#aircraft engine parts

Explore tagged Tumblr posts

Text

Aircraft Propeller Parts and Features: An In-Depth Overview

Overview

Aircraft propellers play a crucial role in the aviation industry, transforming engine power into thrust, which propels the aircraft forward. Understanding the various parts and features of aircraft propellers is essential for anyone involved in aviation maintenance, repair, or manufacturing. In this blog, we will delve into the components that make up an aircraft propeller, their key features, and their applications.

What is an Aircraft Propeller?

An aircraft propeller is a mechanical device with two or more blades that rotate around a central hub. This rotation generates thrust by pushing air backward, following Newton's third law of motion: for every action, there is an equal and opposite reaction. Propellers are commonly found on a wide range of aircraft, from small single-engine planes to large commercial and military aircraft. They are typically driven by piston engines or turboprop engines.

Key Features of Aircraft Propellers

Blades: The most visible part of the propeller, blades are shaped to create lift (thrust in this context) as they spin. The number of blades can vary depending on the design and application of the aircraft.

Hub: The central part of the propeller to which the blades are attached. It connects the propeller to the engine's drive shaft.

Spinner: A streamlined cover that fits over the hub to reduce drag and improve aerodynamics. It also enhances the cooling airflow to the engine.

Pitch Control: Some propellers feature adjustable pitch blades, allowing the angle of the blades to be changed for different phases of flight, such as takeoff, cruising, or landing. This can be done manually or automatically in constant-speed propellers.

Materials: Modern propeller blades are often made from lightweight and durable materials such as aluminum, composite materials, or even advanced wood laminates. This ensures they are both strong and efficient.

Feathering Capability: In some propellers, particularly those used in twin-engine aircraft, the blades can be feathered. This means they are turned edge-on to the airflow to minimize drag in case of engine failure.

Applications

Aircraft propellers are used in various types of aircraft across different sectors of aviation:

General Aviation: Small single-engine planes, trainers, and private aircraft commonly use fixed-pitch or variable-pitch propellers.

Commercial Aviation: Turboprop airliners, which use propeller-driven engines for short to medium-haul flights, rely on advanced variable-pitch propellers for efficiency.

Military Aviation: Many military aircraft, especially transport and surveillance planes, use propellers for their robustness and ability to operate from shorter runways.

Agricultural Aviation: Crop dusters and other agricultural aircraft use propellers to provide the necessary thrust for low-speed, low-altitude flying.

Seaplanes: Designed to take off and land on water, these aircraft use propellers optimized for both air and water operations.

About ASAP Buying

ASAP Buying is a leading supplier of aerospace and aviation parts, providing a comprehensive range of components for various aircraft types. With a commitment to quality and customer service, ASAP Buying ensures that all parts meet stringent industry standards. Whether you are looking for propeller parts or other aircraft components, ASAP Buying offers a streamlined procurement process to get you the parts you need quickly and efficiently. Visit our website to explore our extensive catalog and request a quote today.

By understanding the components and features of aircraft propellers, you can better appreciate their importance in aviation and make informed decisions when sourcing parts for maintenance, repair, or manufacturing.

0 notes

Video

D.VII by Treflyn Lloyd-Roberts Via Flickr: Reproduction Fokker D.VII, built using an original engine and parts, displays above Sywell during the 2024 Air Show. Aircraft: Mikael Carlson's reproduction Fokker D.VII SE-XVO. Location: Sywell Aerodrome (ORM/EGBK), Northamptonshire, UK.

#Reproduction#Fokker#D.VII#built#using#original#engine#parts#display#above#Sywell#during#2024#Air#Show#Great#War#World#WW1#WWI#Aircraft#Mikael#Carlson#SE-XVO#Location#Aerodrome#ORM#EGBK#Northamptonshire#UK

8 notes

·

View notes

Text

��me when I’m Richard C. Legg and the rest of the SL-1 maintenance crew, just coming back from Christmas break 1961

(JFC, the way Legg died is burned into my brain. You should totally read a good higher-level summary of the SL-1 accident, but don’t go looking for the actual autopsy reports unless you’ve got a strong stomach. I didn’t even see the photos; the description alone paints quite enough of a picture. It took a horrifyingly long time to find his remains, because people looked right at him without realizing he had been human.)

(At least it was quick.)

Seriously, though, this kind of NTSB or IAEA accident report is both utterly horrifying and, often, deeply reassuring — because they always end with the lessons learned. From deaths like Legg’s we’ve learned volumes about how to prevent them ever happening again. I’ve actually gotten even more confident about flying since I started reading plane crash reports, because of how mind-bogglingly thorough people are about making sure that no serious accident ever happens twice.

Of course it’s never 100%. Accidents happen and always will; sooner or later, nature or human stupidity or blind, brutal chance will break the strongest possible precautions. But the vigilance of investigators and regulators endures that the accidents are lesser every time. How many people would’ve died in the Hudson without the rigorous training of Chesley Sullenberger and his flight crew, lessons drawn from sixty years of trial and error? How many people should have died when Overseas National Airways 032 or Japan Airlines 516 burned on the runway, without all we've learned about how to evacuate a plane, and how to build one that resists lethal burning and lethal smoke for long enough to make evacuation possible? Those three crashes — all spectacular hull-loss crashes — ended with all 665 total people safe on dry ground.

I’ve really gotten fascinated with this stuff lately, and this is why.

I love those tumblr threads where the first person makes a vague post like "I am extremely sleep-deprived, should not be at work in this condition, and I will fuck technology itself. Behold man about to become a machine." And then someone replies something along the lines of "me when I am a simple engineer in [country that does not exist anymore] at [extremely specifically precise date] about to have a nice day at work."

And you gotta do some googling and find a wikipedia page about some poor fucker in like the 1800s who would not have gone down in history if it weren't for the way he got sucked into a horrible industrial machine dick first.

#engineering#accident reports#you know those silly cartoon evacuation diagrams in the plane seatback pockets?#those annoying repetitive announcements where the flight attendants “demonstrate the safety features of this aircraft?”#those are written in blood. every line. every dot.#written in blood#and worse things than blood#(another thing to not even read about unless you have a strong stomach: what it’s like to die of radiation poisoning)#aaaanyway listen to your flight crew — they know their shit#and ffs when politicians try to reduce safety regulations?#just laugh in their faces#kadigan talks

41K notes

·

View notes

Text

youtube

#youtube video#Aircraft Preservation#Air Force Heritage#tucson#Aircraft Maintenance#arizona#Aviation Enthusiasts#Aerospace Engineering#davis-monthan air force base#Arizona Air Force Base#Aircraft Restoration#aviation#air force#usaf#boneyard#Military History#Aircraft Parts#aircraft#aircraft preservation#aircraft maintenance#aviation enthusiasts#aerospace preservation#aerospace industry#military history#aircraft parts#aircraft collection#us air force#aircraft boneyard#Youtube

5 notes

·

View notes

Text

youtube

#aircraft carrier#aircraft charter#aircraft mechanic#aircraft maintenance engineering#aircraft parts#Youtube

0 notes

Text

Commercial Jet Aircraft Models – Find the Best Fit

Looking for commercial jet aircraft models? We’ve got you covered! We offer a variety of jet models for your needs. Fast service and reliable delivery make it easy to find the right model for you. Check out our selection today.

0 notes

Text

Learn about Aircraft Engine Components with Top Crew Aviation.

✈️From turbines to compressors, each piece is vital in propelling our dreams skyward. If you want to join us on this aviation engineering journey.

Contact us at www.topcrewaviation.com.

#aviation#Aircraft Engine#Engine Components#aviation engineering#aviation engineering course#aviation engineering Parts

0 notes

Text

The Marvels of Blade Set Steam Turbines in Aviation

Introduction:

In the dynamic realm of aviation, where precision and efficiency are paramount, the role of advanced technologies cannot be overstated. Among the groundbreaking innovations that contribute significantly to the smooth operation of aircraft, blade-set steam turbines stand out as key components. In this blog, we'll delve into the intricacies of blade-set steam turbines, exploring their functions, benefits, and indispensable role in the aviation industry.

Understanding Blade Set Steam Turbines:

Blade-set steam turbines play a crucial role in converting thermal energy into mechanical energy, driving various systems within an aircraft. Comprising a set of precisely engineered blades, these turbines harness the power generated by steam, offering a reliable and efficient source of propulsion.

Key Components and Design:

The construction of blade set steam turbines is a testament to the meticulous engineering demanded by the aviation industry. The turbine blades, often crafted from high-strength alloys, are strategically positioned to maximize the conversion of steam energy. This design not only ensures optimal efficiency but also guarantees durability in the demanding conditions of aviation operations.

Functionality and Benefits:

The functionality of blade set steam turbines revolves around their ability to extract energy from steam produced in the aircraft's engines. As steam passes over the turbine blades, it causes them to rotate, converting the thermal energy into mechanical energy that powers essential systems like generators and hydraulic pumps. The efficiency of this process directly impacts the overall performance of the aircraft, contributing to fuel efficiency and operational reliability.

One of the significant benefits of blade set steam turbines is their versatility. These turbines find applications in various aircraft systems, from auxiliary power units (APUs) to hydraulic systems, ensuring a seamless and consistent power supply throughout the flight. Their ability to operate efficiently across different load conditions makes them indispensable components in modern aviation.

Challenges and Innovations:

While blade set steam turbines have proven their worth in aviation, the industry continually seeks innovations to overcome challenges and enhance performance. Ongoing research focuses on improving materials, design, and manufacturing processes to increase efficiency, reduce weight, and prolong the lifespan of these critical components.

Conclusion:

In conclusion, blade set steam turbines emerge as unsung heroes in the aviation landscape, quietly powering essential systems that ensure safe and efficient flights. Their precision engineering and reliability make them indispensable for aviation professionals striving for excellence. As we navigate the skies, these turbines work tirelessly behind the scenes, contributing to the success of each flight.

For a comprehensive range of aviation parts, including those related to blade set steam turbines, visit NSN Stocks. With a commitment to quality and reliability, NSN Stocks is your trusted partner in securing top-notch aviation components. Explore their website for an extensive inventory that meets the highest industry standards.

1 note

·

View note

Text

All-Star Moments in Space Communications and Navigation

How do we get information from missions exploring the cosmos back to humans on Earth? Our space communications and navigation networks – the Near Space Network and the Deep Space Network – bring back science and exploration data daily.

Here are a few of our favorite moments from 2024.

1. Hip-Hop to Deep Space

The stars above and on Earth aligned as lyrics from the song “The Rain (Supa Dupa Fly)” by hip-hop artist Missy Elliott were beamed to Venus via NASA’s Deep Space Network. Using a 34-meter (112-foot) wide Deep Space Station 13 (DSS-13) radio dish antenna, located at the network’s Goldstone Deep Space Communications Complex in California, the song was sent at 10:05 a.m. PDT on Friday, July 12 and traveled about 158 million miles from Earth to Venus — the artist’s favorite planet. Coincidentally, the DSS-13 that sent the transmission is also nicknamed Venus!

NASA's PACE mission transmitting data to Earth through NASA's Near Space Network.

2. Lemme Upgrade You

Our Near Space Network, which supports communications for space-based missions within 1.2 million miles of Earth, is constantly enhancing its capabilities to support science and exploration missions. Last year, the network implemented DTN (Delay/Disruption Tolerant Networking), which provides robust protection of data traveling from extreme distances. NASA’s PACE (Plankton, Aerosol, Cloud, ocean Ecosystem) mission is the first operational science mission to leverage the network’s DTN capabilities. Since PACE’s launch, over 17 million bundles of data have been transmitted by the satellite and received by the network’s ground station.

A collage of the pet photos sent over laser links from Earth to LCRD and finally to ILLUMA-T (Integrated LCRD Low Earth Orbit User Modem and Amplifier Terminal) on the International Space Station. Animals submitted include cats, dogs, birds, chickens, cows, snakes, and pigs.

3. Who Doesn’t Love Pets?

Last year, we transmitted hundreds of pet photos and videos to the International Space Station, showcasing how laser communications can send more data at once than traditional methods. Imagery of cherished pets gathered from NASA astronauts and agency employees flowed from the mission ops center to the optical ground stations and then to the in-space Laser Communications Relay Demonstration (LCRD), which relayed the signal to a payload on the space station. This activity demonstrated how laser communications and high-rate DTN can benefit human spaceflight missions.

4K video footage was routed from the PC-12 aircraft to an optical ground station in Cleveland. From there, it was sent over an Earth-based network to NASA’s White Sands Test Facility in Las Cruces, New Mexico. The signals were then sent to NASA’s Laser Communications Relay Demonstration spacecraft and relayed to the ILLUMA-T payload on the International Space Station.

4. Now Streaming

A team of engineers transmitted 4K video footage from an aircraft to the International Space Station and back using laser communication signals. Historically, we have relied on radio waves to send information to and from space. Laser communications use infrared light to transmit 10 to 100 times more data than radio frequency systems. The flight tests were part of an agency initiative to stream high-bandwidth video and other data from deep space, enabling future human missions beyond low-Earth orbit.

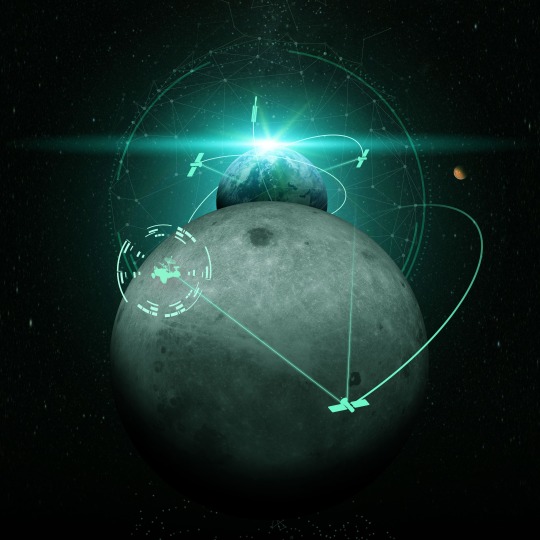

The Near Space Network provides missions within 1.2 million miles of Earth with communications and navigation services.

5. New Year, New Relationships

At the very end of 2024, the Near Space Network announced multiple contract awards to enhance the network’s services portfolio. The network, which uses a blend of government and commercial assets to get data to and from spacecraft, will be able to support more missions observing our Earth and exploring the cosmos. These commercial assets, alongside the existing network, will also play a critical role in our Artemis campaign, which calls for long-term exploration of the Moon.

On Monday, Oct. 14, 2024, at 12:06 p.m. EDT, a SpaceX Falcon Heavy rocket carrying NASA’s Europa Clipper spacecraft lifts off from Launch Complex 39A at NASA’s Kennedy Space Center in Florida.

6. 3, 2, 1, Blast Off!

Together, the Near Space Network and the Deep Space Network supported the launch of Europa Clipper. The Near Space Network provided communications and navigation services to SpaceX’s Falcon Heavy rocket, which launched this Jupiter-bound mission into space! After vehicle separation, the Deep Space Network acquired Europa Clipper’s signal and began full mission support. This is another example of how these networks work together seamlessly to ensure critical mission success.

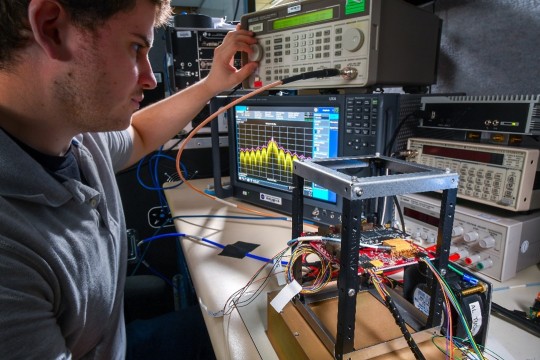

Engineer Adam Gannon works on the development of Cognitive Engine-1 in the Cognitive Communications Lab at NASA’s Glenn Research Center.

7. Make Way for Next-Gen Tech

Our Technology Education Satellite program organizes collaborative missions that pair university students with researchers to evaluate how new technologies work on small satellites, also known as CubeSats. In 2024, cognitive communications technology, designed to enable autonomous space communications systems, was successfully tested in space on the Technology Educational Satellite 11 mission. Autonomous systems use technology reactive to their environment to implement updates during a spaceflight mission without needing human interaction post-launch.

A first: All six radio frequency antennas at the Madrid Deep Space Communication Complex, part of NASA’s Deep Space Network (DSN), carried out a test to receive data from the agency’s Voyager 1 spacecraft at the same time.

8. Six Are Better Than One

On April 20, 2024, all six radio frequency antennas at the Madrid Deep Space Communication Complex, part of our Deep Space Network, carried out a test to receive data from the agency’s Voyager 1 spacecraft at the same time. Combining the antennas’ receiving power, or arraying, lets the network collect the very faint signals from faraway spacecraft.

Here’s to another year connecting Earth and space.

Make sure to follow us on Tumblr for your regular dose of space!

1K notes

·

View notes

Text

Navigating the Seas and Skies: Marine Services and Air Cargo's Symbiotic Relationship

Introduction

The effective transfer of commodities and resources has evolved into a crucial aspect of contemporary civilization in a world characterized by globalization and interconnection. Marine services and air cargo are two of the main participants in this industry. While at first glance they might appear to be separate fields, deeper examination reveals a strong connection that propels global trade and business. The cooperation between maritime and aviation services creates a complex network that supports worldwide logistics, from the delivery of aircraft parts to the exchange of valuable cargo.

The Vital Function of Marine Services

Marine services are the backbone of global trade because they make it possible for cargo ships to transport commodities over great distances. These vessels transport everything from consumer goods to raw resources, acting as floating warehouses. Since the oceans make up more than 70% of the earth's surface, cargo ships must sail complicated routes to link far-off shores, facilitating the interchange of goods on a global scale.

Marine services can include marine traffic management, a system that makes sure that ships can navigate safely and effectively. Ships can be tracked in real-time, optimizing itineraries and avoiding collisions, thanks to innovative technologies like satellite-based tracking systems. This degree of accuracy is necessary to maintain the flow of commodities and avoid supply chain disruptions.

The best timing and routes for cargo ships to depart are also heavily influenced by marine weather forecasts. Shipping businesses can make decisions that protect both their vessels and the cargo they transport by using accurate forecasts of the sea state and impending storms. In this approach, maritime services considerably increase the trustworthiness of international trade.

Air Cargo: Increasing the Supply Chain's Speed

Air cargo leads in terms of speed and urgency, whereas cargo ships handle bulk transit. The desire for prompt delivery of expensive products such perishable foods, medical supplies, and aircraft parts has fueled the expansion of air freight services. Specifically built for carrying freight, cargo planes are able to transport huge cargoes over long distances in a fraction of the time it would take by ship.

To reduce downtime for repairs and maintenance, aircraft parts, which are essential components in the aviation sector, frequently need to be delivered right away. The aviation industry can maintain smooth operations because to air cargo's capacity to quickly carry these components to their required locations. Air cargo makes sure that essential components, whether they be crucial aircraft engines or specialized equipment, arrive at their destinations quickly, minimizing operating delays.

Synthesis at Work

Air cargo and marine services have a complementary rather than merely antagonistic relationship. Imagine that a multinational company needs to ship aircraft parts to a far-off location. Although quick delivery of the parts might be guaranteed via air cargo tracking, the accompanying expenses might be too high. The maritime industry fills this role. In order to strike a balance between speed and cost-effectiveness, large amounts of less urgent components can be transported by cargo ships, while the more vital components are delivered by air.

Additionally, the partnership goes beyond actual transportation. Similar to those used in marine traffic management, air cargo monitoring systems offer real-time information on the whereabouts of cargo flights. This tracking capability improves transparency and allows businesses to keep an eye on and make necessary adjustments to their supply chain processes. Alternative plans might be made in the event that a cargo aircraft has unanticipated delays to guarantee the prompt delivery of products.

Marine and aviation fuel: feeding the Nexus

Air cargo and maritime industries both rely substantially on fuel to run their operations. To move container ships across seas, the maritime sector needs enormous amounts of marine petroleum, which accounts for a sizeable share of the world's fuel consumption. On the other side, aviation fuel maintains cargo planes in the air, ensuring quick delivery of cargo to its destination.

Innovations in fuel efficiency and alternative energy sources are vital for both industries as the world turns its attention to sustainable practices. The aviation sector invests in research to make air travel more environmentally friendly, while the maritime sector investigates cleaner propulsion systems and fuel alternatives. Both industries' parallel efforts to be sustainable demonstrate their dedication to reducing their negative effects on the environment.

Conclusion

Our integrated global economy is built on the dynamic interaction between marine services and air freight. These two fields work together flawlessly to ensure the quick movement of commodities across great distances, from the transportation of aircraft types to the exchange of precious cargo. The effectiveness and dependability of these services are improved by the development of technology like aviation cargo tracking and marine traffic management.

The difficulty comes from trying to achieve sustainability while preserving this delicate balance as we move forward. The maritime and aviation sectors must keep on innovating to find ways to lower their environmental impact and their carbon footprint. We can ensure the smooth circulation of products while conserving the health of our planet for future generations by nurturing this symbiotic relationship and adopting ethical practices.

#Marine service#air cargo#Aircraft Parts#maritime#cargo aircraft#Air cargo tracking#Aircraft engine#Cargo ship#satellite phone#aviation fuel#Marine traffic#marine weather forecast

1 note

·

View note

Text

Injector Pro Clean Diesel Fuel Injector Cleaner

Injector pro clean is a concentrated, one-tank clean-up product that will reduce smoke, improve performance, and reduce emissions. cleans intake manifolds, injectors, combustion chambers, turbochargers, and coolers, restoring lost performance. use injector pro clean annually or whenever deposit-related performance issues are suspected. available in sizes to treat small and commercial vehicles or bulk tanks.

#engine cleaners degreasers#professional fuel injector cleaner#brake repair cleaner#automotive paint cleaner#fallout cleaners#automotive enamel spray paint#carburetor cleaners#professional car odor eliminator#automotive brake parts cleaner#silicone spray grease#rubber care spray#professional car care kits#wheel cleaners#cooling system flush#parts cleaner#heavy duty white lithium grease#battery cleaners#aircraft glass cleaners#fuel additives for cars#fuel injector cleaner for car

0 notes

Text

Commercial Jet Parts – Fast & Reliable

Need commercial jet parts? We’ve got you covered.we provide high-quality parts to keep your jet running smoothly. With fast delivery and great service, we make it easy to get the parts you need. Shop with us today for all your commercial jet part needs!

0 notes

Text

How to source engine mounts from the right aircraft parts distributors?

Aircraft engine mounts may not be the most glamorous part of an airplane, but they are certainly one of the most critical. These mounts are responsible for securing the engine to the aircraft and absorbing the forces generated by its operation. Without them, the engine would shake and vibrate, potentially causing damage to the airframe and compromising the safety of the crew and passengers. So, look for trusted aircraft parts distributors to source them.

The role of engine mounts in aircraft safety:

Engine mounts are an essential component of aircraft safety. They are designed to provide a stable and secure connection between the engine and the airframe. The mounts are responsible for absorbing the forces generated by the engine's operation, such as vibration and torque. They also maintain the alignment of the engine and ensure that it remains in place during flight.

In addition to providing stability and alignment, engine mounts help reduce noise and vibration. This is critical for passenger comfort and reducing fatigue on the airframe. The mounts also play a role in reducing the risk of engine failure and reducing the damage that could occur in the event of an engine failure.

Types of engine mounts:

There are two primary engine mounts used in aircraft: rigid and flexible. Rigid mounts are designed to provide a fixed connection between the engine and the airframe. They are typically made from steel or aluminum. They are used in applications where minimal vibration and noise reduction are required.

On the other hand, flexible mounts are designed to provide some degree of flexibility between the engine and the airframe. They are typically made from rubber or other elastomeric materials. They are used in applications where a high degree of vibration and noise reduction are required.

Materials used in engine mounts:

The materials used in engine mounts are crucial for ensuring their effectiveness and longevity. The most common materials used in engine mounts are steel, aluminum, and rubber.

Steel and aluminum are typically used in rigid mounts, providing a strong and durable connection between the engine and airframe. They also resist fatigue and corrosion, making them ideal for harsh environments.

Rubber and other elastomeric materials are used in flexible mounts as they provide excellent vibration and noise reduction. They are also flexible, allowing them to absorb the forces generated by the engine's operation. However, these materials are more susceptible to wear and tear than steel and aluminum and may require frequent replacement. So, always procure them from trusted aircraft parts distributors.

Factors affecting engine mount design:

Several factors affect engine mount design like the type of engine, it's size and weight, and the intended use. For example, the engines with high torque require more substantial and robust mounts than the engines with low torque. Similarly, more extensive and heavier engines require larger and stronger mounts than smaller engines.

The aircraft's intended use is also critical in engine mount design. For example, aircraft designed for military use may require more robust mounts than aircraft designed for commercial use.

#aircraft parts distributors#aircraft parts distributions#aircraft parts#aircraft parts suppliers#aircraft maintenance engineering

0 notes