#Warehouse Storage Racks Manufacturers

Explore tagged Tumblr posts

Text

https://www.heavydutyrackmanufacturer.com/warehouse-storage-racks-manufacturers.php

0 notes

Text

Multi - Level Module Racks - Storage Rack Manufacturer

Suvidha Storage System, a leading storage rack manufacturer in India, specializes in Multi-Level Module Racks designed for efficient space utilization across industries. Our high-quality racks are built for durability, providing optimal organization and storage in warehouses, factories, and commercial spaces. With customizable multi-level solutions, Suvidha ensures superior performance and flexibility to meet your storage needs. Explore our offerings at www.suvidhass.com

#suvidha storage system#storage rack#storage rack manufacturer#warehouse rack manufacturer#storage rack manufacturer in india#warehouse storage rack#industrial storage rack#rack manufacturer

0 notes

Text

Gravity Flow Rack - Storage Rack Manufacturer

Streamline your warehouse operations with Suvidha Storage System's Gravity Flow Rack. Our racks feature advanced components like rollers, braking areas, and display trays to facilitate easy movement of goods and improve inventory control. Durable and customizable, our racks fit the unique needs of your business. Discover more on our website - Suvidha Storage System.

#Gravity flow rack#Warehouse racking system#First-in first-out inventory management#Industrial storage solutions#Efficient storage rack system#Storage rack manufacturer in India#Customized racking solutions#Gravity-based racking#FMCG storage racks#Pharmaceutical racking solutions#Retail storage racks

0 notes

Text

Cable Tray Rack - Storage Rack Manufacturer

Suvidha Storage System provides high-quality Cable Tray Racks for efficient cable management and durability. Our racks are designed to keep your cables organized and accessible. As the best storage racks manufacturer in India, Suvidha Storage System ensures superior products and service. Discover more at www.suvidhass.com.

#cable tray#cable tray rack#cable tray rack manufacturer#storage rack#storage rack manufacturer#warehouse storage rack#warehouse rack manufacturer#industrial storage rack#storage rack manufacturer in india#rack manufacturer#suvidha storage system#suvidhass

0 notes

Text

Designing for Space Mobile Compactor Storage System Manufacturers

Space efficiency is at the core of modern mobile compactor design. Mobile Compactor Storage System Manufacturers are dedicated to creating solutions that optimize every inch of available space. By employing advanced engineering principles and innovative storage solutions, these manufacturers ensure that their systems can handle large volumes of items in a compact footprint. Key elements such as adjustable shelving, robust track systems, and modular design are crucial for achieving optimal space utilization.

Mobile Compactor Design: What Sets the Best Manufacturers Apart

Leading Mobile Compactor Manufacturers distinguish themselves through innovation and quality. They incorporate cutting-edge technology and advanced materials to create storage systems that are both efficient and durable. Features like electronic control systems, automated movement mechanisms, and smart inventory management are examples of how these manufacturers push the boundaries of traditional storage solutions. By staying at the forefront of technological advancements, they offer superior products that meet diverse and demanding storage needs.

Design Process Behind Effective Mobile Compactors

The journey from concept to reality in mobile compactor design involves several critical stages. Mobile Compactor Storage System Manufacturers begin with detailed needs assessments and feasibility studies to understand the specific requirements of their clients. This is followed by conceptual design, prototyping, and rigorous testing to ensure that the final product meets all performance and safety standards. Collaboration with clients throughout the process ensures that the end result is a tailored solution that effectively addresses their space-saving needs.

Maximize Space Utilization in Mobile Compactors

Effective mobile compactor design incorporates several key elements to maximize space utilization. Adjustable shelves and racks allow for flexible storage arrangements, while high-density configurations ensure that more items can be stored in less space. The use of efficient track systems and compact, movable units enables easy access to stored items without sacrificing space. By integrating these design elements, Mobile Compactor Manufacturers can deliver solutions that provide significant space savings and improve overall storage efficiency.

The Art of Mobile Compactor Design

In the realm of mobile compactor design, balancing aesthetics with functionality is an art form. Leading manufacturers understand that while efficiency is paramount, the visual appeal of the storage system also plays a role in its overall effectiveness. Sleek, modern designs that complement the surrounding environment and intuitive user interfaces enhance the user experience. By harmonizing form and function, Mobile Compactor Storage System Manufacturers create products that are not only practical but also visually appealing.

Tailoring Mobile Compactors to Unique Space Needs

One of the key advantages of working with Mobile Compactor Manufacturers is their ability to offer customization and flexibility. Tailored solutions are essential for addressing the unique requirements of different spaces and industries. Whether it’s adjusting the dimensions of the compactor, incorporating specialized shelving, or integrating custom features, manufacturers can design systems that perfectly fit the client’s specific needs. This level of customization ensures that the storage solution is both functional and efficient.

The Role of Technology in Modern Mobile Compactor Design

Technology plays a pivotal role in the evolution of mobile compactor design. Modern Mobile Compactor Storage System Manufacturers leverage advancements such as automated controls, real-time tracking, and integration with warehouse management systems to enhance functionality. These technological innovations not only improve the efficiency of the storage system but also provide valuable data and insights for better inventory management. The incorporation of smart technology is a key factor in the continued advancement of mobile compactor solutions.

Successful Space-Saving Designs from Leading Manufacturers

Examining case studies from successful mobile compactor projects highlights the practical benefits of advanced design and technology. For instance, a leading Mobile Compactor Manufacturer might showcase a project where a customized compactor system significantly increased storage capacity in a constrained space, leading to enhanced operational efficiency. These real-world examples illustrate how innovative design and engineering solutions can effectively address complex storage challenges.

Mobile Compactor Design: Eco-Friendly Innovations

Sustainability is increasingly becoming a focal point in mobile compactor design. Many Mobile Compactor Storage System Manufacturers are adopting eco-friendly practices, such as using recycled materials, implementing energy-efficient components, and designing systems that minimize waste. These innovations not only contribute to environmental conservation but also help companies meet their sustainability goals. By integrating green practices into their designs, manufacturers are making a positive impact on both the environment and the industry.

Future Trends in Mobile Compactor Design

The future of mobile compactor design is poised to bring even greater advancements in space efficiency. Emerging trends include the integration of artificial intelligence for predictive maintenance, further automation to streamline operations, and the development of more versatile and modular systems. As technology continues to evolve, Mobile Compactor Manufacturers will play a crucial role in driving these innovations, shaping the future of space-efficient storage solutions.

#Industrial Slotted Angle Storage Rack Manufacturers#Mobile Compactor Storage System Manufacturers#Warehouse Pallet Storage Rack Manufacturers#Slotted Angle Storage Rack Manufacturers#Mobile Compactor Manufacturers

0 notes

Text

Warehouse Racks Factory:SHELVING RACKS MANUFACTURERS-INDOSTORAGETECHNOLOGIES

MORE INFORMATION:

+91 97395 49891

#storage solutions#manufacturer#ideas#storage#racks#warehouse#shelving#shelving solutions#book shelves#shelving racks#shelvingracking#BINSTORAGE#LONGSPANRACKS#MEDIUM DUTYRACKS

0 notes

Text

Suvidha Storage steel engineered for wide loads, heavy loads and clear spans, long span racking is designed to meet applications that exceed the capabilities of standard pallet racking. … The result is an ultra-resilient racking system that can achieve up to 40′ spans without the loss of load capacity.

Website-https://suvidhass.com

Blaze

0 notes

#storage box#cable tray sizes#cold storage#pallet rack manufacturer#storage rack#warehouse storage#warehou

0 notes

Text

#Pallet Racks in Delhi#Warehouse Pallet Racks in Delhi#Pallet Racks Manufacturers in Delhi#Warehouse Pallet Racks Manufacturers in Delhi#Pallet Racks Suppliers in Delhi#Warehouse Pallet Racks Suppliers in Delhi#Pallet Racks Exporters in Delhi#Warehouse Pallet Racks Exporters in Delhi#Plastic Pallets in Delhi#Heavy Duty Plastic Pallets in Delhi#Plastic Pallets Manufacturers in Delhi#Heavy Duty Plastic Pallets Manufacturers in Delhi#Plastic Pallets Suppliers in Delhi#Heavy Duty Plastic Pallets Suppliers in Delhi#Plastic Pallets Exporters in Delhi#Heavy Duty Plastic Pallets Exporters in Delhi#Storage Rack in Delhi#Metal Storage Rack in Delhi#Storage Rack Manufacturers in Delhi#Metal Storage Rack Manufacturers in Delhi#Storage Rack Suppliers in Delhi#Metal Storage Rack Suppliers in Delhi#Storage Rack Exporters in Delhi#Metal Storage Rack Exporters in Delhi

0 notes

Text

5 Signs Your Supermarket Racks Need an Upgrade

If you're a supermarket owner or manager, it's important to be able to identify the signs that your supermarket racks need an upgrade. Not only will new shelving make your supermarket look more modern and inviting, but it can also improve efficiency, boost sales, and reduce costs.

Star Interiors Private Limited, one of the best Supermarket Rack Manufacturers in Delhi, is here with this blog, we will highlight some points that give you a hint that it’s time for change. Let’s discuss five signs that your supermarket racks need an upgrade.

Signs That Your Supermarket Rack Needs Upgrade:

Your Racks Are Damaged: This is the most obvious sign that your racks need to be replaced. If your racks are bent, rusted, or cracked, they are a safety hazard. They can also damage your products and make your supermarket look unprofessional.

Your Racks Are Not Adjustable: If your display racks are not adjustable, you're wasting space. You should be able to adjust the height and width of your shelves to accommodate different products. This will allow you to maximize your storage capacity and make your supermarket more efficient.

Your Racks Are Not The Right Size: If your racks are too small or too large for your products, they're not going to function properly. Products will be crammed together, making it difficult for customers to shop. Or, products will be spread out too thin, making your supermarket look empty.

Your Racks Are Not Energy-Efficient: Older hypermarket racks are often not very energy-efficient. They may use outdated lighting systems or refrigeration units. This can waste energy and drive up your costs.

Your Customers Are Complaining: If your customers are complaining about your racks, it's time to listen up. They may be complaining that the racks are difficult to navigate, that the products are hard to reach, or that the supermarket looks outdated.

Our Range of Racking Systems

If you're experiencing any of these signs, it's time to consider upgrading your supermarket racks. We, one of the foremost Display Rack Manufacturers in Delhi, can help you choose the right racks for your needs and budget. We offer a wide variety of shelving and racking solutions, including:

Gondola Rack

Departmental Rack

Retail Rack

Garment Rack

Kirana Store Rack

Some Other Factors To Consider:

In addition to the five signs listed above, here are a few other things to consider when deciding whether or not to upgrade your supermarket racks:

Age of Your Racks: If your racks are more than 10 years old, they may be outdated and inefficient.

Condition of Your Racks: If your retail racks are damaged or in poor repair, they need to be replaced.

Your Budget: Upgrading your supermarket racks can be a significant investment. However, the long-term savings in terms of increased efficiency and sales can make it worthwhile.

Buy Hypermarket Rack in Delhi From Us!

These are some key points, if you find them replace your supermarket display rack at once to prevent any misshapes. If thinking about where to get the best, we, one of the trusted Departmental Display Rack Manufacturers in India, offer a wide variety of shelving and racking solutions, as well as a variety of services, including design and layout, installation, and maintenance.

Contact us today for a free consultation.

#rack#racks#business#Supermarket Rack Manufacturers#Supermarket Display Rack Manufacturers#Departmental Store Rack Manufacturers#Retail Store Rack Manufacturers#Retail Display Rack Manufacturers#Metal Display Rack Manufacturers#Heavy Duty Rack Manufacturers#Warehouse Rack Manufacturers#Slotted Angle Rack Manufacturers#Departmental Display Rack Manufacturer#Departmental Grocery Rack Manufacturers#Departmental Wall Rack Manufacturers#Supermarket Storage Rack Manufacturers

1 note

·

View note

Text

Rashmi Racks provide best Pallet racks in pune, warehouse pallet racks in pune, steel pallet racking in pune, industrial pallet racking systems in pune, industrial racks for warehouse in pune at best cost. It is the best pallet racking Suppliers Company in pune, Mumbai, Nashik, Ahmadnagar, Gujarat, Karnataka, Bangalore, and Delhi India.

#Pallet racks in pune#warehouse pallet racks in pune#steel pallet racking in pune#industrial pallet racking systems in pune#industrial racks for warehouse in pune#Pallet Racking#Pallet Racking System#Pallet racks manufacturer#Pallet racks supplier#Pallet racking system#Heavy Duty Pallet racks#Heavy Duty Pallet racks manufacturer & supplier#Industrial Racks for warehouse#Industrial pallet racking system#Steel Pallet Racking#warehouse storage racks#warehouse pallet racks#Pallet racks manufacturer & supplier in pune#Pallet racks manufacturer & supplier in Mumbai#Pallet racks manufacturer & supplier in Nashik#Pallet racks manufacturer & supplier in Gujrat#Pallet racks manufacturer & supplier in Delhi#Pallet racks manufacturer & supplier in Karnataka#Pallet racks manufacturer & supplier in Indore

0 notes

Text

Innovations in Warehouse Storage Rack Manufacturing

Introduction

The landscape of logistics and supply chain management has undergone a paradigm shift in recent years, with an increasing emphasis on efficiency, space utilization, and automation. At the heart of this transformation lies the pivotal role played by warehouse storage racks. These structures, often overlooked but indispensable, form the backbone of organized storage systems in warehouses. As the demand for optimized storage solutions continues to rise, warehouse storage rack manufacturers are stepping up their game, introducing innovations that redefine the way goods are stored, retrieved, and managed in large-scale distribution centers.

Dynamic Designs for Versatile Storage:

Traditional storage racks were often rigid in their design and functionality. However, contemporary warehouse storage rack manufacturers are introducing dynamic and versatile designs to accommodate a wide range of goods. Adjustable shelving systems, modular racks, and customizable configurations enable warehouses to adapt to the diverse needs of different industries. This flexibility is crucial in an era where e-commerce, retail, and manufacturing requirements can vary significantly.

Material Advancements for Durability and Sustainability:

The choice of materials for warehouse storage racks is evolving to meet the demands of durability and sustainability. While steel remains a popular choice for its strength, manufacturers are exploring advanced alloys and composite materials that offer comparable strength with reduced weight. This not only contributes to the durability of the racks but also supports sustainability efforts by minimizing material usage and transportation costs.

Integration of Automation and Robotics:

Automation has become a buzzword in the logistics industry, and warehouse storage rack manufacturers are incorporating automated systems to enhance efficiency. Automated guided vehicles (AGVs) and robotic arms are designed to work seamlessly with modern storage racks, streamlining the process of moving goods within the warehouse. This integration not only speeds up operations but also reduces the risk of human error, leading to more accurate inventory management.

Smart Warehousing with IoT Technology:

The Internet of Things (IoT) is making significant inroads into the realm of warehouse management. Warehouse storage racks equipped with IoT sensors provide real-time data on inventory levels, temperature, and even the condition of goods. This data-driven approach allows for better decision-making, preventive maintenance, and overall optimization of warehouse operations. Manufacturers are incorporating IoT technology into their rack designs to provide customers with intelligent storage solutions.

Vertical Space Utilization for Maximum Efficiency:

As warehouse space becomes more expensive, the emphasis on vertical space utilization is growing. Manufacturers are developing high-density storage solutions that capitalize on vertical space, such as multi-tiered racks and automated vertical retrieval systems. By efficiently using both horizontal and vertical dimensions, warehouses can maximize their storage capacity without the need for extensive expansions.

Customization for Industry-Specific Requirements:

Recognizing that different industries have unique storage needs, warehouse storage rack manufacturers are offering customization options. Whether it's the automotive sector requiring racks for parts storage or the pharmaceutical industry needing controlled environment storage, manufacturers are tailoring their designs to meet industry-specific requirements. This shift towards customization ensures that warehouse storage solutions are not one-size-fits-all but are precisely engineered for the demands of each sector.

Environmental Considerations:

In an era where environmental sustainability is a key concern, warehouse and storage rack manufacturers are increasingly focusing on eco-friendly solutions. This includes using recyclable materials, optimizing designs for energy efficiency, and implementing green manufacturing processes. By aligning with sustainable practices, manufacturers are not only contributing to environmental conservation but also appealing to businesses with a commitment to corporate social responsibility.

Conclusion:

The evolution of warehouse storage rack manufacturing is indicative of the broader transformations taking place in the logistics and supply chain industry. As warehouses become more sophisticated and demand for efficient storage solutions rises, manufacturers are rising to the challenge with innovative designs, advanced materials, and smart technologies. The result is a landscape where warehouses can maximize their space, streamline operations, and contribute to sustainability goals. The future of warehouse storage rack manufacturing promises to be exciting, as it continues to shape the way goods are stored and distributed across the globe.

0 notes

Text

Mezzanine Flooring System - Storage Rack Manufacturer

Suvidha Storage System is a premier manufacturer of mezzanine flooring systems in India, providing high-quality, space-efficient solutions for businesses. Our durable and customizable mezzanine floors maximize vertical space, allowing you to expand without relocating. Trusted for top-quality materials and precision engineering, we help optimize your storage areas. Discover our innovative mezzanine flooring systems at www.suvidhass.com

#storage rack#storage rack manufacturer in india#suvidha storage system#rack manufacturer#storage rack manufacturer#industrial storage rack#warehouse rack manufacturer#warehouse storage rack

0 notes

Text

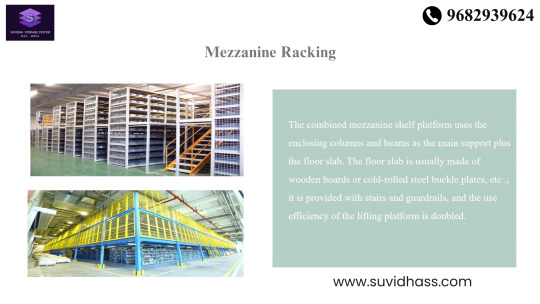

Mezzanine Racking | Efficient Storage Solutions - Suvidha Storage System | Premier Rack Manufacturer

Suvidha Storage System's Mezzanine Racking provides a practical and efficient solution for expanding storage capacity. As a top storage rack manufacturer in India, we are dedicated to delivering quality and innovation. Visit us at suvidhass.com for more information.

#suvidha storage system#High-Density Storage#Efficient Storage Solutions#Double Decker Mezzanine#Custom Racking Solutions#Top Storage Rack Manufacturer#Industrial Storage Rack#Warehouse Storage Rack#Storage Rack System#Heavy Duty Storage Rack#Rack Manufacturer

0 notes

Text

#pallet rack wholesalers#pallet rack manufacturers#Storage Rack in Delhi#Pallet Storage Rack in Delhi#Storage Racks in Delhi#Storage Rack Manufacturers in Delhi#Pallet Storage Rack Manufacturers in Delhi#Storage Racks Manufacturers in Delhi#Storage Rack Suppliers in Delhi#Pallet Storage Rack Suppliers in Delhi#Storage Rack Wholesalers in Delhi#Pallet Storage Rack Wholesalers in Delhi#Pallet Racks in Delhi#Warehouse Pallet Racks in Delhi#Pallet Rack in Delhi#Pallet Racks Manufacturers in Delhi#Warehouse Pallet Racks Manufacturers in Delhi#Pallet Rack Manufacturers in Delhi#Pallet Racks Suppliers in Delhi#Warehouse Pallet Racks Suppliers in Delhi#Pallet Racks Wholesalers in Delhi#Warehouse Pallet Racks Wholesalers in Delhi

0 notes

Text

Designing the Realm of Warehouse Rack Manufacturers

In today's fast-paced world of logistics and supply chain management, the efficiency of warehouse operations can make or break a business. At the heart of these operations lies an often-overlooked component: warehouse racking systems. For Warehouse Rack Manufacturers and Heavy Duty Rack Manufacturers, the challenge is to design systems that maximize space, ensure safety, and enhance productivity. In this blog, we'll explore the critical aspects of designing warehouse racks and how manufacturers are innovating to meet the ever-evolving needs of the industry.

Understanding the Basics of Warehouse Racking

Warehouse racking is a storage system designed to optimize the storage of materials in warehouses. The primary goal is to use vertical space efficiently, allowing for more goods to be stored in a given area. This is crucial for businesses that need to maximize their storage capacity without expanding their physical footprint.

Key Components of Warehouse Racking Systems

Upright Frames: These are the vertical structures that support the load. They must be robust and designed to withstand the weight of stored goods.

Beams: Horizontal bars that connect the upright frames. They provide the shelving on which goods are stored.

Decking: Materials placed on top of the beams to create a shelf. Common types include wire decking, wood, or metal panels.

Accessories: Components like safety bars, guards, and labels that enhance the functionality and safety of the racking system.

Innovations by Warehouse Rack Manufacturers

To meet the diverse needs of modern warehouses, Warehouse Rack Manufacturers are continuously innovating. Some of the latest trends in racking system design include:

1. Adjustable Racking Systems

Flexibility is key in today's dynamic business environment. Adjustable racking systems allow warehouses to reconfigure their storage layout quickly and efficiently, accommodating changes in inventory size and type.

2. High-Density Storage Solutions

To maximize space utilization, manufacturers are developing high-density storage options like mobile racking and drive-in racking. These systems significantly increase storage capacity by minimizing aisles and optimizing the use of available space.

3. Automation and Smart Technology

The integration of automation and smart technology is transforming warehouse operations. Automated racking systems, coupled with robotics and AI, enable faster retrieval and storage of goods, reducing human error and increasing efficiency.

4. Sustainable Materials and Practices

With a growing emphasis on sustainability, manufacturers are using eco-friendly materials and practices in their designs. This includes using recycled materials, designing systems for easy disassembly and recycling, and optimizing production processes to reduce waste.

Challenges Faced by Heavy Duty Rack Manufacturers

For Heavy Duty Rack Manufacturers, the stakes are even higher. These systems must not only be efficient but also capable of supporting significantly heavier loads. The challenges in designing heavy-duty racking include:

1. Structural Integrity and Safety

Ensuring the structural integrity of heavy-duty racks is paramount. Manufacturers must adhere to strict industry standards and conduct rigorous testing to guarantee safety and durability.

2. Customization for Diverse Industries

Heavy-duty racking systems must be tailored to meet the specific needs of various industries, from automotive to aerospace. This requires a deep understanding of industry-specific requirements and challenges.

3. Cost-Effectiveness

Balancing the need for high-quality, durable materials with cost-effectiveness is a constant challenge. Manufacturers must innovate to provide cost-efficient solutions without compromising on quality.

The Future of Warehouse Racking

The future of warehouse racking looks promising, with technological advancements driving new possibilities. As e-commerce continues to grow and consumer expectations rise, the demand for efficient and adaptable racking systems will only increase. Warehouse Rack Manufacturers and heavy duty rack manufacturers are at the forefront of this evolution, pioneering solutions that will shape the future of warehouse management.

In conclusion, the realm of warehouse rack manufacturing is a dynamic and challenging field. By focusing on innovation, safety, and sustainability, manufacturers are not only meeting the current needs of the industry but also paving the way for the future of warehousing. As businesses continue to seek ways to optimize their operations, the role of well-designed racking systems will remain crucial in achieving efficiency and success.

1 note

·

View note

Text

Mezzanine Floor Manufacturers:Multi-Level Metal Storage Steel Mezzanine floor manufacturers

More details : [email protected]

+91 97395 49891

#storage solutions#manufacturer#ideas#storage#racks#warehouse#heavy duty racks#mezzanine#mezzaninefloor#upstairs#retailstore#shop small#shop stuff#online shops offer#shopsmart#exteriors#restaurants#homeorganization

0 notes