#abrasive garnet sand

Explore tagged Tumblr posts

Text

Capstone Abrasives’ Legacy in Industrial Excellence

In the dynamic landscape of industrial abrasives, Capstone Abrasives Company emerges as a beacon of excellence, catering to the diverse needs of businesses worldwide. Specializing in the production and export of premium abrasive products, our company takes pride in being a trusted name synonymous with quality, reliability, and innovation.

A Legacy of Precision: Abrasive Glass Beads Exporters

Capstone Abrasives Company stands as a leading force in the realm of abrasive glass beads. Renowned for their precision and uniformity, our glass beads find applications in a myriad of industries, from automotive surface finishing to the intricate realm of jewelry manufacturing. As dedicated Abrasive Glass Beads Exporters, we ensure that our products meet the highest standards, providing unparalleled surface treatment solutions to our global clientele.

Blasting Grit that Sets Standards: Capstone’s Expertise Unleashed

When it comes to abrasive solutions, Capstone Abrasives Company takes pride in its role as Blasting Grit Exporters of choice. Our blasting grit products are engineered to perfection, offering optimal hardness and durability for a wide range of blasting applications. From cleaning and preparing surfaces to achieving precise profiles, our blasting grit stands as a testament to our commitment to quality and performance.

Steel Grit Excellence: Precision in Every Particle

Capstone Abrasives Company has established itself as a trusted name among Steel Grit Exporters. Our steel grit products are crafted with precision, ensuring consistent and effective results in shot blasting applications. Whether it’s surface cleaning, shot peening, or abrasive blasting, our steel grit delivers the reliability and performance that industries demand.

Sand Blasting Media Near Me: Bringing Quality Closer to You

With a commitment to convenience, Capstone Abrasives Company aims to be your go-to source for Sand Blasting Media. We understand the importance of timely access to quality abrasives, and as a customer-focused company, we ensure that our Sand Blasting Media is readily available, living up to the promise of being “near you” for all your abrasive needs.

Garnet Abrasive Sand: A Finer Touch for Superior Results

Capstone Abrasives Company takes the art of surface preparation to new heights as Garnet Abrasive Sand Exporters. Our garnet abrasive sand, known for its natural hardness and durability, is the ideal choice for achieving superior finishes in sandblasting applications. From shipyards to fabrication workshops, our garnet abrasive sand leaves a mark of excellence in every project.

In conclusion, Capstone Abrasives Company stands as a beacon of quality and innovation in the abrasive industry. As we continue to expand our horizons and serve a global clientele, our commitment to excellence remains unwavering. For all your abrasive needs, trust Capstone Abrasives Company — where precision meets performance, and quality knows no compromise.

#Abrasive Glass Beads Exporters#Blasting Grit Exporters#Steel Grit Exporters#Sand Blasting Media Near Me#Garnet Abrasive Sand Exporters

0 notes

Text

Writing about Mines in your Fictional Universe: A Geology Introduction

Hello! I'm Bird, and I am here to guide you on a journey about different mines that exist, what materials are being mined, what those materials might be mined for, and what rocks/what processes might make these areas mineable. I will also touch briefly on the idea of gem quality, the commonness of the material, and what these things might look like fresh out of the dirt!

First things first, lets talk about the what types of things we might want to mine for in a fictional universe! There are a lot of things that are used daily that require mining, but there are a few that I see written about the most: Gold, Gemstones, Iron, and Coal. I personally would love to see this idea expanded on a bit, so lets talk about some mines that would definitely be necessary but overlooked! First one is pretty easy, glass! those beautiful stained glass windows are useless if no one is mining quartz to be made to glass, and I imagine it would be quite a profitable business seeing as glass, in general, was a luxury in ye olden times. The next thing we need to address is Abrasives! want to sand and polish stone and metal? Want to sharpen your blades for battle? May I introduce you to abrasive minerals! garnet, corundum (Ruby and Sapphire), and yes, diamond! Why are we using such beautiful gemstones to polish other things? Simple, even if you are to find a deposit of these gemstones (garnet being one of the more common ones) most of the time they are inclusion rich, ridiculously small, an undesirable color, or all three of these.

Finding gemstones that are good quality is hard, your character will not stumble upon it, pick up the rock and immediately know if the location is good enough to mine gemstones. If you are determined to make it a gemstone mine, have your character hold the mineral up to the sun/a light source and let them be able to see light coming through, though it is considerably thick.

Moving into metal mining! Metal mining is both easier and more complicated to write! Why is it complicated? Because unless it is gold or silver you are unlikely to see the desired metal itself. Why is it easy? welllll, I am going to try to make it easy. First things first, a lot of metals are chromaphores, this means that when the element is present, it will influence the color! Copper is an excellent example of this, old pennies oxidize and turn blue/teal/green, so do most rocks bearing copper! Looking for iron? It will probably stain the rocks dingy and brownish red. Things to note: copper and iron can be found in mineable amounts together! If you do this, iron will be present in the form of pyrite, or fool's gold, this has a nice cubic shape and can be described as such, the copper will typically leave a teal residue or veining across the rock, which in this case will almost exclusively be black to dark gray (Its basalt) but it can be found as the mineral chalcopyrite also (looks like fool's gold but it doesn't make cute crystals). Malachite is also a copper ore, in my experience I have never seen malachite from a mine that has looked like some of the stuff I have seen in gem shops, azurite (A darker blue mineral) can be present also, but again, these are usually very fine grained and would not be able to be used as jewelry, but obviously, in some places it must happen, just much less frequently.

Another thing I will briefly mention is that, if you are writing about metals remember that these metals will require a smelting process to extract a pure metal, this usually requires some other material (For iron, it is charcoal). Also remember alloys! Most useable metals are a mix of different metals to make them harder. This even includes gold jewelry. Last comment about metals, a very interesting plot for a fictional universe would be the use of lead. Lead ore was a hot commodity before we knew it was toxic, the side effects (Being nuts) could really create some tension.

Lastly in terms of mined material, I will briefly mention coal and stone in general just to say, coal is a sedimentary rock, distinctly different from the typical environments necessary to form most gemstones and heavy metal deposits (Yes, there are exceptions). Coal is dark black/gray, which is quite uncommon for sedimentary rocks which tend to range from reds/tans/browns/grays. When coal is lifted it will feel much lighter than you anticipate, which is the polar opposite of what happens when you lift a metal rich rock, which will feel immensely heavy. Finally, Coal will not turn into diamonds in nature, diamonds need mantle pressures and temperatures to form, there will be no diamonds under a coal mine unless there was a mantle derived eruption that got covered in a swamp, that became coal and as they dug they exposed the kimberlite pipe (I mention this because I just read this in a story and it hurt my feelings). Finally, If you want to write about a mine that is definitely necessary but want the content to be pretty low-maintenance, but profitable for whoever owns it, owning a granite/marble/ or really any desirable stone quarry would be perfect.

Now I will move onto what kind of mining exists today, I will not talk about every exclusive mine, but I will talk about ones that are common that are on my radar. First up, the one everyone talks about in books, underground mining. Underground mining is used when you are getting the material from the 'primary'/original source. The rock is rich in copper? Lets mine said rock. However, mining underground is the most dangerous form of mining, there can easily be a lack of oxygen because of insufficient ventilation (That's why people will carry something with an open flame when going into abandoned mines; if the flame goes out there is not enough oxygen and you have to turn back). There can also be lots of collapses due to overhead rocks, enough said. Cave mining is primarily done when the amount of rock above the deposit is too great to strip mine.

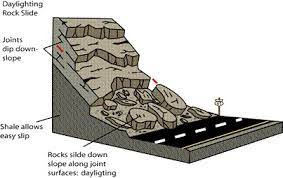

Now lets talk about strip mining! Strip mining is when you just mine on the surface, and dig deeper and deeper into the ground to obtain your desired resource whether it be stone, coal, gemstones, or anything else. It truly is less glamorous, but it is safer than digging a tunnel. That said it has its own issues, sure the oxygen is good, and you don't have to worry about the rocks collapsing over your head, but oh wait, the rocks can collapse over your head. Landslides can occur due to the over steepening of sides, excessive rainfall, and most importantly, old faults or planes of weakness that happen to be facing towards the mine (the diagram will help this make sense). Both of these types of mines can also create ecological damage, which can be mitigated nowadays, but then maybe not so much. Namely acid mine drainage, I will not talk much on the effects but a quick google search will give you plenty of information that might be useful for writing.

Now both of these are trying to mine a targeted rock, but sometimes its best to let nature do the work so we can do less. Diamonds, gold, corundum (rubies/sapphires), and garnets all have one thing in common. They are dense! So when erosion happens, and that sediment makes its way into a river, everything will separate based on its density. This is just because faster moving water can hold heavier sediments, and slower moving water will drop those heavy sediments leaving only the lighter sediments within the water. Lots of places that mine the things listed above will pan/sieve in active rivers and streams, or they can surface mine where rivers and streams used to be! These are called placer deposits. There is one setback though, the gemstones will not be perfect crystal shaped, they will be rounded due to being thrown around in a river (like beach glass). These are sapphires, but they have been rounded over time in the river.

Final thoughts, writing about a mine can seem nerve-racking, intimidating, or just something that you want to briefly mention and move on from, but truly I think going into the weeds could really add something to a story! Even if stories are slightly inaccurate about information, I am still 100x more excited to see it mentioned in more detail than to see it as a sentence. Besides it is fantasy, it doesn't always have to be exactly like earth.

#geology#rocks#stem#science#creative writing#dnd#dnd worldbuilding#fictional world#worldbuilding#worldbuilding stuff#crystals#gemstone#writing resources#writing#fictional writing

71 notes

·

View notes

Text

Let's talk birthstones of the main four in Dead Boy Detectives (aka the ones that we know sun signs for) because man, idk if this was on purpose but they fit SO WELL.

Edit: Sorry for reposting, I realized og thing was so fucking long, so I separated it in two parts. This one is on Charles and Edwin's birthdstones

Let's start with Edwin, our resident Capricorn, whose birth stone is garnet. Dark red stone, that is coincidentally associated with the underworld.

"There are many different myths about the origins of garnet. One such myth suggests that the garnet originated with Persephone, the Greek goddess of sunshine. Persephone was captured by Hades, the god of the underworld. Before Hades released Persephone, he wanted to guarantee her return, so he gave her some pomegranate seeds. The word garnet comes from the Latin "granatus," which means seed. The next time you eat a pomegranate, you will notice the seeds' resemblance to garnet."

Like??? Goddamn?? Quite literally perfect for Edwin.

Furthermore, let look into garnets in their natural state. Garnets are very tough stone, and as it is fairly resistant to abrasion and chemical weathering, garnet is often found in sedimentary rocks or material that is highly weathered and where only the hardest materials have been left behind, like mineral sand dunes.

Quite literally only the toughest ones even survive being collected, in a very difficult environment. Despite that they are very beautiful and prized stones. But let's also take a look at their spiritual meaning.

Garnet cleanses and re-energises the chakras. It revitalises, purifies and balances energy, bringing serenity or passion as appropriate. Inspires love and devotion. Garnet balances the sex drive and alleviates emotional disharmony. It activates and strengthens the survival instinct, bringing courage and hope. Stimulates past-life recall. Sharpens perceptions of oneself and others. Garnet removes inhibitions and taboos. It opens the heart and bestows self-confidence.

I think we can EHEM, all agree that, given Edwin's journey is S1, especially centered around his sexuality that garnet is very fitting stone for him. Especially since it inspires love and devotion, and we see several characters quite literally change themselves due to the fact they fall for Edwin. Boy might be repressed, but he inspired such incredible amount of devotion, both romantic and platonic in people, that it's insane.

Also "removes inhibitions and taboos" could very well fit with his journey of accepting that being gay isn't a taboo. Extra interesting that his inhibits are fully lowered and he confesses his love for Charles while getting out of the underworld for the second time.

Now, onto Charles, a Taurus(and yes, I am aware some people still think he is an Aries and Crystal a Taurus, but I fully subscribe to Charles being a Taurus) whose birth stone is emerald. From a historical context, this is how emerald was described:

Emerald representing youth in the age of man, the power of this lush crystal stirs the soul like the heart of spring, symbolizing hope and the future, renewal and growth. It is a Seeker of Love and a Revealer of Truth, inspiring an ongoing search for meaning, justice, compassion and harmony.

Look at me and tell me this doesn't fit Charles. Representation of youth, not only because he died at 16, but because he seems to always carry that youthful optimism(yes, which is in part a mask, but I do believe he is genuinely a very positive person), also he definitely tries his best to search for meaning, justice, compassion and harmony. Like. This boy died trying to make things right, by fighting for justice because why should someone else suffer when he isn't, and they are so alike? He also has increidble amount of compassion and we see how he best tries to harmonize between Edwin and Crystal.

Now to look at a more spiritual layer of it.

Emerald is a life-affirming stone. It opens the heart chakra and calms the emotions. It provides inspiration, balance, wisdom, and patience. It is said to promote friendship, peace, harmony, and domestic bliss by enabling the wearer to both give and receive unconditional love. Because it promotes honesty and loyalty, it is also beneficial for business transactions and all types of partnerships.

Emerald fortifies the spirit and helps to overcome misfortune. It brings a sense of joy, recovery, and rejuvenation to the downtrodden. It cures claustrophobia and rage as it inspires a sense of wellbeing. It brings subconscious thought to the forefront, and promotes self-awareness.

Life-affirming stone. There is something poetic about an emerald, who is life affirming, being paired up with garnet, who is connected with the unerworld, isn't it?

But also, a stone that helps overcome misfortunes, and help with rage, specifically. Poor Charles clearly had his fair share of misfortunes, and rage as well so he could use an emerald. But he seems to embody it's qualities very well, especially as he begins his healing journey. When he learn how to be more self aware and quells his rage, he truly does embody joy and rejuvenation to others around him.

16 notes

·

View notes

Text

The essential tool for precise sandblasting, Quantum Blast Technologies delivers high-quality sand blasting Garnet to meet industrial needs. Choose from sharp Almandine Garnet for aggressive cuts or Alluvial Garnet for smoother finishes. Our abrasives combine durability, superior cutting speed, and low dust production, ensuring efficient performance and top results. Perfect for general or specialised blasting requirements, transform your projects with unparalleled reliability. Upgrade your performance with sand blasting Garnet today!

0 notes

Text

Thames garnets tend to appear in specific spots along the riverbank, but those locations are carefully guarded among mudlarks.

Photograph courtesy of Jason Sandy.

The following text is from an article on the 'Atlas Obscura' website (link here) which I copied and pasted to share here without the adverts for an easier read.

The Curious Gems of the River Thames. London’s riverbanks are filled with treasures, including scores of deep red garnets with mysterious origins. by Ellery Weil, January 7, 2025.

On the banks of the River Thames, when the tide is low, a person walking along the shore can see all kinds of things. With a keen eye, you can spot blue-and-white shards of 19th-century pottery, delicate stems of 18th-century clay pipes, brass buttons from coats, and coins dating back to the Romans. And if you look in the right spot on a sunny day, you might see something special: the wink of tiny, dark red stones, shining like pomegranate seeds against the pebbles. If you see these, consider yourself lucky—you’ve found one of the river’s little-known treasures: a Thames garnet. Thames garnets are varied. Some are raw stones with jagged edges and uneven shapes, but others are faceted, clearly carved and waiting to be drilled into beads or set into an earring, a bracelet, or a necklace. Their deep purplish red color is especially striking on the brown-gray banks of the Thames. The most striking feature of Thames garnets, though, is that they shouldn’t be there at all. There are gemstones native to Britain—agate in particular, and the famous Whitby jet used in Victorian mourning jewelry. But garnets are not mined in England, and while they “occur widely in the metamorphic rock of the Scottish Highlands,” according to the British Geological Survey, “most are too fractured, too dark in colour and too included for use as gemstones.” Beyond that, it’s hundreds of miles from the Highlands to even the northernmost parts of the Thames. So, how did they get there? And why do they wash up seemingly only in a handful of spots, the locations of which are carefully guarded by the mudlarks who scour the Thames for lost items that wash in with the tide, rather than at random along the foreshore? Some say they’re a remnant of industrial cleaning and polishing. One of the most abrasive forms of sandpaper is made from crushed and ground shards of garnet. Could Thames garnets have been the remnants of garnet paper production? [what?! I've not heard of garnet paper before!!] It is ideal for sanding wood, and London was once a furniture-making center. That’s probably not the case, though—at least not for all Thames garnets. After all, many Thames garnets are visibly faceted, and of uniform size, which paper-production leftovers wouldn’t be.

A map of Roman London (Londinium). It’s not uncommon to find Roman artifacts alongside pieces from the Middle Ages and the Victorian era. Copyright: Chronicle / Alamy Stock Photo.

Academics have been tracing the garnet trade in Britain, which is thousands of years old, and there we might find clues. Archaeologist and Professor Helena Hamerow of Oxford University found through a national survey that garnets, a stone prized by the Anglo-Saxons, have been discovered in a “major concentration” inlaid into metalwork in grave goods dating back to the sixth century across the Thames Valley. With the stones not native to the valley, and before mass transit, garnets destined for London would have traveled by sea, says Hamerow, and then, by river. This means that garnets have been making their way to the River Thames for thousands of years. In all that time, plenty may have gotten lost overboard. Only a few people are legally allowed to hunt for Thames garnets—or even remove them if they find them by chance. Mudlarks are among the few who are legally permitted to remove items from the riverbanks. To be a mudlark, you need a license, and in recent years, the British government suspended the issuing of new licenses for several years following a boom in applications during the pandemic lockdowns, leaving the already tight-knit mudlark community in a holding pattern. Even among experienced mudlarks, Thames garnets are a prized find. Lara Maiklem, a mudlark and author, says that one of the only things we know for certain about the garnets is that they “aren’t native to the Thames,” but that theories of how they got there are far-flung. Heather Stevens, known online as the Thames Wanderer, was one of the last to get a mudlarking license before the pandemic freeze, and she’s been combing the river’s edge ever since. “I went on to the foreshore one day with a friend just looking around and I took some stones home with me. I posted pictures of them on my artistry page, I was contacted by another mudlark via a private message who explained that I needed a permit in order to do mudlarking as the land belongs to the crown. Twenty minutes later I brought a permit.” Stevens found her first garnets two years ago when searching the shore for Tudor dress pins. She initially dismissed them, thinking she’d seen shards of dark red glass. Only thirty minutes later, though, a fellow mudlark told her that she had actually stumbled upon treasure. “I was in total shock that semiprecious stones could be found on the foreshore so I have been collecting them in different forms ever since.” Stevens’ favorite theory on the origins of the gems is that the garnets were the spoils of smuggling. From the 17th through the middle of the 19th century, smuggling was “rife in Britain,” according to the late historian Trevor May in his comprehensive Smugglers and Smuggling. In 1798, the Thames Police was established specifically because smugglers were costing the traders of London hundreds of thousands of pounds per year. Heavy import duties made smuggling an appealing way to get imported goods inexpensively, like fine wines, luxury fabrics, and gemstones. Garnets would have been imported, and faced a nearly 70 percent import duty. Stevens speculates that when the stones were being shipped into London, “crew members on board docking ships would purposely push sacks of garnets … over the side of the ship to later come back and retrieve them at low tide.” Mudlarks are legally prohibited from profiting from their finds—Stevens and others who find the garnets keep them, make them into jewelry, or gift them to friends. As for solving the mystery of where they come from? Garnets are “notoriously hard to date” according to Stevens. In her archaeological work, Hamerow could only date her stones via the surrounding metalwork, and the age of the gravesites they were laid in—meaning that even as the Thames garnets come to light, unadorned, they keep their secrets.

Formed at the turn of the 19th century, the Thames Police patrolled the river in rowboats to combat widespread issues of looting and smuggling. Copyright: KGPA Ltd / Alamy Stock Photo

A single garnet gleams on the muddy foreshore of the River Thames. Copyright: Leon Neal / Getty Images.

For more information re. mudlarking, please see my previous blog posts for excellent book recommendations:

'Mudlark'd: Hidden Histories From the River Thames' by Malcolm Russell, link here.

'Thames Mudlarking: Searching For London's Lost Treasures' by Jason Sandy & Nick Stevens, link here.

0 notes

Text

Garnet Sand: The Ideal Solution for Sandblasting and Waterjet Cutting

Choosing the right abrasive material is crucial for achieving precision, reliability, and efficiency in industrial processes like sandblasting and waterjet cutting. Among the many options, garnet abrasive stands out as a trusted, high-performance material derived from the natural mineral almandine.

Why Garnet Abrasive is the Top Choice ?

Garnet Sand, sourced from almandine, is renowned for its exceptional properties, making it the preferred material for industries worldwide.

Key Benefits of Garnet Abrasive

1. Exceptional Strength and Durability

Garnet is strong enough to handle high-pressure cutting and heavy-duty sandblasting tasks, maintaining its structure for extended use.

2. Sharp, Angular Particles for Precision

When garnet breaks apart, it forms sharp, angular edges, ensuring accurate and effective cutting or blasting.

3. Environmentally Friendly

Garnet is non-toxic, naturally degradable, and safe for users and the planet, making it a sustainable choice compared to synthetic abrasives.

Advantages of Garnet for Industrial Applications

Our garnet abrasive products are designed to deliver superior results in sandblasting, waterjet cutting, and other industrial uses:

Superior Cutting and Blasting Performance Achieve faster, cleaner, and more accurate results with our premium-grade garnet.

Enhanced Surface Finish Our garnet ensures smooth, professional finishes, reducing the need for post-processing.

Increased Equipment Lifespan The durability of our garnet reduces wear on nozzles and machinery, lowering maintenance costs.

Sustainability in Action Reusable and recyclable, our garnet abrasive minimizes waste and environmental harm, aligning with modern sustainability goals.

Why Abrasivestocks Pty Ltd Stands Out

When it comes to sourcing garnet, Abrasivestocks Pty Ltd offers unmatched value: Harder, Purer, and More Cost-Effective

Our garnet abrasive delivers superior hardness and purity, providing better performance at competitive prices.

1 note

·

View note

Text

The Advantages of Employing Garnet Sand as the Sandblasting Medium

Garnet sand is a versatile abrasive ideal for applications like sandblasting, waterjet cutting, and filtration. Known for its exceptional hardness, durability, and eco-friendly properties, garnet ensures precise, efficient performance while minimizing environmental impact. Its reusability and adaptability to various grades make it a cost-effective solution for industries requiring superior surface preparation and cutting results. To learn more, visit our website or read this blog.

0 notes

Text

Garnet Blasting: The Powerful, Eco-Friendly Solution for Precision Surface Preparation

Kia Ora! Do you know that garnet blasting has quickly gained popularity as a leading choice for surface preparation across a variety of industries. Utilizing garnet as an abrasive, this technique combines precision, strength, and eco-friendliness to achieve highly effective results without the environmental impact of traditional sandblasting. For projects requiring careful surface treatment—be it metal restoration, marine applications, or industrial machinery—garnet blasting offers impressive results, efficient processing, and sustainability.

What is Garnet Blasting?

Garnet blasting is a surface preparation method that uses garnet particles as the abrasive medium. Derived from natural mineral deposits, garnet is a hard, angular mineral that breaks down into smaller particles during blasting. This makes it ideal for removing rust, paint, and other coatings while creating a smooth, uniform surface ready for coatings or protective applications.

Unlike other abrasive materials, garnet has unique benefits:

Non-Toxic and Eco-Friendly: Garnet is a naturally occurring mineral and contains no harmful elements, making it safer for the environment and less hazardous to operators.

Minimal Dust Production: Garnet produces less dust than traditional materials like silica sand, providing a cleaner, safer working environment.

High Efficiency: The abrasive power of garnet allows for faster project completion, meaning reduced labor time and cost.

Precision: The hardness of garnet particles allows for controlled abrasion, which helps preserve delicate surfaces while still removing contaminants effectively.

Key Benefits of Garnet Blasting

For industries that require high-quality, environmentally conscious, and cost-effective surface preparation, garnet blasting has several distinct advantages:

Cleaner Work Environment: Unlike silica sand, garnet produces low levels of dust, minimizing air contamination and improving visibility during blasting. This makes it particularly advantageous in closed or restricted areas.

Eco-Friendly Solution: Garnet is non-toxic and can often be recycled for multiple uses, reducing waste and environmental impact. This makes it ideal for companies prioritizing sustainable practices.

Efficient and Precise: Garnet particles provide faster, more aggressive cleaning compared to softer abrasives, achieving uniform surface profiles that are ready for painting or coating applications.

Versatile Application: Garnet blasting is suitable for various surfaces, including metal, glass, wood, and concrete, which makes it a go-to option for diverse industrial needs.

Non-Toxic for Operators: Traditional sandblasting media may contain hazardous materials, but garnet blasting provides a safer alternative, helping to prevent respiratory issues for operators.

Applications of Garnet Blasting Across Industries

Garnet blasting is versatile enough to be used in multiple sectors. Here’s a look at where this method excels:

Marine and Shipbuilding: In marine environments, metals and surfaces are highly susceptible to corrosion. Garnet blasting is widely used in shipyards to remove rust and old coatings from hulls and other metal surfaces, preparing them for protective coatings that prolong durability.

Automotive and Restoration: Garnet blasting can remove paint and rust from car bodies, parts, and restoration projects, leaving surfaces clean without the risk of warping thin metal parts.

Construction and Industrial Machinery: In construction and heavy industries, equipment and machinery must be kept in good condition. Garnet blasting helps remove rust, grime, and old paint from machinery, improving both function and aesthetics.

Metal Fabrication and Refinishing: From steel beams to pipelines, metal components often require precise surface prep before welding, painting, or coating. Garnet’s hardness and uniform shape make it ideal for this purpose.

Aerospace Applications: Aerospace parts need high precision, and garnet blasting provides the right balance of control and strength without damaging sensitive equipment.

How Garnet Blasting Stands Out

What makes garnet blasting particularly advantageous is its adaptability and its ability to be reused multiple times. Here’s how it holds an edge over other blasting techniques:

Reusable and Cost-Efficient: Garnet can be recycled for multiple cycles, which makes it a more cost-effective option than traditional abrasives. This reduces the volume of new materials required and cuts down on waste.

Reduced Surface Contamination: Garnet blasting leaves minimal residue, ensuring a clean surface for coatings. Other abrasives can sometimes embed particles, affecting subsequent coating adhesion.

High-Quality Surface Finish: Garnet’s angular shape and durability create a consistent surface profile ideal for bonding primers, coatings, and paints. This is particularly beneficial in situations requiring long-lasting finishes.

Choosing the Right Garnet Blasting Provider

Selecting a reliable garnet blasting provider is crucial to achieving a top-notch finish on any project. Here are a few points to consider when choosing a garnet blasting service:

Experience with Different Surface Types: Choose a provider who understands how to adapt blasting pressure and media size for different surfaces and materials.

Eco-Friendly Practices: Verify that the provider recycles garnet and adheres to environmentally safe disposal practices.

Modern Equipment: State-of-the-art equipment improves efficiency and ensures consistent, uniform surface treatment.

Safety Compliance: Ensure that the company follows proper safety standards to protect operators and the environment.

Final Thoughts: The Future of Garnet Blasting

For companies seeking sustainable, precise, and effective surface preparation, garnet blasting is the answer. Its non-toxic and recyclable nature makes it a smart choice for environmentally responsible projects, while its abrasive strength ensures reliable, high-quality surface preparation across industries. By investing in garnet blasting, businesses are not only enhancing their operational efficiency but also contributing to safer practices that benefit both the environment and their employees.

Whether for marine, automotive, industrial, or construction applications, garnet blasting stands out as a premier surface preparation solution. With the support of an experienced provider, garnet blasting can elevate your project’s quality while maintaining the integrity and longevity of your materials.

0 notes

Text

Capstone Abrasives - Your Trusted Partner in Precision Surface Preparation Across

Welcome to Capstone Abrasives Company, your trusted partner in surface preparation and blasting solutions. With a commitment to excellence and a focus on quality, we take pride in delivering top-notch abrasive products and services that cater to diverse industrial needs. Let's explore how Capstone Abrasives is making a significant impact in the industry, offering services such as Blasting Grit in Vietnam, Garnet Abrasive Sand in Haryana, Steel Shot in Haryana, Garnet Abrasive Sand in Gujarat, and Garnet Abrasive Sand in Ahmedabad.

Blasting Grit in Vietnam:

At Capstone Abrasives, we understand the critical role that blasting grit plays in achieving optimal surface preparation. Our high-quality Blasting Grit Services in Vietnam are designed to meet the demanding requirements of various industries, ensuring efficient and effective results. From removing rust to preparing surfaces for coating, our blasting grit solutions stand out for their reliability and performance.

Garnet Abrasive Sand in Haryana:

Haryana is a hub of industrial activity, and Capstone Abrasives is proud to be a key player in providing top-grade Garnet Abrasive Sand services in Haryana. Our offerings are tailored to clients' specific needs in Haryana, ensuring that their surface preparation processes are smooth and efficient, and yield superior results. Whether it's metal fabrication or shipbuilding, our Garnet Abrasive Sand is the go-to choice for many industries in the region.

Steel Shot in Haryana:

Capstone Abrasives takes the lead in delivering high-quality Steel Shot in Haryana. Our steel shot products are known for their durability and effectiveness in cleaning, peening, and surface finishing applications. We strive to contribute to the success of industries in Haryana by providing reliable and consistent steel shot solutions that meet the highest quality standards.

Garnet Abrasive Sand in Gujarat:

Gujarat, known for its diverse industrial landscape, relies on Capstone Abrasives for top-tier Garnet Abrasive Sand services in Gujarat. Our offerings in Gujarat are crafted to meet the unique challenges posed by various industries, ensuring that our clients receive abrasive solutions that enhance productivity and efficiency in their surface preparation processes.

Garnet Abrasive Sand in Ahmedabad:

In Ahmedabad, the heart of industrial activity in India, Capstone Abrasives stands out as a trusted provider of Garnet Abrasive Sand in Ahmedabad. Our services are characterized by precision and quality, addressing the intricate needs of industries in Ahmedabad. From precision machining to automotive applications, our Garnet Abrasive Sand plays a pivotal role in achieving impeccable surface finishes.

Conclusion:

Capstone Abrasives Company is not just a provider of abrasive products; we are a partner in your journey toward excellence in surface preparation. With a dedicated focus on quality and customer satisfaction, we continue to set the benchmark for abrasive solutions in Vietnam, Haryana, Gujarat, and beyond. Trust Capstone Abrasives for all your blasting and surface preparation needs, and experience the difference that quality and expertise make in achieving superior results.

#Blasting Grit in Vietnam#Garnet Abrasive Sand in Haryana#Steel Shot in Haryana#Garnet Abrasive Sand in Gujarat#Garnet Abrasive Sand in Ahmedabad

0 notes

Text

Top 3 Suppliers for Abrasive Tools in Australia

Abrasive tools are indispensable in industries that require precision and efficiency for material finishing, cutting, or grinding. From large-scale manufacturing to small workshops, quality abrasives make all the difference. When choosing the right supplier, it's essential to consider quality, consistency, and product range. Here are three top-notch abrasive suppliers in Australia that stand out for their industrial-grade solutions.

1. Hales Australia – Your Trusted Source for Abrasive Industrial Supplies

Hales Australia is a leading name when it comes to providing top-tier abrasive tools. Their wide selection of industrial abrasives and tool supplies caters to various industries, ensuring every job is done with accuracy and quality. From grinding wheels to sanding discs, their products offer reliable performance, backed by years of industry expertise.

2. Garnet Australia – Industry-Leading Solutions for Every Need

For businesses requiring specialised abrasive solutions, Abrasives Australia delivers a diverse product lineup that includes cutting discs, abrasive belts, and more. They focus on providing tailored products for specific industrial applications, ensuring that companies get the right tool for every task.

3. Alpha Tools Abrasives – High-Performance Abrasives for Australian Industries

Known for high-performance and durability, ABC Abrasives offers a wide range of products that include cutting tools, finishing pads, and sanding solutions. As a leading abrasives product supplier in Australia, they have earned a reputation for delivering products that meet stringent industry standards.

Why Quality Matters in Abrasive Tools

Choosing high-quality abrasives is critical for achieving the desired surface finish while ensuring tool longevity. Working with reliable industrial abrasives suppliers like Hales Australia guarantees that your business remains productive and cost-efficient.

#AbrasivesAustralia#IndustrialAbrasivesSuppliers#AbrasivesProductSupplierAustralia#IndustrialAbrasivesandToolSupplies#AbrasiveIndustrialSupplies

0 notes

Text

Dry Sandpaper Market is valued at USD 2,624.69 million and is projected to grow at a compound annual growth rate (CAGR) of 4.82% over the forecast period, reaching approximately USD 3,825 million by 2032. Dry sandpaper, a fundamental abrasive material, plays a pivotal role across numerous industries, including automotive, woodworking, and construction. This market is poised for substantial growth, driven by increasing demand for smoother finishes, the rise in construction activities, and technological advancements in abrasives. In this article, we will explore the key factors contributing to the growth of the global dry sandpaper market, its segmentation, and the challenges and opportunities that shape its future.

Browse the full report at https://www.credenceresearch.com/report/dry-sandpaper-market

Market Overview

Sandpaper, also known as coated abrasive, consists of paper or fabric backing with abrasive materials like aluminum oxide, silicon carbide, or garnet attached to its surface. Dry sandpaper, specifically designed for dry sanding, is commonly used in automotive repairs, metalworking, and woodworking to smooth surfaces or remove material layers. With increasing demand from end-user industries such as automotive, aerospace, and construction, the global dry sandpaper market is experiencing notable growth.

The rise in DIY (Do-It-Yourself) projects, growing construction activities, and the emphasis on smoother and more refined finishes are significant factors that are expected to drive demand over the next decade. Additionally, the global trend toward more eco-friendly products has spurred innovation in sandpaper manufacturing, encouraging the production of biodegradable and reusable abrasives.

Key Drivers of Market Growth

1. Boom in Construction Activities: With rapid urbanization and infrastructure development in emerging economies, the demand for sandpaper in construction-related activities has seen consistent growth. In the construction industry, sandpaper is crucial for surface preparation, making it a necessary tool for painting, varnishing, and repairing surfaces.

2. Growing Automotive Industry: The automotive sector is another major driver of the dry sandpaper market. As manufacturers strive for precision and high-quality finishes in vehicle bodywork, sandpaper is an indispensable tool in painting, surface repair, and refinishing.

3. Increase in DIY Culture: The growing trend of DIY projects has led to a rise in demand for easy-to-use tools and equipment, with sandpaper being one of the essential items for woodworking and home improvement projects. Consumers are increasingly seeking cost-effective and user-friendly solutions, boosting demand in this segment.

4. Technological Advancements: Innovations in abrasives, including the development of more durable and versatile sandpaper products, have expanded the applications of dry sandpaper. Manufacturers are investing in research and development to create products that offer better performance, longer life, and lower environmental impact.

Challenges and Opportunities

Despite the positive outlook, the dry sandpaper market faces some challenges. The growing shift toward mechanized tools, such as power sanders and belt sanders, reduces the manual use of sandpaper in certain industries. Additionally, fluctuations in raw material prices, especially for aluminum oxide and silicon carbide, could impact profitability for manufacturers.

However, opportunities lie in the development of eco-friendly sandpaper products and the expansion of the market into emerging economies. The increasing awareness of sustainable practices is pushing companies to innovate, creating sandpaper that is biodegradable or made from recycled materials. Emerging markets with growing construction and automotive sectors present untapped potential for future expansion.

Key Player Analysis:

3M Company

Saint-Gobain Abrasives, Inc.

Klingspor AG

Mirka Ltd.

Sia Abrasives Industries AG

Carborundum Universal Limited

Kovax Corporation

Norton Abrasives (a brand of Saint-Gobain)

Flexovit USA, Inc.

Gator Finishing Products

Segmentation:

Based on Product Type:

Coated Sandpaper

Non-Woven Sandpaper

Others

Based on Material Type:

Aluminum Oxide

Silicon Carbide

Garnet

Emery

Others

Based on End-User:

Automotive

Woodworking

Metalworking

Other Sectors

Based on Geography:

North America

The U.S

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/dry-sandpaper-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Waterjet Cutting Machine for Sale: Precision Cutting at Its Best

In today’s fast-paced manufacturing and industrial landscape, precision cutting is crucial. Whether you’re in the automotive, aerospace, construction, or creative industries, cutting materials with high accuracy and efficiency can significantly impact the quality and productivity of your operations. Enter the waterjet cutting machine, a game-changing tool that combines cutting-edge technology with versatility. If you’re searching for a waterjet cutting machine for sale, this comprehensive guide will help you understand its benefits, how it works, and what to look for when making a purchase.

What is a Waterjet Cutting Machine?

A waterjet cutting machine is a powerful cutting tool that uses a high-pressure jet of water, sometimes mixed with an abrasive substance, to slice through a variety of materials. This cutting technology is non-thermal, which means it doesn’t generate heat. As a result, it minimizes the risk of heat-affected zones (HAZ), preserving the material’s structural integrity.

Waterjet machines can cut virtually any material, including:

Metals like steel, aluminum, and titanium

Ceramics

Glass

Stone

Rubber and plastics

Composites

This wide range of capability makes it a popular choice for industries that demand precision, efficiency, and versatility in cutting processes.

How Does Waterjet Cutting Work?

Waterjet cutting works by forcing a thin stream of water at ultra-high pressure through a small nozzle. The water pressure can reach up to 60,000 psi (pounds per square inch) or more, creating enough force to cut through tough materials. When an abrasive substance like garnet is added to the water stream, it increases the machine’s cutting ability, allowing it to slice through denser materials like metals and stone.

Waterjet cutting is highly controlled, meaning the operator can create complex and intricate designs with incredible precision. Since the process doesn’t use heat, it eliminates the risk of thermal damage like warping or melting, which is a common problem with traditional cutting methods such as laser or plasma cutting.

Benefits of Waterjet Cutting Machines

When you invest in a waterjet cutting machine for sale, you’re getting a tool that offers several advantages over traditional cutting methods:

Versatility

Waterjet machines can cut virtually any material, from soft rubber to hard metals, making them ideal for various industries. Whether you’re working on architectural projects, industrial manufacturing, or artistic designs, a waterjet machine can handle the task.

Precision and Accuracy

Waterjet cutting allows for extremely fine, detailed cuts with tolerances as tight as 0.1 mm. This makes it perfect for producing intricate shapes and patterns that require high levels of precision, such as in aerospace and automotive manufacturing.

No Heat-Affected Zones

Since waterjet cutting is a cold process, there’s no risk of thermal distortion or material damage. This makes it particularly valuable for materials sensitive to heat, such as metals or composites.

Eco-Friendly

Waterjet cutting doesn’t produce any harmful fumes, smoke, or gases, making it an environmentally friendly cutting option. Additionally, the cutting process generates minimal waste, which can help reduce material costs and contribute to more sustainable production practices.

Reduced Need for Secondary Finishing

The clean, smooth edges created by waterjet cutting mean that there’s often no need for secondary finishing processes like sanding or polishing. This saves both time and money in post-production.

Industries That Benefit from Waterjet Cutting

The waterjet cutting machine is used across numerous industries due to its versatility and efficiency. Here are a few key sectors that heavily rely on this technology:

Aerospace and Aviation

Waterjet machines are used to cut high-performance materials like titanium and carbon composites with precision and without compromising structural integrity.

Automotive

From prototype designs to final parts production, waterjet cutting allows for accurate, repeatable cuts in various materials, including metals and plastics, reducing material waste.

Construction and Architecture

Whether cutting stone, tile, or glass, waterjet machines provide architectural firms with the ability to create intricate designs, custom flooring, or facades with precision and beauty.

Art and Design

Artists and designers use waterjet machines to create detailed sculptures, custom engravings, and other creative projects from materials like glass, wood, and metal.

Manufacturing

Waterjet cutting machines streamline production processes in industries such as electronics, packaging, and heavy equipment manufacturing, where precise and efficient material cutting is essential.

Choosing the Right Waterjet Cutting Machine for Sale

When looking for a waterjet cutting machine for sale, several factors must be considered to ensure you’re getting the best machine for your needs:

Cutting Capacity

Consider the thickness and types of materials you’ll be cutting. Different machines come with varying cutting capacities. For example, some machines are better suited for cutting thin materials, while others are designed for thicker metals or stone.

Pressure and Power

A higher-pressure machine will cut faster and more efficiently, particularly when working with harder materials. Machines with 60,000 psi or more are ideal for industrial-grade projects.

Abrasive or Pure Waterjet?

If you’re cutting soft materials like foam, food products, or rubber, a pure waterjet machine (which doesn’t require an abrasive) might be the best choice. However, if you’re working with harder materials like metals or stone, an abrasive waterjet machine is more suitable.

Maintenance and Operating Costs

Ensure you understand the maintenance requirements of the machine, including pump maintenance, abrasive usage, and water filtration systems. Machines with higher efficiency will have lower operating costs, helping you save in the long run.

After-Sales Support

Many manufacturers and sellers offer after-sales support, including training, maintenance, and spare parts. Make sure your purchase comes with reliable customer service to help you get the most out of your machine.

Conclusion: Is a Waterjet Cutting Machine Right for You?

Investing in a waterjet cutting machine for sale can dramatically improve your production process, offering unmatched versatility, precision, and cost-effectiveness. Whether you’re working with metals, glass, stone, or softer materials, waterjet technology provides a clean, efficient solution for all your cutting needs.

Before making your purchase, carefully evaluate your cutting requirements, machine capabilities, and budget. With the right machine, you can boost your productivity, enhance the quality of your work, and ultimately increase your profitability. Explore the market today and discover how a waterjet cutting machine can revolutionize your operations!

0 notes

Text

Understanding Sandpaper: A Comprehensive Guide

Sandpaper is an essential tool in many industries, particularly in woodworking, metalworking, and automotive refinishing. Though it appears as a simple piece of abrasive material, sandpaper plays a crucial role in achieving smooth finishes, removing imperfections, and preparing surfaces for further treatment. This article explores the different aspects of sandpaper, including its history, types, uses, and the science behind its effectiveness.

The Origins of Sandpaper

The use of abrasives to smooth surfaces dates back thousands of years, with early civilizations employing natural materials like sand, crushed shells, and even fish skins to achieve the desired finish. However, the invention of modern sandpaper is credited to the 13th century Chinese, who used crushed shells, seeds, and sand glued to parchment with natural adhesives.

The sandpaper we recognize today started to take shape in the 19th century. By the mid-1800s, the development of more consistent manufacturing processes allowed for the creation of sandpaper with uniform grit sizes and materials. This evolution marked a significant advancement in surface preparation, making sandpaper an indispensable tool in various trades.

Composition and Structure of Sandpaper

Sandpaper is composed of three main components: the backing, the adhesive, and the abrasive material. Each of these elements is chosen based on the specific application and desired outcome.

Backing: The backing material provides support and flexibility to the sandpaper. It can be made of paper, cloth, or a combination of both. Paper-backed sandpaper is typically used for hand sanding or on lightweight sanding tools, while cloth-backed sandpaper is more durable and suited for heavy-duty applications.

Adhesive: The adhesive binds the abrasive particles to the backing. Historically, natural glues were used, but modern sandpaper often employs synthetic resins like phenolic or urea-formaldehyde, which offer superior bonding strength and resistance to heat.

Abrasive Material: The abrasive is the most critical component, responsible for cutting and smoothing the surface. Common abrasive materials include aluminum oxide, silicon carbide, garnet, and ceramic. Each material has unique properties that make it suitable for specific tasks. For example, aluminum oxide is highly durable and suitable for sanding metals, while garnet is softer and preferred for finishing wood.

Grit Size and Its Importance

The effectiveness of sandpaper is largely determined by the grit size, which refers to the size of the abrasive particles. Grit size is usually expressed as a number, with lower numbers indicating larger, coarser particles and higher numbers representing finer particles.

Coarse grit sandpaper (e.g., 40 to 60 grit) is used for rapid material removal, such as stripping paint or smoothing rough surfaces. Medium grit sandpaper (e.g., 80 to 120 grit) is versatile, often used for general sanding tasks and preparing surfaces for finishing. Fine grit sandpaper (e.g., 150 to 220 grit) is ideal for final smoothing before applying finishes like paint or varnish. Extra fine grit sandpaper (e.g., 240 to 400 grit and above) is used for polishing and creating a silky-smooth surface.

Selecting the appropriate grit size is crucial to achieving the desired result without damaging the material. Starting with a coarse grit to remove imperfections and gradually progressing to finer grits ensures a smooth, even finish.

Applications of Sandpaper

Sandpaper is a versatile tool used in various industries and applications. In woodworking, it is employed to smooth surfaces, remove old finishes, and prepare wood for staining or painting. In metalworking, sandpaper helps to deburr edges, remove rust, and polish metals to a high sheen. The automotive industry uses sandpaper to prepare surfaces for painting, remove scratches, and restore finishes.

Beyond these industries, sandpaper is also used in home improvement projects, from smoothing drywall before painting to refinishing furniture. Its wide range of applications makes sandpaper a staple in both professional workshops and DIY toolkits.

The Science Behind Sanding

Sanding works by abrading the surface of a material, removing tiny particles to smooth out imperfections. When sandpaper is rubbed against a surface, the abrasive particles cut into the material, shearing away small fragments. The effectiveness of sanding depends on factors like pressure, speed, and the type of abrasive used.

Heat generation is a byproduct of sanding, especially when using power tools. Excessive heat can cause the adhesive holding the abrasive to degrade or even damage the workpiece. Therefore, controlling the speed and applying consistent, moderate pressure is key to effective sanding.

Innovations in Sandpaper Technology

While the basic concept of sandpaper has remained unchanged for centuries, modern innovations have improved its performance and durability. Today, there are sandpapers designed for specific materials and tasks, such as waterproof sandpaper for wet sanding, which helps reduce dust and heat.

Additionally, advancements in abrasive materials, like the development of ceramic and diamond-coated sandpapers, have extended the lifespan and cutting power of sandpaper, making it more efficient for heavy-duty tasks.

Sandpaper may appear to be a simple tool, but its importance in achieving precision and quality in various trades cannot be overstated. Understanding the different types of sandpaper, their composition, and their applications allows for better selection and use, ultimately leading to superior finishes in any project. Whether you're a seasoned professional or a DIY enthusiast, mastering the art of sanding with the right sandpaper is essential to achieving the best results.

0 notes

Text

Industrial Garnet Market is ripe for emerging technologies by Smart Manufacturing

The industrial garnet market comprises products such as almandine, andradite, grossular uvarovite, pyrope and spessartine garnets that are formed by metamorphism. These garnets find wide applications owing to their unique physical and chemical properties including high density, hardness and resistance to wear and weathering. Industrial garnets are used as abrasive blasting media for surface preparation and finishing, water jet cutting, water filtration, abrasive powders for application such as abrasive powders in abrasive jets, collision and storage of energy. The Global Industrial Garnet Market is estimated to be valued at US$ 730.61 Mn in 2024 and is expected to exhibit a CAGR of 5.8% over the forecast period 2024 to 2031.

Industrial garnets are highly preferred for their cost effectiveness and environmental friendliness over toxic mediums like silica sand and steel grit. Also, the increasing adoption of garnet abrasives in water jet cutting and growing demand from the automotive and marine industries is propelling the market growth. Key Takeaways Key players operating in the industrial garnet market are GMA Garnet Group, Indian Ocean Garnet Sands Company Ltd., Trimex Sands Private Limited, Barton International, Zircon Mineral Co., Mohawk Garnet Inc., Opta Minerals Inc., V.V. Mineral Pvt. Ltd., Beach Minerals Company, and Rizhao Garnet Ltd. The key players are investing in advanced mining and sorting technologies to increase supply of higher quality industrial garnets. The growing demand for industrial garnets from various end-use industries like water filtration, abrasive blasting, water jet cutting etc. is expected to drive the market growth during the forecast period. The resistance to wear along with cost benefits over other substitutes makes industrial garnets irreplaceable for these applications. The global industrial garnet market is witnessing expansion in regions like Asia Pacific and North America attributed to growing industrial and infrastructure development activities. The availability of garnet reserves and growth of application industries in China, India and U.S. will boost the regional markets in coming years. Market Key Trends Adoption of smart manufacturing approaches is one of the key drivers gaining traction in the Industrial Garnet Market Trend. Various players are focusing on automation, Internet of Things (IoT) and use of analytics to enhance mining, processing, quality inspection and supply chain operations. This is helping players optimize operations, reduce costs and meetings the stringent quality standards of application industries.

Porter’s Analysis Threat of new entrants: New companies can enter the industrial garnet market by establishing manufacturing units and distribution network. However, significant capital investment and established manufacturers make the entry difficult. Bargaining power of buyers: The presence of numerous garnet mines and manufacturers gives buyers multiple options. However, specialized applications of garnet require long-term relationships and maintain consistency in garnet type and quality. Bargaining power of suppliers: The industrial garnet market has a concentration of suppliers as raw garnet sources are limited. The key suppliers have considerable influence over prices. Threat of new substitutes: Alternatives like aluminum oxide and silicon carbide are substitutes for certain abrasive and water jet cutting applications. However, garnet properties like density and hardness make it irreplaceable in major application areas. Competitive rivalry: The market has few leading global players and many medium and small manufacturers. Price-based competition is moderate due to product differentiation based on grade, chemistry and sizes. Geographical regions where the market value is concentrated include Asia Pacific and Europe. Asia Pacific accounts for over 45% share majorly due to growing abrasive, water jet cutting, and filtration applications in automotive, shipbuilding, aerospace and metal industries in China, India and other Asian countries. The fastest growing region is North America led by the US. Increasing usage of natural and eco-friendly garnet abrasives in metal cutting and waterjet cutting as well as growth in waterjet cutting machines is driving the demand up.

Get more insights on Industrial Garnet Market

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

0 notes

Text

Environmental Benefits of Modern Blast Room Systems

Environmental Benefits of Modern Blast Room Systems

Modern blast room system offer several environmental benefits, making them a sustainable choice for various industrial applications. Here’s a detailed look at how these systems contribute to environmental protection and sustainability:

1. Dust and Emission Control

Modern blast room system are designed with advanced dust collection and filtration technologies. These systems capture and contain dust and particulate matter generated during the blasting process, preventing them from being released into the atmosphere. This reduces air pollution and ensures a cleaner, safer working environment.

2. Efficient Media Recycling

blast room system now incorporate efficient media recycling mechanisms that allow abrasive materials to be reused multiple times. This reduces the need for new abrasives, conserving natural resources and minimizing waste generation. By recycling media, industries can significantly decrease their environmental footprint.

3. Energy Efficiency

Innovative design and technology improvements have made modern blast room system more energy-efficient. These systems use less power to operate while maintaining high performance levels, thereby reducing the overall energy consumption and the associated greenhouse gas emissions. Energy-efficient systems contribute to a lower carbon footprint for industrial operations.

4. Noise Reduction

Modern blast room system manufacturer are engineered to minimize noise pollution. Soundproofing materials and advanced acoustic engineering techniques are employed to reduce the noise generated during the blasting process. Lower noise levels not only improve the working conditions for operators but also reduce the impact on surrounding communities and wildlife.

5. Reduction in Hazardous Waste

The containment and proper disposal of hazardous materials are integral to modern blast room system manufacturer. By effectively capturing and managing hazardous substances, these systems prevent the contamination of soil and water sources. This controlled handling of hazardous waste ensures compliance with environmental regulations and protects ecosystems.

6. Water Conservation

Some modern blast room system manufacturer utilize dry blasting techniques that eliminate the need for water. By avoiding the use of water, these systems help conserve this precious resource and reduce the risk of water pollution. This is particularly beneficial in regions facing water scarcity.

7. Use of Eco-Friendly Abrasives

Modern systems often promote the use of eco-friendly abrasives such as recycled glass, garnet, and other natural materials. These abrasives are less harmful to the environment compared to traditional options like silica sand, which can cause respiratory issues and environmental damage. Eco-friendly abrasives minimize health risks and environmental impact.

8. Improved Waste Management

Integrated waste management systems in modern blast rooms ensure that waste products are systematically collected, segregated, and disposed of or recycled appropriately. This organized approach to waste management reduces landfill use and promotes recycling, further reducing environmental impact.

9. Enhanced Operator Safety

By improving the working conditions and reducing exposure to harmful dust and noise, modern blast room system manufacturer protect the health and safety of operators. Healthy workers are more productive and less likely to incur medical costs, indirectly benefiting the environment through sustained productivity and reduced healthcare waste.

Conclusion

Modern blast room system manufacturer represent a significant advancement in industrial technology, offering numerous environmental benefits. By incorporating dust and emission control, efficient media recycling, energy efficiency, noise reduction, hazardous waste reduction, water conservation, eco-friendly abrasives, improved waste management, and enhanced operator safety, these systems contribute to a more sustainable and eco-friendly industrial process. As industries continue to adopt and innovate these technologies, the positive impact on the environment is expected to grow, aligning with global sustainability goals.

0 notes

Text

Exploring Blasting & Painting Equipment: Enhancing Surface Preparation and Finishing

Blasting and painting equipment play crucial roles in industries ranging from construction and automotive to marine and manufacturing. This blog delves into the significance of these tools, their types, benefits, and considerations for choosing the right equipment for your specific needs.

Importance of Blasting Equipment

Blasting equipment, such as sandblasters or abrasive blasters, are used primarily for surface preparation. They remove old coatings, rust, dirt, and other contaminants from surfaces, preparing them for painting or coating. This process ensures a clean substrate, which is essential for achieving a durable and long-lasting finish.

Types of Blasting Equipment

Sandblasters: Utilize high-pressure air or water mixed with abrasive materials like sand or garnet to remove surface contaminants effectively. Sandblasters are versatile and suitable for various materials and applications.

Abrasive Blasters: Include bead blasters, shot blasters, and abrasive blasting cabinets, each tailored for specific surface preparation tasks. Bead blasters, for example, use fine glass beads to clean delicate surfaces without damaging them.

Dry Ice Blasters: Use compressed air to propel dry ice pellets at high speeds, effectively removing contaminants without leaving residue or damaging sensitive surfaces. They are ideal for industries requiring non-abrasive and environmentally friendly cleaning methods.

Benefits of Blasting Equipment

Efficiency: Blasting equipment can significantly reduce surface preparation time compared to manual methods like scraping or chemical stripping.

Uniform Surface Preparation: Ensures a consistent and profiled surface, optimizing the adhesion of coatings for enhanced durability.

Environmental Friendliness: Some blasting methods, such as dry ice blasting, are environmentally friendly as they produce no secondary waste or harmful chemicals.

Versatility: Different types of blasting equipment cater to various surfaces and materials, offering flexibility in application.

Importance of Painting Equipment

Painting equipment complements blasting by applying protective coatings to prepared surfaces. It includes spray guns, paint rollers, and airbrushes, each designed for specific types of coatings and finishes. Proper application of paint or coating ensures aesthetic appeal, corrosion resistance, and longevity of the substrate.

Types of Painting Equipment

Airless Paint Sprayers: Ideal for large surface areas, airless sprayers atomize paint at high pressure, providing uniform coverage and smooth finishes.

HVLP (High Volume Low Pressure) Sprayers: Suited for detailed work and fine finishes, HVLP sprayers use lower pressure to reduce overspray and waste.

Paint Rollers and Brushes: Traditional tools for applying paint to smaller areas or intricate details where precision is required.

Choosing the Right Equipment

Project Requirements: Consider the size of the project, surface material, and desired finish when selecting blasting and painting equipment.

Budget: Evaluate upfront costs and long-term benefits of different equipment options, balancing quality and affordability.

Maintenance: Regular maintenance and proper cleaning of equipment are crucial to ensure optimal performance and longevity.

Conclusion

Blasting and painting equipment are indispensable tools for achieving high-quality surface preparation and finishing in various industries. By understanding the types, benefits, and considerations for choosing these tools, you can enhance efficiency, reduce costs, and achieve superior results in your projects. Whether you're refurbishing a building facade, restoring automotive parts, or maintaining industrial equipment, investing in the right blasting and painting equipment ensures lasting performance and aesthetic appeal. For more details visit our website: www.simsinter.com

#Fire Fighting Equipment#Blasting & Painting Equipment#Special Trucks Equipment#Couplings Fire Hoses#Couplings Anti Corrosion#Power & Hand Tools Kits#Paint Spraying Equipment#Airless Electric Guns#Topcoats Equipment Near Me#Hydraulic Equipment Near Me#Coupling Equipment#Hydraulic Equipment Manufacturers#Hydraulic Tools And Equipment#Hydraulic Equipment Suppliers#Hydraulic Lifting Tools#Hydraulic Pump Manufacturers in Cameroon

0 notes