#alfalfa pellet making machine

Explore tagged Tumblr posts

Text

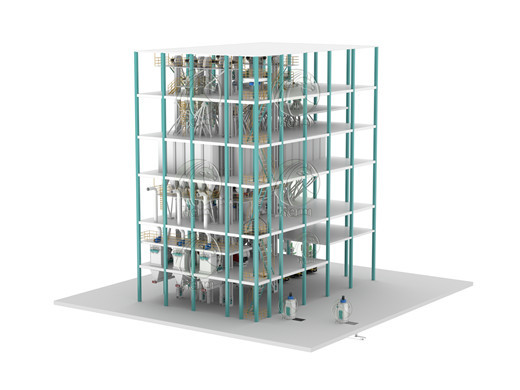

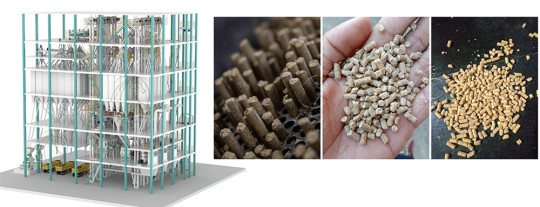

30-35T/H Feed Pellet Line

What is The 30-35T/H Feed Pellet Line ?

Large scale high quality 30-35t/h feed pellet plant is suitable for processing various animal feeds, such as chicken feed, poultry feed, livestock feed, bird feed, duck feed, goose feed, cattle feed, sheep feed, camel feed, horse feed, pig feed, rabbit feed, fish feed, shrimp feed, crab feed, aquatic feed, etc.

youtube

The main equipment of a complete 30-35T/H animal feed pellet mill machine includes an animal feed grinder and feed mixer, feed pellet machine, counter-flow feed pellet cooler, pellet crumbler machine, box cylinder pulse dust remover, vibrating screen classifier, bucket elevator, automatic bagging system, electric control cabinet, etc. This complete feed pellet plant can accomplish raw material mixing, transmission, feeding, and pelletizing. After the raw materials become feed pellets, the following equipment can cool them down and pack them into bags.

The animal-feed pellet plant has good raw material versatility and can be used for the granulation of various raw materials such as corn, sorghum, wheat, beans, and oilseed meal. At the same time, the animal feed production plant has the characteristics of low energy consumption, high production efficiency, and large profits. It is especially suitable for large feed mills, breeding farms, large farms, etc. At the same time, we provide free installation, training, factory design, and timely after-sales service.

Some Questions About the 30-35T/H Feed Pellet Line

1. Who is suitable for this 30-35t/h feed pellet production line?

This animal feed production line is specially designed for large farmers, large animal farm plants, animal feed suppliers, etc.

2. What raw material can be used in the 30-35t/h feed pellet production line?

Animal feed pellet production line raw materials include corn/maize, wheat, grass, alfalfa, oil seed meal & cakes, pasture, bone meal, microelements, etc., and other kinds of raw materials, such as premix, vitamins, wheat bran, salt and other. Different formulations can be made according to different formulas and the needs of the animals being farmed.

3. Why Choose Our Animal Feed Production Line?

Widely Applications: This animal feed pellet mill plant can make feeds for poultry, livestock, sheep, pig, cattle, chicken, duck, fish, shrimp, crab, aquatic, and other animals, it makes pellets of 1-12mm in diameter, and the pellet size can be changed with our feed pellet machine by adjust die. It also can produce mash and crumble.

Small Investment: the compact design of this small feed mill plant can reduce the investment in workshops, etc.

Low Installation Cost: Our feed production line comes with detailed installation and commissioning instructions, it is easy to install the machine, and you can use it immediately after the machine is installed.

Low Production Cost: The animal feed factory only needs 1-2 production workers to complete the production operation. With less labor and lower production costs, your profits will increase.

4. What kind of animal feed pellet production line produce?

This feed pellet production line can produce feed for meat chicken, broilers, laying hens, small baby chicken feed, cattle feed, pig feed, duck feed, sheep feed, poultry feed, livestock feed, goat feed, fish feed, shrimp feed, crab feed, aquatic feed, etc. Such as 2-4mm diameter chick feed pellets and pig feed pellets. 2-5mm rabbit feed pellets, 4-8mm cattle or sheep feed pellets.

This feed pellet mill with a ring die, makes pellets of 1-12mm in diameter, the pellet size can be changed with our feed pellet machine by adjusting the die. It also can produce mash and crumble.

5. What we can do for you?

We can provide the project design, flow chart, feed-making machine manufacturer, project installation and commission, your staff training, after-sales service, etc. Also, our professional install team will serve you if you need it.

What is The Complete Animal Feed Pellet Production Line Working Process?

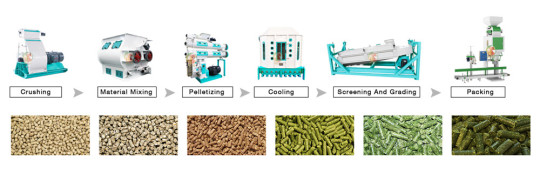

Feed Pellets Processing Technology Raw Material → Feed Grinding → Feed Mixing → Feed Pelletizing → Pellet Cooling → Pellet Crushing → Screening & Grading → Pellet Packing

1. Storage of the raw materials

There are many different raw materials and materials in the feed, so various types of silos must be used. There are three types of silo that can be used in the feed pellet line, such as hopper silo, flat bottom silo, and galvanized silo.

2. Cleaning of raw materials

Impurities in feed raw materials not only affect the quality of feed products but also directly affect the use of feed processing equipment and the personal safety of staff. In severe cases, the entire equipment will be damaged and the smooth progress of feed production will be affected. Therefore, impurities in the feed raw materials should be removed in time.

3. Crushing of raw materials

The technological process of feed crushing is determined according to the required particle size, feed variety, and other conditions. According to the number of raw material crushing, it can be divided into primary crushing process and circulating crushing process or secondary crushing process. The combination with the batching process can be divided into the first batching and then crushing process and the first crushing and then batching process.

4. Batching process The rational design of the batching process is to correctly select the specifications and quantities of the batching metering device so that it is fully coordinated with the combination of batching feeding equipment, mixing units, and other equipment.

5. Mixing process The mixing process refers to the technological method and process of weighing the ingredients in the feed formula and then entering the mixer for uniform mixing. The mixing section requires a short mixing cycle, high mixing quality, fast discharge, low residual rate, good air tightness, and no dust spillage.

6. Pelleting process The pelleted feed obtained by compacting and extruding a single raw material or compound mixture by mechanical action is called feed pelleting. The purpose of pelleting is to use the heat, moisture, and pressure in the pelleting process to pelletize the feed that is finely divided, easily dusty, poorly palatable, and difficult to transport.

7. Cooling process During the pelleting process, when the pellet feed comes out of the feed pellet machine, the water content reaches 16%-18%, and the temperature is as high as 75°C-85°C. It will also cause adhesion and mildew during storage. The moisture must be reduced to below 14%, the temperature must be below 8°C higher than the air temperature, and cooling is required.

8. Crumbling process In the production process of the feed pellet mill, in order to save electricity, increase production and improve quality, the material is often made into a certain size of pellets, and then crushed into qualified products according to the size of the feed pellets.

9. Screening process After the pellet feed is processed by the crushing process, some unqualified materials such as powder will be produced. Therefore, the crushed pellet feed needs to be sieved into a product with neat particles and uniform size.

10. Packaging process After weighing, put the finished product into the packing scale and pack it. During this process, the package should be calibrated until the package weight standard is met.

0 notes

Text

The Advantages of a Vertical Wood Pellet Machine

When making wood pellets, a pellet machine is the equipment used to compress raw materials into solid blocks. These blocks are then used to create strong and durable furniture pieces, such as tables and chairs. ODM Wood Hammer Mill Manufacturers Using this type of machinery also helps to reduce waste and conserve natural resources.

Wood pellet machines are available in various sizes and capacities, so it’s important to choose one that meets your needs. For example, a small pellet machine can be sufficient for a home use, while a large pellet machine can handle the needs of a commercial operation. Some types of machines are powered by electricity, while others are powered by diesel or gasoline.

While wood pellets are made from a renewable resource, they can still be expensive to purchase. This is why it’s essential to look for a wood pellet machine that offers competitive pricing. By doing this, you’ll be able to save money while getting high-quality furniture.

One type of wood pellet machine that you should consider is a vertical ring die pellet mill. This type of machine is designed to be energy-efficient and easy to maintain. It also has the advantage of being able to process a wide range of materials, including sawdust, straw, rice hulls, soybeans, chaff, bagasse, oat groats, alfalfa and palm kernel shells.

The key to this type of wood pellet machine is its ring die, which allows it to produce higher quality pellets. When the material is fed into the pelleting chamber, it is heated by the ring die and rollers. The resulting pellets are more uniform in size and shape, and the material is less likely to jam during the production process.

The ring die pellet machine is also designed to be easy to operate. The feed auger is placed vertically, which makes it easier to feed the material into the pelleting chamber. This allows the machine to be more efficient and provides a better return on investment.

Unlike the flat die wood pellet machine, which uses centrifugal force to mold the material, the ring die machine uses compression pressure to form the material into pellets. This helps to ensure that the pellets have a high density and hardness. The machine also has a double layer design, which can make different pellets of varying sizes in the same production run.

The vertical ring die pellet machine is equipped with an automatic lubrication system that ensures the machine is well-maintained and in good working condition. It can be used to make both wood and feed pellets, and it can be easily adjusted to change the length of the pellets. The machine can be operated 24 hours a day, and it has a cooling device to prevent the material from overheating. It also has a hopper that can be easily emptied, and it is made of stainless steel to improve its service life. It also features a high-quality German vacuum furnace, which is known for its durability.

0 notes

Video

tumblr

0 notes

Text

How To Make Pig Feed?

Pig is among the most populous large mammals in the world. It is the most commonly consumed meat worldwide.Pigs are omnivores and can consume a wide range of food.There is a large market on pig feed production.

What Is Pig Feed?

Pig feed are divided into 2 types, first is raw feed which is not artificial feed.it’s mainly include following types. 1. Coarse feed: It refers dry grass, stalk and agricultural by-product,which crude fiber content more than 18%. 2.Green feed: It refers fresh alfalfa,vegetables, which natural moisture content more than 60%. 3.Silage: It refers roughage, which is the green feed was chopped and fermented. 4.Energy feed: It refers crude fiber content of less than 18%, crude protein content less than 20%. 5.Protein feed: It refers crude fiber content of less than 18%, crude protein content of more than 20%. 6.Additives: It refers natural minerals,vitamin,antibiotics, antioxidants, etc. Second is compound feed, it’s artificial feed. Along with the development of cultural technique and breeding technique, compound feed play an import role in modern pig farm. It can significantly reduce production costs, protein and phosphorous intake and excretion, and greenhouse gases emissions by increasing individual nutrient efficiency. We are here to talking about how to make artificial feed pellet.

Why Pig Feed Is Important?

Pigs are known for their appetites, and they have a collection of favorite foods to match. However, just like humans, pigs need a complete, well-balanced diet in order to stay well and avoid unhealthy weight gain. The nutritional needs of pigs can be divided into six categories or classes. These are water, carbohydrates, fats, proteins, vitamins and minerals. Accurate formulation makes sure the diet meets the needs of the specific pig. Each pig with different feed Requirements, to properly nourish the pig, we need to understand its nutritional idiosyncrasies, its physiology and nutrient requirements, and how it responds to feedstuff and additive combinations. We must also realize that feeding goes beyond diet formulation, because diets must be properly processed, transported, stored, and finally presented for consumption before their potential is realized. Good feed is necessary for growth, body maintenance and the production of meat and milk. You can use locally feeds that are less expensive, but also can be made by your own animal feed pellet mill. So you can go to see the animal feed pellet machine. Making your own pig feed is far more cost-effective than buying expensive commercial brands from the local market. In fact, if you are only raising a small pig farm, a hundred dollars’ worth of homemade feed might be enough to last you a few months. Making your own hog feed is not too difficult, as long as you know the proper ingredients and proportions to use. When you mix and formulate your own feed, you need know some information to help you produce high quality pig feed pellet.

More details about the feed pellet, please go to limapoultrymach.

#lima feed machine#Lima Machinery#animal feed pellet machine#animal feed machine#poultry feed production line#pig#pig farm#feed pellet

1 note

·

View note

Video

youtube

pasture cubing machine alfalfa cube machine for cattle/ cow/ horse food ...

pasture cubing machine alfalfa cube machine for cattle/ cow/ horse food pellet machine

animal feed making machine, also known as a pellet press is a type of mill or machine press used to create pellets from powder material. Pellet mills are unlike grinding mills, in that they combine small materials into a larger, homogeneous mass, rather than break large materials into smaller pieces. Raw material as below:

animal feed making machine with flat die is an original machine for pellet burning and animal feed. This machine is equipped with high quality die and rollers and has advanced technology. For driving system we use double motor V-belt, which is of little space occupation, uniform stress, simple structure and easy operation. Users can change motor and die to meet the needs of different production capacities and specs, thereby obtains ideal technology and economy effect.

Electric Motor animal feed plant: The electrical pellet mill is the most widespread kind machine for electricity is everywhere in our daily life. If the working place and material resources are steady, a electrical pellet mill can totally meet your home processing needs. Inquire for details. Contact directly at [email protected] WhatsApp:0086 18790806903

0 notes

Text

KuneKune Pigs: A Hardy Homestead Breed

Kathy Petersen – KuneKune pigs are making their way into small scale farming operations across the country. You may ask yourself what makes these pigs so special … the simple answer is everything! This breed is extremely friendly, docile, and easy to handle. First-time pig farmers are just amazed at how easy they truly are.

If you’re looking to start free range pig farming, look no further than KuneKune pigs. They are easy on the environment and prefer to grass instead of rooting up the earth. They are made to graze with a short snout unlike other breeds making them very efficient grazing machines. The fact that they do not require much in the way of supplementary grains makes them very cost effective as well.

The pork that they produce is a succulent red marbled meat locked in a layer of fat around it keeping it juicy and locking in the flavor. Sure they are slower to mature, but if you’re raising pig for meat, their pork is so worth the wait. From bacon to BBQ, feeding your family from the KuneKune pigs that you raise yourself gives you a great sense of pride.

Ready to Start Your Own Backyard Flock?

Get tips and tricks for starting your new flock from our chicken experts. Download your FREE guide today! YES! I want this Free Guide »

This is a breed to teach your children with. Mothers are very prolific and allow the entire family to interact with the babies from birth to weaning. Getting the kids into farming and out of electronics is always a plus. Children can learn so much about life from interactions with KuneKune pigs and you don’t have to worry about them being chased through the pastures.

Here are some other facts about this incredible breed:

Temperament

KuneKune pigs are very easy going and social creatures. They will run to greet you when they hear you come to the pastures. They enjoy human interaction and will plop for a belly rub at a moment’s notice. They are fantastic with chickens, ducks, goats, cats, and dogs. Children are delighted to hear them “speak” to you during feeding time.

Breed Characteristic

Unlike most other breeds, KuneKune pigs have wattles. They are called Piri Piri in their original land of New Zealand. These are similar to goat wattles and hang just under the jowl. They are born with and without wattles. The inheritance of these wattles appears to have no rhyme or reason. You can mate two double wattled Kunes and get both double wattled and unwattled offspring. You can mate two unwattled Kunes together and get double wattled animals.

Climates

KuneKune pigs are very hardy little pigs and fair quite well in most climates. In the low winter temperatures, mature pigs just need draft-free housing and bedding to stay warm. In the summer months, it is vital for them to have a mud puddle to cool off in, keep the biting insects off and to prevent sunburn.

Size

KuneKune pigs are a mid-size pig weighing 200-400 pounds (boars would be on the higher end and females on the lower end) and 24-36 inches tall. This is usually about to your knee. (Of course, this can vary depending on how much you feed them.) Kune Kune means“fat and round” in the Maori language and that is exactly what they are!

Feeding

KuneKune pigs primarily graze “for a living” which makes them a great pig breed for the homestead. You can feed your KuneKune pigs on pasture if you have a nice rich pasture year-round. It is recommended that you give some grain during the growing years. However, they only get about two cups twice a day. You may need to supplement in the winter with Alfalfa hay and/or alfalfa pellets and a mini pig pellet food such as Blue Seal Pig & Sow, Purina Complete Pig and Sow food, or Purina Nature’s Match. The feed can be found at your local feed and seed store or a local Tractor Supply. This breed requires a lower protein level of about 16 percent.

Pigs also enjoy a variety of fruits and vegetables. You can give them the surplus from your gardens. They would be delighted to assist with cleaning out your garden for you at the end of the year as well. Maybe you have an orchard … they will make sure no fruit stays on the ground for long. If you do fodder (hydroponic barley or wheat) for other livestock, the KuneKune pigs will also enjoy a nice daily feeding of that.

Housing

The main thing with KuneKune pigs is having a warm hay or straw bedded house in the winter months that is draft-free. It can be an elaborate house or a simple calf hut. Whatever suits your budget.

Colors

KuneKune pigs come in a variety of colors; ginger/black, black/ginger, ginger, cream, black/white, brown/white, and more. The combinations give them a very distinct look and sets them apart from other breeders.

Transportation

Pigs can fly. We have shipped KuneKune pigs across the U.S. using Delta and United Airlines. They can fly as weaned piglets in a dog carrier that is airline approved. They take it all in stride and do well traveling. We also offer grounds transporting to reasonable distances and even meeting halfway if you are traveling long distances.

Virginia KuneKunes is a small-scale farm and long-standing breeder. Our farm is owned and operated by our family. We have a very diverse herd with a strong focus on conformation, quality, and bloodlines. We currently breed from 19 different bloodlines and offer piglets for sale year-round to suit a variety of purposes from homesteading production, USDA processed pork cuts, breeding, show animals, and pets.

I invite you to contact us if you have questions about the breed or to visit our website should you wish to learn more. We offer unparalleled mentoring and support when you have our pigs. Having been one of the four original founders of the American KuneKune Pig Society, our pigs are registered with AKKPS, microchipped (unless for pork), vaccinated, and dewormed.

I hope that you have enjoyed your introduction into this amazing grazing animal called KuneKune pigs. Visit us to learn more at www.virginiakunekunes.com or www.vakunekunes.com.

Do you raise pigs? What are your favorite breeds and why? We’d loved to hear from you!

Happy Farming!

KuneKune Pigs: A Hardy Homestead Breed was originally posted by All About Chickens

0 notes

Text

making hay pellets

what is hay?

Hay, according to Wikipedia, is the cut and dried grass, alfalfa, legumes or other herbaceous plants in large round bales. It is often used as animal fodder, especially for grazing cattle, horses, goats, sheep, etc.

In fact, hay can be made into pellets by feed pellet machine. It can make hay into unique shape pellets with mixture of other ingredients to make animals nutritionally…

View On WordPress

0 notes

Text

35-40T/H Feed Pellet Line

What is The 35-40T/H Feed Pellet Line?

Large-scale long-life guarantee 35-40t/h feed mill production plant is suitable for processing various animal feeds, such as chicken feed, poultry feed, livestock feed, bird feed, duck feed, goose feed, cattle feed, sheep feed, camel feed, horse feed, pig feed, rabbit feed, fish feed, shrimp feed, crab feed, aquatic feed, etc.

youtube

The main processing flow of the 35-40t/h animal feed production line is raw material receiving and cleaning system, raw material crushing, batching & mixing, pelletizing, cooling, screening, and packaging. This is just the general 35-40ton per hour feed process, according to different feed types, different output configurations can be customized. If you want to make powder feed, the manufacturing process only needs cleaning, crushing, mixing, and packing sections.

The animal-feed pellet plant has good raw material versatility and can be used for the granulation of various raw materials such as corn, sorghum, wheat, beans, and oilseed meal. At the same time, the animal feed production plant has the characteristics of low energy consumption, high production efficiency, and large profits. It is especially suitable for large feed mills, breeding farms, large farms, etc. At the same time, we provide free installation, training, factory design, and timely after-sales service.

Some Questions About the 35-40T/H Feed Pellet Line

1. Who is suitable for this 35-40t/h feed pellet production line?

This animal feed production line is specially designed for large farmers, large animal farm plants, animal feed suppliers, etc.

2. What raw material can be used in the 35-40t/h feed pellet production line?

Animal feed pellet production line raw materials include corn/maize, wheat, grass, alfalfa, oil seed meal & cakes, pasture, bone meal, microelements, etc., and other kinds of raw materials, such as premix, vitamins, wheat bran, salt and other. Different formulations can be made according to different formulas and the needs of the animals being farmed.

3. Why Choose Our Animal Feed Production Line?

Widely Applications: This animal feed pellet mill plant can make feeds for poultry, livestock, sheep, pig, cattle, chicken, duck, fish, shrimp, crab, aquatic, and other animals, it makes pellets of 1-12mm diameter, and the pellet size is can be changed with our feed pellet machine by adjust die. It also can produce mash and crumble.

Small Investment: the compact design of this small feed mill plant can reduce the investment in workshops, etc.

Low Installation Cost: Our feed production line comes with detailed installation and commissioning instructions, it is easy to install the machine, and you can use it immediately after the machine is installed.

4. What kind of animal feed pellet production line produce?

This feed pellet production line can produce feed for meat chicken, broilers, laying hens, small baby chicken feed, cattle feed, pig feed, duck feed, sheep feed, poultry feed, livestock feed, goat feed, fish feed, shrimp feed, crab feed, aquatic feed, etc. Such as 2-4mm diameter chick feed pellets and pig feed pellets. 2-5mm rabbit feed pellets, 4-8mm cattle or sheep feed pellets.

This feed pellet mill with a ring die, makes pellets of 1-12mm in diameter, the pellet size can be changed with our feed pellet machine by adjusting the die. It also can produce mash and crumble.

5. What we can do for you?

We can provide the project design, flow chart, feed-making machine manufacturer, the project installation and commission, your staff training, after-sales service, etc. Also, our professional install team will serve you if you need it.

What is The Complete Animal Feed Pellet Production Line Working Process ?

Feed Pellets Processing Technology Raw Material → Feed Grinding → Feed Mixing → Feed Pelletizing → Pellet Cooling → Pellet Crushing → Screening & Grading → Pellet Packing

1. Storage of the raw materials

There are many different raw materials and materials in the feed, so various types of silos must be used. There are three types of silo that can be used in the feed pellet line, such as hopper silo, flat bottom silo, and galvanized silo.

2. Cleaning of raw materials

Impurities in feed raw materials not only affect the quality of feed products but also directly affect the use of feed processing equipment and the personal safety of staff. In severe cases, the entire equipment will be damaged and the smooth progress of feed production will be affected. Therefore, impurities in the feed raw materials should be removed in time.

3. Crushing of raw materials

The technological process of feed crushing is determined according to the required particle size, feed variety, and other conditions. According to the number of raw material crushing, it can be divided into primary crushing process and circulating crushing process or secondary crushing process. The combination with the batching process can be divided into the first batching and then crushing process and the first crushing and then batching process.

4. Batching process The rational design of the batching process is to correctly select the specifications and quantities of the batching metering device so that it is fully coordinated with the combination of batching feeding equipment, mixing units, and other equipment.

5. Mixing process The mixing process refers to the technological method and process of weighing the ingredients in the feed formula and then entering the mixer for uniform mixing. The mixing section requires a short mixing cycle, high mixing quality, fast discharge, low residual rate, good air tightness, and no dust spillage.

6. Pelleting process The pelleted feed obtained by compacting and extruding a single raw material or compound mixture by mechanical action is called feed pelleting. The purpose of pelleting is to use the heat, moisture, and pressure in the pelleting process to pelletize the feed that is finely divided, easily dusty, poorly palatable, and difficult to transport.

7. Cooling process During the pelleting process, when the pellet feed comes out of the feed pellet machine, the water content reaches 16%-18%, and the temperature is as high as 75°C-85°C. It will also cause adhesion and mildew during storage. The moisture must be reduced to below 14%, the temperature must be below 8°C higher than the air temperature, and cooling is required.

8. Crumbling process In the production process of the feed pellet mill, in order to save electricity, increase production, and improve quality, the material is often made into a certain size of pellets, and then crushed into qualified products according to the size of the feed pellets.

9. Screening process After the pellet feed is processed by the crushing process, some unqualified materials such as powder will be produced. Therefore, the crushed pellet feed needs to be sieved into a product with neat particles and uniform size.

10. Packaging process After weighing, put the finished product into the packing scale and pack it. During this process, the package should be calibrated until the package weight standard is met.

0 notes

Text

3-4T/H Poultry Feed Production Plant in Tanzania

It is profitable to develop the poultry industry in Tanzania. A Tanzanian customer ordered a turnkey project for a 3-4t/h poultry feed plant production line from Herm. The customer mainly produces 2mm, 3mm, 4mm, and 6mm chicken feed. The customer also asked a number of feed pellet machine manufacturers, compare their products, services, installation, and after-sales, and finally chose Herm Machinery. At present, the feed production line equipment required by the customer has been completely installed and can be used normally.

The 3-5 tons per hour low output good feedback chicken poultry feed powder mill plant equipment required in the entire production line includes a double ribbon type mixer, a 132KW pellet machine with a side feeder, and galvanized storage silos with two different volumes.

youtube

What is The Poultry Feed Mill Plant?

Starting a poultry feed processing plant has always been a profitable business in many countries. Poultry feed plant specializes in producing duck feed, goose feed, chicken feed, bird feed, parrot feed, and other poultry feed machinery and equipment. How to make poultry feed? You need a poultry feed pellet production line first. Our fully automatic poultry feed mill plant with output ranging from 1ton/h-100ton/h. The complete poultry feed pellet production line includes raw material storage, a washing machine, a crusher, a mixer, a poultry feed pelleting machine, a cooler, a screening machine, a packaging system, transportation, and an electronic control system.

The poultry feed pellet plant has good raw material versatility and can be used for the granulation of various raw materials such as corn, sorghum, wheat, beans, and oilseed meal. At the same time, the poultry feed production plant has the characteristics of low energy consumption, high production efficiency, and large profits. It is especially suitable for large feed mills, breeding farms, large farms, etc. At the same time, we provide free installation, training, factory design, and timely after-sales service.

Some Questions About the Poultry Feed Mill Plant

1. Who is suitable for this poultry feed mill plant?

This poultry feed mill plant is specially designed for farmers, animal farm plants, and animal feed suppliers, etc.

2. What raw material can use in the poultry feed mill plant?

Poultry feed mill plant raw materials include corn/maize, wheat, grass, alfalfa, oilseed meal & cakes, pasture, bone meal, microelements, etc., and other kinds of raw materials, such as premix, vitamins, wheat bran, salt and other. Different formulations can be made according to different formulas and the needs of the animals being farmed.

3. Why Choose Our Poultry Feed Production Line?

Widely Applications: This poultry feed pellet mill plant can make feeds for poultry, livestock, sheep, pig, cattle, chicken, duck, and other animals, it makes pellets of 2-12mm in diameter, and the pellet size can be changed with our feed pellet machine by adjusting die.

Small Investment: the compact design of this feed mill plant can reduce the investment in workshops etc.

Low Installation Cost: our poultry feed production line comes with detailed installation and commissioning instructions, it is easy to install the machine, and you can use it immediately after the machine is installed.

4. What kind of poultry feed pellet production line can produce?

This feed pellet production line can produce feed for meat chicken, broilers, laying hens, small baby chicken feed, cattle feed, pig feed, duck feed, sheep feed, poultry feed, livestock feed, goat feed, etc. Such as 2-4mm diameter chick feed pellets and pig feed pellets. 2-5mm rabbit feed pellets, 4-8mm cattle or sheep feed pellets.

This feed pellet mill with a ring die, make pellets of 2-10mm in diameter, the pellet size can be changed with our feed pellet machine by adjusting the die.

5. What we can do for you?

We can provide the project design, flow chart, feed-making machine manufacturer, the project installation and commission, your staff training, after-sales service, etc. Also, our professional install team will serve you if you need it.

What is The Complete Animal Feed Pellet Production Line Working Process?

Feed Pellets Processing Technology Raw Material → Feed Grinding → Feed Mixing → Feed Pelletizing → Pellet Cooling → Pellet Crushing → Screening & Grading → Pellet Packing

Equipment Related to Complete Feed Manufacturing Plant Feed Grinder →Feed Mixer → Feed Pellet Mill → Counterflow Cooler → Feed Pellets Crumbler → Feed Pellets Grading Sieve → Automatic Weighing and Packing Machine

Storage of the raw materials

There are many different raw materials and materials in the feed, so various types of silos must be used. There are three types of silo that can be used in the feed pellet line, such as hopper silo, flat bottom silo, and galvanized silo.

Cleaning of raw materials

Impurities in feed raw materials not only affect the quality of feed products but also directly affect the use of feed processing equipment and the personal safety of staff. In severe cases, the entire equipment will be damaged and the smooth progress of feed production will be affected. Therefore, impurities in the feed raw materials should be removed in time.

Crushing of raw materials

The technological process of feed crushing is determined according to the required particle size, feed variety, and other conditions. The number of raw material crushing can be divided into primary crushing process and circulating crushing process, or secondary crushing process. The combination with the batching process can be divided into the first batching and then crushing process and the first crushing and then batching process.

Mixing process The mixing process refers to the technological method and process of weighing the ingredients in the feed formula and then entering the mixer for uniform mixing. The mixing section requires a short mixing cycle, high mixing quality, fast discharge, low residual rate, good airtightness, and no dust spillage.

Pelleting process The pelleted feed obtained by compacting and extruding a single raw material or compound mixture by mechanical action is called feed pelleting. The purpose of pelleting is to use the heat, moisture, and pressure in the pelleting process to pelletize the feed that is finely divided, easily dusty, poorly palatable, and difficult to transport.

Cooling process During the pelleting process, when the pellet feed comes out of the feed pellet machine, the water content reaches 16%-18%, and the temperature is as high as 75°C-85°C. It will also cause adhesion and mildew during storage. The moisture must be reduced to below 14%, the temperature must be below 8°C higher than the air temperature, and cooling is required.

Crumbling process In the production process of the feed pellet mill, in order to save electricity, increase productivity and improve quality, the material is often made into a certain size of pellets and then crushed into qualified products according to the size of the feed pellets.

Screening process After the pellet feed is processed by the crushing process, some unqualified materials such as powder will be produced. Therefore, the crushed pellet feed needs to be sieved into a product with neat particles and uniform size.

Packaging process After weighing, put the finished product into the packing scale and pack it. During this process, the package should be calibrated until the package weight standard is met.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10-year experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: [email protected]

Whatsapp: 0086 18037508651

0 notes

Text

35-40T/H Feed Pellet Line

What is The 35-40T/H Feed Pellet Line?

Large-scale long-life guarantee 35-40t/h feed mill production plant is suitable for processing various animal feeds, such as chicken feed, poultry feed, livestock feed, bird feed, duck feed, goose feed, cattle feed, sheep feed, camel feed, horse feed, pig feed, rabbit feed, fish feed, shrimp feed, crab feed, aquatic feed, etc.

Some Questions About the 35-40T/H Feed Pellet Line

1. Who is suitable for this 35-40t/h feed pellet production line?

This animal feed production line is specially designed for large farmers, large animal farm plants, animal feed suppliers, etc.

2. What raw material can be used in the 35-40t/h feed pellet production line?

Animal feed pellet production line raw materials include corn/maize, wheat, grass, alfalfa, oil seed meal & cakes, pasture, bone meal, microelements, etc., and other kinds of raw materials, such as premix, vitamins, wheat bran, salt and other. Different formulations can be made according to different formulas and the needs of the animals being farmed.

3. Why Choose Our Animal Feed Production Line?

Widely Applications: This animal feed pellet mill plant can make feeds for poultry, livestock, sheep, pig, cattle, chicken, duck, fish, shrimp, crab, aquatic, and other animals, it makes pellets of 1-12mm diameter, and the pellet size is can be changed with our feed pellet machine by adjust die. It also can produce mash and crumble.

Small Investment: the compact design of this small feed mill plant can reduce the investment in workshops, etc.

Low Installation Cost: Our feed production line comes with detailed installation and commissioning instructions, it is easy to install the machine, and you can use it immediately after the machine is installed.

4. What kind of animal feed pellet production line produce?

This feed pellet production line can produce feed for meat chicken, broilers, laying hens, small baby chicken feed, cattle feed, pig feed, duck feed, sheep feed, poultry feed, livestock feed, goat feed, fish feed, shrimp feed, crab feed, aquatic feed, etc. Such as 2-4mm diameter chick feed pellets and pig feed pellets. 2-5mm rabbit feed pellets, 4-8mm cattle or sheep feed pellets.

This feed pellet mill with a ring die, makes pellets of 1-12mm in diameter, the pellet size can be changed with our feed pellet machine by adjusting the die. It also can produce mash and crumble.

5. What we can do for you?

We can provide the project design, flow chart, feed-making machine manufacturer, the project installation and commission, your staff training, after-sales service, etc. Also, our professional install team will serve you if you need it.

What is The Complete Animal Feed Pellet Production Line Working Process ?

1. Storage of the raw materials

There are many different raw materials and materials in the feed, so various types of silos must be used. There are three types of silo that can be used in the feed pellet line, such as hopper silo, flat bottom silo, and galvanized silo.

2. Cleaning of raw materials

Impurities in feed raw materials not only affect the quality of feed products but also directly affect the use of feed processing equipment and the personal safety of staff. In severe cases, the entire equipment will be damaged and the smooth progress of feed production will be affected. Therefore, impurities in the feed raw materials should be removed in time.

3. Crushing of raw materials

The technological process of feed crushing is determined according to the required particle size, feed variety, and other conditions. According to the number of raw material crushing, it can be divided into primary crushing process and circulating crushing process or secondary crushing process. The combination with the batching process can be divided into the first batching and then crushing process and the first crushing and then batching process.

4. Batching process The rational design of the batching process is to correctly select the specifications and quantities of the batching metering device so that it is fully coordinated with the combination of batching feeding equipment, mixing units, and other equipment.

5. Mixing process The mixing process refers to the technological method and process of weighing the ingredients in the feed formula and then entering the mixer for uniform mixing. The mixing section requires a short mixing cycle, high mixing quality, fast discharge, low residual rate, good air tightness, and no dust spillage.

6. Pelleting process The pelleted feed obtained by compacting and extruding a single raw material or compound mixture by mechanical action is called feed pelleting. The purpose of pelleting is to use the heat, moisture, and pressure in the pelleting process to pelletize the feed that is finely divided, easily dusty, poorly palatable, and difficult to transport.

7. Cooling process During the pelleting process, when the pellet feed comes out of the feed pellet machine, the water content reaches 16%-18%, and the temperature is as high as 75°C-85°C. It will also cause adhesion and mildew during storage. The moisture must be reduced to below 14%, the temperature must be below 8°C higher than the air temperature, and cooling is required.

8. Crumbling process In the production process of the feed pellet mill, in order to save electricity, increase production, and improve quality, the material is often made into a certain size of pellets, and then crushed into qualified products according to the size of the feed pellets.

9. Screening process After the pellet feed is processed by the crushing process, some unqualified materials such as powder will be produced. Therefore, the crushed pellet feed needs to be sieved into a product with neat particles and uniform size.

10. Packaging process After weighing, put the finished product into the packing scale and pack it. During this process, the package should be calibrated until the package weight standard is met.

1 note

·

View note

Text

Cat litter pellet making machine price

Today, I will introduce some knowledge about cat litter pellet making machine price.

Lima series cat litter pellet making machine is popular and applicable for processing cat litter pellets with pellet size: 1.5-10mm. It can be used to process cat litter pellets using bentonite, wood, wood fiber, bark, sawdust, wheat, corn, grass, alfalfa, peanut shells, citrus, biodegradable recycled paper, newspapers, recycled paper mill by-products, and biodegradable silica gel. It’s suitable for various small pet store with small scale capacity. Cat litter making machine had the industry standards, cost-effective, high efficiency and low maintenance . Cat litter always has some odor, it is important for cat owners. Good cat litter features strong water absorption and odor removing. Pellet is an ideal form of cat litter and it is especially easy to clean up.There are multiple ways to manufacture cat litter pellets depending on the base raw material that are used. For example, clay and silica-based material which accounts for over 70% of the market, and the eco-friendly version (wood, paper, pine, grain, corncobs, wheat grasses, etc.). Now there are condensed sand, wood sand, and crystal sand, bentonite sand, etc. So do you know the animal feed pellet machine?

While clay-based pellets continue to dominate the market, growing concerns about disposing them and the potential health hazard to the pet is being a driver to adoption of eco-friendly versions. The proportion of tofu cat litter in the market increases year by year.

Tofu Cat litter is an object used by the owner to bury feces and urine for its cats. It has good water absorption. Generally, it is used together with a litter box (or cat toilet). In the litter box, the trained cat will enter the litter box and excrete it when it needs to be excreted. The advantages of tofu cat litter: environmental protection, waste utilization, you can directly flush the toilet. No harm to cats and people. There are many kinds of derivatives, adding carbon and no dust.

Advantages cat litter pellet making machine Compact structure. A flat sequence structure is to ensure the continuous cat litter production with suitable height. Adjustable conditioner Cat litter pellet machine can match with one-layer or double-layer conditioner according to customer’s requirements. With internationally advanced technology manufacturing. Durable driving system Cat litter making machine adopts gear driving system, with good transmission rate, stable and reliable performance and low noise. Reasonable design Raw material contacting parts are made by stainless steel. Convenient installation All machines are integrated for shipment, the buyer can set up the cat litter production line easily as our installation drawing. Reasonable technology According to the customers raw material requests and their investment budget, Lima pellet machine can supply cat litter pellet production line design to meet their requirements. It mainly contains mixer, ring die feed pellet mill, dryer, cooler and vacuum packing machine.

If you have any question about animal feed machine, please leave a massage.

#lima#limapoultrymach#animal feed machine#animal feed pellet machine#nachine#limamachine#animals feed machine

0 notes

Text

Small Pellet Plant | Feed Pellet Production Line Supplier

450-500kg/h Feed Pellet Plant Introduction This small feed pellet plant also called feed pellet production line, it is specially designed for produced animal feed pellet. It can produce 500kg feed pellet per hour. This small feed line include feed grinder, feed mixer, and feed pellet machine. So, it can product animal pellet by the process of grinding, mixing, conveying and pelleting. Feed Pellet Size: 2-8mm

Feed Pellets Processing Capacity: 450-500kg/h Feed Pellet Forming Rate: >90% Suitable for: livestock, poultry and fish farmes, hennery, small feed production workshop, etc. Raw materials: feed pellet plants raw materials can include corn, wheat, grass, alfalfa, oil seed meal & cakes, pasture, bone meal, microelements, etc. 450-500kg/h Feed Pellet Plant Working Process Grinding: once you have your raw materials for making animal feed, you might need grinding them all to powders, especially like grass, if it is long, it must be cut first, this process will make sure the materials are more easier to be mixed formed pellet. The ground materials helps the digestion of the animal and greatly helps the healthy growth of the animal, so that grinding process is a very important process in the feed production line. Mixing: after grinding the raw materials, and confirmed the proportions on each materials, you need to mix the premix accordingly, the feed mixing machine is the “heart” of the entire feed production line, the capacity of the mixer determines the feed production line’s capacity. Using the mixing machine can mix the premix materials evenly and make the final product better quality. Pelleting: the flat die pellet machine make use of the interaction of pressing force and friction force between the press roller and the press die to make the material into granules shape. During the production process, the starch in the feed can be ripened and make the feed more aromatic. The particle formation process can degenerate the resistance factors in grains and beans, reduce the adverse effects on digestion. Also the production process can kill various parasite eggs and other pathogenic microorganisms and reduce various parasitic diseases and digestive system diseases. By using the feed pellet machine, it is more easier to feed the poultry, comparing to powder feed, the pellet feeds’ utilization rate is higher and you can reduce a lot of waste of the feed.

0 notes

Text

Feed Pellet Plant | Feed Pellet Line for Making Animal Pellet

600-800kg/h Feed Pellet Plant Introduction This small feed pellet plant also called feed pellet line, which is specially designed for homemade pellet mill plants about manufacturing forage pellets for fish, sheep, cattle, rabbit, horse, duck, chicken, goose, pig and other livestock, etc. The diameter of feed pellets made by the feed pellet machine in this small feed pellet production line ranges from 2mm to 8mm. This small animal feed production line contains all the necessary machine you need in manufacturing feed pellets (feed crusher machine, feed mixer machine, feed cooler machine and feed pellet machine ) and combines all the production process from grinding, mixing, cooling, and pelletizing raw material and conveying, cooling the final pellets. Feed Pellet Size: 2-8mm Feed Pellets Processing Capacity: 600-800kg/h Feed Pellet Forming Rate: >90% Suitable for: livestock, poultry and fish farms, hennery, small feed production workshop, etc. Raw materials: feed pellet plants raw materials can include corn, wheat, grass, alfalfa, oil seed meal & cakes, pasture, bone meal, microelements, etc. 600-800kg/h Feed Pellet Plant Working Process Crusher-----conveyor-----mixer-----conveyor----feed pellet machine----bucket elevator-----cooling machine-----bucket elevator-----packing machine 600-800kg/h Feed Pellet Plant Features 1. Feed pellets discharged from this machine are in moderate temperature. Various micronutrients in raw material are all kept and it’s conducive to digest and absorb nutrition for animals 2. Feed pellets are uniformity in size with good appearance and smooth surface. Diameter can be changed between 1.5-6mm with various length to 5-30mm. Because of high density, feed pellets are easy to storage and transport. Therefore, it is suited for different kinds of animals in different growth periods. 3. Fish feed can be well kept in water for long time which increase the use efficiency and avoids water contamination 4. Both powder feed with low moisture content and fresh feed with high moisture content can be made into pellets

0 notes

Text

Complete Feed Pellet Production Line | Feed Pellet Plant Manufacturer

Complete Feed Pellet Production Line Introduction The feed pellet production line also called feed pellet plant, which is an ideal equipment for animal husbandry. It integrates the functions of dust removing system, crushing, mixing, conveying, pelletizing, cooling, screening, and packing in one. We can design medium size and large scale sizes to meet different client’s requirements. This feed pellet line with high degree automation. The whole feed pellet line process is continuous and reasonable, and the performance of each single machine is good. The feed pellet production line has a compact structure, small floor space, low energy consumption, and high efficiency. The pellet size can be from 2mm to 10mm to suitable for different animals such as cow, sheep, rabbit, pig, chicken, duck, sinking fish feed, etc. We can supply different capacity animal feed production lines, such as 0.5-1t per hour, 2-4ton per hour, 5-6ton per hour, 8-10ton per hour 10-15ton per hour, 15-20ton per hour. Our factory has a strong technology team, so we can design different feed pellet plants according to different customer’s requirements. Feed Pellet Size: 2-12mm Feed Pellets Processing Capacity: 1-15t/h Feed Pellet Forming Rate: >90% Suitable for: livestock, poultry, and fish farms, hennery, feed production workshop, etc. Raw materials: feed pellet plants raw materials can include corn, wheat, grass, alfalfa, oilseed meal & cakes, pasture, bone meal, microelements, etc. Feed Pellet Production Line Process Step 1. Raw materials receiving and cleaning process-to remove the input materials impurity and other iron materials. Usually use the Permanent magnet tube and siever. Step 2. Crushing process---hammer mill is mainly used to crush raw materials into powder. Step 3. Mixing process---to mix the crushed materials with higher uniformity which helps make high-quality pellet feed. Step 4. Pellet making process---it is the key parts of the whole line which to make the materials into feed pellet. The pellet size can be different by change the mold. Step 5. Pellet cooling process---counter flow cooler The newly pressed pellets are very high in temperature. This process is to cool the pellets to ±3-5℃ of the room temperature. Step 6. Pellet crumbling process----feed crumbler (roller crusher) This process is mainly to crush the big pellets into small ones. It is mainly used for small animals. Step 7. Sifting process-- This process is mainly to sort out the inappropriate pellets and powder and send the standard pellets to the next process. Step 8. Packing process -----packaging machine This process is to pack the pellets into bags which is convenient for storage and transportation. Animal Feed Pellet Production Line Structure 1. The structural form has two types: integral steel frame and floor type. The overall steel frame layout is compact, beautiful shape, and style; the floor type is easy to use and maintain. 2. Small and medium-sized feed pellet production line adopts manual metering and ingredients, and the equipment investment is small, economical, and practical. 3. Large and medium-sized complete feed pellet production line adopts computer automatic metering and batching, with good batching precision, high degree of mechanization and automation. 4. the project is designed by our company is keeping up with domestic and international development trends.

0 notes