#Waste Heat Recovery System Market

Explore tagged Tumblr posts

Text

Waste Heat Recovery System Market: Role in Reducing Industrial Energy Consumption

The Waste Heat Recovery System Market Size was valued at USD 76.4 billion in 2023 and is expected to reach USD 136.3 billion by 2031 and grow at a CAGR of 7.5 % over the forecast period 2024–2031.

Waste heat recovery systems are designed to capture excess heat generated in various industrial processes and convert it into useful energy, such as electricity or heating. With energy costs on the rise and stricter environmental regulations, waste heat recovery is becoming essential for industries aiming to achieve cost savings and carbon reduction. This market is witnessing increased adoption as companies recognize the economic and environmental benefits of recovering waste heat.

The market’s growth is further supported by advancements in heat exchanger technologies, the adoption of organic Rankine cycle (ORC) systems, and integration with renewable energy systems. These innovations are enabling more efficient heat recovery and utilization, driving interest and investment in waste heat recovery solutions.

Key Market Drivers

Stringent Environmental Regulations: Governments and environmental bodies worldwide are imposing regulations to reduce carbon emissions and energy waste. Waste heat recovery systems provide a solution for companies to achieve compliance with these regulations.

Rising Energy Costs: With the increase in energy prices, industries are turning to waste heat recovery to lower their energy bills and improve overall operational efficiency.

Industrial Expansion: The expansion of energy-intensive industries such as chemicals, cement, and steel is driving demand for waste heat recovery systems to optimize energy use and reduce operating costs.

Sustainability Goals: Companies are increasingly focused on sustainability and corporate social responsibility. Waste heat recovery helps organizations reduce their carbon footprints and align with global sustainability goals.

Technological Advancements: Innovations in waste heat recovery technologies, including improved heat exchanger materials and ORC systems, are enhancing the efficiency of heat recovery systems, making them more attractive to industries.

Market Segmentation

The Waste Heat Recovery System Market can be segmented by application, end-use industry, technology, and region.

By Application

Steam and Power Generation: Waste heat recovery is widely used in steam and power generation, where recovered heat is converted into electricity or used for heating processes in industries.

Preheating: Preheating of combustion air or other materials using waste heat reduces the energy demand in furnaces, kilns, and other high-temperature equipment.

Others: Waste heat is also recovered for various applications, such as district heating and combined heat and power (CHP) systems, improving energy efficiency across multiple industries.

By End-Use Industry

Cement Industry: The cement sector is a significant user of waste heat recovery systems, as it involves high-temperature processes that generate substantial waste heat.

Oil and Gas: Waste heat recovery is increasingly adopted in oil refineries and natural gas processing facilities to reduce energy consumption and greenhouse gas emissions.

Chemicals and Petrochemicals: Energy-intensive chemical processes produce large amounts of waste heat, which can be recovered to reduce energy costs and emissions.

Metal Processing: The metals industry, especially steel production, generates a significant amount of waste heat, which can be utilized in preheating and power generation applications.

Power Generation: Power plants, particularly combined-cycle plants, use waste heat recovery systems to maximize energy output and efficiency.

By Technology

Heat Exchangers: Heat exchangers are widely used to capture and transfer waste heat. Innovations in exchanger designs and materials are enhancing heat recovery efficiency.

Organic Rankine Cycle (ORC) Systems: ORC systems are gaining popularity for waste heat recovery, as they can convert low-temperature heat into electricity, expanding the scope of applications.

Thermoelectric Generators (TEGs): TEGs use semiconductor materials to convert waste heat directly into electricity, representing an emerging technology with potential for widespread adoption.

Steam Rankine Cycle: This technology uses steam generated from waste heat to drive turbines for electricity production and is commonly used in power generation applications.

Regional Analysis

North America: North America is a major market for waste heat recovery systems, driven by stringent regulations on emissions and energy efficiency in industries such as manufacturing and power generation. The U.S. is at the forefront, with industries adopting waste heat recovery to cut costs and meet environmental standards.

Europe: Europe is a leading market due to strict regulations on emissions and energy efficiency. Countries such as Germany and the U.K. are focused on industrial decarbonization, driving demand for waste heat recovery systems in heavy industries like chemicals, cement, and metal processing.

Asia-Pacific: The Asia-Pacific region is experiencing rapid growth in the waste heat recovery market due to industrial expansion in countries like China, Japan, and India. With rising energy costs and growing environmental awareness, industries are increasingly adopting waste heat recovery technologies.

Middle East & Africa: In the Middle East and Africa, waste heat recovery is gaining traction in the oil and gas and petrochemical sectors. Countries such as Saudi Arabia and the UAE are exploring waste heat recovery systems as part of their broader energy efficiency and sustainability initiatives.

Latin America: Latin America is an emerging market for waste heat recovery, with countries such as Brazil and Mexico investing in energy efficiency solutions across industrial sectors, particularly in cement and oil refining.

Read Complete Report Details of Waste Heat Recovery System Market: https://www.snsinsider.com/reports/waste-heat-recovery-system-market-2793

Current Market Trends

Integration with Renewable Energy: Waste heat recovery is increasingly being integrated with renewable energy systems to optimize energy use and minimize emissions, aligning with global sustainability goals.

Increased Adoption of ORC Technology: Organic Rankine Cycle technology is gaining traction for its ability to convert low-temperature waste heat into electricity, providing an efficient solution for industries.

Focus on Industrial Decarbonization: As industries face pressure to reduce emissions, waste heat recovery is becoming a key strategy for decarbonization, particularly in sectors like cement and steel production.

Government Incentives: Various governments are offering incentives to encourage industries to adopt waste heat recovery systems as part of broader energy efficiency and environmental initiatives.

Technological Innovation in Heat Exchangers: Advances in heat exchanger technology, including improvements in materials and design, are enhancing the efficiency of waste heat recovery systems, making them more accessible to diverse industries.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us: Akash Anand — Head of Business Development & Strategy [email protected] Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

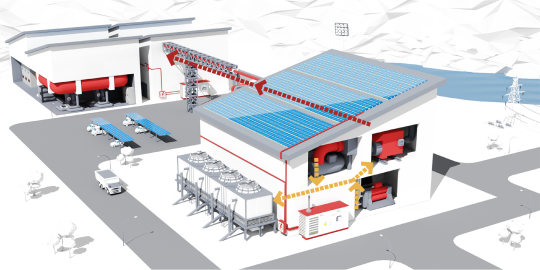

BECIS - Waste Heat Recovery Solution

BECIS waste heat recovery solution reduces GHG emissions and brings energy cost-savings to your plant. A waste heat recovery system helps save the cost of cooling towers and reduces steam consumption.

For more information, please visit: https://be-cis.com/energy-as-a-service/waste-heat-recovery/

0 notes

Text

Global Metallurgical Waste Heat Recovery Steam System Market Analysis and Future Growth Forecasts 2024 - 2032

The metallurgical industry is one of the largest consumers of energy globally, making the efficient management of energy resources critical. Waste heat recovery systems have emerged as a vital technology for improving energy efficiency and reducing carbon emissions. This article explores the global metallurgical waste heat recovery steam system market, examining its current landscape, trends, challenges, and future prospects.

Overview of Waste Heat Recovery Systems

The global metallurgical waste heat recovery steam system market is poised for significant growth, driven by the need for energy efficiency and regulatory compliance. While challenges exist

What are Waste Heat Recovery Systems?

Waste heat recovery systems (WHRS) capture excess heat generated during metallurgical processes and convert it into useful energy. This recovered energy can be used to produce steam, which can then drive turbines to generate electricity or be utilized in various heating processes.

Importance in the Metallurgical Sector

In the metallurgical sector, WHRS not only helps in minimizing energy costs but also plays a crucial role in meeting regulatory requirements for emissions. By recovering and reusing waste heat, companies can significantly improve their overall energy efficiency.

Market Dynamics

Key Drivers

Rising Energy Costs: Increasing energy prices compel metallurgical companies to seek cost-effective solutions, driving demand for WHRS.

Regulatory Pressure: Stricter environmental regulations encourage industries to adopt technologies that lower emissions and enhance energy efficiency.

Technological Advancements: Innovations in waste heat recovery technologies, such as improved heat exchangers and advanced steam systems, contribute to market growth.

Challenges

High Initial Investment: The upfront cost of implementing WHRS can be a significant barrier for many companies, particularly small and medium-sized enterprises.

Technological Complexity: The integration of WHRS into existing systems can be complex and may require specialized knowledge and training.

Market Fragmentation: The market is characterized by a large number of players, which can lead to intense competition and price wars.

Market Segmentation

By Type

Heat Recovery Steam Generators (HRSG)

Thermal Oxidizers

Heat Exchangers

By Application

Iron and Steel Production

Aluminum Production

Copper and Other Non-ferrous Metal Production

By Region

North America

Europe

Asia-Pacific

Latin America

Middle East and Africa

Regional Analysis

North America

The North American metallurgical waste heat recovery steam system market is driven by technological advancements and a strong focus on energy efficiency. The region is home to numerous key players investing in innovative solutions.

Europe

Europe is witnessing significant growth due to stringent environmental regulations and government incentives for energy efficiency. Countries like Germany and the UK are leading in the adoption of WHRS technologies.

Asia-Pacific

The Asia-Pacific region is expected to dominate the market, fueled by rapid industrialization, particularly in countries like China and India. The increasing demand for metals and minerals is propelling investments in waste heat recovery systems.

Latin America and Middle East

Emerging economies in Latin America and the Middle East are gradually adopting waste heat recovery systems, motivated by rising energy costs and environmental concerns.

Future Trends

Integration with Renewable Energy

The future of the metallurgical waste heat recovery steam system market may see a shift towards integrating renewable energy sources, enhancing overall energy sustainability.

Digitalization and IoT

The incorporation of digital technologies and the Internet of Things (IoT) into WHRS will lead to improved monitoring and optimization of systems, further enhancing efficiency and performance.

Sustainable Practices

As industries globally move towards sustainability, the demand for energy-efficient solutions like WHRS will continue to grow, shaping the market's future landscape.

Conclusion

The global metallurgical waste heat recovery steam system market is poised for significant growth, driven by the need for energy efficiency and regulatory compliance. While challenges exist, the continuous evolution of technology and increasing awareness of sustainability will create ample opportunities for stakeholders. By embracing waste heat recovery systems, the metallurgical sector can not only reduce costs but also contribute to a greener planet.

#Global Metallurgical Waste Heat Recovery Steam System Market Size#Global Metallurgical Waste Heat Recovery Steam System Market Trend#Global Metallurgical Waste Heat Recovery Steam System Market Growth

0 notes

Text

#United Arab Emirates Waste Heat Recovery Systems Market#Market Size#Market Share#Market Trends#Market Analysis#Industry Survey#Market Demand#Top Major Key Player#Market Estimate#Market Segments#Industry Data

0 notes

Text

South Korea Waste Heat Recovery System Market Size is forecast to reach $2.9 million by 2026, at a CAGR of 8.8% during forecast period 2021-2026.

#South Korea Waste Heat Recovery System Market#South Korea Waste Heat Recovery System Market share#South Korea Waste Heat Recovery System Market size

0 notes

Text

Data Bridge Market Research analyses that the waste heat recovery system market was valued at USD 64.87 billion in 2021 and is expected to reach USD 132.13 by 2029, registering a CAGR of 9.30% during the forecast period of 2022 to 2029. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

#Waste Heat Recovery System Market Market#Waste Heat Recovery System Market Demand#Waste Heat Recovery System Market Share#Waste Heat Recovery System Market Forecast#Waste Heat Recovery System Market Trend#Waste Heat Recovery System Market Segment#Waste Heat Recovery System Market Overview#Waste Heat Recovery System Market Growth

0 notes

Link

#market research future#oil & gas waste heat recovery#oil & gas waste heat system#waste heat recovery industry

0 notes

Text

It can often feel like you need a PhD in material science just to understand the textiles that appear on garment care labels. While natural fibres including wool and cotton are pretty easy to identify, synthetics such as polyester and viscose can be harder to decode.

Generally speaking, human-made materials fall into one of two categories: those derived from fossil fuels and those derived from chemically processed cellulose (the building block of plants).

Fossil fuel-based fibres

Polyester

Polyester is the most common fibre on the planet, making up over half of the overall fibre market. It is a type of plastic called polyethylene terephthalate or PET which is moulded into yarn then woven into a fabric.

Dr Georgia McCorkill, a fashion lecturer at RMIT, says fossil fuels are the basis of the chemicals that make PET, so from an environmental and sustainability standpoint, their origins are already problematic. Since plastic does not so much biodegrade as split into smaller and smaller pieces (it was only invented last century, so we can’t really know how long it will hang around), polyester is also problematic when it is washed, as it can shed microplastics into waterways and at the end of a garment’s life.

“In an ideal world [polyester] would exist in a closed-loop system where it would be perpetually melted down and reformed into new fabrics,” says McCorkill. “However the design, production and waste recovery systems required to make this a reality don’t exist.”

Recently, there has been a push towards recycled polyester – which uses plastic bottles as an input – instead of virgin resources. While recycled polyester has a lower carbon footprint than conventional polyester, it is not a perfect solution. Turning plastic bottles into new plastic bottles is more efficient than recycling them into polyester, and it can be done on a loop. Current methods for turning plastic into polyester at scale do not result in a material that can be recycled again post-use.

McCorkill says polyester is an extremely strong material and can be necessary in activewear, sportswear or outdoor gear. But, she says, “polyester can get very smelly over time and become unwearable”. This is because it clings to odour and stains, making them impossible to remove.

Nylon

Like polyester, nylon is also a plastic derived from fossil fuels but it is more expensive to make and therefore used less frequently. It makes up about 11% of the clothing fibre market. Since nylon is stretchier and stronger than polyester, it is often found in swimwear and yoga gear.

Manufacturing nylon releases nitrous oxide into the atmosphere, contributing to global heating, and because nylon is a plastic it won’t biodegrade. The founder of Cloth & Co, Caroline Poiner, suggests looking for recycled alternatives such as Econyl that are made with recovered waste products, including fishing lines and other waste pulled from the ocean.

Unlike recycled polyester, recycled nylon can be regenerated into new nylon more than once, provided it has not been blended with other fibre types.

Elastane

The other fossil fuel-based fibre you’ll often encounter on a garment care label is elastane (also called spandex or Lycra). It is commonly blended with other fibres to provide added stretch (it can expand and recover up to five times its own length).

This elasticity makes it similar to rubber. But while natural rubber or elastic is derived from trees, elastane is derived from polyurethane and will not biodegrade. While elastane’s capacity for stretch and recovery makes it very useful in athletic gear and underwear, when exposed to heat or too much strain, its elasticity will degrade over time.

Man-made cellulosic fibres

Viscose rayon is the umbrella term for fibres manufactured from cellulose, but as many fibres fall into this broad category, it can be very confusing. The list includes rayon, viscose, modal, lyocell, acetate, bamboo and cupro. Aside from cupro, which is made from cotton waste, all of these materials are derived from wood pulp.

Poiner warns that although bamboo and the like are often marketed on their eco credentials, it can be “comparable to synthetic fibres in its impact on the environment and also the health and wellbeing of workers."

Sourcing viscose rayon has historically been linked to deforestation, and even now the environmental not-for-profit Canopy estimates that of the 200m trees cut down each year to make viscose, at least half come from ancient or endangered forests. If you want to be sure these fabrics have been sustainably sourced, look for FSC or PEFC certifications.

The process of turning wood or cotton waste into a fabric “requires highly toxic chemicals in its production”, says Poiner, who notes some manufacturers choose factory sites where they can avoid strict health and safety regulations.

Less harmful cellulose fabrics are manufactured using a closed-loop system, that recovers and reuses toxic solvents. EcoVero and Tencel are types of lyocell, trademarked by fabric giant Lenzing, which are made using best practice pulp-sourcing and chemical management during the production process.

There are also exciting innovations in this space, with new types of viscose rayon made using agricultural, food or clothing waste as a source material instead of trees, however these are not yet widely available.

7 notes

·

View notes

Text

Green Building Practices: Incorporating Sustainability in Home Construction

As the world becomes more conscious of environmental issues, incorporating green building practices in home construction has gained significant importance. Sustainable construction not only reduces the negative impact on the environment but also promotes healthier living spaces. In this blog post, we will explore the various ways homeowners and builders can embrace green building practices to create sustainable homes.

Energy Efficiency: Energy-efficient homes minimize energy consumption and reduce carbon footprint. Incorporate energy-efficient appliances, LED lighting, and properly insulated windows and walls. Consider renewable energy sources like solar panels to power your home and reduce reliance on traditional energy grids.

Water Conservation: Implement water-saving techniques by installing low-flow fixtures, dual-flush toilets, and rainwater harvesting systems. Efficient irrigation systems and landscaping choices can also reduce water consumption.

Sustainable Materials: Choose eco-friendly building materials, such as recycled or reclaimed wood, bamboo flooring, and low-VOC (volatile organic compound) paints. Opt for products with recognized certifications like Forest Stewardship Council (FSC) for wood or Cradle to Cradle for sustainable manufacturing practices.

Waste Management: Develop a comprehensive waste management plan to reduce construction waste. Recycle and reuse materials whenever possible, and dispose of waste responsibly. Collaborate with local recycling facilities and donate usable materials to minimize environmental impact.

Passive Design: Implement passive design strategies to maximize natural lighting, ventilation, and thermal comfort. Orienting the house to take advantage of sunlight, incorporating efficient insulation, and using strategic landscaping can significantly reduce energy needs.

Water Efficiency: Install high-efficiency plumbing fixtures, such as low-flow showerheads and faucets, and consider graywater systems for recycling water from sinks and showers for non-potable uses like irrigation.

Indoor Air Quality: Promote a healthy living environment by using low-VOC paints, sealants, and adhesives. Proper ventilation systems with heat recovery can improve air quality and reduce the presence of pollutants.

Green Roofing and Insulation: Consider green roofs, which provide insulation, reduce stormwater runoff, and improve air quality. Optimize insulation to minimize heat loss or gain, reducing the need for excessive heating or cooling.

Smart Home Technology: Integrate smart home systems to optimize energy consumption, such as programmable thermostats, motion sensor lighting, and smart energy monitoring devices.

Incorporating sustainable practices in home construction benefits both homeowners and the environment. By adopting green building practices, we can reduce our carbon footprint, conserve resources, and create healthier and more energy-efficient living spaces. Whether you're building a new home or renovating an existing one, embracing sustainability in construction is a positive step toward a greener future. Let's work together to build homes that are not only beautiful but also contribute to a sustainable and eco-friendly world.

At Sparks Construction, we take great pride in being one of the leading custom home builders in Lake City, FL. With a deep understanding of the local market, we offer personalized and exceptional services as a trusted home builder in Lake City. Whether it's a new construction or a renovation project, we are committed to bringing your vision to life. As one of the premier home builders in Lake City, we prioritize quality craftsmanship, attention to detail, and exceeding your expectations. Choose Sparks Construction for your custom home building needs in Lake City and experience the difference firsthand.

#new home construction#home builders gainesville fl#new home construction gainesville fl#home construction#new home#home builders

5 notes

·

View notes

Text

https://www.verifiedmarketreports.com/pt/product/industrial-waste-heat-recovery-systems-market/

0 notes

Text

Waste to Energy Market: Key Players and Market Dynamics

The Waste to Energy Market size was valued at USD 33.68 billion in 2022 and is expected to grow to USD 48.63 billion by 2030 with a growing CAGR of 4.7% over the forecast period of 2023–2030.

The Waste to Energy market involves converting waste materials into usable energy forms, offering an alternative to traditional waste disposal and fossil fuels. This sustainable solution not only helps manage waste but also generates renewable energy, supporting environmental goals and reducing dependency on non-renewable resources. Major WtE technologies include incineration, gasification, pyrolysis, and anaerobic digestion, each offering specific benefits for waste conversion.

In recent years, WtE technology has gained traction worldwide as an effective solution for sustainable waste management. Governments and companies are heavily investing in WtE plants, especially in areas where landfill space is scarce and the demand for clean energy is high.

Key Market Drivers

Increase in Waste Generation: Urbanization and industrialization are leading to higher levels of waste production, making efficient waste disposal and management a necessity.

Demand for Renewable Energy: Rising energy demands, combined with environmental concerns, are encouraging the adoption of WtE solutions as an alternative to fossil fuels.

Government Incentives and Policies: Supportive regulations and incentives for renewable energy projects are fostering the growth of the WtE market globally.

Focus on Reducing Landfill Usage: With limited space for landfills, particularly in urbanized regions, WtE presents a viable option to reduce waste and repurpose it for energy generation.

Technological Advancements: Innovations in WtE technologies, such as improved incineration methods and advanced gasification techniques, are enhancing the efficiency and sustainability of waste-to-energy conversion processes.

Market Segmentation

The Waste to Energy Market can be segmented by technology, application, waste type, and region.

By Technology

Thermal Technologies: Includes incineration, pyrolysis, and gasification. Thermal processes are highly effective for converting waste into energy and are widely used due to their efficiency.

Biological Processes: Includes anaerobic digestion, where organic waste is broken down by microorganisms to produce biogas, a sustainable fuel source.

Physical Processes: Advanced recycling methods are used for waste separation and material recovery, reducing the amount of waste that needs energy conversion.

By Application

Electricity Generation: Most WtE plants focus on converting waste to electricity, making it a valuable addition to the energy grid.

Heating Applications: Some WtE facilities generate heat for district heating systems or industrial processes.

Biofuel Production: Certain WtE processes produce biofuels, such as bioethanol or biodiesel, for transportation and industrial applications.

By Waste Type

Municipal Solid Waste (MSW): The largest waste category, primarily consisting of household and commercial waste, suitable for thermal and biological processing.

Industrial Waste: Includes waste from manufacturing and production, often requiring specific treatment methods before energy conversion.

Agricultural Waste: Organic waste generated from agriculture can be converted into biofuels or biogas.

Regional Analysis

North America: The United States and Canada are focusing on reducing landfill reliance, with increasing investments in WtE plants supported by government incentives.

Europe: The region leads in WtE adoption, driven by strict environmental regulations and a focus on sustainable waste management.

Asia-Pacific: Rapid urbanization and population growth in countries like China and India are propelling demand for effective waste management solutions, including WtE.

Latin America: Emerging markets in Latin America are recognizing the benefits of WtE for both energy production and waste reduction, with a rise in WtE project investments.

Middle East & Africa: The region is gradually adopting WtE technologies, supported by government initiatives and increasing energy demand.

Current Market Trends

Shift Toward Sustainable Waste Management: With an emphasis on circular economies, companies are turning waste from a disposal challenge into an energy asset.

Hybrid WtE Plants: Hybrid facilities that combine multiple WtE technologies to improve efficiency and handle diverse waste streams are emerging.

Digital Monitoring and IoT Integration: The integration of IoT and digital monitoring systems in WtE facilities is enabling efficient process control, predictive maintenance, and optimized energy recovery.

Focus on Carbon Reduction: Many WtE plants are adopting carbon capture and storage (CCS) to reduce emissions, supporting global environmental goals.

Investment in Research & Development: Governments and private companies are investing in R&D to improve WtE technologies and expand the range of waste types that can be converted into energy.

Key Players:

Suez

Veolia

Covanta Holding Corporation

Hitachi Zosen Inova AG

China Everbright International Limited

Wheelabrator Technologies Inc

Ramboll Group A/S

EDF

Allseas

Babcock & Wilcox Enterprises, Inc.

Xcel Energy Inc.

Read Complete Report Details of Waste to Energy Market: https://www.snsinsider.com/reports/waste-to-energy-market-2887

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us: Akash Anand — Head of Business Development & Strategy [email protected] Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

Manufacturing and Sustainability: Reducing Waste and Energy Consumption

In today’s rapidly evolving global landscape, manufacturing industries face a dual challenge: meeting growing consumer demands while addressing environmental sustainability concerns. As economies expand and consumer expectations evolve, the pressure on manufacturers to minimize waste and energy consumption, and adopt sustainable practices has never been greater. In this blog, we explore the critical importance of reducing waste and energy consumption in manufacturing, examine innovative approaches and technologies driving sustainability efforts, and highlight the benefits for both businesses and the environment.

The Imperative of Sustainability in Manufacturing

Manufacturing processes have historically been associated with significant environmental impacts, including resource depletion, pollution, and greenhouse gas emissions. As awareness of climate change and environmental degradation grows, stakeholders across industries are increasingly recognizing the urgent need to adopt sustainable practices. Sustainable manufacturing not only mitigates environmental harm but also enhances operational efficiency, reduces costs, and strengthens corporate social responsibility.

Reducing Waste in Manufacturing

Reduction in waste and energy consumption is a cornerstone of sustainable manufacturing practices. Manufacturing operations generate various types of waste, including raw material waste, energy waste, and by-products or emissions. By implementing waste reduction strategies, manufacturers can minimize their environmental footprint while improving resource efficiency and operational effectiveness.

1. Lean Manufacturing Principles:

Lean manufacturing principles focus on maximizing value and minimizing waste throughout the production process. Techniques such as value stream mapping, just-in-time inventory management, and continuous improvement (kaizen) help identify and eliminate inefficiencies, reduce overproduction, and optimize resource utilization.

For example, Toyota pioneered lean manufacturing principles, emphasizing waste reduction, efficient use of materials, and streamlined processes. This approach not only enhances productivity and quality but also reduces waste generation and environmental impact.

2. Circular Economy Practices:

Embracing circular economy principles involves designing products for longevity, reuse, remanufacturing, and recycling. Manufacturers can adopt closed-loop systems where materials and resources are continuously cycled back into production processes, minimizing waste generation and reducing dependence on virgin resources.

For instance, companies like Interface, a global flooring manufacturer, have implemented closed-loop recycling programs where old carpets are collected, recycled into new products, and reintroduced into the market. This circular approach not only reduces waste but also creates new revenue streams and enhances brand reputation.

3. Waste-to-Energy and Resource Recovery:

Waste-to-energy technologies convert waste materials into energy sources such as electricity, heat, or biofuels. This not only reduces waste disposal volumes but also generates renewable energy, contributing to energy security and sustainability goals.

Some manufacturing facilities integrate waste-to-energy systems to convert organic waste, biomass, or non-recyclable materials into usable energy. By capturing value from waste streams, manufacturers can achieve cost savings, reduce environmental impact, and contribute to a circular economy framework.

Energy Efficiency in Manufacturing

Energy consumption is another critical focus area for sustainable manufacturing. Manufacturing processes are energy-intensive, consuming significant amounts of electricity, fossil fuels, and other energy sources. Improving energy efficiency not only reduces operational costs but also lowers greenhouse gas emissions, enhances competitiveness, and strengthens energy security.

1. Energy Management Systems (EMS):

Energy management systems help manufacturers monitor, control, and optimize energy use across facilities. By implementing EMS, companies can identify energy-intensive processes, set energy reduction targets, and implement energy-saving measures such as equipment upgrades, lighting retrofits, and operational adjustments.

For example, Unilever has implemented EMS across its global manufacturing sites, leveraging data analytics and smart technologies to optimize waste and energy consumption, reduce carbon emissions, and achieve sustainability goals.

2. Renewable Energy Integration:

Transitioning to renewable energy sources such as solar, wind, hydroelectric, and biomass can significantly reduce manufacturing’s carbon footprint and dependence on fossil fuels. Many manufacturers are investing in onsite renewable energy generation or purchasing renewable energy credits (RECs) to support clean energy initiatives.

Companies like IKEA have committed to sourcing 100% renewable energy for their global operations, investing in solar panels, wind farms, and energy-efficient technologies to reduce carbon emissions and promote sustainable manufacturing practices.

3. Energy-Efficient Technologies and Processes:

Advancements in technology have enabled manufacturers to adopt energy-efficient equipment, processes, and automation systems. Technologies such as energy-efficient motors, LED lighting, advanced HVAC systems, and intelligent manufacturing systems optimize energy use, improve process efficiency, and reduce operational costs.

For instance, General Motors has implemented energy-efficient technologies and practices across its manufacturing facilities, achieving significant reductions in energy intensity and greenhouse gas emissions while enhancing production efficiency and sustainability performance.

Innovations Driving Sustainability in Manufacturing

Innovation plays a crucial role in driving sustainability in manufacturing. From technological advancements to collaborative initiatives, innovative approaches are transforming traditional manufacturing practices and paving the way for a more sustainable future.

1. Digitalization and Industry 4.0:

Industry 4.0 technologies, including IoT (Internet of Things), artificial intelligence (AI), big data analytics, and cloud computing, are revolutionizing manufacturing operations. These technologies enable real-time monitoring, predictive maintenance, and data-driven insights that optimize resource utilization, improve energy efficiency, and reduce waste generation.

For example, Bosch’s smart factory in Germany leverages IoT and AI to optimize production processes, minimize energy consumption, and enhance overall operational efficiency, demonstrating the transformative potential of digitalization in sustainable manufacturing.

2. Collaborative Supply Chain Initiatives:

Collaborative supply chain initiatives promote transparency, traceability, and sustainability across the entire value chain. Manufacturers partner with suppliers, customers, and stakeholders to implement ethical sourcing practices, reduce environmental impacts, and promote responsible consumption and production patterns.

Initiatives like the Sustainable Apparel Coalition (SAC) bring together global brands, retailers, and manufacturers to measure and improve sustainability performance throughout the apparel supply chain. By fostering collaboration and shared responsibility, these initiatives drive industry-wide change towards sustainable manufacturing practices.

3. Biomimicry and Sustainable Design:

Biomimicry principles draw inspiration from nature to design products, materials, and processes that are inherently sustainable and resource-efficient. By mimicking biological strategies and systems, manufacturers can reduce waste, improve product performance, and enhance environmental sustainability.

For instance, Nike’s Flyknit footwear incorporates biomimicry principles, using digital knitting technology to create lightweight, seamless shoes with minimal material waste. This innovative design approach not only reduces environmental impact but also meets consumer demand for sustainable products.

Benefits of Sustainable Manufacturing

The shift towards sustainable manufacturing offers numerous benefits for businesses, communities, and the environment:

– Cost Savings and Efficiency: Implementing a reduction in waste and energy consumption and energy efficiency measures reduces operational costs, improves resource utilization, and enhances profitability.

– Environmental Stewardship: Minimizing waste and energy consumption reduces environmental impact, conserves natural resources, and mitigates climate change.

– Competitive Advantage: Embracing sustainability enhances brand reputation, attracts environmentally-conscious consumers, and differentiates businesses in competitive markets.

– Regulatory Compliance: Adhering to environmental regulations and sustainability standards ensures compliance and reduces regulatory risks.

– Community Engagement: Sustainable manufacturing practices foster positive relationships with local communities, enhancing social license to operate and promoting shared value creation.

Conclusion

In conclusion, manufacturing industries play a pivotal role in driving economic growth and technological innovation globally. However, the environmental impacts associated with traditional manufacturing practices necessitate a shift towards sustainable manufacturing approaches that prioritize reduction in waste and energy consumption, energy efficiency, and responsible resource management.

By embracing lean manufacturing principles, circular economy practices, energy-efficient technologies, and innovative solutions, manufacturers can minimize their environmental footprint while enhancing operational efficiency, reducing costs, and promoting long-term sustainability. Collaborative efforts, technological advancements, and regulatory frameworks are key enablers in accelerating the transition toward sustainable manufacturing practices that benefit businesses, communities, and the planet alike.

Did you find this article helpful? Visit more of our blogs! Business Wolf Magazine

0 notes

Text

Heat Exchangers Market: Innovations and Key Players to Watch

The global heat exchangers market was valued at approximately USD 18.19 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2024 to 2030. This growth is driven by an increasing focus on efficient thermal management across a wide range of industries, including oil & gas, power generation, chemical & petrochemical, food & beverage, and HVAC & refrigeration. As industries strive for greater energy efficiency, heat exchangers are becoming integral to optimizing thermal processes, reducing energy consumption, and enhancing overall operational effectiveness.

A significant driver of growth in the market is the rising demand from the chemical industry. The chemical sector’s need for more efficient processes is leading to an increased focus on energy savings, improved heat transfer, and enhanced system efficiency, all of which are directly supported by the use of advanced heat exchangers. The petrochemical industry, in particular, often operates under conditions of high pressure and temperature, where the optimization of heat transfer is crucial to maintaining system performance and minimizing energy waste. These conditions create a strong demand for energy-efficient heat exchangers capable of handling such harsh environments while improving energy recovery and cost efficiency.

Additionally, technological advancements are playing a pivotal role in shaping the future of the heat exchangers market. For example, tube inserts have become a key innovation, improving the efficiency of heat exchangers by promoting better heat transfer. As the need for greater energy efficiency continues to grow, ongoing developments in heat exchanger design are addressing factors such as total lifecycle cost, compactness, durability, and overall energy performance. Manufacturers are constantly introducing new features that enhance energy savings, reduce environmental impact, and extend the operational lifespan of heat exchangers, which is expected to further drive the market’s growth over the coming years.

Gather more insights about the market drivers, restrains and growth of the Heat Exchanger Market

Regional Insights

Europe

Europe led the global heat exchangers market, accounting for 31.7% of the total revenue share in 2023. This dominant position is primarily driven by increasing investments in both public and private infrastructure across the region. The demand for heat exchangers is notably strong in the HVAC & refrigeration industry, which benefits from the growing infrastructure development. As Europe continues to focus on energy efficiency and sustainability, the need for heat exchangers that offer greater durability, enhanced efficiency, and reduced fouling is expected to rise. These features are critical for improving operational performance and reducing maintenance costs, further boosting market growth in the region. Additionally, industries across Europe are emphasizing eco-friendly solutions, which is likely to continue driving the adoption of high-performance heat exchangers.

North America

In North America, the U.S. and Canada are experiencing a surge in oil and gas exploration activities, which is expected to significantly drive the demand for heat exchangers, particularly in industries requiring robust thermal management solutions. The oil and gas sector is a major consumer of heat exchangers, as these systems play a vital role in managing high-pressure and high-temperature processes in refineries and extraction plants. Furthermore, increasing energy demand across various industrial and commercial sectors is expected to propel the power and energy sectors in North America. As the region continues to modernize its energy infrastructure and diversify its energy sources, the demand for efficient heat exchange technologies will continue to grow, providing further momentum for the market.

Asia Pacific

Asia Pacific is expected to experience the fastest growth in the global heat exchangers market, with a projected CAGR of 6.8% from 2024 to 2030. The region’s rapid industrialization is a key factor driving this expansion, particularly in emerging economies such as China and India. The growth of manufacturing, commercial, and industrial sectors is driving investments in various infrastructure projects, which in turn boosts the demand for heat exchangers. The region's expanding industrial base, along with increased demand for energy-efficient solutions, is expected to fuel the adoption of heat exchangers in industries such as power generation, chemical manufacturing, and HVAC systems.

China

China, as one of the largest economies in the Asia Pacific region, is expected to see significant growth in the heat exchangers market. The demand for heat exchangers in China is being driven by increasing investments in critical sectors such as chemical, petrochemical, and HVAC. With China’s large and rapidly growing population, coupled with the government’s efforts to enhance infrastructure and modernize power generation capabilities, the demand for heat exchangers in the power generation and HVAC & refrigeration industries is expected to rise substantially. The government’s focus on industrial and technological development is likely to contribute to the sustained growth of the market in China, supporting the need for advanced heat exchanger systems to improve energy efficiency, reduce operational costs, and meet environmental goals.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The global laser debonding equipment market size was estimated at USD 2,108.2 million in 2023 and is projected to grow at a CAGR of 6.4% from 2024 to 2030.

• The global geosynthetics market size was valued at USD 16.52 billion in 2024 and is projected to grow at a CAGR of 8.3% from 2025 to 2030.

Key Companies & Market Share Insights

The global heat exchangers market is highly competitive and is characterized by the presence of both multinational corporations and regional players. These companies are actively engaged in the design, manufacturing, and distribution of heat exchangers, with a focus on differentiating their products through innovation and enhanced performance. To gain a competitive edge, manufacturers are adopting a variety of growth strategies, including:

• New Product Development: Companies are continually innovating their product offerings to meet the evolving demands of industries. The development of energy-efficient, compact, and durable heat exchangers is key to staying ahead in the market.

• Diversification: Manufacturers are expanding their product portfolios to cater to various end-use industries, such as HVAC, oil & gas, chemical, and power generation. Diversification allows companies to tap into new markets and expand their customer base.

• Mergers & Acquisitions (M&A): Strategic M&A activities are helping companies strengthen their market presence, improve manufacturing capabilities, and enhance their technological expertise. Acquiring smaller players with niche technologies can also enable larger companies to expand their technological capabilities.

• Geographical Expansion: Expanding into emerging markets, especially in Asia Pacific and Latin America, is a key strategy for companies looking to capture a larger share of the market. As demand for heat exchangers grows in developing regions, companies are setting up production and distribution channels in these areas to improve market penetration.

Key Heat Exchangers Companies:

• Alfa Laval

• Danfoss

• Kelvion Holding GmbH

• Güntner Group GmbH

• Xylem Inc

• API Heat Transfer

• Mersen

• Hisaka Works, Ltd.

• Chart Industries, Inc

• Johnson Controls International

• HRS Heat Exchangers

• SPX FLOW, Inc.

• Funke Wärmeaustauscher Apparantebau GmbH

• Koch Heat Transfer Company

• Southern Heat Exchanger Corporation

Order a free sample PDF of the Heat Exchanger Market Intelligence Study, published by Grand View Research.

#Heat Exchangers Market#Heat Exchangers Market Analysis#Heat Exchangers Market Report#Heat Exchangers Market Regional Insights

0 notes

Text

Multi-functional organic fertilizer equipment lies in the development and innovation

The development and innovation of multi-functional organic fertilizer equipment is mainly reflected in the following aspects:

1. Comprehensive processing capacity: modern multi-functional organic fertilizer equipment can handle a variety of raw materials, such as crop waste, livestock manure, urban waste, etc. This combined utilization capability improves resource utilization and reduces waste.

2. Intelligent control: Organic fertilizer production line through the introduction of automation technology and intelligent control system, the equipment can achieve accurate production process monitoring, optimize production efficiency, reduce labor costs, and improve product consistency.

3. Energy saving and environmental protection design: The new equipment pays more attention to energy saving and environmental protection in design, such as through heat recovery, low emission processes, etc., to reduce the impact on the environment and meet the requirements of sustainable development.

4. Modular structure: Multi-functional equipment usually adopts modular design, easy to expand and upgrade. Users can flexibly adjust production scale and function configuration according to actual requirements.

5. Technological innovation: The introduction of advanced biological fermentation, microbial addition and other technologies to improve the quality and nutrient content of organic fertilizer, so that it has an advantage in the market competition.

6. User-friendly interface: The device is equipped with an intuitive and easy-to-use operation interface, which facilitates daily management and maintenance and improves user experience.

7. Multi-product output: In addition to the production of organic fertilizer, some equipment can also produce liquid fertilizer, compound fertilizer and other products at the same time to meet the needs of different markets.

Through these innovations, multi-functional organic fertilizer equipment not only improves production efficiency and product quality, but also promotes sustainable agricultural development and creates greater value for users.

0 notes

Text

South Korea Waste Heat Recovery System Market and Future Growth Insights 2024 - 2032

The waste heat recovery system (WHRS) market in South Korea is emerging as a critical component of the country’s energy strategy, aiming to enhance energy efficiency and reduce greenhouse gas emissions. As industries face increasing pressure to optimize resource use and meet environmental regulations, waste heat recovery technologies offer a viable solution. This article explores the dynamics of the South Korean waste heat recovery system market, including key drivers, challenges, market segmentation, regional insights, and future trends.

Understanding Waste Heat Recovery Systems

Waste heat recovery systems capture and utilize excess heat generated during industrial processes, converting it into useful energy. This process not only enhances energy efficiency but also contributes to significant cost savings and environmental benefits.

Importance of Waste Heat Recovery in South Korea

Economic Benefits

The WHRS market presents substantial economic advantages for South Korean industries. By recovering waste heat, companies can lower energy costs, improve productivity, and enhance competitiveness in the global market.

Environmental Impact

As South Korea seeks to achieve its carbon reduction targets, waste heat recovery systems play a vital role in minimizing emissions. These systems contribute to the transition towards a more sustainable and low-carbon economy.

Energy Security

With rising energy demands, improving energy efficiency through waste heat recovery can enhance South Korea's energy security, reducing reliance on imported fossil fuels and promoting a more resilient energy infrastructure.

Market Dynamics

Growth Drivers

Government Policies and Incentives

The South Korean government has implemented various policies and incentives to promote energy efficiency and sustainability. Initiatives such as the Energy Efficiency Resource Standard (EERS) encourage industries to adopt waste heat recovery technologies.

Rising Energy Costs

Increasing energy prices have compelled industries to seek cost-effective solutions. Waste heat recovery systems provide a compelling return on investment by reducing energy consumption and associated costs.

Technological Advancements

Ongoing innovations in waste heat recovery technologies, such as improved heat exchangers and advanced control systems, are enhancing system efficiency and effectiveness, driving market growth.

Challenges

High Initial Investment

The initial cost of implementing waste heat recovery systems can be significant, which may deter some businesses from making the investment. Financial incentives and subsidies are essential to encourage adoption.

Technical Complexity

Integrating waste heat recovery systems into existing industrial processes can be technically challenging. Companies may require specialized expertise to design and implement effective solutions.

Awareness and Knowledge Gaps

There remains a lack of awareness and understanding of the benefits and technologies associated with waste heat recovery among some industries, which can hinder market growth.

Market Segmentation

By Technology Type

Heat Exchangers

Heat exchangers are the most commonly used technology in waste heat recovery systems. They transfer heat from hot exhaust gases or liquids to a working fluid, converting waste heat into useful energy.

Organic Rankine Cycle (ORC)

The ORC technology converts low-temperature waste heat into electricity. This technology is particularly suitable for industrial processes that generate waste heat at lower temperatures.

Combined Heat and Power (CHP)

CHP systems simultaneously generate electricity and useful heat from the same energy source, maximizing the efficiency of waste heat recovery in industrial applications.

By End-Use Industry

Manufacturing

The manufacturing sector is a major adopter of waste heat recovery systems, particularly in industries such as steel, cement, and chemical manufacturing, where significant heat is generated.

Power Generation

In the power generation sector, waste heat recovery systems can enhance the efficiency of thermal power plants by capturing excess heat and converting it into electricity.

Oil and Gas

The oil and gas industry can benefit from waste heat recovery by improving efficiency in refining processes and reducing energy consumption.

Regional Insights

Seoul and Gyeonggi Province

The capital region, including Seoul and Gyeonggi Province, is a hub for industrial activity and innovation. Many companies in this area are increasingly adopting waste heat recovery systems to enhance energy efficiency.

Busan and Ulsan

As significant industrial centers, Busan and Ulsan have seen growing interest in waste heat recovery technologies, particularly in the shipbuilding and petrochemical sectors.

Future Trends

Increasing Focus on Sustainability

As South Korea aims for carbon neutrality by 2050, the emphasis on sustainability will drive the adoption of waste heat recovery systems. Companies will be increasingly motivated to implement energy-efficient technologies to meet regulatory requirements.

Digitalization and Smart Technologies

The integration of IoT and smart technologies into waste heat recovery systems will enhance monitoring, control, and optimization, leading to improved efficiency and performance.

Collaboration and Innovation

Increased collaboration between industry stakeholders, research institutions, and government agencies will foster innovation in waste heat recovery technologies, promoting advancements that meet evolving market needs.

Conclusion

The South Korea waste heat recovery system market is positioned for substantial growth as industries seek to enhance energy efficiency, reduce costs, and comply with environmental regulations. Supported by government initiatives and technological advancements, the adoption of waste heat recovery systems is set to increase across various sectors. By focusing on sustainability and innovation, South Korea can harness the potential of waste heat recovery to create a more energy-efficient and environmentally friendly economy, reinforcing its commitment to achieving carbon neutrality and energy security.

More Trending Reports

Pipeline & Process Services Market Growth

Solar Rooftop Market Growth

Turboexpander Market Growth

Cryogenic Valve Market Growth

0 notes