#aluminum 6061

Explore tagged Tumblr posts

Video

tumblr

"Aluminium Round Bars Manufacturer & Exporter."

Aluminium 1100 Round Bar is manufactured and supplied by Bhansali Enterprise and is utilized in numerous industries and applications. These round bars, which are admirable for their resistance to erosion, are basically plates of mid-range quality. These round bars are made by us from raw materials of superior quality that have been thoroughly inspected by professionals to ensure that they are of the highest quality. Also, present day machines and instruments are utilized for assembling prevalent quality and exact components of the bar. We make products while keeping in mind what customers want and need. The softest and gentlest aluminum alloy, the 1100, is not used in high-pressure or high-strength applications. Additionally, we offer these bars to customers in a variety of sizes, shapes, and forms to meet their requirements. Bhansali Enterprise is one of the reputable businesses that has initiated the global distribution of beautiful Aluminum Alloy 2014 Round Bars. The compound 2014 round bars is by and large a sturdy, somewhat delicate, moldable metal, and lightweight item with wide appearance ranges. We are renowned for providing high-quality round bars with rods in custom sizes and built thicknesses to meet client demand as a leading exporter, manufacturer, and stockist. Our renowned customers place large orders to obtain it at a competitive price. You can order it as well and get it for a good price.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#aluminum 6061#aluminium square pipes#aluminum vs stainless steel#polished stainless steel#stainless steel manufacturers in india

0 notes

Text

Aluminum 6061 T6 vs T651: Key Differences Explained for CNC Machining

CNC machining requires selecting an aluminum alloy temper carefully in order to ensure optimal quality and performance of the final product. One of the most widely-used alloys is 6061, available with T6 and T651 temper options - although these two share similar composition, understanding their variations is essential in precision manufacturing.

What Is Aluminum 6061?

Aluminum 6061 is a precipitationhardened alloy known for its excellent strength, corrosion resistance, and machinability properties - qualities which make it widely utilized across industries including aerospace, automotive, electronics and construction due to its versatile properties.

Understanding Temper Designations: T6 and T651

Temper designations refer to processes designed to increase mechanical properties in materials. Both T6 and T651 go through solution heat treatment and artificial aging processes, though their final processing stages differ considerably.

6061T6: Overview

Heat Treatment Process:

Solution Heat Treatment: Heated at high temperatures to dissolve alloying elements.

Quenching: Rapid cooling to set these elements in their proper places.

Aging: Heating it again at lower temperatures until optimal strength has been attained.

Key Properties:

High tensile strength (approx. 290 MPa / 42,000 psi).

Good corrosion resistance.

Applications: for structural parts and assemblies where stress relief is not an immediate concern.

Applications:

Commonly used for structural parts, frames, and welded assemblies where stress relief is not a major concern.

6061T651: Overview

To reduce internal stresses, T651 goes through an additional stretching step (of about 13% elongation) after being subjected to the T6 process.

Key Properties:

Similar tensile strength as T6 (approx. 290 MPa / 42,000 psi). Reduced residual stresses to minimize distortion during machining. Better dimensional stability for complex or large parts.

Application areas:

Ideal for precision CNC machining of aerospace components and components with tight tolerances that require stability.

Key Differences: T6 vs. T651

Factor

6061T6

6061T651

Internal Stress

Higher residual stresses due to quenching.

Reduced stresses due to stretching.

Dimensional Stability

May warp or distort during machining.

Better stability, less deformation.

Machinability

Good but internal stresses may affect results.

Excellent, better surface finish and accuracy.

Typical Applications

Simple, small components or welded structures.

Large, complex, or precisioncritical parts.

Cost Consideration

Slightly more economical.

Slightly higher due to additional processing.

Which Metal Should You Select?

Select 6061T6 when:

Your part is simple or small in nature and cost efficiency is of primary concern, and minor deformation during machining is acceptable.

Select 6061T651 when:

You require high precision and dimensional stability; Your component is large, thinwalled or complex; Machining distortion must be kept to a minimum;

Practical Considerations for CNC Machining

1. Tool Selection:

Use sharp carbide tools to maximize efficiency when machining either temper.

2. Cutting Parameters:

Adjust feed rates and cutting speeds according to the alloy's temper. T651 can handle higher cutting speeds without warping.

3. Stress Management:

If you choose T6, consider postmachining stress relief for critical parts to reduce warping.

Conclusion

Understanding the differences between 6061T6 and 6061T651 is vital for optimizing CNC machining projects. T651's stressrelief process makes it an excellent choice for precision applications while T6 provides costeffective performance in simpler applications. At Shenzhen Yixin Precision, we guarantee each CNCmachined aluminum part meets the highest standards of accuracy and reliability by selecting an appropriate temper according to each client's specific requirements.

0 notes

Text

Aluminum 6061 T6 vs T651: Understanding the Differences in Heat Treatments

Aluminum 6061 is one of the most versatile and widely used aluminum alloys, known for its combination of strength, machinability, and corrosion resistance. However, understanding the specific heat treatment designations, such as T6 and T651, is crucial when selecting the right material for your project. These designations represent different heat treatment processes that impact the mechanical properties of the aluminum. In this article, we’ll explore the distinctions between Aluminum 6061 T6 vs T651 to help you make informed decisions based on their strengths, applications, and limitations.

For an in-depth look, check out our comprehensive guide on Aluminum 6061 T6 vs Aluminum T651 vs Aluminum T6511.

What is Aluminum 6061?

Aluminum 6061 is a precipitation-hardened alloy with magnesium and silicon as its primary alloying elements. This alloy is well-known for its excellent corrosion resistance, good mechanical properties, and high strength-to-weight ratio. It’s commonly used in aerospace, automotive, and structural applications due to its durability and machinability. However, to maximize the alloy's strength and utility, 6061 is often subjected to specific heat treatments.

Understanding T6 and T651 Heat Treatments

Both T6 and T651 refer to specific tempers of aluminum, each achieved through controlled heating and cooling processes. Here’s a breakdown of each:

T6 Temper

The T6 temper indicates that the alloy has been solution heat-treated and then artificially aged. This process enhances the alloy’s strength by dispersing alloying elements uniformly throughout the metal.

T6 treatment provides high tensile strength and is commonly used in applications requiring durability and strength.

T651 Temper

T651 is similar to T6, but with an added step of stress relief by stretching the material. This additional step minimizes internal stresses, which can help prevent warping during machining and improve dimensional stability.

T651 offers similar strength to T6 but with added stability, making it suitable for applications requiring precise machining.

Key Differences Between Aluminum 6061 T6 and T651

Here are some of the main differences between T6 and T651 tempers:

Stress Relief:

T6: Solution heat-treated and artificially aged, without any stress-relief process.

T651: Includes a stretching process for stress relief, making it ideal for machining where dimensional stability is critical.

Dimensional Stability:

T6: May be more prone to warping under high machining loads due to residual stresses.

T651: More stable and less likely to warp, thanks to the stress-relief stretching.

Applications:

T6: Often used in structural applications where high strength is required but precision machining is not a priority.

T651: Preferred for applications needing tight tolerances and precise machining, like aerospace and automotive components.

Advantages of Aluminum 6061 T6

High Strength: T6 temper provides excellent strength, making it suitable for load-bearing applications.

Corrosion Resistance: Good resistance to corrosion in atmospheric and seawater environments.

Machinability: Offers good machinability, especially when using proper cutting techniques and tools.

Advantages of Aluminum 6061 T651

Stress Relief for Machining: T651’s stretching process minimizes internal stress, reducing the risk of warping during machining.

Enhanced Dimensional Stability: Maintains dimensions well during and after machining, which is essential in aerospace and automotive industries.

Uniform Properties: More consistent performance, especially in applications requiring high precision and reliability.

Frequently Asked Questions (FAQs)

1. What is the primary difference between 6061 T6 and T651?

The primary difference is that T651 undergoes an additional stress-relief process through stretching, making it more dimensionally stable than T6. T6 does not go through this process, so it may retain internal stresses that could affect machining.

2. Which is stronger, T6 or T651?

Both T6 and T651 tempers offer similar strength levels; however, T651 provides more stability due to the stretching process. In terms of pure tensile strength, there’s minimal difference.

3. Is 6061 T651 better for machining than T6?

Yes, T651 is generally better for machining because the stretching process minimizes internal stress, which helps prevent warping and deformation during cutting.

4. Can I use 6061 T6 for aerospace applications?

While 6061 T6 has good strength and corrosion resistance, many aerospace applications prefer T651 due to its enhanced dimensional stability under machining loads.

5. What is the significance of the ‘1’ in T651?

The "1" in T651 indicates that the metal has been stretched after heat treatment. This step relieves internal stresses and improves dimensional stability, a significant benefit for high-precision applications.

6. Is there a cost difference between T6 and T651?

T651 typically costs slightly more than T6 because of the added stretching process, which involves extra time and resources. However, the cost difference is often justifiable for applications where machining stability is crucial.

7. Can T6 and T651 be welded easily?

Both T6 and T651 tempers of aluminum 6061 are weldable. However, the strength of the heat-affected zone around the weld may be lower, as welding can disturb the heat treatment effects.

8. Which is better for structural applications, T6 or T651?

For general structural applications where precise machining is not required, T6 is usually sufficient. However, for applications needing precise cuts and tight tolerances, T651 is a better choice due to its dimensional stability.

Conclusion

When comparing Aluminum 6061 T6 vs T651, the key factor is whether the application demands precision machining and dimensional stability. T6 is ideal for structural applications where high strength is essential, while T651 is preferable for projects involving extensive machining where stability is critical. Both tempers offer similar strength and corrosion resistance, making them suitable for a wide range of uses in construction, automotive, aerospace, and manufacturing.

To learn more about the differences and applications of these aluminum grades, read our complete guide on Aluminum 6061 T6 vs Aluminum T651 vs Aluminum T6511.

0 notes

Text

Channel Aluminum

Looking for high-quality channel aluminum? SteelNow has you covered with a wide selection of aluminum channel products. Our business specializes in providing top-notch materials for your construction and fabrication needs. Choose SteelNow for fast and convenient sourcing of channel aluminum at competitive prices. Find the perfect aluminum channel for your project and get it delivered right to your doorstep with SteelNow. Trust us for all your aluminum channel requirements!

#Channel Aluminum#aluminium steel sheet#aluminum u channel#steel pipe supplier#6061 plate aluminum#square aluminum tube#a36 plate steel

0 notes

Text

7075 and 6061 Aluminum Alloys in Cars

Aluminium alloys in cars have excellent ductility, half the density of steel and good corrosion resistance, making it the material of choice for lightweight structures. Taking 7075 aluminum alloy as an example. Its tensile strength is 560MPa, which is no lower than steel. For the same weight of steel and aluminum, aluminum is larger and can increase structural strength without increasing…

View On WordPress

0 notes

Text

Arch Metals, the premier aluminum bar stock supplier Texas explains the true and considerable advantages of 6061 extruded aluminum bar.

#Aluminum bar stock supplier Texas#Aluminum supplier Dallas Texas#6061 Extruded Aluminum bar#Aluminum round bar Dallas#Square Aluminum bar supplier Texas#Flat Aluminum bar Dallas#6061 Aluminum distributor Texas#Dallas Aluminum extrusion company#6061 Aluminum bar manufacturer Texas#6061 Aluminum supplier Austin

0 notes

Text

Versatility and Precision: The Superior Qualities of 6061 Aluminum Plate

https://www.howardprecision.com/aluminum/wrought-aluminum-plate-stock-list/6061-t651-aluminum-plate/ - The 6061 aluminum plate, a staple in general-purpose applications, is distinguished by its composition of Silicon and Magnesium, making it a heat treatable alloy with excellent formability, weldability, and corrosion resistance, suited for various machined part applications. Highlighting its versatility, the 6061 aluminum tooling plate is ideal for a wide range of industries from electronics to agriculture, offering a cost-effective solution with superior welding potential and the ability to withstand weather, moisture, and extreme temperatures due to its corrosion resistance. Howard Precision Metals takes pride in stocking 6061 aluminum plate from the finest mill sources, providing products like Hulamin’s M-61 and Kaiser’s Select Precision Plate, known for their exceptional flatness tolerances, ensuring fewer setups, longer runs, and reduced scrap for customers. In addition to our high-quality aluminum plate stock, we also offer a range of other aluminum products, including sheets, bars, and tubing. Our knowledgeable sales team can help you find the right materials for your project and provide technical support throughout the process. Distinguished by its wrought manufacturing, the 6061 precision plate surpasses cast products in mechanical and physical properties, featuring a durable satin brush finish, making it easily machinable and anodizable, with improved thickness and flatness tolerances exclusive to the 6061-T651 alloy. Understanding the unique requirements of each customer, Howard Precision Metals specializes in 6061 T6 aluminum, offering custom-tailored solutions and expert guidance for challenging specifications, backed by a commitment to premium quality and a dedicated focus on aluminum as their sole metal offering.

Contact Us: Howard Precision Metals Inc. 8058 North 87th Street Milwaukee, WI 53224 Phone: (414) 355-9611 https://www.howardprecision.com

#6061 Aluminum Plate#6061 T6 aluminum#6061 T6 Aluminum Plate#Aluminum Jig & Mold Plate Supplier#Aluminum Plate For Sale#6061 T6 Aluminum Tooling Plate#How to Purchase 6061 Aluminum

0 notes

Text

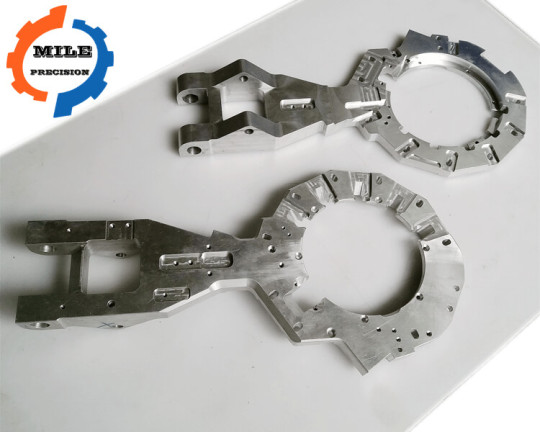

6061/7075 aluminum parts, film making equipment Accessories,follow focus,CNC machining parts,turning and milling service

OEM parts manufacturers,

Welcome to our website www.milemetal.com

Contact Us [email protected]

NINGBO MILE PRECISION MACHINERY CO.,LTD

#follow focus#matte box#milling parts#OEM PARTS#turning parts#auto turning#CNC machining#6061 aluminum#7075#manufacturers

0 notes

Text

aluminium round bar manufacturers Ahmedabad in India

Grade : 6061 | 6082 | 6063 | 2014 | 2024 | 5083 | 7075 | 7020 All Aluminium round bars are available in ready stock. About Aluminium Round bar We are an aluminum round bar manufacturer in Ahmedabad in India, We offer Aluminum Round bars, Square bars, and Hex bar products specially tailored for the general engineering and aerospace industries. We always keep large stock of the aluminum round…

View On WordPress

0 notes

Note

Ah, my mistake, I misread Ripcord's page.

I mean, I got sat down with a knife and two forks And made to eat my words there. The primary reason 4140 and unlined barrels are for the trash is because there is no reason to settle for them. QPQ barrels are just as cheap, have 100% of the benefits, and 0% of the detriments.

The difference between that And 6061 versus 7075 aluminum is price! Keep in mind, I was under the impression that BCM And Daniel's defense both used 7075 rails. Essentially only a dozen manufacturers make real 7075 T6 rails, and they're all expensive. But hundreds of people make 6061 T6 rails. And cheap.

Now- the performance gap metallurgically is still massive:

But as was pointed out to me WHAT ARE YOU DOING THAT YOU NEED 572 MPa TENSILE STRENGTH FOR YOUR RAIL?? You can shoot a rifle without a rail push comes to shove- a rail is optional. You can use the rifle without it as long as the barrel nut is intact.

Where 6061 vs 7075 actually matters a lot is the receivers. 100% you want 7075 receivers. Especially the upper. Your steel bolt carrier is... Steel. And it rides against the upper, trigger pins rotate too. A 6061 receiver will wear massively faster than a 7075 one.

It's really only a consideration with billet receivers, But unless it's going to be a safe Queen, you don't want a 6061 receiver.

14 notes

·

View notes

Text

The baddest wheel in the whole darn town. When Dodge launched the incredible 1025HP Demon 170, they offered an option to equip the vehicle with the most technologically-advanced road wheels ever sold by any automotive manufacturer: The Lacks Carbon Fiber Drag Pack. This same 18x8/17x11 setup is now available here in the LCF205 with fitments available for both the D170 and widebody Hellcat. The lightweight Carbon+Forged LCF205 wheel combines a weight-optimized CNC-machined forged aluminum center with a revolutionary proprietary Lacks Enterprises carbon fiber barrel to deliver the ultimate in technological advancement, exclusive styling, and unparalleled performance. The LCF205 combines its carbon fiber barrel with a unique precision-machined forged 6061-T6 aluminum center featuring lightweight racing-inspired ten spoke design, open-lug hub center, and aggressive I-beam machining to yield a wheel with absolutely impressive performance metrics: very low static mass, very low rotational inertia, minimal deflection, and excellent fatigue strength! Learn more about the LCF205 at: https://www.forgeline.com/lcf205/p410

#forgeline#forgelinewheels#forgedwheels#customwheels#LCF205#ForgelineLCF205#CarbonFiber#carbonforged#lackscarbonfiber#notjustanotherprettywheel#doyourhomework#madeinUSA#carenthusiast#wheelsofinstagram#Dodge#Demon170#D170#Hellcat#DragRacing#🇺🇸

8 notes

·

View notes

Text

EvolutionGear IS-EG NGAL Laser Aiming Module

For those of you that shake your fist to the heavens cursing L3Harris for not releasing a civilian version of their famed NGAL, you're probably at least tangentially familiar with EvolutionGear -

They do the OEM parts manufacturing for InvisibleSight, who offers a higher quality level of QC, but is infamous for their astonishingly long lead times.

EvolutionGear sells the 'cheaper' version of the IS-EG NGAL which you can buy direct from them if you wanna bypass the year-long inspection wait and don't need all the different options offered through InvisibleSight.

Before I get into the details of the unit itself, I'd like to clear up a lot of myths about EG - the common consensus about them is that they're known for not shipping their items, but from my own research, I really could only find an evidence case of one from a dude who was dumb enough to order during Chinese New Year and threw a tantrum when it took longer than expected to receive a tracking.

I opted for the more expensive UPS shipping option, and while it was kinda awkward having to wait for a live representative to email me a paypal invoice rather than going though a site-based payment portal, I didn't have any issues ordering from them and everything arrived within a week of receiving a tracking.

Here's where I'll get into the initial impressions.

The body of the unit is forged 6061 aluminum, and unlike the Somogear NGAL's, these actually have recoil lugs integrated into the body with a proper L3Harris-style screw clamp, as opposed to the crappy PEQ15 clamp the Somo units have.

The selector switch, I find somewhat mushy (due to the integral o-ring added for waterproofing), but still tactile enough to satisfy me, and the button has a positive enough click for my needs as well. The rear focus knob for the IR illuminator is a little bit stiff, but no major red flags about it.

Another nice feature of the EG NGAL is the fact it includes actual diffuser caps whereas the Somo units are only provided with blackout covers. The visible potting of the unit seems very well-done and I'm definitely excited to see how well this holds up considering EG touts this as a 5.56-capable laser where Somogear continues to scream "airsoft only" from the rooftops.

The unit included two different sets of stickers (one laminated, one not, interestingly) as well as a pressure pad and an eggcrate-padded plastic storage case.

The pressure pad is where I'm going to focus a majority of my initial critique.

On the website, EvolutionGear claims they offer the option of an LA23 Plug or an ATPIAL Crane Plug version. I triple checked that I'd be receiving a crane-ported NGAL, and the customer service acknowledged this.

The switch they provided is an LA23 version and upon testing the port with a surplus Insight PEQ-2 Pressure Pad, there was no function from the laser, meaning my request was completely disregarded and I'd been given an LA23-ported version instead.

Not a humongous deal to me, but it would have been nice to have a wider choice of aftermarket switches instead of proprietary ones that cost 100-300 fucking dollars.

Anywho, the switch they include is what I'd describe as solidly "meh" - it feels like a very cheap silicone, the click is positive enough, but the cable is visibly hot glued in and it's just left me wishing that Somogear offered their fantastic Modbutton Lite knock-offs a la carte.

Might email them later to see if I can get one.

The build it resides on presently is my FDE A2 Retromod, and despite being an offset beam unit, I still find the lasers are just a little too close to a standard FSB for my comfort.

I plan on possibly doing a URG-I build out of my Colt LE6920 in the near future, so this is definitely not the build the EG NGAL is staying on forever.

Later I'll give it a look under NODs and see how that goes.

18 notes

·

View notes

Text

You know, the thing I really wanted for Christmas this year was a 12x12x1/16 inch sheet of 6061 aluminum, but did I get any 12x12x1/16 inch sheets of 6061 aluminum? No

4 notes

·

View notes

Text

Rectangular Aluminum Tubes

Looking for high-quality rectangular aluminum tubes? SteelNow offers a wide selection of durable aluminum tubes in various sizes and thicknesses. Find the perfect fit for your project and enjoy fast and convenient ordering through SteelNow. Get the materials you need quickly and efficiently with SteelNow's reliable service. Shop now for top-notch rectangular aluminum tubes at competitive prices.

#Rectangular Aluminum Tubes#6061 plate aluminum#a36 plate steel#aluminum u channel#aluminium steel sheet#steel pipe supplier#square aluminum tube

0 notes

Text

Marine Grade Aluminum Grade 6061 6063 Properties

Aluminum profiles have the advantages of small specific gravity, high specific strength, good seawater corrosion resistance, non-magnetic properties, and good low-temperature performance. As structural materials, they are increasingly valued in the shipbuilding industry. Marine aluminum alloy is particularly suitable for high-speed boats, hydrofoils, hovercrafts, fishing boats and some special…

View On WordPress

0 notes

Text

Arch Metals, the 6061 extruded aluminum bar supplier in Dallas Austin Texas explain the advantages of 6061 extruded aluminum bar.

#6061 Extruded Aluminum bar#6061 Aluminum distributor Texas#Aluminum supplier Dallas Texas#Aluminum round bar Dallas#Square Aluminum bar supplier Texas#Flat Aluminum bar Dallas#6061 Aluminum supplier Austin#Aluminum bar stock supplier Texas#Dallas Aluminum extrusion company#6061 Aluminum bar manufacturer Texas

0 notes