#World Synthetic Fibre Rope Market

Explore tagged Tumblr posts

Text

Sisal Fibre Suppliers in Kenya: Pioneers of Sustainable Agriculture

Kenya has long been recognized as a global leader in sisal production, contributing significantly to the country’s economy and agricultural sector. As demand for sustainable materials grows worldwide, Kenyan sisal fibre suppliers are playing a crucial role in meeting this need. Sisal, a natural fibre derived from the Agave sisalana plant, is prized for its durability, versatility, and eco-friendly properties. Kenyan suppliers are at the forefront of this industry, providing high-quality sisal fibre to markets around the globe.

1. The Legacy of Sisal in Kenya

Sisal has been cultivated in Kenya for over a century, with the country’s first sisal estates established in the early 1900s. Today, Kenya is one of the world’s top producers of sisal, exporting the fibre to countries across Europe, Asia, and the Americas. The success of Kenya’s sisal industry is rooted in the country’s ideal growing conditions—warm temperatures, well-drained soils, and low rainfall—making it perfect for cultivating sisal plants.

The sisal industry is a vital part of Kenya’s agricultural landscape, providing employment for thousands of workers, particularly in rural areas. The industry supports local economies and contributes to national export revenues, positioning Kenya as a key player in the global sisal market.

2. Sustainable Production Practices

Kenyan sisal fibre suppliers are committed to sustainable agriculture, employing practices that minimize environmental impact while maximizing yield and quality. Sisal is a drought-resistant crop that requires minimal water and no chemical fertilizers or pesticides, making it an eco-friendly alternative to synthetic fibres. The plants are harvested manually, which reduces the carbon footprint of production and supports traditional farming methods.

Moreover, the entire sisal plant is utilized, ensuring that nothing goes to waste. After the fibres are extracted, the remaining plant material is used for various purposes, including the production of biofuels, animal feed, and organic fertilizers. This zero-waste approach not only benefits the environment but also adds value to the sisal supply chain, making it a truly sustainable industry.

3. High-Quality Fibre for Diverse Applications

Kenyan sisal fibre suppliers are known for producing some of the highest-quality fibre in the world. The fibres are strong, durable, and resistant to wear and tear, making them ideal for a wide range of applications. Sisal is commonly used in the production of ropes, twines, and mats, but its versatility extends far beyond these traditional uses. In recent years, sisal has found its way into the fashion industry, where it is used to create eco-friendly textiles, handbags, and shoes. It is also used in the automotive and construction industries as a reinforcement material in composite products.

Kenyan suppliers work closely with international buyers to ensure that their products meet the specific requirements of different industries. By offering customized solutions and maintaining high standards of quality, these suppliers have earned a reputation for reliability and excellence on the global stage.

4. Economic and Social Impact

The sisal industry in Kenya not only supports the economy but also has a significant social impact. Many sisal farms and processing facilities are located in rural areas, providing employment opportunities and improving the livelihoods of local communities. The industry empowers farmers by providing them with a steady income and opportunities for growth.

In addition, Kenyan sisal fibre suppliers are increasingly adopting fair trade practices, ensuring that workers receive fair wages and work in safe conditions. This commitment to social responsibility is helping to create a more equitable and sustainable industry, where the benefits are shared by all stakeholders.

Conclusion

Sisal fibre Supplier in Kenya are leading the way in sustainable agriculture, providing high-quality, eco-friendly fibre to markets around the world. With a strong legacy, commitment to sustainability, and a focus on quality, these suppliers are helping to shape the future of the global textile and industrial markets. As the demand for natural and sustainable materials continues to rise, Kenya’s sisal industry is well-positioned to thrive, offering solutions that benefit both people and the planet.

0 notes

Text

Research On World Synthetic Fibre Rope Market Report 2025

Report on World Synthetic Fibre Rope Market by Product Type, Market, Players and Regions-Forecast to 2025 offered by DecisionDatabases.com.

Synthetic Fibre Rope market research report provides the newest industry data and industry future trends, allowing you to identify the products and end users driving Revenue growth and profitability.

The industry report lists the leading competitors and provides the insights strategic industry Analysis of the key factors influencing the market.

The report includes the forecasts, Analysis and discussion of important industry trends, market size, market share estimates and profiles of the leading industry Players.

Final Report will cover the impact of COVID-19 on this industry.

Access Full Report with Table of Contents @ https://www.decisiondatabases.com/ip/52873-world-synthetic-fibre-rope-market-report

The Players mentioned in our report

Wireco World Group

Samson Rope Technologies

Bridon International Ltd

Teufelberger Holding AG

Marlow Ropes Ltd.

Yale Cordage Inc

Juli Sling

Cortland Limited

Southern Ropes

Garware-Wall Ropes Ltd.

Lanex A.S

GRPP

English Braids Ltd

Taizhou Hongda

Katradis

Jiangsu Shenyun

Global Synthetic Fibre Rope Market: Product Segment Analysis

Polypropylene

Polyester

Polyamide Fiber

Polyethylene

Global Synthetic Fibre Rope Market: Application Segment Analysis

Marine & Fishing

Sports and Leisure

Oil & Gas

Construction

Cranes

Global Synthetic Fibre Rope Market: Regional Segment Analysis

USA

Europe

Japan

China

India

South East Asia

Download Free Sample Report of World Synthetic Fibre Rope Market @ https://www.decisiondatabases.com/contact/download-sample-52873

There are 10 Chapters to Deeply Display the World Synthetic Fibre Rope Market. Chapter 1 About the Synthetic Fibre Rope Industry Chapter 2 World Market Competition Landscape Chapter 3 World Synthetic Fibre Rope Market share Chapter 4 Supply Chain Analysis Chapter 5 Company Profiles Chapter 6 Globalisation & Trade Chapter 7 Distributors and Customers Chapter 8 Import, Export, Consumption and Consumption Value by Major Countries Chapter 9 World Synthetic Fibre Rope Market Forecast through 2025 Chapter 10 Key success factors and Market Overview

Purchase full World Synthetic Fibre Rope Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-52873

Other Reports by DecisionDatabases.com:

World Synthetic Resin Market by Product Type, Market, Players and Regions-Forecast to 2025

World Synthetic Quartz Glass UV-LED Market Research Report 2025 (Covering USA, Europe, China, Japan, India and etc)

World Synthetic Resin Teeth Market by Product Type, Market, Players and Regions-Forecast to 2025

About-Us: DecisionDatabases.com is a global business research report provider, enriching decision makers and strategists with qualitative statistics. DecisionDatabases.com is proficient in providing syndicated research report, customized research reports, company profiles and industry databases across multiple domains.

Our expert research analysts have been trained to map client’s research requirements to the correct research resource leading to a distinctive edge over its competitors. We provide intellectual, precise and meaningful data at a lightning speed.

For more details: DecisionDatabases.com E-Mail: [email protected] Phone: +91 9028057900 Web: https://www.decisiondatabases.com/

#Synthetic Fibre Rope#Synthetic Fibre Rope Market#Synthetic Fibre Rope Market Report#World Synthetic Fibre Rope Market#Synthetic Fibre Rope Industry Size

0 notes

Text

Real Innovations: 3 biobased building materials of the future

Hempcrete is insulating and breathable. An ideal building material.

Which innovations are really going to make a difference and should we keep an eye on them? We ask experts in their field. This time: architect Daan Bruggink on biobased building materials of the future.

Anyone who says biobased construction refers to wood construction in the first place. [1] The sector is developing rapidly and is only expected to grow in size in the coming decades. But of course there are many more promising biobased materials in the proverbial starting blocks. Whether they all have a future is another matter, says Bruggink. “Mycelium, for example, is a promising material that fits perfectly into the story of biobased construction. But it has not yet been tried out, tested, certified, you name it. That is the essence for many biobased materials, when going through that entire process. It costs a lot of time and money and not every start-up has the means to perpetrate this.”[2]

Which biobased materials (apart from wood) are ready for rapid upscaling and the future? Bruggink selected three:

1. Agricultural (residual) material

Bruggink: “The biggest development I see at the moment is the use of agricultural crops. Think, for example, of wheat stalks, hemp and bulrush. They have very strong fibres; hemp, for example, was also used to make rope and sails. Agricultural crops have enormous potential as insulation material and can also be scaled up fairly quickly, I expect. It is produced, certified, put it in a wooden sleeve and you're done. Very short-sighted, of course, but that's basically what it ends up to. Which specific agricultural crops will win the race is difficult to predict. In an ideal world, per project one considcers the crops that are available and suitable.”

Straw is a commonly used biobased product for construction (especially roofs for new construction). It is not only a residual product of livestock farming, but can also be grown, harvested and replanted specifically for the construction industry.

2. Hempcrete

“Some agricultural crops can also be combined very well with other materials. Hemp is a good example of this. When it is combined with lime, a biobased material is obtained that can be used for insulation, but one can also build with it. Think of it as a kind of biobased sand-lime brick. To actually build, wooden posts are currently still needed in between, to support the construction. But I expect that there is a lot of future in hemplime.”

Hempcrete insulation

3. Biocomposite

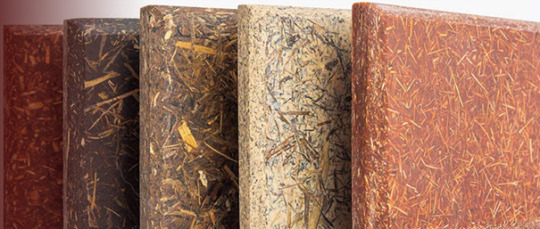

“A third important trend is the emergence of biocomposite[3]. A company like Nabasco[4] is already showing the possibilities. They have facade panels in their product portfolio, made from reed clippings. But other natural fibres, such as flax and hemp, are also possible.

Circular Matters launches new biocomposite sheet material

The question is: will it be possible to make a biocomposite that is 100 percent biobased? The products currently on the market are around 80 percent. But I expect it to be a matter of time before there are biocomposite panels on the market that are completely biobased.”[5]

Source

Hidde Middelweerd: Echte Innovaties: 3 biobased bouwmaterialen van de toekomst, in: Change Inc, 20-12-2022, https://www.change.inc/infra/echte-innovaties-3-biobased-bouwmaterialen-van-de-toekomst-39348

[1] Read also: https://at.tumblr.com/earaercircular/the-climate-helps-building/5cri1jglt8q4 & https://at.tumblr.com/earaercircular/new-technology-from-norway-ensures-that-we-dont/6tzs3iij57jr

[2] Read also: https://at.tumblr.com/earaercircular/mushrooms-to-insulate-houses/xwe12tc02hri

[3] A biocomposite is a composite material formed by a matrix (resin) and a reinforcement of natural fibres. Environmental concern and cost of synthetic fibres have led the foundation of using natural fibre as reinforcement in polymeric composites.

[4] Nabasco products realizes innovative and sustainable facades with its partner NPSP. Our facade systems are composed and produced customer-specifically. With Nabasco® Sign they introduce the most environmentally friendly and at the same time high-quality traffic sign that shows that top quality and sustainability go hand in hand. https://nabasco.nl/collections/all

[5] Read also: https://at.tumblr.com/earaercircular/new-technology-from-norway-ensures-that-we-dont/6tzs3iij57jr

0 notes

Text

A Review of Some Significant Research Breakthroughs in Banana Fibre by Gokarneshan N* in in Open Access Journal of Biogeneric Science and Research

Abstract

The article reviews some significant research trends in the banana fibre. Bannana is a natural fibre and belongs to the category of bast fibres. One area of research explore the areas of applications, particularly in handicraft products such as mat, rope and twines, but only 10% of its pseudo stem is being used for making products and the remaining is used as waste or fertilizer. Owing to its many special properties it can be beneficial to farmers and also serve as a good raw material for the textile and packaging industry. In another area of research, flame retardant functionality has been imparted in cellulosic fabric using mixed formulation of banana psueudo stem sap and boric acid. Flame retardant characteristics of both the control and treated fabrics have been analyzed in terms of limiting oxygen index, vertical flammability, and temperature generation profile during burning. Another area of research reports the influence of treatment with caustic soda at various concentrations, on the physical, morphological, structural and thermal properties. An interesting study has focused on the production of bannana fibre yarns for textile reinforced composites. Thus the viability of spinning a yarn from banana fibres and weaving for the composite is explored. Attempt has been made to produce reinforced composite by weaving enzyme treated banna fibres.

Keywords: Bannana fibres; enzymatic treatment; value addition, composites; Alkali treatment; enzymatic treatment; reinforcement, sustainability.

Introduction

The banana plant not only yields fruit, but also fibre which finds use in textile and related applications. It grows under tropical conditions. All varieties of banana fibres have fibres in abundance. The banana fibre is basically a bast fibre, and is obtained after the fruit is harvested. After the plant yields the fruit, its trunk the pseudo stem largely goes as agricultural waste. These pseudostems can be effectlvely utilized in production of the banana fibres, as annually about 1.5 million tons of dry banana fibres can be produced from the outer sheath of pseudostem. Biomass (pseudostem) waste, a rich source of natural fibres the pseudostem can be profitably utilized for numerous applications and preparation of various products. Cotton being a cellulosic material is flammable and hence can create problems for health and life of mankind. Considerable attempts have been made over the years for enhancement of flame-retardant property of cotton textile materials through utilization of different synthetic chemicals and a number of them are commercially available. Of these, the common ecofriendly admixture formulation of boric acid and borax is considered the simplest [1]. But, higher quantity of chemicals used in this formulation degrades the treated fabric quality. The present days are witnessing increased use of natural lingo cellulosic fibres in composite production [2]. Natural lignocellulose fibres, such as sisal, hemp, coir, kenaf and jute, have low density, good thermal properties, better specific strength, ecofriendly nature and can be used as replacement for glass fibres during composite manufacturing [3,4]. Banana fibres, due to its high specific strength can be used as replacement of glass fibres as reinforcement in the manufacture of composites. Banana fibre is extracted from the pseudo stem waste of the plant after harvesting the fruits. Like any other ligno cellulosic fibre, the major constituents of these fibres are cellulose, lignin, and hemicelluloses [5]. The rising interest in natural fibers in the composites field is undeniable, mainly due to sustainability, but also because of their good mechanical properties and low cost. The differences observed among different natural fibers are due to their chemical composition, origin, climate conditions, etc. On average, vegetable fibers are made of 60%–70% of cellulose, 10%–20% of hemicellulose, 5%–15% of lignin and up to 2% of pectin and waxes [6]. Banana fiber is obtained from the superimposed leaves forming the pseudostem of the plant, which currently has no use, apart from a low percentage dedicated to cattle feed. It belongs to Musa genre, as a monocot. Banana is the most important crop in Canary Islands, which are the most important producers of bananas in Europe. It is important to highlight that fibers are obtained from the pseudostems of the plant once the fruit has been harvested, and that each plant only bears fruit once; this is one of the main benefits of banana fibers in comparison with other natural fibers, as this one is obtained from an agricultural residue.

Potential of Banana Fibre for Product Development

Lignocellulosic are used for various applications depending on their composition and physical properties. All varieties of banana trees abound in fibres. In fact almost each and every part of the banana plant gives fibres of various strength, color and beauty and staple length which can be used for various purposes.All varieties of banana trees abound in fibres. In fact, almost each and every part of the banana plant gives fibres of various strength, color and beauty and staple length which can be used for various purposes. Out of the 14-18 sheaths available in a stem, the outermost 4-6 sheaths yield coarse fibre, the outer 6-8 sheath soft lustrous fibre and the rest middle sheath excluding the innermost 4-6 sheaths yield very soft fibres. The quantity of fibre in each sheath depends upon its width and its location in the stem, as does its quality. In addition to fruit production, huge quantity of biomass (pseudostem, leaves, suckers etc.) is generated [7,8].In india, the fibres extracted from pseudostem of banana plant, is being used for preparing ropes, handicrafts, etc. which otherwise can be used for making home furnishings and good quality papers. The major problem of non-adoption of fibre extraction technology is low recovery of fibres leading to high transport cost. This plant has long been a good source for high quality textiles in many parts of the world especially in japan and Nepal [9-11].

Most of the banana fibers produced today is used for ropes and cordage. The resistance of the fibre to the sea water and its natural buoyancy has created a ready market for it in the manufacture of shipping cables. It is also widely used for making power transmission ropes and cordage, wall drilling cables, fishing nets, lines and other types of cordage. Banana fibers are being utilized in various ways in different countries. In japan, banana fibres are being used for making traditional dresses like kimono and kamishimo during earlier periods. Due to its being lightweight and comfortable to wear, it is still being preferred by people there as summer wear. Banana fiber is also used to make fine cushion covers, neck ties, bags, table cloths, curtains, etc. Rugs made from banana silk yarn fibers are also very popular world over. Owing to its high tenacity, banana fibre made as single composite withstands more strain before failure in tensile testing than the hybrid fiber composite. The fiber was extracted by hand stripping using a stripping device applying low pressure to prevent the fibres from breaking [12,13].

Several products have been made from banana fibres around the globe. These include paper board, tissue paper, natural absorbent, bio remediation agent for bacteria in natural water purifier, mushroom production, handicrafts, quality paper cards, tea bags, string thread, high quality fabric material, paper for currency notes, rope for tyeing, dress materials, wedding gowns and barongs, and many more. It is interesting to note that banana fibre is also being used as lining for car interiors [14-16]. Development of softening processes have been reported for the inherently coarse banana fibres making it more suitable for spinning operations, spinning of the softened fibres into yarns, after blending them with suitable natural fibres and testing the physical and mechanical properties of the yarns.The yarns were further converted into fabrics and again assessed for their physical and mechanical properties. The fabrics were further passed through various finishing processes and then tested for all the mechanical and physical properties. The fabrics were further taken for dyeing with two classes of dyes and then assessed for the various fastness properties [17].

The development of green packaging from banana fibre for instant food products has been studied. Variables considered in this issue include packaging design of green packaging from banana fibre for instant food products of the envelope(stand up pouch), box(paper box), paper cups(paper cup), paper bags(zip lock paper bag). Banana fibre has been used to produce packaging to select the quality of the physical, chemical and consumer product safety. Packaging is recycling based that is ecofriendly disposal [18].

Banana is cultivated in about 2.3 lakh hectares of land and the fibre yield is about 8.7 tons. Though banana fibre extraction is not done on any large scale at present, banana fibres are reported to have been spun on the jute spinning machinery and used for hand bags and other fancy articles [19]. Agro based bio fibres have the composition, properties and structure that make them suitable for uses such as composite, textile, pulp and paper manufacture. In addition, bio fibres can also be used to produce fuels, chemicals, enzymes and food. Byproducts produced from the cultivation of corn, wheat, rice, sorghum, barley, surgarcane, pineapple, banana and coconut are the major sources of agro based bio fibres. Likewise, banana fibre based production processes, structure, properties and suitability of these biofibres are to be identified for various industrial applications.

Influence of Alkali Treatment on Fibre Properties

The use of natural lignocellulose fibres in the manufacture of composites is increasing day by day [20]. Natural lignocellulose fibres, such as sisal, hemp, coir, kenaf and jute, have low density, good thermal properties, better specific strength, ecofriendly nature and can be used as replacement for glass fibres during composite manufacturing [21,22]. Banana fibres, due to its high specific strength can be used as replacement of glass fibres as reinforcement in the manufacture of composites. Banana fibre is extracted from the pseudo stem waste of the plant after harvesting the fruits. Like any other ligno cellulosic fibre, the major constituents of these fibres are cellulose, lignin, and hemicelluloses [23]. The removal of lignin and hemicellulose substances and roughening of surface is required to improve the interfacial strength of composites [24]. Banana fibres are hydrophilic and have poor adhesion with the matrix materials. To improve adhesion of the natural fibres with matrix materials various treatments, such as alkali, acetylation and benzoylation, are given. Among all these treatments, mercerization or alkali treatment is a versatile one, which brings about changes in dimensions, fine structure, chemical composition, morphology, and crystalline component as well as it improves the wettability, resin pick up of natural fibres like coir, sisal, flax and cotton [25,26]. Alkali treatment improves adhesion between these hydrophilic fibres and the hydrophobic matrix by roughening and exposing more cellulose on the surface.

The alkali treatment modifies the chemical constituents which results in changes in mechanical properties, surface roughening, crystallinity and also in the thermal behavior of fibres [27,28]. Available literature reveals that NaOH treatment removes the binding materials, depending on the treatment time, concentration of NaOH used, temperature of treatment and liquor ratio. Study on effect of NaOH treatment on properties of banana fibre has already been performed by few researchers [29,30]. The effect of NaOH concentration on fibre yield (extraction) from the pseudo stem has also been reported [31]. However, the changes in the fibre due to such treatment at various levels are unknown. This is essential for optimum use of alkali and also to avoid degradation of fibres which will happen at higher concentration treatments. Similarly, the effect of NaOH concentration on the other fibre properties is not yet been studied. Hence in this study, the banana fibres are treated with sodium hydroxide (NaOH) at three different concentrations of 10, 15 and 20% and the treated fibres are tested for chemical composition and physical, morphological, structural and thermal properties.

It is found that the hemicellulose and lignin removal occur till 15% NaOH treatment concentration, and after that there is no much removal occurred. In line with those finding, the density of the fibre also shows an increment up to 15% NaOH and further increment in alkali percentage reduces the density. The moisture regain of the banana fibre also shows the same trend as that of density [32]. At 20% NaOH treatment, the moisture regains are found higher than at 15% NaOH treatment. Increment in the NaOH concentration also increases the lignin and hemicelluloses removal percentage, which is confirmed by the scanning electron microscope analysis. The breaking strength and the tenacity values of the banana fibre increase with NaOH concentration up to 15%. Further increment in alkali concentration degrades the fibre. The removal of lignin and hemicellulose contents from the banana fibre is confirmed by the FTIR and crystallinity analyses. The thermal stability analysis also confirms that the alkali treatment improvs the thermal stability value up to 15% NaOH concentration. The colour assessment studies show that the appearance of banana fibre becomes darker and red in colour due to the alkali treatment.

Production of Technical Textile Reinforced Composites

The rising interest in natural fibers in the composites field is undeniable, mainly due to sustainability, but also because of their good mechanical properties and low cost. The differences observed among different natural fibers are due to their chemical composition, origin, climate conditions, etc. On average, vegetable fibers are made of 60%–70% of cellulose, 10%–20% of hemicellulose, 5%–15% of lignin and up to 2% of pectin and waxes [33]. Banana fiber is obtained from the superimposed leaves forming the pseudostem of the plant, which currently has no use, apart from a low percentage dedicated to cattle feed. It belongs to Musa genre, as a monocot. Banana is the most important crop in Canary Islands, which are the most important producers of bananas in Europe. It is important to highlight that fibers are obtained from the pseudostems of the plant once the fruit has been harvested, and that each plant only bears fruit once; this is one of the main benefits of banana fibers in comparison with other natural fibers, as this one is obtained from an agricultural residue.

The use of natural fibers as reinforcement of polymeric parts has been widely studied, special focusing on injection molding technology. In fact, around 21,000 tons of natural fibers were used in 2003 in the European industry; the most relevant fibers for the industrial production of plastic composites are flax, sisal and hemp. Natural fibers are less harmful to humans, machinery and the environment, thus being realistic alternatives to glass fiber [34]. Some studies have also been carried out for the compression molding technology, some withlong fibers and others with woven fibers, both for thermoset and thermoplastic polymers [35-39]. These studies show that specific mechanical properties of natural fibers composites are similar to those reinforced with glass fiber, although mechanical properties under humid conditions show an important decrease for the natural fiber composites, due to their moisture absorption. These studies mainly focus on the production of non-structural parts for the automotive sector. It is known that mechanical properties of composites strongly depend on the orientation of the fibers, getting better properties when the fiber is woven and placed in the composite in an appropriate orientation. The BANTEX project (MAT2013-47393-C2-1-R) is aimed at obtaining a composite material made of woven banana fibers. Woven fabrics have the advantage of enabling the orientation of the fibers, allowing control of the density of the fabric and its mechanical properties. Nonwovens provide multiaxial orientation but lower and non-predictable mechanical properties. There is wide bibliography about the production of composite materials with natural fibers (flax, hemp, jute) in woven and non-woven fabrics [40-43]; however, no references have been found in the use of banana fibers to produce them. Furthermore, the use of banana fibers to produce yarns for technical textile products has not been reported.

Banana fibers are made of cellulose (43.6%), hemicellulose (14%), lignin (11%) and other substances (such as pectin, wax, 31.4%) [44]. Chemical methods for fiber extraction are usually performed with NaOH, although other chemicals are also used (KMnO4, benzoyl chloride, stearic acid, among others); these processes may cause environmental problems due to the need for treating the residues produced. Mechanical means are not able to remove the non-cellulosic constituents (lignin). An alternative is the use of biological processes, such as the immersed or solid-state fermentations. Enzymatic means are considered more environmentally friendly, and also avoid the fibers breakage, while altering the properties of the cellulosic fibers [45-48]. There are different parameters which affect the enzyme choice, such as the type of substrate, composition, size, lignin content, etc. Previous studies show Pectinase and Xylanase as the most suitable ones for fiber extraction [49,50]. Enzymatic treatments have been applied to hemp, flax or pineapple for fiber refining. Celullases are used to remove fibrils from the surface and increase the smoothness of the fiber, although this treatment can also damage the fibers and reduce their mechanical properties. Pectinases are used in the textile industry for retting and degumming fiber crops, as they are capable of breaking down complex molecules of plant tissues into simpler ones, such as galacturonic acid; on the other hand, endoglucanases only act on amorphous celluloses [51].

Hemicellulases are able to reduce water absorption by pentosan hydrolysis; xylanase and mannanase are used to dissolve hemicellulose (mainly xylan and glucomannan, respectively) [52]. Tests have been performed using a cocktail of two different enzymes made of pectinase and hemicellulase. In this research, different formulations of the enzymatic treatment have been applied to the banana fibers in order to determine the optimal conditions (time, temperature, enzymes content, bath renewal, fiber/enzymes ratio, etc.) for the refining process, in order to obtain a banana textile grade fiber. Fibers have been characterized prior to and after the enzymatic treatment, in terms of length, diameter and thermal stability. The spinning process at the lab scale has taken place, resulting in the production of a yarn with enough quality to be woven and produce a technical textile suitable for composite reinforcement.

The enzymatic treatment has proven to be useful for banana fiber treatment, achieving an improvement in terms of cleanliness and fibrillation. The most effective enzyme for banana fiber treatment is poligalacturonase (Biopectinase K), showing a high specific activity and being specific for substrates not damaging the cellulosic structure of fibers [53]. Long duration treatments (24 h, 48 h and 7 days) did not provide good results, due to enzyme deactivation. 6 h was optimal to obtain a textile grade banana fiber.Optimal conditions for banana fiber enzymatic treatment are: 100% Biopectinase K, 6 h; 45oC, pH = 4.5, with bath renewal after 3 h.Stability studies have demonstrated that over 80% of its activity takes place in the first 3 h; afterwards, the enzyme activity decreases reaching 12% 24 h later.Enzymatic treatments improve the thermal stability of fibers by the removal of pectin and hemicellulose, while producing a slight decrease in mechanical properties, probably due to defibrillation found under SEM observations. Banana fiber can be spun to produce yarns, mixed or not mixed with other fibers, while the most suitable for industrial scale-up without major equipment changes would be the blend of banana fiber and wool. Banana/PP yarn shows higher tenacity than flax/PP yarn and is more homogeneous

Conclusion

Banana is a natural bast fibre which has wide range of uses in handicraft product developments such as mat, rope and twines, but only 10% of its pseudo stem is being used for making products and remaining is waste or used as fertilizer. As it has a property like weather proof, UV protection (because of lignin content), moisture absorption, anti-oxidant and biodegradable, etc., it can be used to make a variety of products that help farmers economically and have wide scope to create new market. Recent studies have indicated that banana fibre possesses a lot of advantageous physical and chemical properties which can be used a very good raw material for the textile and packaging industry [54]. Banana fibres treated with varied concentrations of caustic soda show improvement in cellulose content, lignin removal, tenacity, crystallinity, and thermal resistance till 10% concentration, and after that no improvement is observed beyond 15%. Colour has turned the fibre towards darker side slightly aesthetically unappealing. It is noted that the 15% NaOH concentration is optimum for treating banana fibres used as reinforcement.

More information regarding this Article visit: OAJBGSR

https://biogenericpublishers.com/pdf/JBGSR.MS.ID.00170.pdf https://biogenericpublishers.com/jbgsr-ms-id-00170-text/

#Bannana fibres#enzymatic treatment#value addition composites#Alkali treatment#reinforcement#sustainability#Gokarneshan N*#OAJBGSR#JBGSR#biogeneric publishers

0 notes

Text

Steel Wire Rope And Plastic Rope Market To Witness Growth Acceleration By 2028

Global Steel Wire Rope and Plastic Rope Market: Overview

One of the most multi-functional pieces of mechanical machinery to be used across industries, ropes are made of varied material, which determines their utility, performance and service life. The development of new and advanced fibres have led to high performance ropes, which in turn have led to a rise in their applications. As higher breaking loads and increased abrasion resistance and fatigue resistance become more and more important, the global steel wire rope and plastic rope market is looking at an upward trajectory. Projected to grow at a moderate rate.

Get Brochure of the Report @ https://www.tmrresearch.com/sample/sample?flag=B&rep_id=5967

Global Steel Wire Rope and Plastic Rope Market: Notable Development

June 2017: Agreement between PSC Crane and Rigging from Piqua signed for supply of Plasma synthetic rope slings. The slings, as a lifting and lowering solution, are seen as an evolutionary development in the world of rope – 7 times lighter than wire ropes and 1/2x the size of a round one. These are expected to stiffen the competition for steel wire ropes and plastic ropes market in the coming years.

April 2018: Samson, through its partnership with Baitra, increased its distribution capacity in Spain; it increased facility size by a factor of 6. This might be read as the partners’ foray into untapped territory created by an increase in demand.

March 2019: Turbolite M, an 8 strand compacted hybrid hoist rope with high strength and fatigue resistance, developed which is helping break new grounds in underground mining.

FRES: Developed by National Oilwell Varco, Fibre Rope Extension System (FRES) can help increase lifting capacity of existing steel rope cranes for deep-water operations

Some of the most prominent competitors operating in the competitive landscape of global steel wire rope and plastic rope market include –

WireCo World Group Inc

Bekaert SA

Tuefelberger Holding AG

Cortland Limited

DSR

Samson Rope

Usha Martin

Jiangsu Langshan

Marlow Ropes Ltd

Current focus for most companies to chart growth in the global steel wire ropes and plastic ropes market is through improving efficiency and shelf life. In order to capture opportunities, it is important to focus on process improvement and financial flexibility to invest in the right kind of strategies.

Global Steel Wire Rope and Plastic Rope Market: Key trends

A move for steel sheaves over plastic ones in order to increase life of steel wire ropes is seen as driving adoption of the ropes. Here, it is important to note that good steel comes at a higher price than conventional steel, thereby impacting end-use industries negatively but nonetheless, opening gates to a more durability.

Increase in demand for steel wire ropes and plastic ropes from industries such as marine and fishing, mining, industrial and crane end-use, oil and gas, sports and leisure, and construction is expected for sheer virtue of the ropes being lightweight and sturdy apart from having a low specific gravity and superior elasticity. Besides, these have a high resistance to corrosion and can handle bending stresses exceptionally well.

Global Steel Wire Rope and Plastic Rope Market: Drivers

Owing to excellent impact resistance, flexibility, load-bearing capacity, and lifespan, a swift adoption of steel wire ropes and plastic ropes by industries such as mining and industrial and crane end-use is noted.

Plastic ropes are gaining better foothold, especially in cranes industry due to their ability to withstand harsh conditions during handling, installation and maintenance.

To get Incredible Discounts on this Report, Click Here @https://www.tmrresearch.com/sample/sample?flag=D&rep_id=5967

Global Steel Wire Rope and Plastic Rope Market: Regional Analysis

The APAC (Asia-Pacific) region would be prominent in terms of market value for steel wire ropes and plastic ropes in the forecasted period. China would be a key player; with the country’s industrial activities growing at a steady pace, the demand for steel wire ropes and plastic ropes is predicted to grow. Other countries representing a rosy outlook are India, Indonesia, Thailand and Malaysia. Brazil and GCC (Gulf Cooperation Council) countries are expected to play a key role too.

Global steel wire rope and plastic rope market is segmented based on:

Type of lay

Regular lay

Lang lay

Material type

Polypropylene

Polyester

Nylon

HMPE

Specialty Fibers

Application

Marine & Fishing

Sports & Leisure

Oil & Gas

Industrial & Crane

Mining

Construction

Others

Request For TOC @ https://www.tmrresearch.com/sample/sample?flag=T&rep_id=5967

About TMR Research:

TMR Research is a premier provider of customized market research and consulting services to business entities keen on succeeding in today’s supercharged economic climate. Armed with an experienced, dedicated, and dynamic team of analysts, we are redefining the way our clients’ conduct business by providing them with authoritative and trusted research studies in tune with the latest methodologies and market trends.

Contact:

TMR Research, 3739 Balboa St # 1097, San Francisco, CA 94121 United States

Tel: +1-415-520-1050

0 notes

Text

Everything You Need To Know About Polyester Yarn

Across the world, polyester yarn is used the most among all synthetic yarn for commercial purposes. Polyester yarn is known for its certain distinctive features such as insulation properties, wrinkle resistance, elasticity, and durability and so on. High tenacity yarn such as Polyester yarn is cost-effective which is another factor contributing to its popularity. Because of these features, polyester is used extensively to produce apparel, home ware such as bath and kitchen towels, rugs, upholstery etc. and industrial application include bottles, tapes, ropes, safety belts etc.

Before you buy polyester yarn know the different types of polyester available in the market which are used to manufacture various items.

Types of polyester

There are three major variants of polyester available. They are –

PCDT – fabric made from this variant of polyester is resilient and offers better elasticity. This polyester is mostly used to produce fabrics like upholstery and curtains since it is more durable than PET polyester.

PET or ethylene polyester – this type of polyester is used most widely compared to PCDT since it is a more stronger. This high tenacity yarn is used mostly to produce fabric, disposable water and soft drinks bottles.

Apart from the synthetic polyesters mentioned above, there is also another type of polyester which has been derived from plants. However, this variant of polyester is less durable and costs more than the synthetic ones. Which is why, it is used less compared to its synthetic counterparts.

Polyester fabrics manufactured from polyester yarn is used in textile industry because it possess certain characteristics which makes them more desirable compared to natural fabric.

Characteristics of fabrics made from polyester yarn

Polyester fabric is the perfect material for outdoor and sports activities Because of its durability. Since polyester is hydrophobic in nature, it does not absorb water at all and dries quickly compared to natural fabrics. Also because of this property it is easy to wash and wear and suitable for use in any wet and damp environment.

Polyester fabric require very low maintenance compared to natural fabrics like cotton or silk. It does not get wrinkled and when blended with cotton it also becomes crease resistance. It is also the perfect Material to use in situations where there are chances of the fabric getting dirty. Fabric made of polyester yarn resists most kinds of soiling except for oil based stains.

Polyester fabrics combined with wool is mostly used to design winter clothing such as parkas and jackets. Tents for outdoor activities are also made from polyester for similar reasons. Polyester fabrics do not allow air and moisture to pass easily thus resulting in trapping the heat.

Microfibre is a type of synthetic fibre derived from polyester. This fibres are extremely thin, even thinner than a single strand of silk. Some Microfibre absorb water and are non-abrasive. Because of these properties, fabrics made from microfibre are used to make bathing and cleaning products.

Modern technology has made it possible to make polyester feel and look like natural fabrics such as wool and silk. Along with that, its characteristic properties like its durability and insulation properties make it the fabric of choice. Buy polyester yarn because it has a number of advantages which greatly overshadows its few disadvantages.

0 notes

Text

2015-2023 World Synthetic Fibre Rope Market Research Report by Product Type, End-User / Application and Regions / Countries

2015-2023 World Synthetic Fibre Rope Market Research Report by Product Type, End-User / Application and Regions / Countries

Get Market Research publishes the following report: 2015-2023 World Synthetic Fibre Rope Market Research Report by Product Type, End-User / Application and Regions / Countries

Summary

Date Published: 2017-07-01 00:00:00

Pages: 107

Category: Chemicals and Materials

This report includes market status and forecast of global and major regions, with introduction of vendors, regions, product types and…

View On WordPress

#2015-2023 world synthetic fibre rope industry analysis#2015-2023 world synthetic fibre rope market data#2015-2023 world synthetic fibre rope market growthrate#2015-2023 world synthetic fibre rope market research#2015-2023 world synthetic fibre rope market size#2015-2023 world synthetic fibre rope market structure#2015-2023 world synthetic fibre rope market study#2015-2023 world synthetic fibre rope market trends#growth drivers and issues

0 notes

Text

Synthetic Fibre Rope Market To Observe Exponential Growth By 2020-2026 | Global Marketers

Global Marketers has added the latest research study on Global Synthetic Fibre Rope Market. The report presents a dashboard outline of leading companies covering their successful marketing strategies, market contribution, and recent developments in both historic and present contexts. The report reveals the latest market insights, current situation analysis with upcoming trends, and breakdown of the products and services.

The Synthetic Fibre Rope Market report on the Global Synthetic Fibre Rope Market covers details about market segmentation based on technology, product type, end-user industry, and regional analysis. The report provides a brief overview of the market for Synthetic Fibre Rope and current and future market trends. The report considers 2017-2018 as historical years, 2019 as the base year, and provides an estimate for the forecast period of 2020-2026. The Synthetic Fibre Rope Market report provides a comprehensive analysis in an organized manner in the form of tables, graphs, charts, figures, and diagrams.

Get Sample Copy of Synthetic Fibre Rope Market Report:

https://www.globalmarketers.biz/report/chemicals-and-materials/global-synthetic-fibre-rope-market-2019-by-manufacturers,-regions,-type-and-application,-forecast-to-2024/132363#request_sample

Some of the key players operating in the Synthetic Fibre Rope Market include:

Wireco World Group Samson Rope Technologies Garware-Wall Ropes Ltd. Bridon International Ltd Teufelberger Holding AG Marlow Ropes Ltd. Yale Cordage Inc Juli Sling Cortland Limited Southern Ropes Lanex A.S GRPP English Braids Ltd Taizhou Hongda Katradis Jiangsu Shenyun

Regional Outlook (Revenue in USD Billion; 2020–2026)

North America

Europe

Asia Pacific

Middle East & Africa

Latin America

The Synthetic Fibre Rope Market has witnessed a dynamic change in the market scenario and demands owing to changes in the economic landscape of the world. The report provides market growth and shares analysis with regards to the COVID-19 pandemic. It also covers the analysis of the present and future impact of the crisis on the overall development of the industry.

Request a discount on the report @

https://www.globalmarketers.biz/discount_inquiry/discount/132363

Synthetic Fibre Rope Market Segmentation:

Market Segment by Type:

Polypropylene Polyester Polyamide Fiber Polyethylene Others

Market Segment by Applications:

Marine & Fishing Sports and Leisure Oil & Gas Construction Cranes Others

The Synthetic Fibre Rope Market report covers a detailed analysis of the significant market players and their market share and global position. This report s include a SWOT analysis, Porter’s Five Forces Analysis. The report provides comprehensive coverage of the developments and strategic advancements such as mergers and acquisitions, joint ventures, collaborations, product launches, etc. undertaken by the key companies.

Make an Inquiry of this Report @

https://www.globalmarketers.biz/report/chemicals-and-materials/global-synthetic-fibre-rope-market-2019-by-manufacturers,-regions,-type-and-application,-forecast-to-2024/132363#inquiry_before_buying

Key Highlights of the Synthetic Fibre Rope Reports:

Comprehensive overview of Synthetic Fibre Rope Market

Changing market dynamics of the Synthetic Fibre Rope industry

In-depth market segmentation by Type, Application, etc.

Current Synthetic Fibre Rope industry trends

The viable landscape of Synthetic Fibre Rope Industry Market

Strategies of key players and product offerings

Key pointers of the Table of Contents:

Chapter 1 Synthetic Fibre Rope Industry Overview

Chapter 2 Production Synthetic Fibre Rope Market Analysis

Chapter 3 Sales Market Analysis

Chapter 4 Consumption Market Analysis

Chapter 5 Production, Sales and Consumption Synthetic Fibre Rope Market Comparison Analysis

Chapter 6 Major Manufacturers Production

Chapter 7 Major Material Analysis

Chapter 8 Major Synthetic Fibre Rope Type Analysis

Chapter 9 Industry Chain Analysis

Chapter 10 Global and Regional Market Forecast

Chapter 11 Major Manufacturers Analysis

Chapter 12 Conclusions

Chapter 13 Appendix

Click the Below link and Get a Full Table of Content @:

https://www.globalmarketers.biz/report/chemicals-and-materials/global-synthetic-fibre-rope-market-2019-by-manufacturers,-regions,-type-and-application,-forecast-to-2024/132363#table_of_contents

0 notes

Text

Global Aramid Fiber Market 2019 | Manufacturers In-Depth Analysis Report to 2024

The latest trending report Global Aramid Fiber Market 2019-2024 added by DecisionDatabases.com

Aramid Fiber is man-made high-performance fiber, with molecules that are characterized by relatively rigid polymer chains. These molecules are linked by strong hydrogen bonds that transfer mechanical stress very efficiently, making it possible to use chains of relatively low molecular weight. Aramid fibers are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated body armor fabric and ballistic composites, in bicycle tires, and as an asbestos substitute. The name is a portmanteau of aromatic polyamide. They are fibers in which the chain molecules are highly oriented along the fiber axis, so the strength of the chemical bond can be exploited.

The worldwide market for Aramid (Aramid Fiber) is expected to grow at a CAGR of roughly 2.9% over the next five years, will reach 4980 million US$ in 2024, from 4200 million US$ in 2019.

This report focuses on the Aramid (Aramid Fiber) in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Browse the complete report and table of contents @ https://www.decisiondatabases.com/ip/17618-aramid-fiber-market-analysis-report

Market Segment by Manufacturers, this report covers

· Dupont

· Teijin

· JSC Kamenskvolokno

· Kolon

· Hyosung

· Huvis

· TAYHO

· Bluestar

· Sinopec Yizheng Chemical Fibre

· Guangdong Charming

· Hebei Silicon Valley Chemical

· Zhaoda Specially Fiber

· SRO

Market Segment by Regions, regional analysis covers

· North America (United States, Canada and Mexico)

· Europe (Germany, France, UK, Russia and Italy)

· Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

· South America (Brazil, Argentina, Colombia etc.)

· Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

Market Segment by Type, covers

· Para-aramid Fibers

· Meta-aramid Fibers

Market Segment by Applications, can be divided into

· Body Armor & Helmet

· Aerospace Materials

· Sports Materials

· Tire

· High Strength Rope

· Others

Download Free Sample Report of Global Aramid (Aramid Fiber) Market @ https://www.decisiondatabases.com/contact/download-sample-17618

The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe Aramid (Aramid Fiber) product scope, market overview, market opportunities, market driving force and market risks. Chapter 2, to profile the top manufacturers of Aramid (Aramid Fiber), with price, sales, revenue and global market share of Aramid (Aramid Fiber) in 2017 and 2018. Chapter 3, the Aramid (Aramid Fiber) competitive situation, sales, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the Aramid (Aramid Fiber) breakdown data are shown at the regional level, to show the sales, revenue and growth by regions, from 2014 to 2019. Chapter 5, 6, 7, 8 and 9, to break the sales data at the country level, with sales, revenue and market share for key countries in the world, from 2014 to 2019. Chapter 10 and 11, to segment the sales by type and application, with sales market share and growth rate by type, application, from 2014 to 2019. Chapter 12, Aramid (Aramid Fiber) market forecast, by regions, type and application, with sales and revenue, from 2019 to 2024. Chapter 13, 14 and 15, to describe Aramid (Aramid Fiber) sales channel, distributors, customers, research findings and conclusion, appendix and data source.

Purchase the complete Global Aramid (Aramid Fiber) Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-17618

Other Reports by DecisionDatabases.com:

Global Aramid Fiber Protective Apparel Market 2019 by Manufacturers, Regions, Type and Application, Forecast to 2024 @ https://www.decisiondatabases.com/ip/18353-aramid-fiber-protective-apparel-market-analysis-report

Global Para-aramid Fiber Market 2019 by Manufacturers, Regions, Type and Application, Forecast to 2024 @ https://www.decisiondatabases.com/ip/41269-para-aramid-fiber-industry-analysis-report

About-Us: DecisionDatabases.com is a global business research reports provider, enriching decision makers and strategists with qualitative statistics. DecisionDatabases.com is proficient in providing syndicated research report, customized research reports, company profiles and industry databases across multiple domains.

Our expert research analysts have been trained to map client’s research requirements to the correct research resource leading to a distinctive edge over its competitors. We provide intellectual, precise and meaningful data at a lightning speed.

For more details: DecisionDatabases.com E-Mail: [email protected] Phone: +91 9028057900 Web: https://www.decisiondatabases.com/

#Aramid Fiber Market#Aramid Fiber Market Report#Aramid Fiber Industry Report#Aramid Fiber Market Analysis#Aramid Fiber Market Growth#Aramid Fiber Market Trends#Aramid Fiber Market Outlook#Global Aramid Fiber Industry Report

0 notes

Text

Synthetic Rope Market - Global Opportunity Analysis and Industry Forecast, 2019-2025

The Global Synthetic Rope Market was valued around US$ XX Mn by 2018 and growing at a significant CAGR over next seven years 2019-2025 due to increasing demand for oil and gas extraction activities.

The global Synthetic Rope market accounted for US$ XX Mn in 2018 and burgeoning over the forthcoming years. Some of the key factors responsible for the market growth include growth in awareness regarding sports, safety aspects of synthetic ropes, increasing demand for oil and gas extraction activities, increase in demand for crude oil and growing demand for construction industries. In addition, high demand from emerging economies provides huge growth opportunity for the market. However, factors such as lack of awareness and high cost of raw materials are hindering the market growth.

Global Synthetic Rope market segmented on the basis of material type, end user and region.

Avail Sample Report of the Market @ https://precisionbusinessinsights.com/request-sample?product_id=30737

Polypropylene (PP) Materials Dominate the Global Synthetic Rope Market

Based on the product type, global Synthetic Rope market segmented into Nylon, Polyester, Polyethylene, Polypropylene and Specialty Fibers. Polypropylene (PP) is a thermoplastic “addition polymer” made from the combination of propylene monomers. Polypropylene rope is commonly used for fishing and other general marine applications. This type of rope is characterized by an average abrasion resistance, good strength and good UV radiation resistance. It has a density of 0.91 meaning this is a floating rope. This is usually manufactured using monofilament, splitfilm or multifilament fibres.

Asia Pacific Leads the Global Synthetic Rope market

PBI’s global Synthetic Rope market report analyses the market in different regions such as North America, Europe, Asia Pacific, Latin America, and Middle East and Africa. According to regional analysis. Asia Pacific accounted for larger revenue share in global synthetic rope market with considerable CAGR. The growth in this region can be attributed to unexplored offshore oil & gas fields in the region, growing construction industry and rising marine offshore mooring systems. Moreover, high aquaculture production or fishing activities in the region is other major factor boosting the market growth.

Strategic Expansions are the key strategies adopted by market players

Global Synthetic Rope market further reveals that the key players increasingly adopting strategies such as launch of newer products, frequent product approvals, and long term alliance to improve market revenue share and gaining significant geographic presence across the region. For instance, Samson, a provider of synthetic rope in numerous marine applications has expanded its footprint with a new facility in various areas. The expansion is expected to increase Samson’s market penetration in addition to uplifting its facility to increase production capabilities, therefore impacting growth of market in a significant way.

Key player’s profiles in the report are Bridon International Limited (U.K.), Cortland Limited (U.S.), English Braids Ltd (England), Honeywell International Inc. (U.S.), Marlow Ropes (U.K.), Royal DSM (Netherlands), Samson Rope Technologies (U.S.), Teijin Aramid (Netherlands), WireCo World Group (U.S.) and Yale Cordage Inc. (U.S).

For More Information @ https://precisionbusinessinsights.com/market-reports/global-synthetic-rope-market/

Precision Business Insights (PBI) in its report titled “Global Synthetic Rope Market: Market Estimation, Dynamics, Regional Share, Trends, Competitor Analysis 2014-2018 and Forecast 2019-2025” assesses the market performance over seven years forecast period over 2019-2025. The report analyses the market value forecast and provides the strategic insights into the market driving factors, challenges that are hindering the market revenue growth over forecast period. Moreover, the report also includes the total revenue and volume for the market.

Detailed Segmentation

By Material Type

o Nylon

o Polyester

o Polyethylene

o Polypropylene

o Specialty Fibers

By End User

o Sports

o Oil & Gas

o Mining

o Marine & Fishing

o Cranes

o Building & Construction

o Others

Geography

o North America

· US

· Canada

o Europe

· Germany

· France

· UK

· Italy

· Spain

· Russia

· Poland

· Rest of Europe

o Asia-Pacific

· Japan

· China

· India

· Australia & New Zealand

· ASEAN (Includes Indonesia, Thailand, Vietnam, Philippines, Malaysia, and Others)

· South Korea

· Rest of Asia-Pacific

o Latin America

· Brazil

· Mexico

· Argentina

· Venezuela

· Rest of Latin America

o Middle East and Africa (MEA)

· Gulf Cooperation Council (GCC) Countries

· Israel

· South Africa

· Rest of MEA

Key Features of the Report:

The report provides granular level information about the market size, regional market share, historic market (2014-2018) and forecast (2019-2025)

The report covers in-detail insights about the competitor’s overview, company share analysis, key market developments, and their key strategies

The report outlines drivers, restraints, unmet needs, and trends that are currently affecting the market

The report tracks recent innovations, key developments and startup’s details that are actively working in the market

The report provides plethora of information about market entry strategies, regulatory framework and reimbursement scenario

The report analyses the impact of socio-political environment through PESTLE Analysis and competition through Porter’s Five Force Analysis in addition to recent technology advancements and innovations in the market

Request Customization @ https://precisionbusinessinsights.com/request-customisation?product_id=30737

About Us:

Precision Business Insights is one of the leading market research and management consulting firm, run by a group of seasoned and highly dynamic market research professionals with a strong zeal to offer high-quality insights.

Contact Us:

Shreya Paul

Senior Business Development Executive

Email @ [email protected]

Call @ +1-866-598-1553

Precision Business Insights

0 notes

Text

Gas Pipes by Garware Technical Fibres

Garware Technical Fibres Ltd. (Formerly Garware-Wall Ropes Ltd.) is one of India’s leading players in the technical textiles sector. They are Pioneers of synthetic cordage in India. Established in 1976, the company today is a multi-divisional, multi-geographical technical textiles company and is known for providing world-class innovative solutions in high-performance aquaculture cage nets, fishing nets, sports nets, safety nets, agricultural nets, coated fabrics, polymer ropes, and geosynthetics.

Garware Technical Fibres Ltd. offers threads and yarns solutions under their Garlon brand. These solutions find multiple applications across various industries starting from portable bag closing machines and port bagging thread to Shoe stitching and manufacture of Fibrillated Bulk Containers.

The Garlon brand by Garware Technical Fibres has the highest brand recall and recognition among almost all the PPMF yarn and thread requirements in India. They have better seam strength for the bags with continuous packaging resulting in low downtime and minimum wastage. The yarn and threads under the Garlon brand have high breaking strength. These threads and yarns may be used in places where they may come in contact with different chemicals and keeping this in mind they are made chemical resistant.

The threads are packed in a knotless package and can be removed without getting them tangled. These threads are compatible with almost all kinds of portable sewing machines. These yarns and threads are also used as a reinforcement material.

Such applications under which the Garlon threads and yarns are used are Concrete reinforcement and Pipe reinforcement. Here are two Garlon yarn categories that are used for these two applications. One is Garlon Flat Yarn for pipe reinforcement and the other is Garlon Twisted yarn for concrete reinforcement. The Garlon Flat yarn is uniformly heat set for better running on the braiding machines for reinforcing the pipes. These braiding methods ensure that the pipe is reinforced for a strong body at the same time maintaining the aesthetic value of the product. The Garlon threads and yarns come in a variety of forms. It starts from 500/80 HS (Harmonized System) to 700/100 HS.

Garware Technical Fibres is an organization that works together with a team of experienced and skillful managers, engineers and technicians. They truly believe that customer is the king. They constantly work to enhance the experience of their customers. This is the reason this organization has received the largest sports goods and sport nets exporter award from the Sports Goods Export Promotion Council, sponsored by the Ministry of Commerce, Govt. of India. They are a dividend paying Public Limited Company since inception. Listed on the Bombay Stock Exchange and the National Stock Exchange of India. Day to day operations are managed by a team of experienced professionals having techno-commercial expertise with a vast industrial and marketing experience

Their success can be measured by the boost in their business they received in the past years. The organization has setup 6 office premises overseas. They have also expanded their business with customers in over 75 countries in almost every field.

0 notes

Text

Steel Wire Rope and Plastic Rope Market Analysis By Trends, Forecast

Global Steel Wire Rope and Plastic Rope Market: Overview

One of the most multi-functional pieces of mechanical machinery to be used across industries, ropes are made of varied material, which determines their utility, performance and service life. The development of new and advanced fibres have led to high performance ropes, which in turn have led to a rise in their applications. As higher breaking loads and increased abrasion resistance and fatigue resistance become more and more important, the global steel wire rope and plastic rope market is looking at an upward trajectory. Projected to grow at a moderate rate.

Get Brochure of the Report @ https://www.tmrresearch.com/sample/sample?flag=B&rep_id=5967

Global Steel Wire Rope and Plastic Rope Market: Notable Development

June 2017: Agreement between PSC Crane and Rigging from Piqua signed for supply of Plasma synthetic rope slings. The slings, as a lifting and lowering solution, are seen as an evolutionary development in the world of rope – 7 times lighter than wire ropes and 1/2x the size of a round one. These are expected to stiffen the competition for steel wire ropes and plastic ropes market in the coming years.

April 2018: Samson, through its partnership with Baitra, increased its distribution capacity in Spain; it increased facility size by a factor of 6. This might be read as the partners’ foray into untapped territory created by an increase in demand.

March 2019: Turbolite M, an 8 strand compacted hybrid hoist rope with high strength and fatigue resistance, developed which is helping break new grounds in underground mining.

FRES: Developed by National Oilwell Varco, Fibre Rope Extension System (FRES) can help increase lifting capacity of existing steel rope cranes for deep-water operations

Some of the most prominent competitors operating in the competitive landscape of global steel wire rope and plastic rope market include –

WireCo World Group Inc

Bekaert SA

Tuefelberger Holding AG

Cortland Limited

DSR

Samson Rope

Usha Martin

Jiangsu Langshan

Marlow Ropes Ltd

Current focus for most companies to chart growth in the global steel wire ropes and plastic ropes market is through improving efficiency and shelf life. In order to capture opportunities, it is important to focus on process improvement and financial flexibility to invest in the right kind of strategies.

Global Steel Wire Rope and Plastic Rope Market: Key trends

A move for steel sheaves over plastic ones in order to increase life of steel wire ropes is seen as driving adoption of the ropes. Here, it is important to note that good steel comes at a higher price than conventional steel, thereby impacting end-use industries negatively but nonetheless, opening gates to a more durability.

Increase in demand for steel wire ropes and plastic ropes from industries such as marine and fishing, mining, industrial and crane end-use, oil and gas, sports and leisure, and construction is expected for sheer virtue of the ropes being lightweight and sturdy apart from having a low specific gravity and superior elasticity. Besides, these have a high resistance to corrosion and can handle bending stresses exceptionally well.

Global Steel Wire Rope and Plastic Rope Market: Drivers

Owing to excellent impact resistance, flexibility, load-bearing capacity, and lifespan, a swift adoption of steel wire ropes and plastic ropes by industries such as mining and industrial and crane end-use is noted.

Plastic ropes are gaining better foothold, especially in cranes industry due to their ability to withstand harsh conditions during handling, installation and maintenance.

To get Incredible Discounts on this Report, Click Here @https://www.tmrresearch.com/sample/sample?flag=D&rep_id=5967

Global Steel Wire Rope and Plastic Rope Market: Regional Analysis

The APAC (Asia-Pacific) region would be prominent in terms of market value for steel wire ropes and plastic ropes in the forecasted period. China would be a key player; with the country’s industrial activities growing at a steady pace, the demand for steel wire ropes and plastic ropes is predicted to grow. Other countries representing a rosy outlook are India, Indonesia, Thailand and Malaysia. Brazil and GCC (Gulf Cooperation Council) countries are expected to play a key role too.

Global steel wire rope and plastic rope market is segmented based on:

Type of lay

Regular lay

Lang lay

Material type

Polypropylene

Polyester

Nylon

HMPE

Specialty Fibers

Application

Marine & Fishing

Sports & Leisure

Oil & Gas

Industrial & Crane

Mining

Construction

Others

Request For TOC @ https://www.tmrresearch.com/sample/sample?flag=T&rep_id=5967

About TMR Research:

TMR Research is a premier provider of customized market research and consulting services to business entities keen on succeeding in today’s supercharged economic climate. Armed with an experienced, dedicated, and dynamic team of analysts, we are redefining the way our clients’ conduct business by providing them with authoritative and trusted research studies in tune with the latest methodologies and market trends.

Contact:

TMR Research, 3739 Balboa St # 1097, San Francisco, CA 94121 United States

Tel: +1-415-520-1050

0 notes

Link

0 notes

Link

0 notes

Text

How to Clean Your Domin8r X or Grande Mk3’s Winch Rope

Recent updates to technology have greatly benefited 4WDers in the last couple of years!

One of our greatest advancements of new technology has been the introduction of durable and lightweight synthetic winch rope as standard equipment right across the entire range of our winches here at 4WD Supacentre.

Even as recent as five years ago, the vast majority of winches on the market came with old-style heavy weight dangerous steel cable. Here at 4WD Supacentre we believe in synthetic rope’s benefits so much that we now make sure it comes standard on every single winch that we sell!

SAFETY

By using a synthetic rope for your 4×4 winch we gain stacks more safety and ease of use on the tracks. Firstly, a synthetic winch rope by its nature doesn’t ‘store’ kinetic energy as much as steel cable this is due to its low mass as well as its inelasticity (amount of stretch).

Surprisingly enough a steel cable is a bit like a spring, and if you’ve ever seen a steel cable let go when it’s under tension, you’ll know it is a frightening experience and one that can very easily turn deadly.

By using a synthetic winch rope not only is it much more user-friendly, if it does break from wear and tear or misuse, it simply drops in its place as it doesn’t ‘store’ any of that stored energy from being put under tension. It’s lighter, much easier to handle and work with, it doesn’t splinter, it floats on water and it’s just as strong as its steel cable counterpart and that’s a huge win for all of us!

One major thing that synthetic winch rope has working against it compared to its heavier and less safe steel cable is its inability to handle abrasive, sharp and rugged terrain, this includes the internal fibres being abraded by particles of dirt on the inside. Over time this can cause a catastrophic failure of the winch cable, resulting in a failed recovery.

Because synthetic rope is made of thousands of strands of ultra-fine fibres twisted together, there is the potential for these to be damaged if your rope is dragged against sharp or abrasive surfaces. Whilst a winch cable may take small amounts of damage, this is not the end of the world – it just means you need to be a little more careful about the way you use your rope.

There are ways to prevent damage to your winch rope, if you’re winching up and over a rise that means the synthetic rope is potentially going to cut into the ground, it’s a good idea to use something like a tarp or even a floor matt or the handle of a shovel to help keep the rope up out of the dirt and sliding smoothly.

There are more things that can potentially damage your winch rope than just direct contact with sharp and abrasive surfaces. If you have to do a long, extended recovery in really sloppy mud, then it’s vital that you thoroughly clean your winch rope when you get home to save it from internal damage. This is especially true for that sandy, silty type of mud that finds its way as the small bits of grit can work their way in between the cables internal fibres and over time can cut the winch rope from inside out.

Thankfully cleaning your winch rope, is extremely easy to do and takes next to no effort or time (approximately 1-2 beers on a sunny Sunday afternoon). When you get home from your next adventure and you’re parked up on your grass lawn washing your 4WD, unspool your entire synthetic winch rope all the way out, so there’s only clean rope left still wrapped around the drum.

Get a large bucket, something like those 20L buckets that fertiliser or pool chemicals come in and give it a thorough rinse out. It is very important that it’s completely clean as any harsh chemicals can potentially damage your synthetic rope. You might want to give it a quick wash out with some mild dishwashing detergent to ensure that the bucket is completely clean.

Now, sit the bucket in front of your 4WD and put the winch rope in it, then fill the bucket with clean water from the tap.

Gently massage the entire winch rope to get the majority of the mud out of it, then tip it all out and repeat the process with fresh water. Only, this time you want to let the winch rope soak in the bucket for at least half an hour to let the water get right into the rope and soak out all the mud. Empty the bucket and leave the winch rope dangling over your bull bar to drip-dry, somewhere in the shade and out of direct sunlight. When it’s mostly dry you can re-spool the rope back onto the drum under slight tension (put on a pair of gardening gloves or your recovery gloves and hold tension against the rope as you spool it in).

As a pro tip you should never never use your pressure-washer to wash your winch rope, as although it might look like it gets it clean, all it is doing is forcing the dirt right up inside the synthetic winch rope.

Do this cleaning routine every time your winch gets used hard in a muddy environment and you’ll massively extend its service life and get even more bang for buck out of your massive powerful Domin8r X 12,000lb winch or your Grande MKIII!

from 4WD Supacentre via 4WD Supacentre on Inoreader https://www.4wdsupacentre.com.au/news/how-to-clean-your-domin8r-x-or-grande-mk3s-winch-rope-2/ from 4WD Supacentre https://frwdsupacentre.tumblr.com/post/174561067031

0 notes

Text

How to Clean Your Domin8r X or Grande Mk3’s Winch Rope

Recent updates to technology have greatly benefited 4WDers in the last couple of years!

One of our greatest advancements of new technology has been the introduction of durable and lightweight synthetic winch rope as standard equipment right across the entire range of our winches here at 4WD Supacentre.

Even as recent as five years ago, the vast majority of winches on the market came with old-style heavy weight dangerous steel cable. Here at 4WD Supacentre we believe in synthetic rope’s benefits so much that we now make sure it comes standard on every single winch that we sell!

SAFETY

By using a synthetic rope for your 4×4 winch we gain stacks more safety and ease of use on the tracks. Firstly, a synthetic winch rope by its nature doesn’t ‘store’ kinetic energy as much as steel cable this is due to its low mass as well as its inelasticity (amount of stretch).

Surprisingly enough a steel cable is a bit like a spring, and if you’ve ever seen a steel cable let go when it’s under tension, you’ll know it is a frightening experience and one that can very easily turn deadly.

By using a synthetic winch rope not only is it much more user-friendly, if it does break from wear and tear or misuse, it simply drops in its place as it doesn’t ‘store’ any of that stored energy from being put under tension. It’s lighter, much easier to handle and work with, it doesn’t splinter, it floats on water and it’s just as strong as its steel cable counterpart and that’s a huge win for all of us!

One major thing that synthetic winch rope has working against it compared to its heavier and less safe steel cable is its inability to handle abrasive, sharp and rugged terrain, this includes the internal fibres being abraded by particles of dirt on the inside. Over time this can cause a catastrophic failure of the winch cable, resulting in a failed recovery.

Because synthetic rope is made of thousands of strands of ultra-fine fibres twisted together, there is the potential for these to be damaged if your rope is dragged against sharp or abrasive surfaces. Whilst a winch cable may take small amounts of damage, this is not the end of the world – it just means you need to be a little more careful about the way you use your rope.

There are ways to prevent damage to your winch rope, if you’re winching up and over a rise that means the synthetic rope is potentially going to cut into the ground, it’s a good idea to use something like a tarp or even a floor matt or the handle of a shovel to help keep the rope up out of the dirt and sliding smoothly.