#Wire cutting machine

Text

I photographed a factory tour for my job and it was FINALLY a facility with clicky clacky automated machines in it, instead of mostly being people hand-assembling semi-secret electrical prototypes I am not supposed to photograph

#it was mostly wire cutting/bending#lots of tiny little precisely formed wire loops and squiggles clicking out of big oily machines...very fun#boring text posts#job 3

14 notes

·

View notes

Text

Old sci fi robots.

I love you. I wish to touch you in more than just the paper you were drawn on, or the words that crafted you.

#shine post#i really like robots#robots#sci fi robot#romantic#i want to kiss robots#and feel their bodies with my fingers#i got to open up an old computer in kindergarden as a hands on thing with supervision#after that i would ask each grade if we could take apart computers#my mom gave me a broken one and let me rip it open#i still have some pieces and i long yet again to open up the casing of a machine and go over it#cutting through wires and unscrewing everything i can and seeing the chips inside#i dream about it

2 notes

·

View notes

Text

had a very intense semi lucid dream last night where i was the daughter/acolyte of an insane cult leader/my dad who performed non consenual surgery on me and molested and raped me. it inspired me to start writing a lil sci fi novella but also to clean out my closet and find my vibrator cuz i was desperate for it after waking up lmfao

#he had like. grown me & a few other and inserted more and more mechanical parts into us through our lives#so we were mostly machine inside. but human-looking outside#and i tried to run away and got the shit kicked out of me by my sister/fellow cult member#she patched me up most of the way but for the complicated stuff dad had to help#one of my arms had been broken so he just cut the whole thing open to fuck with the wires and stuff. it felt so awful guhhhhh#and after that he started trying to finger me and asking questions about wether id slept with anyone while i had been away#and told me he knew id been touching myself and that made me disgusting and corrupt and that was why id tried to leave. and he had to fix#my mind too.#there was blood on his fingers when he pulled them out of me and he got so so pissed#i was crying and trying to explain i was on my period but he said that was a lie and id been trying to hide more injuries from him so he#couldnt finish fixing me#and he spent a solid twenty minutes beating me for it while groping me & continuing to finger me#he had a metal arm n that was the one he was using too so i kept getting cut and bleeding more and hed yell and hit me more and he just#wouldnt stop 😵💫😵💫#i was tied down by my wrists laying on my tummy but he forced me to roll over so he could punch my stomach a lot too ;-;#toward the end he got on top of me and started grinding against me#talking to me nice again and saying i was his girl and he just wanted to make me better and i only had to cooperate#i was sobbing and panicking still but he was just petting me#he tried to push his cock in me but he like. couldnt fit.#he could only get a couple inches in and he stayed sweet for a little longer but then he started getting frustrated#yelling at me to stop fighting him and slapping my face#and i was trying so so hard to relax and let him in so it could be over but i was just too small#he gave up after awhile and finished cleaning me up without saying anything then left me alone down there. still tied down and crying.#that was only one part of the dream there was a whole plotline where i had made contact with 2 people (a brother and sister) on the outside#who were trying to save me. and i was trying to talk my sister into leaving with me because i was so terrified of losing her#eventually i did get out and ended up living with the brother and sister and it was super cute and sweet#parts of the dream were from her pov too. she made us all matching hats :]

4 notes

·

View notes

Text

https://berlin-machineries.com/

Buy Cnc fiber laser cutting machine, cnc edm wire cut machine, vertical turret milling machine, znc electric spark discharge machine, radial and pillar drill machine at best cost.

#CNC Fiber Laser Cutting Machine#CNC Fiber Laser Cutting Machine supplier#CNC Fiber Laser Cutting Machine Manufacturer#CNC Fiber Laser Cutting Machine supplier in pune#CNC Fiber Laser Cutting Machine Manufacturer in pune#Hydraulic Brake Press Machine#Hydraulic Brake Press Machine supplier#Hydraulic Brake Press Machine Manufacturer#Hydraulic Brake Press Machine supplier in pune#Hydraulic Brake Press Machine Manufacturer in pune#CNC EDM Wire Cut Machine#CNC EDM Wire Cut Machine supplier#CNC EDM Wire Cut Machine Manufacturer#CNC EDM Wire Cut Machine supplier in pune#CNC EDM Wire Cut Machine Manufacturer in pune#EDM Drilling Machine#EDM Drilling Machine supplier#EDM Drilling Machine Manufacturer#EDM Drilling Machine supplier in pune#EDM Drilling Machine Manufacturer in pune#ZNC Electric Spark Discharge Machine#ZNC Electric Spark Discharge Machine supplier#ZNC Electric Spark Discharge Machine Manufacturer#ZNC Electric Spark Discharge Machine supplier in pune#ZNC Electric Spark Discharge Machine Manufacturer in pune#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

3 notes

·

View notes

Text

Also with so little time before the con and so much Outfit left for me to make, I'm starting to enter hyperfocus when I'm working on it 👁👁

#threading the 2nd wing and didnt stop only until i had to heat up a rat for my snake#and now i really don't feel like going back to it now lmao; tomorrow i can hypothetically finish threading it#and line the last piece with wire and then run them through my sewing machine; I'll need to cut the dart for the coat as well#and figure out how to make the sleeves more comfy.. iron down the seams maybe? or cover them with cotton..#might do yarn for the antennae bc that's easier to get ahold of.. as soon as i figure out the tails I'll go back to the fabric store#and try to find more of the specific yarn i used for my plushie bc that might be my best bet rn#i doubt I'll get the antennae exactly as ive been drawing them but i just need them to be long if i can 🥺#might have to compromise between size and fullness ://// depends on how much yarn I'm willing to buy lmao#need to get some boots and spray paint them.. style and dye the wig 😔 looked at it and briefly considered using it for pouf#bc i don't have bangs but i love using my actual bleached hair for him lmao; i do need to bleach my roots again#i need con tickets i STILL havent bought those and it's in like 2 weeks#shai speaks

2 notes

·

View notes

Text

1 note

·

View note

Text

ARC Welding Machine Manufacturer in india -Paragweld

Paragweld is a leading ARC welding machine manufacturer in India, renowned for its high-quality and durable welding solutions. With advanced technology and a commitment to excellence, Paragweld provides reliable and efficient welding machines, catering to diverse industrial needs.

#Submerged ARC Auto Welder Series Manufacturers#MIG Welder Series Manufacturers#TIG Welder Series Manufacturers#ARC Welder Series Manufacturers#LGK air plusma cutter series Manufacturers#Welding Electrodes Manufacturers#Welding Wire Manufacturers#Pulse TIG/MMA AC/DC Welder Series Manufacturers#CNC Plasma Cutting Machine Manufacturers#Special Purpose Machinery Manufacturers#Mig Welding Accessories Manufacturers#Tig Welding Accessories Manufacturers#Air Plasma Cutting Machine Accessories Manufacturers#Water Cooling Unit Manufacturers

0 notes

Text

Force aac plant provide the best horizontal wire cutting machine for aac block at best cost. It is the best horizontal wire cutting machine for aac block Manufacturers, supplier company in Pune, Mumbai, Nashik, Kolhapur, Satara, sangli, Bangalore, Chennai, Gujrat, Ahmedabad, India

0 notes

Text

Auto Cutter USA

USA manufacturer of industrial cutting machines. We deliver affordable and precision equipment to cut to length wire, tubing and cable.

#automatic cable cutter machine#automatic tubing cutter#automatic wire cutting machine#heat shrink tubing cutter machine.

0 notes

Text

Cnc Cutting Machine - Manufacturers Suppliers In India

Our CNC Wire Cutting Machine, painstakingly designed for accuracy, speed, and adaptability across a variety of industrial applications, will revolutionize your cutting processes. As a trusted provider, our cutting-edge CNC wire cutting machines offer superior performance for industries such as manufacturing, automotive, and more. These machines deliver high-quality results with adaptability and reliability, ensuring precise and efficient cutting of wires and materials. Our provided a machine is highly appreciated by our clients owing to its low maintenance and rugged construction. It is used for increased bulk density. Our manufactured CNC Cutting Machine is highly demanded in the market due to our maximum efficiency, effectiveness, and long working life. With our cutting-edge CNC wire cutting machine technology, you can streamline your production processes and ensure excellent quality for your products. You can also increase productivity and shorten production times in your industrial operations. You can rely on us to deliver cutting-edge, customized solutions that meet your demands.

0 notes

Text

Advantages and working principle of small EDM wire cut machine

The small EDM wire cut machine is an advanced metal processing equipment that has been widely used in industrial production due to its unique working principle and many advantages. This article will introduce in detail the advantages and working principles of small EDM wire cut machine.

First, let us understand the working principle of small EDM wire cut machine. Wire EDM is a processing method that uses electric pulse discharge to cut metal. Its basic principle is to melt and corrode metal through electrical pulse discharge between the electrode and the workpiece under the action of the working fluid, thereby achieving the purpose of cutting. During the cutting process, the wire EDM machine can achieve precise cutting of metal materials by controlling the distance between the electrode and the workpiece and the frequency, amplitude and other parameters of the electric pulse discharge, and the cutting surface is smooth and burr-free.

Advantages of small EDM wire cut machine

1. High precision: small EDM wire cut machine can achieve micro-size processing with high precision and is suitable for the processing and manufacturing of precision parts.

2. High processing efficiency: Using the principle of electric spark discharge, it can perform efficient processing on hard materials and improve production efficiency.

3. Good surface quality: No mechanical stress is generated during the processing, so the processed surface quality is high and it is not easy to produce deformation and cracks.

4. Wide scope of application: small EDM wire cut machine is suitable for processing various metal materials, including carbide, stainless steel, aluminum alloy, etc.

5. Easy to operate: The equipment has a high degree of automation and is simple to operate, reducing the possibility of human operating errors.

6. Saving materials: Since no chips are generated during processing, the use of raw materials is saved.

With its advantages of high precision, high efficiency, good surface quality, and working method based on the principle of electric spark discharge, small EDM wire cut machine has become an indispensable and important equipment in the modern manufacturing industry, providing precision machining in various industries. Reliable technical support. It can not only precisely cut metal materials of various hardnesses with good cutting effects but also can cut complex-shaped workpieces with fast cutting speed and high efficiency, which greatly improves production efficiency. Therefore, a small EDM wire cut machine is of great significance in improving production efficiency, ensuring product quality, and reducing production costs. It is an indispensable and important equipment in modern industrial production.

By having an in-depth understanding of the advantages and working principles of small EDM wire cut machines, we can better understand and apply this advanced processing technology and promote the development and progress of the manufacturing industry.

1 note

·

View note

Text

wire nail making machine

A wire nail making machine is a type of mechanical equipment designed for the production of nails from wire rods or coils. These machines are widely used in industries that require large-scale nail production, such as construction, carpentry, and packaging.

Here is a basic overview of how a wire nail making machine typically works:

Wire Feeding: The process begins with the feeding of a coil or straight wire into the machine. The wire used is usually made of materials like steel.

Wire Straightening and Cutting: The machine often includes a straightening and cutting mechanism to ensure that the wire is straight and of the desired length. This step is crucial to produce uniform nails.

Nail Forming: The straightened and cut wire is then fed into the nail forming mechanism. This part of the machine shapes the wire into the desired nail size and configuration. Different dies and tools may be used to create various nail shapes.

Head and Point Formation: After the initial forming, the machine typically has processes for creating the nail head and sharpening the nail point. These steps give the nail its final shape.

Nail Ejection: Once the nail is formed, it is ejected from the machine. Some machines may have a conveyor or other mechanism to collect and transport the nails for packaging.

Quality Control: Many machines are equipped with quality control features to ensure that the produced nails meet the required standards. This may include inspections for length, diameter, and overall quality.

Automation: Modern wire nail making machines often incorporate automation to enhance efficiency and productivity. Computerized controls may be used to set parameters and monitor the production process.

It’s important to note that the specific design and features of wire nail making machines can vary among manufacturers. The capacity of these machines can also vary, ranging from smaller units suitable for smaller operations to large-scale industrial machines for high-volume production.

When considering the purchase of a wire nail making machine, factors such as production capacity, nail size variability, automation features, and overall durability are important considerations.

Automatic nail making machine:

An automatic nail making machine is a mechanical device designed to produce nails in a highly automated fashion. These machines are commonly used in industries that require large-scale and efficient nail production, such as construction, woodworking, and packaging. Here are some key features and aspects of automatic nail making machines:

Wire Feeding: These machines are designed to handle wire coils or straight wire rods as input material. The wire is usually made of materials like steel.

Straightening and Cutting: Automatic nail making machines often include mechanisms for straightening and cutting the wire into the desired lengths. This step is essential for producing uniform nails.

Nail Forming: The machine has a forming mechanism that shapes the straightened wire into the desired nail size and configuration. Various dies and tools may be used to create different nail shapes.

Head and Point Formation: After the initial forming, the machine typically incorporates processes for creating the nail head and sharpening the nail point. These steps contribute to the final shape and functionality of the nail.

Automatic Operation: As the name suggests, these machines are designed for automation. They may feature computerized controls and sensors to regulate the production process, monitor parameters, and make adjustments as needed.

Nail Ejection and Collection: Once a nail is formed, it is automatically ejected from the machine. Some machines have conveyors or collection systems to gather the nails for packaging.

Quality Control: Many automatic nail making machines include quality control features to ensure that the produced nails meet specific standards. This can involve inspections for length, diameter, and overall quality.

Capacity and Speed: These machines vary in production capacity and speed. Industrial-scale machines can produce thousands of nails per minute, while smaller units are suitable for lower-volume operations.

Maintenance and Durability: Like any machinery, regular maintenance is essential for optimal performance. Automatic nail making machines should be durable and designed for long-term use.

When considering the purchase of an automatic nail making machine, it’s important to assess factors such as production capacity, the range of nail sizes the machine can produce, automation features, and the overall build quality. Manufacturers often provide specifications and details about the capabilities of their machines

Wire nail cutter grinder machine

A wire nail cutter grinder machine, also known as a nail cutter grinder or wire nail sharpener, is a specific type of machine designed for sharpening the cutting edges of wire nails. Nails can become dull over time with use, and a grinder is used to restore their sharpness. Here are the key features and functions of a wire nail cutter grinder machine:

Cutter Sharpening: The primary purpose of the machine is to sharpen the cutting edges of wire nail cutters. This is crucial for maintaining the effectiveness and efficiency of the nail cutting process.

Automatic Operation: Many modern wire nail cutter grinder machines are designed for automatic or semi-automatic operation. This can include features such as automated feeding of the nail cutters into the grinder and the ability to set and control parameters for the sharpening process.

Grinding Mechanism: The machine typically includes a grinding mechanism that grinds and reshapes the cutting edges of the nail cutters. The grinding process removes any dullness, burrs, or irregularities from the cutting surfaces.

Adjustable Settings: Users can often adjust settings on the machine to achieve the desired sharpness and shape of the nail cutters. This may include adjustments for the angle of the grind and the depth of the cut.

Cooling System: Some grinder machines are equipped with a cooling system to prevent the nail cutters from overheating during the grinding process. This is especially important when dealing with high-speed or continuous operation.

Safety Features: Safety is a critical consideration, and these machines may include features such as safety guards and emergency stop mechanisms to ensure safe operation.

Compatibility: Wire nail cutter grinder machines are designed to work with specific types and sizes of nail cutters. Compatibility with the nail cutting equipment used in a particular production setup is crucial.

When using a wire nail cutter grinder machine, operators should follow safety guidelines and manufacturer instructions to ensure proper operation and maintenance. Regular maintenance, such as cleaning and lubrication, is important to keep the machine in optimal condition.

It’s worth noting that specific features and specifications can vary among different models and manufacturers, so it’s essential to refer to the user manual and guidelines provided by the manufacturer for the specific machine in use.

Automatic nail cutting grinder

An automatic nail cutting grinder is a machine designed to automate the process of cutting and sharpening nails. This type of machine is commonly used in industries where large-scale and precise nail production is required. Here are the key features and functions of an automatic nail cutting grinder:

Wire Feeding and Cutting: These machines often integrate a mechanism for feeding wire into the system. The wire is typically made of materials like steel. The machine automatically cuts the wire into desired lengths to form individual nails.

Nail Cutter Sharpening: The automatic nail cutting grinder includes a grinding mechanism for sharpening the cutting edges of nail cutters. This is important for maintaining the sharpness and efficiency of the cutting process.

Automatic Operation: The machine is designed for fully or semi-automatic operation. It can include features such as automated feeding of wire, cutting, and sharpening, reducing the need for manual intervention.

Adjustable Settings: Users can often adjust various settings on the machine to achieve the desired nail size, length, and sharpness. This may include settings for the angle and depth of the cut.

Grinding Mechanism: The grinder mechanism is responsible for reshaping and sharpening the nail cutters. It removes any dullness, burrs, or irregularities from the cutting surfaces.

Cooling System: To prevent overheating during continuous operation, some automatic nail cutting grinders are equipped with a cooling system. This ensures the longevity of the grinding components.

Quality Control: These machines may incorporate quality control features to ensure that the produced nails meet specific standards. Quality checks can include inspections for length, diameter, and sharpness.

Safety Features: Safety is a priority, and automatic nail cutting grinders may include features such as safety guards, emergency stop mechanisms, and other safety precautions to protect operators.

Compatibility: Automatic nail cutting grinders are designed to work with specific types and sizes of nail cutters. Compatibility with the nail cutting equipment used in a particular production setup is crucial.

When considering the purchase of an automatic nail cutting grinder, it’s important to assess factors such as production capacity, the range of nail sizes it can handle, automation features, and the overall build quality. Manufacturers often provide specifications and details about the capabilities of their machines. Operators should also follow safety guidelines and adhere to manufacturer instructions for proper operation and maintenance.

#wire nail making machine#nail making machine#automatic nail cutting grinder#nail manufacturing machine

0 notes

Video

youtube

5 axis plasma metal pipes cutting cutting machine

More details or free tutorials ,please contact on whatsapp :008618053182392/ [email protected], Our website : jxautocnc.com

0 notes

Text

Buy Cnc fiber laser cutting machine, cnc edm wire cut machine, vertical turret milling machine, znc electric spark discharge machine, radial and pillar drill machine at best cost.

#CNC Fiber Laser Cutting Machine#CNC Fiber Laser Cutting Machine supplier#CNC Fiber Laser Cutting Machine Manufacturer#CNC Fiber Laser Cutting Machine supplier in pune#CNC Fiber Laser Cutting Machine Manufacturer in pune#Hydraulic Brake Press Machine#Hydraulic Brake Press Machine supplier#Hydraulic Brake Press Machine Manufacturer#Hydraulic Brake Press Machine supplier in pune#Hydraulic Brake Press Machine Manufacturer in pune#CNC EDM Wire Cut Machine#CNC EDM Wire Cut Machine supplier#CNC EDM Wire Cut Machine Manufacturer#CNC EDM Wire Cut Machine supplier in pune#CNC EDM Wire Cut Machine Manufacturer in pune#EDM Drilling Machine#EDM Drilling Machine supplier#EDM Drilling Machine Manufacturer#EDM Drilling Machine supplier in pune#EDM Drilling Machine Manufacturer in pune#ZNC Electric Spark Discharge Machine#ZNC Electric Spark Discharge Machine supplier#ZNC Electric Spark Discharge Machine Manufacturer#ZNC Electric Spark Discharge Machine supplier in pune#ZNC Electric Spark Discharge Machine Manufacturer in pune#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

3 notes

·

View notes

Text

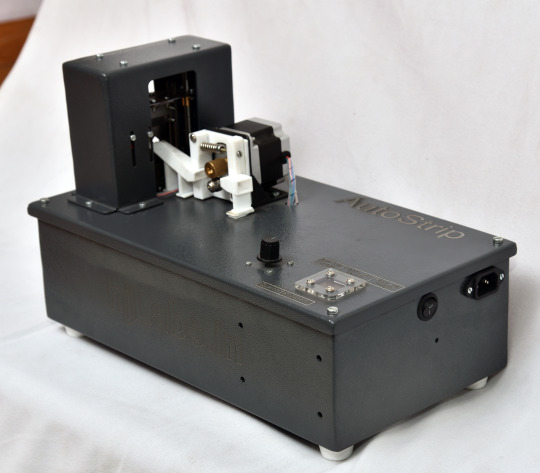

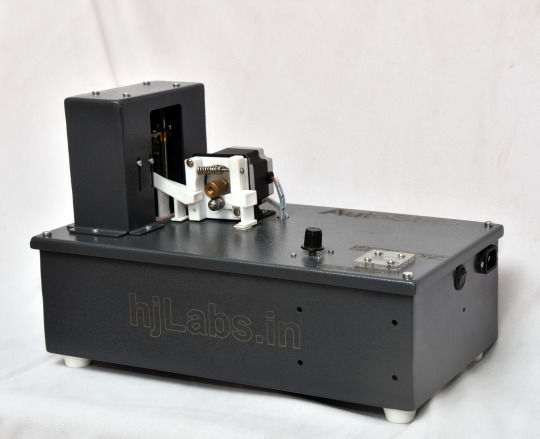

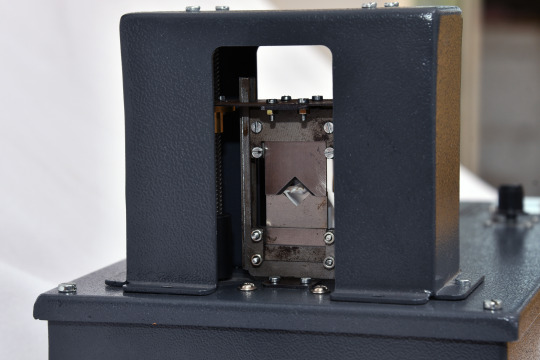

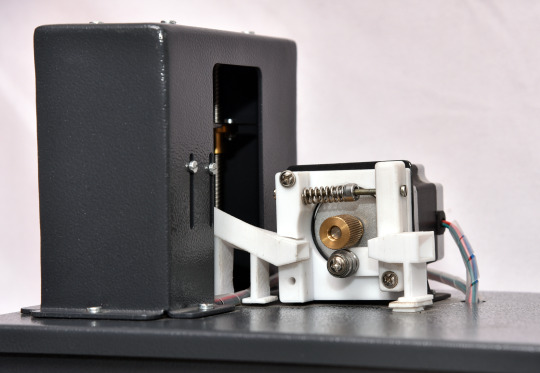

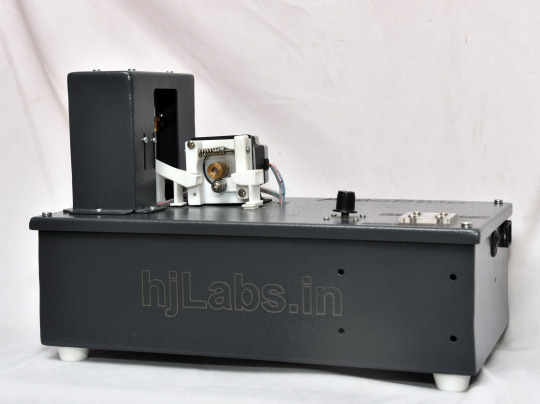

🔌 Ultimate Cable Processing Machine | Boost Efficiency & Precision! Discover the Future Today!

Experience unmatched efficiency with our 🚀 Auto Wire Cutting & Stripping Machine. Say goodbye to manual labor with our 🔧 #InnovativeTool. Ideal for electrical, automotive, and telecommunications industries.👩🔧👨🏭. For purchases, message us on WhatsApp or Telegram at 📱 +917016525813. Buy now : https://hjlabs.in/product/%f0%9f%94%8c-industrial-wire-cable-cutting-stripping-machine-precision-automatic-cutter-for-efficient-production/ #WireStripper #AutomationTech #ElectricalTools #TimeSaver 🎯 https://youtu.be/hi66O8-YRXs https://www.youtube.com/watch?v=MlTAD-kieaw 3d Design and Code files on grabcad : https://grabcad.com/library/automatic-wire-cutter-and-stripper-machine-1 only cutting machine : https://www.youtube.com/watch?v=TzW5WMWv-x8 Acrylic version : https://www.youtube.com/watch?v=bnWMskTA5V4 https://linktr.ee/hemangjoshi37a WhatsApp & Telegram : +917016525813 Email : [email protected] Place a custom order on hjLabs.in : https://hjLabs.in ----------------------------------------------------------------------------- Checkout Awesome Videos : SWiBoard - A Killer Gadget to Boost Your Boring Switchboard : https://youtu.be/BrakSGmQZB8 રુધિર વહીનીઓ અને એના કર્યો. : https://youtu.be/T7mMcEYNKyQ મનુષ્યમાં પરિવહન તંત્ર | परिसंचरण तंत्र : https://youtu.be/vxa6o_wrWnY હદય અને હદયના ધબકારા : https://www.youtube.com/watch?v=9v3MK6oTOeA AutoCut V2 - Automatic Wire Cutting Machine : https://www.youtube.com/watch?v=bnWMskTA5V4 મનુષ્યમાં ઉત્સર્જન-તંત્ર : https://www.youtube.com/watch?v=UUGI-CFKsWI

#industrial wire cutter#cable stripping machine#automatic cable cutter#precision wire processing#efficiency#manufacturing equipment#automation#wire and cable industry#quality control#productivity#industrial technology#wire cutting technology#cable stripping equipment#industrial automation#electrical industry#manufacturing solutions#wire processing machinery#cutting-edge tools#automation benefits#production efficiency#cable management#wire manufacturing

1 note

·

View note

Text

1 note

·

View note