#Winding Rewinding Manufacturer

Explore tagged Tumblr posts

Text

Optimized Wire Management with Traverse Spool Rewind Machines

The Traverse Wire Spool Rewind Machine is an essential tool for industries that demand precision and efficiency in wire management. Its innovative design and user-friendly features make it an invaluable asset for businesses dealing with wire spooling and rewinding. Whether you're in manufacturing, electrical, or telecommunications, this machine ensures smooth operations and top-notch performance.

Why Precision Matters in Wire Management

Managing wire spools manually can lead to inaccuracies, wasted resources, and even safety risks. The Traverse Wire Spool Rewind Machine eliminates these challenges by providing automated solutions. Its advanced features allow businesses to handle spooling tasks with ease, reducing labor costs and enhancing productivity. By improving precision, this tool also minimizes material waste, translating into significant cost savings for businesses over time.

Key Features That Stand Out

Compact Design: The machine’s sleek and compact structure ensures it can fit into any workspace, no matter how small.

Versatility: Suitable for a wide range of wire types and sizes, making it adaptable for various industrial needs.

Precision Engineering: Its high-precision controls ensure accurate wire winding, preventing errors and material wastage.

Durability: Constructed with robust materials to withstand the demands of daily industrial use.

Ease of Operation: Intuitive controls make it accessible for operators of all skill levels.

Applications Across Industries

This Machine is widely used in industries such as:

Manufacturing: For assembling electronic components or preparing wire harnesses.

Telecommunications: To manage and organize wires for installations.

Electrical Engineering: For efficient cable spooling and handling.

Automotive: In wire preparation for vehicle assembly and maintenance.

Tips for Optimal Use

Regularly inspect the machine for wear and tear to ensure consistent performance.

Use appropriate settings based on wire type and size to maximize efficiency.

Clean the machine periodically to maintain its longevity.

Ensure operators are trained to utilize its features effectively for optimal results.

Why This Machine Is a Game-Changer

Investing in the Traverse Wire Spool Rewind Machine gives businesses a competitive edge. Its ability to handle tasks with precision and speed allows companies to take on more projects without compromising on quality. Moreover, its user-friendly design means minimal training time for employees, ensuring a quick return on investment.

Conclusion

For businesses looking to optimize their wire management processes, the Traverse Wire Spool Rewind Machine is a game-changer. Its efficiency, reliability, and user-friendly operation make it an indispensable tool for industries requiring precision and organization. This machine is an excellent addition to your range of industrial tool and supplies.

0 notes

Text

Ensure Optimal Performance with Transformer Rewinding and Repair in Abu Dhabi

Transformers play a critical role in ensuring smooth power distribution and reliable electrical systems. Over time, wear and tear can affect their performance, leading to inefficiencies and potential downtime. To keep your transformers operating at their best, transformer rewinding and repair services in Abu Dhabi offer the perfect solution. In this blog, we will explore the importance of these services, their benefits, and how SEA Global UAE can help you maintain optimal performance.

Why Transformer Rewinding and Repair is Important

Transformers are essential components of power systems in industries, businesses, and homes. Without proper maintenance, they may experience:

Power losses: Inefficient transformers can lead to energy wastage.

Performance issues: Damaged windings and components may reduce the transformer's effectiveness.

Operational downtime: Faulty transformers can disrupt business operations.

Increased costs: Repairs can be more expensive if problems are left unaddressed.

By investing in transformer rewinding and repair, you can ensure that your equipment remains efficient and safe.

What is Transformer Rewinding?

Transformer rewinding is a process of replacing or repairing the windings (coils) within the transformer. This service is essential when:

The transformer windings are damaged.

The insulation is worn out.

There is a need to enhance performance or capacity.

Rewinding helps restore the transformer’s functionality and ensures efficient energy transfer.

Benefits of Transformer Rewinding and Repair

Opting for transformer rewinding and repair services in Abu Dhabi can provide several advantages:

1. Cost-Effective Solution

Rewinding or repairing a transformer is more affordable than replacing it.

Extends the lifespan of the equipment.

2. Improved Efficiency

Enhances the performance of older transformers.

Reduces energy losses and operational costs.

3. Minimized Downtime

Quick repairs ensure uninterrupted operations.

Prevents potential outages that could impact productivity.

4. Environmental Benefits

Reduces the need for manufacturing new transformers, lowering the carbon footprint.

Promotes sustainable practices by reusing existing equipment.

Common Transformer Issues That Require Repair

Several problems can arise with transformers, such as:

Overheating: Caused by overloading or faulty components.

Worn-out insulation: Leads to short circuits and reduced efficiency.

Damaged windings: Affects the transformer's energy transfer.

Oil leaks: Decreases cooling efficiency and causes overheating.

Addressing these issues promptly through professional repair services can prevent further damage.

Why Choose SEA Global UAE for Transformer Rewinding and Repair in Abu Dhabi?

SEA Global UAE is a trusted provider of transformer maintenance and repair services in Abu Dhabi. Here’s why you should consider them for your needs:

1. Expertise and Experience

Skilled technicians with years of experience.

In-depth knowledge of transformer systems.

2. Advanced Technology

State-of-the-art equipment for accurate repairs.

Use of high-quality materials for durable results.

3. Customized Solutions

Tailored services to meet your specific requirements.

Support for transformers of all sizes and capacities.

4. Quick Turnaround Time

Efficient service delivery to minimize downtime.

Emergency repair services available.

5. Commitment to Quality

Adherence to international standards and guidelines.

Focus on safety and reliability.

How SEA Global UAE Ensures Quality Transformer Repairs

At SEA Global UAE, the repair process is designed to ensure long-lasting results. Here are the steps involved:

Initial Inspection:

Diagnose the transformer’s condition.

Identify damaged components and underlying issues.

Detailed Analysis:

Conduct tests to assess performance.

Determine whether rewinding or repair is necessary.

Rewinding or Repair:

Replace or repair damaged windings.

Use high-grade materials to ensure durability.

Testing and Quality Assurance:

Perform rigorous testing to ensure optimal performance.

Verify compliance with safety standards.

Delivery and Installation:

Deliver the repaired transformer.

Provide installation and maintenance guidance.

Tips to Extend the Life of Your Transformer

To keep your transformer in excellent condition, follow these maintenance tips:

Regular Inspections: Schedule periodic checks to identify potential issues.

Monitor Load Levels: Avoid overloading to prevent overheating.

Maintain Cooling Systems: Ensure proper functioning of fans and oil coolers.

Clean Components: Keep the transformer clean to prevent dust and debris buildup.

Address Problems Quickly: Fix minor issues before they escalate into major repairs.

#Transformer Rewinding Abu Dhabi#Transformer Repair Abu Dhabi#Electrical Transformer Maintenance#Transformer Services Abu Dhabi#Transformer Rewinding and Repair

0 notes

Text

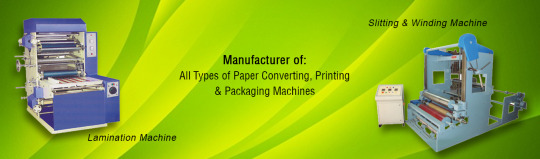

Jandu Printing and Packaging Machines Manufacturer

Jandu PPM is a trusted printing & packaging machine manufacturer and supplier in India. Which offers high-quality Heavy Duty Simplex Reel to Sheet Cutting Machines, Mill Type Paper Slitting & Rewinding Machines, Reel to Sheet Cutting Machines, Roll to Sheet Cutting Machines, Rotary Sheet Cutting Machines, Slitting Machines, Lamination Machines, Winding Machines, slitter and rewinder machines, and centre drum slitting and rewinding machines, etc., specially designed to provide a better outcome for longer and are manufactured using the high-grade materials by Jandu PPM.

Contact Jandu PPM

Company: Jandu Printing & Packaging Machines

Mobile: +91 9811100842, 9811510842

Email: [email protected]

Address: 25/18, Gali No. 6, Master Mohalla Libaspur, Delhi, India, 110042

#SlittingandRewindingMachine#SlitterandRewinderMachine#CentreDrumSlittingAndRewindingMachine#ReelToSheetCuttingMachine#RollToSheetCuttingMachine

1 note

·

View note

Text

Motor Rewinding Machines: Restoring Efficiency and Performance

Electric motors are integral to industrial and commercial operations, powering everything from machinery to appliances. Over time, these motors can suffer from wear and tear, leading to reduced performance or complete failure. A motor rewinding machine is a valuable tool for restoring motors to optimal condition by rewinding the coils. In this article, we’ll explore what motor rewinding machines are, their benefits, and how they play a critical role in maintaining and repairing electric motors.

What is a Motor Rewinding Machine?

A motor rewinding machine is specialized equipment used to remove old or damaged windings from an electric motor and replace them with new windings. This process restores the motor’s functionality and extends its lifespan.

Key Features:

Automatic Coil Removal: Efficiently strips old windings.

Programmable Winding Control: Allows precise winding of new coils.

Wire Tension Regulation: Ensures uniform winding to maintain motor performance.

Benefits of Motor Rewinding Machines

1. Cost Savings

Rewinding a motor is often more cost-effective than replacing it, especially for large or custom motors.

2. Extended Motor Life

Rewinding restores the motor to its original specifications, prolonging its operational life.

3. Energy Efficiency

A properly rewound motor operates more efficiently, reducing energy consumption and operational costs.

4. Customizability

Motor rewinding machines can be programmed to handle various winding configurations, making them versatile for different motor types.

Types of Motor Rewinding Machines

1. Manual Rewinding Machines

These machines require operator input and are ideal for small-scale operations or custom rewinding tasks.

2. Semi-Automatic Rewinding Machines

Combine manual setup with automated winding, offering a balance of control and efficiency.

3. Fully Automatic Rewinding Machines

These machines handle the entire process, from coil removal to new winding, maximizing productivity and precision.

Applications of Motor Rewinding Machines

Motor rewinding machines are used in various industries to repair and maintain electric motors:

Manufacturing Plants: Keeps industrial machinery running smoothly.

Automotive Industry: Rewinds motors in electric vehicles and automotive components.

HVAC Systems: Essential for repairing motors in heating, ventilation, and air conditioning systems.

Power Generation: Maintains generators and other power equipment.

Marine and Aerospace: Repairs specialized motors used in ships and aircraft.

Innovations in Motor Rewinding Technology

Technological advancements have made motor rewinding machines more efficient and user-friendly:

1. Smart Automation

Modern machines use AI to optimize winding patterns and adjust parameters for different motor types.

2. Digital Interfaces

Touchscreen controls and digital monitoring make it easier to operate and track the rewinding process.

3. Eco-Friendly Operation

Energy-efficient designs reduce power consumption and minimize waste.

Factors to Consider When Choosing a Motor Rewinding Machine

Motor Size Compatibility: Ensure the machine can handle the range of motor sizes you work with.

Automation Level: Decide between manual, semi-automatic, or fully automatic machines based on your needs.

Customization Capabilities: Look for machines that allow flexible winding patterns.

Budget and ROI: Assess the machine’s cost-effectiveness and potential long-term savings.

Conclusion

Motor rewinding machines are essential tools for restoring electric motors to peak performance. By enabling cost-effective repairs and extending motor life, these machines play a critical role in various industries. With advancements in automation and technology, motor rewinding has become more efficient and precise, ensuring motors operate at their best.

Are you ready to revitalize your electric motors with the latest motor rewinding solutions?

0 notes

Text

Trusted Printing & Packaging Machines Manufacturer

Jandu PPM is a trusted Printing & Packaging Machines manufacturer and supplier based in Delhi, India, We offer high-quality machines like - Heavy Duty Simplex Reel to Sheet Cutting Machine, Mill Type Paper Slitting & Rewinding Machines, roll to sheet cutting machines, Rotary Sheet Cutting Machine, Slitting Machine, Lamination Machine, Winding Machine, slitter and rewinder machine, and centre drum slitting and rewinding machines, etc specially designed to provide a better outcome for longer and are manufactured using the high-grade of materials by Jandu PPM.

Types of Printing and Packaging Machines, We offer

Slitting & Rewinding Machine Slitter & Rewinder Machine Centre Drum Slitting And Rewinding Machine Mill Type Paper Slitting and Rewinding Machine Paper Slitting and Rewinding Machine in Delhi Reel To Sheet Cutting Machine Roll To Sheet Cutting Machine Heavy Duty Simplex Reel to Sheet Cutting Machine Lamination Machine Manufacturer Rotary Sheet Cutting Machine Slitting Machine Manufacturer Slitting & Winding Machine Manufacturer

Contact Jandu PPM

Company: Jandu Printing & Packaging Machines - Mobile No: +91 9811100842, 9811510842 - Address: 25/18, Gali No.6, Master Mohalla Libaspur, Delhi, India – 110042 - Email: [email protected]

#janduppm#ReelToSheetCuttingMachine#RollToSheetCuttingMachine#SlitterandRewinderMachine#SlittingandRewindingMachine

1 note

·

View note

Text

THE ULTIMATE GUIDE TO CHOOSING A SLITTER REWINDER MACHINE THAT FITS YOUR NEEDS

A slitter rewinder machine is designed to take large rolls of material—such as paper, plastic film, or textiles—and split them into smaller, precisely sized rolls. It’s used to maximize productivity by cutting and winding materials in one smooth, efficient process. This machinery is commonly used in various manufacturing sectors, enabling businesses to meet their production demands with accuracy and speed.

#krishnaengineeringworks#slitterrewindermachine#machinemanufacturer#exporter#supplier#textiles#industrial

0 notes

Text

The Role of Motor Rewinding in Uganda's Growing Industrial Sector

Uganda’s industrial sector is experiencing significant growth, fueled by advancements in technologies, infrastructure development, and increasing foreign investments. As industries expand, so does the demand for efficient and reliable machinery. One of the critical aspects that ensures the longevity and efficiency of industrial machinery is motor rewinding. At the forefront of providing these essential services, Mak General Services is recognized for offering the best motor rewinding in Uganda.

The Importance of Motor Maintenance

Industrial motors form the backbone of many manufacturing processes. However, these vital components can wear out over time, leading to decreased efficiency and potential breakdowns. Regular maintenance and, when necessary, motor rewinding can extend the life of these essential machines, ensuring smooth operations and minimizing costly downtime.

Why Motor Rewinding Matters

Motor rewinding is a specialized process that involves replacing the wire windings in an electric motor. This procedure can restore a motor to its original performance specifications, often at a fraction of the cost of purchasing a new motor. For Uganda's growing industries, this cost-effective solution is particularly valuable.

The best motor rewinding in Uganda offers several benefits:

1. Cost savings

2. Improved energy efficiency

3. Extended motor lifespan

4. Reduced environmental impact

Mak General Services: Leading the Way in Motor Rewinding

As Uganda's industrial sector continues to expand, the demand for quality motor rewinding services has grown correspondingly. Mak General Services has emerged as a leader in this field, providing top-notch motor rewinding solutions to businesses across the country.

With its state-of-the-art facilities and highly trained technicians, Mak General Services ensures that each motor rewinding project is completed to the highest standards. Their expertise covers a wide range of motor types and sizes, catering to various industries including manufacturing, agriculture, and mining.

The Impact on Uganda's Industrial Growth

The availability of reliable motor rewinding services has had a significant impact on Uganda's industrial growth. By enabling businesses to maintain and repair their existing equipment more efficiently, these services have helped to:

1. Reduce operational costs

2. Increase productivity

3. Enhance competitiveness in the global market

Moreover, the growth of the motor rewinding industry itself has created new job opportunities and contributed to the development of specialized technical skills within the Ugandan workforce.

Looking to the Future

As Uganda continues its journey towards industrialization, the role of motor rewinding services will likely become even more critical. Companies like Mak General Services are poised to play a pivotal role in supporting this growth, ensuring that Uganda's industries remain competitive and efficient.

For businesses looking to optimize their operations and reduce maintenance costs, partnering with a reputable motor rewinding service provider is essential. To learn more about how motor rewinding can benefit your business, visit makgeneralservices.com for comprehensive information on Mak General Services' offerings.

In conclusion, motor rewinding services are playing a crucial role in supporting Uganda's industrial growth. By providing cost-effective solutions for motor maintenance and repair, these services are helping to drive efficiency, reduce costs, and promote sustainable industrial development across the country.

0 notes

Text

Who Should Consider Transformer Rewinding Services?

At Tristar Electrical, we understand the critical role that transformers play in ensuring smooth electrical operations for various industries. However, over time, even the most well-maintained transformers can experience wear and tear. This deterioration can lead to decreased efficiency, increased downtime, and ultimately, higher operational costs.

Industries Facing High Electrical Demand

Industries that rely heavily on electrical systems, such as manufacturing, telecommunications, and healthcare, often utilize transformers to manage and distribute power efficiently. These sectors operate under stringent uptime requirements and cannot afford prolonged disruptions due to transformer failures. For them, proactive maintenance, including transformer rewinding, is not just beneficial but essential to ensure uninterrupted operations.

Aging Infrastructure

Infrastructure aging is another crucial factor. Many facilities have transformers that have been in service for decades. As transformers age, their insulation and winding can degrade, increasing the risk of malfunctions and safety hazards. For facilities with older transformers, our transformer rewinding services offer a cost-effective solution to extend their lifespan and enhance reliability.

Companies Expanding Operations

Business expansion often means increased electrical loads. This growth may strain existing transformers beyond their designed capacity, leading to overheating and inefficiencies. Before upgrading to larger transformers, consider consulting with us. Our experts can assess your current transformer's condition and recommend whether rewinding can restore its performance to meet new demands effectively.

Utilities and Power Distribution

Utilities and power distribution companies manage vast networks of transformers. Ensuring these transformers operate optimally is crucial for maintaining a reliable supply of electricity to homes and businesses. Regular maintenance, including rewinding when necessary, helps these organizations prevent costly outages and ensure consistent service delivery.

Facilities Focused on Sustainability

In today's world, sustainability is a top priority for many organizations. Upgrading existing transformers through rewinding not only extends their lifespan but also reduces waste associated with premature replacements. By choosing Tristar Electrical for your rewinding needs, you contribute to sustainable practices while optimizing your electrical infrastructure.

Trust Tristar Electrical for Your Transformer Rewinding Needs

At Tristar Electrical, we specialize in transformer rewinding services tailored to meet the diverse needs of industries and utilities. Our experienced team uses state-of-the-art equipment and industry-best practices to deliver reliable, cost-effective solutions. Whether you're facing increasing electrical demands, maintaining aging infrastructure, or simply seeking to enhance efficiency, we are here to support you.

Contact us today to learn more about how our transformer rewinding services can benefit your operations. Trust Tristar Electrical for quality, expertise, and peace of mind in managing your electrical infrastructure.

0 notes

Text

Trim Winder Machine Manufacturers

Blueeye Machine, located in Ahmedabad, is specialised in the manufacture of trim winders, which are designed to meet the needs of the industries that require precise winding solutions for a variety of materials.

#trim winder machine#trim winder machine manufacturer#trim winder machine supplier#trim winder machine in india#trim winder machine manufacturer in Ahmedabad

0 notes

Text

A paper tube cutting machine is a versatile and essential machine used in the paper industry. It is designed to cut large rolls of paper into smaller, more manageable rolls of desired width and length. This machine is crucial in various sectors, including printing, packaging, and converting industries.

Unwinding: The process begins with loading a large roll of paper onto the unwinding shaft. The machine then unwinds the paper roll at a controlled speed.

Slitting: The unwound paper is then passed through sharp blades or rotary knives that slit the paper into smaller widths. The number of blades can be adjusted based on the number of rolls required.

Rewinding: The slit paper is then rewound onto separate cores to form smaller rolls. The tension and speed of rewinding can be controlled to ensure the rolls are wound tightly and evenly.

Cutting: Some machines also have an integrated cutting mechanism that cuts the rewound rolls to the desired length.

Quality Control: Many Paper Slitter Rewinders come with built-in inspection systems that check for defects or irregularities in the paper.

The Paper Slitter Rewinder is known for its high efficiency, precision, and speed. It can handle a wide range of paper types and thicknesses, making it a versatile choice for businesses. With its robust construction and advanced features, this paper core machine ensures smooth and consistent operation, enhancing productivity and reducing waste. Whether you’re a small print shop or a large paper mill, a Paper Slitter Rewinder can be a valuable addition to your production line.

Paper Slitter Rewinder: Enhancing Efficiency in Manufacturing

The Paper Slitter Rewinder is a game-changer in the manufacturing industry, significantly enhancing efficiency and productivity. This machine is designed to transform large rolls of paper into smaller ones, tailored to specific requirements. Here’s how it contributes to manufacturing efficiency:

High-Speed Operation: paper tube winder machine operate at high speeds, capable of processing large volumes of paper in a short time. This speed significantly reduces production time, enabling businesses to meet high demand quickly.

Precision Cutting: With adjustable blades, the machine ensures precise and consistent cuts every time. This precision eliminates waste from inaccurate cuts, saving materials and costs.

Automation: Many models come with automated features, reducing the need for manual intervention. This automation not only saves labor costs but also minimizes human error, ensuring consistent quality.

Quality Control: With built-in inspection systems, the machine can detect and rectify defects or irregularities in the paper. This feature ensures that only high-quality paper rolls reach the end of the production line.

Space Efficiency: Despite its robust capabilities, the Paper Slitter Rewinder has a compact design that saves valuable floor space in manufacturing facilities.

By investing in a Paper Slitter Rewinder, businesses can significantly enhance their manufacturing efficiency. This core pipe-making machine not only speeds up the production process but also ensures the consistent quality of the final product, leading to increased customer satisfaction and profitability.

Paper Slitter Rewinders for Every Industry Need

Paper slitter rewinders play a pivotal role across diverse industries, addressing unique needs with precision and efficiency:

Printing Industry: In printing, these machines facilitate the production of custom-sized paper rolls, optimizing printing processes and reducing waste.

Packaging Sector: The packaging industry benefits from the adaptability of paper slitter rewinders, ensuring the creation of tailored rolls for various packaging applications, enhancing efficiency and minimizing material costs.

Converting Industries: Paper converting relies on these machines to transform large paper rolls into smaller, usable rolls with specific dimensions, meeting the requirements of different product lines.

Flexibility in Width and Length: The versatility of paper slitter rewinders allows for the customization of roll width and length, catering to the unique specifications of each industry and product.

Enhanced Productivity: With precise cutting and rewinding capabilities, these machines contribute to increased productivity, reducing downtime and enhancing overall operational efficiency in multiple sectors.

0 notes

Text

Top Benefits Of An Air Shaft In Manufacturing

The manufacturing industry-centric air shaft is employed for fitting into the core that wounds a variety of materials, including paper, cards, and plastic films. It readily expands on fitting into a core, leading to flawless operation during the manufacturing cycle.

Plenty of industrial converting machines employ the product. A slitting machine, widely known as a slitter rewinder has an air shaft in its core. It is basically designed to cut or slit large rolls of different types of material into smaller rollers. How does its engineering work? In this regard, you can connect with a reputed air shaft manufacturer.

An air shaft is also recognized by many other names in the industry circles, including air expandable shaft and air expanding shaft.

Salient Features of the Air Shaft

A premium quality air shaft displays the following salient features during application:

Competent to adjust to different speed variations

Proficient to adjust to different core widths

Demonstrates high speed, when repositioning of the product doesn’t happen

Efficient gripping

Efficient core centering

Manages uneven cores

For detailed information, collaborate with a prominent air shaft manufacturer in Ahmedabad.

Manufacturing Industries Drawing Benefits from the Air Shaft

Manufacturing industries galore are drawing benefits from mechanical product, including:

Packaging

Steel

Paper

As far as dimension of the air shaft is concerned, it is available in different dimensions. In case, you are searching for a custom-designed air shaft, you can collaborate with a reputed air shaft manufacturer.

Applications

An airshaft is a mechanical device designed for handling winding reels in the processing of web-fed materials.

0 notes

Text

Why You Should Choose Professional Motor Rewinding Services in Abu Dhabi

Motor rewinding is essential for the smooth and safe operation of industrial machines. Choosing a reliable provider, like SEA Global UAE, can help keep your motors running at peak efficiency and ensure longevity. Below, we discuss the importance of professional motor rewinding services, covering everything from repair benefits to specific services available in Abu Dhabi.

1. What is Motor Rewinding?

Motor rewinding involves repairing and replacing the coils within an electric motor. This process restores a motor’s efficiency and performance by rewinding the electrical windings that power it. Skilled technicians can rewind various motors, including AC/DC motors, generators, crane motors, industrial motors, and blower motors.

Key Benefits of Motor Rewinding:

Restores Motor Efficiency: Professional rewinding can bring a motor close to its original performance.

Cost-effective Solution: Rewinding costs less than purchasing a new motor, offering savings without compromising quality.

Reduces Downtime: Fast and efficient rewinding minimizes interruptions to production, helping businesses maintain productivity.

2. Why Choose SEA Global UAE for Motor Rewinding?

SEA Global UAE specializes in motor rewinding services in Abu Dhabi and offers a range of services to meet industrial needs. With an experienced team and advanced tools, they provide reliable and efficient motor rewinding, ensuring the highest standards for each job.

Reasons to Trust SEA Global UAE:

Skilled Technicians: Professionals with extensive experience in motor rewinding.

Advanced Equipment: The use of quality tools ensures accuracy in repairs.

Customized Services: Tailored solutions for various motor types and needs.

Quality Assurance: Each motor is tested after rewinding to confirm performance.

3. Understanding the Rewinding Process

The rewinding process requires detailed steps to ensure motors are restored to optimal working conditions. SEA Global UAE follows a structured process to provide quality service.

Steps in Motor Rewinding:

Inspection and Testing: Identify the issues and plan for rewinding.

Removing Old Windings: Carefully remove the old windings to prevent core damage.

Cleaning and Insulating: Clean the motor parts and add insulation to ensure durability.

Rewinding Coils: Use new wire to rewind the coils and secure them properly.

Testing: Confirm that the motor meets performance and safety standards.

4. Key Motor Rewinding Services Offered by SEA Global UAE

SEA Global UAE offers comprehensive rewinding and repair services in Abu Dhabi for various types of motors. Here are the specialized services they provide:

A. Electric AC/DC Motor Rewinding Service

Ideal for all AC and DC motors.

Restores motors to peak performance for various applications.

Extends motor lifespan and enhances energy efficiency.

B. Generator Rotor and Motor Rewinding Service

Essential for generators and motors used in heavy industries.

Maintains the power output of generators, reducing the risk of failures.

Ensures generator reliability during critical operations.

C. Crane Motor Repair Services Abu Dhabi

Specialized rewinding for crane motors used in construction and industrial lifting.

Provides stable and safe operations for heavy-duty machinery.

Enhances crane reliability and safety for daily use.

D. Industrial Motor Repair Services Abu Dhabi

Focuses on motors used in factories, manufacturing, and other industries.

Minimizes downtime by offering rapid, quality rewinding solutions.

Reduces operational costs by improving motor efficiency.

E. Blower Motor Repair Services Abu Dhabi

Maintains performance in blowers used for ventilation and cooling.

Prevents overheating and keeps ventilation systems running effectively.

Extends the lifespan of blower motors, saving on replacement costs.

5. Benefits of Choosing Professional Motor Rewinding Services

Choosing a professional for motor rewinding provides several advantages, especially for businesses that rely on uninterrupted motor function.

Key Benefits:

Increased Motor Life: Rewinding extends the motor’s service life by restoring functionality.

Enhanced Efficiency: Professional rewinding can improve energy efficiency, leading to lower power consumption.

Cost Savings: Rewinding is typically more affordable than replacing a motor, especially for high-powered industrial motors.

Reduced Environmental Impact: Reusing motors by rewinding helps reduce waste and conserves resources.

Safety Assurance: Rewound motors undergo testing to ensure they meet safety standards, reducing the risk of failures.

6. The Importance of Motor Rewinding for Industrial Applications

In industries where motors power essential machinery, maintaining reliable and efficient performance is crucial. SEA Global UAE supports industries by providing specialized motor rewinding services that meet high standards and reduce operational risks.

Industries That Benefit from Motor Rewinding:

Manufacturing Plants: Ensures production equipment runs without interruptions.

Construction Companies: Keeps cranes and heavy machinery safe and operational.

Utilities and Energy Plants: Maintains generator efficiency to prevent power issues.

HVAC Systems: Keeps ventilation and air conditioning systems running smoothly.

7. Why Choose Motor Rewinding Over Replacement?

While replacing a motor may seem like an easier option, rewinding often offers several advantages. Here’s why rewinding can be a smarter choice:

Advantages of Motor Rewinding:

Cost-Effective: Rewinding is less expensive than buying a new motor, making it ideal for budget-conscious operations.

Environmental Impact: Rewinding reduces waste by reusing existing motor components.

Customizable: Rewinding allows for custom adjustments to improve motor performance based on specific needs.

Quicker Turnaround: Rewinding services are generally faster than ordering and installing new motors, minimizing downtime.

8. Factors to Consider When Choosing Motor Rewinding Services in Abu Dhabi

Selecting the right motor rewinding provider is essential for achieving optimal performance. Here’s what to look for when choosing a service:

Key Considerations:

Experience and Expertise: Look for a company with trained professionals in motor rewinding.

Quality Standards: Ensure the provider follows strict quality and safety guidelines.

Range of Services: Choose a provider that offers services for various motor types, including AC/DC motors, generators, and blowers.

Availability of Parts: Confirm that the provider has access to quality parts for motor repairs.

Customer Reviews: Look for feedback from other clients to gauge service reliability.

9. SEA Global UAE: Leading Provider of Motor Rewinding Services in Abu Dhabi

SEA Global UAE has earned a reputation as a trusted provider of motor rewinding services in Abu Dhabi. Here’s why many businesses choose them for motor repairs:

Why SEA Global UAE Stands Out:

Reliable Customer Support: SEA Global UAE provides attentive service, answering questions and addressing concerns promptly.

Proven Results: With successful rewinding projects across multiple industries, they have a track record of delivering quality work.

Affordable Solutions: Their services offer high value for money, making rewinding a cost-effective option.

Comprehensive Service Range: From generators to industrial blowers, they cover all types of motor rewinding needs.

10. How to Get Started with SEA Global UAE

Getting your motor rewinding needs addressed with SEA Global UAE is easy. Here’s how to get started:

Steps to Start Motor Rewinding Service:

Contact SEA Global UAE: Reach out via phone or website to discuss your needs.

Consultation: Receive guidance on the best options for your specific motor type.

Inspection and Quotation: Technicians will inspect the motor and provide a cost estimate.

Service Schedule: Set a date for the rewinding service to minimize operational disruption.

Receive Rewound Motor: Once completed, the motor will be tested and returned, ready for use.

Conclusion

Choosing professional motor rewinding services in Abu Dhabi offers numerous advantages for businesses and industries. SEA Global UAE’s expertise in motor rewinding services ensures optimal performance, cost savings, and long-term reliability. Whether you need electric AC/DC motor rewinding, generator rotor repairs, or industrial motor services, SEA Global UAE provides trusted, quality solutions tailored to your needs.

#Motor Rewinding Services in Abu Dhabi#Electrical Repair in Abu Dhabi#Professional Motor Rewinding Abu Dhabi#Electric AC/DC Motor Rewinding Service#Generator Rotor Rewinding Abu Dhabi#Crane Motor Repair Services Abu Dhabi#Blower Motor Repair Abu Dhabi#Industrial Motor Repair Abu Dhabi#Motor Maintenance Abu Dhabi#Abu Dhabi Industrial Motor Services#Reliable Motor Repair Abu Dhabi

0 notes

Text

Apply now: https://canadianjobbank.org/electrical-products-labourer-2/

0 notes

Text

Get High Quality and Exceptional Load Capacity with Expanding Shafts from Zen Coretech Engineers

For various industries across India and beyond, Zen Coretech Engineers is a trusted air shaft manufacturers in India. With a focus on quality, innovation, and customer satisfaction, the company has become a go-to provider for businesses seeking reliable solutions that enhance their operational efficiency and productivity.

At Zen Coretech Engineers, the company’s air shaft manufacturing process is the result of decades of experience and innovation. As air expanding shaft manufacturers, our air shafts offer world-class performance, durability, and precision for all your web handling needs. The company’s products have been designed with customer requirements in mind and have found success in numerous industries, including printing, packaging, and paper processing. With a large portfolio of customizable air shaft products, Zen Coretech Engineers is uniquely positioned to meet every customer’s specific requirements, including quick turnaround times and specialized designs.

Among Zen Coretech Engineers product range, the expanding shaft deserves special mention. These shafts provide a high degree of grip and are suitable for use in virtually any industry. They’re commonly used in rewind and unwind applications, as well as core winding and slitting processes. Offering exceptional load capacity, durability, and accuracy, expanding shafts are an excellent choice for businesses seeking to optimize production efficiency.

World-Class Performance, Durability & Precision - Zen Coretech Engineers

In addition to air shafts and expanding shafts, the company also produces banana rollers. These uniquely shaped rollers are ideal for use in the printing industry, where they can help to reduce wrinkles and improve print quality. Zen Coretech Engineers metal bow banana rollers offer superior performance and durability, making them especially well-suited for high-volume production environments. Whether you’re printing on paper, plastic, or a range of other materials, these rollers can help ensure a smooth, wrinkle-free process.

For businesses seeking to remove wrinkles from their production process, Zen Coretech Engineers’ wrinkle removing bowed roller are the perfect solution. Featuring a special shape that makes them ideal for smoothing out wrinkles, these rollers can play an important role in improving the quality of your end product. Zen Coretech Engineers wrinkle-removing bowed rollers feature precise engineering, ensuring that you get the results you need each and every time.

#air expanding shaft#bow banana roller#wrinkle removing bowed roller#air expanding shaft manufacturers

0 notes

Text

Taming The Variable Speed Motor With Fluke Test & Measurement Tools

System reliability can be increased by being aware of harmonics and motor issues. The preferred ac variable speed drive technology, particularly for low to medium horsepower applications, is now pulse-width modulated (PWM) motor driving.

The technology is clearly superior to other setups since it is often less expensive, more efficient, and causes fewer harmonic issues for the input power lines. It might also be challenging to troubleshoot.

to comprehend the PWM driving issues that are commonly encountered better.

Let’s first look at the fundamental components of a variable speed drive. Its circuit is simple: the input circuit has a full-wave diode bridge that rectifies the line voltage and charges a capacitor bank to a dc voltage equal to the line voltage’s halfwave peak.

Fast-switching power transistors in the drive’s output stage transform the direct current (dc) into a string of tiny voltage pulses that are then applied to the motor leads.

The pulses’ height is the same as the capacitor bank’s dc value, but their width is modulated (or changed) so that the motor current resembles a sine wave.

In general, problems with variable-speed motor drives can be separated into two parts:

Power line harmonics generated by the drive’s input circuit

Motor difficulties caused by the output circuit

If we are going to tame the variable speed drive circuit, we need to divide it into two parts: input and output. The requirements for test equipment will vary according to which end of the drive we are measuring. variable speed motor

At the input, we will want to measure true-RMS current, plus harmonic current spectrum and power factor using a harmonic analyzer like the Fluke 1773/1775/1777 Power Quality Analyzer.

At the output, we need the same harmonic analyzer to look at the motor current and a fast oscilloscope such as the ScopeMeter 190 series to look at the motor voltage.

Both instruments feature high EMI shielding which is needed when taking measurements near the fast pulses on the drive’s output leads.

Troubleshooting motor problems

Winding insulation failures are the greatest concern for obvious reasons. Damaged insulation means replacement or rewinding, which can translate to a logistics problem if you don’t have a spare handy.

Winding insulation can fail from too much heat, too much voltage, or both. Unfortunately, a misapplied variable speed drive can deliver both simultaneously.

Overvoltage can occur when the distance between the drive and the motor exceeds the drive manufacturer’s maximum cable length specification.

The theory here does not involve the National Electrical Code. Instead, it comes from the laws of radio frequency transmission lines. Remember what’s happening at the drive’s output terminals.

Very fast rise time pulses are being sent down a set of conductors with distributed inductance and capacitance. That is, the cable resembles a transmission line. Each pulse travels down the cable at near the speed of light.

When the leading edge hits the motor inductance, it is reflected in the source, where it adds to the base value of the pulse. The resulting combination puts a sharp spike on the leading edge of each pulse. The spikes can be as high as twice the base pulse value. Longer cables make the problem worse.

To see this effect, you will need an oscilloscope or a handheld portable ScopeMeter test tool with a bandwidth of at least 10 MHz and the ability to trigger on a PWM waveform. (See Figure 3).

If you plan to install a variable-speed drive where the distance to the motor exceeds the drive manufacturer’s maximum cable length specification, be sure to ask for recommendations involving output filters or other methods of reducing the overvoltage spike problem.

Work safely Variable Speed Motor

The high voltage and currents present in electrical power systems can cause serious injury or death by electrocution and burns. Consequently, only trained, experienced electricians who have knowledge of electrical systems in general and the equipment under test should perform testing and modification of electrical systems.

We cannot anticipate all possible precautions that you must take when performing the measurements described here. At a minimum, however, you should:

Use appropriate safety equipment such as safety glasses, insulated gloves, insulating mats, etc.

Be sure that all power has been turned off, locked out, and tagged in any situation where you will be in direct contact with circuit components. Be certain that the power can’t be turned on by anyone but you.Work safely Variable Speed Motor

Read and understand all of the applicable manuals before applying the information in this application note. Take special note of all safety precautions and warnings in the instruction manuals.

Do not use instruments on applications for which they are not intended, and always be aware that if the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

0 notes

Text

How Many Types Of Winding Machines Are There?

Textile engineers should possess a comprehensive understanding of the various types of winding machines utilized in the textile industry for converting yarn from bobbins, hanks, etc. into appropriate packaging. This article outlines the classification of these winding machines. Winding machines play a crucial role in the textile and paper industries, where large spools of material are commonly used. These machines enable the efficient wrapping of a variety of materials such as fabric, paper, string, cord, yarn, wire, tape, rope, twine, thread, and wire onto an industrial-sized spool as required. In essence, winding machines facilitate the initial spooling of vast quantities of materials. Are you looking for a textile machinery manufacturer in Gujarat that offers various types of winding machines? If yes, don’t wait and connect with Weavetech today.

How Does Winding Machine Work?

Winding machines typically consist of a rotating spindle or shaft that holds the core or spool onto which the material is wound. The material to be wound is usually fed through a guide mechanism that ensures uniform distribution across the spool. The spindle or shaft rotates, pulling the material onto the spool in a precise and controlled manner, with tension and speed being closely monitored to ensure quality winding. Depending on the type of winding machine, the spool may rotate, the material may be fed at a variable speed, or both. Some machines also have features such as automatic stop mechanisms or sensors to detect and alert the operator to any problems during the winding process. Overall, the winding machine operates with precision and consistency to ensure that the material is wound onto the spool in a uniform and efficient manner.

Types of Winding Machine?

Precision Winding Machines: These machines are used for winding fine wires, threads, and fibers onto spools, bobbins, or cones with high precision and accuracy. These machines are commonly used in the textile industry for manufacturing yarn, thread, and other fibers. Gujarat is a hub for textile machinery manufacturers in India, and there are several well-known manufacturers of precision winding machines in the state and Weavetech is one amongst them.

Drum Winding Machines: These machines are used for winding heavy wires, cables, and ropes onto large drums or spools. They are commonly used in the wire and cable industry. Drum winding machines are equipped with sensors and controls that monitor the tension, speed, and other parameters to ensure consistent winding quality. Textile machinery manufacturers in India produce a wide range of drum winding machines to meet the needs of various applications. These manufacturers design their machines to be durable, reliable, and efficient, with high levels of automation to minimize operator involvement.

Coil Winding Machines: These machines are used for winding coils of wire onto magnetic cores, such as those used in transformers and inductors. These machines are designed to handle a variety of wire sizes and types, including copper, aluminum, and other specialty wires. Coil winding machines can produce coils of different shapes and sizes, including rectangular, cylindrical, and toroidal shapes.

Toroidal Winding Machines: These machines are used for winding wire onto toroidal cores, which are donut-shaped magnetic cores used in transformers, inductors, and other electrical components. Toroidal winding machines use advanced technology to ensure precise winding of the wire onto the core. They are equipped with sensors and controls that monitor tension, speed, and other parameters to ensure consistent winding quality. These machines can handle high-speed winding, producing large quantities of toroidal cores with consistent winding quality.

Rewinding Machines: These machines are used for rewinding rolls of paper, film, and other materials into new rolls with different sizes and lengths. Several textile machinery manufacturers in Gujarat specialize in winding machines, including Weavetech. We offer a range of winding machines, from manual to fully automated models, to meet the needs of different applications.

Bobbin Winding Machines: These machines are used for winding yarn, thread, and other fibers onto small bobbins or spools, typically used in the textile industry. They are equipped with sensors and controls that monitor tension, speed, and other parameters to ensure consistent winding quality. Some advanced bobbin winding machines also have the capability to detect and correct for any winding errors, ensuring a high level of winding accuracy.

Cheese Winding Machines: These machines are used for winding yarn or thread onto large cones or cheese-shaped spools, typically used in the textile industry. Cheese winding machines are used in the textile industry for winding yarn onto cylindrical tubes called cheese. These machines are designed to handle a variety of yarn types and sizes, including natural and synthetic fibers, and can produce cheese of different diameters and lengths.

If you are looking for reliable and high-quality textile machinery solutions in Gujarat, look no further than Weavetech. As a leading textile machinery manufacturer in Gujarat, Weavetech offers a wide range of machines that cater to the needs of textile manufacturers across various sectors. Contact Weavetech today to learn more about their textile machinery solutions and how they can help you improve your textile production operations in Gujarat.

Original Source: https://www.weavetech.com/blog-detail/32/how-many-types-of-winding-machines-are-there/

0 notes