#YQXPOLYMER

Explore tagged Tumblr posts

Text

Epoxy Resin Carbon Fiber Composite Material Helps Lighten New Energy Vehicles

In recent years, as global environmental protection standards have become stricter and consumer demand has increased, many countries have introduced industrial support policies to support the research and development of new energy vehicle technologies and further promote the entire industry chain and ecological construction of new energy vehicles.

According to statistics from the authoritative organization EV-Volumes: In May 2023, global electric vehicle sales exceeded one million units for the first time, reaching 1,057,509 units. This is the fifth time in history that this feat has been achieved.

As the global electric vehicle market continues to grow and consumer demand for environmentally friendly travel increases, the sales momentum of electric vehicles will continue to grow. In order to meet market demand, major automobile manufacturers are continuously increasing investment and launching more electric vehicle products.

However, the electric vehicle market still faces some challenges. How to further improve the performance of new energy vehicles? The answer is automobile lightweighting.

Lightweighting of automobiles--reducing the mass of the automobile body as much as possible without reducing the strength and safety performance of the automobile.

How to choose lightweight materials?

From the performance comparison between carbon fiber composite materials and other lightweight materials, we can clearly see that carbon fiber composite materials have the smallest density and their strength performance is far superior to other lightweight materials. Using carbon fiber reinforced epoxy resin composites (CFRP) to partially replace traditional metal materials is currently one of the most effective ways to achieve lightweighting in automobiles.

How are carbon fiber composite materials produced?

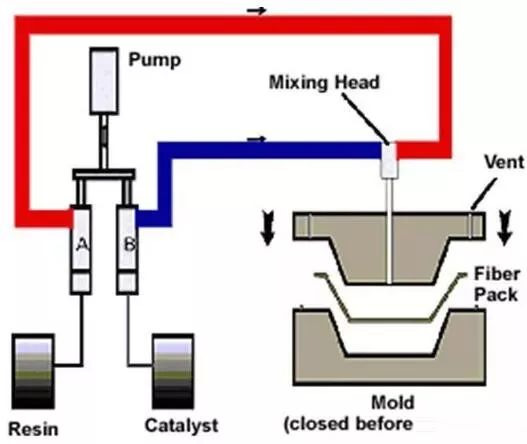

High-pressure resin transfer molding process, referred to as HP-RTM molding process. It refers to the molding process of using high-pressure pressure to mix and inject resin into a vacuum-sealed mold pre-laid with fiber reinforced materials and pre-set inserts, and then through resin flow filling, impregnation, curing and demoulding to obtain composite products. Low-cost, short-cycle (large-volume), and high-quality production can be achieved.

Carbon fiber composite products for automotive use

These exquisite carbon fiber composite materials are made from high-performance epoxy resin systems and carbon fiber materials through the HP-RTM process, and have been used in new energy vehicles on a large scale, effectively achieving the effect of lightweighting the vehicle.

What are the characteristics of the epoxy resin formula system used in HP-RTM process?

The epoxy resin formula system used in the HP-RTM process has the characteristics of fast curing speed, high defoaming, high wettability, low viscosity, low volatility, low curing shrinkage, low exothermic peak, and etc.

The 0164 series epoxy resin produced by YQXPOLYMER, combined with the HP-RTM special epoxy resin curing agent system, has the advantages of fast curing and molding speed, low exothermic peak during the curing process, good wettability with reinforcing fibers, and high physical and mechanical strength of the product. It is completely suitable for HP-RTM molding process and is a high-quality material for preparing carbon fiber composite materials for automobiles.

YQXPOLYMER will use its consistent high quality to protect automotive carbon fiber composite materials and efficiently promote the development of the new energy vehicle lightweight industry.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#epoxy resin supplier#carbon fiber composite material#automobile lightweighting#YQXPOLYMER

1 note

·

View note

Text

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

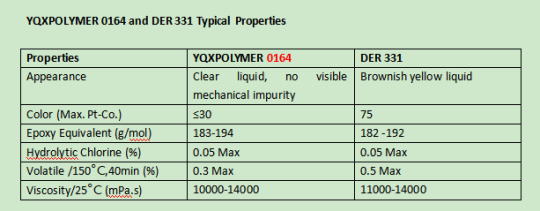

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes

Text

What is the RTM Molding Process for Composite Material?

RTM refers to a process technology in which low-viscosity resin flows in a closed mold, infiltrates reinforced materials and solidifies into shape. It belongs to the category of liquid forming or structural liquid forming technology of composite materials. The specific method is to pre-place reinforced materials that have been rationally designed, cut or mechanized pre-formed into the designed mold. The mold needs to be sealed and tightened around the perimeter to ensure smooth resin flow. After the mold is closed, a certain amount of resin is injected. And after the resin solidifies, the desired product can be obtained by demoulding.

The RTM molding process has the following main characteristics

RTM is a closed mold molding process. The infiltration of the reinforcement and the resin is completed by the rapid flow of pressurized resin in a closed mold cavity, instead of manual infiltration in hand lay-up and spraying processes, nor expensive mechanized infiltration in prepreg and SMC processes. RTM is a low-cost, high-quality semi-mechanized fiber/resin impregnation method.

The RTM molding process uses reinforced material preform technology that is similar to the shape of the product. Once the fiber/resin infiltration is completed, it can be cured, so a low-viscosity fast-curing resin system can be used. It can also heat the RTM mold to further improve production efficiency and product quality.

The reinforced material preform in the RTM molding process can be prepared from chopped strand mat, fiber cloth, wrinkle-free fabric, three-dimensional knitted fabric, three-dimensional braided fabric, etc. And according to the performance requirements, selective reinforcement, local reinforcement, hybrid reinforcement, and embedded and sandwich structures can be used, which can give full play to the performance designability of FRP/composite materials.

The closed-mold resin injection method of the RTM molding process can greatly reduce the toxicity of harmful resin components to the human body and the environment, and meet the increasingly stringent restrictions on the volatilization concentration of harmful gases such as styrene in advanced industries.

The RTM molding process generally adopts a low-pressure injection process, which is conducive to the preparation of complex overall structures with large sizes, complex shapes, and two-sided surfaces.

According to the requirements of the production scale, RTM molds can be selected from different grades of molds such as polyester molds, epoxy molds, surface nickel-plated material molds, alloy molds, aluminum molds and steel molds to reduce costs.

Requirements of RTM technology on epoxy resin systems

Epoxy resin has low viscosity at room temperature or lower temperature, and has a certain storage period.

Epoxy resin has good wettability, matching and adhesion to reinforced materials.

The epoxy resin system has good curing reactivity and does not produce volatile matter and other undesirable side reactions during the curing reaction. The curing temperature should not be too high, and the curing speed should be appropriate.

As a high-performance composite material, epoxy resin is also required to have high heat resistance and moisture resistance, excellent mechanical properties, especially toughness. In some special applications, it should also have certain functionalities, such as low dielectric loss, high conductivity, excellent flame retardancy, etc.

High-performance epoxy resin system is still the most widely used high-performance composite matrix. Epoxy resin systems usually used to make prepregs are difficult to mold using the RTM process due to their high viscosity and short storage life. In order to be suitable for RTM molding, YQXPOLYMER launched the 9320A/B epoxy resin curing system. 9320A/B is a special epoxy resin curing system for RTM process. This system product is composed of special epoxy resin and modified amine curing agent. The 9320A/B epoxy resin curing system has the characteristics of fast curing speed, good water resistance, high hardness, good adhesion, mechanical properties of the cured material and high Tg temperature. It can be widely used in automotive composite materials for RTM molding, cultural and sports products (fishing rods, badminton rackets, golf clubs, etc.) and other carbon fiber composite materials. The RTM process has a wide range of advantages. The molded parts have high fiber system content, low porosity, low water absorption, and good mechanical properties. Conventional resins and reinforcing materials can be used in the RTM process.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#RTM#RTM molding process#epoxy resin supplier#epoxy resin system#RTM process#resin transfer molding#epoxy composite material#epoxy resin curing system#composite material

0 notes

Text

9201A/B Epoxy Resin Helps the Development of Wind Power Industry

Epoxy resin is widely used in wind power, electronic and electrical, chemical anti-corrosion, aerospace, rail transportation, machinery manufacturing, ship transportation and other fields due to its strong adhesion, good corrosion resistance, strong electrical insulation and high mechanical properties.

The series of epoxy resin products for wind turbine blades mainly include vacuum infusion resin, hand lay-up resin and mold resin, etc., which have the characteristics of good mechanical properties, fatigue resistance, high and low temperature resistance, excellent mechanical properties, rapid prototyping, and typhoon resistance.

YQXPOLYMER 9201A/B epoxy resin is a product developed to meet the development needs of "lightweight" and "large-scale" wind turbine blades. YQXPOLYMER 9201A/B is an epoxy resin curing agent system specially designed for megawatt wind turbine blades, and it has long operating time and excellent mechanical strength and DNV certified.

Epoxy resin has excellent mechanical properties, chemical stability and corrosion resistance, and can be used as blade structural parts, connectors and coatings for wind power generation. In the supporting structure, skeleton and connectors of the blade, epoxy resin can provide high strength, high stiffness and fatigue resistance to ensure the stability and reliability of the blade. In addition, epoxy resin can also improve the wind shear resistance and impact resistance of the blades, reduce the vibration noise of the blades, and improve wind power generation efficiency.

The application of epoxy resin in wind turbine blade coating is also very critical. By coating epoxy resin on the blade surface, the wear resistance and UV resistance of the blade can be improved, and the service life of the blade can be extended. At the same time, it can also reduce the weight and resistance of the blades and improve the efficiency of wind power generation.

Epoxy resin needs to be used in many aspects of the wind power industry, with a wide range of applications. Currently, among the blade materials for wind power generation, epoxy resin is mainly used in wind turbine blades, the core component of the front end of wind turbines. It is used to make the main beams, shells, webs, blade molds and blade trailing edge bonding.

Due to the development needs of "lightweight" and "large-scale" wind turbine blades, the material properties of epoxy resin can optimize the basic parameters such as strength, stiffness and dynamic fatigue of wind turbine blades, making the wind turbine blades lighter, with longer service life, better maintenance performance and shorter maintenance cycle.

The epoxy resin curing agent contributes particularly crucially to the performance of the wind turbine blade system. Only curing agents with good structural properties can effectively enhance the overall strength of the epoxy resin and thereby enhance the blade strength. In addition, curing agents also have an important impact on process control of blade manufacturing. If the viscosity of the curing agent is too high, it will be difficult to operate. If the reaction speed is too fast, the opening time will be too short. During the curing process of the blade, the reaction will be exothermic and smoke will be emitted, posing risks to the operation. YQXPOLYMER 9201A/B has low mixing viscosity, excellent fiber wettability, long gel time and operable time, low exothermic peak, and excellent comprehensive mechanical properties after curing.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#epoxy resin supplier#epoxy resin curing agent system#wind power#megawatt wind turbine blade#wind turbine blade#wind turbine blade coating#curing agent

0 notes

Text

YQXPOLYMER Epoxy Resin 0614/0614DL were Launched into International Market

April 9, 2024, YQXPOLYMER, a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider is pleased to launch its 0614/0614DL epoxy resin worldwide. To expand its business operations, YQXPOLYMER is now open to exploring partnerships with like-minded organizations, businesses, and individuals interested in the epoxy industry.

YQXPOLYMER 0614/0614DL are diluted liquid epoxy resins, which is manufactured from C12~C14 aliphatic glycidyl ether and bisphenol A epoxy resin.

YQXPOLYMER 0614/0614DL are special low viscosity liquid epoxy resins, which are widely used in Stone adhesive. YQXPOLYMER 0614/0614DL can be used to paste fiberglass mesh on the back of marble to enhance the strength and stability of the stone, prevent the stone from falling off and improve the impact resistance of the stone. Also they are used in Ceramic tile adhesive, Epoxy floor, Road bridge tunnel filling, and so on.

A wide variety of curing agents is available to cure liquid epoxy resins at ambient conditions. The most frequently used are aliphatic polyamines, polyamides, alicyclic amines, cycloaliphatic amines and modified versions of these curing agents. Elevated temperature cures are necessary and long post-cures are required to develop full end properties if anhydrides or catalytic curing agents are employed.

YQXPOLYMER 0614/0614DL Typical Properties

YQXPOLYMER 0614/0614DL Key Features

Low viscosity and strong fluidity, good performance at room temperature, and easier to paint and construct.

It can better penetrate into the surface to be coated or bonded, improving performance stability and durability.

Widely used in Stone adhesive, Ceramic tile adhesive, Epoxy floor, Road bridge tunnel filling, etc.

Packing variety: drums, IBC container, or customization.

YQXPOLYMER 0614/0614DL Typical Applications

This product is suitable for use in applications such as:

• Stone adhesive

• Ceramic tile adhesive

• Epoxy floor

• Building repair adhesive( Road bridge tunnel filling)

• Solventless coatings

• Composite materials

• Liquid molding compounds

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally. And we provide highly cost-effective products, short lead time, in-time after-sales service, even OEM service.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#epoxy adhesive#epoxy resin supplier#epoxy floor#tile adhesive#YD-114#Kukdo YD-114E#stone adhesive

0 notes