#Wheat flour plant manufacturers

Explore tagged Tumblr posts

Text

Gain insights into the automated revolution transforming wheat flour production, as state-of-the-art facilities integrate cutting-edge technologies, streamlining processes from grain intake to packaging, ensuring consistent quality and maximizing output.

0 notes

Note

Bread is a staple food prepared from a dough of flour (usually wheat) and water, usually by baking. Throughout recorded history and around the world, it has been an important part of many cultures' diet. It is one of the oldest human-made foods, having been of significance since the dawn of agriculture, and plays an essential role in both religious rituals and secular culture.

Bread may be leavened by naturally occurring microbes (e.g. sourdough), chemicals (e.g. baking soda), industrially produced yeast, or high-pressure aeration, which creates the gas bubbles that fluff up bread. In many countries, commercial bread often contains additives to improve flavor, texture, color, shelf life, nutrition, and ease of production.

Etymology

The Old English word for bread was hlaf (hlaifs in Gothic: modern English loaf), which appears to be the oldest Teutonic name.[1] Old High German hleib[2] and modern German Laib derive from this Proto-Germanic word, which was borrowed into some Slavic (Czech: chléb, Polish: bochen chleba, Russian: khleb) and Finnic (Finnish: leipä, Estonian: leib) languages as well. The Middle and Modern English word bread appears in Germanic languages, such as West Frisian: brea, Dutch: brood, German: Brot, Swedish: bröd, and Norwegian and Danish: brød; it may be related to brew or perhaps to break, originally meaning "broken piece", "morsel".[3][better source needed]

History

Main article: History of bread

Bread is one of the oldest prepared foods. Evidence from 30,000 years ago in Europe and Australia revealed starch residue on rocks used for pounding plants.[4][5] It is possible that during this time, starch extract from the roots of plants, such as cattails and ferns, was spread on a flat rock, placed over a fire and cooked into a primitive form of flatbread. The oldest evidence of bread-making has been found in a 14,500-year-old Natufian site in Jordan's northeastern desert.[6][7] Around 10,000 BC, with the dawn of the Neolithic age and the spread of agriculture, grains became the mainstay of making bread. Yeast spores are ubiquitous, including on the surface of cereal grains, so any dough left to rest leavens naturally.[8]Woman baking bread (c. 2200 BC); Louvre

An early leavened bread was baked as early as 6000 BC in southern Mesopotamia, cradle of the Sumerian civilization, who may have passed on the knowledge to the Egyptians around 3000 BC. The Egyptians refined the process and started adding yeast to the flour. The Sumerians were already using ash to supplement the dough as it was baked.[9]

There were multiple sources of leavening available for early bread. Airborne yeasts could be harnessed by leaving uncooked dough exposed to air for some time before cooking. Pliny the Elder reported that the Gauls and Iberians used the foam skimmed from beer, called barm, to produce "a lighter kind of bread than other peoples" such as barm cake. Parts of the ancient world that drank wine instead of beer used a paste composed of grape juice and flour that was allowed to begin fermenting, or wheat bran steeped in wine, as a source for yeast. The most common source of leavening was to retain a piece of dough from the previous day to use as a form of sourdough starter, as Pliny also reported.[10][11]

The ancient Egyptians, Greeks, and Romans all considered the degree of refinement in the bakery arts as a sign of civilization.[9]

The Chorleywood bread process was developed in 1961; it uses the intense mechanical working of dough to dramatically reduce the fermentation period and the time taken to produce a loaf. The process, whose high-energy mixing allows for the use of grain with a lower protein content, is now widely used around the world in large factories. As a result, bread can be produced very quickly and at low costs to the manufacturer and the consumer. However, there has been some criticism of the effect on nutritional value.[12][13][14]

Types

Main article: List of breads

Brown bread (left) and whole grain bread

Dark sprouted bread

Ruisreikäleipä, a flat rye flour loaf with a hole

Bread is the staple food of the Middle East, Central Asia, North Africa, Europe, and in European-derived cultures such as those in the Americas, Australia, and Southern Africa. This is in contrast to parts of South and East Asia, where rice or noodles are the staple. Bread is usually made from a wheat-flour dough that is cultured with yeast, allowed to rise, and baked in an oven. Carbon dioxide and ethanol vapors produced during yeast fermentation result in bread's air pockets.[15] Owing to its high levels of gluten (which give the dough sponginess and elasticity), common or bread wheat is the most common grain used for the preparation of bread, which makes the largest single contribution to the world's food supply of any food.[16]Sangak, an Iranian flatbreadStrucia — a type of European sweet bread

Bread is also made from the flour of other wheat species (including spelt, emmer, einkorn and kamut).[17] Non-wheat cereals including rye, barley, maize (corn), oats, sorghum, millet and rice have been used to make bread, but, with the exception of rye, usually in combination with wheat flour as they have less gluten.[18]

Gluten-free breads are made using flours from a variety of ingredients such as almonds, rice, sorghum, corn, legumes such as beans, and tubers such as cassava. Since these foods lack gluten, dough made from them may not hold its shape as the loaves rise, and their crumb may be dense with little aeration. Additives such as xanthan gum, guar gum, hydroxypropyl methylcellulose (HPMC), corn starch, or eggs are used to compensate for the lack of gluten.[19][20][21][22]

Properties

Physical-chemical composition

In wheat, phenolic compounds are mainly found in hulls in the form of insoluble bound ferulic acid, where it is relevant to wheat resistance to fungal diseases.[23]

Rye bread contains phenolic acids and ferulic acid dehydrodimers.[24]

Three natural phenolic glucosides, secoisolariciresinol diglucoside, p-coumaric acid glucoside and ferulic acid glucoside, can be found in commercial breads containing flaxseed.[25]Small home made bread with pumpkin and sunflower seeds

Glutenin and gliadin are functional proteins found in wheat bread that contribute to the structure of bread. Glutenin forms interconnected gluten networks within bread through interchain disulfide bonds.[26] Gliadin binds weakly to the gluten network established by glutenin via intrachain disulfide bonds.[26] Structurally, bread can be defined as an elastic-plastic foam (same as styrofoam). The glutenin protein contributes to its elastic nature, as it is able to regain its initial shape after deformation. The gliadin protein contributes to its plastic nature, because it demonstrates non-reversible structural change after a certain amount of applied force. Because air pockets within this gluten network result from carbon dioxide production during leavening, bread can be defined as a foam, or a gas-in-solid solution.[27]

Acrylamide, like in other starchy foods that have been heated higher than 120 °C (248 °F), has been found in recent years to occur in bread. Acrylamide is neurotoxic, has adverse effects on male reproduction and developmental toxicity and is carcinogenic. A study has found that more than 99 percent of the acrylamide in bread is found in the crust.[28]

A study by the University of Hohenheim found that industrially produced bread typically has a high proportion of FODMAP carbohydrates due to a short rising time (often only one hour). The high proportion of FODMAP carbohydrates in such bread then causes flatulence. This is particularly problematic in intestinal diseases such as irritable bowel syndrome. While in traditional bread making the dough rises for several hours, industrial breads rise for a much shorter time, usually only one hour. However, a sufficiently long rising time is important to break down the indigestible FODMAP carbohydrates. Some flours (for example, spelt, emmer and einkorn) contain fewer FODMAPs, but the difference between grain types is relatively small (between 1 and 2 percent by weight). Instead, 90% of the FODMAPs that cause discomfort can be broken down during a rising time of 4 hours. In the study, whole-grain yeast doughs were examined after different rising times; the highest level of FODMAPs was present after one hour in each case and decreased thereafter. The study thus shows that it is essentially the baking technique and not the type of grain that determines whether a bread is well tolerated or not. A better tolerance of bread made from original cereals can therefore not be explained by the original cereal itself, but rather by the fact that traditional, artisanal baking techniques are generally used when baking original cereals, which include a long dough process. The study also showed that a long rising time also breaks down undesirable phytates more effectively, flavors develop better, and the finished bread contains more biologically accessible trace elements.[29][30]

Culinary uses

Bread pudding

Bread can be served at many temperatures; once baked, it can subsequently be toasted. It is most commonly eaten with the hands, either by itself or as a carrier for other foods. Bread can be spread with butter, dipped into liquids such as gravy, olive oil, or soup;[31] it can be topped with various sweet and savory spreads, or used to make sandwiches containing meats, cheeses, vegetables, and condiments.[32]

Bread is used as an ingredient in other culinary preparations, such as the use of breadcrumbs to provide crunchy crusts or thicken sauces; toasted cubes of bread, called croutons, are used as a salad topping; seasoned bread is used as stuffing inside roasted turkey; sweet or savoury bread puddings are made with bread and various liquids; egg and milk-soaked bread is fried as French toast; and bread is used as a binding agent in sausages, meatballs and other ground meat products.[33]

Nutritional significance

Bread is a good source of carbohydrates and micronutrients such as magnesium, iron, selenium, and B vitamins. Whole grain bread is a good source of dietary fiber and all breads are a common source of protein in the diet, though not a rich one.[34][35]

Crust

Crust of a cut bread made of whole-grainrye with crust crack (half right at the top)

Bread crust is formed from surface dough during the cooking process. It is hardened and browned through the Maillard reaction using the sugars and amino acids due to the intense heat at the bread surface. The crust of most breads is harder, and more complexly and intensely flavored, than the rest. Old wives' tales suggest that eating the bread crust makes a person's hair curlier.[36] Additionally, the crust is rumored to be healthier than the remainder of the bread. Some studies have shown that this is true as the crust has more dietary fiber and antioxidants such as pronyl-lysine.[37]

Preparation

Steps in bread making, here for an unleavened Chilean tortilla

Doughs are usually baked, but in some cuisines breads are steamed (e.g., mantou), fried (e.g., puri), or baked on an unoiled frying pan (e.g., tortillas). It may be leavened or unleavened (e.g. matzo). Salt, fat and leavening agents such as yeast and baking soda are common ingredients, though bread may contain other ingredients, such as milk, egg, sugar, spice, fruit (such as raisins), vegetables (such as onion), nuts (such as walnut) or seeds (such as poppy).[38]

Methods of processing dough into bread include the straight dough process, the sourdough process, the Chorleywood bread process and the sponge and dough process.Baking bread in East Timor

Formulation

Professional bread recipes are stated using the baker's percentage notation. The amount of flour is denoted to be 100%, and the other ingredients are expressed as a percentage of that amount by weight. Measurement by weight is more accurate and consistent than measurement by volume, particularly for dry ingredients. The proportion of water to flour is the most important measurement in a bread recipe, as it affects texture and crumb the most. Hard wheat flours absorb about 62% water, while softer wheat flours absorb about 56%.[39] Common table breads made from these doughs result in a finely textured, light bread. Most artisan bread formulas contain anywhere from 60 to 75% water. In yeast breads, the higher water percentages result in more CO2 bubbles and a coarser bread crumb.

Dough recipes commonly call for 500 grams (about 1.1 pounds) of flour, which yields a single loaf of bread or two baguettes.

Calcium propionate is commonly added by commercial bakeries to retard the growth of molds.[citation needed]

Flour

Main article: Flour

Flour is grain ground into a powder. Flour provides the primary structure, starch and protein to the final baked bread. The protein content of the flour is the best indicator of the quality of the bread dough and the finished bread. While bread can be made from all-purpose wheat flour, a specialty bread flour, containing more protein (12–14%), is recommended for high-quality bread. If one uses a flour with a lower protein content (9–11%) to produce bread, a shorter mixing time is required to develop gluten strength properly. An extended mixing time leads to oxidization of the dough, which gives the finished product a whiter crumb, instead of the cream color preferred by most artisan bakers.[40]

Wheat flour, in addition to its starch, contains three water-soluble protein groups (albumin, globulin, and proteoses) and two water-insoluble protein groups (glutenin and gliadin). When flour is mixed with water, the water-soluble proteins dissolve, leaving the glutenin and gliadin to form the structure of the resulting bread. When relatively dry dough is worked by kneading, or wet dough is allowed to rise for a long time (see no-knead bread), the glutenin forms strands of long, thin, chainlike molecules, while the shorter gliadin forms bridges between the strands of glutenin. The resulting networks of strands produced by these two proteins are known as gluten. Gluten development improves if the dough is allowed to autolyse.[41]

Liquids

Water, or some other liquid, is used to form the flour into a paste or dough. The weight or ratio of liquid required varies between recipes, but a ratio of three parts liquid to five parts flour is common for yeast breads.[42] Recipes that use steam as the primary leavening method may have a liquid content in excess of one part liquid to one part flour. Instead of water, recipes may use liquids such as milk or other dairy products (including buttermilk or yogurt), fruit juice, or eggs. These contribute additional sweeteners, fats, or leavening components, as well as water.[43]

Fats or shortenings

Fats, such as butter, vegetable oils, lard, or that contained in eggs, affect the development of gluten in breads by coating and lubricating the individual strands of protein. They also help to hold the structure together. If too much fat is included in a bread dough, the lubrication effect causes the protein structures to divide. A fat content of approximately 3% by weight is the concentration that produces the greatest leavening action.[44] In addition to their effects on leavening, fats also serve to tenderize breads and preserve freshness.

Bread improvers

Main article: Bread improver

Bread improvers and dough conditioners are often used in producing commercial breads to reduce the time needed for rising and to improve texture and volume and to give antistaling effects. The substances used may be oxidising agents to strengthen the dough or reducing agents to develop gluten and reduce mixing time, emulsifiers to strengthen the dough or to provide other properties such as making slicing easier, or enzymes to increase gas production.[45]

Salt

Salt (sodium chloride) is very often added to enhance flavor and restrict yeast activity. It also affects the crumb and the overall texture by stabilizing and strengthening[46] the gluten. Some artisan bakers forego early addition of salt to the dough, whether wholemeal or refined, and wait until after a 20-minute rest to allow the dough to autolyse.[47]

Mixtures of salts are sometimes employed, such as employing potassium chloride to reduce the sodium level, and monosodium glutamate to give flavor (umami).

Leavening

See also: Unleavened breadA dough trough, located in Aberdour Castle, once used for leavening bread

Leavening is the process of adding gas to a dough before or during baking to produce a lighter, more easily chewed bread. Most bread eaten in the West is leavened.[48]

Chemicals

A simple technique for leavening bread is the use of gas-producing chemicals. There are two common methods. The first is to use baking powder or a self-raising flour that includes baking powder. The second is to include an acidic ingredient such as buttermilk and add baking soda; the reaction of the acid with the soda produces gas.[48] Chemically leavened breads are called quick breads and soda breads. This method is commonly used to make muffins, pancakes, American-style biscuits, and quick breads such as banana bread.

Yeast

Main article: Baker's yeastCompressed fresh yeast

Many breads are leavened by yeast. The yeast most commonly used for leavening bread is Saccharomyces cerevisiae, the same species used for brewing alcoholic beverages. This yeast ferments some of the sugars producing carbon dioxide. Commercial bakers often leaven their dough with commercially produced baker's yeast. Baker's yeast has the advantage of producing uniform, quick, and reliable results, because it is obtained from a pure culture.[48] Many artisan bakers produce their own yeast with a growth culture. If kept in the right conditions, it provides leavening for many years.[49]

The baker's yeast and sourdough methods follow the same pattern. Water is mixed with flour, salt and the leavening agent. Other additions (spices, herbs, fats, seeds, fruit, etc.) are not needed to bake bread, but are often used. The mixed dough is then allowed to rise one or more times (a longer rising time results in more flavor, so bakers often "punch down" the dough and let it rise again), loaves are formed, and (after an optional final rising time) the bread is baked in an oven.[48]

Many breads are made from a "straight dough", which means that all of the ingredients are combined in one step, and the dough is baked after the rising time;[48] others are made from a "pre-ferment" in which the leavening agent is combined with some of the flour and water a day or so ahead of baking and allowed to ferment overnight. On the day of baking, the rest of the ingredients are added, and the process continues as with straight dough. This produces a more flavorful bread with better texture. Many bakers see the starter method as a compromise between the reliable results of baker's yeast and the flavor and complexity of a longer fermentation. It also allows the baker to use only a minimal amount of baker's yeast, which was scarce and expensive when it first became available. Most yeasted pre-ferments fall into one of three categories: "poolish" or "pouliche", a loose-textured mixture composed of roughly equal amounts of flour and water (by weight); "biga", a stiff mixture with a higher proportion of flour; and "p��te fermentée", which is a portion of dough reserved from a previous batch.[50][51]

Before first rising

After first rising

After proofing, ready to bake

Sourdough

Main article: SourdoughSourdough loaves

Sourdough is a type of bread produced by a long fermentation of dough using naturally occurring yeasts and lactobacilli. It usually has a mildly sour taste because of the lactic acid produced during anaerobic fermentation by the lactobacilli. Longer fermented sourdoughs can also contain acetic acid, the main non-water component of vinegar.[52][53][54]

Sourdough breads are made with a sourdough starter. The starter cultivates yeast and lactobacilli in a mixture of flour and water, making use of the microorganisms already present on flour; it does not need any added yeast. A starter may be maintained indefinitely by regular additions of flour and water. Some bakers have starters many generations old, which are said to have a special taste or texture.[52] At one time, all yeast-leavened breads were sourdoughs. Recently there has been a revival of sourdough bread in artisan bakeries.[55]

Traditionally, peasant families throughout Europe baked on a fixed schedule, perhaps once a week. The starter was saved from the previous week's dough. The starter was mixed with the new ingredients, the dough was left to rise, and then a piece of it was saved to be the starter for next week's bread.[48]

Steam

The rapid expansion of steam produced during baking leavens the bread, which is as simple as it is unpredictable. Steam-leavening is unpredictable since the steam is not produced until the bread is baked. Steam leavening happens regardless of the raising agents (baking soda, yeast, baking powder, sour dough, beaten egg white) included in the mix. The leavening agent either contains air bubbles or generates carbon dioxide. The heat vaporises the water from the inner surface of the bubbles within the dough. The steam expands and makes the bread rise. This is the main factor in the rising of bread once it has been put in the oven.[56] CO2 generation, on its own, is too small to account for the rise. Heat kills bacteria or yeast at an early stage, so the CO2 generation is stopped.

Bacteria

Salt-rising bread does not use yeast. Instead, it is leavened by Clostridium perfringens, one of the most common sources of food-borne illness.[57][58]

Aeration

Aerated bread is leavened by carbon dioxide being forced into dough under pressure. From the mid-19th to mid-20th centuries, bread made this way was somewhat popular in the United Kingdom, made by the Aerated Bread Company and sold in its high-street tearooms. The company was founded in 1862, and ceased independent operations in 1955.[59]

The Pressure-Vacuum mixer was later developed by the Flour Milling and Baking Research Association for the Chorleywood bread process. It manipulates the gas bubble size and optionally the composition of gases in the dough via the gas applied to the headspace.[60]

Cultural Significance

A Ukrainian woman in national dress welcoming with bread and salt

Main article: Bread in culture

Bread has a significance beyond mere nutrition in many cultures because of its history and contemporary importance. Bread is also significant in Christianity as one of the elements (alongside wine) of the Eucharist,[61] and in other religions including Paganism.[62]

In many cultures, bread is a metaphor for basic necessities and living conditions in general. For example, a "bread-winner" is a household's main economic contributor and has little to do with actual bread-provision. This is also seen in the phrase "putting bread on the table". The Roman poet Juvenal satirized superficial politicians and the public as caring only for "panem et circenses" (bread and circuses).[63] In Russia in 1917, the Bolsheviks promised "peace, land, and bread."[64][65] The term "breadbasket" denotes an agriculturally productive region. In parts of Northern, Central, Southern and Eastern Europe bread and salt is offered as a welcome to guests.[66] In India, life's basic necessities are often referred to as "roti, kapra aur makan" (bread, cloth, and house).[67]

Words for bread, including "dough" and "bread" itself, are used in English-speaking countries as synonyms for money.[1] A remarkable or revolutionary innovation may be called the best thing since "sliced bread".[68] The expression "to break bread with someone" means "to share a meal with someone".[69] The English word "lord" comes from the Anglo-Saxon hlāfweard, meaning "bread keeper."[70]

Bread is sometimes referred to as "the staff of life", although this term can refer to other staple foods in different cultures: the Oxford English Dictionary defines it as "bread (or similar staple food)".[71][72] This is sometimes thought to be a biblical reference, but the nearest wording is in Leviticus 26 "when I have broken the staff of your bread".[73] The term has been adopted in the names of bakery firms.[74]

See also

Food portal

Bark bread – Scandinavian bread used as famine food

Bread bowl – Round loaf of bread which has had a large portion of the middle cut out to create an edible bowl

Bread clip – Closure device for plastic bags

Bread dildo – Dildo prepared using bread, allegedly made in the Greco-Roman era around 2,000 years ago

Breading – Residue of dried bread

Bread machine – Type of home appliance for baking bread

Bread pan – Kitchen utensil

Crouton – Rebaked breads

List of breads

List of bread dishes – Dishes using bread as a main ingredient, listed by category

List of toast dishes

Quick bread – Bread leavened with agents other than yeast

Sliced bread – Loaf of bread that has been sliced with a machine

Slow Bread – Type of bread made using very little yeast

Sop – Piece of bread or toast that is drenched in liquid and then eaten.

Stuffing – Edible mixture filling a food's cavity

White bread – Type of bread made from white wheat flour

oh fuck yes bread

5 notes

·

View notes

Photo

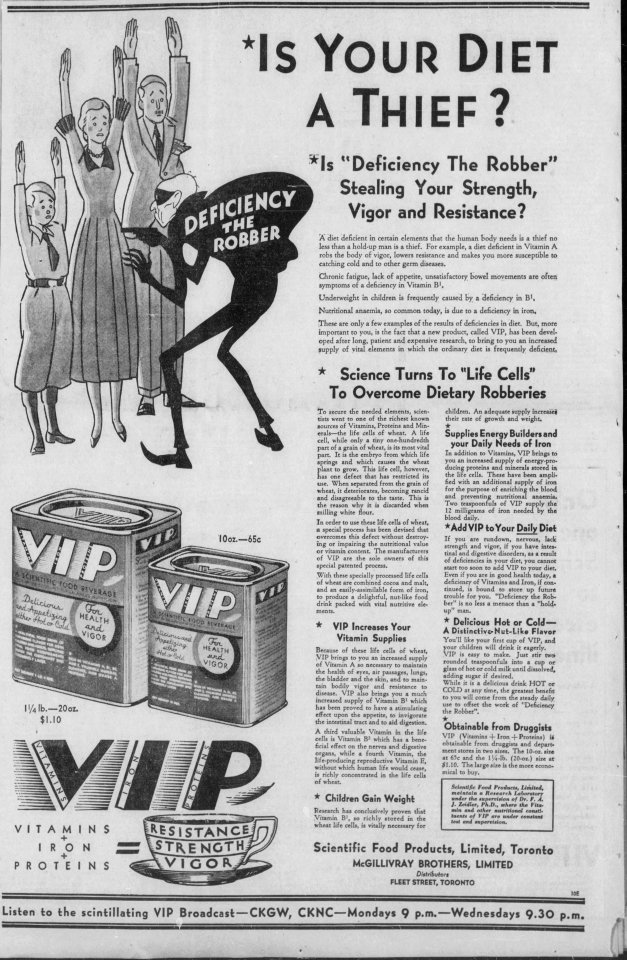

“Is Your Diet A Thief?” Kingston Whig-Standard. February 15, 1933. Page 10, --- Is Deficiency The Robber Stealing Your Strength Vigor and Resistance? --- A diet deficient in certain elements that the human body needs is a thief no less than a hold-up man is a thief For example a diet deficient in Vitamin A robs the body of vigor lowers resistance and makes you more susceptible to catching cold and to other germ diseases.

Chronic fatigue, lack of appetite, unsatisfactory bowel movements, are often symptoms of a deficiency in Vitamin B1.

Underweight in children is frequently caused by a deficiency in B1.

Nutritional anaemia, so common today, is due to a deficiency in iron.

These are only a few examples of the results of deficiencies in diet. But more important to you is the fact that a new product called VIP has been developed after long patient and expensive research to bring to you an increased supply of vital elements in which the ordinary diet is frequently deficient.

Science Turns To "Life Cells” To Overcome Dietary Robberies To secure the needed elements scientists went to one of the richest known source of Vitamins, Proteins, and Minerals— the life cells of wheat. A life cell, while only a tiny one-hundredth part of a grain of wheat, is its most vital part. It is the embryo from which life springs and which causes the wheat plant to grow. This life cell however has one defect that has restricted its use. When separated from the grain of wheat, it deteriorates, becoming rancid and disagreeable to the taste. This is the reason why it is discarded when milling white flour.

In order to use these life cells of wheat, a special process has been devised that overcomes this defect without destroying or impairing the nutritional value or vitamin content. The manufacturers of VIP are the sole owners of this special patented process.

With these specially processed life cells of wheat are combined cocoa and malt, and an easily-assimilable form of iron, to produce a delightful nut-like food drink packed with vital nutritive elements.

VIP Increases Your Vitamin Supplies Because of these life cells of wheat, VIP brings to you an increased supply of Vitamin A so necessary to maintain the health of eyes, air passages, lungs, the bladder, and the skin and to maintain bodily vigor and resistance to disease. VIP also brings you a much increased supply of Vitamin B1 which has been proved to have a stimulating effect upon the appetite to invigorate the intestinal tract and to aid digestion.

A third valuable Vitamin in the life cells is Vitamin B which has a beneficial effect on the nerves and digestive organs, while a fourth Vitamin, the life-producing reproductive Vitamin E, without which human life would cease, is richly concentrated in the life cells of wheat.

Children Gain Weight Research has conclusively proven that Vitamin B1 so richly stored in the wheat life cells, is vitally necessary for children. An adequate supply increase! their rate of growth and weight.

Supplies Energy Builders and your Daily Needs of Iron In addition to Vitamins VIP brings to you an increased supply of energy-pro-during proteins and minerals stored in the life cells. These have bean amplified with an additional supply of iron for the purpose of enriching the blood and preventing nutritional anaemia. Two teaspoonfuls and preventing nutrition teaspoonfuls of VIP supply 12 milligrams of iron needed by the blood daily.

Add VIP to Your Dally Diet If you are rundown, nervous, lack of strength and vigor if you have intestinal and digestive disorders as a result of deficiencies in your diet, you cannot start too soon to add VIP to your diet. Even if you are in good health today a deficiency of Vitamins and Iron if continued is bound to store up future trouble for you "Deficiency the Robber” is no less a menace than a "hold up” man.

Delicious Hot or Cold— A Distinctive-Nut-Like Flavor You'll like your first cup of VIP and your children will drink it eagerly VIP is easy to make Just stir two rounded teaspoonfuls into a glass of hot or cold milk until adding sugar if desired.

While it is a delirious drink HOT or COLD at any time the greatest benefit to you will come from die steady daily use to offset the work of "Deficiency the Robber.”

Obtainable from Druggists VIP (Vitamins + Iron + Proteins) is obtainable from druggists and department stores in two sizes...

Scientific Feed Products Limited Toronto McGILLIVRAY BROTHERS LIMITED Distributors FLEET STREET TORONTO

#toronto#health drink#vitamin drink#crime and society#crime wave#history of crime and punishment in canada#patent medicine#wheat germ#health cure#iron deficient anemia#iron deficiency#vitamin deficiency#vintage ads#vintage advertising

5 notes

·

View notes

Text

Whenever someone complains about gluten-free labeling, I say, did you know that yogurt was thickened with wheat starch? Would you have ever guessed that?

No one has time to make all their own food. (God save us from professional bakers who blather on about grinding their own flour. That’s like writing software in assembly language.)

No one has time to read and re-read every food label in the grocery store on the off chance the manufacturer decided to add gluten or move to a plant that processes nuts. Labeling needs clear, eye-catching warnings of the most common allergens. (Will it make people wonder why there is fucking gluten in the goddamn yogurt? That’s a corporate problem, not a consumer problem.)

People’s brains don’t “connect the dots” all the time, and it doesn’t matter why. Assigning blame doesn’t prevent tragedy. It’s far, far easier for every food manufacturer to meet labeling and safety standards than for every consumer to to be 100% vigilant All. The. Time.

My hot take is that actually food allergies are a disability and more people need to realize that. The amount of research people with food allergies have to do when they want to go visit places but arent sure if they’ll have access to any food there is insane. Allergy friendly food is almost ALWAYS incredibly expensive in stores bc of all those fucking fad diets that like yoga instructors and middle age soccer moms make popular. And on top of the price, it is so hard to FIND! Almost evrry grocery store ive been to has a tiny ass allergy section that is almost always near empty. Plus what about people who don’t have the money to pay 10$ for a loaf of bread? You go to starbucks and non-dairy milks are like 70 cents extra? People are definitely out there buying and eating stuff that is destroying their digestive systems because they have no other choice. I am begging people to stop pretending that catering to people’s food allergies is elitist and not worth is. We need to make these options openly available.

47K notes

·

View notes

Text

Chickpea Flour Market: Impacting Factors in a Dynamic Food Industry

The chickpea flour market is influenced by various factors that shape its growth and development in the food industry. Understanding these impacting factors is essential for businesses looking to capitalize on the increasing demand for this versatile ingredient.

One of the primary factors driving the chickpea flour market is the growing health consciousness among consumers. As more people seek nutritious food options, chickpea flour, rich in protein, fiber, and essential nutrients, has gained popularity. Its reputation as a healthy alternative to traditional flours appeals to a wide audience, including those pursuing weight management, fitness, and overall well-being.

The rising trend of gluten-free diets is another significant factor impacting the market. With a growing number of individuals diagnosed with gluten intolerance or celiac disease, the demand for gluten-free alternatives has surged. Chickpea flour naturally lacks gluten, making it an excellent substitute for wheat flour in various recipes. This has prompted food manufacturers to innovate and create a range of gluten-free products that utilize chickpea flour, thereby expanding its market presence.

Additionally, the increasing popularity of plant-based diets is reshaping consumer preferences. As more individuals adopt vegetarian or vegan lifestyles, the demand for plant-based protein sources has risen. Chickpea flour, known for its high protein content, fits perfectly into this trend, providing an essential ingredient for plant-based meals and snacks. This shift encourages food companies to develop innovative products that cater to this growing demographic.

Sustainability concerns also play a crucial role in the chickpea flour market. As consumers become more aware of the environmental impact of their food choices, the eco-friendly nature of chickpea cultivation appeals to those seeking sustainable options. Chickpeas require less water and are generally more sustainable to grow compared to other crops, making chickpea flour an attractive choice for environmentally conscious consumers.

In summary, the impacting factors of the chickpea flour market include rising health awareness, the gluten-free trend, the shift toward plant-based diets, and sustainability concerns. By understanding these influences, businesses can better position themselves to meet the demands of an evolving consumer landscape.

For a sample report click on:

0 notes

Text

Rice Noodles Market Key Highlights and Future Opportunities - 2030

Rice Noodles Expected to Reach USD 9.53 Billion by 2030 with a CAGR of 14.63%

The Rice Noodles Market Share, valued at USD 3.19 billion in 2022, is anticipated to grow significantly, reaching an estimated value of USD 9.53 billion by 2030. This expansion reflects a compound annual growth rate (CAGR) of 14.63% during the forecast period from 2023 to 2030. The increasing demand for convenient and nutritious food, coupled with the rising popularity of rice noodles among health-conscious consumers, is driving this 's dynamic growth.

Dynamics

Growing Popularity of Asian Cuisines

In recent years, Asian cuisines, especially dishes like rice noodles, have seen a surge in popularity across the globe. The demand for authentic, culturally diverse food experiences has led to rice noodles becoming a staple in both households and restaurants outside of their traditional s. Western countries, particularly in North America and Europe, have witnessed a growing trend of incorporating rice noodles into fusion dishes as well as traditional Asian recipes.

As a gluten-free alternative to wheat-based noodles, rice noodles cater to the rising number of consumers with gluten intolerance or celiac disease. Additionally, their appeal as a healthier, lower-calorie option compared to traditional pasta further accelerates growth. The increasing adoption of vegan and plant-based diets also benefits the rice noodles , as they align well with the preferences of these consumer segments.

Health and Wellness Trends Drive Growth

The global shift toward healthier eating habits is a major catalyst for the growth of the rice noodles . Rice noodles, being made from rice flour and water, are naturally free from gluten, fat, and cholesterol. Consumers are becoming more aware of the benefits of rice noodles, including their easy digestibility, low calorie content, and ability to fit into various dietary requirements, including vegan, gluten-free, and low-carb diets.

This focus on health and wellness is also encouraging manufacturers to develop new product variants that cater to different nutritional needs, such as fortified rice noodles with added vitamins and minerals or organic versions that appeal to eco-conscious consumers.

Convenience and Versatility

Another driving force behind the rising demand for rice noodles is the increasing need for convenient and quick-to-prepare meal options. With more consumers leading fast-paced lifestyles, the need for time-saving yet nutritious food products is growing. Rice noodles, which cook quickly and can be incorporated into a wide variety of dishes, offer an ideal solution.

Their versatility in different cuisines—ranging from traditional Asian stir-fries and soups to modern, creative dishes in Western cuisine—also plays a key role in expansion. Rice noodles can be prepared with a variety of flavors and ingredients, making them suitable for a diverse range of consumers.

Segmentation

The rice noodles can be segmented based on type, distribution channel, and region. Each of these segments is poised for significant growth during the forecast period.

By Type:

Chinese Style: This segment dominates the , with Chinese-style rice noodles being the most commonly used globally. These noodles are available in various shapes and textures, including thin vermicelli, flat rice noodles, and thick noodles, making them popular in a wide range of dishes.

Western Style: Western-style rice noodles are gaining popularity in North America and Europe. Often used in fusion cuisine, these noodles are being adopted in non-traditional dishes, where chefs and home cooks experiment with incorporating them into Western-style stir-fries, salads, and casseroles.

Others: This segment includes specialty rice noodles, such as those flavored or mixed with ingredients like spinach, turmeric, or seaweed, to offer unique tastes and added nutritional benefits.

By Distribution Channel:

Supers and Hypers: As the most prominent distribution channel, supers and hypers hold the largest share of rice noodle sales globally. These large retail stores provide consumers with a variety of options and price points.

Convenience Stores: With their growing presence, convenience stores have become an essential distribution channel for rice noodles, especially for consumers seeking quick and easy meal solutions.

Independent Retailers: This segment, which includes smaller grocery stores and ethnic food s, is crucial in distributing rice noodles, particularly in regions with a high concentration of Asian communities.

Online Stores: E-commerce is growing rapidly as a distribution channel for rice noodles. With the increasing penetration of the internet and the rise of online grocery platforms, consumers are opting for the convenience of purchasing rice noodles from the comfort of their homes. This channel is expected to witness the fastest growth during the forecast period.

Regional Outlook

The global rice noodles is segmented into key regions including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Asia-Pacific: Dominating the , the Asia-Pacific region, led by China, Thailand, and Vietnam, accounts for the largest share of rice noodle consumption. This region’s deep-rooted culture of rice-based diets and the prevalence of rice noodles as a staple food continue to drive growth. The increasing population and urbanization in countries like India and Indonesia are also contributing to the rising demand.

North America: The North American is projected to experience rapid growth during the forecast period. The growing demand for gluten-free and healthy food options is a significant factor contributing to this growth. Additionally, the increasing influence of Asian cuisines in the region, along with the rising adoption of rice noodles in fusion dishes, is further driving expansion.

Europe: Europe is also witnessing increased demand for rice noodles, fueled by the growing trend of health-conscious and dietary-specific food consumption. The region’s focus on organic and natural food products aligns well with the consumption of rice noodles, particularly in countries like the UK, Germany, and France.

Latin America and Middle East & Africa: These regions are emerging s for rice noodles, with growing urbanization and an increasing awareness of global cuisines driving demand. The adoption of rice noodles in these regions is anticipated to rise steadily as international cuisines become more accessible.

Conclusion

The rice noodles is set for robust growth in the coming years, driven by the increasing demand for healthier, convenient, and versatile food products. As consumers around the world embrace gluten-free and plant-based diets, the for rice noodles is expected to expand significantly. Manufacturers and retailers are capitalizing on this trend by offering innovative product variants and expanding their distribution channels to meet the evolving needs of modern consumers.

With a projected CAGR of 14.63% from 2023 to 2030, the rice noodles is poised for a bright future, providing ample opportunities for growth and innovation in the global food industry.

Read More Details @ https://www.snsinsider.com/reports/rice-noodles-market-1921

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

SNS Insider Offering/ Consulting Services:

Go To Market Assessment Service

Total Addressable Market (TAM) Assessment

Competitive Benchmarking and Market Share Gain

1 note

·

View note

Text

Instant Noodles Manufacturing Plant Project Report 2024: Industry trends and Plant Setup

Introduction

Instant noodles have become a staple food in many households around the world due to their convenience, affordability, and variety. The global market for instant noodles continues to grow, driven by busy lifestyles and an increasing demand for quick meal solutions. Setting up a manufacturing plant for instant noodles presents a lucrative business opportunity. This article provides a comprehensive overview of a Instant Noodles Manufacturing Plant Project Report for establishing an Instant Noodles Manufacturing Plant, covering feasibility, technology, financial considerations, and operational aspects.

Project Overview

Objectives

The primary goal of setting up an Instant Noodles Manufacturing Plant is to produce high-quality noodles efficiently and meet the rising market demand. Key objectives include:

Meeting Market Demand: Addressing the increasing consumption of instant noodles due to their convenience and diverse flavor options.

Economic Contribution: Stimulating local economic development by creating jobs and supporting the supply chain.

Quality and Compliance: Ensuring that the manufacturing processes adhere to food safety regulations and quality standards.

Scope

The project encompasses several critical phases from initial planning to full-scale production. Essential components include:

Site Selection: Identifying a location with access to raw materials, utilities, transportation, and a skilled workforce.

Design and Engineering: Developing detailed plans for plant layout, production processes, and equipment.

Construction: Building the facility, installing machinery, and setting up production lines.

Operations: Managing daily production, quality control, and distribution of instant noodles.

Compliance: Adhering to food safety regulations and industry standards.

Get a Free Sample Report with Table of Contents @

https://www.expertmarketresearch.com/prefeasibility-reports/instant-noodles-manufacturing-plant-project-report/requestsample

Technical and Operational Aspects

Technology

The production of instant noodles involves several key steps:

Ingredient Preparation: Sourcing and preparing raw materials such as wheat flour, water, salt, and various seasonings. Ingredients must be of high quality to ensure the final product’s taste and texture.

Dough Mixing: Mixing the wheat flour with water and other ingredients to create a dough. This step requires precise control to achieve the desired consistency and quality of the noodles.

Sheeting and Cutting: The dough is rolled into thin sheets and then cut into noodle strands. The sheeted dough is also steamed to partially cook the noodles.

Frying or Air-Drying: The noodles are then either fried in oil or air-dried to remove moisture. Fried noodles have a crispy texture, while air-dried noodles are less greasy.

Seasoning and Packaging: The noodles are seasoned with various flavorings and packaged in convenient containers or packets. Packaging must be done in a sterile environment to maintain product freshness and safety.

Equipment

Key equipment used in an instant noodle manufacturing plant includes:

Mixing Machines: For combining flour, water, and other ingredients.

Sheeting Machines: For rolling dough into thin sheets.

Cutting Machines: For slicing the dough into noodle strands.

Frying or Drying Equipment: For cooking the noodles, either through frying or air-drying methods.

Seasoning Units: For adding flavorings and seasonings to the noodles.

Packaging Machines: For filling and sealing the noodle packets.

Workforce

A skilled workforce is essential for efficient plant operations. Key roles include:

Production Engineers: To design and optimize manufacturing processes.

Food Technologists: For developing and testing recipes and ensuring product quality.

Machine Operators: To operate and maintain production and packaging equipment.

Quality Control Inspectors: To perform tests and ensure the noodles meet safety and quality standards.

Administrative Staff: For managing plant operations, finance, and human resources.

Financial Considerations

Investment

The financial investment required for an Instant Noodles Manufacturing Plant includes:

Capital Expenditure: Costs associated with site acquisition, construction, machinery, and installation.

Operational Expenses: Ongoing costs for raw materials, utilities, labor, maintenance, and quality control.

Funding Sources

Potential funding sources for the project include:

Equity Investment: From private investors or venture capital firms.

Loans: From banks or financial institutions.

Grants and Subsidies: Potentially available for food manufacturing projects.

Revenue Generation

Revenue is generated from the sale of instant noodles to retailers, wholesalers, and distributors. Pricing is influenced by production costs, market demand, and competition. The plant can also explore various product lines and packaging options to maximize revenue.

Environmental and Safety Considerations

Environmental Impact

The plant must adhere to environmental regulations to minimize its impact. Key measures include:

Waste Management: Proper disposal or recycling of production waste and packaging materials.

Energy Efficiency: Implementing energy-efficient technologies to reduce consumption and lower costs.

Water Management: Managing and recycling water used in the production process.

Safety Measures

Ensuring a safe working environment involves:

Food Safety Standards: Adhering to food safety regulations to ensure the noodles are safe for consumption.

Safety Training: Providing regular training for employees on handling equipment, working safely, and responding to emergencies.

Protective Equipment: Supplying personal protective equipment (PPE) such as gloves, masks, and safety glasses.

Emergency Protocols: Establishing clear procedures for responding to accidents, spills, or equipment failures.

FAQs

What are instant noodles made of?

Instant noodles are primarily made from wheat flour, water, salt, and seasonings. The dough is processed into noodle strands, which are then either fried or air-dried and packaged with flavoring.

How long does it take to build an instant noodle manufacturing plant?

Building and commissioning an instant noodle manufacturing plant typically takes between 18 to 36 months, depending on the project's complexity and regulatory requirements.

What factors are important in choosing a plant location?

Key factors include proximity to raw material suppliers, access to transportation and utilities, compliance with environmental regulations, and availability of a skilled workforce.

How can the plant ensure product quality and safety?

Ensuring product quality involves adhering to food safety standards, implementing rigorous quality control measures, and conducting regular testing of raw materials and finished products. Compliance with regulatory requirements is achieved through adherence to industry guidelines and obtaining necessary approvals.

What are the major risks associated with this project?

Major risks include fluctuations in raw material prices, regulatory changes, production challenges, and market competition. Proper planning, risk management strategies, and financial controls are essential to mitigate these risks.

Related Reports

https://www.expertmarketresearch.com/reports/packaged-food-market

https://www.expertmarketresearch.com/reports/north-america-customer-journey-analytics-market

https://www.expertmarketresearch.com/reports/flexible-plastic-packaging-market

Media Contact:

Company Name: Claight Corporation Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A. Email: [email protected] Toll Free Number: +1–415–325–5166 | +44–702–402–5790 Address: 30 North Gould Street, Sheridan, WY 82801, USA Website: www.expertmarketresearch.com Aus Site: https://www.expertmarketresearch.com.au

0 notes

Text

Best Corn starch manufacturers in India - Bluecraft Agro

Corn starch manufacturers in India - Bluecraft Agro

Corn starch is a fine white powdery substance that is derived from corn kernels. It is used in various cooking and food preparation forms, primarily as a thickening agent for sauces, soups, stews, and gravies.

The process of extracting corn starch from corn involves milling the corn kernels to remove the germ and bran, then soaking the remaining endosperm in water to release the starch. The resulting liquid is then filtered and dried to form a powder.

Corn starch is used in small quantities in cooking to thicken sauces, soups, and gravies. It is a popular alternative to flour, as it results in a clearer, smoother sauce compared to flour, which can leave lumps in the mixture. Corn starch is also used to make light, flaky pie crusts, dust the dough’s surface when rolling out pasta or pie crust, and sweet treats such as pudding, custard, and jellies.

One of the key benefits of corn starch is its ability to withstand high heat and acidic conditions, making it ideal for use in many recipes. It also has a neutral flavor and does not alter the dish’s taste. corn starch is a versatile ingredient that plays a crucial role in many culinary applications. From thickening sauces to making light, flaky crusts, cornstarch is a staple in kitchens worldwide.

What is corn starch made of?

Corn starch is made from the endosperm of the corn kernel, which is a starchy component that makes up the largest part of the kernel. Making corn starch involves removing the germ and bran from the corn kernels and milling the endosperm into a fine powder.

The endosperm is then soaked in water to release the starch, which is filtered and dried to form a powder. The resulting corn starch is a pure white powder that is odorless and has a neutral flavor.

Corn starch is made of long chains of glucose, which are complex carbohydrates. These chains give corn starch its thickening properties, making it a popular ingredient in cooking and baking. It adds thickness and texture to sauces, soups, stews, gravies, and many other dishes.

In conclusion, corn starch is made of the starchy endosperm of corn kernels and is a versatile ingredient that is widely used in cooking and baking. Its thickening properties make it an essential ingredient in many recipes, adding texture and structure to sauces, soups, and other dishes.

What is the difference between starch and cornstarch?

Starch and cornstarch are similar in many ways, but they have some key differences. Starch is a carbohydrate found in many plants, including corn, potatoes, wheat, and rice. It is used as a thickener and binding agent in cooking and baking.

On the other hand, cornstarch is a specific type of starch derived exclusively from corn kernels. It is a fine, white powder that is used in cooking and baking as a thickening agent for sauces, soups, stews, and gravies.

One of the main differences between starch and cornstarch is their source. Starch is found in many plants, whereas cornstarch is derived only from corn. This means that the properties of cornstarch can vary from other types of starch, such as potato or wheat starch.

Another difference between the two is their thickening power. Cornstarch is a stronger thickener compared to other starches, making it a popular choice in cooking and baking. It is also less likely to leave lumps in the mixture compared to other starches, such as flour.

In conclusion, starch and cornstarch are both carbohydrates used as thickeners in cooking and baking. While they are similar in many ways, their source and thickening power is the main difference between them. Cornstarch is derived only from corn and is a stronger thickener compared to other starches.

#bluecraftagro#starchmanufacturer#manufacturer#maize starch#corn starch#bluecraft#ingredientsforahappylife#specialty starch brands#corn starch manufacturers in gujarat#maize starch supplier

0 notes

Text

Plant-based edible fork for Maggi cup noodles in India

Nestlé has introduced a limited-edition plant-based fork for Maggi cup noodles in India. Nestlé food science and packaging experts at our R&D center in India collaborated with a local startup to develop a two-piece edible fork made from wheat flour and salt. The two ingredients, coupled with a proprietary fork design and manufacturing process, ensure the desired functionality while maintaining the nutritional values and taste of the noodles.

Redesigning accessories like straws, cups, or cutlery is an integral part of Nestlé's commitment to eliminate or reduce the use of plastics in packaging. This comes in addition to simplifying packaging materials, scaling reusable and refillable systems wherever possible, and exploring alternative packaging materials for different product categories.

Gerhard Niederreiter, head of Nestlé's Institute of Packaging Sciences, says: "At Nestlé, we continuously explore different types of alternative sustainable packaging solutions that ensure food safety, consumer experience, and product taste and quality. In this case, our packaging experts developed a unique alternative fork that built on our scientific expertise across different kinds of food-grade packaging materials and shapes."

Antonia Wanner, group head of ESG Strategy and Deployment, explains: "Reducing packaging and designing packaging for recycling are both key pillars to Nestlé's sustainability commitments. Our teams are constantly exploring novel materials and cutting-edge technologies for packaging solutions that are convenient, protect the food inside, and are good for the planet."

In addition, Nestlé packaging experts in R&D Nutrition and China are piloting a patented paper scoop for adult milk powders in China. Thanks to the flat foldable scoop alongside a metal cap, the use of plastic could be completely avoided in this packaging design.

By 2021, Nestlé had already replaced 4.5 billion plastic straws globally with paper straws. Since then, Nestlé R&D teams are continuing to drive innovation with recyclable straws to identify alternative solutions or improve the functionalities of existing paper straws. The Nestlé Institute of Packaging Sciences has also focused significant efforts in developing new paper cups. This includes researching non-plastic coatings for paper cups that can resist hot beverages.

These are just a few recent examples to underline Nestlé's commitment to find innovative solutions to reduce the use of virgin plastics by using less plastic, recycled plastic, and alternatives to plastic packaging.

0 notes

Text

Explore the revolutionary impact of technology on wheat flour plant manufacturing. Discover how advancements are reshaping processes and efficiency for the future.

0 notes

Text

Innovative Designs in Biodegradable Tableware: Balancing Functionality and Sustainability

Introduction

In today's environmentally conscious world, the demand for sustainable alternatives to conventional tableware is on the rise. Biodegradable tableware has emerged as a frontrunner in this space, offering innovative designs that not only prioritize functionality but also contribute to environmental sustainability. Let's delve into the world of biodegradable tableware and explore how innovative designs are reshaping dining experiences while promoting eco-friendliness.

Versatility in Design

Biodegradable tableware comes in a wide range of designs, catering to various dining needs and occasions. From elegant dinnerware sets for formal gatherings to casual picnic sets for outdoor adventures, manufacturers have embraced versatility in design to meet the diverse preferences of consumers. Innovative shapes, textures, and colors add aesthetic appeal to biodegradable tableware, elevating the dining experience while minimizing environmental impact.

Functional Yet Sustainable

One of the key challenges in designing biodegradable tableware is balancing functionality with sustainability. Manufacturers are continuously innovating to create products that are not only durable and practical but also eco-friendly. Advanced materials engineering techniques allow for the development of biodegradable tableware that withstands heat, moisture, and heavy usage, ensuring a seamless dining experience without compromising on sustainability.

Creative Solutions for Eco-Friendly Dining

Innovation in biodegradable tableware extends beyond traditional utensils and plates. Creative solutions such as edible cutlery made from wheat or rice flour, compostable straws crafted from bamboo or paper, and plant-based disposable containers offer novel alternatives to single-use plastics. These innovative designs not only minimize waste but also provide unique dining experiences that resonate with environmentally conscious consumers.

Conclusion

As the world shifts towards sustainable living practices, innovative designs in biodegradable tableware are paving the way for a greener future. By combining functionality with sustainability, manufacturers are revolutionizing the dining experience and empowering consumers to make eco-friendly choices without compromising on style or convenience. With continued innovation and creativity, biodegradable tableware is poised to play a significant role in shaping the future of dining, one innovative design at a time.

0 notes

Text

Potato Starch market Report | Global Forecast From 2023 To 2030 With Top Key Players

The Global Potato Starch market size was reasonably estimated to be approximately USD 8200 Million in 2023 and is poised to generate revenue over USD 12530 Million by the end of 2030, projecting a CAGR of around 6.20% from 2023 to 2030.

In order to extract the starch grains, potatoes are crushed to release them. The starch grains are then extracted from the solution and dried until they have a light, powdery consistency. Because of its flour-like consistency, it is a common ingredient in many recipes. Leucoplast-containing potato root tuber cells are where the starch is taken from the plant. It's a multipurpose ingredient that works well in baking, cooking, and food processing.

Because potato starch is a versatile ingredient that may thicken and enhance the texture of a wide range of meals, including puddings, baked goods, and sauces, the market for it is growing.As a supplement, it may also help with digestion, boost immunity, and control blood sugar, among other possible health advantages.

Because of its enticing texture, flavor, and possible health benefits, starch has become an essential ingredient in many innovative products developed by the food and beverage industry. The rising demand for organic food is driving growth in the worldwide starch market.

In the paper industry, potato starch is widely employed, mostly as an adhesive, surface sizer, and bonding agent in a variety of products such coatings, laminated grades, and corrugated boards. Starch is a necessary component of numerous paper grades since it is consumed by weight in the processes of papermaking and paper conversion after cellulose fiber and mineral pigments.

The market for potato starch is expected to grow due to a number of factors, including the growing popularity of processed and convenience foods, the growing demand for potato starch in the paper industry, the rising prevalence of food allergies, including celiac disease, and the growing demand for functional foods.

Get Sample Report: -

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Leading players involved in the Potato Starch Market include:

"Cargill, Incorporated (U.S), Pepees S.A(Poland), Ingredion, Incorporated (U.S), KMC a.m.b.a (U.S), AGRANA Beteiligungs -AG (Austria), Tereos (France), Avebe (Netherlands), Emsland Group (Germany), Novidon, Roquette (France), Tata & Lyle (UK), VIMAL PPCE (Ukraine), Lyckeby (Sweden), Radchen USA (US), AKV Langholf (Denmark), and Other Key Players".

Market Driver:

One significant market driver for potato starch is its rising popularity as a gluten-free alternative in the food industry. With the increasing prevalence of gluten-related disorders and the growing health consciousness among consumers, there's a heightened demand for gluten-free products. Potato starch serves as an excellent substitute for wheat-based thickeners and binders in gluten-free formulations, making it a preferred choice for manufacturers aiming to cater to this expanding consumer segment. As a result, the demand for potato starch is expected to continue its upward trajectory, driven by the gluten-free trend.

Market Opportunity:

An emerging market opportunity lies in the utilization of potato starch in biodegradable packaging materials. With the growing environmental concerns and the push towards sustainable packaging solutions, there's a rising demand for biodegradable and compostable packaging materials. Potato starch-based bioplastics offer a promising alternative to conventional petroleum-based plastics, providing similar functionality while being eco-friendly and renewable. The development of innovative packaging solutions using potato starch presents a significant opportunity for market players to tap into the burgeoning sustainable packaging market.

If You Have Any Query Potato Starch Market Report, Visit:

Segmentation of Potato Starch Market:

By Type

Native

Modified

By Nature

Conventional

Organic

By Application

Food & Beverage

Textile & Paper Industry

Pharmaceutical Industry

Animal Feed

By Function

Thickener

Binder

Stabilizer

Disintegrant

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Effective Points Covered in Potato Starch Market Report: -

Details Competitor analysis with accurate, up-to-date demand-side dynamics information.

Standard performance against major competitors.

Identify the growth segment of your investment.

Understanding most recent innovative development and supply chain pattern.

Establish regional / national strategy based on statistics.

Develop strategies based on future development possibilities.

Purchase This Reports: -

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopaedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96367

Email: [email protected]

#Potato Starch#Potato Starch Market#Potato Starch Market Size#Potato Starch Market Share#Potato Starch Market Growth#Potato Starch Market Trend#Potato Starch Market segment#Potato Starch Market Opportunity#Potato Starch Market Analysis 2022#US Potato Starch Market#Potato Starch Market Forecast#Potato Starch Industry#Potato Starch Industry Size#china Potato Starch Market#UK Potato Starch Market

0 notes

Text

Exporter of Multi Layer Blown Film Machine in Palestine

Adroit Extrusion is a Manufacturer, Supplier, and Exporter of Multi-Layer Blown Film Machine in Palestine, and our setup is situated in Ahmedabad, Gujarat, India. Our Products: Monolayer Blown Film ABA and AB Blown Film MultiLayer Blown Film Adroit Extrusion Offers Various Multilayer Blown Films like 7/5 Layer Barrier, 5 Layer POD, 3 Layer Blown Film Plant. Multi-layer blown film technology revolutionizes packaging solutions by offering enhanced strength, flexibility, and barrier properties. With multiple layers of polymers fused seamlessly, these films provide optimal protection against moisture, oxygen, and UV radiation. Ideal for food packaging, medical applications, and industrial purposes, multi-layer blown films ensure product freshness and integrity. Our advanced manufacturing process guarantees consistent quality and customizable options to meet specific packaging needs. Experience the innovation and reliability of multi-layer blown film technology for your packaging requirements. Features: Auto profile film thickness control Gravimetric dosing system Bubble Scanner ExtruTouch Control System - UL-CSA Approved Application: Liquid Packaging: Water, Milk, Oil, Ghee, Liquor Food Packaging: Wheat flour, Rice, Sugar, Salt, Cereals Lamination Film: Biscuits, Chips, Chocolates, Confectionary, snacks, spices, etc. Shrink Film & stretch Wraps Hygiene and medical Packaging Industrial Packaging: Lubrication oil pouch, Grease, Chemical packaging, etc. Adroit Extrusion is Exporter of Multi Layer Blown Film Machine in Palestine including Various locations like Jerusalem, Gaza, Hebron, Bani Suheila, Jerusalem, Tulkarm, Jenin, Yata, Khan Yunis, Nablus, Deir al Balah, Beit Hanoun, Al Qarara, Az Zawayda. For additional information, please feel free to contact us. Read the full article

0 notes

Text

How Bread Manufacturers Ensure Quality from Field to Table

The concept of quality in flour production has a lot to do with the plurality of processes under different circumstances through the entire production chain from the field to the consumer. Everybody in the world consumes bread, which might seem the most uncomplicated food in the Universe.

Bread nevertheless has an intricate way it is made before the average person sits down to eat it. Bread makers are at the forefront of the lengthy process of bread, applying conventional approaches and standards to achieve quality and freshness. This content is dedicated to the investigation of bread quality-compliant measures specially used by bread manufacturers in Uttar Pradesh, India.

Understanding the Bread Manufacturing Process

Although the first phase of bread production occurs from the moment the wheat grain is born to the arrival of flour, manufacturing begins much earlier than when the flour meets the factory floor. It begins on the fields where green discs count the harvest from which most of the straightforward bread recipes are made.

The millers in Uttar Pradesh, a predominantly agricultural area, maintain a close working relationship with farmers who provide them with excellent quality wheat crops used for bread-making. Building solid partnerships with farmers in sourcing wheat through the use of sustainable farming methods is what ensures these manufacturers secure quality wheat which provides the basis of their great bread products.

Next, the wheat is subjected to intense examinations to ensure that its quality is on par with superior bread-making standards. This assessment deals with parameters that measure Nitrogen (protein) content, viscosity (gluten), and water absorption (moisture).

Local Bread Manufacturing in Uttar Pradesh allocates resources for upgrading their testing facilities if need be, to execute these tests accurately and on time without any delays. Eventually, only the top-quality grains are permitted to be thrown into the production process.

Quality Control in Production

The next step is to run this raw material through the quality controller where they are inspected and the material that meets the standards takes the path to the production facility where a set of precise processes are executed, ultimately transforming them into the best loaves of bread.

Each step from mixing and kneading, to proofing and baking, is closely followed as it contributes to consistency and quality. The bread manufacturers in Uttar Pradesh embrace the usage of the latest technology and zealously implement strict quality control guidelines to assuredly check that each batch surpasses most of the high-quality standards.

Not only does the company work on the manufacturing process but it also emphasizes hygiene and sanitation in its workshop. Routinely carry out inspections, see to it that food-handling practices are standardized and enforced, and follow food safety regulations form part of their usual operations.

These manufacturers maintain high hygienic standards in their plants which help to eliminate the risk of contamination and at the same time ensure their products are safe for consumption.

Packaging and Distribution

The last stage is the packaging which is as critical as the baking that takes us from the field to the table. The packaging materials employed by the bread manufacturers in Uttar Pradesh are a combination of preservation and extension of shelf time as well as promoting environmental sustainability.

Whether it's plastic-free packaging or creative solutions made for reducing food waste companies play a big role in the area of sustainability and consumer desire.

FAQs on Bread Manufacturers

1. What measures do bread producers implement so that their products stay fresh when being transported?

- Bakers make use of specific shipment procedures like refrigerated trucks so that their products stay fresh while in transit. Moreover, they keep their logistics system tight to reduce delivery time and thus ensure fast shipments to wholesale distributors.

2. Are bakery manufacturers in Uttar Pradesh under the banner of ecology-friendly manufacturing?

- Yes, most of the bread makers in Uttar Pradesh are particular about the sustainability of their manufacturing procedure. They focus on the local supply of healthy ingredients and they try to use eco-friendly packaging solutions. The business's goal is to reduce the damage it causes to the environment and create a better world.

3. Is it the bread industry that consistently monitors and controls the quality of its products?

- Absolutely. Quality checks are a crucial activity in bread manufacturing. Bread makers conduct a battery of tests and reviews before the final product is ready for the market to adhere to the industry’s quality and regulatory requirements.

Gomti Foods A Leading Example

Among the vast variety of bread manufacturers in Uttar Pradesh that we have, let’s take the example of Gomti Food being one of the notable companies. Throughout the years, the Gomti food industry has obligated its standing in the field of quality finished goods and innovation.

What Gomti Foods does by providing top-class customer satisfaction and embracing modern technology acts as a milestone in modern bread manufacturing. To get the familiar foods that we remember with quality also a part of its philosophy, Gomti Foods began from the onset focusing on bringing humble foods to the next level thus the initiation of artisanal creations.

0 notes

Text

Bread and Roll Market: The Struggles and Solutions for Today's Bakers

The bread and roll market is a vital component of the global food industry, but it faces a range of challenges that impact producers, retailers, and consumers alike. These challenges can affect everything from production processes to consumer preferences, making it essential for stakeholders to navigate a complex landscape to ensure success and sustainability. Understanding these challenges provides insight into the current state of the market and highlights areas that require attention and innovation.

One significant challenge facing the bread and roll market is the rising cost of raw materials. Fluctuations in the prices of essential ingredients like wheat, flour, and yeast can strain production budgets and impact profit margins. These fluctuations can arise from various factors, including climate change, supply chain disruptions, and geopolitical events. As producers strive to maintain quality while managing costs, they may be forced to raise prices, which can lead to decreased consumer demand, particularly in price-sensitive segments of the market.

Another pressing issue is the competition from alternative products. As consumers become more health-conscious and adventurous in their eating habits, they are increasingly drawn to alternatives such as gluten-free, low-carb, and plant-based options. This shift can pose a threat to traditional bread and rolls, compelling producers to innovate and adapt their offerings. The challenge lies not only in creating new products that meet changing preferences but also in effectively marketing these alternatives to attract and retain customers.

Additionally, the bread and roll market faces the challenge of changing consumer behaviors influenced by convenience and lifestyle choices. With the rise of fast-paced living, many consumers seek quick and easy meal solutions. This has led to increased demand for pre-packaged and ready-to-eat products. While this trend presents opportunities for growth, it also forces traditional bakeries to compete with large-scale manufacturers who can provide convenience at lower prices. Small and artisanal producers may struggle to keep pace, highlighting the need for differentiation and unique value propositions to stand out in a crowded market.

Health and wellness concerns also pose challenges to the bread and roll market. As more consumers prioritize healthy eating, they are scrutinizing ingredient lists and seeking products that align with their dietary goals. This trend has led to an increase in demand for whole grain, organic, and minimally processed bread. Producers must invest in research and development to create products that not only meet health standards but also satisfy taste preferences. Failure to address these evolving consumer expectations could result in a loss of market share to competitors who are more responsive to health trends.