#What Are Flexible Pipe Joints?

Explore tagged Tumblr posts

Text

Durable Flexible Pipe Joints Available Now

When it comes to maintaining the integrity of your piping systems, durable flexible pipe joints are essential. At Udhhyog, we provide a wide selection of high-quality flexible pipe joints designed to meet the needs of various industrial applications.

What Are Flexible Pipe Joints?

Flexible pipe joints are specialized connectors that allow for movement and flexibility in piping systems. They help accommodate thermal expansion, reduce stress, and absorb vibrations, making them crucial for efficient operations.

Why Choose Udhhyog for Durable Flexible Pipe Joints?

High-Quality Materials: Our flexible pipe joints are manufactured using robust materials that ensure long-lasting performance even in demanding conditions.

Versatile Applications: These joints are perfect for use in a variety of settings, including plumbing, HVAC systems, and industrial processes.

Expert Assistance: Our knowledgeable team is ready to assist you in selecting the right flexible pipe joints tailored to your specific needs.

Competitive Pricing: At Udhhyog, we offer durable flexible pipe joints at prices that fit your budget without compromising on quality.

Features of Our Flexible Pipe Joints

Excellent Flexibility: Designed to handle movement and thermal expansion, our pipe joints help prevent stress on pipelines.

Vibration Dampening: These joints effectively reduce vibrations, contributing to smoother operation of your systems.

Simple Installation: Engineered for ease of installation, our flexible pipe joints help minimize downtime during setup.

How to Order Durable Flexible Pipe Joints from Udhhyog

Browse Our Selection: Visit our Pipe Fittings category to explore a wide range of flexible pipe joints.

Select Your Preferred Product: Choose the durable flexible pipe joints that best fit your project requirements.

Order Online: Enjoy the convenience of our straightforward online ordering process for fast shipping and delivery.

Ensure your piping systems are equipped with the best flexible pipe joints available. Trust Udhhyog for quality products that enhance the performance and longevity of your operations.

#Durable Flexible Pipe Joints Available Now#Meta Search Description:#Explore durable flexible pipe joints at Udhhyog for reliable connections in your systems. Shop now for the best quality!#When it comes to maintaining the integrity of your piping systems#durable flexible pipe joints are essential. At Udhhyog#we provide a wide selection of high-quality flexible pipe joints designed to meet the needs of various industrial applications.#What Are Flexible Pipe Joints?#Flexible pipe joints are specialized connectors that allow for movement and flexibility in piping systems. They help accommodate thermal ex#reduce stress#and absorb vibrations#making them crucial for efficient operations.#Why Choose Udhhyog for Durable Flexible Pipe Joints?#High-Quality Materials: Our flexible pipe joints are manufactured using robust materials that ensure long-lasting performance even in deman#Versatile Applications: These joints are perfect for use in a variety of settings#including plumbing#HVAC systems#and industrial processes.#Expert Assistance: Our knowledgeable team is ready to assist you in selecting the right flexible pipe joints tailored to your specific need#Competitive Pricing: At Udhhyog#we offer durable flexible pipe joints at prices that fit your budget without compromising on quality.#Features of Our Flexible Pipe Joints#Excellent Flexibility: Designed to handle movement and thermal expansion#our pipe joints help prevent stress on pipelines.#Vibration Dampening: These joints effectively reduce vibrations#contributing to smoother operation of your systems.#FlexiblePipeJoints#DurableSolutions#Udhhyog#PipingSystems#IndustrialApplications

1 note

·

View note

Text

Buy MS Seamless Pipe from Leading Manufacturers in Delhi

When it comes to purchasing MS seamless pipes in Delhi, finding a reliable and trusted supplier is essential for ensuring quality and performance. Mild Steel (MS) seamless pipes are widely used in various industries, such as construction, oil and gas, plumbing, and manufacturing, due to their strength, durability, and resistance to corrosion.

In this article, we’ll explore why MS seamless pipes are important, their applications, and how you can find the best suppliers in Delhi.

What Are MS Seamless Pipes?

MS seamless pipes are made from mild steel, a low-carbon steel known for its flexibility and weldability. These pipes are manufactured without any seams or joints, providing a smoother finish and superior strength compared to welded pipes. The seamless construction ensures that the pipe can withstand high pressure and temperature without weakening, making it ideal for demanding applications.

Applications of MS Seamless Pipes

MS seamless pipes have a variety of uses across multiple industries, such as:

Construction: Used for building frames, scaffolding, and structural support due to their high tensile strength.

Oil & Gas Industry: Perfect for transporting fluids and gases under high pressure, ensuring safety and efficiency.

Water Supply: MS seamless pipes are used in water distribution systems as they prevent leakage and can handle large volumes of water.

Automotive: Employed in making parts for vehicles due to their strength and lightweight properties.

The versatility of MS seamless pipes makes them essential in industries where strength and reliability are paramount.

Why Buy MS Seamless Pipes from Leading Manufacturers?

Purchasing MS seamless pipes from leading manufacturers offers several advantages:

Guaranteed Quality: Leading manufacturers ensure that the pipes meet international standards, providing high durability and strength.

Wide Range of Sizes: Established suppliers offer a variety of sizes and specifications to cater to different industrial needs.

Competitive Pricing: Leading suppliers often provide the most competitive prices due to their ability to source materials and manufacture in bulk.

After-Sales Support: Trusted manufacturers provide excellent customer service, helping you with installation, maintenance, and any other post-purchase concerns.

Where to Buy MS Seamless Pipes in Delhi?

If you’re looking for the best MS seamless pipe supplier in Delhi, Udhhyog is a top choice. Udhhyog is known for its wide selection of MS seamless pipes at the lowest prices in India. They cater to both large industrial needs and small business requirements, ensuring that every customer finds the right solution.

Why Choose Udhhyog?

High-Quality Products: Udhhyog ensures that their pipes meet stringent quality standards, making them durable and efficient for various uses.

Competitive Pricing: By leveraging their strong supply chain, Udhhyog offers MS seamless pipes at highly competitive rates, helping businesses cut costs without compromising on quality.

Wide Availability: As one of the leading suppliers in Delhi, Udhhyog ensures that you can easily get the sizes and specifications you need for your project.

Reliable Service: Udhhyog prides itself on excellent customer service, offering prompt delivery and responsive after-sales support.

How to Order from Udhhyog?

Ordering MS seamless pipes from Udhhyog is straightforward. You can visit their website to explore their product range, check specifications, and place an order. You can also contact their sales team for any specific inquiries or bulk orders. Udhhyog offers flexible payment options and ensures timely delivery across India, making procurement easier for businesses

#MSSeamlessPipes#MSPipes#SeamlessPipes#PipeFittings#IndustrialPipes#SteelPipes#DelhiSuppliers#DelhiManufacturers#DelhiBusiness#ConstructionMaterials#OilAndGas#WaterSupplyPipes#AutomotiveParts#BuyMSSeamlessPipes#SteelAtLowestPrices#Udhhyog#MSSeamlessPipeSupplier#MSSteelPipesIndia#PipeSuppliersIndia#SteelManufacturersDelhi

5 notes

·

View notes

Note

"Hey Shinsō..." Sero's hand raises and gestures in a casual wave as he crosses the training field with a grin. The easy-going hero in training glances up and down, taking in the gym uniform and gestures over his shoulder towards the towering, busy Ground Gamma, head tipping with a sway of raven locks.

"Thinking of heading over there... if you wanted to join." The daunting urban landscape poses the best challenge for his agility and movement training, the heavy piping and large buildings offering plenty of obstacles but also purchase for his tape to connect to. It is his staple to his training routine, one that keeps his speed competitive with even the likes of the superstars of Class 1A. "Could teach you a couple of my tricks if you want to start swinging around with that scarf of yours..."

Shinsō would be honest if he said he feels weird being in 2-A, there's something so...otherworldly about this class. That being said, he's an awkward fuck besides all his snarky deliveries to the people he's close to and the members of 2-A are friendly enough that it's persistent and he can't just shake them off even if he wanted to. But they are people he would trust to have his back, regardless.

Eyeing Sero for a moment, he returns the wave with a nod, hand rising to scratch at the back of his head. ❝ ━ Hey Sero, that's....❞ Brows furrowed as he contemplates the offer, feeling his tension ease out of his shoulders. ❝ ━ Yeah actually, I think that'd be neat, thank you. ❞ Training with Aizawa-sensei helped with using the capture weapon to tie someone up, to latch unto things but with Sero's tape, maybe the applications were similar enough that he'd gain a better enlightment of how to shift his weight around while using it in the air.

Walking alongside his classmate, a cheshire grin curls across his features, ❝ ━ How many times did you fall trying to distribute your weight the first time trying to swing around ? ❞ Even he can't count the many times he had managed to wrap himself in the capture weapon or nearly yanked a joint out of place while trying to swing around. It was an unfathomable number and many times, he'd been self-deprecating that his Uncle had outright scolded him for giving up. But here he was now, all the more stronger and flexible for it. It's nice to have a classmate whose willing to teach him though. ❝ ━ Heh, sure you wanna show me your tricks ? What if I manage to show you up ? ❞ Not that he plans on that, Sero definitely has more stamina then he does, for sure, but banter between classmates is normal, right ?

pls forgive him. he's new at this ppl things. | @resolutepath

#( psyren ic. ) just a snarky & awkward teen.#resolutepath#shinso in year 1: im not looking for friends. shinso now:....i guess i need to make friends maybe#👑ˑ » ( answered. ) ᶜʰᵒᵒˢᶤᶰᵍ ᵇᵉᵗʷᵉᵉᶰ ᵈᵉˢᵗʳᵘᶜᵗᶤᵒᶰ ᵃᶰᵈ ᵖᵉᵃᶜᵉˑ

6 notes

·

View notes

Text

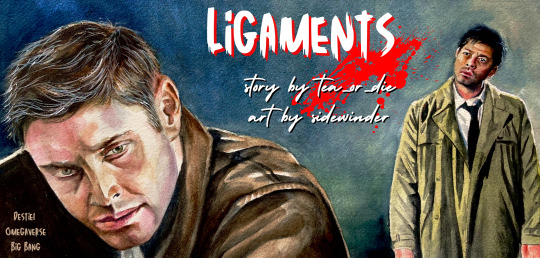

Ligaments

Posting 25th September 2023!

Fic by tea_or_die Art by sidewinder

Rating: Explicit

Summary: lig·a·ment noun ANATOMY a short band of tough, flexible fibrous connective tissue which connects two bones or cartilages or holds together a joint. a membranous fold that supports an organ and keeps it in position. ARCHAIC a thing which unites people or things; a bond.

Tags: Graphic Depictions of Violence; Tags: Alternate Universe- Canon Divergence, POV Alternating, TransAlpha Dean, Omega Cas, Serial Killers, Righteous Killers, Murder Husbands/Murder Mates, A/B/O Dynamics, Idiots in Love, Mutual Pining, Dismembering, Bodyparts Everywhere, Mutilation, Strangers to Lovers, Latin, Sexy Anatomy Talk, Murder as Foreplay, Knives, Blood&Violence, Torture-not the sexy kind, Smut, Fluff Too, Sexual Tension, Self-worth Issues, Charlie Is a Good Friend, Mention of Abuse- but the bitch dies for it so it’s fine, Assholes Die in This Universe, Scenting, True Mates, Mating Bites, Frotting, Anal Fingering, Anal Sex, Consent Is Sexy, Unsafe sex, Impala Sex, Gift Giving, Happy Ending

Excerpt: Below the readmore

Dean unceremoniously dumps the shitty valet onto the ground behind the car. Rummaging in the trunk, he selects a length of lead pipe, a sheet of sandpaper, and one of two iron brands that now rest below the false bottom of the Impala’s trunk. He and Castiel had discussed their plan on the way to their destination, but that last item is one that should take Castiel by surprise. A pleasant one, Dean hopes.

“Hey Cas,” Dean calls, heading towards the run-down cabin, “I’m just gonna start running supplies in. Can you keep an eye on douchebag over here?”

Castiel ambles over, hands still in his pockets and looks down at the teen in disdain.

“He’s not going anywhere, darling, take your time.”

The crooked smirk and the look of menace in Castiel’s eyes is unbearably hot to Dean. His blood is set aflame, and he nearly trips as he carries a handful of tarps in next, he’s so distracted.

When the temporary kill room is set up to Dean’s satisfaction, he and Castiel haul the young man in from outside to rest on the tarps Dean has laid out on the floor. He’s not sure this one will get particularly messy, but it’s better to be safe than sorry. For all that he’s not been gagged, their victim is unusually quiet. This is the part where they generally start begging and pleading, but Dean’s not going to complain about the lack of sniveling and crying. He does, however, like to play with his food so he rearranges his tools where Beverly can see them, and begins to speak.

“You understand what you did, right you little asshole?” Dean asks, tauntingly. The beta man simply glares up at Dean from his position on his knees.

15 notes

·

View notes

Note

thank you for being so funky about mugram and being a funky mutual

I think I already sent this ask in, but do you have any interesting facts about yumemi? (I think I spelt that right I forgor)

mug!! thank u thank u 🥺💜 fellow funky mutuals unite! but in all seriousness I'm really looking forward to seeing more mugram I love OC stuff so so much with all my heart,,,

Yes I have interesting fun facts for you about Yumemi!! I've accumulated together several bits of information that are probably harmless to let free into the world (probably)... so without further ado:

✨️Fun Facts About Koike Yumemi✨️

She is hypermobile! As in, 'double-jointed', as in super bendy and flexible. Naturally inclined towards things like gymnastics and dance even if she's out of practice! Can also freak people out with weird backwards bending fingers and other fun party tricks :)

A lot of Yumemi's high school time was taken up with idol activities and responsibilities... which has led to a lower level of kanji reading comprehension. Also her maths isn't great. Also she probably has undiagnosed dyslexia that she doesn't know about which isn't exactly helping the situation! have a doodle to illustrate this point:

Her childhood 'what do you want to be when you grow up?' career choice was to be a nurse!! She wasn't actually one of those kids who said 'pop star' or 'famous'... *side eyes the present* Anyways. Sometimes life throws you curveballs! she is not coping well

She hates bugs (only certain ones) but is also the person who will Remove the bug for you. If there's one person in the room not standing on a chair because of a spider it's Her.

She doesn't have many hobbies, but the ones she does are very tactile. Yumemi is pretty good at origami!! She can fold you a crane or a swan or a pinwheel or a hat or a dragon or much much more. Also enjoys sculpting small creatures with clay <3

my voice claim for Yumemi that I've settled on for now is Minori Chihara (I've linked one of those voice reels because they're cute but this va has SO much music released it's insane here listen to this as an example). I think the slightly nasally and soft voice works super well for Yumemi! Plus her singing voice fits my vision of her too... a little more mature sounding with some very powerful pipes!!

Anyway, that's it for now!! Thank you for the ask I had a lot of fun putting this together hehe 💜

#milgram oc#ocgram#ask#I felt in the mood to draw some of this and hey look! finally a scenario where haruka and amane are kind of interacting with each other!#I truly make miracles happen :')#It was kinda hard to think of enough interesting things at first which weren't 'major plot point' but I got in the flow of things!!#thank u again for the lovely ask 💜#koike yumemi#amane momose#haruka sakurai#one day I'll draw her looking happy I swear 🥲#my art

17 notes

·

View notes

Text

Expansion joint Manufacturer in Ahmedabad

Meghmani Metal is a prominent Supplier and Expansion joint Manufacturer in Ahmedabad, Gujarat, India. We are Based in Ahmedabad, Gujarat, India. Industries use expansion joints as crucial components to absorb thermal expansion, vibrations, and misalignment in piping systems. These joints play a vital role in maintaining the safety, efficiency, and durability of systems, such as boilers, pressure vessels, pipelines, and HVAC systems. We provide top-notch expansion joints designed for high performance, exceptional durability, and precise adaptability to different industrial needs. An Expansion joint is a device installed in pipelines, machinery, or structural systems to absorb the movement resulting from thermal expansion, contraction, or vibration. What are the different types of expansion joints? Axial Expansion Joints: These joints are specifically designed to accommodate axial movements in a linear direction. Universal Expansion Joints: Featuring two bellows, these joints can absorb not only axial movement but also lateral displacement and angular rotation. Rubber Expansion Joints: Typically made by wrapping rubber sheets around a bellows-shaped mandrel, these joints offer flexibility in handling various types of motion. Where are Expansion Joints in use? Energy Sector: Power plants, nuclear power plants, district heating systems, etc. Steel Plants: To manage thermal expansion and contraction. Petrochemical Industry: Oil refineries, pumping stations, oil rigs, etc. Chemical Industry: Asphalt manufacturing and related processes. Process Industry: Sugar factories and other processing plants. Exhaust Systems & Engines: In automotive and industrial exhaust systems. Pulp & Paper Industry: To accommodate movement in machinery. LNG/LPG Tankers & Carriers: For managing stresses in shipping systems. FAQs: What is the lifespan of an expansion joint? The lifespan of an expansion joint depends on the material, operating conditions, and maintenance. On average, a well-maintained expansion joint can last between 5 to 20 years. What are expansion joints made of? Expansion joints can be made from a variety of materials, including rubber, metal (stainless steel, alloys), fabric, and elastomers, depending on the application requirements. Can I customize my expansion joint? Yes, Meghmani Metal offers customizable expansion joints tailored to your system's specific size, movement range, pressure, and temperature requirements. Meghmani Metal is an Expansion joint Manufacturer in Ahmedabad, Gujarat, India including locations like Sanand, Vani, Kathawada, Odhav, Vatva, Rakhial, Singarva, Bakrol, Kadi, Kalol, Kanbha, Kujad, Changodar, Naroda, Dhandhuka, Dholka, Viramgam, Kerala. For further inquiries or customized solutions, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Bakrol#Changodar#Dhandhuka#Dholka#Expansionjoint#ExpansionjointinAhmedabad#ExpansionjointinGujarat#ExpansionjointinIndia#ExpansionjointManufacturer#ExpansionjointManufacturerinAhmedabad#ExpansionjointSupplier#ExpansionjointSupplierinAhmedabad#Gujarat#India#Kadi#Kalol#Kanbha#Kathawada#Kerala#Kujad#Manufacturer#ManufacturerofExpansionjoint#Naroda#Odhav#Rakhial#Sanand#Singarva#supplier#SupplierofExpansionjoint

0 notes

Text

Megatop – Your One-Stop Shop for Premium Plumbing Hardware and Supplies

When it comes to plumbing projects, the quality of your materials can make or break the success of your installation or repair. Whether you are a professional plumber, contractor, or DIY enthusiast, finding a reliable supplier for high-quality plumbing hardware and supplies is crucial.

At Megatop, we pride ourselves on being a trusted, one-stop shop for all your plumbing needs. From pipes and fittings to valves, faucets, and accessories, we provide a comprehensive selection of plumbing products to ensure efficient and durable solutions for any project.

If you're looking for premium plumbing hardware at competitive prices, Megatop has got you covered. Let’s explore what makes us the go-to choice for plumbing professionals and homeowners alike.

1. Why Choosing the Right Plumbing Supplier Matters

Plumbing is the backbone of any residential, commercial, or industrial building. Using low-quality materials can result in:

✅ Leaks and water damage✅ Frequent repairs and high maintenance costs✅ Reduced efficiency and performance✅ Non-compliance with safety standards

By choosing Megatop, you ensure that your plumbing system is built with reliable, high-performance components that offer long-lasting durability and optimum functionality.

2. Extensive Range of Plumbing Products at Megatop

At Megatop, we stock a wide variety of plumbing supplies, ensuring you find everything you need in one place. Here’s what we offer:

a) Pipes and Fittings

Pipes and fittings are the foundation of any plumbing system. We offer:

PVC Pipes & Fittings – Lightweight, corrosion-resistant, and perfect for water supply lines.

Copper Pipes & Fittings – Durable, antimicrobial, and ideal for high-pressure applications.

PEX Pipes & Fittings – Flexible, easy to install, and suitable for both hot and cold water supply.

Stainless Steel & Brass Fittings – Strong, corrosion-resistant, and excellent for commercial plumbing.

b) Valves and Faucets

For efficient water flow control, we provide:

Ball Valves – Reliable and long-lasting shut-off valves.

Gate Valves – Best for on/off water control in large plumbing systems.

Mixing Valves – Perfect for regulating hot and cold water in heating systems.

High-Efficiency Faucets – Water-saving and stylish designs for residential and commercial use.

c) Plumbing Accessories and Tools

Every plumbing project requires the right accessories and installation tools, including:

Sealants & Teflon Tape – To ensure leak-proof joints.

Plumbing Wrenches & Cutters – For quick and precise installations.

Water Pumps & Filtration Systems – For clean and efficient water distribution.

Drain Cleaners & Unclogging Tools – To maintain a smooth-flowing system.

Whatever your plumbing needs, Megatop provides top-quality products to get the job done right.

3. Benefits of Buying Plumbing Supplies from Megatop

There are plenty of plumbing hardware suppliers, but why choose Megatop? Here’s what sets us apart:

a) High-Quality Materials for Lasting Performance

We source our plumbing supplies from reputable manufacturers, ensuring that every item meets industry standards for durability and efficiency.

b) Competitive Prices and Bulk Discounts

Whether you're buying a single valve or bulk materials for a large-scale project, we offer fair pricing and discounts on large orders.

c) A One-Stop Shop for All Plumbing Needs

Forget the hassle of searching multiple stores for different parts. Megatop stocks everything from pipes to tools, making it easy to order everything in one place.

d) Expert Customer Support and Advice

Not sure what you need? Our knowledgeable team is ready to assist you with product recommendations, technical support, and installation tips.

e) Fast and Reliable Shipping

We understand the importance of timely delivery. With quick order processing and shipping, we ensure you get your plumbing hardware exactly when you need it.

4. How to Choose the Right Plumbing Supplies for Your Project

When purchasing plumbing hardware, consider the following:

✅ Material Compatibility – Choose materials that suit your plumbing system (e.g., copper for high-pressure, PVC for low-cost installations). ✅ Water Pressure Requirements – Ensure your pipes and fittings can handle the water flow. ✅ Leak Prevention – Invest in quality valves, seals, and adhesives to avoid costly water damage. ✅ Ease of Installation – If you're doing a DIY project, look for user-friendly fittings and tools. ✅ Environmental Impact – Opt for water-saving faucets and energy-efficient components.

If you need help selecting the right supplies, Megatop’s team is here to guide you.

5. Who Can Benefit from Megatop’s Plumbing Hardware?

Megatop caters to a wide range of customers, including:

🏠 Homeowners & DIY Enthusiasts – Whether fixing a leaky faucet or upgrading your home plumbing, we have the right tools and parts.

🔧 Professional Plumbers & Contractors – Need bulk supplies for construction projects? We offer wholesale pricing and top-tier materials.

🏢 Businesses & Property Managers – Keep your commercial buildings running smoothly with high-quality maintenance and repair supplies.

🏭 Industrial Facilities – Get heavy-duty plumbing hardware for factories, warehouses, and large infrastructure projects.

6. Shop Plumbing Supplies Online with Megatop

Shopping for plumbing hardware online has never been easier. At Megatop, you can:

✔ Browse a wide selection of plumbing products✔ Compare specifications and pricing easily✔ Place secure online orders anytime, anywhere✔ Enjoy fast delivery and responsive customer service

With a user-friendly website and trusted payment options, we ensure a seamless shopping experience for all our customers.

7. Conclusion: Megatop – The Best Choice for Plumbing Hardware

When it comes to quality, affordability, and convenience, Megatop stands out as the best plumbing hardware supplier for professionals and DIYers alike.

✔ High-quality plumbing materials✔ Competitive pricing and bulk discounts✔ Wide range of products for every need✔ Expert customer support and advice✔ Fast and secure online shopping experience

If you’re looking for reliable plumbing hardware, visit Megatop’s Plumbing Section today and get the best supplies for your next project! 🚰🔧 visit ; https://megatop.com/

0 notes

Text

Polyurethane Injection Grouting- A Modern Solution for Waterproofing

When do you need Polyurethane Injection (PU) injection?

Polyurethane (PU) injection is a waterproofing technique used to stop water leakage through cracks or gaps in concrete structures. Here are some common situations where you might need PU injection:

Polyurethane (PU) injection is a highly effective waterproofing technique used to stop water leakage through cracks or gaps in concrete structures. It involves injecting polyurethane resin into the affected area, where it expands and seals the leak. Here are some common situations where PU injection grouting waterproofing might be necessary:

Common Scenarios for PU Injection:

Water Leakage:

Cracks in Concrete: If you notice water seeping through cracks in your walls, floors, or ceilings, PU injection can effectively seal these cracks and prevent further water damage.

Joint Leakage: Leaky joints between concrete slabs or around pipes and conduits can also be addressed with PU injection.

Basement Flooding: If your basement is prone to flooding, PU injection can help seal cracks and prevent water from entering.

Structural Damage:

Cracks in Foundations: PU injection can help stabilize and strengthen cracked foundations by filling the voids with expanding polyurethane foam.

Structural Joints: Leaky joints in structural elements like beams and columns can be sealed with PU injection to prevent water damage and maintain structural integrity.

What is Polyurethane Injection?

PU(Polyurethane Injection Grouting) is a form of repair whereby chemicals are pumped to cracks in concrete structures through pressure injection. Sealing hairline cracks, expansion joints, wide cracks, pipe joints, pipe penetrations.

Benefits of PU Injection:

Effective Waterproofing: PU injection provides a long-lasting solution to water leakage problems.

Non-Destructive: The process is minimally invasive, requiring only small holes to be drilled.

Fast and Efficient: PU injection can be completed quickly, minimizing disruption to your property.

Durable and Flexible: The polyurethane foam is highly durable and can withstand various environmental conditions.

If you suspect water leakage or structural damage in your property, it’s advisable to consult with a professional waterproofing contractor to determine if PU injection is the right solution for your specific needs.

If you suspect water leakage or structural damage in your property, it’s advisable to consult with a professional waterproofing contractor. They can assess the situation and determine if polyurethane injection grouting waterproofingor polyurethane grout injection is the right solution for your specific needs. This effective method is commonly used to seal cracks and gaps in concrete, providing a durable waterproof barrier to prevent further damage.

Contact Source waterproofing

We are a trusted and reliable roofing contractor in Singapore and have been in the trade line for 20 years. Willing to cater to the construction needs and demand from the clients. If you require a waterproofing contractor to inspect your property for leakage issues, Source waterproofing is here to assist. Our experienced specialists have performed thousands of inspections and will be able to solve your leakage/damage issues. Contact us today at 6744 4693 / 80313294 or drop us an email at [email protected]

To request for a free quote and schedule a consultation.

0 notes

Text

HDPE Fittings Supplier in Bihar

Sunfiber is a Manufacturer and Supplier of HDPE Fittings in Bihar, India. Our Manufacturing Unit is in Ahmedabad, Gujarat, India. High-Density Polyethylene (HDPE) Fittings for Sunfiber are a crucial component in modern piping systems, known for their strength, flexibility, and durability. These fittings connect, seal, or change the direction of pipes in various applications, ensuring a reliable and leak-free system. HDPE is a strong, lightweight material that offers excellent resistance to a wide range of chemicals, corrosion, and physical stresses. Benefits: High Resistance to Impact & Abrasion: HDPE fittings can withstand rough handling and the wear and tear of abrasive materials in pipelines. Seamless Jointing: The fusion welding process creates seamless joints that are stronger and more durable than mechanical joints, preventing leakage and improving system reliability. Reduced Maintenance: HDPE systems require minimal maintenance due to their resistance to corrosion, chemicals, and UV rays. Environmentally Safe: Made from non-toxic materials, HDPE fittings do not leach harmful substances into the environment. Long-Term Performance: With a life expectancy of over 50 years, HDPE fittings offer superior longevity, making them a sound investment. Applications: Water Supply Systems Wastewater Systems Agricultural Irrigation Chemical Processing Gas Distribution FAQs: What are the joining methods for HDPE fittings? HDPE fittings are typically joined using heat fusion, electrofusion, or mechanical fittings, with heat fusion providing the most durable and leak-proof connection. Are HDPE fittings compatible with other pipe materials? Yes, HDPE fittings can be connected to other materials like PVC, metal, and concrete using appropriate adapters. How do HDPE fittings compare to metal fittings? HDPE fittings offer superior resistance to corrosion, chemicals, and UV rays compared to metal fittings. They are also lighter and easier to handle and install, offering better cost-effectiveness and longevity. Sunfiber is a Manufacturer and Supplier of HDPE Fittings in Bihar, India including location like Araria, Arwal, Aurangabad, Banka, Begusarai, Bhagalpur, Bhojpur, Buxar, Darbhanga, East Champaran, Gaya, Gopalganj, Jamui, Jehanabad, Khagaria, Kishanganj, Kaimur, Katihar, Lakhisarai, Madhubani, Munger, Madhepura, Muzaffarpur, Nalanda, Nawada, Patna, Purnia, Rohtas, Saharsa, Samastipur, Sheohar, Sheikhpura, Saran, Sitamarhi, Supaul, Siwan, Vaishali, West Champaran. For detailed information or inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Araria#Arwal#Aurangabad#Banka#Begusarai#Bhagalpur#Bhojpur#Bihar#Buxar#Darbhanga#EastChamparan#Exporter#ExporterofHDPEFittings#Gaya#Gopalganj#Gujarat#HDPEFittingsExporter#HDPEFittingsinAhmedabad#HDPEFittingsinBihar#HDPEFittingsinGujarat#HDPEFittingsinIndia#HDPEFittingsManufacturer#HDPEFittingsSupplier#HDPEFittingsSupplierinBihar#India#Jamui#Jehanabad#Kaimur#Katihar

0 notes

Text

The Ins and Outs of Dab Rigs: A Comprehensive Guide

In the world of smoking concentrates, dab rigs have emerged as a popular and efficient method of consumption. Whether you're a seasoned smoker or just dipping your toes into the world of dabs, understanding the intricacies of dab rigs can greatly enhance your smoking experience. This blog post aims to provide a comprehensive guide to dab rigs, covering everything from their origins and designs to tips on how to choose and use one.

What is a Dab Rig?

A dab rig is a filtration device specifically designed for consuming concentrates, commonly referred to as "dabs." Unlike traditional bongs or pipes, dab rigs provide a more refined smoking experience, offering better flavor and vapor consistency. They work by using water to cool the vapor produced when a small amount of concentrate is placed onto a hot nail. As the concentrate melts, users inhale the vapor through the mouthpiece, which is pulled through the downstem and water chamber, cooling it to a comfortable temperature.

History and Popularity of Dab Rigs

The popularity of dab rigs has surged in recent years, thanks to the increasing availability of concentrates both in the United States and internationally. As smoking concentrates became more mainstream, the demand for specialized equipment grew, leading to the development and refinement of dab rigs.

Design and Functionality

Dab rigs come in a variety of designs, each offering unique features and benefits. However, they all share some common components:

Nail: The nail is the heating element where the concentrate is placed. It can be made of various materials, such as titanium, quartz, or ceramic, and is heated using a torch or e-nail.

Joint: The joint connects the nail to the rest of the dab rig, typically using a male or female fitting.

Downstem: The downstem directs the vapor from the nail into the water chamber.

Water Chamber: The water chamber cools the vapor as it passes through, making it smoother and easier to inhale.

Base: The base supports the entire dab rig and holds the water chamber.

Mouthpiece: The mouthpiece is where users inhale the cooled vapor.

In addition to these basic components, dab rigs may also feature:

Diffusion: Diffusion refers to the process of breaking the vapor into smaller bubbles as it passes through the water chamber. This increases the surface area of the vapor in contact with the water, resulting in faster cooling and a smoother hit.

Percolators: Some dab rigs incorporate percolators, which are additional chambers designed to further diffuse and cool the vapor.

Types of Dab Rigs

With the growing popularity of dab rigs, there are now many different types and styles to choose from. Here are some of the most popular options:

Classic Dab Rigs: Classic dab rigs are the traditional, go-to option for many smokers. They feature a simple, straightforward design and are often made of durable materials like glass or borosilicate.

Mini Rigs: Mini rigs are smaller, more portable versions of classic dab rigs. They're perfect for smokers who want to enjoy their dabs on the go without sacrificing quality.

Nectar Collectors: Nectar collectors are a unique type of dab rig that resembles a long straw. They're designed to be used directly with silicone jars of concentrate, allowing users to take dabs right out of the container.

E-Rigs: E-rigs, or electronic dab rigs, are the latest innovation in the world of dab smoking. They feature an electronic heating element that maintains a consistent temperature, making it easier to control the smoking experience. E-rigs also tend to be more portable and user-friendly than traditional dab rigs.

Silicone Dab Rigs: Silicone dab rigs are made of flexible, durable silicone material. They're perfect for smokers who are prone to accidents or who want a rig that can withstand the elements.

Dab Pens: Dab pens are small, portable devices that combine the functionality of a dab rig with the convenience of a vaporizer. They're perfect for smokers who want to enjoy their dabs discreetly and on the go.

Choosing the Right Dab Rig

With so many different types and styles of dab rigs available, choosing the right one can be overwhelming. Here are some factors to consider when making your selection:

Style: Choose a style that appeals to you and fits your lifestyle. Whether you prefer the classic look of a traditional rig or the sleek, modern design of an e-rig, there's a dab rig to suit your taste.

Material: The material of your dab rig can affect its durability, weight, and overall smoking experience. Glass rigs are popular for their clarity and smoothness, while silicone rigs are more durable and flexible.

Portability: If you plan to take your dab rig with you on the go, portability is an important consideration. Mini rigs, nectar collectors, and dab pens are all great options for smokers who want to enjoy their dabs on the move.

Ease of Use: Some dab rigs can be more complicated to use than others. If you're new to the world of dabbing, choose a rig that's easy to set up and use. E-rigs and dab pens are both great options for beginners.

Budget: Dab rigs can range in price from a few dollars to several hundred dollars. Set a budget before you start shopping and stick to it. Remember, the most expensive rig isn't always the best one—it's all about finding the right balance of quality, features, and price.

Using a Dab Rig

Now that you've chosen your dab rig, it's time to learn how to use it. Here's a step-by-step guide to getting started:

Prepare Your Rig: Fill the water chamber with water to the appropriate level. Attach the nail to the joint and make sure it's securely fastened.

Heat Your Nail: Use a torch to heat the nail until it's glowing red-hot. Be careful not to overheat it, as this can damage the nail and produce harmful chemicals.

Apply Concentrate: Once the nail is hot, quickly place a small amount of concentrate onto it. Use a dab tool to avoid touching the hot nail with your fingers.

Inhale: Place your lips on the mouthpiece and inhale slowly and steadily. The suction will pull the vapor through the downstem, water chamber, and into your lungs.

Repeat: Repeat the process as needed, heating the nail and applying concentrate each time. Remember to let the nail cool down slightly between hits to avoid overheating.

Maintenance and Care

Like any piece of smoking equipment, dab rigs require regular maintenance and care to stay in good working condition. Here are some tips for keeping your dab rig clean and functioning properly:

Clean Regularly: Clean your dab rig regularly to prevent build-up and residue from affecting the taste and quality of your smoke. Use a glass cleaner or isopropyl alcohol to clean the rig, and make sure to rinse it thoroughly with water before using it again.

Change Water: Change the water in your dab rig regularly to prevent bacteria and mold from growing. It's a good idea to empty and refill the water chamber after each use.

Inspect for Damage: Regularly inspect your dab rig for cracks, chips, or other damage. If you notice any damage, stop using the rig immediately and replace it with a new one.

Store Properly: Store your dab rig in a cool, dry place to prevent it from breaking or becoming damaged. Avoid exposing it to extreme temperatures or direct sunlight.

Conclusion

Dab rigs are a popular and efficient way to enjoy smoking concentrates. With a variety of designs and styles to choose from, there's a dab rig to suit every smoker's needs and preferences. By understanding the basics of dab rigs and how to use and maintain them, you can enhance your smoking experience and enjoy the best that dabbing has to offer. So, whether you're a seasoned smoker or just starting out, dive into the world of dab rigs and discover the perfect rig for you.

0 notes

Text

Spiral Wound Gaskets vs. Other Gasket Types: A Comparison for Optimal Performance

When it comes to ensuring the integrity and reliability of industrial sealing applications, choosing the right gasket is crucial. Gaskets are essential components in industries such as manufacturing, oil & gas, automotive, and petrochemicals. They help create leak-proof seals between different parts and prevent the escape of fluids or gases. However, not all gaskets are created equal, and with numerous types available, it can be difficult to determine which one is best suited for a particular application.

Among the many gasket types, spiral wound gaskets have earned a reputation for their exceptional performance in high-pressure and high-temperature applications. But how do they compare to other gasket types like solid gaskets, ring-type joint gaskets, and compression sheet gaskets? In this article, we’ll explore the differences between spiral wound gaskets and other common gasket types to help you make an informed decision when selecting the best gasket for your business.

1. What Are Spiral Wound Gaskets?

Spiral wound gaskets are made from a combination of metal and filler material that is wound into a spiral shape. The metal typically used in these gaskets is a form of stainless steel, although other metals like carbon steel or alloy steel may also be used, depending on the application. The filler material, often made of graphite, PTFE (Polytetrafluoroethylene), or asbestos, provides additional sealing properties.

Spiral wound gaskets are designed to offer excellent performance under extreme conditions, such as high pressure, temperature fluctuations, and chemical exposure. The metal winding provides strength and flexibility, while the filler material ensures an airtight seal. These gaskets are widely used in industries where tight seals are critical, including the chemical, petrochemical, and energy sectors.

2. Common Gasket Types and Their Features

Before diving into a direct comparison, let’s briefly explore some of the most common gasket types used across various industries:

a) Solid Gaskets:

Solid gaskets are made from a single material, such as rubber, cork, or metal. These gaskets are often used for applications with relatively low pressure and temperature requirements. They are simpler and more cost-effective but may not provide the same level of performance as more complex gasket types under extreme conditions.

Pros of Solid Gaskets:

Affordable and widely available

Easy to install

Suitable for low-pressure applications

Cons of Solid Gaskets:

Limited sealing capabilities under high temperature and pressure

Prone to deformation over time

b) Ring-Type Joint (RTJ) Gaskets:

Ring-type joint gaskets are primarily used in high-pressure applications, especially in the oil and gas industries. These gaskets are made of metal and are designed to create a tight seal by compressing into the groove of the flanged joint. RTJ gaskets are typically used in flanged connections and can handle both extreme pressures and temperatures.

Pros of RTJ Gaskets:

Ideal for high-pressure and high-temperature applications

Strong, metal-to-metal sealing

Cons of RTJ Gaskets:

Expensive compared to other gasket types

Can be difficult to install and maintain

c) Compression Sheet Gaskets:

Compression sheet gaskets are made from a sheet of flexible material, such as rubber, cork, or fiber, which is compressed to form a seal. These gaskets are often used for sealing flanged joints in piping systems. They provide a more uniform seal than solid gaskets but may not be as durable as spiral wound gaskets in harsh conditions.

Pros of Compression Sheet Gaskets:

Cost-effective and easy to install

Good for sealing irregular surfaces

Cons of Compression Sheet Gaskets:

Can fail under high temperature or pressure

Not suitable for all industrial applications

3. Key Differences Between Spiral Wound Gaskets and Other Gasket Types

Now, let’s take a deeper dive into how spiral wound gaskets compare to the other gasket types mentioned above.

a) Performance in Extreme Conditions

Spiral Wound Gaskets: One of the most significant advantages of spiral wound gaskets is their ability to maintain a reliable seal under extreme pressure, temperature, and chemical exposure. The combination of metal and filler material allows these gaskets to be flexible and compressible, providing excellent sealing performance even in fluctuating conditions.

Other Gaskets:

Solid Gaskets tend to fail in extreme conditions, especially under high temperatures and pressures, as they lack the flexibility and strength needed for effective sealing.

RTJ Gaskets are designed to handle extreme pressures but are less flexible, making them more suited for static joints than dynamic ones.

Compression Sheet Gaskets can perform well in moderate conditions but may degrade over time under high pressure and temperature.

b) Ease of Installation

Spiral Wound Gaskets: Due to their flexibility, spiral wound gaskets are relatively easy to install. They can conform to irregular surfaces and are often preferred when a tight seal is required in difficult-to-reach areas.

Other Gaskets:

Solid Gaskets are easy to install, but they may not provide a reliable seal over time, especially under pressure.

RTJ Gaskets require careful installation due to their rigid nature and the need for precise alignment in the groove.

Compression Sheet Gaskets are also easy to install, but their performance can be inconsistent over time.

c) Longevity and Durability

Spiral Wound Gaskets: These gaskets have excellent durability due to their high resistance to corrosion, temperature fluctuations, and pressure changes. The combination of metal and filler material ensures that spiral wound gaskets can withstand harsh industrial conditions, making them ideal for long-term use in critical applications.

Other Gaskets:

Solid Gaskets typically do not have the same longevity as spiral wound gaskets, especially in environments with high pressure or temperature.

RTJ Gaskets are highly durable in high-pressure environments, but they can be expensive to replace and maintain.

Compression Sheet Gaskets may degrade over time, especially under extreme pressure and temperature, which can shorten their lifespan.

d) Cost Considerations

Spiral Wound Gaskets: While spiral wound gaskets are more expensive than solid gaskets, they offer significant value for money due to their superior performance, durability, and versatility. In applications where a reliable seal is essential, investing in spiral wound gaskets can save costs associated with maintenance and leakage problems.

Other Gaskets:

Solid Gaskets are the most affordable option but may incur higher long-term costs due to their limited sealing capabilities and potential need for frequent replacements.

RTJ Gaskets are typically more expensive than spiral wound gaskets and may require specialized tools and expertise for installation and maintenance.

Compression Sheet Gaskets are affordable but may not perform as reliably as spiral wound gaskets in critical applications.

4. Applications for Spiral Wound Gaskets and Other Gasket Types

To make an informed decision, it’s essential to understand the types of applications best suited for each gasket type.

Spiral Wound Gaskets:

High-pressure and high-temperature systems

Chemical processing plants

Power generation and petrochemical industries

Applications requiring a flexible seal that can withstand dynamic loads

Solid Gaskets:

Low-pressure and low-temperature applications

General sealing for less critical systems

Food and beverage industries (where non-metallic options are preferred)

RTJ Gaskets:

High-pressure applications, especially in the oil and gas industry

Flanged connections in industrial piping systems

Environments requiring metal-to-metal sealing

Compression Sheet Gaskets:

Applications with moderate pressure and temperature requirements

General sealing in HVAC and plumbing systems

Sealing irregular surfaces in low-stress applications

5. Conclusion: Which Gasket Type Should You Choose?

In conclusion, selecting the right gasket type for your application is crucial for ensuring optimal performance and preventing costly leaks or system failures. While solid gaskets, RTJ gaskets, and compression sheet gaskets have their specific uses, spiral wound gaskets provide unmatched reliability and versatility, especially in high-pressure, high-temperature, and chemically challenging environments.

When choosing the best gasket for your needs, consider factors like:

Operating conditions (pressure, temperature, and chemical exposure)

Performance requirements (long-lasting, reliable seal)

Ease of installation and maintenance

Budget and overall cost-effectiveness

If your application demands a high-performance seal that can withstand extreme conditions, spiral wound gaskets are the ideal choice. However, for less demanding applications, other gasket types may be more appropriate.

By understanding the unique properties of each gasket type, you can make an informed decision that ensures the longevity and efficiency of your operations. For industries where sealing performance is critical, investing in spiral wound gaskets could save both time and money in the long run.

0 notes

Text

MS Flanges at the Lowest Price

When it comes to industrial piping systems, mild steel (MS) flanges play a crucial role in ensuring a secure and leak-proof connection. At Udhhyog, we offer high-quality MS flanges at the lowest price, making it easier for you to access reliable and durable components for your projects. Whether you’re in the construction, engineering, or water supply industry, our MS flanges are designed to meet your specific needs. In this article, we’ll explore the benefits, applications, and why Udhhyog should be your first choice for MS flanges.

What are MS Flanges?

MS flanges are made from mild steel, a material known for its strength, flexibility, and cost-effectiveness. These flanges are used to connect pipes, valves, and other equipment in a piping system, providing a strong and durable joint. Their versatility and affordability make them a popular choice across various industries.

Key Features of MS Flanges

High Strength: MS flanges are strong and can withstand high pressure and temperature variations, making them suitable for demanding applications.

Corrosion Resistance: With the right coating or treatment, MS flanges can offer good resistance to corrosion, extending their lifespan.

Affordability: Mild steel is an economical material, allowing us to offer MS flanges at the lowest price without compromising on quality.

Benefits of Choosing MS Flanges

Durable and Reliable: Designed for long-term use, MS flanges provide a secure connection that can withstand harsh conditions.

Versatile Applications: Suitable for various industries, including construction, water supply, and engineering.

Cost-Effective Solution: Offering the best value for money, MS flanges are an affordable choice for large-scale projects.

Applications of MS Flanges

Water Supply Systems: Commonly used in water pipelines due to their strength and reliability.

Construction Industry: Ideal for structural applications such as building frameworks and scaffolding.

General Engineering: Used in various mechanical applications, including automotive and machinery manufacturing.

Why Choose Udhhyog for MS Flanges?

At Udhhyog, we are committed to providing high-quality products at competitive prices. Here’s why we should be your preferred supplier for MS flanges:

Top-Quality Products: We ensure that all our flanges meet industry standards and are manufactured using the best materials.

Lowest Price Guarantee: We offer MS flanges at the lowest price, making us an affordable choice for your projects.

Excellent Customer Service: Our team is dedicated to providing timely support and reliable delivery across India.

How to Order MS Flanges from Udhhyog

Ordering from Udhhyog is easy and convenient. Simply visit our website and click on MS flanges lowest price to place your order. We ensure a smooth shopping experience with quick delivery and excellent customer support.

#MSFlanges#LowestPriceFlanges#IndustrialFlanges#SteelFlanges#PipingComponents#Udhhyog#AffordableFlanges#ConstructionMaterials

5 notes

·

View notes

Text

Reliable Flanged Expansion Joints - Afsjoints for Seamless System Performance

Afsjoints provides high-quality flanged expansion joints designed for optimal performance in demanding industrial environments. These durable joints are ideal for piping systems that require a strong, leak-free connection, offering exceptional flexibility to absorb thermal expansion, vibrations, and movement. Perfect for applications in power plants, chemical processing, and HVAC systems, Afsjoints' flanged expansion joints ensure a smooth, efficient operation while reducing stress on pipes.

https://afsjoints.com/what-are-fabric-expansion-joints-types-and-uses/

#expansion joints manufacturer#custom expansion joints#metal bellows expansion joints#ducting expansion joints#high temperature expansion joint#fluoropolymer expansion joints#elastomeric joints#flue gas expansion joints

0 notes

Text

Exploring the Impact of Seals, Gaskets, and Engine Mounts on Automotive and Industrial Systems

In both automotive and industrial machinery, certain components, though often overlooked, are crucial for ensuring smooth and efficient operation. Among these are seals, gaskets, and engine mounts. These parts are vital in preventing leakage, minimizing vibration, and securing the engine or equipment in place. Whether it's in vehicles, industrial equipment, or machinery, each of these components plays a specialized role in enhancing the longevity and functionality of complex systems.

What Are Seals and Gaskets?

Seals and gaskets are both designed to prevent leakage between two or more surfaces, but they have distinct applications.

Seals: Seals are typically used to stop the flow of fluids, gases, or contaminants between moving or rotating parts. In an automotive engine, for instance, seals are used to prevent oil, coolant, or air from leaking out of areas where parts rotate or slide, such as around crankshafts, camshafts, or pistons. In industrial equipment, seals are essential in pumps, hydraulic systems, and compressors, where they maintain pressure and prevent leakage.

Seals are generally made from flexible materials such as rubber, silicone, or elastomers, which allow them to conform to the mating surfaces while maintaining a tight seal even under pressure. Their ability to function in high-temperature environments makes them indispensable in engines, transmissions, and other machinery that experience extreme conditions.

Gaskets: Unlike seals, gaskets are used in static situations, where parts are bolted or clamped together. Their primary function is to create an airtight or watertight seal between two stationary surfaces. In engines, gaskets are commonly used to seal joints such as those between the cylinder head and engine block. Gaskets are made from materials that can withstand high pressure, temperature variations, and vibrations, including rubber, cork, graphite, and metal.

In industrial settings, gaskets are found in pipe joints, flanges, and pressure vessels, where they prevent the leakage of liquids or gases. A failure of a gasket can lead to system inefficiencies, costly repairs, and even safety hazards, making it vital to select the correct gasket material for the intended application.

Engine Mounts: More Than Just Support

An engine mount is another often-underappreciated component that serves multiple functions. Engine mounts are designed to secure the engine in place within the vehicle or machinery while minimizing the effects of engine vibrations on the rest of the system. These mounts are typically made from a combination of metal and rubber, which allows them to absorb shocks and vibrations that would otherwise be transmitted to the vehicle’s chassis or the industrial equipment’s frame.

Vibration Isolation: Engine mounts are critical in isolating vibrations caused by the engine’s operation. Without proper vibration damping, the rest of the vehicle or machinery would experience excessive noise, discomfort, and wear. In automobiles, this means a smoother ride for passengers and less stress on the vehicle’s frame and interior components. For industrial machinery, vibration isolation ensures that sensitive equipment is not damaged by engine-induced movements.

Stability and Alignment: The engine mount holds the engine in place, ensuring that it remains aligned with the drivetrain, transmission, and other critical components. Proper alignment ensures smooth operation, prevents undue wear on moving parts, and maximizes the efficiency of power transmission. This is particularly crucial in high-performance vehicles and heavy industrial machinery, where precise operation is essential.

Durability: Over time, engine mounts can wear out due to exposure to heat, oil, and vibrations. Worn-out mounts can lead to excessive engine movement, which can cause misalignment, increased vibration, and potential damage to other components. Regular inspection and replacement of engine mounts help maintain the vehicle’s performance and reduce the risk of damage to other critical parts.

Applications in Automotive and Industrial Systems

In automotive systems, engine mounts, Seals & Gaskets, are essential for the proper functioning of internal combustion engines. Seals prevent oil and coolant leaks, gaskets maintain pressure and prevent exhaust gases from escaping, and engine mounts keep the engine secure while reducing vibrations. These components contribute to the overall performance, efficiency, and comfort of the vehicle.

In industrial machinery, these components play a similar role in ensuring that engines, pumps, compressors, and turbines operate smoothly and efficiently. Seals and gaskets prevent the leakage of fluids and gases, while engine mounts reduce vibrations that could harm sensitive equipment. Whether in manufacturing plants, power generation, or heavy-duty machinery, these components help ensure that the machinery remains reliable and durable.

Conclusion

Though often hidden from view, seals, gaskets, and engine mounts are integral to the performance and longevity of both automotive and industrial systems. Their ability to prevent leaks, reduce vibrations, and maintain the proper alignment of critical components ensures that vehicles and machinery run smoothly and efficiently. By understanding the importance of these components, manufacturers and vehicle owners can take proactive steps to maintain their systems and avoid costly repairs. Proper selection, installation, and maintenance of seals, gaskets, and engine mounts are key to keeping any engine or mechanical system running at its best.

0 notes

Text

Flanges: An Essential Component in Pipe Connections

Metalica Forging Inc. is a leading Flanges Manufacturer in India. Flanges are a crucial component in the world of piping systems, offering a reliable and secure method for connecting pipes, valves, pumps, and other equipment. These devices are commonly used in industries such as oil and gas, As a trusted Flange Suppliers in India, chemical processing, water treatment, and even construction, where safe and efficient transport of liquids, gases, and other materials is essential.

What is a Flange?

A flange is a mechanical component used to join two pieces of equipment or piping by bolting them together. It typically consists of a flat circular disc with holes for bolts around its perimeter. Flanges are designed to allow easy and secure connection and disconnection of components. They are usually made from durable materials like stainless steel, carbon steel, or alloy metals to withstand pressure, temperature, and corrosive environments.

Types of Flanges

There are several types of Flanges, each designed for specific applications. The most common types include:

Hub Flanges – Hub Flanges are available in a variety of sizes, dimensions, shapes, and can also be customized Hub Flanges as per customer requirements.

Without Hub Flanges – As a leading Without Hub Flanges Manufacturer, our without hub flanges are widely used in various industries such as food processing, paper & pulp, plumbing, automotive, transporting and others..

Blind Flange – Blind flanges are solid, circular discs used to close the end of a piping system. They are typically used to block or seal off pipes temporarily or permanently.

Threaded Flange – Threaded flanges have internal threads that allow them to screw directly onto a pipe with corresponding external threads. This type of flange is commonly used in systems where welding is not possible or desired.

Socket Weld Flange – Socket weld flanges have a recessed area that allows the pipe to be inserted into the flange. This design is commonly used for small-diameter pipes under high pressure.

Lap Joint Flange – Lap joint flanges consist of a flange and a separate backing flange. The pipe is inserted into the backing flange and does not require welding. This flange type is often used for applications where frequent disassembly is necessary.

We Supply flanges in several cities like.

Flanges Supplier In Rajkot

Flanges Supplier In Ahmedabad

Flange Supplier In Surat

Flange Supplier In Bhavnagar

Flange Supplier In pune

Material Selection for Flanges

Flanges Manufacturers are available in a wide variety of materials, each selected based on the specific requirements of the system. Common materials include:

Stainless Steel – Known for its resistance to corrosion, stainless steel is widely used in industries dealing with chemicals, food processing, and marine environments.

Carbon Steel – Carbon steel flanges are used in lower-cost applications where corrosion resistance is not as critical.

Alloy Steel – For high-temperature or high-pressure applications, alloy steel flanges are designed to withstand extreme conditions.

Cast Iron – Cast iron is often used for low-pressure applications or in systems where flanges are not subjected to harsh environments.

Why Are Flanges Important?

Flanges suppliers play a pivotal role in ensuring the safety, efficiency, and longevity of a piping system. Some key advantages of using flanges include:

Secure Connection: Flanges provide a solid, leak-free connection between piping and equipment, even under high pressure or temperature conditions.

Ease of Maintenance: Flanged connections can be easily disassembled for cleaning, repair, or replacement, minimizing downtime in industrial systems.

Flexibility: With various designs and materials available, flanges can be tailored to meet specific needs, making them versatile components in diverse industries.

0 notes

Text

What Is Roof Flashing? Understanding Its Role in Protecting Your Home

Roof flashing is a critical component in safeguarding your home from water intrusion. It involves the installation of thin, impervious materials at vulnerable points on your roof—such as joints, seams, and areas surrounding protrusions like chimneys and vents—to direct water away and prevent leaks.

Purpose of Roof Flashing

The primary function of roof flashing is to create a watertight barrier at intersections and terminations on your roof. Without proper flashing, water can seep into these vulnerable areas, leading to structural damage, mold growth, and compromised insulation. By directing water away from critical points, flashing extends the lifespan of your roof and maintains the integrity of your home.

Common Materials Used in Roof Flashing

Various materials are used for roof flashing, each selected based on durability, compatibility with roofing materials, and environmental considerations:

Aluminum: Lightweight and resistant to corrosion, making it suitable for many applications.

Copper: Highly durable and offers a long service life; however, it is more expensive.

Lead: Malleable and long-lasting but raises environmental concerns due to toxicity.

Stainless Steel: Offers excellent corrosion resistance and strength, ideal for harsh environments.

Rubberized Asphalt: Flexible and adhesive-backed, commonly used around windows and doors.

Types of Roof Flashing

Different types of flashing are employed based on their specific applications:

Step Flashing: Used where the roof meets a vertical wall, with pieces overlapping in a step-like pattern to guide water away.

Valley Flashing: Installed in roof valleys where two roof planes intersect, channeling water off the roof.

Drip Edge: Placed along the roof's edge to direct water into the gutters, preventing damage to the fascia and soffit.

Counter Flashing: Works in conjunction with base flashing to provide a secondary barrier, often seen around chimneys.

Vent Pipe Flashing: Seals around pipes that penetrate the roof, preventing leaks at these junctions.

Importance of Professional Installation

Proper installation of roof flashing is crucial. Incorrectly installed flashing can lead to water being directed into, rather than away from, the structure. Professional roofing contractors, like those at ZamZam Roofing, have the expertise to ensure flashing is correctly installed, providing long-term protection for your home.

Environmental Considerations

When selecting flashing materials, it's essential to consider environmental impacts. For instance, while lead flashing is effective, it poses environmental hazards. Alternatives like soft zinc offer similar benefits without the associated risks. Additionally, some metals can corrode when in contact with certain materials; for example, aluminum should not be used in contact with pressure-treated wood due to rapid corrosion.

Conclusion

Roof flashing is an essential element in protecting your home from water damage. Understanding its purpose, the materials used, and the importance of professional installation can help you make informed decisions about your roofing needs. For homeowners in Milwaukee and surrounding areas, ZamZam Roofing offers comprehensive roofing services, including inspections, repairs, and replacements, ensuring your roof remains in optimal condition.

ZamZam Roofing

Milwaukee, WI

A trusted partner for roofing repair services, offering comprehensive inspections, repairs, and replacements to protect your home.

Zamzam Roofing

1 note

·

View note