#alloy 718

Text

Did You Know the Advantages of Inconel Alloy Bolts?

Inconel alloy fasteners like Inconel alloy bolts consist of nickel, molybdenum, chromium, iron, niobium, titanium, and cobalt. The material quantity in the alloy varies per their grade. Inconel alloy fasteners are known for their high strength, corrosion resistance, durability, and strength, making them perfect for critical applications. Inconel alloy bolts, like other Inconel fasteners, offer extensive benefits in multiple applications. To know more, continue reading.

Advantages of Inconel Alloy Bolts

High-Temperature Resistance

Inconel alloy works well at extreme temperature conditions. They can maintain their mechanical properties, allowing the Inconel alloy 600 fasteners like bolts to function well in critical applications like power generation and aerospace. These fasteners operate well in severe atmospheric conditions and do not require frequent replacement like other materials. For instance, Inconel 718 fasteners do not lose strength at temperatures up to 704 degrees Celsius.

Following are some of the highlights of using Inconel bolts with high-temperature resistance:

High durability across different temperatures.

Unaffected by thermal fluctuation.

Provide scaling and oxidation resistance at extremely high temperatures.

Withstands high load at high temperatures due to its high-stress rupture and creep strength

Inconel bolts have high endurance in critical environments.

Applications: Heat exchangers, Furnace components, Commercial applications, oil and gas

extraction, and processing

Enhanced strength

Inconel alloys are known for their high tensile strength, making Inconel bolts one of the sought-after Inconel 625 fasteners. These bolts find applications that deal with high stress, like power generation and aerospace. The tensile strength of the Inconel bolts also prevents issues like warping or shearing.

Apart from tensile strength, Inconel alloy also has high yield strength. It makes Inconel alloy 718 fasteners like bolts to spring back to their original form. They can also sustain permanent deformation under high loads.

Following are some of the highlights of using Inconel bolts with high strength:

Maintains toughness at high temperature

Does not crack like other material fasteners

Constant thermal functioning (non-fluctuating)

Inconel bolts have high creep resistance, especially Inconel 625 bolts at high temperatures and stress.

The moderate impact strength of Inconel 725 fasteners is a contributing factor to its toughness, ultimately offering shatter-proof functioning.

Applications: Power generation, aerospace, jet engine casings, nuclear reactor components, gas turbines, heat exchangers, etc.

Corrosion resistance

Inconel bolts showcase seamless functioning in applications dealing with corrosive surroundings. Inconel 625 bolts have high chemical resistance and do not react in environments dealing with sulfuric acid, hydrochloric acid, chlorides, etc. These bolts and other Inconel fasteners like nuts and bolts also provide sea-water corrosion resistance. They are perfect in the marine sector and they do not corrode easily. Inconel 718 fasteners, like bolts, have high crevice and pitting corrosion resistance due to chloride ions.

Following are some of the highlights of using Inconel bolts with excellent corrosion resistance:

High performance in marine applications.

High compatibility in reductive and oxidizing environments.

Enhanced safety and reliability.

Compatible for sour gas environments as Inconel bolt adaptors.

They offer sulfide stress cracking and hydrogen embrittlement resistance in sour gas

· applications.

Applications: Scrubbers, chemical storage tanks, reactors, oil rigs, subsea machinery, naval ships, petrochemical processing, etc.

Extended service life

Inconel alloy bolts do not loosen at high temperatures. Inconel 625 fasteners are unaffected by extensive exposure to high stress and temperature conditions. Their stress and temperature resistance ensures additional safety and avoids loosening or degradation issues, leading to optimal outcomes over time.

Following are some of the highlights of using Inconel bolts in context to durability:

Excellent performance in extreme conditions, leading to a longer lifespan.

High wear resistance.

Ease of replacement and seamless operation.

Inconel fasteners provide high fatigue and creep resistance at high stress and temperatures

Applications: Jet engines, oil and gas exploration, nuclear reactors, etc.

Final thoughts!

Inconel alloy bolts have extensive industrial applications due to their benefits. They are available in multiple grades at Inconel Bolts manufacturer in Mumbai, like Fasteners and Fixtures LLP.

0 notes

Text

ASTM B473 Alloy 20 Round Bar Supplier & Stockist | Anand steels

In the area of commercial substances, excessive-performance alloys are essential, especially in environments that call for superb corrosion resistance and mechanical strength. Among these, Alloy 20, distinct underneath ASTM B473, is a standout desire for lots programs. Anand Steel, a leading dealer and stockist, is well-identified for imparting top-first-rate ASTM B473 Alloy 20 Round Bars, Alloy 20 Hexagonal Bars, and other high-overall performance alloys. This blog delves into the advantages, programs, and specifics of those substances, along side the exceptional services presented with the aid of Anand Steel.

Understanding ASTM B473 Alloy 20

What is Alloy 20?

Alloy 20, also called Carpenter 20, is a nickel-iron-chromium austenitic alloy designed more often than not for maximum resistance to acid attack, particularly sulfuric acid. This alloy is a part of the superalloy category and is surprisingly valued for its fantastic resistance to pitting, chloride ion corrosion, and sulfuric acid.

Key Properties

- Corrosion Resistance: Alloy 20 is mainly proof against sulfuric acid, making it a top desire for chemical processing industries.

- Mechanical Strength: This alloy continues top notch mechanical houses in high-temperature environments.

- Fabrication Ease: Alloy 20 can be fabricated and welded using traditional techniques, including its versatility.

ASTM B473 20 Alloy Round Bar

Overview of ASTM B473

ASTM B473 is a specification that covers nickel-iron-chromium-molybdenum-copper alloy (UNS N08020) bar and twine. These materials are in particular designed to be used in exceptionally corrosive environments.

Applications

- Chemical Processing: Utilized in warmth exchangers, blending tanks, and technique piping that handle sulfuric acid and other harsh chemicals.

- Food and Pharmaceutical Industries: Used in system and machinery wherein excessive ranges of sanitation and corrosion resistance are required.

- Power Generation: Suitable for use in warmness exchangers and other components uncovered to harsh working conditions.

ASTM B473 Alloy 20 Hexagonal Bars

Features and Uses

ASTM B473 Alloy 20 Hexagonal Bars provide the same top notch corrosion resistance and mechanical homes as spherical bars however are often utilized in programs wherein particular geometric shapes are required for meeting or structural functions.

Key Applications

- Construction: Used in frameworks and assist systems requiring high corrosion resistance.

- Marine Environments: Ideal for components exposed to seawater and other marine situations.

- Petrochemical Industry: Utilized in components that handle chemical reactions and excessive-temperature tactics.

Comparing ASTM B473 Alloy 20 and ASTM B408 Inconel Round Bars

What is ASTM B408 Inconel?

ASTM B408 Inconel Round Bars covers nickel-iron-chromium alloys (Inconel), recognized for his or her excessive power and resistance to oxidation and corrosion at high temperatures.

Inconel UNS N08 718 Round Bars

- Composition: Inconel 718 is a nickel-chromium alloy with additions of molybdenum and niobium, which give excessive energy and correct corrosion resistance.

- Applications: Primarily utilized in aerospace, gas generators, and different excessive-temperature business packages.

Key Differences

- Corrosion Resistance: While each alloys offer incredible corrosion resistance, Alloy 20 is advanced in sulfuric acid environments, while Inconel is more suited for excessive-temperature oxidizing situations.

- Temperature Stability: Inconel 718 can face up to better temperatures in comparison to Alloy 20, making it perfect for packages concerning severe heat.

Anand Steel: Your Trusted Supplier and Stockist

A reputable supplier and stockist of excessive-performance alloys, which includes ASTM B473 Alloy 20 Round Bars and ASTM B408 Inconel Round Bars. Here are some reasons why Anand Steel is a preferred preference:

- Quality Assurance: Ensures that all products meet stringent exceptional standards and specs, presenting reliability and overall performance.

- Extensive Inventory: They hold a complete stock of Alloy 20 and Inconel bars, making sure of quick availability and prompt transport.

- Technical Expertise: Group possesses deep technical know-how, offering professional recommendation and solutions tailor-made to purchaser wishes.

- Customer Support: They offer incredible customer support, from product selection to after-sales support, making sure an unbroken and fine experience.

Applications of Products

- Chemical Plants: Utilized in critical additives like reactors, piping systems, and heat exchangers to handle corrosive chemicals.

- Oil and Gas Industry: Employed in drilling devices, pipelines, and processing flora exposed to harsh environments.

- Aerospace: Inconel round bars are used in turbine engines and other components that require excessive-temperature resistance and durability.

Conclusion

ASTM B473 Alloy 20 Round Bars and ASTM B408 Inconel Round Bars are important substances in industries requiring excessive corrosion resistance and mechanical electricity. Alloy 20, with its superior resistance to sulfuric acid and different harsh chemical substances, is a crucial cloth for chemical processing and related industries. In assessment, Inconel 718 is right for excessive-temperature programs in the aerospace and strength era.

Anand Steel stands proud as a leading provider and stockist of those high-performance alloys in Saudi Arabia. Their dedication to nice, full-size inventory, technical expertise, and excellent customer support lead them to the pass-to preference for all your alloy wishes. Whether you're in the chemical processing enterprise, oil and fuel area, or aerospace, you need the right solution for your precise requirements. By choosing Anand Steel, you ensure that your tasks are ready with the great materials, contributing to their achievement and durability.

#ASTM B473 20 Alloy Round Bar#ASTM B473 Alloy 20 Hexagonal Bars#ASTM B408 inconel round bars#Inconel UNS N08 718 round bars

0 notes

Text

Inconel in the Chemical Industry: Defying Corrosion and Harsh Chemicals

In the vast world of the chemical industry, where the constant battle against corrosion rages on, the value of materials that can withstand harsh environments cannot be overstated. Among these resilient materials, Inconel alloys have risen to prominence, offering an impressive level of resistance to corrosion and harsh chemicals. This blog delves into the significance of Inconel in the chemical industry, shedding light on its distinctive properties and versatile applications.

Understanding Inconel Alloys

Inconel Alloys belong to a family of superalloys based on nickel and chromium. Renowned for their exceptional ability to withstand high temperatures, oxidation, and corrosion, these alloys consist of a combination of nickel, chromium, iron, and other elements. Their unique blend of mechanical strength and resistance to corrosion makes them highly suitable for a wide range of applications in the chemical industry.

The Corrosive Challenge

Chemical processing plants often grapple with corrosive substances that can wreak havoc on conventional materials. Corrosion refers to the gradual deterioration caused by chemical reactions that can result in equipment failure, safety risks, and costly downtime. However, Inconel alloys stand tall as formidable defenders against these corrosive challenges.

Applications of Inconel in the Chemical Industry

Aside from their impressive resistance to corrosion and harsh chemicals, Inconel alloys find diverse applications throughout various sectors within the chemical industry:

Chemical Processing Equipment

Inconel alloys are extensively used in manufacturing chemical processing equipment. Reactors, heat exchangers, and pipelines that come into contact with aggressive chemicals benefit greatly from Inconel's corrosion resistance properties. This ensures longevity and reliability for these vital components.

Catalyst Support Structures

Thanks to its ability to withstand high temperatures and aggressive chemical environments effectively; Inconel is a favored choice for catalyst support structures. These structures play a crucial role in catalytic processes where stability is paramount. And with its remarkable resistance, Inconel ensures the efficiency and durability of these processes over time.

Piping Systems

Transporting corrosive chemicals through pipelines requires materials that can withstand degradation. Inconel's corrosion resistance and exceptional strength make it an excellent option for constructing piping systems in chemical plants. This choice reduces the risk of leaks and failures, enhancing overall safety.

Inconel: A Key Player in Safety and Reliability

Ensuring Operational Integrity

In the chemical industry, maintaining operational integrity is of utmost importance. One key factor that contributes to this is the use of Inconel in critical components. By withstanding corrosive attacks, Inconel plays a crucial role in preventing equipment failures, leaks, and accidents. This not only ensures a safer working environment but also promotes overall operational integrity.

Longevity and Cost-Efficiency

When it comes to making smart investments, choosing Inconel alloys proves to be a cost-effective choice in the long run. The extended lifespan of equipment constructed with Inconel translates to reduced maintenance costs, minimized downtime, and enhanced overall efficiency. It's clear that investing in Inconel pays off both in terms of longevity and cost-efficiency.

Invaluable Significance in the Chemical Industry:

The exceptional resistance of Inconel to corrosion and harsh chemicals solidifies its significance in the chemical industry. Acting as a stalwart ally against degradation, Inconel alloys contribute significantly to the longevity, reliability, and efficiency of critical components in chemical processing plants. Their role cannot be understated when it comes to ensuring smooth operations within this industry.

Alloyed Sustainables LLP: Your Trusted Inconel Partner

From chemical processing equipment to catalyst support structures and piping systems, Inconel alloys play an indispensable role in ensuring safety, reliability, and longevity within the chemical industry. At Alloyed Sustainables LLP, we find ourselves in a time where industries are constantly changing and evolving. The need for materials that can resist corrosion, like Inconel, has never been higher. We take great pride in being at the forefront of addressing this demand.

As one of the top importers and stockists of Inconel Alloys, we make sure to always have a steady and dependable supply of high-quality alloys. This allows us to meet the demanding requirements of different industries. With our support, businesses are empowered to keep their operations running smoothly, even in the face of corrosive challenges.

0 notes

Text

Nickle Alloys Bars Supplier

Are you looking out for Quality Nickel Alloys Bars?

Maniar and company is a leading name in the Importers and Stockiest of nickel alloys and nickel alloy bars.

We are in the market since years and meet most ASME, ASTM, AMS certified specifications and meet most of international standards.

Our diversity of products makes them stand out in the market. We are satisfy the demands of wide range of industries like Oil & gas, shipbuilding, petrochemical, aerospace, etc. for over a decade now.

On-time delivery and supreme quality has helped to grow and flourish.

Nickel Alloys Bars

Nickel Alloy bars has excellent mechanical characteristics even at zero temperatures. We have excellent corrosion-resistant properties, are resistant to chloride stress corrosion, and are fully weldable.

The nickel alloys that Maniar and company deal with are:

Monel Nickel Alloy 400 Bars

Monel Nickel Alloy 405 Bars

Nickel Alloy K500 Bars

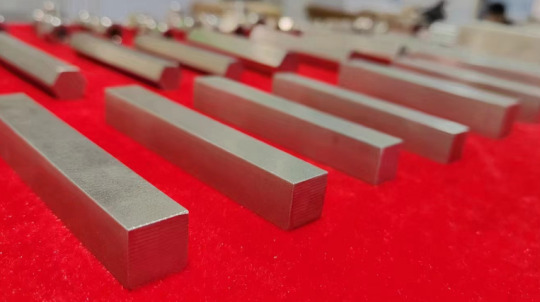

Nickel Alloy 718 Bars

Nickel Alloy 625 Bars

All of the above varieties are used in oil and gas industry, aircraft ducting systems, jet engine exhaust systems, valves, tubing hangers, mechanical industry, marine industry etc.

You can reach out:

Website – maniarsteels.com

Email – [email protected]

Phone number – +919820011879

Summary –

Maniar and company is a reputed name in India for the Importers and Stockiest of nickel alloys and bars. We are being highly recommended for their superior quality products and prompt delivery. We meet almost all the national and international quality standards and specifications for the equipment. Our nickel alloys are excellent in quality and are procured with exact specifications as per the requirements of the customer.

0 notes

Text

Is Monel similar to Inconel?

Many of our customers have such a question: Is Monel similar to Inconel? As a matter of fact, both Monel and Inconel are nickel-based alloys with exceptional corrosion resistance and high-temperature performance, but they differ significantly in composition, properties, and applications. In this article, let’s delve into the key aspects of these two alloys to understand their similarities and differences.

Is Monel similar to Inconel?

Composition:

Monel, also known as Monel alloy, is primarily a nickel-copper alloy, typically containing up to 67% nickel and 28% copper, with the remaining portion composed of iron, manganese, carbon, and silicon. This composition gives Monel its excellent corrosion resistance, particularly against acids and alkalies.

On the other hand, Inconel is a nickel-chromium alloy, with chromium content ranging from 15% to 25%, depending on the specific grade. Inconel alloys also contain significant amounts of other elements like iron, molybdenum, and titanium, which contribute to their high-temperature strength and oxidation resistance.

Properties:

Both Monel and Inconel exhibit excellent corrosion resistance, but the specific environments they thrive in differ. Monel’s corrosion resistance is particularly noteworthy in marine and chemical processing applications, where it can withstand the corrosive effects of saltwater and various acids.

Inconel, on the other hand, is renowned for its ability to maintain its mechanical properties at extremely high temperatures. It is often used in aerospace and power generation applications where materials must withstand extreme heat and pressure. Inconel’s chromium content also gives it superior resistance to oxidation and sulfidation at high temperatures.

When it comes to mechanical properties, Inconel generally offers higher strength and hardness compared to Monel. However, Monel has better formability and weldability, making it easier to shape and join into complex structures.

Applications:

The differences in composition and properties lead to distinct applications for Monel and Inconel. Monel is commonly used in the chemical processing, marine, and food processing industries due to its resistance to corrosion and ease of fabrication. Its ability to withstand the corrosive effects of saltwater makes it a popular choice for marine applications like shipbuilding and offshore drilling.

Inconel, on the other hand, finds its niche in high-temperature applications where strength and oxidation resistance are paramount. Aerospace, power generation, and petrochemical industries rely on Inconel alloys for components that must operate in extreme environments.

Conclusion:

While Monel and Inconel are both nickel-based alloys with exceptional corrosion resistance, they are not interchangeable. Each alloy has its unique composition, properties, and applications. Monel excels in corrosive environments and offers good formability and weldability, while Inconel is renowned for its high-temperature performance and oxidation resistance.

Thank you for reading our article and we hope it can help you to find the answer to the question: Is Monel similar to Inconel? If you are looking for Monel and Inconel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel and Inconel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality products such as Monel 400, Monel K500, Inconel 600, Inconel 601, Inconel 625, and Inconel 718 at a very competitive price.

2 notes

·

View notes

Text

Monel K500 Blind Flanges Exporters

Monel Blind Flanges are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types. A Blind flange is round plate which has all of the relevant boltholes but no center hole, and because of this feature this flange is used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened.

However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure temperature applications.

Monel Blind Flanges are used for testing the flow of gas or liquid through a pipeline or vessel. It helps to close the end of piping systems or vessel openings. It allows easy access to the pipeline when there is a requirement to work done inside the line. They are used in high pressure applications available in all grades, materials, size and specifications. Blind pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind pipe flanges, the standard height is 1/16" for blind pipe flanges under 400 ( 2.4360)#. For blind pipe flanges of 400 ( 2.4360)# and up, the standard blind pipe flange raised face height is 1/4".

B16.5 ASTM A182 Blind Flange, Fusion Bonded Epoxy Coating, EN 1092-2 PN16 Blind Flange, ASME B16.5 Dual Monel Alloy Blind Flange, ANSI B16.5 Class 150 Flat Face Blind Flange, Monel Alloy Reducing Blind Flange Stockiest.

Standards Specification:

Size : 1/2" to 48"

Specifications : ASTM A182

Rating: 150#, 300#, 600 (2.4640)#, 900#, 1500#, 2500#,

Material & Grade :

Stainless Steel :Grade: 304 (1.4301), 304L (1.4307), 304H (1.4948), 309 (1.4828), 309S, 310, 310S (1.4845) , 316 ( 1.4401), 316H, 316L( 1.4404 /1.4432) , 317, 317L (1.4438), 321 (1.4541), 321 H(1.4878), 347 (1.4550), 347H (1.4961), 904L (1.4539)

Duplex Steel:Grade: 2205 (1.4507)

Super Duplex Steel:Grade: 2507 (UNS S32750) (1.4410) (UNS S32750)

Inconel :Grade: Inconel 600 (2.4640), Inconel 601 (2.4851), Inconel 625 (2.4856), Inconel 718(2.4668)

Incoloy :Grade: Incoloy 800 (2.4958), Incoloy 800H, Incoloy 800HT

Nickel :Grade: Nickel 200, Nickel 201

Titanium :Grade: Gr.1 (3.7025) , Gr.2 (3.7035) , Gr.3:(3.7055) , Gr.5(3.7164/65), Gr. 7(3.7235) , Gr. 11 (3.7225)

Hastalloy :Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X.

For More Information

Visit Our Website - http://www.kobsindia.in/monel-blind-flange.html

Contact Us -9819523999

Email Id - [email protected]

4 notes

·

View notes

Text

Ananka

1: Introduction to Inconel Fastener Manufacturing

Introduction

Inconel fasteners are known for their exceptional resistance to heat, oxidation, and corrosion, making them ideal for high-stress environments like aerospace, chemical processing, and marine applications. Understanding the intricate manufacturing process of Inconel fasteners reveals the meticulous steps taken to ensure they meet rigorous standards for performance and durability. This series of articles will explore the detailed process of Inconel fastener manufacturing, starting with an overview of the entire process.

Material Selection

The journey begins with selecting the right grade of Inconel, a family of nickel-chromium-based superalloys known for their ability to withstand extreme conditions. The most common grades used in fastener manufacturing are Inconel 600, 625, and 718, each chosen based on the specific requirements of the application.

Forming

The next step is forming the raw Inconel material into the desired shape. This is often achieved through hot forging, which involves heating the material to high temperatures to make it malleable. The heated material is then placed in a die and pressed into the shape of the fastener.

Heat Treatment

Heat treatment is a critical step to enhance the mechanical properties of Inconel fasteners. This process involves heating the fasteners to a specific temperature and then cooling them rapidly to increase their strength and hardness.

Machining

After heat treatment, the fasteners undergo machining to achieve precise dimensions and threads. This step requires high-precision equipment and skilled operators to ensure the fasteners meet strict tolerances.

Surface Finishing

The final manufacturing step is surface finishing, which provides additional corrosion resistance and improves the fastener's appearance. Common finishing techniques include passivation, plating, and coating with anti-corrosive materials.

Conclusion

The manufacturing process of Inconel fasteners involves several critical steps, each contributing to the final product's strength, durability, and performance. In the following articles, we will delve deeper into each of these steps, starting with material selection and its impact on fastener quality.

Inconel Bolts Price

2: Material Selection in Inconel Fastener Manufacturing

Introduction

The foundation of a high-quality Inconel fastener lies in the selection of the right material. Different applications require fasteners with specific characteristics, which are largely determined by the grade of Inconel used. This article explores the various grades of Inconel used in fastener manufacturing and their properties.

Inconel 600

Inconel 600 is a nickel-chromium alloy known for its excellent resistance to oxidation and corrosion at high temperatures. It is commonly used in applications such as furnace components, chemical processing, and nuclear reactors. Fasteners made from Inconel 600 offer reliable performance in extreme environments.

Inconel 625

Inconel 625 contains additional elements like molybdenum and niobium, enhancing its strength and resistance to pitting and crevice corrosion. This grade is ideal for applications exposed to seawater and acidic environments, such as marine and chemical processing industries. Inconel 625 fasteners are known for their toughness and durability.

Inconel 718

Inconel 718 is a precipitation-hardenable nickel-chromium alloy with significant amounts of iron, niobium, and molybdenum. It offers exceptional tensile and creep-rupture properties at high temperatures. This grade is widely used in aerospace applications, including gas turbines and jet engines. Fasteners made from Inconel 718 are prized for their high strength and resistance to heat and corrosion.

Conclusion

Selecting the right grade of Inconel is crucial in fastener manufacturing as it directly affects the fastener's performance and suitability for specific applications. Each grade offers unique properties, and understanding these can help in choosing the right fastener for the job. The next article will focus on the forming process and how it shapes the Inconel material into fasteners.

Hastelloy Fasteners

3: The Forming Process in Inconel Fastener Manufacturing

Introduction

Forming is a pivotal stage in Inconel fastener manufacturing, where the raw material is shaped into the desired fastener. This article delves into the hot forging process, explaining how it creates fasteners that meet stringent standards for strength and precision.

Hot Forging

Hot forging involves shaping the Inconel material at high temperatures, making it malleable and easier to form. This method is preferred for Inconel fastener manufacturing because it enhances the metal's grain structure, resulting in stronger and more durable fasteners. The process begins with heating the Inconel material to a specific temperature.

Heating

The Inconel material is heated in a furnace to temperatures ranging from 1800°F to 2200°F (980°C to 1200°C). This heating process is critical as it makes the material pliable and ready for forging.

Forging

Once the material reaches the desired temperature, it is placed in a die and subjected to high-pressure deformation. This step requires precise control to ensure the shape and size meet the specifications. The forged fasteners are then cooled slowly to maintain their structural integrity.

Precision and Consistency

Hot forging ensures that the fasteners have a uniform grain structure, which enhances their mechanical properties. The process also allows for the production of complex shapes with high precision and consistency.

Conclusion

The forming process is a critical step in Inconel fastener manufacturing, setting the foundation for the fastener's strength and durability. Hot forging, heating, and precision control all contribute to creating a fastener that meets precise specifications. The next article will explore the heat treatment process, which enhances the fastener's mechanical properties.

Fasteners Manufacturers in Mumbai

4: Heat Treatment in Inconel Fastener Manufacturing

Introduction

Heat treatment is a crucial step in Inconel fastener manufacturing that enhances the mechanical properties of the fasteners, such as hardness, strength, and resistance to creep. This article explores the heat treatment process, its various stages, and its importance in producing high-quality Inconel fasteners.

Purpose of Heat Treatment

Heat treatment involves heating and cooling the fasteners to alter their physical and mechanical properties. The primary goals are to increase hardness, improve strength, and enhance resistance to wear and fatigue.

Stages of Heat Treatment

The heat treatment process typically involves three stages: solution annealing, quenching, and aging.

Solution Annealing

The first stage is solution annealing, where the fasteners are heated to a high temperature to dissolve any precipitated phases and create a homogeneous structure. This process improves the material's ductility and prepares it for the next stage.

Quenching

After solution annealing, the fasteners are rapidly cooled, usually by immersion in water or oil. This process, known as quenching, locks the dissolved elements in place, creating a uniform microstructure. Quenching enhances the fastener's strength but can also make it brittle, so it is often followed by aging.

Aging

Aging involves reheating the fasteners to a lower temperature and then cooling them slowly. This process precipitates secondary phases, which strengthen the material and reduce brittleness. The result is a fastener with a balanced combination of strength and toughness.

Conclusion

Heat treatment is essential for producing Inconel fasteners with the desired mechanical properties. The solution annealing, quenching, and aging stages work together to enhance the fastener's hardness, strength, and durability. The next article will discuss the machining process, which achieves precise dimensions and threads.

Suppliers of Fasteners

5: Machining in Inconel Fastener Manufacturing

Introduction

Machining is a critical step in Inconel fastener manufacturing, where the fasteners are shaped to precise dimensions and threads are created. This article delves into the machining process, explaining how it ensures the high precision and quality required for Inconel fasteners.

Challenges of Machining Inconel

Inconel is a difficult material to machine due to its high strength, work hardening properties, and tendency to generate heat during cutting. These challenges require specialized techniques and equipment to achieve the desired precision and finish.

Cutting Tools

Machining Inconel requires cutting tools made from high-speed steel, carbide, or ceramic materials, which can withstand the high temperatures and stresses involved. These tools are designed to maintain sharp edges and resist wear.

Coolant and Lubrication

Using appropriate coolants and lubricants is essential to control the heat generated during machining. These fluids help dissipate heat, reduce friction, and prevent the cutting tools from overheating and wearing out prematurely.

Precision Machining

Precision machining involves several steps to ensure the fasteners meet exact specifications:

- Turning: This process shapes the fastener by rotating it against a cutting tool. It is used to create the basic cylindrical shape and remove excess material.

- Milling: Milling involves moving a rotating cutting tool across the fastener to create flat surfaces, grooves, and other features.

- Threading: Threads are created using taps or thread rolling techniques. Thread rolling is preferred for Inconel fasteners as it enhances the material's strength by displacing rather than cutting the material.

Quality Control

After machining, the fasteners undergo rigorous inspection to ensure they meet the required dimensions and tolerances. This includes checking the thread pitch, diameter, and surface finish.

Conclusion

Machining is a critical step in Inconel fastener manufacturing, requiring specialized techniques and equipment to achieve high precision and quality. The use of appropriate cutting tools, coolants, and precision machining processes ensures that the fasteners meet exact specifications. The next article will focus on surface finishing, the final step in the manufacturing process.

Fasteners Manufacturers Mumbai

6: Surface Finishing in Inconel Fastener Manufacturing

Introduction

Surface finishing is the final step in Inconel fastener manufacturing, providing additional protection against corrosion and improving the fastener's appearance. This article examines

the various surface finishing techniques used to produce high-quality Inconel fasteners.

Purpose of Surface Finishing

Surface finishing enhances the fastener's resistance to environmental factors, such as moisture, chemicals, and heat. It also improves the fastener's aesthetic appeal and can provide additional functional benefits, such as reduced friction.

Common Surface Finishing Techniques

Several surface finishing techniques are used for Inconel fasteners, each offering unique benefits:

Passivation

Passivation involves treating the fasteners with an acid solution to remove surface contaminants and enhance the natural oxide layer. This process improves the fastener's corrosion resistance without altering its appearance.

Plating

Plating involves applying a thin layer of metal, such as zinc, nickel, or chrome, to the fastener's surface. This layer provides additional protection against corrosion and can enhance the fastener's appearance. Electroplating and electroless plating are common methods used for this purpose.

Coating

Coating techniques, such as powder coating or ceramic coating, provide a protective layer that resists wear, corrosion, and high temperatures. These coatings can also reduce friction and prevent galling, making them ideal for fasteners used in high-stress environments.

Quality Control

After surface finishing, the fasteners undergo a final inspection to ensure the coating is uniform and free of defects. This includes visual inspection, adhesion testing, and corrosion resistance testing.

Conclusion

Surface finishing is a critical step in Inconel fastener manufacturing, providing enhanced protection against corrosion and improving the fastener's appearance. Techniques like passivation, plating, and coating ensure that the fasteners are durable and perform well in demanding environments. This series of articles has provided a comprehensive overview of the Inconel fastener manufacturing process, from material selection to surface finishing, highlighting the meticulous steps involved in producing high-quality fasteners.

Final Thoughts

The manufacturing of Inconel fasteners is a complex process that involves careful material selection, precise forming, rigorous heat treatment, detailed machining, and thorough surface finishing. Each step is essential to ensuring that the final product meets the highest standards of quality, performance, and durability. Understanding these processes not only highlights the expertise and technology involved but also underscores the importance of using high-quality fasteners in critical applications.

Elevator Bolt Manufacturers in Mumbai

0 notes

Text

Inconel Products

Inconel is used in a wide range of fields. One of the most common uses for Inconel is in the aerospace industry, especially in the jet engine, which has a high temperature. Inconel is often used to make fuel nozzles, afterburner rings, and other engine parts. This is because they work well in the high temperatures that happen when they are being used. They are also not likely to rust when exposed to jet fuel and other liquids. Inconel is also often used in rockets and ships that go into space to learn more about it. Inconel 625 and Inconel 718 are two common alloys used in the aerospace industry. The nuclear industry is another place where Inconel superalloys are often used. Inconel is often used in nuclear reactors because it has high strength, is resistant to corrosion, and works well at high temperatures. Inconel 600 and Inconel 690 are two common alloys used in the nuclear industry. Other industries that use Inconel less often are automotive, oil and gas, firearms, manufacturing equipment and tools, and a few others. Inconel is usually a good choice for any application that needs high strength and high corrosion resistance in an environment with high temperatures.

0 notes

Text

Sankalp Alloys Overseas, based in Mumbai, India, is a renowned manufacturer, supplier, Stockists, Exporters of Inconel 718 fasteners. We produce these fasteners using high-quality steels and alloys that adhere to global standards.

0 notes

Text

What Are the Key Usages of Stainless Steel 420 Round Bar?

Requests requiring high strength, hardness, and reasonable corrosion resistance are the key uses for stainless steel 420 round bar. Since of its fine polishing capacity, it finds wide application in the manufacture of surgical instruments, dental equipment, and cutlery. In addition, it is utilized in the industrial of gears, pumps, and valves, all of which depend on wear resistance. Because it is very robust and effortlessly machined, stainless steel 420 round bar is also used to make shear blades, hand tools, and nozzles. It is a valued material in a diversity of sectors due to its adaptability.

Round Inconel Bar: Superior Alloy

Because of its unresolved performance in corrosive and high-temperature circumstances, Inconel Round Bar is well-known. Its excellent resistance to oxidation and corrosion, subsequent from its typically nickel-chromium composition, renders it a faultless optimal for use in gas turbine components, chemical processing, and aerospace applications. In crucial industrial environments, Chennai providers assuring dependability and endurance, offer a change of Inconel Round Bar in grades like Inconel 600, 625, and 718.

Stainless Steel 420 Round Bar: Adaptable Sturdiness and Power

The excessive strength, hardness, and moderate corrosion resistance of Stainless Steel 420 Round Bar make it extremely valued. It is extensively used in sectors with cutlery, surgical instruments, and industrial equipment mechanisms that demand wear resistance and ease of industrial. Stainless Steel 420 Round Bars that satisfy strict quality standards are available from Chennai vendors guaranteeing top performance in a variety of applications.

Machinability and Corrosion Opposition of Stainless Steel 416 Round Bar

The decent machinability and reasonable corrosion resistance of stainless steel 416 round bar make it extremely observed. Pump shafts, valve components, and automobile portions are among the many areas where it finds recurrent use. These applications require both mechanical qualities and ease of machining. Guaranteeing dependability and consistency in performance across numerous industrial sectors, suppliers in Chennai proposal Stainless Steel 316 Round Bar that satisfy ASTM standards.

Stainless Steel Round Bar 321: Stability at High Temperatures

Because of its strong resistance to intergranular corrosion and oxidation, stainless steel 321 round bar is ideal for requests requiring great temperatures. In gear for chemical processing, furnace parts, and aviation use systems where lengthy exposure to high temperatures is anticipated, it is often employed. With their exceptional mechanical qualities and thermal stability, Chennai suppliers provide a selection of Stainless Steel 321 Round Bars that guarantee dependable performance in demanding conditions.

Multiple Uses for SS Rectangular Bar Suppliers in Chennai

Since of its structural strength and flexibility, SS Rectangular Bar is used for a variety of uses in engineering, manufacturing, and construction. Chennai is home to reliable vendors that offer SS Rectangular Bars in a diversity of grades and sizes. Because of its toughness, resistance to corrosion, and aesthetic appeal, these bars are used in manufacturing gear, machinery supports, and architectural edges.

0 notes

Text

Hastelloy C276 Coils Manufacturers In India

Hastelloy is an aggravate that is in a general sense settled of Nickel, molybdenum and chromium and is known for its high adversary of dangerous nature. It has a few distinct properties like flexibility, adaptable, strong, etc that make it a hero among the most loved mixes for current correspondingly as private use.

Hastelloy has various assessments that delineate its quality and properties. C276 is a victor among the best grades Hastelloy. Hastelloy C276 sheets plates turns are fabulously unquestionable all the all year for their obvious use. These sheets plates and turns are made out of against annoying impeccable material that have phenomenal security from mileage.

Hastelloy C276 Coils have bewildering security from setting, stress use and crevice separating part. Hastelloy C276 Slatting Coils has unfathomable machinability, at any rate the amalgam work toughens as is right of the nickel base mixes everything considered. The high molybdenum and nickel substance in Hastelloy C276 Perforated Coils (UNS N10276) make this nickel steel amalgam particularly safe to part utilization and setting in diminishing conditions while chromium substance passes on security from oxidizing media.

Hastelloy C276 Coils can be warmth treated up to 1800 Degree F (982 Degree C), an hour, oil covered, made 1325 Degree F (718 Degree C), 16 hours, and some time later air cooled. In the methodology treated condition, Alloy C276 Slatting Coils can be pleasingly cool drawn and encased. It is genuinely stiffer than treated steels, for instance, SS 316 and SS 310, and it work bonds rapidly. These Alloy C276 Perforated Coils has uniform use hindrance and gives mind blowing high – temperature oxidation resistance moreover.

HASTELLOY C276 COILS SPECIFICATIONS

Specifications: ASTM / ASME SB575

Size:1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm

Thickness:0.1mm to 12 mm Thk

Form:Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange)

Finish:Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Hardness:Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

For More Information:

Visit Our Website: https://www.padmavatisteel.com/

Contact No: +91-9930388308

E-Mail ID: [email protected]

#Hastelloy C276 Coils Manufacturers#Hastelloy C276 Coils Exporters#Hastelloy C276 Coils Suppliers#Hastelloy C276 Coils Importers#Hastelloy C276 Coils Stockists

0 notes

Text

Iconel Alloy fastener in India - Fastenersllp

Fastenersllp is a leading manufacturer and supplier of Inconel alloy fasteners in India. We offer a wide range of fasteners in a variety of grades, including Inconel 600, 625, 718, and 800. Our Inconel alloy fasteners are manufactured to the highest quality standards and meet all applicable international specifications. Fastenersllp can also provide custom-made Inconel alloy fasteners to meet your specific needs.

#Inconel Alloy Fastener#Inconel Alloy 718 fastener#Inconel Alloy 800 fastener#Iconel Alloy fastener in India

0 notes

Text

Inconel 718 Round Bars Supplier, Stockist in Saudi Arabia | Anand steels

Anand steel Inconel 718 round bars are high-performance nickel-chromium alloy products, renowned for their exceptional strength and corrosion resistance. These bars are ideal for applications in extreme environments, including aerospace, oil and gas, and chemical processing industries. Exported from Saudi Arabia, they meet stringent quality standards and are available in various sizes to accommodate diverse engineering requirements. The unique properties of Inconel 718 ensure reliability and durability, making it a preferred choice for critical components and structures.

0 notes

Text

0 notes

Text

Inconel 718 Flanges Exporters in India

Inconel 718 flanges are essential components used in numerous industrial applications due to their exceptional mechanical properties, corrosion resistance, and ability to withstand high temperatures. Made from Inconel 718, a high-strength, nickel-chromium alloy, these flanges are designed to meet the demands of industries such as aerospace, chemical processing, oil and gas, and power generation.

Composition and Properties

Inconel 718 is renowned for its excellent combination of strength, toughness, and corrosion resistance. The alloy's composition typically includes:

Nickel (50-55%)

Chromium (17-21%)

Iron (remainder)

Niobium (4.75-5.5%)

Molybdenum (2.8-3.3%)

Titanium (0.65-1.15%)

Aluminum (0.2-0.8%)

Cobalt (1% maximum)

This specific composition grants Inconel 718 its unique properties:

High Tensile and Yield Strength: Inconel 718 maintains its mechanical properties at both cryogenic and elevated temperatures, making it suitable for a wide range of temperatures.

Excellent Corrosion Resistance: The alloy exhibits outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking in harsh environments.

Good Weldability: Inconel 718 can be easily welded using conventional welding techniques without the risk of post-weld cracking, which is a common issue with other high-strength alloys.

Types of Inconel 718 Flanges

Inconel 718 flanges come in various types, each designed for specific applications and connection requirements:

Slip-On Flanges: These flanges are slipped over the pipe and welded both inside and outside to provide sufficient strength and prevent leakage. They are easy to align and commonly used in low-pressure applications.

Weld Neck Flanges: Designed for high-pressure applications, weld neck flanges are connected to the pipe by a butt weld. They offer excellent stress distribution and are ideal for use in critical applications.

Blind Flanges: Used to close the end of a pipe system, blind flanges can withstand high pressure and provide an excellent sealing mechanism. They are commonly used for testing and maintenance purposes.

Socket Weld Flanges: These flanges are used in small-diameter high-pressure applications. The pipe is inserted into the socket end and then welded, ensuring a strong and leak-proof connection.

Lap Joint Flanges: Used with a corresponding stub-end, lap joint flanges are ideal for systems requiring frequent disassembly for inspection and maintenance.

Threaded Flanges: These flanges have a threaded bore, allowing them to be assembled without welding. They are suitable for low-pressure applications and where welding is hazardous.

Applications of Inconel 718 Flanges

The exceptional properties of Inconel 718 make these flanges suitable for a wide range of demanding applications:

Aerospace: Inconel 718 flanges are used in aircraft engines, gas turbines, and other aerospace components due to their high strength and resistance to oxidation and corrosion at high temperatures.

Chemical Processing: The alloy's resistance to highly corrosive environments makes it ideal for use in chemical plants, where it ensures longevity and reliability.

Oil and Gas: Inconel 718 flanges are employed in oil and gas extraction and processing, particularly in environments with high pressure, high temperatures, and corrosive conditions.

Power Generation: These flanges are used in both nuclear and fossil fuel power plants, where they must withstand extreme temperatures and corrosive environments.

Marine Engineering: The alloy's resistance to seawater corrosion makes it suitable for offshore oil rigs, shipbuilding, and other marine applications.

Advantages of Inconel 718 Flanges

Durability: Inconel 718 flanges are incredibly durable and can withstand harsh operating conditions, reducing the frequency of maintenance and replacement.

Versatility: The alloy's properties make it suitable for a wide range of applications across various industries.

Reliability: Inconel 718 flanges offer consistent performance, ensuring the reliability of the systems in which they are used.

Cost-Effectiveness: Although the initial cost of Inconel 718 may be higher than some other materials, its longevity and reduced maintenance costs make it a cost-effective solution in the long run.

0 notes

Text

Inconel 718 Sheets & Plates Exporters In India

Navneet Metal Corporation is a prominent supplier and stockist of Inconel 718 sheets and plates in India. Inconel 718 is a high-strength, nickel-chromium alloy that is well-regarded for its outstanding resistance to corrosion, oxidation, and extreme temperatures. It is widely used in aerospace, power generation, and various industrial applications due to its excellent mechanical properties, including high tensile and yield strength.

Navneet Metal Corporation provides Inconel 718 sheets and plates that comply with international standards such as ASTM B670, ensuring the products are suitable for high-performance applications. The company offers these materials in a range of thicknesses and dimensions, catering to various industrial needs. Their stock includes thicknesses ranging from 0.1mm to 100mm and sizes up to 2000mm in width and 6000mm in length. This makes them a versatile supplier capable of meeting specific customer requirements for both large and small-scale projects (Navneet Metal Corporation) (Never Brokes).

In addition to providing high-quality products, Navneet Metal Corporation emphasizes their commitment to rigorous quality control and testing. They ensure that their Inconel 718 sheets and plates are thoroughly tested for mechanical and chemical properties before delivery, guaranteeing reliable performance in demanding environments. The company also offers value-added services such as cutting, shaping, and custom fabrication to meet precise specifications, making them a one-stop solution for industrial clients (Navneet Metal Corporation) (Never Brokes).

With a strong presence in Mumbai and a wide distribution network across India, Navneet Metal Corporation is well-positioned to provide timely delivery and excellent customer service. Their experience and expertise in handling specialty alloys like Inconel 718 make them a trusted partner for industries requiring high-performance materials (Navneet Metal Corporation).

For more details on their Inconel 718 products, you can visit their official website.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

0 notes