industries—from automotive to chemicals—positions it as a cornerstone in the future clean energy mix.

With continued investment, policy support, and technology development, the biohydrogen market is set to play a pivotal role in global decarbonization efforts by 2034 and beyond.

0 notes

Text

How to tell if the fermentation process in a bio-organic fertilizer production line is normal?

Fermentation is the key step in bio-organic fertilizer production lines. Good fermentation breaks down organic matter, kills pathogens and weed seeds, and boosts fertilizer efficiency.

1.Temperature Trends

Normal: Early stage (days 1-3): Temperature rises quickly to 50–65°C. High-temperature stage (55–70°C) lasts 5–7 days. Later stage: Temperature cools down slowly.

Abnormal: Too low (<50°C): Could be due to high moisture, imbalanced C/N ratio, or poor aeration, causing slow fermentation. Too high (>75°C): Could be from too much air or overly compacted material, which kills beneficial microbes.

2.Odor Changes

Normal: Slight ammonia smell early on, then turns into an earthy scent or sour fermentation smell.

Abnormal: Foul odors (like rotting or sulfur smell): Likely due to anaerobic conditions or too much sulfur. Fix by compost turning machines the pile or adjusting airflow.

3.Changes in Material Appearance

Normal: Material turns dark brown, becomes loose and fluffy, with no large chunks of raw stuff.

Abnormal: Hard, clumped material: May be from low moisture or not turning enough. Add water or turn more often.

4.pH Changes

Normal: pH might be slightly high early on (7.5–8.5), then stabilizes at 6.5–7.5.

5.Fermentation Duration

Normal: Usually takes 15–30 days (depends on material and method). When the pile cools to room temperature, it’s basically mature.

By monitoring the temperature, smell, appearance, pH and fermentation cycle, it is possible to accurately determine whether the fermentation of the bio-organic fertilizer production line is normal.

0 notes

Text

Operating standards for organic fertilizer production line equipment

Standardized operation of organic fertilizer production line equipment can ensure production safety. Whether it is processing livestock and poultry manure, straw or kitchen waste, organic fertilizer equipment needs to strictly follow the operating specifications.

1.Fermentation Management

Regular Turning: In tank-style fermentation, use a compost turning machine every 1–2 days to ensure oxygen supply and prevent localized overheating (>70°C), which could kill beneficial microbes.

Temperature Control: Maintain fermentation temperature at 55–65°C for 7–15 days to fully eliminate pathogens and weed seeds.

Rain Protection: Cover outdoor piles with waterproof tarps to prevent nutrient loss from rainwater.

2.Equipment Safety

Regular Lubrication: Apply lubricant weekly to bearings, chains, and other transmission parts to reduce wear.

Electrical Checks: Keep motors and control panels dry and dust-free to prevent short circuits and downtime.

Emergency Stop Tests: Test emergency brakes and safety guards monthly to ensure quick response during incidents.

3.Quality Control

Full Decomposition: Finished compost should be dark brown, odor-free, with a pH of 6.5–8.5.

Thorough Screening: Use a drum screen to remove undecomposed debris; ideal particle size is 2–4mm.

Airtight Packaging: Pack finished products (<30% moisture) in moisture-proof bags to prevent clumping during storage.

4.Environmental and Worker Safety

Exhaust Treatment: Install bio-deodorizers in fermentation areas to control ammonia and hydrogen sulfide emissions.

Personal Protection: Workers must wear masks and gloves. Wash hands after handling compost to prevent pathogen exposure.

In short, standardized operation of organic fertilizer production line equipment is the core to ensure production safety and improve fertilizer quality, and every link needs to be strictly controlled.

0 notes

Text

How can a fermentation turning machine improve its environmental performance

The improvement of environmental protection performance of the fermentation compost turning machine can be achieved in the following multiple ways:

1. Reduce odors and harmful gas emissions: The use of closed fermentation tanks or fermentators can effectively reduce the emissions of harmful gases such as ammonia and hydrogen sulfide produced during the fermentation process. Equipped with waste gas collection and treatment devices, such as biological deodorization towers or activated carbon adsorption devices, to purify and treat the waste gas produced during the fermentation process. By precisely controlling the fermentation temperature, humidity and ventilation volume, the generation of odorous substances can be reduced.

2. Energy conservation and consumption reduction: Efficient motors and transmission systems are adopted to reduce the energy consumption of organic fertilizer equipment during operation. The waste heat generated during the fermentation process is utilized to provide thermal energy for other production stages through heat exchangers.

3. Intelligent control: Through sensors, parameters such as temperature, humidity, and oxygen concentration during the fermentation process are monitored in real time, and the frequency of turning the pile and ventilation volume are automatically adjusted to ensure that the fermentation process is efficient and environmentally friendly. It supports remote monitoring and fault early warning. Operators can keep track of the equipment's running status in real time through their mobile phones or computers, and promptly identify and solve problems.

4. Resource utilization: By optimizing the fermentation process, the nutrient content and fertilizer efficiency of organic fertilizers can be enhanced, reducing reliance on chemical fertilizers. Quickly handle organic waste to reduce the pressure on the environment caused by waste accumulation.

Through the above measures, the fermentation turning machine can not only effectively enhance its environmental protection performance, but also achieve efficient utilization of resources and promote the sustainable development of organic fertilizer production.

0 notes

Text

Odor Control in the Pharmaceutical Industry: Ensuring Compliance and Clean Air

Introduction

The pharmaceutical industry is synonymous with precision, safety, and regulatory compliance. However, one often-overlooked aspect is Odor Control For Pharma. With the use of volatile compounds, solvents, and complex chemical reactions, many pharmaceutical processes emit strong odors that can impact worker health, community well-being, and environmental compliance. Implementing an effective odor control system is not just a regulatory requirement — it’s a commitment to operational excellence and social responsibility.

Why Odor Control Matters in Pharma

In pharmaceutical manufacturing, odors typically arise from:

Active pharmaceutical ingredient (API) production

Solvent recovery and handling

Fermentation and biological processes

Effluent treatment plants (ETPs)

These odors can be persistent and unpleasant, often containing volatile organic compounds (VOCs), ammonia, hydrogen sulfide, and other noxious gases. Left uncontrolled, these emissions can lead to:

Worker complaints and health concerns

Negative community perception

Non-compliance with environmental regulations (e.g., by CPCB and SPCBs)

Risk of shutdowns and penalties

Odor Control Solutions for Pharma Facilities

Here are some of the most effective technologies used in the pharma sector:

1. Activated Carbon Adsorption

This method is widely used for removing VOCs and organic odors. Carbon filters are particularly effective where low concentrations of odorants are involved.

2. Chemical Scrubbers

Wet scrubbers use neutralizing chemicals to remove acidic or basic odor-causing compounds such as ammonia or sulfur compounds.

3. Biofilters

Biofiltration systems utilize microorganisms to break down organic and inorganic odorants. This is an eco-friendly solution often used in ETPs.

4. Ozone and UV-Based Systems

Advanced oxidation processes like ozonation can destroy odor molecules at the source, especially useful for air disinfection in controlled environments.

5. Enclosure and Capture Systems

Enclosing odor-generating processes and using localized exhaust and capture systems ensures pollutants don’t escape into the ambient environment.

Best Practices for Odor Management in Pharma

Conduct regular odor audits to identify sources and evaluate system performance.

Use real-time odor monitoring technologies for VOCs and other emissions.

Ensure preventive maintenance of odor control systems.

Train personnel on handling odor-generating chemicals safely.

Engage with local communities and address any odor-related grievances proactively.

Regulatory Compliance in India

The Central Pollution Control Board (CPCB) and respective State Pollution Control Boards (SPCBs) mandate that pharmaceutical facilities control emissions — including odor — as part of their environmental compliance. Failure to do so can lead to:

Rejection of Environmental Clearance (EC)

Suspension of Consent to Operate (CTO)

Public litigation and local protests

Implementing robust odor control systems helps maintain compliance and builds community trust.

Conclusion

For pharmaceutical companies in India and worldwide, odor control is not just a technical requirement but a symbol of responsible manufacturing. Investing in high-quality odor mitigation systems enhances environmental performance, supports regulatory compliance, and protects brand reputation.

Whether you’re setting up a new facility or upgrading an existing one, integrating an advanced

Odor Control For Pharma solution should be at the top of your environmental strategy.

Visit:- https://www.odorcontrol.in/odor-control-pharma.html

0 notes

Text

Pyridine Is a Pillar of the Agrochemical Industry

The Pyridine Market is expanding steadily, driven by its essential role in chemical synthesis, agrochemical manufacturing, pharmaceuticals, and industrial solvents. Pyridine, a colorless, flammable, and volatile liquid with a strong odor, is a basic heterocyclic organic compound used as a precursor and reagent in a wide range of industries.

With rising demand for herbicides, insecticides, vitamins, and advanced materials, pyridine remains a vital component in global chemical supply chains. Its versatility and reactivity make it indispensable for both bulk chemical and specialty chemical applications.

Market Overview

Pyridine (C₅H₅N) is primarily produced through chemical synthesis—either via acetaldehyde, ammonia, and formaldehyde, or from coal tar extraction. It's widely used in:

Agrochemicals – especially as an intermediate for herbicides, insecticides, and fungicides

Pharmaceuticals – for the synthesis of antihistamines, antituberculosis agents, and vitamins (e.g., B3/Niacin)

Solvents – in adhesives, dyes, rubber, and paints

Food Additives and Flavors – trace use in artificial flavoring agents

Electronics and Catalysts – as a ligand and precursor in advanced materials

Key Market Trends

High Demand in Agrochemical Production

Pyridine is a core component in producing paraquat, diquat, and chlorpyrifos, widely used in crop protection.

Expansion of Pharmaceutical Sector

Growing global need for vitamins and synthetic drugs is boosting pyridine consumption as an intermediate.

Rise in Solvent Applications Across Industries

Pyridine's polar nature and ability to dissolve a range of substances make it ideal for resins, dyes, and coatings.

Growth in Niacinamide Production

The surge in nutritional supplements and fortified foods is raising demand for vitamin B3 derivatives, which require pyridine.

Growth Drivers

Population Growth and Food Security Needs

Rising food demand increases the use of herbicides and pesticides, thus driving pyridine usage in agriculture.

Pharmaceutical Innovation and Demand for APIs

Pyridine is a key building block for many active pharmaceutical ingredients (APIs) in modern medicine.

Emergence of Pyridine-Based Catalysts and Reagents

Pyridine derivatives are used in fine chemical and green chemistry applications due to their catalytic properties.

Shift Toward Synthetic and High-Purity Derivatives

With quality control becoming crucial in pharma and food, high-purity pyridine is gaining demand globally.

Challenges in the Pyridine Market

Environmental and Toxicity Concerns

Pyridine is flammable and toxic, leading to strict handling regulations and disposal challenges.

Stringent Regulatory Frameworks

Bans or restrictions on pyridine-based agrochemicals in certain countries can limit market growth.

Volatile Raw Material Prices

Fluctuating costs of feedstock chemicals affect the profitability of pyridine production.

Competition from Bio-Based Alternatives

Emerging bio-derived pyridine compounds may pose a future competitive threat to traditional manufacturers.

Future Outlook

Growth in Green Agrochemical Synthesis

Innovations in eco-friendly crop protection products using pyridine derivatives are on the rise.

Asia-Pacific Region to Dominate Market Growth

China and India, with strong agrochemical and pharmaceutical sectors, are expected to lead global consumption.

Increased R&D in Specialty Pyridine Derivatives

Development of advanced pyridine-based compounds for battery electrolytes, specialty polymers, and pharma is expected.

Potential in Renewable Pyridine Pathways

Long-term, bio-based pyridine production from biomass or fermentation may address environmental concerns.

Conclusion

The Pyridine Market is central to modern chemical manufacturing, providing a versatile and reactive compound used in sectors ranging from agriculture to pharmaceuticals. As sustainability, innovation, and health demand grow, pyridine's role as a core chemical intermediate is set to expand even further.

0 notes

Text

Windrow compost turning machine: Key equipment for boosting organic fertilizer fermentation efficiency

The windrow compost turning machine is a core piece of modern organic fertilizer fermentation equipment. Known for being efficient, thorough, and energy-saving, it significantly boosts composting productivity.

1.Speeds up aerobic fermentation

Organic fertilizer fermentation relies on aerobic microbes. The turner mechanically flips the pile, loosening the material to increase oxygen exposure. This boosts microbial activity and shortens the fermentation time.

2.Regulates moisture and temperature

Moisture: While working, the turner can spray water to keep the pile from getting too dry or too wet, maintaining the best moisture level.

Temperature: Even turning prevents hot spots, keeping the pile temperature stable at 55-65°C to speed up decomposition.

3.Breaks up clumps

Its powerful breaking device crushes large chunks, ensuring raw materials (like manure or crop stalks) mix more evenly. This improves the final fertilizer's consistency and nutrient content.

4.Cuts labor costs

Highly automated, the windrow compost turning machine greatly reduces manpower needs. It's especially suited for large fertilizer plants or livestock manure treatment projects.

5.Reduces odor emissions

Regular turning cuts down on harmful gases (like hydrogen sulfide and ammonia) produced in anaerobic pockets, lowering smelly pollution and meeting environmental standards.

In short, the windrow compost turning machine not only improves fertilizer quality but also lowers production costs, driving the sustainable development of organic agriculture.

0 notes

Text

Nicotinic Acid Market growth drivers and future trends shaping the global industry landscape

The Nicotinic Acid Market is undergoing significant transformation as consumer awareness, industry demand, and technological progress converge. As a derivative of vitamin B3, nicotinic acid is widely used across food, pharmaceutical, and chemical sectors. These applications are steadily expanding, driven by factors such as rising global health concerns, changing dietary habits, and advancements in formulation techniques.

Key Growth Drivers Fueling Market Expansion

The surge in health-conscious consumers is one of the biggest contributors to the nicotinic acid market’s expansion. Increased cases of vitamin deficiency, particularly in developing regions, have led to growing supplementation needs. Governments and health organizations are increasingly recommending niacin-enriched food and pharmaceuticals, directly enhancing the market scope.

Additionally, rising incidences of cholesterol-related health conditions are encouraging the use of nicotinic acid-based drugs. It has been widely recognized for its role in reducing LDL (bad cholesterol) and increasing HDL (good cholesterol), making it an essential ingredient in cardiovascular health treatments.

The animal feed industry is another major sector driving demand. Nicotinic acid plays a critical role in animal nutrition, particularly in poultry and swine diets. The rising global meat consumption is, therefore, indirectly boosting the requirement for vitamin supplements like nicotinic acid in feed additives.

Global Industry Trends Shaping the Future

Several trends are defining the future of the global nicotinic acid market. The most notable is the growing demand for nutraceuticals. Consumers are leaning more toward preventive healthcare, which has created a robust market for food supplements. Nicotinic acid, being a vital component of metabolic health, is increasingly used in such products.

Another trend is the preference for natural and bio-based ingredients. Companies are now looking to source vitamins and additives from sustainable and eco-friendly production methods. This trend has prompted R&D investments in fermentation-based and bio-catalytic production of nicotinic acid, reducing dependency on petrochemical routes.

Further, the market is witnessing integration with digital supply chain technologies. Automation and AI-based inventory management are improving production planning and ensuring consistent availability of raw materials and finished goods. These improvements in logistics and forecasting systems are making the global market more responsive and efficient.

Regional Outlook and Demand Highlights

Asia-Pacific remains the fastest-growing region in the nicotinic acid market. Countries like China and India are not only leading producers but are also showing strong domestic consumption across pharmaceutical and animal feed sectors. Government initiatives supporting vitamin supplementation and livestock growth are driving consistent demand.

In North America and Europe, demand is relatively stable and mature but shows promise through innovation in pharmaceutical formulations and dietary supplement blends. Stringent regulations and consumer preference for high-quality products keep the competition strong in these regions.

The Middle East and Africa are emerging as niche markets where demand is growing in tandem with rising healthcare infrastructure and increasing awareness about nutrition.

Challenges in the Current Landscape

Despite a strong growth trajectory, the market faces several challenges. The primary concern is fluctuating prices of key raw materials like 3-cyanopyridine and ammonia derivatives. Any supply chain disruption, especially in Asia, where much of the production is concentrated, can affect global pricing.

Regulatory constraints also play a role. Different safety standards and approval timelines across countries often delay product launches or create entry barriers for new manufacturers. Additionally, over-supplementation risks and side effects associated with high niacin intake require continuous education and regulation.

Another bottleneck is the limited awareness of nicotinic acid’s benefits in certain regions. Though its medical relevance is established, broader consumer knowledge remains lacking in underdeveloped areas, affecting adoption rates.

Future Opportunities and Innovations

The nicotinic acid market presents promising opportunities, particularly in specialized formulations. Research is underway to develop extended-release tablets and combination therapies, where niacin is paired with other vitamins or cholesterol-reducing agents for synergistic effects.

Companies are also investing in personalized nutrition, creating targeted supplement plans based on genetic or lifestyle profiling. These innovations are likely to increase the consumption of vitamins, including nicotinic acid, in tailored health packages.

Another opportunity lies in expanding industrial applications, such as the use of nicotinic acid in organic synthesis and dye manufacturing. As chemical industries look for versatile intermediates, nicotinic acid could witness increased demand beyond traditional uses.

Strategic Outlook Toward 2032

The global nicotinic acid market is poised for steady growth, with projections indicating a favorable compound annual growth rate through 2032. To maintain this trajectory, companies will need to focus on innovation, sustainable production, and global market penetration. Collaborations with pharmaceutical firms, investments in clean technologies, and expanding digital infrastructure are likely to be critical success factors.

As trends in wellness, sustainable agriculture, and pharmaceutical advancements evolve, nicotinic acid’s role in the global supply chain will continue to expand. Its significance in addressing health issues and improving product quality across sectors ensures its position as a vital compound in the years ahead.

#nicotinicacidmarket#vitaminB3#healthsupplements#animalnutrition#pharmaceuticalindustry#markettrends#futureforecast#nutraceuticals#sustainableproduction#globalhealth

0 notes

Text

Long lasting Deodorant in Manure Fermentation

In today's era of growing environmental awareness, composting fermentation, as a green and eco-friendly method for treating organic waste, is gradually being widely adopted. However, the pungent odor generated during the composting fermentation process has become a major concern. The emergence of long-acting deodorants has provided an effective solution to this problem. Deodorants refer to a category of products used to remove odors from the environment. There are many types of deodorants commonly available on the market, among which plant-based deodorants and industrial deodorants have attracted much attention. Plant-based deodorants, mainly composed of natural plant extracts, achieve deodorization by neutralizing and decomposing odor molecules. They are safe, environmentally friendly, and free from secondary pollution, making them suitable for places with high environmental requirements. Industrial deodorants, on the other hand, focus more on addressing complex odors generated during industrial production, featuring strong deodorizing capabilities and a wide application range. As a "leader" in the deodorant field, long-acting deodorants play an important role in areas such as composting fermentation due to their unique advantages. The core advantage of long-acting deodorants lies in their excellent long-term deodorizing performance, ensuring the deodorizing effect lasts for more than 48 hours. This benefits from their special formula and mechanism of action. Long-acting deodorants adopt advanced slow-release technology, which slowly releases effective deodorizing components, allowing them to continuously react with odor molecules and maintain the deodorizing effect for a long time. Compared with ordinary deodorants, long-acting deodorants do not require frequent use, significantly reducing usage costs and manual maintenance costs. Long-acting deodorants also have many remarkable features. They have wide applicability, demonstrating good deodorizing effects whether dealing with domestic waste, agricultural waste, or industrial organic waste. In terms of safety, long-acting deodorants are non-toxic and harmless, causing no harm to the environment or human health. Meanwhile, they have good stability, capable of maintaining stable deodorizing performance under different temperature and humidity conditions. In the practical application of composting fermentation, long-acting deodorants have shown powerful functions. In the early stage of composting, as organic matter in the composting materials begins to decompose, a large amount of irritating odors such as hydrogen sulfide and ammonia are produced. By evenly spraying long-acting deodorants on the composting materials, their effective components can quickly bind with these odor molecules, eliminating odors from the source. In the middle and late stages of composting, as the fermentation progresses and temperature and humidity change continuously, the effect of ordinary deodorants may be greatly reduced. However, relying on their slow-release technology and stable performance, long-acting deodorants can still continue to function, ensuring a fresh environment throughout the entire composting process. Take a large organic fertilizer plant as an example. Before using long-acting deodorants, the area around the plant was often filled with pungent odors, seriously affecting the lives of surrounding residents and triggering multiple environmental complaints. After adopting long-acting deodorants and using them scientifically and reasonably, it not only effectively solved the odor problem in the composting fermentation process but also improved the working environment of the plant. At the same time, it enhanced the enterprise's environmental image, achieving a win-win situation between economic benefits and environmental benefits. In conclusion, long-acting deodorants have irreplaceable advantages and important roles in the field of composting fermentation.

0 notes

Text

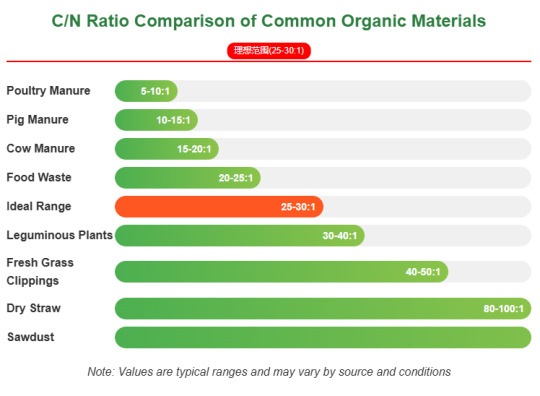

Two Major Challenges in Organic Fertilizer: Perfect Solutions for C/N Ratio & Fiber

Optimizing the production of organic fertilizers can be achieved by addressing the challenges of C/N ratio and fibrous materials.In fertilizer production lines, balancing C/N ratio and fiber content is crucial for efficient organic fertilizer manufacturing, ensuring proper decomposition and quality output.

Challenge 1: The C/N Ratio Dilemma

The carbon-to-nitrogen ratio (C/N) is a critical parameter affecting composting efficiency. The ideal range is 25-30:1. Deviation causes:

Too high (>40:1): Microbes lack nitrogen, decomposition slows by 50%+

Too low (<20:1): Significant nitrogen loss (up to 30%) with strong ammonia odor

Four Golden Rules for C/N Adjustment

Pro Tip: Use portable C/N testers (±2 accuracy), test every 48 hours for dynamic adjustment. Increase C/N by 5-10% in summer, decrease by 5-10% in winter.

Challenge 2: High Fiber Content

When lignin/cellulose exceeds 35%:

Temperature struggles to reach 55°C+ (pathogen kill rate insufficient)

Composting extends to 60-90 days (normal 30-45 days)

Final product contains 10-20% undigested fibers

Three-Step Advanced Fiber Treatment

Step 1: Mechanical Pretreatment

Shred to 1-3cm particles (invest in 15-30kW straw crusher)

Use fiber disruptors (40% efficiency gain)

Step 2: Biological Enhancement

Inoculate with composite microbes (Trichoderma, etc.), 0.2-0.5% dosage

Add 5-10% mature compost as "starter"

Step 3: Chemical Assistance

Adjust pH to 7.5-8.5 (wood ash or lime)

Add 0.5-1% urea solution for fast nitrogen

Innovation: Try novel cellulase enzymes (e.g. from Trichoderma reesei) - reduces cycle by 30% but increases cost 15-20%.

Benefits of Solving C/N Ratio & Fiber Challenges

Optimizing C/N ratio and fiber content in organic fertilizer production improves decomposition efficiency, enhances product quality, and reduces processing time. This leads to more stable, nutrient-rich fertilizers with better market value.

Connection to Production Process

Proper C/N balance (25-30:1) accelerates composting in the fermentation stage, while fiber adjustment ensures optimal porosity for aerobic digestion. These solutions directly impact critical process parameters like temperature control and maturation time in organic fertilizer production.

References:

[1] "Compost Science & Technology" (3rd Ed.), China Agriculture Press, 2022

[2] FAO Organic Fertilizer Production Guide, 2023 Revision

[3] German Composting Association Technical Report, 2021

0 notes

Text

Biohydrogen Market to Double by 2034: Key Growth Drivers

The global biohydrogen market, valued at US$ 73.4 Mn in 2023, is forecast to more than double in size, reaching approximately US$ 146.7 Mn by 2034, expanding at a CAGR of 6.5% from 2024 to 2034. This growth is driven by a global shift toward renewable energy sources amid intensifying climate change concerns and dwindling fossil fuel reserves.

A Green Alternative in a Climate-Conscious Era

The mounting impact of fossil fuel consumption on global warming has intensified the search for clean and sustainable energy sources. Biohydrogen has emerged as a promising contender. Unlike conventional hydrogen produced through fossil fuel-based processes, biohydrogen is derived from biological means—making it a low-emission, environmentally safe alternative.

Green hydrogen derived from wind and solar power is gaining attention for its vast potential in reducing greenhouse gas emissions, particularly in hard-to-abate sectors such as refineries, industrial processes, and ammonia production.

Biohydrogen: Understanding the Process

Biohydrogen production involves the utilization of renewable biomass, photosynthetic bacteria, and dark fermentation techniques. It leverages microbial metabolism to convert organic substrates into hydrogen without releasing greenhouse gases. Two key processes dominate the production landscape:

Moreover, biomass gasification—a thermochemical process using heat, steam, and oxygen—has proven to be an efficient method for hydrogen generation, utilizing agricultural and organic waste.

Market Drivers: Climate Policies and Energy Security

Several factors are fueling the rapid adoption of biohydrogen:

Regional Insights: Asia Pacific Leads the Charge

Asia Pacific emerged as the leading region in the global biohydrogen market in 2023. Countries such as Japan, China, India, and South Korea have outlined aggressive hydrogen strategies. These nations are:

Japan’s revised Basic Hydrogen Strategy targets hydrogen supply growth from 3 million tons by 2030 to 20 million tons by 2050, setting a strong precedent for other countries.

Challenges: Infrastructure and Cost Barriers

Despite strong growth projections, the biohydrogen industry faces notable obstacles:

Competitive Landscape: Major Players and Recent Developments

Key companies like ExxonMobil Corporation, Linde Group, Air Products and Chemicals, Inc., BP, Shell Plc, and Chevron Corporation are driving innovation in the biohydrogen value chain. These firms are actively pursuing:

In April 2024, H2Carrier proposed two offshore wind farms in Norway to produce green hydrogen aboard floating vessels. Likewise, White Martins, a Linde subsidiary, announced a new 5MW electrolyzer in Brazil to serve the local glass industry—signaling industrial-scale applications of biohydrogen.

Outlook: The Road Ahead for Biohydrogen

As climate action intensifies and petroleum dependency declines, biohydrogen stands at the forefront of the next energy revolution. Its potential to serve multiple industries—from automotive to chemicals—positions it as a cornerstone in the future clean energy mix.

With continued investment, policy support, and technology development, the biohydrogen market is set to play a pivotal role in global decarbonization efforts by 2034 and beyond.

0 notes