#Winder Rewinder Machine Manufacturer

Explore tagged Tumblr posts

Text

Pacific Laminates to invest Rs 50 crore over the next three years

Pacific Laminates based in Pardi in Gujarat has announced plans to invest approximately Rs 50 crore (US$ 6 million) over the next three years to triple its flexible packaging printing and converting capacity. The company’s current manufacturing capacity stands at 600 metric tons monthly, generating a revenue of Rs 70 crore.

Through strategic and concerted investments in technology, infrastructure, and talent, the aim is to increase its output capacity to 1500 metric tons monthly over two to three years. The company envisions an increase in A-grade clients and a shift to more sustainable materials and solutions to make up at least 30% of its product mix. The overall attempt is to achieve annual revenues from Rs 300 to Rs 400 crore with an EBITDA of 12 to 15% in the coming years.

The decades-old company is a supplier to domestic and global brands and markets with exports of packaging materials to the United States, Europe, and the Middle East. Its current capacity includes two multilayer LDP blown film lines, three rotogravure presses with ARC and turret winders, a pair of solventless laminators, an extrusion coater, several slitter rewinders, and a battery of 34 pouching machines.

This comprehensive setup enables Pacific Laminates to produce a wide range of flexible laminates, pouches, and packaging solutions catering to diverse industry needs. With a commitment to innovation and quality, Pacific Laminates delivers exceptional flexible packaging solutions.

The company is well known for its pouch solutions for food, FMCG, automobile, soaps, detergents, beverages, pharmaceuticals, and cosmetics, using laminates and structures with combinations of PE, PP, PET, Nylon, aluminum, BOPP, BOPA, PVC, PVDC, EVOH, and EVA. Pacific’s BOPP pouches are known for their excellent barrier properties and heat sealability and are used widely in the food, stationery, garment, and hosiery segments.

Pacific Laminates specializes in shaped and broom pouches. While unique shapes of certain products present challenges in packaging and branding the company through its experience and specialized machinery and skills can provide innovative packaging solutions for such products.

Aligned with customer’s sustainability goals

Recognizing the growing importance of sustainability in the packaging industry, the company has been actively exploring eco-friendly alternatives that it plans to extend in its projected capacity expansion. Committed to reducing its environmental footprint by using recyclable and biodegradable materials, the company is investing in research and development to develop packaging solutions compatible with sustainable practices.

These efforts include minimizing material usage and streamlining packaging processes to reduce waste and improve efficiency. The company has undertaken responsible and ethical sourcing of materials in its effort to maintain its reputation as a trusted partner of leading consumer product brands for their high and sustainable packaging solutions.

0 notes

Text

Trim Winder Machine Manufacturers

Blueeye Machine, located in Ahmedabad, is specialised in the manufacture of trim winders, which are designed to meet the needs of the industries that require precise winding solutions for a variety of materials.

#trim winder machine#trim winder machine manufacturer#trim winder machine supplier#trim winder machine in india#trim winder machine manufacturer in Ahmedabad

0 notes

Text

A paper tube cutting machine is a versatile and essential machine used in the paper industry. It is designed to cut large rolls of paper into smaller, more manageable rolls of desired width and length. This machine is crucial in various sectors, including printing, packaging, and converting industries.

Unwinding: The process begins with loading a large roll of paper onto the unwinding shaft. The machine then unwinds the paper roll at a controlled speed.

Slitting: The unwound paper is then passed through sharp blades or rotary knives that slit the paper into smaller widths. The number of blades can be adjusted based on the number of rolls required.

Rewinding: The slit paper is then rewound onto separate cores to form smaller rolls. The tension and speed of rewinding can be controlled to ensure the rolls are wound tightly and evenly.

Cutting: Some machines also have an integrated cutting mechanism that cuts the rewound rolls to the desired length.

Quality Control: Many Paper Slitter Rewinders come with built-in inspection systems that check for defects or irregularities in the paper.

The Paper Slitter Rewinder is known for its high efficiency, precision, and speed. It can handle a wide range of paper types and thicknesses, making it a versatile choice for businesses. With its robust construction and advanced features, this paper core machine ensures smooth and consistent operation, enhancing productivity and reducing waste. Whether you’re a small print shop or a large paper mill, a Paper Slitter Rewinder can be a valuable addition to your production line.

Paper Slitter Rewinder: Enhancing Efficiency in Manufacturing

The Paper Slitter Rewinder is a game-changer in the manufacturing industry, significantly enhancing efficiency and productivity. This machine is designed to transform large rolls of paper into smaller ones, tailored to specific requirements. Here’s how it contributes to manufacturing efficiency:

High-Speed Operation: paper tube winder machine operate at high speeds, capable of processing large volumes of paper in a short time. This speed significantly reduces production time, enabling businesses to meet high demand quickly.

Precision Cutting: With adjustable blades, the machine ensures precise and consistent cuts every time. This precision eliminates waste from inaccurate cuts, saving materials and costs.

Automation: Many models come with automated features, reducing the need for manual intervention. This automation not only saves labor costs but also minimizes human error, ensuring consistent quality.

Quality Control: With built-in inspection systems, the machine can detect and rectify defects or irregularities in the paper. This feature ensures that only high-quality paper rolls reach the end of the production line.

Space Efficiency: Despite its robust capabilities, the Paper Slitter Rewinder has a compact design that saves valuable floor space in manufacturing facilities.

By investing in a Paper Slitter Rewinder, businesses can significantly enhance their manufacturing efficiency. This core pipe-making machine not only speeds up the production process but also ensures the consistent quality of the final product, leading to increased customer satisfaction and profitability.

Paper Slitter Rewinders for Every Industry Need

Paper slitter rewinders play a pivotal role across diverse industries, addressing unique needs with precision and efficiency:

Printing Industry: In printing, these machines facilitate the production of custom-sized paper rolls, optimizing printing processes and reducing waste.

Packaging Sector: The packaging industry benefits from the adaptability of paper slitter rewinders, ensuring the creation of tailored rolls for various packaging applications, enhancing efficiency and minimizing material costs.

Converting Industries: Paper converting relies on these machines to transform large paper rolls into smaller, usable rolls with specific dimensions, meeting the requirements of different product lines.

Flexibility in Width and Length: The versatility of paper slitter rewinders allows for the customization of roll width and length, catering to the unique specifications of each industry and product.

Enhanced Productivity: With precise cutting and rewinding capabilities, these machines contribute to increased productivity, reducing downtime and enhancing overall operational efficiency in multiple sectors.

0 notes

Link

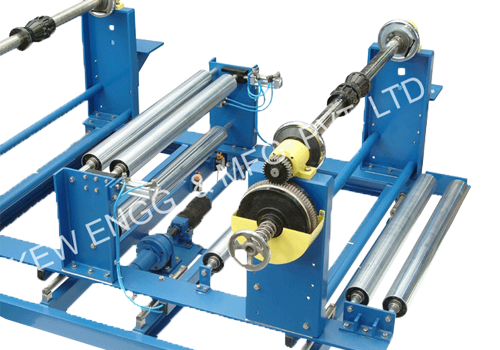

We are a specialized manufacturer of Winding Rewinding Machine, heavy duty equipment, high-quality material used in Winding Rewinder Machine. Our Product range includes Machines Like: Winding Rewinder Machine, Winding Rewinding Table Top, Heavy Duty Winding Rewinding, High Speed Winding Rewinding, Custom Application Doctoring Rewinding, Film Winding Rewinding with Slitter, Winding and Slitting Rewinding, Winding Rewinding for Label Stock, Winding Rewinding for Special Application, Film Winding Rewinding for Batch Coding.

#Winding Rewinder Machine#Winding Rewinder Machine Manufacturer#Winding Rewinder#Winding Rewinding Machine#Winding Rewinding#Winding Rewinding Machine Manufacturer#Winding Rewindings#Winder Rewinder Machine#Winder Rewinder Machines#Winder Rewinder Machine Manufacturer#Winder Rewinder#Winder Rewinding Machine#Winder Rewinding Machines#Winder Rewinding#Winder Rewindings

1 note

·

View note

Link

Our Specialized on manufacturing exporter, and supplier high quality and High Speed Doctoring Rewinding Machine. We offer Different types of High Speed Doctoring Rewinding Machine Manufacturer, exporter, and supplier, high-quality equipment Winder rewinder, Manufacturer. It is designed to use for all types of Laminates also, recover defective printed parts. As well as it is dealing on Paper, LDPE, Foil, HDPE, PVC and many more. Also, dealing with Winding Rewinding for Inkjet Printer & Batch Printing Machine, Winding Rewinding Machine, Winder Rewinder Machine.

#High Speed Doctoring Rewinding Machine#Doctoring Rewinding Machine#Doctoring Rewinding Machine Manufacturer#Doctoring Rewinding#Doctoring Rewinding Machines#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Winding Rewinding#Winder Rewinder Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder#Winder Rewinder Machines

1 note

·

View note

Link

#Doctoring Rewinding Machine Manufacturer#Doctoring Rewinding Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder Machine

0 notes

Link

#Doctoring Rewinding Machine#Doctoring Machine#Doctoring Rewinding Machine Manufacturers#Winder Rewinder Machine#Winder Rewinder Machine Manufacturer

0 notes

Link

We are manufacturer Of Winding Rewinding Machines, Winding Rewinder Machine, Rewinding Machine, Winding Rewinder Machine. Winder Rewinding Machine with 25 different types of models. Winding Rewinding Table Top, Heavy Duty Winding Rewinding, High Speed Winding Rewinding, Custom Application Doctoring Rewinding, Film Winding Rewinding with Slitter, Winding Rewinding for Label Stock, Film Winding Rewinding for Batch Coding, Winding Rewinding for Batch Printing, Winding Rewinding With Inkjet Printer.

#Winding Rewinding Machines#Winding Rewinder Machine#Winder Rewinder Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder#Winding Rewinding#Film Winding Rewinding#Batch Printing#Batch Printing Machine

0 notes

Link

We have been manufacturing, exporting and supplying Winding Unwinding Machine since last 25 years from India, heavy duty Winding Rewinding Machine, Winding Rewinder Machine, Winder Rewinder Machine, Roll To Roll Winding Rewinding Machine For Batch Printing, Winding Rewinding Machine With Slitting System, Winding Unwinding Machine with high performance winding quality with an integral part of winding technology depending on stretch wrap film, cling film and many more.

#Winding Unwinding Machine#Winding Unwinding#Winding Unwinding Machine Manufacturer#Winding Rewinding Machine#Winding Rewinding#Winding Rewinding Machine Manufacturer#Winder Rewinder Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder#Winding Unwindings#Batch Printing#Batch Printing Machine

0 notes

Link

We are Manufacturer Of Winder Rewinder for Inkjet Printer, Winding Rewinding Machine, Industrial Inkjet Printer, doctoring rewinding, for batch coding and printing Machine Industrial Inkjet Printer With Winder Rewinder Machine. Using Ink- jet printer or other contact coding machines from Roll to Roll at high speeds & then these printed roll are used in various packaging machines. Provision for incorporating Ink Jet Printing System with Hot air ink drying. Cantilever design-balancing body for easy loading and unloading of parent / rewound reel.

#Winder Rewinder for Inkjet Printer#Winding Rewinding Machine#Winding Rewinding#Winding Rewinding Machine Manufacturer#Winding Rewindings#Winder Rewinder Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder#Industrial Inkjet Printer#doctoring rewinding#batch coding Machine

0 notes

Link

Rewinder Machine Manufacturer India, Winding Rewinding Machine for different types of Industries, Rewinder Machine diameter can be achieved up to 1200 mm. Our Heavy Duty Paper Slitting Rewinding Machine comes in use for Slitting of all types of Paper Material like Coated Paper, Ice Cream Cup Paper, Fax Roll, Photograph Paper, Stationery Paper, etc. Our Slitter Rewinder Machine, Paper Slitting Rewinding Machine is able to process all types of Paper of any GSM thickness.

#Rewinder Machine#Rewinder Machine Manufacturer#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Winding Rewinding#Winder Rewinder machine#Winder Rewinder machine Manufacturer#Winder Rewinder#Rewinding Machine Manufacturer#Rewinding Machine Manufacturers#Rewinding Machine

0 notes

Link

We are dealing in high quality Batch Coding Printing Machine Manufacturer, Doctoring Rewinding Machine, Batch Printing Machine, Industrial Inkjet Printers Manufacturer batch numbers on packaging materials. Our Doctoring Rewinding is highly used for all types of Laminates like, Foil, Paper, LDPE, HDPE, PVC and many more. We have been successfully Manufacturing, Exporting & Supplying all types of Doctoring Rewinding Machine and Winding Rewinding Machine for Inkjet Printer & Batch Printing Machine Manufacturer.

#Batch Coding Printing Machine#Batch Coding Printing Machine Manufacturer#Batch Coding Machine#Batch Coding Machines#Batch Printing Machine#Batch Printing Machines#Doctoring Rewinding#Doctoring Rewinding Machine#Industrial Inkjet Printers#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Winding Rewinding#Winder Rewinder Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder Machines

0 notes

Link

We are Manufacturing Of Winding Unwinding Machine for different material and industries, winder Rewinder machine, winder unwinder, Winding Rewinding Machine, Winding Rewinding, Winding Unwinding machine, Doctoring Rewinding Machine, Doctoring Rewinding, Doctor Rewinder Machine, Doctor Rewinder. Winding Unwinding Machine manufacturer with standard technology for stretch film, cling film and more for the packaging industries. various types of Roll Winding Equipment Industry and per client's requirements.

#Winding Unwinding Machine#Winding Unwinding Machine Manufacturer#Winding Unwinding#Winder Rewinder Machine#Winder Rewinder#Winder Rewinder Machine Manufacturer#Winding Rewinding#Winding Rewinding Machine#Doctoring Rewinding#Doctoring Rewinding Machine#Doctor Rewinder Machine#Doctor Rewinder

0 notes

Link

We are specializing manufacturing doctoring film strip winding rewinding machine. Specially built for film strip winding with correction doctoring winding Machine, Doctoring Rewinding Machine, Winding Rewinding Machine, Rewinding Machine, Doctoring rewinding, Doctor Rewinder Machine, Winder Rewinder Machine, Doctoring Film Strip Winding Rewinding, Film Strip Winding Rewinding. Strip Winding Rewinding, Inspection Rewinding Machine, Rewinder Unwinder System for widest converting & flexible packaging industries.

#Doctoring Film Strip Winding Rewinding Machine#Doctoring Film Strip Winding Rewindng#Film Strip Winding Rewinding Machine#Film Strip Winding Rewinding#Doctoring Rewinding Machine#Doctoring Rewinding Machine Manufacturer#Doctoring Rewinding#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Winding Rewinding#Rewinding Machine#Doctoring rewindings#Winder Rewinder Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder#Strip Winding Rewinding#Doctoring Film Strip Winding Rewinding#Doctoring Rewinding Machines

0 notes

Link

We are manufacturer of specialized manufacturer of Winding Unwinding Machine Manufacturer India. Winding Rewinder Machine, Winder Rewinder Machine, Rewinder Machine, Unwinding and Winding Machines, Doctoring Rewinding Machine, Batch Printing Machine, Rewinder Unwinder System. Winding Rewinding Machine, Non Woven Rewinding Machine, Trim Rewinder, Winder Rewinder Machine and Inspection Cum Rewinder Machine with high quality and heavy duty equipment.

#Winding Unwinding Machine#Winding Unwinding#Winding Unwinding Machines#Winding Unwindings#Winding Rewinder Machine#Winding Rewinder Machines#Winding Rewinder#Winder Rewinder Machine#Winder Rewinder Machines#Winder Rewinder Machine Manufacturer#Winder Rewinder#Winder Rewinders#Doctoring Rewinding#Doctoring Rewindings#Doctoring Rewinding Machine#Doctor Rewinder Machine#Doctor Rewinder Machines#Doctor Rewinder

0 notes

Link

We have been manufacturing, exporting and supplying Winding Unwinding Machine since last 25 years from India, heavy duty Winding Rewinding Machine, Winder Rewinder Machine, high speed Winding Rewinding Machine. Winding Unwinding Machine with high performance winding quality with an integral part of winding technology depending on stretch wrap film, cling film and many more. We are Winder Rewinder Machine offering premium quality range of Winding Unwinding Machine. Winding Rewinding Machine Manufacturer India for various types of Industry and per client’s requirements.

#Winding Unwinding Machine#Winding Rewinding Machine#Winder Rewinder Machine#Winding Rewinding#Winder Rewinder#Winding Unwinding Machine Manufacturer#Winding Rewinding Machine Manufacturer#Winder Rewinder Machine Manufacturer#Winder Rewinder Manufacturer

1 note

·

View note