#Zinc Oxide Pigments Industry

Text

Zinc Oxide Pigments Market risks and challenges that the industry is facing

Zinc Oxide Pigments Market risks and challenges that the industry is facing

The Zinc Oxide Pigments Market research report 2022-2030 provides an in-depth analysis of the changing trends, opportunities, and challenges influencing the growth over the next decade. The study includes a detailed summary of each market along with data related to demand, supply and distribution. The report examines Zinc Oxide Pigments market growth strategies adopted by leading manufacturers…

View On WordPress

#Covid-19 Impact Analysis#Zinc Oxide Pigments#Zinc Oxide Pigments forecast#Zinc Oxide Pigments Industry#Zinc Oxide Pigments Market#Zinc Oxide Pigments price#Zinc Oxide Pigments report#Zinc Oxide Pigments research#Zinc Oxide Pigments share#Zinc Oxide Pigments trends

0 notes

Text

Analysis of Mineral Pigments from the Gnishikadzor Area, Southeastern Armenia

Authored by: Yeghis Keheyan

Abstract

The territory of the Republic of Armenia is very rich with ores and different types of deposits, including resources of natural mineral pigments. They differ by large variation of colours and are represented by painted ores, clays, and earths, among which the most significant is the group of paints with yellow, red and brown shades (ochre). Vayots Dzor Province in South-Eastern Armenia is among the rich areas where painted earths are widely spread. Presence of red and brown ochre are very well visible in the south-western part of the province, in the gorge of the Gnishik River, which is also known as the Noravank Gorge, due to the monastic complex of Noravank located here. Red colour rocks in the area of the Noravank Gorge (Gnishikazdor) represented by the sedimentary strata of the Upper Devonian and are determined by the Famennian Stage (375-359 million years). The samples analysed were taken from the foothills of the Noravank Monastery and analysed by different techniques: Scanning electron microscopy (SEM) with energy dispersive spectroscopy (EDS); FT-IR spectroscopy; XRD diffraction analysis, which allow to indicate the presence of different elements trough contrast variations (atomic number contrast), to determine spectral ranges where absorption peaks were detected, as well as to perform phase identifications. The results show that the concretion is a hard, compact mass of matter formed by the precipitation of mineral cement within the spaces between particles, and is found in sedimentary rock or soil. It is composed of a carbonate mineral such as calcite; an amorphous or microcrystalline form of silica such as chert, flint, jasper or an iron oxide or hydroxide such as goethite and hematite. Implementation of such kind of study is valuable for the future comparison of similar finds from the nearby prehistoric archaeological contexts, where inhabitants exploited red ochre as a pig.

Keywords: Mineral paints; Red ochre; Areni-1 cave; Vayots Dzor Province; Republic of Armenia

Introduction

The mountains of Armenia conceal deposits of ores. Alaverdi (Northern Armenia) and Kapan (Southern Armenia) localities are rich of copper deposits, molybdenum was found in the southeast (Dastakert deposit), in the central and southeastern areas are iron ore deposits (Hrazdan, Abovyan and Svarants deposits). Besides, there are industrial stocks of aluminium-nepheline-syenites, as well as barite with admixture of gold and silver, the deposits of lead, zinc, manganese, gold, platinum, antimony, mercury, and arsenic. There are also rare earth metals: bismuth, gallium, indium, selenium, thallium, tellurium, rhenium. Tuffs (red, orange, yellow, pink, and black), marble, travertines, limestones, are great as building and finishing materials. Semiprecious and ornamental stones are represented by agates, jaspers, amethysts, beryls, rubies, obsidians, onyxes, turquoise.

The area of the country is also rich with resources of natural mineral pigments, where 17 deposits were registered and studied. They differ by large variation of colours and are represented by painted ores, clays and earths, among which the most significant is the group of paints with yellow, red and brown shades (ochre) [1,2].

The colour shade of ochre depends on the type of the iron oxide chromophore. The red ochre contains mainly haematite (Fe2O3), while the yellowish one is rich in hydrated iron oxide goethite, FeO·OH), [3]. The presence of other minerals, such as clay minerals or some metal oxides, can also influence the colour of the ochre. The classification of ochre can be also made according to the matrix composition of kaolinite (Al2SiO5) (OH)4 and/or gypsum (CaSO4·2H2O), and/or sulphate, [4]). Green earth is a clay pigment consisting of hydrated iron, magnesium, and aluminium potassium silicates. Colour varies from a dark, greyish blue green to a dark, dull yellowish green. The colour of green earth is derived from the presence of the following minerals: glauconite or celadonite. As the yellow and red ochre, the green earth or “terreverte” has been used as a pigment all over the world since ancient times [4,5]. They have been found in artworks all over the world and in any historical period, probably due to their availability, high coloring capacities and stability to the light and to the different weather conditions.

Armenian mineral pigments were also used since the dawn of the human civilization and their exploitation by the local inhabitants continued until 1940, after which they were processed on industrial level [2,6].

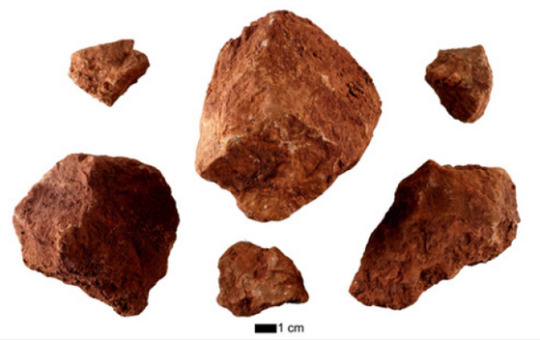

Vayots Dzor Province in South-Eastern Armenia is among the rich areas where painted earths are widely spread and are represented by large deposits in Agarakadzor and Yeghegnadzor [6]. Meanwhile presence of red and brown ochre are very well visible in the south-western part of the province, in the gorge of the Gnishik River (Gnishikadzor, “dzor” in Armenian means gorge), which is also known as the Noravank Gorge, due to the monastic complex of Noravank (means New Monastery in Armenian) located here The samples analysed in this article was taken from the foothills of the Noravank Monastery, left from the road, where section of red coloured sediment is exposed during the construction of the road (Figure 1). Red colour rocks in the area of the Noravank Gorge (Gnishikazdor) are represented by the sedimentary strata of the Upper Devonian and are determined by the Famennian Stage (375-359 million years). In this area, they are exposed in the core of the so-called Gnishik anticline, spread in the basin of the middle reaches the Gnishik River. The entire stratum of Devonian deposits here is 385 m thick and is represented by ferruginous dark gray and fractured organogenic limestones, which then turn into sandy limestones with a phosphorite content. Ferruginous quartzites with large impregnations of iron oxides are also exposed in ferruginous sandy limestones, shales with carbonate nodules and rich brachiopod fauna: Productella capetatiformis Abrahamian, Plicatifera meisteri, Cyrtospirifer verneuili, Camarotoechia baitaversis, etc (Figure 2).

First evidence of exploitation of similar red coloured ochre from the area was recorded in Late Chalcolithic horizons of Areni-1 cave, located 7km north from the exposure, 2km northeast from the village of Areni, on the left bank of the Arpa River, near the point of its confluence with the tributary Gnishik and at an elevation of 1070m above the sea level. Areni-1 is a threechambered karstic cave. The excavations here began in 2007 and the major significance of this archaeological site was abundantly clear during the initial excavations when very well preserved Chalcolithic (4,300 – 3,400 BCE) and Medieval (4th –18th centuries CE) occupations were exposed. Areni-1 exhibits a transitional culture between Chalcolithic and EBA, which sheds light on the formation and the early stages of the Kura-Araxes culture in the region. Chalcolithic finds from the first gallery of the cave include numerous large storage vessels, some of which contained human skulls – of two adolescent males and a female. Grape remains and vessels typically used for wine storage, together with the results of chemical analyses of the contents, point to Chalcolithic wine production at the site. The cave had been used for different purposes since the end of the 5th millennium BCE: it was a shelter, a storeroom for food; it was used for wine production and for ritual purposes, including burial. All the data indicate clear social complexity and a ritual/productive area. Its strategic location, suitable climate of the Vayots Dzor Province compared to the surrounding mountainous area, and its numerous watercourses and highly fertile soils, make this area especially suitable for human settlement and agricultural development. Indeed, the oldest leather shoe in Eurasia and one of the oldest pieces of evidence for wine production was discovered in the Areni-1 Cave, dated to the Late Chalcolithic – and wine is still today one of the area’s main products [7-15].

Local red ochre was used by the Chalcolithic inhabitants of the cave in different purposes, i.e., for rock-paintings, in symbolic behavior (for coloring the inner parts of the ritual vessels and clay constructions, the compacted floors, as red ochre was the symbol of blood and revival as well as for decorating basketry and pottery [11,13] (Figure 2).

Experimental

The samples from Gnishikadzor or the Noravank were analysed by different techniques. Below are reported the techniques applied to characterize completely these fabulous stones.

Techniques

Scanning electron microscopy (SEM) with energy dispersive spectroscopy (EDS): SEM-EDS micro-morphological and chemical investigations were carried out by a LEO 1450 VP -INCA 300 scanning electron microscope coupled with a electronic probe for X-ray microanalysis, resolution of 3,5nm with the possibility to analyze nonconductive sample by operating in novacuum conditions. The interfacing with EDS gives the possibility to have qualitative and quantitative composition of elements into area observed. For quantitative analysis this method is not sensible under 0.1% in weight. Electron beam energy is 20keV to allow the detection most of the chemical elements starting from boron. Under these experimental conditions the ancient samples have been analysed without any treatment, by using the apparatus in low vacuum. The observations in backscattered electron allow suggest the presence of different elements trough contrast variations (atomic number contrast).

FT-IR spectroscopy: The FTIR microspectra were collected with a Bruker Optic Alpha-R portable interferometer with an external reflectance head covering a circular area of about 5mm in diameter. The samples were placed directly in front of the objective and spots were selected for analysis. The recorded spectral range was 7500-375cm-1 acquired with 200 scans or more, with a resolution of 4cm-1. Spectra reported in the text, however, show only the spectral range where absorption bands were observed (4000-375cm-1). This analysis is non-destructive and non-invasive. The spectra of powdered samples were obtained using the diffuse reflectance infrared Fourier transform (DRIFT) module. In addition, very small amounts of samples were dispersed in potassium bromide (KBr, FTIR grade purity, Fluka) at different concentrations (sample/ KBr 1/100 to sample/KBr 1/1000). These were studied by collecting 200 scans or more in the same spectral range and resolution. Fourier-Transform infrared (FTIR) spectra were recorded using an Alpha FT-IR spectrometer (Bruker) equipped with the Diffuse Reflection Infrared Fourier Transform (DRIFT) module in the spectral range 7500-375cm-1 at a resolution of 2cm-1 cumulating at least 200 scans. The powdered samples were dispersed in potassium bromide (KBr), FT-IR grade of purity, Fluka) in excess. Figures reported spectral ranges where absorption peaks were detected

XRD diffraction analysis: The X-ray powder diffraction analysis has been performed in the angular range 10-90° in 2θ with a Panalytical X’Pert Pro MPD diffractometer (Cu Kα radiation, λ=1.54184 Å) equipped with X’Celerator ultrafast RTMS detector. The angular resolution (in 2θ) was 0.001°. A 0.04 rad soller slit, a 1° divergence slit, and a 20mm mask have been used on the incident beam path, while a 6.6mm anti-scatter slit and a 0.04 rad collimator have been used on the diffracted beam path. Phase identification has been performed with the Panalytical High Score Plus software.

Results and Discussion

XRD spectra (Figure 3) show prevalently the presence of ochre. From phase analysis the following chemical composition was evidenced; CaCO3, SiO2, Al2O3, Fe2O3, Al2S2(OH)4.

Different stones from the same locality have been cut off. The stone has been cut and analyzed in all parts by FTIR. It was very hard to cut it. Internal part was grey and white. The spectra obtained is reported and compared in figure 4. At 536cm-1 is hematite band and at 473cm-1 is iron oxide band. Quartz band is at 799cm-1. Infrared spectroscopy was employed to analyze the exterior red surface of the stone samples. In addition, a small stone was cut in order to examine the inner side, which appeared grey and white.

Specular reflectance produces derivative- shaped peaks in the region below 1200cm-1 because of the restrahlen effect [16]. All spectra show intense band with peaks at 1545 and 1418cm-1 assigned to the C-O stretching mode of calcite (sparitic limestone). The features at 880 and 2515cm-1 also belong to calcite and respectively assigned to O-C-O bending and combination mode. The features in the 1200-1000 cm-1 interval confidently suggest the presence of silicates, probably kaolin, characterizes by the peaks at about 3690 and 3620 cm-1 assigned to C-H stretching modes [17]. At the lower frequency range of the spectra reported in figures 5a & 5b, bands are also observed at 545 and 466cm-1, indicating the existence of iron oxides molecules in the samples [18].

The proposed assignment seems supported by the absence of mentioned features in the spectra of clear and dark points of the samples. In the last case infrared analysis shows the presence of calcium carbonate as unique component of the stone. Compares micro-FTIR (a) and DRIFT spectra (b) of a red point of the Noravank stone. Spectral differences observed can be attributed only to the different techniques employed. In fact, DRIFT spectrum confirms the components individuated in reflectance analysis suggesting only a minor content of calcium carbonate with respect to the silicates content. In addition, the DRIFT spectrum of a sample of Armenian bole is also reported (c).

SEM- EDS. The micromorphological analysis, using SEM the image detector with secondary electron resolution in non-in-air conditioning has obtained a very well-defined aspect compared to the petrographic material, with clear crystalline formations of a solid structure is observable figure 6.

Other parts of the same stone were analyzed by SEM to identify the different structures, as tested with the other techniques used figure 7 (Table 1). Various points in the area shown in figure 7 and are analyzed in EDS as reported in table 2. Several EDS analyses were carried out on several areas of the sample, the more significative are reported in table 2.

What was observed at the SEM-EDS is in line with the other types of investigations, while not providing data on the molecular formulations, but only on the composition of elements, it may be useful to consider the morphological and microstructural aspect, where, for example, it is never found its trigonal crystalline habit, but the observation of powdery material, figure 7, could be associated with its presence in conjunction with quartz and other minerals, which would explain the red color felt when handling the stone.

Hematite gave following oxide compositions; FeO 29.8%, Fe2O3 15, MgO 2,6, Al2O3 8.1, CaO 16.55, SiO2 26.7, K2O 0.55, TiO2 0.4%. The concretions with following oxide composition have been detected FeO 5.63, Fe2O3 2.8, MgO 1.55, Al2O3 11.42, CaO 33.34, SiO2 44.4.

A concretion is a hard, compact mass of matter formed by the precipitation of mineral cement within the spaces between particles and is found in sedimentary rock or soil. Concretions form within layers of sedimentary strata that have already been deposited. They usually form early in the burial history of the sediment before the rest of the sediment is hardened into rock. This concretionary cement often makes the concretion harder and more resistant to weathering than the host stratum. They are commonly composed of a carbonate mineral such as calcite; an amorphous or microcrystalline form of silica such as chert, flint, or jasper; or an iron oxide or hydroxide such as goethite and hematite. They can also be composed of other minerals that include dolomite, ankerite, siderite, pyrite, marcasite, barite, and gypsum. Although concretions often consist of a single dominant mineral, other minerals can be present depending on the environmental conditions, which created them. For example, carbonate concretions, which form in response to the reduction of sulfates by bacteria, often contain minor percentages of pyrite. Other concretions formed as a result of microbial sulfate reduction, consist a mixture of calcite, barite, and pyrite.

Conclusion

Implementation of different techniques applied to characterize completely the mineral pigment sample from Noravank is а valuable data, showing a need to conduct similar analyses for the other deposits in the Vayots Dzor Province and all Armenia. Such a study can help to create a reliable database of the mineral pigments of the country and to compare the results with the similar studies of the samples discovered from the archaeological contexts. The mineral pigments, especially, ochre, have been intensively used by prehistoric and historic populations for different purposes, especially in creation of rock-paintings, decorating the pottery and basketry, as well as in rituals. Exploitation of pigments by ancient societies will shed new light on the questions of utilization of mineral resources in the territory of Armenia and the raw-material circulation in the landscape, as well as aspects of symbolic behaviour during the complex ritual games, which took place inside the caves and other sacral spaces. This also can be significant example of benefit achieved by the combination of different scientific disciplines and tools regarding deeper study of the ancient past (Figure 8).

To Know More About Juniper Online Journal Material Science Please click on:

https://juniperpublishers.com/jojms/index.php

For more Open Access Journals in Juniper Publishers please click on:

https://juniperpublishers.com/index.php

#Juniper Publishers#Material Science#Materials Theory#Structural Materials#Juniper publisher reviews#Juniper publisher journals

3 notes

·

View notes

Text

Zinc Oxide Furnace Manufacturers in India: Pioneers of Industrial Innovation

In the dynamic world of industrial manufacturing, zinc oxide plays a crucial role in various sectors, including automotive, rubber, ceramics, and pharmaceuticals. This versatile compound is produced through sophisticated processes involving zinc oxide furnaces. India, with its burgeoning industrial sector, is home to several leading manufacturers of zinc oxide furnaces, each contributing to the country's technological advancements and economic growth.

The Role of Zinc Oxide in Industry

Zinc oxide, a white, powdery substance, is integral to numerous industrial applications:

Rubber Industry: Enhances the durability and performance of rubber products.

Ceramics: Used in glazes and pigments to produce high-quality ceramics.

Pharmaceuticals: Acts as an astringent and skin protectant in ointments and creams.

Paints and Coatings: Provides protective and decorative qualities in paints.

The production of high-quality zinc oxide relies heavily on advanced furnace technologies, underscoring the importance of sophisticated manufacturing equipment.

Key Players in the Indian Market

India boasts several prominent Zinc Oxide Furnace Manufacturers India known for their technological expertise and innovation. Here are a few of the leading names in the industry:

Hindustan Zinc Ltd.: A major player in the zinc industry, Hindustan Zinc is renowned for its state-of-the-art furnaces and commitment to sustainable practices.

Kothari Industrial Corporation: Specializes in designing and manufacturing efficient zinc oxide furnaces with a focus on energy savings and high output.

Mohan Metal Corporation: Known for their custom-built furnaces, Mohan Metal Corporation excels in providing tailored solutions to meet specific industrial needs.

Siddharth Enterprises: Offers a range of furnaces designed for optimal performance and durability, catering to both small and large-scale operations.

Innovative Features of Modern Zinc Oxide Furnaces

The evolution of zinc oxide furnace technology has brought about several innovative features, enhancing efficiency and performance:

Advanced Control Systems: Modern furnaces are equipped with sophisticated control systems that ensure precise temperature regulation and process monitoring.

Energy Efficiency: New furnace designs focus on reducing energy consumption, helping manufacturers lower operational costs and environmental impact.

High Purity Production: Enhanced furnace technology allows for the production of zinc oxide with minimal impurities, meeting the stringent quality requirements of various industries.

Automated Operations: Automation in furnace operations reduces manual intervention, improving safety and consistency in the production process.

Challenges and Solutions in Furnace Manufacturing

Despite the advancements, manufacturers face several challenges in the zinc oxide furnace industry:

High Initial Investment: The cost of advanced furnace technology can be substantial. However, long-term savings in energy and operational efficiency often justify the investment.

Maintenance and Repairs: Regular maintenance is crucial to ensure the longevity and optimal performance of furnaces. Many manufacturers offer comprehensive service packages to address these needs.

Regulatory Compliance: Meeting environmental and safety regulations can be challenging. Leading manufacturers stay ahead by incorporating eco-friendly technologies and adhering to industry standards.

The Future of Zinc Oxide Furnace Technology

As industries continue to evolve, the demand for high-quality zinc oxide and advanced furnace technologies is expected to rise. Indian manufacturers are well-positioned to lead this transformation due to their commitment to innovation and quality. Key trends shaping the future include:

Sustainability: Increasing emphasis on sustainable practices is driving the development of more eco-friendly furnace technologies.

Digital Integration: The integration of digital technologies and IoT (Internet of Things) in furnace operations is set to enhance efficiency and data analytics capabilities.

Customization: Growing demand for customized solutions is prompting manufacturers to offer more tailored furnace designs.

Conclusion

Zinc oxide furnace manufacturers in India are at the forefront of technological innovation, contributing significantly to the country's industrial landscape. Their commitment to quality, efficiency, and sustainability ensures that India remains a key player in the global zinc oxide market. As technology continues to advance, these manufacturers are poised to meet the evolving needs of various industries, driving growth and setting new standards in furnace manufacturing.

In conclusion, the evolution of zinc oxide furnace technology reflects the broader trends of industrial advancement. Indian manufacturers, with their blend of traditional expertise and modern innovation, are well-equipped to tackle future challenges and seize emerging opportunities. The future looks promising as they continue to lead in producing high-quality, efficient, and sustainable zinc oxide furnaces.

1 note

·

View note

Text

Epoxy Coatings Manufacturer & Supplier in Ahmedabad by Angel Coating

Epoxy Coatings Manufacturer & Supplier in Ahmedabad

Angel Coating is top most Epoxy Coating, Epoxy Primer and Epoxy Pigment, Epoxy Paint Manufacturer in Ahmedabad, India.

Types of Epoxy Coating:

⁍⁍ Epoxy Primer:

Angel Coating's Epoxy Primer 2k primer can be used for auto body refinishing with high chemical and anticorrosive protection with very good adhesion on all types of substrates like iron, steel, galvanized and aluminum.

We offer large range of epoxy primers from general industrial epoxy primers to high corrosion resistance epoxy primers including zinc phosphate, red oxide, zinc chromate and MIO based epoxy primers.

We also offer range of zinc rich epoxy primers for application requiring very high corrosion resistance like marine applications, windmills, chemical tanks etc.

⁍⁍ Epoxy Pigmented:

Epoxy Pigment is excellent corrosion resistance, acid & alkali resistance and UV resistance. With strong film properties and chemical & heat resistance along with competitive pricing these are preferred coatings for applications like internal automotive parts, under bodies, industrial equipment etc.

Flooring of industrial buildings especially for Chemical, Bulk Drug, Pharmacy, Auto-mobile Industries, Electroplating Plants, Power Plants, Process Floor Areas, Acid Storage Plants where chemical, abrasion resistance is required.

⁍⁍ Epoxy Coating Features:

Highly effective

Excellent gloss

Smooth finish

For further information, please contact to "Angel Coating" on below details;

📧 Mail: [email protected]

📱 Call Us: +91 94290 02704

🌐 Website: https://angelcoating.com/products/industrial-coatings/epoxy-coatings/

0 notes

Text

Different Types of Pigments Used in Cosmetics

A pigment is a powder used to add color or change the visual appearance of a product. Pigments are a type of compound color when applied to any material. Fashion, art, medicine, and even computer displays have all been shaped by the simple application of this compound. The majority of their applications are in the textile, chemical, cosmetic, food, drugs, plastics, and paint industries.

When it comes to using products with these pigments, it is crucial to apply high-quality products to the skin. No doubt, almost every woman today uses some kind of cosmetics on a daily basis, making it crucial to understand what color additives they contain. Talking about superior quality pigment colors, Hridhan Chem Pvt. Ltd. is India’s leading manufacturer and supplier of dyes and pigments that follow stringent FDA safety measurements and quality standards to ensure 100% reliability and efficacy.

All right! In this blog post, we will walk you through different types of pigments used in cosmetics and personal care products.

So, let’s get started!

What Are Pigments?

A pigment refers to a powder that is added to impart color or change the visual appearance of any product, making it more appealing and attractive. Pigments are not soluble and chemically don’t show any reaction when dissolved in water or another medium. On the other hand, dyes refer to water-soluble color additives at some stage.

Pigments are colorants broadly classified into two types – organic pigments and inorganic pigments.

Iron oxides, chromium, ultramarine, etc., are examples of inorganic pigments used in cosmetic manufacturing. In contrast, Zinc oxide and titanium dioxide are white colorants most commonly found in every cosmetic. The colorants used to produce cosmetics and personal care products tend to be quite opaque and are more resilient to solvents.

Organic Colors

Organic colors are further classified on the basis of:

Botanicals:

These color additives are naturally derived for use in different cosmetic applications.

Beetroot powder and henna are the two most popular botanicals used in cosmetics.

There are limited botanicals approved and permitted for use in cosmetics.

These colorants do not stick well with makeup.

These botanicals are 100% safe to be used on any skin or body.

Synthetic Dyes:

These color additives are produced from coal-tar derivatives and petroleum and are refined in laboratories as they include toxic heavy metals.

It is possible for these pigments to be absorbed by the oral cavities around the mouth.

They can be harmful as they drain the oxygen when they get absorbed into the skin.

Synthetic dyes tend to have bright hues on their list.

Lakes:

Lakes are manufactured through the reaction of a binder, like a dye or metallic salt.

Lakes tend to have carcinogenic properties which are not good for health.

Lakes are best known for imparting bright colors.

It contains aluminum as one of its elements.

Understanding Different Pigments Colors

There is a diverse range of inorganic color pigments containing inorganic colorants, Lo Micron colors, and blended inorganic are used in the formulation of cosmetic product manufacturers. India exports these pigments as well as caters to the pigment needs of locally produced cosmetic products with the help of reputed cosmetic color manufacturers.

Organic color pigments are classified on the basis of regulatory requirements, such as D&C Lake Colors (Drug and Cosmetics Lake Colors), FD&C Lake Colors (Food Drug and Cosmetics Lake Colors), Non-D&C and FD&C Pigments, and EEC Lake Colors. To meet the needs of the European market for cosmetic products, EEC lake colors are prepared according to the directive from the European Economic Community (EEC).

To create cosmetics color solutions for the US market, leading pigment manufacturers in India like Hridhan Chem Pvt Ltd follow FD&C color guidelines.

Conclusion

In the bottom line, it can be said that the use of pigments is widespread for the manufacturing of cosmetics & personal care products. There are some stringent rules and guidelines by the FDA on the usage of these pigment colors to ensure the safety and efficacy of a product. They are advised to use only FDA-certified and approved pigment colors from reliable manufacturers and exporters of synthetic dyes and pigments for the formulation of cosmetic products.

Hridhan Chem is a leading manufacturer and exporter of cosmetic colors and pigments exporting superior quality dyes and pigments to clients worldwide. If you are a cosmetic product manufacturer in need a high-quality synthetic dyes or pigment colors, Hridhan Chem is your go-to choice for your business. For more information on a wide range of colors and pigments that we manufacture at our facility, contact us today!

0 notes

Text

Water-Based Pigment Inks For Textile & Apparel Market - Forecast(2024 - 2030)

Water-Based Pigment Inks For Textile & Apparel Market Overview

Water-Based Pigment Inks For Textile & Apparel Market size is expected to be valued at $272.0 million by the end of the year 2026 and is set to grow at a CAGR of 5.3% during the forecast period 2021-2026. Water-based pigment ink contains pigments in a colloidal suspension with water as solvent. In comparison to other types of pigment inks, water-based pigment inks produce brighter colors and also provide light-fastness. The water-based pigment inks come in larger particle levels and therefore, it is not easily decomposed by the light. Water-based pigment inks tend to resist water and UV light better than dye-based ink and can restrain from fading for a longer period. The increasing adoption of water-based pigment inks owing to their economical uses and the growth surge of the textile industry is also contributing to the growth of the Water-Based Pigment Inks For Textile & Apparel Market. This is majorly driving the demand for Water-Based Pigment Inks For Textile & Apparel Market.

COVID-19 impact

Amid the Covid-19 pandemic, the water-based pigment inks market was hugely affected, owing to the various legal and economic restrictions laid by governments across the world. The decline in the growth of the related industries is also restricting the growth of the Water-Based Pigment Inks For Textile & Apparel Market. For instance, Indian textile and apparel exports in 2020-2021 are almost 13% less (in dollar terms) than the previous year, provisional data available with the Cotton Textiles Export Promotion Council shows. The exports were worth US$29 billion last year as against US$34 billion in 2019-2020. According to the National Council of Textile Organizations (NCTO), the U.S. textile and apparel shipments decreased from US$75.8 billion in 2019 to US$64.4 billion in 2020. This is majorly restricting the growth of the Water-Based Pigment Inks For Textile & Apparel Market.

Report Coverage

The report: “Water-Based Pigment Inks For Textile & Apparel Market– Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the Water-Based Pigment Inks for Textile & Apparel Industry.

By Resin Type: Acrylic, Alkyd, Epoxy, Polyamide, Hydrocarbon, Melamine, Maleic, Shellac, and Others.

By Pigment Type: Organic Pigment, Inorganic Pigment (White [Titanium Dioxide, Zinc Oxide, Zinc Sulfide and Others], Colored [Chrome Yellow, Molybdenum Orange, Iron Red and Others], Black, Metallic, and Others.

By Application: T-shirts, Signage Flags, Home Furnishing Fabrics, Sports Apparel, Fashion Textile and Others.

By Geography: North America (USA, Canada, Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), APAC (China, Japan India, South Korea, Australia & New Zealand, Indonesia, Taiwan, Malaysia, Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and Rest of South America) and RoW (Middle East and Africa).

Request Sample

Key Takeaways

Asia-Pacific market held the largest share in the Water-Based Pigment Inks For Textile & Apparel Market owing to increase in investments in the textile industry and growth of the textile industry.

Increasing adoption of water-based pigment inks is one of the major factors driving the Water-Based Pigment Inks For Textile & Apparel Market.

The growth in the textile industry is driving the demand for Water-Based Pigment Inks For Textile & Apparel Market.

Amid the Covid-19 pandemic, the Water-Based Pigment Inks For Textile & Apparel Market were majorly affected in terms of sales and distribution during the global pandemic. The situation is however set to improve by the end of the year 2021.

Water-Based Pigment Inks For Textile & Apparel Market Segment Analysis –By Resin Type

Acrylic segment held the largest share of 38% by revenue in the Water-Based Pigment Inks For Textile & Apparel Market in the year 2020. Acrylic based pigments are water-based pigments and is produced through the process of rheology. It is mostly used on textile substrates such as cotton/polyester combined fabric, cotton fabric and other textile materials. Acrylic resin emulsion is soft, anti-crocking agent and acts as the printing binder for textile printing and finishing. Acrylic resin emulsion is soft, anti-crocking agent and acts as the printing binder for textile printing and finishing. This will exponentially increase the demand for acrylic segment in the Water-Based Pigment Inks For Textile & Apparel Market.

Inquiry Before Buying

Water-Based Pigment Inks For Textile & Apparel Market Segment Analysis – By Pigment Type

Inorganic pigment segment held the largest share of 59% by revenue in the Water-Based Pigment Inks For Textile & Apparel Market in the year 2020, with a growing CAGR of 4.89% during the forecast period 2021-2026. The color pigment inks, especially chrome yellow garnered the most demand owing to its power of lightfastness. Chrome yellow consists of lead chromate and solid solutions of lead chromate and lead sulfate, which reacts to acid and alkalis and changes color accordingly. Reaction of chrome yellow with acid leads to the formation of orange dichromate ion and the reaction with alkali leads to the formation of pale-yellow chromate ion. Chrome yellow is a crystalline mineral consisting of lead chromate which can vary in hue from primrose yellow to orange. The yellow chrome pigments consist of fine particles that are dense and opaque. This is driving the demand for inorganic pigment in the Water-Based Pigment Inks For Textile & Apparel Market.

Water-Based Pigment Inks For Textile & Apparel Market Segment Analysis – By Application

Fashion textile segment held the largest share in the Water-Based Pigment Inks For Textile & Apparel Market in the year 2020, with a growing CAGR of 6.0% during the forecast period 2021-2026. The increase in the use and production of fashion textiles in the recent days is one of the major factors driving the demand for Water-Based Pigment Inks For Textile & Apparel Market. According to World Resource Institute, 20% of water pollution comes from the traditional textile coloration. Whereas the use of water-based pigment inks is eco-friendly, eliminates VOC emissions due to which manufacturers are leaning towards water-based printing ink which is driving the demand for Water-Based Pigment Inks For Textile & Apparel Market.

Schedule a Call

Water-Based Pigment Inks For Textile & Apparel Market Segment Analysis – By Geography

Asia-Pacific region held the largest share of 37% in the Water-Based Pigment Inks For Textile & Apparel Market in the year 2020, and is growing with a CAGR of 6.2% during the forecast period 2021-2026. According to data released to the Global Times by e-commerce giant Alibaba in China, clothing products were the best performer in the second half of the year 2020, climbing from ninth to fourth place on a list of the most popular product categories. The amount of apparel sold on Alibaba.com increased by 274 percent year over year in September, with the number of purchasers increasing by 266 percent. Furthermore, the textiles and apparel industry in India accounts for 13% of industrial production and 12% of export revenues, with a GDP contribution of 2.3%. The Ministry of Industry and Commerce of Paraguay stated in February 2021 that it will invest US$1.1 million in the manufacturing sector, primarily helping the apparel, textiles, and footwear industries, as well as other assembly operations. According to a recent report by the Australian Fashion Council (AFC), the Australian fashion and textile industry contributed more than US$18.6 billion (Au$27.2 billion) to the country's GDP in 2020-21. This is driving the Water-Based Pigment Inks For Textile & Apparel Market in the Asia-Pacifc region.

Water-Based Pigment Inks For Textile & Apparel Market Drivers

Increasing adoption of water-based pigment inks is one of the major factors driving the Water-Based Pigment Inks For Textile & Apparel Market

Water-based pigment inks has more advantages such as improved plant safety and a significantly lower environmental impact as compared to other types of pigment inks. Water-based pigment inks provide viable solutions to rather complicated problems in the textile industry such as pattern printing, dye ink absorption into the fibre and others. The usage of water-based pigment inks also poses less environmental threat as water-based ink pigments usually contains large volumes of water and a substantially lower content of (>1%) volatile organic compounds as compared to other types of pigment inks. This also makes water-based pigment inks to be easily stored, without much damage to the surroundings. Water-based pigment inks absorbs better than solvent-based pigment inks and thus gives consistent pigment to the fabric. Water-based pigment inks are also inflammable as compared to solvent-based pigment inks. This is majorly driving the demand for Water-Based Pigment Inks For Textile & Apparel Market.

Water-Based Pigment Inks For Textile & Apparel Market Challenges

Volatile price of water-based pigment ink is significantly restricting the growth of the Water-Based Pigment Inks For Textile & Apparel Market

The volatile prices of the various raw materials used in manufacturing water-based pigment inks is one of the major challenges restricting the growth of the Water-Based Pigment Inks For Textile & Apparel Market. For instance, Allnex, a global producer of industrial coating resins and additives, increased the prices of solvent borne and waterborne acrylics resins in Europe, Middle East and Africa during March 2021. This price hike further increased the price of critical raw materials, leading to an increase to US$0.18 /Kg (€/0.15 kg). Thus, the cost of raw materials is continuously increasing or fluctuating because of factors such as transportation & logistics, increasing demand, depletion of natural resources and more, which is affecting the price of water-borne pigment inks. Furthermore, in March 2021, the British Coatings Federation (BCF) has warned that a lack of critical raw materials and packaging, as well as major price hikes, could be the most pressing challenges for the coatings and printing ink industries in 2021. Thus, the volatility and increase in prices of raw materials such as titanium dioxide, acrylic, epoxy, polyamide and more is expected to create a significant challenge for the water-borne pigment inks market manufacturers during the forecast period.

Buy Now

The curing time, printing speed, and cost restriction of water-based pigment inks is also restricting the growth of the Water-Based Pigment Inks For Textile & Apparel Market

As much as water-based pigment inks has advantages, it also has various disadvantages such as high cost, more curing time, and printing speed restriction. This is limiting the growth of the Water-Based Pigment Inks For Textile & Apparel Market. When compared to solvent based pigment inks, water-based pigment inks take significantly longer time to cure. During the curing phase, water-based pigment inks are more vulnerable to effect of environmental conditions, such as temperature and humidity. Hence, solvent-based resins are preferred for applications in humid environments that don't allow water-based pigment inks to cure properly. Also, solvent-based pigment inks are typically more resilient than water-based resins during the curing of the coating. According to the Lawson Screen & Digital Products, Inc., water-Based Ink can be more expensive and it doesn't work well dark colored garments because of its lack of opacity and bleed-resistance. In addition, the capital and fixed costs of switching from solvent-based to water-based technology are significant. Hence, solvent-based resins are still widely used by small-scale businesses in developing countries. Furthermore, due to the high surface energy of the water component, water-based pigment inks cannot wet and print smoothly on textile and apparel materials. According to the Ink Intelligence LLC, in the modern textile printing, the biggest challenge for water-based inks is to keep up with the high press speeds (in excess of 1000 ft/min) commonly in place for solvent inks. This is restricting the growth of the Water-Based Pigment Inks For Textile & Apparel Market.

Water-Based Pigment Inks For Textile & Apparel Market Industry Outlook

Acquisitions and mergers, production expansion, facility expansion collaborations, partnerships, investments, are some of the key strategies adopted by players in the Water-Based Pigment Inks For Textile & Apparel Market. Major players in the Water-Based Pigment Inks For Textile & Apparel Market are:

Sun Chemical

DuPont de Nemours, Inc.

Huntsman Corporation

INX International Ink Co.

Mimaki Engineering Co., Ltd.

Avient Corporation

Huber Group

Spectrachem

Velvet Jet

Molkem

Inknovators

Achitex Minerva Group

Livingink

Virusinks

Covestro AG

Acquisitions/Technology Launches

In June 2021, Sun Chemical and DIC Corporation finalized the acquisition of BASF’s global pigments business, known as BASF Colors & Effects (BCE), a strategic partner which aims for high growth and high added value by expanding functional pigments into niche applications.

In June 2019, Huntsman Corporation launched a water-based digital ink “Novacron Advance. The product is used in cellulosic and polyester/cotton blends.

#Water-Based Pigment Inks For Textile & Apparel Market#Water-Based Pigment Inks For Textile & Apparel Market Share#Water-Based Pigment Inks For Textile & Apparel Market Size#Water-Based Pigment Inks For Textile & Apparel Market Forecast#Water-Based Pigment Inks For Textile & Apparel Market Report#Water-Based Pigment Inks For Textile & Apparel Market Growth

0 notes

Text

An Overview of Metallic Stearates for PVC Applications

Have you ever wondered what makes your plastic pipes so smooth and your window profiles so lustrous? It isn’t a magic trick – it’s the influence of metallic stearates. These additives play a crucial role in keeping the PVC world running seamlessly, contributing to the polished finish, consistency and overall quality of various products.

So, what are these metallic stearates for Polymer Applications anyway?

Metallic stearates are metal soaps formed by the reaction of metal salts with 18-carbon chain fatty acid, known as stearic acid. The process of creating metallic stearates involves substituting the hydrogen in stearic acid’s carboxylic group with a metal cation.

This metal cation is derived from various sources, including direct metal, metal oxide, metal hydroxide, as well as metal sulphates and chlorides. These metal cations can include calcium, zinc, magnesium and aluminium.

Metallic stearates are commonly used as lubricants, release agents, and stabilizers in various industries such as plastics, rubber and paints.

Metallic Stearates play several crucial roles

Lubrication.

Good for lubrication, metallic stearates reduce friction during processing. This leads to smoother operations, less wear and tear of equipment, better finished products and an overall more efficient production process.

Prevents Degradation

Metallic Stearates have a relatively higher melting point. It develops a lubricating interface and prevents the degradation of materials, especially PVC. This maintains the strength and performance of the product, even in highly demanding applications.

Maintains Integrity of PVC Products.

Particularly in the plastics industry, metallic stearates prevent polymers like PVC from sticking to molds and dies, ensuring easy release, reducing porosity and maintaining the integrity of the final products.

These properties allow its use in a wide range of applications, from simple plastic components to complex structures in several industries such as Plastics & Rubber, Building & Construction and the Paints & Coatings industry.

But the story doesn’t end there. Each metallic stearate has its own set of advantages, making them essential additives in their respective industries.

Calcium Stearate

This lightweight PVC processing aid provides excellent lubrication properties, improves processability and adds volume to PVC formulations.

Zinc Stearate

This metal stearate acts as a heat stabilizer and an anti-blocking agent, ensuring a consistent quality of production output.

Barium Stearate

This high-performance metal soap is ideal for high-speed processing and boasts excellent heat resistance.

Aluminium Stearate

It serves as a vital component for achieving uniform dispersion of pigments within plastic formulations, enhancing colour consistency throughout the formulation.

Sodium Stearate

This additive is often used as an emulsifying agent and a thickener in various industries. It helps stabilize mixtures of oil and water, enhancing the consistency of formulations.

Lead Stearate

(Use with caution considering environmental regulations)

The ultimate lubricant that offers unmatched smoothness and can prevent PVC from breaking down under high processing temperatures.

Our range of metallic stearates

In summary, metallic stearates go beyond being mere additives for processing – they form the essential foundation for creating top-notch PVC products.

The key lies in selecting the right stearate tailored to your specific application, and that is where our expertise comes in. We are here to help you navigate the world of PVC additives and find the perfect blend for your needs.

At Rewa Stabilizers & Lubricants, we specialize in providing metallic stearates and powder lubricants for PVC applications according to your specifications.

As India’s premier metallic stearates manufacturer, our new-age production facilities enable us to deliver high-quality metal stearates. Rigorous quality checks are integral to our process, reflecting our commitment to producing premium metallic stearates in the PVC industry.

Contact us for the best quality metallic stearates for your PVC applications.

0 notes

Text

Navigating the Zinc phosphate Price chart: Understanding Dynamics and Implications

Zinc phosphate, a versatile chemical compound with diverse applications in industries such as paints and coatings, corrosion protection, and metal surface treatment, plays a pivotal role in various manufacturing processes. Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as Excel files that can be used offline. The Zinc phosphate Price chart, including India Zinc phosphate price, USA Zinc phosphate price, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Overview of Zinc Phosphate:

Zinc phosphate, represented by the chemical formula Zn3(PO4)2, is an inorganic chemical compound consisting of zinc cations and phosphate anions. It is commonly used as a corrosion inhibitor, pigment, and metal surface treatment agent in various industrial applications. Zinc phosphate is available in different forms, including crystalline powder, granules, and aqueous solutions, to cater to specific application requirements. It is valued for its ability to provide effective corrosion protection, improve adhesion, and enhance paint performance in coatings formulations.

Request for Real-Time Zinc Phosphate Prices: https://www.procurementresource.com/resource-center/zinc-phosphate-price-trends/pricerequest

Expanded production capacities led to oversupply, contributing to ongoing price declines. In Europe, geopolitical disruptions related to the Russia-Ukraine crisis created challenges throughout the first quarter, resulting in a significant and gradual decline in zinc phosphate prices that extended into the second quarter.

Meanwhile, North America experienced gradual price declines in the first quarter due to low demand and diminishing market confidence. The second quarter saw declining demand from the automobile and construction industries, with a weakening economy further eroding buyer confidence, intensifying the drop in zinc phosphate prices.

Industrial Uses Impacting the Zinc phosphate Price Trend:

Zinc phosphate finds a multitude of industrial applications owing to its excellent anti-corrosive properties and versatile nature. One of its primary uses is in the coatings industry, where it is employed as a corrosion inhibitor and rust converter. Zinc phosphate coatings are extensively used in the automotive and construction sectors to protect metal surfaces from corrosion and enhance their longevity.

It also acts as a pigment in paints, contributing to both the anti-corrosive properties and the coloration of the coatings. Furthermore, zinc phosphate is utilized as a bonding agent in dental cements for dental applications. In the chemical industry, it plays a role in the synthesis of various chemicals. These wide-ranging industrial uses highlight the significance of zinc phosphate in corrosion protection and other applications across different sectors.

Factors Influencing the Zinc Phosphate Price Trend:

Raw Material Prices:

The cost of raw materials, primarily zinc oxide and phosphoric acid, significantly impacts the price of zinc phosphate. Zinc oxide serves as the primary source of zinc in zinc phosphate production, while phosphoric acid provides the phosphate component. Fluctuations in zinc oxide prices, influenced by factors such as mining costs, supply-demand dynamics, and currency fluctuations, directly affect the production cost of zinc phosphate. Changes in phosphoric acid prices, driven by factors such as phosphate rock prices, production capacity, and market conditions, also impact zinc phosphate pricing.

Supply-Demand Dynamics:

The price trend of zinc phosphate is closely monitored by stakeholders across different sectors due to its significance in production processes and end-use applications. Understanding the factors driving the price fluctuations of zinc phosphate is essential for businesses to make informed decisions regarding procurement, production planning, and market positioning. In this article, we delve into the intricacies of the zinc phosphate price trend, exploring the key drivers and dynamics shaping its pricing landscape.

Technological Advances:

Technological advancements in zinc phosphate production processes and synthesis methods can impact production costs and pricing dynamics. Innovations in process technology, reaction conditions, and catalysts may improve production efficiency, yield, and quality, leading to cost reductions and enhanced competitiveness. Adoption of advanced process control systems, automation, and digitization can optimize operations, minimize resource consumption, and reduce production costs. Continuous research and development efforts aimed at process optimization and product innovation drive technological advancements in the zinc phosphate industry.

Regulatory Environment:

Regulatory factors, including environmental regulations, safety standards, and import-export regulations, can influence the zinc phosphate market. Compliance with environmental regulations related to emissions, waste disposal, and chemical handling practices may necessitate investments in pollution control technologies and process modifications, leading to increased production costs. Safety standards and regulations governing the handling, storage, and transportation of zinc phosphate also impact operational practices and costs. Changes in import-export regulations and trade policies can affect market access and pricing competitiveness.

Market Competition:

The competitive landscape within the zinc phosphate market influences pricing dynamics. Presence of multiple producers, both domestic and international, fosters competitive pricing strategies aimed at gaining market share. Pricing pressure from substitute products, imports, and new market entrants can constrain pricing power, especially in commoditized market segments. Factors such as product quality, supply chain efficiency, and customer relationships play crucial roles in maintaining pricing stability and profitability amidst competitive pressures.

Monitoring and Analyzing Zinc Phosphate Price Trends:

Tracking the price trend of zinc phosphate involves comprehensive analysis of market fundamentals, industry dynamics, and external factors impacting pricing dynamics. Insights gleaned from industry reports, market intelligence, pricing indices, and supplier announcements offer valuable perspectives on price movements, supply-demand dynamics, and market sentiment. Historical price data and trend analysis aid in identifying patterns, correlations, and seasonal variations, facilitating anticipation of future price movements and risk mitigation.

Conclusion:

The price trend of zinc phosphate is influenced by a complex interplay of factors, including raw material prices, supply-demand dynamics, technological advances, regulatory environment, and market competition. Continuous monitoring, analysis, and proactive risk management are essential for stakeholders to navigate price volatility, optimize procurement decisions, and maintain competitiveness in the global zinc phosphate market. By staying informed about market trends, industry developments, and regulatory changes, businesses can effectively respond to market dynamics and capitalize on opportunities for growth and profitability in the zinc phosphate industry.

Contact Us:

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: [email protected]

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537 132103 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA

0 notes

Text

Navigating Regulatory Challenges in the Ilmenite Industry

Ilmenite: An Important Mineral For Titanium Dioxide Production

It is a weakly magnetic mineral that contains iron, titanium, and oxygen. Its chemical formula is FeTiO3 and it crystallizes in the trigonal system. Its usually contains around 50-65% titanium dioxide and ranges between 35-49% iron(II) oxide. Trace amounts of other elements like magnesium, manganese, chromium are also sometimes present in the mineral. Ilmenite has a black to steel-gray color and its hardness on the Mohs scale ranges between 5-6.5. It has a submetallic to dull luster and leaves a brown streak.

Occurrence and Deposits

It is one of the most abundant titaniferous minerals found on Earth. It occurs in igneous and metamorphic rocks as well as in some sedimentary deposits formed by erosional processes. Some of the major occurrences of ilmenite deposits include Australia, South Africa, Canada, Norway, India, Ukraine, Russia and the United States. Australia has some of the largest deposits in the world located in Western Australia. Its deposits often form placers and heavy mineral sands near ancient or contemporary coastlines. Alluvial deposits concentrated by ocean currents and wave actions have also produced many ilmenite accumulations over geologic time.

Uses and Application

It is primarily used for the production of titanium dioxide which possesses valuable properties like brightness, high refractive index and stability under light exposure. Around 95% of the mined element is processed to obtain titanium dioxide, which is used extensively as a white pigment in paints, paper, plastics, textiles, ceramics, floor coverings etc. Titanium dioxide has superior opacity and hiding power compared to other white pigments like zinc oxide and lead carbonate. It is also used as a reinforcing agent in laminates, abrasives and welding rods. Ilmenite can be transformed into titanium tetrachloride or titanium sponge - important intermediates needed for the manufacturing of titanium metal. Due to its magnetite content, it also finds applications as an important source of iron.

Mining and Processing

Ilmenite deposits are mined through conventional open-pit mining methods. Overburden and waste rock are first removed to expose the ore bodies. Heavy mining equipment like excavators and haul trucks are used to extract and transport the run-of-mine ore rocks. The mined element is crushed and ground to liberate individual mineral grains before being concentrated through gravity or magnetic separation techniques. This results in an upgraded ilmenite concentrate ranging between 55-65% TiO2. The concentrate is then subjected to various pyrometallurgical processes to convert it into usable materials. The sulfate process and chloride processes are commonly used for transforming the concentrate into synthetic rutile, titanium slag or titanium tetrachloride respectively. These intermediates serve as feedstock for various titanium products worldwide.

Market Dynamics and Industry Trends

The global market was valued at around USD 2.5 billion in 2020 and has been growing steadily. China, India and Japan are the leading consumers of ilmenite due to large-scale paint, plastic and paper manufacturing industries prevalent in these countries. China alone accounts for more than 40% of the total global demand. Rising population and economic growth in Asia Pacific are projected to elevate its consumption in the coming decade. Tightening environmental regulations regarding the use of lead and other toxic pigments will also boost demand for titanium dioxide pigments produced from it. New mining projects coupled with advancement of mining and processing methods are helping to augment global ilmenite supplies.

0 notes

Text

Methylamine: Its Synthesis, Properties, and Diverse Applications

Methylamine, a compound pivotal to various industries, is prized for its multifaceted uses. This article delves into the synthesis, chemical attributes, and broad applications of methylamine, shedding light on its indispensable role in contemporary chemistry and industrial processes.

The production of methylamine involves several methods, with one prevalent approach being the reaction between methanol and ammonia over a catalyst. This gas-phase synthesis, often employing metal oxide catalysts like copper oxide-zinc oxide-alumina catalysts, stands as a commonly utilized method. Alternatively, another method involves the reaction of formaldehyde with ammonia under specific conditions, yielding methylamine along with water. Each synthesis route offers unique benefits in terms of efficiency, yield, and purity, tailored to meet specific industrial requirements.

Chemically, methylamine presents itself as a colorless gas with a distinct odor, highly soluble in water, forming a clear, colorless solution. Demonstrating basic properties, methylamine readily forms salts with various acids, finding applications across pharmaceuticals, agriculture, and chemical synthesis. Additionally, methylamine acts as a vital precursor in the production of numerous compounds, including pharmaceuticals like ephedrine and pesticides such as carbofuran.

In the pharmaceutical industry, methylamine serves as a critical intermediate in the synthesis of various drugs, ranging from antidepressants and antihistamines to anti-inflammatory medications. Its significance extends to the production of analgesics and muscle relaxants, emphasizing its central role in medicinal chemistry.

Moreover, methylamine plays a pivotal role in agriculture, serving as a precursor in the synthesis of herbicides, insecticides, and fungicides. Compounds derived from methylamine exhibit potent pesticidal properties, contributing significantly to enhanced crop yields and pest management efforts worldwide.

Beyond pharmaceuticals and agriculture, methylamine is indispensable in chemical synthesis. Its reactivity and versatility enable the production of numerous organic compounds, including dyes, pigments, specialty chemicals, and polymers. The incorporation of methylamine-derived compounds into various industrial processes underscores its significance as a fundamental building block in chemical manufacturing.

In conclusion, methylamine, with its diverse synthesis methods and broad applications, holds a vital position in modern chemistry and industry. Its versatility spans pharmaceuticals, agriculture, and chemical synthesis, facilitating the production of essential compounds and driving technological advancements. Continued exploration and innovation in methylamine chemistry are crucial for fully harnessing its potential and addressing evolving industrial demands.

0 notes

Text

Dispersant NNO (A)

The Dispersant NNO is a powder ranging in color from light yellow to yellowish brown. It serves as an anionic surfactant, renowned for its exceptional diffusion and protective colloidal properties. The Dispersant NNO effortlessly dissolves in water, acid, alkali, and hard water. It demonstrates excellent dispersibility and shows a strong affinity for protein and polyamide substances.

Specification of Dispersant NNO (A)

Dispersant NNO-A

ITEMS

SPECIFICATIONS

Appearence

Light Brown Powder

Dispersion force

≥95%

pH (1% aq. Solution)

7-9

Na2SO4

≤3%

Water

≤9%

Insoluble impuries content

≤0.05%

Ca+Mg content

≤4000ppm

Function of Dispersant NNO (A)

1. Printing and dyeing industry: mainly used for vat dye suspension, dyeing, dispersion and dyeing of soluble vat dyes. It can also be used in the dyeing of silk/wool interwoven fabrics to make silk colorless. It is mainly used as a dispersant and dispersant in the dye industry.

2. Building materials industry: It is used as early strength cement to reduce water, so that the cement has a good dispersion effect after the impact of cement, enhances the strength of cement, shortens the construction period, saves cement and water. Dispersant NNO improves the tensile, anti-seepage, antifreeze and compressive modulus of elasticity of the mixed soil. Agricultural industry: It can be widely used in wet pesticides. It has good dispersibility and solubilization, and can obviously improve the efficacy of the pesticide.

3. Electroplating industry: Adding dispersant NNO to color electroplating can make the pigment disperse evenly and significantly improve the brightness of the electroplating surface.

4. Rubber industry: in the production process of rubber (latex) industry. For dispersion materials such as sulfur accelerators and anti-oxidation zinc oxide fillers (such as barium sulfate and calcium carbonate), the dispersion effect can be improved and the ball milling time can be shortened.

5. Paper industry: Water-soluble paint, pigment dispersant, water treatment agent, carbon black dispersant.

Package of Dispersant NNO (A)

25 kg woven bags lined with plastic bags for storage and transportation; the finished packaged dispersant NNO should be lightly loaded and unloaded, and should be stored in a cool, dry, and ventilated warehouse. The shelf life is two years.

0 notes

Text

The Role of White Inorganic Pigments in the Evolving APAC Region: A Market Analysis by Product and Application

White inorganic pigments are a type of pigment made from inorganic materials such as titanium dioxide, zinc oxide, and barium sulphate. These pigments are used in a variety of industries, including paint, coatings, and plastics, to provide a white color or a reflective effect. They are also used in paper and ink applications, as well as in food colouring. The demand for white inorganic pigments…

View On WordPress

#COVID-19 Impact on White Inorganic Pigments Market#Demand of White Inorganic Pigments#Global White Inorganic Pigments Market#inorganic blue pigment#inorganic color pigments#inorganic dyes#inorganic pigments#Inorganic Pigments Market#organic and inorganic pigments#pigment inorganic#White Inorganic Pigment Market Forecast#White Inorganic Pigment Market Growth#White Inorganic Pigment Market Report#White Inorganic Pigment Market Size#White Inorganic Pigments#White Inorganic Pigments Industry#White Inorganic Pigments Market#White Inorganic Pigments Sales#White Inorganic Pigment Market Analysis#White Inorganic Pigment Market Key players#White Inorganic Pigment Market Share#White Inorganic Pigment Market Survey#White Inorganic Pigment Market Trend#White Pigment Market

0 notes

Text

Zinc Carbonate Market Strategic Insights of Developing Industry by Top Growing Prominent Players Profile

Zinc carbonate is an inorganic compound that occurs naturally as the mineral smithsonite. It is a white crystalline solid that is commonly used in various industries due to its unique properties. The zinc carbonate market refers to the global market for this compound, including its production, consumption, trends, and key players. Here is some information about the zinc carbonate market:

Market Overview:

The zinc carbonate market is driven by its wide range of applications in industries such as rubber, ceramics, chemicals, pharmaceuticals, and others. It is primarily used as a raw material for the production of zinc compounds, which find applications in diverse sectors.

Production:

Zinc carbonate is produced through the reaction of zinc oxide or zinc hydroxide with carbon dioxide. It can also be obtained as a byproduct during the processing of zinc ore. The compound is manufactured in both natural and synthetic forms.

Applications:

• Rubber Industry: Zinc carbonate is used as an activator in rubber formulations to enhance the cross-linking process and improve the mechanical properties of rubber products.

• Ceramics Industry: It is used as a fluxing agent to reduce the firing temperature and enhance the glaze properties in ceramic manufacturing.

• Chemicals Industry: Zinc carbonate serves as a raw material for the production of various zinc compounds like zinc oxide, zinc chloride, zinc sulfate, and zinc phosphate, which have applications in industries such as paints, pigments, and fertilizers.

• Pharmaceuticals: It is used in certain medications and supplements as a source of zinc, which is an essential mineral for human health.

• Other Applications: Zinc carbonate finds use in areas like wastewater treatment, cosmetics, and catalysts.

Market Trends and Drivers:

Growing Demand for Rubber Products: The increasing demand for rubber products in industries such as automotive, construction, and healthcare is driving the demand for zinc carbonate.

Advancements in Ceramic Manufacturing: With technological advancements and the need for high-performance ceramics, the demand for zinc carbonate as a fluxing agent is expected to grow.

Environmental Regulations: Stringent regulations regarding wastewater treatment and air pollution control are creating opportunities for the use of zinc carbonate in these applications.

Emerging Markets: The market for zinc carbonate is expanding in developing regions due to industrialization, urbanization, and rising consumer demand.

Key Players:

The zinc carbonate market is characterized by the presence of several global and regional players. Some of the key players in the market include:

American Elements

Bruggemann Chemical

Zincore Metals

American Chemet Corporation

GHC Limited

Zinc Nacional

Regional Analysis:

The zinc carbonate market is geographically segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Asia Pacific is expected to dominate the market due to the presence of major manufacturing industries and increasing industrial activities in countries like China and India.

Challenges:

• Fluctuating Zinc Prices: The market is influenced by the volatility of zinc prices, which can impact the overall cost of zinc carbonate.

• Environmental Concerns: Zinc carbonate is classified as hazardous, and its production and usage must comply with environmental regulations, which can pose challenges for manufacturers.

It's important to note that market dynamics can change over time due to various factors such as technological advancements, economic conditions, and regulatory changes. For the most up-to-date information on the zinc carbonate market, it is recommended to refer to market research reports, industry publications, and consult with industry experts.

0 notes

Text

Understanding The Market Forecast For Cosmetic Colorants

Cosmetic colorants play an important role in many cosmetic products. The cosmetic industry relies heavily on dyes and pigments to provide color for a wide range of cosmetic products. Dyes and pigments are the two main categories of colorants in cosmetics. In cosmetics, dyes are used to color products such as nail paints, hair color, lip products, foundations, blushes, mascaras, and eye makeup.

They are derived from chemically refined petroleum oil or coal-tar derivatives that contain heavy metals, such as zinc oxide and titanium dioxide. Chemical clarity is vital for facial makeup compositions that use cosmetic pigments. Regulatory requirements for personal care products are strict for leading cosmetic color manufacturers. Since foundations and compacts are becoming more popular, the cosmetic pigment market is expected to grow much faster.

According to market forecasts, the global market for cosmetic dyes is forecast to grow at an unexpected CAGR from 2023 to 2028. In addition, the cosmetic dye market size is projected to be USD 412.7 million by 2028, a 4.6% CAGR due to the COVID-19 pandemic, from USD 316 million in 2022. What's next? The global cosmetic colorants market will continue to grow constantly in the next five years.

If you are searching for meaningful information on the global cosmetic colorants market and its size, competitors' landscape, and trends, then you have come to the right place. In this blog, you will learn about the global market prediction for cosmetic colorants in 2023.

So, let's get into it!

The Uses Of Dyes and Pigments in Cosmetics

It depends on the end product's desired characteristics whether pigments or dyes are used in lip makeup formulations or other purposes. leading cosmetic color manufacturers use higher concentrations of dyes to create a matte look, while they use pigments to create a glossy look. As the face makeup industry requires a high volume of pearlescent pigments, product innovation in the pearlescent pigment sector is increasing. In addition, the cosmetic dyes market will witness growth during the forecast period due to the increasing demand for matte lipsticks.

Global Cosmetic Colorants Market Overview

As consumers become more aware of the use of personal care products in developing economies, the market is forecast to be driven by an increase in the demand for cosmetic products such as hair color, lip products, eye makeup, and others. The increasing young population and improved living standards as a result of industrialization & urbanization are forecast to increase the market growth in the coming years. Moreover, the latest trends in the fashion industry and the introduction of natural dyes will boost the market growth.

On the other hand, the market is facing some restraints and challenges which can stop its significant growth at a certain level. These market restraints include the high cost of natural dyes and the toxic and harmful effects of dyes used in cosmetics. Furthermore, cosmetic companies are highly recommended for buying cosmetic colorants from leading cosmetic dyes manufacturers in India which offers superior quality dyes at affordable prices.

Factors Driving The Growth of the Cosmetic Colorants Market

Rising awareness of cosmetic products and cosmetic product expenditures in emerging economic countries like India and China drive the cosmetic colorants market. In addition, the cosmetic colorants market will also prosper when Asian economies improve and strengthen in the next few years. Therefore, several factors have led to the current growth of the Asian cosmetic industry, including increased consumer purchasing power, an improved fashion consciousness, and industry participants spending readily on promotional activities.

Role of Pigments in Cosmetic Colorants Market Growth

Color additives are the most often dyes used in toiletries, while pigments are commonly used in color cosmetics. Synthetic colorants are found to be shiny and brighter and offer more vibrant colors with higher durability and improved PH value than natural ones. The use of pigments in the cosmetic industry has significantly improved in the past recent years. Due to this fact, pigments held the largest share of the cosmetic colorants market.

Moreover, eco-friendly products have increased industry responsibility to improve product ranges with an improved focus on R&D, with a greater focus on being more selective. It would ensure that colorants with superior quality and high performance would meet market expectations. Additionally, cosmetic color manufacturers will increase the emphasis on the use of cutting-edge technologies that could restrain the growth rate of the cosmetic colorants market.

Cosmetic Dyes Market Trends

Cosmetics industry growth and the increasing demand for personal care products drive the global cosmetic dyes market. There has been a strong surge in social media exposure and celebrity endorsements since the ever-growing social media platforms and celebrities influencing the marketing of cosmetics, personal care products, and grooming products. As a result, consumers are becoming increasingly conscious of their individual appearance and changing beauty standards.

In light of this, consumers have become more wealthy and changed their lifestyles, which is facilitating the growth of cosmetic products for skin and sun care. Furthermore, premier color manufacturers and exporters have introduced organic cosmetic dyes made from naturally sourced ingredients due to the increased prevalence of dermatological disorders.

In turn, this is providing an impetus to the growth of the market, since it protects the skin from harmful effects and allergies caused by chemical dyes. In addition, cosmetic dyes are extensively used in the production of various hair colors, which is another factor stimulating growth. Moreover, a changing climate is also expected to contribute to growth in the market, as will the introduction of innovative product variants with enhanced quality.

Global Cosmetic Dyes Market: Key Segmentation

There are many uses for cosmetic colorants, including make-up, skin care, hair care, fragrances, and personal hygiene. The products are generally colored using pigments. Several end-user industries produce a significant amount of colorants for use in cosmetics in the Asia Pacific region, which is mainly due to a large number of export-oriented manufacturing capacities and an intense domestic demand.