#alloy chains and components

Explore tagged Tumblr posts

Text

#Aerospace & Defense Springs Market#Springs for Aerospace Applications#Defense Industry Components#Market Research Report#Aerospace Springs Demand#High-Performance Springs#Precision Engineering Components#Aircraft Suspension Systems#Military Equipment Springs#Market Size and Forecast#Spring Manufacturing Industry#Lightweight Springs for Aerospace#Durable Defense Springs#Technological Advancements in Springs#Global Aerospace Industry Trends#Competitive Landscape#Spring Applications in Defense#Emerging Markets for Aerospace Springs#High-Strength Alloy Springs#Aerospace Component Supply Chain

0 notes

Text

Sterling Silver vs. Other Metal Jump Rings: Which Is Best for Your Jewelry

Jump rings are essential components in jewelry making, serving as connectors for clasps, charms, chains, and more. While many metals are used for jump rings, sterling silver remains a top choice for jewelry makers. But how does it compare to other materials like stainless steel, aluminum, brass, and gold-filled jump rings? In this guide, we’ll explore the advantages and disadvantages of sterling silver jump rings and how they compare to alternative metals, helping you determine the best choice for your jewelry projects.

What Are Sterling Silver Jump Rings?

Sterling silver jump rings are made from an alloy containing 92.5% pure silver and 7.5% other metals, usually copper. This combination enhances the durability and strength of the silver while maintaining its lustrous appearance. Sterling silver jump rings are highly popular due to their classic aesthetic, ease of use, and versatility.

Pros of Sterling Silver Jump Rings

Elegant Appearance: Sterling silver has a bright, reflective surface that enhances the beauty of jewelry designs.

Hypoallergenic: Ideal for those with sensitive skin, sterling silver is less likely to cause allergic reactions.

Easy to Work With: Softer than stainless steel and other metals, sterling silver jump rings are easier to manipulate for intricate designs.

Valuable Material: Sterling silver is a precious metal, adding value to handmade jewelry.

Can Be Soldered: Sterling silver jump rings can be soldered closed, ensuring a more secure connection.

Cons of Sterling Silver Jump Rings

Prone to Tarnishing: Exposure to air and moisture can cause oxidation, leading to tarnish over time.

Softer than Other Metals: While easy to manipulate, sterling silver is also more prone to bending or deforming under pressure.

Higher Cost: As a precious metal, sterling silver is more expensive than many alternative metals.

Comparing Sterling Silver to Other Metals

1. Stainless Steel Jump Rings

Stainless steel is a strong and corrosion-resistant metal, making it a popular alternative to sterling silver.

Pros:

Extremely durable and resistant to bending

Does not tarnish or rust

More affordable than sterling silver

Cons:

Harder to manipulate and may require stronger tools

Less flexible, making intricate designs challenging

Can cause skin irritation in some individuals due to nickel content

Best For: Durable jewelry designs, chainmaille, and pieces that will experience frequent wear and tear.

2. Aluminum Jump Rings

Aluminum is a lightweight and affordable metal used frequently in costume and fashion jewelry.

Pros:

Very lightweight, making it ideal for larger designs

Does not tarnish or rust

Available in a variety of anodized colors

Cons:

Softer and more prone to bending than sterling silver

Not as durable for high-stress applications

Lacks the luxury appeal of precious metals

Best For: Colorful and lightweight jewelry designs, particularly in costume jewelry.

3. Brass Jump Rings

Brass is an alloy of copper and zinc, offering a warm gold-like hue at a lower cost.

Pros:

Attractive golden tone at an affordable price

Stronger than aluminum but still easy to work with

Readily available and budget-friendly

Cons:

Prone to tarnishing and oxidation, which can leave green residue on the skin

Requires regular polishing to maintain its shine

May contain traces of lead or nickel, causing allergic reactions in some wearers

Best For: Vintage-style and bohemian jewelry where a warm, antique look is desired.

4. Gold-Filled Jump Rings

Gold-filled jump rings have a thick layer of real gold bonded to a base metal, offering the appearance of solid gold at a fraction of the cost.

Pros:

Looks like solid gold but is more affordable

Hypoallergenic and safe for sensitive skin

More durable and tarnish-resistant than gold-plated options

Cons:

More expensive than other alternatives like brass or stainless steel

Can wear down over time, revealing the base metal underneath

Cannot be soldered without damaging the gold layer

Best For: High-quality, affordable gold-tone jewelry that needs to be tarnish-resistant and hypoallergenic.

Which Metal Should You Choose?

The best choice depends on your jewelry-making needs and budget. Here’s a quick summary to help you decide:

For high-end, classic jewelry: Choose sterling silver for its elegance, value, and hypoallergenic properties.

For durability and strength: Opt for stainless steel, especially for men’s jewelry or chainmaille designs.

For lightweight, colorful designs: Go with aluminum, especially for casual or statement pieces.

For an affordable gold look: Select brass or gold-filled jump rings, depending on budget and durability needs.

Final Thoughts

Sterling silver jump rings remain a favorite for jewelry makers due to their beauty, ease of use, and intrinsic value. However, other metal options, like stainless steel, aluminum, brass, and gold-filled jump rings, each have their own advantages depending on the project. By understanding the pros and cons of each, you can choose the right jump rings to create stunning, durable, and high-quality jewelry pieces.

Whether you’re crafting fine jewelry, statement pieces, or functional accessories, selecting the right metal for your jump rings is key to achieving both aesthetics and longevity. Experimenting with different materials can help you find the best balance between style, durability, and cost for your unique creations

2 notes

·

View notes

Text

Rhodium Nanoparticle Market Outlook Report: Emerging Opportunities, Growth Drivers, and Forecast to 2032

Global Rhodium Nanoparticle Market demonstrates robust growth momentum, with its valuation reaching USD 97 million in 2023. According to comprehensive analysis by industry experts, the market is projected to expand at a CAGR of 4.60%, reaching approximately USD 132.89 million by 2032. This growth is fueled by increasing applications in catalytic converters, fuel cells, and advanced electronic components, particularly in regions with stringent emission regulations and growing clean energy initiatives.

Rhodium nanoparticles are ultra-fine particles renowned for their exceptional catalytic properties, chemical stability, and high reflectivity. Their unique surface-to-volume ratio makes them indispensable in sectors demanding high efficiency and precision. As industries increasingly prioritize sustainable solutions, rhodium nanoparticles are gaining traction in green chemistry applications and emission control technologies.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/286629/global-rhodium-nanoparticle-forecast-market-2025-2032-6

Market Overview & Regional Analysis

North America leads the rhodium nanoparticle market with a 35% revenue share, driven by advanced automotive emission control systems and significant investments in fuel cell technology. The U.S. Environmental Protection Agency's stringent emission standards continue to propel demand for rhodium-based catalytic converters.

Europe follows closely, with Germany and the UK accounting for over 50% of regional consumption. The European Green Deal initiatives are accelerating adoption in sustainable industrial processes. Meanwhile, Asia-Pacific shows the fastest growth trajectory, with China's electronics manufacturing sector and Japan's automotive industry driving 60% of regional demand expansion.

Key Market Drivers and Opportunities

The market thrives on three critical drivers: automotive emission regulations (contributing 45% of demand), hydrogen fuel cell development (30% growth sector), and electronics miniaturization trends (25% application share). Catalysis applications dominate current usage, but emerging opportunities in medical diagnostics and renewable energy storage present untapped potential.

Notable opportunities include nanotechnology breakthroughs enhancing catalytic efficiency and the development of rhodium-embedded sensors for industrial IoT applications. The push for green hydrogen production technologies particularly favors rhodium nanoparticle adoption in electrolyzer components.

Challenges & Restraints

Market growth faces significant headwinds from rhodium's price volatility (peaking at USD 29,800 per ounce in 2021) and supply chain complexities. Environmental concerns regarding nanoparticle disposal and recyclability pose regulatory challenges, while technical limitations in large-scale synthesis methods constrain production capacity expansion. Market Segmentation by Type

Rhodium Metal Nanoparticles

Rhodium Oxide Nanoparticles

Rhodium Alloy Nanoparticles

Rhodium Nanoclusters

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/286629/global-rhodium-nanoparticle-forecast-market-2025-2032-6 Market Segmentation by Application

Catalysts

Fuel Cell

Chemical Processing

Electrical Instrumentation

Polishing Agent

Others

Market Segmentation and Key Players

NanoResearch Elements Inc

Nanochemazone

Otto Chemie Pvt. Ltd.

Sood Chemicals

Nanoshel

MTIKOREA

Okchem

Hongwu International Group

Jiechuang New Materials Technology

Report Scope

This comprehensive report analyzes the global rhodium nanoparticle market from 2024 to 2032, providing detailed insights into:

Market size estimations and growth projections

In-depth segmentation by type and application

Technology adoption trends and innovation pathways

The study offers exhaustive profiles of leading market participants, including:

Production capabilities and capacity analysis

Product portfolios and technological benchmarks

Financial performance metrics and market positioning

Strategic initiatives and expansion plans

Our research methodology combines extensive primary interviews with industry stakeholders and sophisticated analytical modeling to deliver actionable market intelligence.

Get Full Report Here: https://www.24chemicalresearch.com/reports/286629/global-rhodium-nanoparticle-forecast-market-2025-2032-6

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

#rhodiumnanoparticlemarketoutlook#rhodiumnanoparticleoverview#rhodiumnanoparticlemarketsize#rhodiumnanoparticlemarketsshare#rhodiumnanoparticlemarketforecasts#rhodiumnanoparticlemarketcagr#rhodiumnanoparticlemarketopportunityanalysis

1 note

·

View note

Text

How Israeli Tech is Shaping the Future of Additive Manufacturing Worldwide

Overview of Israel’s Strategic Position in Additive Manufacturing

Israel has rapidly emerged as a global force in additive manufacturing (AM), fortified by a powerful high-tech ecosystem, robust government support, and a legacy of innovation in defense, aerospace, and medical technologies. With the Israel additive manufacturing market valued at USD 221.4 billion in 2024 and forecasted to exceed USD 280.3 billion by 2032, the nation is positioned to lead transformative advances in 3D printing technologies. The Israel additive manufacturing market compound annual growth rate (CAGR) of approximately 7% reflects both escalating domestic demand and global interest in Israeli AM innovation.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40589-israel-additive-manufacturing-market-research

Driving Forces of Growth in Israel's Additive Manufacturing Market

Innovation Across Key Industrial Verticals

Israel additive manufacturing market sector is evolving as a backbone for modernization in:

Aerospace and Defense: Lightweight components, complex geometries, and high-performance materials enable operational efficiency and reduced lead times.

Healthcare: Customized prosthetics, implants, bioprinting, and surgical models offer patient-centric care and improved clinical outcomes.

Automotive and Industrial Manufacturing: Rapid prototyping, tooling, and small-batch production optimize supply chains and cut production timelines.

These sectors benefit from the convergence of additive technologies with AI, machine learning, and advanced robotics, all core competencies of Israel's high-tech sector.

Rising Demand for Customization and Sustainability

The shift toward sustainable manufacturing and personalized solutions is fueling AM adoption. Israeli startups and research institutions are developing biocompatible, recyclable, and multi-material printing solutions that meet stringent regulatory and industry-specific standards.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40589-israel-additive-manufacturing-market-research

Technological Landscape of the Israeli Additive Manufacturing Ecosystem

Polymer-Based Additive Manufacturing

Valued at USD 306.31 million in 2024, this segment dominates due to its cost-effectiveness, versatility, and compatibility with lightweight, complex part production. With an expected CAGR of 17.3%, applications in consumer goods, automotive interiors, and medical devices continue to surge.

Metal-Based Additive Manufacturing

Growing at a robust 20.1% CAGR, metal AM is the cornerstone of defense and aerospace advancements. In 2024, it accounted for USD 180.86 million, projected to exceed USD 775.48 million by 2032. Israel’s focus on titanium, aluminum alloys, and nickel-based superalloys supports structural applications with high thermal and mechanical stability.

Hybrid Additive Manufacturing

By blending subtractive and additive processes, hybrid AM enhances surface finish and dimensional accuracy, critical in precision tooling, aerospace, and dental prosthetics. This segment is rapidly gaining traction due to its versatility and integration into smart manufacturing systems.

Segmental Breakdown of the Israel Additive Manufacturing Market

By Component

Hardware: Represents the largest share, valued at USD 1,137.28 million in 2024, supporting high-throughput production and industrial-scale fabrication.

Software: Fueled by AI-powered design, generative modeling, and process simulation, this segment is experiencing 19.9% CAGR, revolutionizing digital twin applications and real-time process monitoring.

Services: The on-demand printing ecosystem is expanding, empowering SMEs to access advanced AM capabilities with minimal capital expenditure.

By Deployment Model

In-House Manufacturing: With a Israel additive manufacturing market valuation of USD 317.09 million in 2024, large enterprises prefer internal AM operations for confidentiality and operational control.

Service-Based Models: Growing at 19.4% CAGR, third-party service bureaus are crucial in democratizing access to advanced AM technologies for startups and research institutions.

By Functionality

Prototyping: Dominates with USD 340.60 million in 2024, essential for R&D, iterative design, and proof-of-concept validation.

Production: The rising shift to end-use part manufacturing is catalyzing growth in this segment, valued at USD 197.73 million in 2024.

Tooling: Customized, high-durability tooling supports faster transitions from design to production across various industrial sectors.

By Printer Size

Small/Compact Printers: Most accessible and dominant segment, valued at USD 253.09 million in 2024, ideal for labs, healthcare, and educational institutions.

Medium and Large Printers: Increasingly adopted in industrial manufacturing, these enable batch production and larger component fabrication.

End-Use Industries Driving Adoption

Aerospace & Defense

USD 159.32 million in 2024, this sector prioritizes weight reduction, material performance, and supply chain agility. With Israel’s defense sector being R&D intensive, 3D printing significantly enhances manufacturing autonomy and mission-readiness.

Healthcare & Medical

USD 131.40 million in 2024, growing due to demand for patient-specific devices, bioprinted tissues, and anatomical models. With innovations in regenerative medicine, Israel is at the forefront of personalized healthcare.

Industrial & Automotive

Israel’s industrial ecosystem leverages AM for lightweighting, thermal management, and low-volume production, especially in EV components and robotics enclosures.

Strategic Movements and Competitive Intelligence

Leading Israel Additive Manufacturing Market Participants

Stratasys: A global pioneer, deeply rooted in Israel, with continuous development in multi-material, high-resolution systems.

XJet: Revolutionizing ceramic and metal printing with NanoParticle Jetting™ technology.

Nano Dimension: Innovator in multi-layer electronics and PCB printing, driving miniaturization and functional integration.

Recent Developments

XJet (June 2024): Launched new ceramic printers with applications in automotive and aerospace, enhancing resolution and mechanical strength.

Nano Dimension (Sept 2024): Acquired startups to advance multi-material electronics printing, expanding their capabilities in embedded sensor systems.

Challenges and Strategic Opportunities

Major Israel Additive Manufacturing Market Challenges

Capital Intensity: High upfront costs limit adoption, especially among SMEs.

Talent Gap: Scarcity of AM-trained professionals hampers rapid scaling.

Scaling Complexity: Transitioning from prototype to full production requires new QA methodologies and workflow optimization.

Strategic Israel Additive Manufacturing Market Opportunities

Workforce Development: Partnerships with universities and technical institutes to offer AM-centric curricula.

Material Innovation Hubs: Support from government and private sectors to develop high-strength composites, bioresorbable materials, and nanostructured alloys.

Sustainability Mandates: Incentives for closed-loop manufacturing systems, energy-efficient printers, and recyclable materials.

Future Outlook: Israel’s Role in Global Additive Manufacturing Leadership

Israel is poised to lead the next frontier of digital manufacturing, where data-driven fabrication, machine learning-enhanced design, and autonomous production lines define industry 4.0. With unmatched cross-sector collaboration between startups, research centers, and government agencies, the nation’s AM sector is evolving from rapid prototyping to full-fledged production infrastructure.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40589-israel-additive-manufacturing-market-research

Conclusion

Israel additive manufacturing market is entering a golden era, driven by its technological prowess, strategic policy initiatives, and vibrant innovation culture. As the global demand for agile, sustainable, and customized manufacturing solutions intensifies, Israel is uniquely equipped to lead the charge. Enterprises, investors, and policy makers must align to fully harness this momentum and establish Israel as a global additive manufacturing powerhouse.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Israel#Additive Manufacturing#3D Printing#Israeli Tech#Advanced Manufacturing#Industrial 3D Printing#Aerospace#Medical Devices#Defense Technology#Innovation#Startups#Tel Aviv#Prototyping#Manufacturing Industry#AM Materials#Digital Manufacturing#Smart Manufacturing#High-Tech Industry#Metal 3D Printing#Polymer Printing#R&D#Technology Trends#Engineering#Robotics#Supply Chain#Product Development

1 note

·

View note

Text

How Binding Wire and TMT Bars Create the Backbone of Modern Construction

A steel pipe company that produces components knows something essential about modern-day building practices: the invisible elements regularly determine a shape's integrity. While concrete might also seem like the hero of creation tasks, the fact is it's a ways more complicated. The fusion of binding twine and reinforcement bars creates the hidden framework that allows concrete structures to face up to the test of time.

When employees pour concrete around a carefully built skeleton of metal rebars, they may be collaborating in a production method that has revolutionized structure and infrastructure improvement globally. But how precisely does this system paint, and why is the connection between binding wire and substances from TMT bar manufacturers so essential?

The Critical Role of Binding Wire

Binding wires serves as the unsung hero of this creation symphony. This especially thin, malleable cord performs the essential feature of securing reinforcement bars in their designed positions before concrete placement. When construction people tie rebar grids or cages, binding wire ensures that the reinforcement continues the right spacing and alignment all through the concrete pour.

Proper positioning is non-negotiable due to the fact that the effectiveness of reinforcement relies absolutely on unique placement in the concrete matrix. Even minor displacement can considerably lessen structural capacity and sturdiness. This is in which the relationship among binding twine and materials from TMT bar producers will become crucial.

The Science Behind TMT Bar Manufacturing

TMT (thermo-mechanically treated) bars constitute a widespread development in reinforcement technology. Unlike traditional steel bars, products from TMT bar manufacturers go through a complicated production system concerning managed heating, speedy quenching of the surface layer, and self-tempering of the center as residual warmth flows outward.

This method creates a completely unique micro structure: a sturdy outer layer with martensite formation providing high yield strength and a ductile ferrite-pearlite center that ensures flexibility and weldability.

The Binding Process: Where Precision Meets Craftsmanship

The connection among binding wire and reinforcement from TMT bar producers requires both technical information and practiced talent. Workers usually use specialized tools known as rebar stages to create steady connections at intersection points. The binding pattern follows engineer-specific requirements, with different styles (parent-8, saddle, or wrap-and-twist ties) used depending on structural demands.

Binding cord itself is available in several sorts, with black annealed wire being the most not unusual for popular packages. For specialized tasks, galvanized or PVC-coated binding wire prevents corrosion in aggressive environments. A legit steel pipe business enterprise regularly components the entire range wished for numerous programs.

Industry Integration: From Manufacturing to Construction

The journey from uncooked fabric to finished shape demonstrates extremely good supply chain integration. A steel pipe agency that still materials binding cord and collaborates with TMT bar producers represents an evolution closer to incorporated cloth answers that make sure compatibility and performance.

This delivery chain integration matters because inconsistencies among reinforcement elements can create unexpected weaknesses. When materials come from assets with coordinated pleasant requirements, builders gain confidence in long-term structural overall performance.

Looking Forward: Innovation in Reinforcement Technology

The binding cord and TMT bar production industries retain evolving collectively. Recent improvements consist of self-connecting reinforcement systems that reduce binding cord requirements, corrosion-resistant alloys for severe environments, and digital tracking technology that files reinforcement placement for fine guarantee.

For developers and contractors, staying knowledgeable about these improvements through relationships with a complete metallic pipe company gives competitive benefits in terms of creation efficiency and structural performance.

Final Thoughts

The next time you walk past a production web page or input a concrete construction, don't forget that beneath the gray floor lies a cautiously orchestrated community of materials operating in harmony—concrete, TMT bars, and binding twine growing systems that define our built environment.

#binding wire#TMT bars#construction materials#structural strength#building materials#steel reinforcement#construction basics#TMT bar price#wire for construction#construction wire#steel binding wire#durability#modern construction#building foundations#TMT bars use#construction steel#construction industry#TMT bar quality#steel bars#wire for reinforcement#building projects

1 note

·

View note

Text

✨️🐞🍃 Available in my Etsy shop! 🍃🐞✨️

★•°♡°•Adorable hand crafted piece filled with Czech glass beads, ruby red crystals & fun dangly charms in a woodland nature theme w/cute little ladybugs & leaves. It features a convertible design which allows you to wear it as a wrapped bracelet, long necklace or anklet. Completely designed & handmade by me, & all beads are strung & wire wrapped w/extra care & attention to detail•°♡°•★

○•°🪷°• ~JEWELRY DETAILS~ •°🪷°•○

▪︎FIT SIZE: Wraps five times comfortably around a 6.5" wrist & features an extension chain if a longer length is needed.

▪︎TOTAL LENGTH: Approx 36"

▪︎EXTENSION CHAIN LENGTH: 2"

▪︎CHARM LENGTH: 1"

▪︎BEAD SIZE: 4mm to 8mm

▪︎SEED BEAD SIZE: 2mm

▪︎BRACELET CLOSURE: Textured lobster clasp

▪︎METAL COMPONENTS: Silver plated brass & antiqued metal alloy bead components

❊Nickel & Lead Free❊

▪︎BEADS: Czech glass beads in red, black, yellow & grey, faceted glass crystals & matching glass seed beads

🪷•°LINK°•🪷

✦ETSY✦

https://sparkledlotus.etsy.com/listing/1753498255

🪷•°Enjoy 10% OFF your order as a TY for following!°•🪷

╰┈➤Coupon Code: FBTHANX10 •◌ೄ◌ྀ

★Spend $35 & get FREE shipping!

★Spend $60 & get 25% OFF!

✨️🪷✨️🪷✨️🪷✨️🪷✨️🪷✨️🪷✨️🪷✨️

🪷•°SOCIAL MEDIA LINKS°•🪷

Follow me @SparkledLotus on my socials!

✦Facebook✦

https://www.facebook.com/profile.php?id=100094758376667&mibextid=ZbWKwL

✦Instagram✦

http://instagram.com/sparkledlotus

✦X "Twitter"✦

http://x.com/sparkledlotus

✦Pinterest✦

http://pinterest.com/sparkledlotus

✦Tumblr✦

http://tumblr.com/sparkledlotus

✦Blogger✦

http://sparkledlotus.blogspot.com

Thanks for stopping by!

🪷•°Sparkled Lotus°•🪷

#beading #beadwork #zipperpulls #charms #beadednecklace #wrapbracelet #beadedbookmarks #keychains #jewelrymaking #earrings #handmadejewelry #artisanjewelry #crafts #bracelets #beadedbracelets #jewelry #etsy #ebay #giftsforher #handmade #gifts #handmadewithlove #artisan #handcrafted #fashion #shopsmall #women #womenownedbusiness #smallbusiness #ladybug

#etsyfinds#etsygifts#etsyhandmade#etsyseller#etsyshop#etsysmallbusiness#etsystore#artists on etsy#etsysale#etsy#etsylove#etsy owner#etsy product#etsyartist#etsyjewelry#etsyusa#handcrafted#handmade earrings#handmade jewelry#handmade#handmade bracelets#handmade necklace#wrap bracelets#bohostyle#boho#beaded bracelet#beaded jewelry#beading#beaded bookmark#jewelry making

2 notes

·

View notes

Text

Are you looking for Tool and Die Steel Supplier in Pithampur, Madhya Pradesh, India?

Today, Pithampur stands as a testament to industrial growth and innovation, particularly in the manufacturing and supply of tool and die steel components. The city's industrial clusters are a hive of activity, where small and medium-sized enterprises (SMEs) thrive on specialization in tool and die production. These clusters are not just local powerhouses but also vital cogs in the national supply chain, providing essential components to industries across India.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA , a reputable Tool & Die Steels Supplier in Pithampur, Madhya Pradesh, India. It’s great to know that they deal with a wide range of steel types, including tool steel, die steel, plastic mold steel, high-speed steel, and alloy steel. Their value-added services, such as material machining, cut pieces, and tailor-made materials, demonstrate their commitment to meeting customer needs.

Having a state-of-the-art plant in #Gurugram and #Ludhiana is a significant advantage, as it allows them to maintain quality standards and efficiently serve their clients. Additionally, their strong distribution network across India ensures accessibility for customers in various regions.

For more information, you can explore here: https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-pithampur/

If you have any other queries or need further assistance, feel free to ask! 🌐https://www.viratsteels.com/ 📬 [email protected] ☎ +91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#steel#iso9001#Pithampur#madhya pradesh#DB6ToolSteel#DieSteels#ToolSteel#SteelTrades#MetalIndustry#MetalTraders#ENSeries#HCHCr

2 notes

·

View notes

Text

Your Trusted Ammonium Hepta Molybdate Manufacturer, Supplier, and Exporter in India

Introduction:

PalviChemical stands as a pioneer in the chemical industry, providing high-quality products to meet diverse industrial needs. With a commitment to excellence and customer satisfaction, we have established ourselves as a leading manufacturer, supplier, and exporter of Ammonium Hepta Molybdate in India. In this blog, we delve into the significance of Ammonium Hepta Molybdate, its applications, and why PalviChemical is your go-to source for this essential chemical compound.

Understanding Ammonium Hepta Molybdate:

Ammonium Hepta Molybdate, also known as Ammonium Paramolybdate, is a vital chemical compound widely used in various industrial processes. It is a white crystalline powder with the chemical formula (NH4)6Mo7O24•4H2O. This compound is valued for its versatility and unique properties, making it indispensable in industries such as agriculture, metallurgy, and chemical synthesis.

Applications of Ammonium Hepta Molybdate:

Agriculture: Ammonium Hepta Molybdate plays a crucial role in agriculture as a source of molybdenum, an essential micronutrient for plant growth. It is used as a fertilizer additive to enrich the soil with molybdenum, promoting healthy plant development and increasing crop yields. Farmers rely on this compound to address molybdenum deficiencies in soils, ensuring optimal nutrient uptake by crops.

Metallurgy: In the metallurgical industry, Ammonium Hepta Molybdate is utilized in various processes, including metal surface treatment, corrosion inhibition, and alloy production. It serves as a corrosion inhibitor in metal coatings, protecting surfaces from degradation and extending their lifespan. Additionally, this compound is a key component in the production of specialty alloys with enhanced strength, durability, and corrosion resistance.

Chemical Synthesis: Ammonium Hepta Molybdate finds application in chemical synthesis, particularly in the synthesis of other molybdenum compounds and catalysts. It serves as a precursor for the preparation of molybdenum oxide catalysts used in organic synthesis, petroleum refining, and chemical manufacturing. The versatility of this compound makes it a valuable resource for chemical researchers and manufacturers worldwide.

Why Choose PalviChemical?

Superior Quality: At PalviChemical, quality is our top priority. We adhere to stringent manufacturing standards and quality control measures to ensure that our Ammonium Hepta Molybdate meets the highest industry specifications. Our state-of-the-art facilities and experienced team of professionals ensure consistency and purity in every batch of product we deliver.

Reliable Supply: As a trusted manufacturer, supplier, and exporter of Ammonium Hepta Molybdate in India, PalviChemical maintains a robust supply chain network to fulfill the diverse needs of our customers. Whether you require small-scale quantities or bulk orders, we guarantee timely delivery and uninterrupted supply to keep your operations running smoothly.

Customized Solutions: At PalviChemical, we understand that every customer has unique requirements. That is why we offer customized solutions tailored to your specific applications and preferences. Whether you need a specialized grade of Ammonium Hepta Molybdate or assistance with product customization, our team is dedicated to meeting your needs with precision and efficiency.

Competitive Pricing: We believe in offering competitive pricing without compromising on quality. PalviChemical strives to provide cost-effective solutions that add value to your business while maintaining affordability and accessibility. Our transparent pricing policies ensure that you receive exceptional value for your investment, making us the preferred choice for Ammonium Hepta Molybdate in India.

Conclusion:

As a leading manufacturer, supplier, and exporter of Ammonium Hepta Molybdate in India, PalviChemical is committed to excellence, reliability, and customer satisfaction. With our superior quality products, reliable supply chain, customized solutions, and competitive pricing, we have earned the trust of customers across diverse industries. Whether you are in agriculture, metallurgy, or chemical synthesis, trust PalviChemical to be your partner in success. Contact us today to learn more about our Ammonium Hepta Molybdate offerings and how we can fulfill your chemical needs with distinction.

#Ammonium Hepta Molybdate exporter in India#Ammonium Hepta Molybdate supplier in India#Ammonium Hepta Molybdate manufacturer in India#India

5 notes

·

View notes

Text

India’s metals processing industry is a key driver of industrial growth, with manufacturers and suppliers producing high-quality metal components for automotive, aerospace, construction, and machinery sectors. Leading companies offer precision engineering, advanced alloys, and reliable supply chains to meet global demand.

Visit - https://www.rpalloys.com/lq-project/metals-processing/

#Materials Processing#Material grades for casting#Cast Steel Production#Properties#Steel Castings#casting material grade#Metals Processing Manufacturing Industry#RP AlloysMetal Processing Industry Components#Metal Components Manufacturers & Suppliers in India

0 notes

Text

Europe Metal Injection Molding (MIM) Market Size, Share, Trends, Growth and Competitive Outlook

Executive Summary Europe Metal Injection Molding (MIM) Market :

Data Bridge Market Research analyses that the metal injection molding (MIM) market was valued at USD 885.3 million in 2021 and is expected to reach USD 2207.68 million by 2029, registering a CAGR of 12.1% during the forecast period of 2022 to 2029.

The high quality Europe Metal Injection Molding (MIM) Market report not only takes into consideration all the market drivers and restraints which are derived from SWOT analysis but also gives all the CAGR projections. This market report underlines the specific study of the industry which explains what the market definition, classifications, applications, engagements, and global industry trends are. This market research report emphasizes on the global key manufacturers to define, illustrate and analyze the market competition landscape using SWOT analysis. Europe Metal Injection Molding (MIM) Market business report makes to focus on the vital aspects of the market such as recent market trends and market conditions.

Several market analysis factors covered in the credible Europe Metal Injection Molding (MIM) Market report include industry outlook with respect to critical success factors (CSFs), industry dynamics that mainly covers drivers and restraints, market segmentation & value chain analysis, key opportunities, application and technology outlook, regional or geographical insight, country-level analysis, key company profiles, competitive landscape, and company market share analysis. Thus, this market research report provides comprehensive analysis on the study of industry with respect to number of aspects. Europe Metal Injection Molding (MIM) Market report is a valuable source of assistance for companies and individuals that provides industry chain structure, business strategies and proposals for new project investments.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Europe Metal Injection Molding (MIM) Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/europe-metal-injection-molding-mim-market

Europe Metal Injection Molding (MIM) Market Overview

**Segments**

- By Material: Stainless Steel, Low Alloy Steel, Soft Magnetic Materials, Cobalt Alloys, Titanium Alloys, Others. - By End-Use Industry: Aerospace, Automotive, Consumer Products, Medical & Healthcare, Industrial, Others. - By Application: Orthopedic, Automotive Components, Industrial Parts, Firearms, Watch Components, Others.

Metal Injection Molding (MIM) is gaining traction in the European market, driven by the increasing demand for complex-shaped metal components with high precision and excellent surface finish. The market can be segmented based on material, end-use industry, and application. Stainless steel remains a prominent material choice due to its corrosion resistance and durability. Low alloy steel is also witnessing significant adoption in industries like automotive and aerospace for its strength and toughness properties. Soft magnetic materials are utilized in electrical applications, while cobalt alloys find applications in high-temperature environments. Titanium alloys are increasingly being used in medical implants and aerospace components.

In terms of end-use industries, aerospace and automotive sectors are major contributors to the European MIM market. The aerospace industry demands lightweight components with high strength, making MIM a preferred manufacturing method. In the automotive sector, MIM is utilized for producing intricate parts that meet stringent performance requirements. Consumer products, medical and healthcare, and industrial sectors are also utilizing MIM technology for cost-effective production of complex parts at scale. The medical and healthcare industry, in particular, benefits from MIM for manufacturing orthopedic implants and surgical instruments with excellent biocompatibility.

The application of MIM technology in various sectors continues to expand in Europe. Orthopedic applications in the healthcare industry are witnessing significant growth due to the increasing demand for customized implants with enhanced integration properties. Automotive components produced through MIM offer advantages in terms of design flexibility and material properties, leading to improved vehicle performance and fuel efficiency. Industrial parts manufactured using MIM exhibit high precision and durability, catering to diverse industrial applications. Firearms industry utilizes MIM for producing intricate components with tight tolerances, enhancing weapon performance. Additionally, watch components manufactured through MIM showcase intricate designs and superior finishes, meeting the high standards of luxury watchmakers in Europe.

**Market Players**

- Indo-MIM - PSM Industries Inc. - CMG Technologies - ARC Group Worldwide - Dynacast - Form Technologies Company - Smith Metal Products - Advanced Forming Technology - NetShape Technologies, Inc. - Molex, LLC

For a comprehensive analysis of the Europe Metal Injection Molding (MIM) market, visit: The European Metal Injection Molding (MIM) market is witnessing robust growth driven by the demand for intricately shaped metal components with high precision and exceptional surface finish. The segmentation by material showcases the diverse preferences within the market, with stainless steel being a preferred choice for its corrosion resistance and durability. Low alloy steel is gaining traction in automotive and aerospace industries owing to its strength and toughness. Soft magnetic materials cater to electrical applications, while cobalt alloys are favored in high-temperature environments. Titanium alloys are finding increased usage in medical implants and aerospace components, highlighting the versatility of MIM technology.

Within the end-use industry segmentation, aerospace and automotive sectors emerge as significant contributors to the European MIM market. The aerospace industry's requirement for lightweight yet strong components aligns well with the capabilities of MIM. In the automotive sector, MIM is utilized for manufacturing intricate parts that meet demanding performance criteria. Consumer products, medical and healthcare, and industrial sectors are also embracing MIM for cost-effective production of complex components. The medical field benefits from MIM's ability to produce orthopedic implants and surgical instruments with superior biocompatibility, driving adoption in healthcare applications.

The application of MIM technology across sectors in Europe is witnessing a broad spectrum of growth opportunities. Orthopedic applications in the healthcare industry are growing steadily, driven by the need for customizable implants with enhanced integration features. Automotive components manufactured through MIM offer improved design flexibility and material properties, enhancing vehicle performance and fuel efficiency. Industrial parts made using MIM technology exhibit high precision and durability, catering to diverse industrial applications. The firearms industry utilizes MIM for manufacturing intricate components with precise tolerances, thereby enhancing weapon performance. Additionally, MIM-produced watch components showcase intricate designs and premium finishes, meeting the exacting standards of luxury watchmakers in Europe.

The market players in the European Metal Injection Molding (MIM) industry exhibit a competitive landscape with key players such as Indo-MIM, PSM Industries Inc., CMG Technologies, ARC Group Worldwide, Dynacast, Form Technologies Company, Smith Metal Products, Advanced Forming Technology, NetShape Technologies, Inc., and Molex, LLC. These players bring diverse capabilities and expertise to the market, driving innovation and quality standards. With a focus on technological advancements and strategic collaborations, these market players are poised to capitalize on the growing opportunities within the European MIM market.

Overall, the European Metal Injection Molding market presents a dynamic landscape characterized by increasing demand across diverse end-use industries and applications. The robust presence of key market players and the continued technological advancements in MIM technology are set to propel further growth and innovation within the European MIM market.The European Metal Injection Molding (MIM) market is poised for significant growth driven by the increasing demand for intricately shaped metal components with high precision and exceptional surface finish. The segmentation of the market by material reveals a diverse landscape of preferences, with stainless steel being a popular choice due to its corrosion resistance and durability. Low alloy steel is gaining traction in industries like automotive and aerospace for its strength and toughness properties. Soft magnetic materials cater to electrical applications, while cobalt alloys find favor in high-temperature environments. Titanium alloys are witnessing growing adoption in medical implants and aerospace components, underscoring the versatility of MIM technology in fulfilling diverse industry needs.

Among the end-use industry segments, aerospace and automotive sectors emerge as significant contributors to the European MIM market. The aerospace industry's demand for lightweight yet robust components aligns well with the capabilities offered by MIM technology. In the automotive sector, MIM is utilized for manufacturing intricate parts that meet stringent performance requirements, demonstrating the versatility of the technology across different industries. Consumer products, medical and healthcare, and industrial sectors are also leveraging MIM for cost-effective production of complex components, showcasing the broad applicability of this manufacturing method across various sectors.

The application of MIM technology across different sectors in Europe is witnessing notable growth opportunities. In the healthcare industry, orthopedic applications are experiencing steady growth driven by the need for customizable implants with enhanced integration properties. Automotive components produced through MIM offer advantages in terms of design flexibility and material properties, contributing to enhanced vehicle performance and fuel efficiency. Industrial parts manufactured using MIM exhibit high precision and durability, catering to diverse industrial applications. The firearms industry utilizes MIM technology for producing intricate components with tight tolerances, thereby enhancing weapon performance. Moreover, MIM-produced watch components showcase intricate designs and superior finishes, meeting the high-quality standards of luxury watchmakers in Europe.

The competitive landscape of the European Metal Injection Molding market is characterized by the presence of key players such as Indo-MIM, PSM Industries Inc., CMG Technologies, ARC Group Worldwide, Dynacast, Form Technologies Company, Smith Metal Products, Advanced Forming Technology, NetShape Technologies, Inc., and Molex, LLC. These market players bring a range of capabilities and expertise to the industry, driving innovation and setting high standards for quality. With a focus on technological advancements and strategic collaborations, these players are well-positioned to capitalize on the growing opportunities within the European MIM market. Overall, the European Metal Injection Molding market presents a dynamic landscape with promising growth prospects across various end-use industries and applications, supported by the continuous advancements in MIM technology and the competitive strategies of key market players.

The Europe Metal Injection Molding (MIM) Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/europe-metal-injection-molding-mim-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Key Benefits of the Report:

This study presents the analytical depiction of the global Europe Metal Injection Molding (MIM) Market Industry along with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global Europe Metal Injection Molding (MIM) Market

The current market is quantitatively analyzed to highlight the Europe Metal Injection Molding (MIM) Market growth scenario.

Porter's five forces analysis illustrates the potency of buyers & suppliers in the market.

The report provides a detailed global Europe Metal Injection Molding (MIM) Market analysis based on competitive intensity and how the competition will take shape in coming years.

Browse More Reports:

Global Coconut Water Market Global Medical Billing Software Market Global Public Safety Solution Market Global Gourmet Salt Market Middle East and Africa API Intermediates Market Asia-Pacific Loyalty Management Market Global Bone Substitutes Market Global Heat Transfer Film Market Global Aquafeed Premix Market Global Soy Protein Isolate Market Global Vaginitis Therapeutics Market Global Methyl Methacrylate (MMA) Film and Sheet Market North America API intermediates Market Global Remote Patient Monitoring and Care Market Global Minocycline Hydrochloride Market Global In Vivo Preclinical Brain Imaging Devices Market Europe and U.S. Cleaner and Degreaser Market Global Necrotizing Fasciitis Market Global Household Cooking Appliances Market India Non-Stick Cookware Market Global Catheter Stabilization Device/Catheter Securement Devices Market Global Antidepressants Market Global Electronics Access Control Systems Market Global Vapour Recovery Units Market Global Golf Trolley Market Global Trichiasis Treatment Market Global Baricitinib Market Middle East and Africa Microbial Air sampler Market Global Weight Management Diet Market Global Data Center Server Market Global Cell Culture Market Middle East and Africa Metal Injection Molding (MIM) Market Global Patient Engagement Solutions Market Global Rock Salt Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

Europe Metal Injection Molding (MIM) Market, Europe Metal Injection Molding (MIM) Market Trends, Europe Metal Injection Molding (MIM) Market Growth, Europe Metal Injection Molding (MIM) Market Demand, Europe Metal Injection Molding (MIM) Market Size, Europe Metal Injection Molding (MIM) Market Scope, Europe Metal Injection Molding (MIM) Market Insights, Europe Metal Injection Molding (MIM) Market Analysis

0 notes

Text

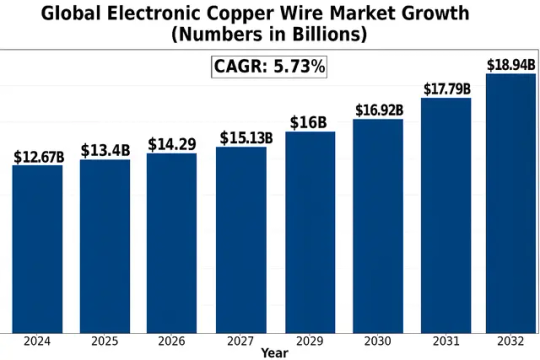

Electronic Copper Wire Market - Business Outlook and Innovative Trends | New Developments, Current Growth Status

Global Electronic Copper Wire Market Research Report 2025(Status and Outlook)

The global Electronic Copper Wire Market size was valued at US$ 12.67 billion in 2024 and is projected to reach US$ 18.94 billion by 2032, at a CAGR of 5.73% during the forecast period 2025-2032.

Electronic copper wire is a fundamental conductive material used extensively in semiconductor packaging, printed circuit boards (PCBs), and various electronic components. These wires are manufactured with different diameters (typically ranging from 0-20 μm to above 50 μm) to accommodate diverse applications in the electronics industry. The superior electrical conductivity, thermal properties, and cost-effectiveness of copper make it the preferred choice over alternatives like gold or aluminum for most electronic interconnects.

The market growth is driven by expanding semiconductor manufacturing capabilities, particularly in Asia-Pacific, and increasing demand for consumer electronics and electric vehicles. However, supply chain disruptions in raw copper materials and the ongoing miniaturization trend in electronics present challenges. Key players like Heraeus and Sumitomo Metal Mining are investing in advanced copper wire bonding technologies to maintain competitiveness in this evolving market landscape.

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://semiconductorinsight.com/download-sample-report/?product_id=95876

Segment Analysis:

By Type

20-30 µm Segment Holds Major Share Due to Optimal Bonding Performance in Semiconductor Packaging

The market is segmented based on type into:

0-20 µm

Subtypes: Ultra-fine pitch bonding wires for advanced ICs

20-30 µm

30-50 µm

Subtypes: Standard diameter wires for conventional packaging

Above 50 µm

Others

By Application

Semiconductor Packaging Dominates Due to Increasing Demand for Advanced Electronics

The market is segmented based on application into:

Semiconductor packaging

Subtypes: Flip chips, chip-on-board, multi-chip modules

PCB interconnects

Power electronics

LED packaging

Others

By End User

Consumer Electronics Sector Leads Owing to Proliferation of Smart Devices

The market is segmented based on end user into:

Consumer electronics

Automotive electronics

Industrial electronics

Medical devices

Others

Regional Analysis: Global Electronic Copper Wire Market

North America The North American electronic copper wire market is driven by high-tech semiconductor manufacturing and significant investments in electronics infrastructure. The U.S. accounts for over 65% of regional demand, supported by major players like AMETEK and The Prince & Izant. Despite stricter environmental regulations influencing production costs, the region maintains a competitive edge through advanced wire bonding technologies and robust R&D investments in semiconductor packaging. Recent CHIPS Act allocations of $52 billion for domestic semiconductor production are expected to further stimulate demand for high-purity copper wires in chip manufacturing.

Europe Europe’s market is characterized by stringent quality standards and growing adoption of copper wire in automotive electronics, particularly in Germany and France. Heraeus, a key regional player, dominates the premium segment with specialized alloys for high-frequency applications. The EU’s push for electronics recycling (following WEEE Directive guidelines) has accelerated development of eco-friendly copper wire formulations, though higher production costs limit market penetration compared to Asia. Recent supply chain disruptions have prompted increased localization of wire production, particularly for aerospace and medical device applications where precision is critical.

Asia-Pacific As the world’s largest consumer of electronic copper wire, Asia-Pacific accounts for approximately 58% of global volume, with China, Japan, and South Korea leading demand. The region benefits from vertically integrated electronics ecosystems, where companies like Sumitomo Metal Mining and MK Electron supply wires directly to nearby semiconductor fabs and PCB manufacturers. While price competition is intense (especially in consumer electronics segments), Japanese suppliers maintain premium positioning for finer (<30 μm) bonding wires used in advanced chip packaging. India’s emerging semiconductor policy initiatives present new growth avenues, though infrastructure limitations persist.

South America South America represents a nascent but growing market, primarily serving local electronics assembly operations in Brazil and Argentina. Import dependence exceeds 70% for high-grade copper wires, as regional production focuses on thicker gauges (>50 μm) for power applications rather than precision electronics. Economic instability and currency fluctuations have discouraged major investments in local wire production facilities, though some multinational PCB manufacturers are establishing operations to serve the automotive and appliance sectors, creating opportunities for mid-tier suppliers.

Middle East & Africa This region shows promising long-term potential as electronics manufacturing begins to diversify beyond oil-dependent economies. The UAE and Saudi Arabia are investing in semiconductor testing and packaging facilities, driving demand for imported copper wires. However, the market remains constrained by limited technical Expertise in fine wire production and underdeveloped local supply chains. South Africa serves as a regional outlier with some specialty wire production for mining and industrial electronics, though volumes remain modest compared to global standards.

List of Key Electronic Copper Wire Companies Profiled

Heraeus Holding GmbH (Germany)

Tanaka Holdings Co., Ltd. (Japan)

Sumitomo Metal Mining Co., Ltd. (Japan)

MK Electron Co., Ltd. (South Korea)

AMETEK, Inc. (U.S.)

Doublink Solders (U.S.)

Yantai Zhaojin Kanfort Co., Ltd. (China)

Tatsuta Electric Wire & Cable Co., Ltd. (Japan)

Kangqiang Electronics Co., Ltd. (China)

The Prince & Izant Company (U.S.)

The global semiconductor market is experiencing unprecedented growth, with projections indicating it will reach over $950 billion by 2030. This exponential expansion directly drives demand for electronic copper wire used in wire bonding applications. As semiconductor devices become smaller and more sophisticated, the need for high-purity copper wire with diameters between 20-50 microns has surged by approximately 18% annually. The transition to copper from gold bonding wires in over 75% of new semiconductor packages demonstrates copper’s cost-effectiveness and superior electrical conductivity, making it indispensable in modern electronics manufacturing.

The automotive industry’s shift toward electrification represents a significant growth driver for electronic copper wire. Electric vehicles contain nearly triple the copper content of conventional vehicles, with power electronics and battery management systems requiring extensive use of fine copper wires. The EV market is projected to grow at a compound annual rate of 29% through 2030, directly correlating with increased copper wire consumption. Furthermore, advanced driver-assistance systems (ADAS) in modern vehicles utilize numerous semiconductor components that rely on copper wire bonding, creating additional demand across automotive applications.

Global 5G network rollout has created substantial demand for electronic copper wire across telecommunications infrastructure. 5G base stations require 30-40% more copper content than 4G equivalents, particularly in power amplifiers and RF components. The ongoing deployment of over 3 million 5G base stations worldwide necessitates reliable copper wire bonding solutions for high-frequency applications. Additionally, the proliferation of IoT devices connected through 5G networks further stimulates demand for copper wires used in sensor packaging and microelectronics.

The emergence of 2.5D and 3D semiconductor packaging creates substantial opportunities for innovative copper wire solutions. These advanced packaging techniques, growing at 22% annually, require specialized copper wires capable of vertical interconnects and fine-pitch bonding. Development of copper-palladium alloy wires with enhanced strength characteristics addresses these emerging needs, potentially capturing 35% of the advanced packaging wire market by 2028.

The global renewable energy sector’s growth presents significant opportunities for electronic copper wire in power conversion systems. Solar inverters and wind turbine power electronics require reliable copper bonding wires with enhanced thermal cycling performance. This niche market segment is projected to grow at 28% CAGR through 2030, with specialized oxidation-resistant copper alloys gaining traction in harsh environmental applications.

Developing semiconductor ecosystems in Southeast Asia and India create new geographic opportunities for electronic copper wire suppliers. Government initiatives supporting local chip production, combined with growing electronics manufacturing in these regions, are expected to drive 40% of future market growth. Strategic partnerships with emerging foundries and OSAT providers present avenues for market expansion beyond traditional manufacturing hubs.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=95876

Key Questions Answered by the Electronic Copper Wire Market Report:

What is the current market size of Global Electronic Copper Wire Market?

Which key companies operate in Global Electronic Copper Wire Market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014

[+91 8087992013]

0 notes

Text

Global Electronic Copper Wire Market Key Players, Segmentation, Application And Forecast to 2032

Global Electronic Copper Wire Market size was valued at US$ 12.67 billion in 2024 and is projected to reach US$ 18.94 billion by 2032, at a CAGR of 5.73% during the forecast period 2025-2032.

Electronic copper wire is a fundamental conductive material used extensively in semiconductor packaging, printed circuit boards (PCBs), and various electronic components. These wires are manufactured with different diameters (typically ranging from 0-20 μm to above 50 μm) to accommodate diverse applications in the electronics industry. The superior electrical conductivity, thermal properties, and cost-effectiveness of copper make it the preferred choice over alternatives like gold or aluminum for most electronic interconnects.

The market growth is driven by expanding semiconductor manufacturing capabilities, particularly in Asia-Pacific, and increasing demand for consumer electronics and electric vehicles. However, supply chain disruptions in raw copper materials and the ongoing miniaturization trend in electronics present challenges. Key players like Heraeus and Sumitomo Metal Mining are investing in advanced copper wire bonding technologies to maintain competitiveness in this evolving market landscape.

Get Full Report with trend analysis, growth forecasts, and Future strategies : https://semiconductorinsight.com/report/global-electronic-copper-wire-market/

Segment Analysis:

By Type

20-30 µm Segment Holds Major Share Due to Optimal Bonding Performance in Semiconductor Packaging

The market is segmented based on type into:

0-20 µm

Subtypes: Ultra-fine pitch bonding wires for advanced ICs

20-30 µm

30-50 µm

Subtypes: Standard diameter wires for conventional packaging

Above 50 µm

Others

By Application

Semiconductor Packaging Dominates Due to Increasing Demand for Advanced Electronics

The market is segmented based on application into:

Semiconductor packaging

Subtypes: Flip chips, chip-on-board, multi-chip modules

PCB interconnects

Power electronics

LED packaging

Others

By End User

Consumer Electronics Sector Leads Owing to Proliferation of Smart Devices

The market is segmented based on end user into:

Consumer electronics

Automotive electronics

Industrial electronics

Medical devices

Others

Regional Analysis: Global Electronic Copper Wire Market

North America The North American electronic copper wire market is driven by high-tech semiconductor manufacturing and significant investments in electronics infrastructure. The U.S. accounts for over 65% of regional demand, supported by major players like AMETEK and The Prince & Izant. Despite stricter environmental regulations influencing production costs, the region maintains a competitive edge through advanced wire bonding technologies and robust R&D investments in semiconductor packaging. Recent CHIPS Act allocations of $52 billion for domestic semiconductor production are expected to further stimulate demand for high-purity copper wires in chip manufacturing.

Europe Europe’s market is characterized by stringent quality standards and growing adoption of copper wire in automotive electronics, particularly in Germany and France. Heraeus, a key regional player, dominates the premium segment with specialized alloys for high-frequency applications. The EU’s push for electronics recycling (following WEEE Directive guidelines) has accelerated development of eco-friendly copper wire formulations, though higher production costs limit market penetration compared to Asia. Recent supply chain disruptions have prompted increased localization of wire production, particularly for aerospace and medical device applications where precision is critical.

Asia-Pacific As the world’s largest consumer of electronic copper wire, Asia-Pacific accounts for approximately 58% of global volume, with China, Japan, and South Korea leading demand. The region benefits from vertically integrated electronics ecosystems, where companies like Sumitomo Metal Mining and MK Electron supply wires directly to nearby semiconductor fabs and PCB manufacturers. While price competition is intense (especially in consumer electronics segments), Japanese suppliers maintain premium positioning for finer (<30 μm) bonding wires used in advanced chip packaging. India’s emerging semiconductor policy initiatives present new growth avenues, though infrastructure limitations persist.

South America South America represents a nascent but growing market, primarily serving local electronics assembly operations in Brazil and Argentina. Import dependence exceeds 70% for high-grade copper wires, as regional production focuses on thicker gauges (>50 μm) for power applications rather than precision electronics. Economic instability and currency fluctuations have discouraged major investments in local wire production facilities, though some multinational PCB manufacturers are establishing operations to serve the automotive and appliance sectors, creating opportunities for mid-tier suppliers.

Middle East & Africa This region shows promising long-term potential as electronics manufacturing begins to diversify beyond oil-dependent economies. The UAE and Saudi Arabia are investing in semiconductor testing and packaging facilities, driving demand for imported copper wires. However, the market remains constrained by limited technical Expertise in fine wire production and underdeveloped local supply chains. South Africa serves as a regional outlier with some specialty wire production for mining and industrial electronics, though volumes remain modest compared to global standards.

MARKET OPPORTUNITIES

Advanced Packaging Technologies Open New Application Frontiers

The emergence of 2.5D and 3D semiconductor packaging creates substantial opportunities for innovative copper wire solutions. These advanced packaging techniques, growing at 22% annually, require specialized copper wires capable of vertical interconnects and fine-pitch bonding. Development of copper-palladium alloy wires with enhanced strength characteristics addresses these emerging needs, potentially capturing 35% of the advanced packaging wire market by 2028.

Renewable Energy Expansion Drives Specialty Wire Demand

The global renewable energy sector’s growth presents significant opportunities for electronic copper wire in power conversion systems. Solar inverters and wind turbine power electronics require reliable copper bonding wires with enhanced thermal cycling performance. This niche market segment is projected to grow at 28% CAGR through 2030, with specialized oxidation-resistant copper alloys gaining traction in harsh environmental applications.

Emerging Economies Offer Untapped Growth Potential

Developing semiconductor ecosystems in Southeast Asia and India create new geographic opportunities for electronic copper wire suppliers. Government initiatives supporting local chip production, combined with growing electronics manufacturing in these regions, are expected to drive 40% of future market growth. Strategic partnerships with emerging foundries and OSAT providers present avenues for market expansion beyond traditional manufacturing hubs.

ELECTRONIC COPPER WIRE MARKET TRENDS

Miniaturization of Electronic Devices Driving Demand for Ultra-Thin Copper Wires

The global electronic copper wire market is experiencing significant growth due to the increasing demand for miniaturized electronic components across industries. With semiconductor packaging technologies advancing toward smaller nodes (5nm and below), there’s a parallel need for finer copper bonding wires that maintain conductivity while reducing diameter. Currently, wires below 20μm dominate nearly 40% of the high-performance packaging segment, particularly in advanced consumer electronics and automotive sensors. Furthermore, the shift from gold to cost-effective copper wires in wire bonding applications continues to accelerate, supported by improved anti-corrosion coatings that enhance longevity.

Other Trends

Sustainability Initiatives Reshaping Material Preferences

Environmental regulations and corporate sustainability goals are pushing manufacturers toward high-purity recycled copper, which now accounts for approximately 25% of the raw material supply in wire production. The EU’s Circular Economy Action Plan and similar frameworks globally have incentivized closed-loop recycling systems in electronics manufacturing. This trend aligns with the broader industry movement toward reducing Scope 3 emissions, given that copper mining contributes significantly to carbon footprints. Leading suppliers are now offering copper wires with 98.5%+ recycled content without compromising on conductivity standards.

Expansion of 5G Infrastructure Fuelling Specialty Copper Wire Demand

The rollout of 5G networks worldwide has created a surge in demand for high-frequency compatible copper wires used in base stations and network equipment. These applications require wires with exceptional signal integrity, driving innovation in oxygen-free copper (OFC) variants that minimize signal loss at high frequencies. The Asia-Pacific region, particularly China and South Korea, accounts for over 60% of this demand spike due to aggressive 5G deployment schedules. Additionally, the automotive sector’s growing adoption of advanced driver-assistance systems (ADAS) and in-vehicle networking continues to expand the addressable market for automotive-grade copper wires with enhanced thermal stability.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Strategic Expansion Define Market Leadership in Copper Wire Electronics

The global electronic copper wire market exhibits a moderately fragmented competitive structure, with established multinational corporations dominating alongside regional specialists. Heraeus Holding GmbH leads the market with its vertically integrated supply chain and proprietary copper purification technologies, controlling approximately 18% of the high-precision wire segment used in semiconductor packaging as of 2023.

Japanese competitors Tanaka Holdings Co. and Sumitomo Metal Mining Co. maintain strong positions through their advanced alloy compositions and strategic partnerships with automotive semiconductor manufacturers. Their combined market share in Asia-Pacific exceeds 25%, driven by increasing demand for electric vehicle components.

The competitive intensity is further heightened by technological specialization – while larger players focus on high-volume standardization, mid-sized companies like MK Electron and Yantai Zhaojin Kanfort compete through niche applications. MK Electron’s recent breakthrough in oxidation-resistant coating for fine copper wires (below 20μm) has captured 12% of the advanced packaging segment.

North American presence is consolidating through acquisitions, as demonstrated by AMETEK‘s 2022 purchase of Doublink Solders’ copper wire division. This strategic move expanded AMETEK’s product portfolio to cover the full spectrum from 15μm ultra-fine wires to heavy-duty 60μm industrial bonding wires.

List of Key Electronic Copper Wire Companies Profiled

Heraeus Holding GmbH (Germany)

Tanaka Holdings Co., Ltd. (Japan)

Sumitomo Metal Mining Co., Ltd. (Japan)

MK Electron Co., Ltd. (South Korea)

AMETEK, Inc. (U.S.)

Doublink Solders (U.S.)

Yantai Zhaojin Kanfort Co., Ltd. (China)

Tatsuta Electric Wire & Cable Co., Ltd. (Japan)

Kangqiang Electronics Co., Ltd. (China)

The Prince & Izant Company (U.S.)

Learn more about Competitive Analysis, and Global Forecast of Global Electronic Copper Wire Market : https://semiconductorinsight.com/download-sample-report/?product_id=95876

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Electronic Copper Wire Market?

-> Electronic Copper Wire Market size was valued at US$ 12.67 billion in 2024 and is projected to reach US$ 18.94 billion by 2032, at a CAGR of 5.73% during the forecast period 2025-2032.

Which key companies operate in Global Electronic Copper Wire Market?

-> Major players include Heraeus, Tanaka, Sumitomo Metal Mining, MK Electron, AMETEK, Doublink Solders, and Yantai Zhaojin Kanfort.

What are the key growth drivers?

-> Key drivers include increasing semiconductor demand, growth in consumer electronics, and automotive electronics expansion, particularly in electric vehicles.

Which region dominates the market?

-> Asia-Pacific dominates with over 65% market share, driven by semiconductor manufacturing in China, Taiwan, South Korea, and Japan.

What are the emerging trends?

-> Emerging trends include adoption of ultra-fine pitch bonding wires, copper alloy innovations, and automation in wire bonding processes.

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 +91 8087992013 [email protected]

Follow us on LinkedIn: https://www.linkedin.com/company/semiconductor-insight/

0 notes

Text

Alloy Steel Fasteners Manufacturer & Supplier in Chennai – Akbar Fasteners

Chennai, with its rapidly expanding industrial infrastructure, power plants, automotive manufacturing units, and oil & gas facilities, demands the highest quality in industrial components—especially fasteners. These small yet vital components are the backbone of structural stability and mechanical integrity. When it comes to high-strength, reliable fastening solutions, alloy steel fasteners are among the top choices for engineers and procurement specialists. As a trusted Alloy Steel Fasteners Manufacturer & Supplier in Chennai, Akbar Fasteners delivers products that match international quality benchmarks and are designed for demanding applications.

Introduction to Alloy Steel Fasteners

Alloy steel fasteners are made using steel that is alloyed with various elements such as chromium, nickel, molybdenum, or vanadium to enhance specific properties like strength, hardness, wear resistance, and corrosion resistance. These fasteners are known for their durability and ability to perform under extreme stress and temperature variations. In sectors like heavy machinery, automotive manufacturing, and energy plants, the performance of alloy steel fasteners is unmatched.

From simple bolts to more complex studs, nuts, and washers, these fasteners are engineered to meet the rigorous demands of industrial applications. Their mechanical integrity ensures fewer breakdowns, extended lifecycle, and overall cost efficiency for large-scale operations.

Applications of Alloy Steel Fasteners in Chennai’s Industrial Sector

Chennai has evolved into a major industrial hub with sectors ranging from automobile manufacturing and shipbuilding to petrochemical and renewable energy. Each of these industries requires fastening components that can withstand high loads and corrosive environments. Alloy steel fasteners fit the bill perfectly, offering the strength and reliability these sectors demand.