#Warehouse Automation Market Trends

Explore tagged Tumblr posts

Text

As per Business Intelligence Insights (BII) study, the global Warehouse Automation Market attained revenue growth of USD 15.10 billion in 2021 and it is projected to reach around USD 44.29 billion by 2030, growing at a 14.40% CAGR.

#Warehouse Automation Market#Warehouse Automation Market Trends#Warehouse Automation Market Share#Warehouse Automation Market Size#Warehouse Automation Market Analysis#Warehouse Automation Market Demand#Warehouse Automation Market Growth 2023#Warehouse Automation Market Industry

0 notes

Text

Decoding KSA's Warehousing Automation: Demand and Supply Insights: Ken Research

Saudi Arabia (KSA) drives warehousing automation as a regional logistics epicenter, fueled by a consolidated market and booming e-commerce demand.

Storyline

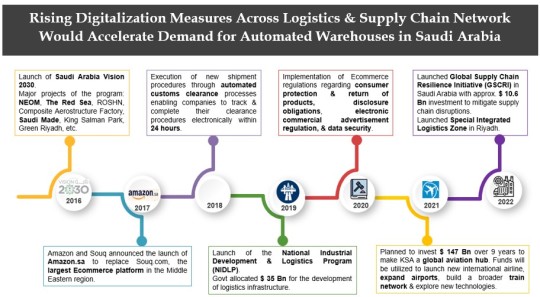

Saudi Arabia's infrastructure initiatives drive demand for automated warehouses.

Growing demand for cold storage services presents growth opportunities.

Focus on e-commerce and retail fuels demand for automation.

As per Ken Research estimates, Warehousing and logistics industry poised to undergo a transformative automation phase.

Existence of a consolidated market scenario amongst the growing warehousing automation industry globally, KSA’s government has made the push to turn the nation into a Regional Logistics Epicenter necessitating automation as the key parameter for a Regional Logistics Chain, enabling faster growth of KSA’s warehouse automation industry. On the other hand, an unprecedented surge in E-commerce market has balanced the demand side of the market. In this piece, we uncover the industry landscape, demand & supply side of KSA’s Warehousing automation industry.

1.Supply side boost: Government Plans and E-commerce Fuel Automated Warehouses in KSA.

To learn more about this report Download A Free Sample Report

Saudi Arabia's ambitious government infrastructure plans, including initiatives like NEOM, The Red Sea, ROSHN, and the National Industrial Development & Logistics Program (NIDLP), have created a solid foundation for the logistics network in the country. These developments, supported by a $35 Bn allocation for logistics infrastructure, have led to an increased demand for automated warehouses. (~$ 100 Bn in its transportation & logistics infrastructure) The focus on efficiency, speed, and accuracy in the supply chain has made the implementation of automated warehouse solutions essential. This growing demand is driven by the booming e-commerce industry's evolving requirements, the need to streamline operations, and ensure timely deliveries.

2.Demand Surge: Saudi Arabia's Rise as a Transshipment Hub Spurs Demand for Affordable Modern Warehouse Solutions.

Visit This Link: - Request For Custom Report

The rising demand for cold storage services in Saudi Arabia, primarily driven by the food and beverage (F&B) and pharmaceutical sectors, is leading to significant growth opportunities. To cater to this demand, companies are adopting asset-light models and relying on third-party logistics (3PL) providers who offer specialized cold storage solutions, given that only 5% of the warehouses are currently automated. These providers leverage innovative technologies to ensure efficient operations and maintain the quality and integrity of stored products. As a result, companies are strategically expanding their warehouses and investing in cutting-edge solutions. This transformative phase is focused on meeting the evolving needs of the F&B and pharmaceutical sectors while gaining a larger market share.

3.“A balance to be the solution:” The demand and market share of e-commerce and retail is expected to increase in the future due to increasing focus towards reducing the overall sales cycle duration.

Request For 30 Minutes Analyst Call

Experience the transformative power of automation as it reshapes the warehousing and logistics landscape, propelling the retail and e-commerce industry into a new era. In this fast-paced world, e-commerce automation software becomes the key driver, enabling businesses to focus on their core strengths and strategic goals. The adoption of automated warehouse management systems empowers 3PL companies to achieve unprecedented efficiency, accuracy, and real-time inventory visibility, while reducing costs and enhancing customer service. As per our estimates at Ken Research, the market will grow at a steady pace undergoing transformative warehouse automation process.

#KSA Warehouse Automation Market#KSA Supply Chain Automation Market#KSA Inventory Automation Market#Trends KSA Warehouse Automation Market#KSA Warehouse Automation Market Opportunities#Challenges KSA Warehouse Automation Market#Number of Warehouses in KSA#Number of Logistics Service Providers in KSA#Competition KSA Warehouse Automation Markets#Schaffer Warehouse Automation KSA Market Share#Oracle KSA Market Share#Swisslog KSA Market Revenue#CIN7 KSA Annual Revenue#Grey Orange KSA Market Share#Ancra KSA Market Revenue#Fizyr KSA Market Share#Caja KSA Annual growth#Investment KSA Warehouse Automation Market#Leading Companies KSA Warehouse Automation Market#Emerging Companies KSA Warehouse Automation Market#Major Players KSA Warehouse Automation Market#KSA AMR Market#Handplus Robotics KSA Market Share#Fetchr KSA Market Revenue#Flytbase KSA Market#Warehouse Automations Lab KSA Market#Saco KSA Market Share#Actiw KSA Market Revenue#Airmap KSA Market Share#Welcome Bank KSA Market Share

0 notes

Text

Guide for Importers on Manufacturing Control

Efficient Manufacturing Control in China

1. Understand the Chinese Manufacturing Environment:

Diverse Ecosystem: China offers a vast range of manufacturers, from small workshops to large factories. This variety is beneficial but also poses challenges in ensuring consistent quality.

IP Concerns: Despite improvements, IP protection in China can be inconsistent, requiring robust measures to safeguard your innovations.

Regulatory Landscape: China’s complex and changing regulations make compliance crucial to avoid fines and reputational damage.

Quality Control: While quality has improved, some sectors still prioritize quantity over quality. Rigorous quality protocols are essential.

Labor & Costs: Labor costs are rising, pushing manufacturers toward automation. Infrastructure is robust, but supply chains can be disrupted by natural disasters or policy changes.

Government Policies: China’s government heavily influences manufacturing through policies and incentives, which can affect costs and market access.

2. Build a Strong Foundation:

Supplier Selection: Choose reliable suppliers through thorough due diligence, including factory visits and financial checks.

Clear Communication: Provide detailed specifications and maintain open communication to avoid misunderstandings.

Quality Management: Implement a Quality Management System (QMS) and conduct regular audits to ensure consistent product quality.

Strong Relationships: Develop long-term partnerships with suppliers to build trust and collaboration.

3. Implement Effective Control Strategies:

QA & QC: Establish a robust QA/QC framework to ensure consistent product quality.

Supplier Development: Invest in your suppliers’ capabilities to improve quality and efficiency.

Risk Management: Prepare for disruptions with backup plans and diversified suppliers.

Contractual Coverage: Clearly define product specifications and include IP protections in contracts.

Third-Party Verification: Use third-party inspections to ensure compliance and quality.

4. Manage Logistics & Supply Chain:

Transportation: Choose the best transport mode and routes to minimize costs and delays.

Warehousing & Inventory: Optimize warehouse locations and use management systems to track inventory.

Customs & Documentation: Ensure compliance with customs regulations and prepare accurate documentation.

Supply Chain Visibility: Use technology to monitor shipments and collaborate with suppliers.

Risk Assessment: Develop contingency plans for disruptions like natural disasters or strikes.

5. Overcome Common Challenges:

Language & Cultural Barriers: Hire experts to bridge gaps in communication and cultural understanding.

IP Protection: Secure your IP with patents, trademarks, and NDAs; monitor for infringements.

Regulatory Compliance: Stay updated on regulations and partner with local experts for compliance.

Supply Chain Disruptions: Diversify suppliers, maintain sufficient inventory, and use smart tools for monitoring.

6. Continuous Improvement:

Use data analytics to track trends and improve processes.

Regularly evaluate supplier performance and invest in employee training.

Embrace technology to enhance communication and efficiency.

7. Build a Culture of Quality:

Encourage employees to propose improvements.

Reward contributions to quality enhancement.

Focus on exceeding customer expectations.

Conclusion: Effective manufacturing control in China requires ongoing effort, attention, and adaptation. Invest in strong practices to improve product quality, reduce costs, protect your brand, and optimize your supply chain.

2 notes

·

View notes

Text

Enterprises Explore These Advanced Analytics Use Cases

Businesses want to use data-driven strategies, and advanced analytics solutions optimized for enterprise use cases make this possible. Analytical technology has come a long way, with new capabilities ranging from descriptive text analysis to big data. This post will describe different use cases for advanced enterprise analytics.

What is Advanced Enterprise Analytics?

Advanced enterprise analytics includes scalable statistical modeling tools that utilize multiple computing technologies to help multinational corporations extract insights from vast datasets. Professional data analytics services offer enterprises industry-relevant advanced analytics solutions.

Modern descriptive and diagnostic analytics can revolutionize how companies leverage their historical performance intelligence. Likewise, predictive and prescriptive analytics allow enterprises to prepare for future challenges.

Conventional analysis methods had a limited scope and prioritized structured data processing. However, many advanced analytics examples quickly identify valuable trends in unstructured datasets. Therefore, global business firms can use advanced analytics solutions to process qualitative consumer reviews and brand-related social media coverage.

Use Cases of Advanced Enterprise Analytics

1| Big Data Analytics

Modern analytical technologies have access to the latest hardware developments in cloud computing virtualization. Besides, data lakes or warehouses have become more common, increasing the capabilities of corporations to gather data from multiple sources.

Big data is a constantly increasing data volume containing mixed data types. It can comprise audio, video, images, and unique file formats. This dynamic makes it difficult for conventional data analytics services to extract insights for enterprise use cases, highlighting the importance of advanced analytics solutions.

Advanced analytical techniques process big data efficiently. Besides, minimizing energy consumption and maintaining system stability during continuous data aggregation are two significant advantages of using advanced big data analytics.

2| Financial Forecasting

Enterprises can raise funds using several financial instruments, but revenue remains vital to profit estimation. Corporate leadership is often curious about changes in cash flow across several business quarters. After all, reliable financial forecasting enables them to allocate a departmental budget through informed decision-making.

The variables impacting your financial forecasting models include changes in government policies, international treaties, consumer interests, investor sentiments, and the cost of running different business activities. Businesses always require industry-relevant tools to calculate these variables precisely.

Multivariate financial modeling is one of the enterprise-level examples of advanced analytics use cases. Corporations can also automate some components of economic feasibility modeling to minimize the duration of data processing and generate financial performance documents quickly.

3| Customer Sentiment Analysis

The customers’ emotions influence their purchasing habits and brand perception. Therefore, customer sentiment analysis predicts feelings and attitudes to help you improve your marketing materials and sales strategy. Data analytics services also provide enterprises with the tools necessary for customer sentiment analysis.

Advanced sentiment analytics solutions can evaluate descriptive consumer responses gathered during customer service and market research studies. So, you can understand the positive, negative, or neutral sentiments using qualitative data.

Negative sentiments often originate from poor customer service, product deficiencies, and consumer discomfort in using the products or services. Corporations must modify their offerings to minimize negative opinions. Doing so helps them decrease customer churn.

4| Productivity Optimization

Factory equipment requires a reasonable maintenance schedule to ensure that machines operate efficiently. Similarly, companies must offer recreation opportunities, holidays, and special-purpose leaves to protect the employees’ psychological well-being and physical health.

However, these activities affect a company’s productivity. Enterprise analytics solutions can help you use advanced scheduling tools and human resource intelligence to determine the optimal maintenance requirements. They also include other productivity optimization tools concerning business process innovation.

Advanced analytics examples involve identifying, modifying, and replacing inefficient organizational practices with more impactful workflows. Consider how outdated computing hardware or employee skill deficiencies affect your enterprise’s productivity. Analytics lets you optimize these business aspects.

5| Enterprise Risk Management

Risk management includes identifying, quantifying, and mitigating internal or external corporate risks to increase an organization’s resilience against market fluctuations and legal changes. Moreover, improved risk assessments are the most widely implemented use cases of advanced enterprise analytics solutions.

Internal risks revolve around human errors, software incompatibilities, production issues, accountable leadership, and skill development. Lacking team coordination in multi-disciplinary projects is one example of internal risks.

External risks result from regulatory changes in the laws, guidelines, and frameworks that affect you and your suppliers. For example, changes in tax regulations or import-export tariffs might not affect you directly. However, your suppliers might raise prices, involving you in the end.

Data analytics services include advanced risk evaluations to help enterprises and investors understand how new market trends or policies affect their business activities.

Conclusion

Enterprise analytics has many use cases where data enhances management’s understanding of supply chain risks, consumer preferences, cost optimization, and employee productivity. Additionally, the advanced analytics solutions they offer their corporate clients assist them in financial forecasts.

New examples that integrate advanced analytics can also process mixed data types, including unstructured datasets. Furthermore, you can automate the process of insight extraction from the qualitative consumer responses collected in market research surveys.

While modern analytical modeling benefits enterprises in financial planning and business strategy, the reliability of the insights depends on data quality, and different data sources have unique authority levels. Therefore, you want experienced professionals who know how to ensure data integrity.

A leader in data analytics services, SG Analytics, empowers enterprises to optimize their business practices and acquire detailed industry insights using cutting-edge technologies. Contact us today to implement scalable data management modules to increase your competitive strength.

2 notes

·

View notes

Text

Your One-Stop Solution for Digital Marketing

In today's digital age, businesses are increasingly realizing the importance of a strong online presence to attract and engage with customers. As a result, the demand for comprehensive and effective digital marketing strategies has skyrocketed. This is where the concept of the "Digital Warehouse" comes into play. The Digital Warehouse is a revolutionary concept that serves as a one-stop solution for all your digital marketing needs. In this article, we will explore the various aspects of the Digital Warehouse, its benefits, services offered, success stories, and why it should be your go-to choice for all things related to digital marketing. Understanding the Digital WarehouseThe Digital Warehouse is essentially a centralized hub that brings together a wide range of digital marketing services and tools under one roof. It acts as a repository of various resources, such as marketing software, analytics tools, content creation platforms, advertising platforms, and more. By leveraging the power of technology and automation, the Digital Warehouse streamlines the entire digital marketing process, making it more efficient and effective.

Benefits of Utilizing the Digital Warehouse

Cost-Effectiveness: One of the major advantages of using the Digital Warehouse is the cost-effectiveness it offers. By consolidating all your digital marketing needs in one place, you can streamline your operations and eliminate the need to invest in multiple tools and services separately. This ultimately leads to significant cost savings.

Time-Saving: With everything you need in one place, the Digital Warehouse eliminates the need for switching between multiple platforms or juggling different tools. This results in a considerable amount of time-saving, allowing you to focus on other important aspects of your business.

Enhanced Collaboration: The Digital Warehouse promotes collaboration among different teams, such as marketing, sales, and content creation. With all the resources available in a centralized location, teams can easily communicate, share insights, and work together seamlessly to achieve common goals.

Data-Driven Insights: One of the key features of the Digital Warehouse is its ability to generate comprehensive and real-time data insights. The analytics tools integrated into the platform provide valuable data and metrics that can be used to measure the effectiveness of your marketing campaigns, identify trends, and make data-driven decisions.

Scalability: The Digital Warehouse is designed to cater to businesses of all sizes, from startups to large enterprises. It offers scalable solutions that can be customized to meet the specific needs and goals of your business. As your business grows, you can easily scale up your digital marketing efforts without any hassle.

Services Offered by the Digital Warehouse

The Digital Warehouse encompasses a wide range of services to cater to all your digital marketing needs. Some of the key services offered include:

Search Engine Optimization (SEO): The Digital Warehouse provides advanced SEO tools and techniques to optimize your website for search engines, improve your organic rankings, and drive more targeted traffic to your website.

Pay-Per-Click (PPC) Advertising: The Digital Warehouse offers robust PPC advertising platforms that enable you to create and manage highly targeted ad campaigns across various channels, such as Google Ads, Facebook Ads, and LinkedIn Advertising.

Content Marketing: Content is the king in today's digital landscape. The Digital Warehouse provides access to content creation platforms, content management systems, and content distribution tools to help you create, publish, and promote engaging content that resonates with your target audience.

Social Media Marketing: The Digital Warehouse includes social media management tools and social advertising platforms that allow you to effectively manage your social media presence, engage with your audience, and run targeted ad campaigns across popular social channels.

Email Marketing: Email marketing continues to be a highly effective digital marketing strategy. With the Digital Warehouse, you can access powerful email marketing platforms that facilitate email campaign creation, automation, and analysis to drive customer engagement and conversions.

Analytics and Reporting: The Digital Warehouse integrates advanced analytics tools that provide in-depth insights into the performance of your digital marketing campaigns. You can track key metrics, measure ROI, and generate comprehensive reports to assess the effectiveness of your strategies. Why Choose the Digital Warehouse for Your Digital Marketing Needs

The Digital Warehouse stands out as the preferred choice for businesses looking to streamline their digital marketing efforts for several reasons:

Comprehensive Solutions: The Digital Warehouse offers a wide range of services, tools, and resources, ensuring all your digital marketing needs are met in one place.

Expertise and Support: The Digital Warehouse is backed by a team of experienced digital marketing professionals who are dedicated to providing expert guidance and support. They are well-versed in the latest trends and best practices, helping you stay ahead of the curve.

User-Friendly Interface: The Digital Warehouse is designed with user experience in mind. It offers an intuitive interface that makes it easy for users of all levels of expertise to navigate and utilize the platform effectively.

Continuous Innovation: The Digital Warehouse keeps up with the ever-evolving digital marketing landscape and continuously updates its services and tools to meet the changing needs of businesses.

In conclusion, the Digital Warehouse is a game-changer in the world of digital marketing. It provides businesses with a centralized hub where they can access a wide range of digital marketing services, tools, and resources. By leveraging the benefits of the Digital Warehouse, businesses can enhance their online presence, drive more targeted traffic, and achieve their marketing goals more effectively. So, why wait? Embrace the power of the Digital Warehouse and take your digital marketing efforts to new heights.

2 notes

·

View notes

Text

2023 Wrapped: Here Are Top 10 Logistics Trends That Defined The Year

2023 has been a year of new beginnings for the Indian logistics industry. It is the year logistics companies bounced back from the post-pandemic slump and set out to recover from their losses. The year also witnessed a steady growth in eCommerce, with the spotlight on quick commerce and last mile logistics. The later part of 2023 saw the government extending generous support to digital commerce and logistics, through initiatives like Open Network for Digital Commerce (ONDC) and National Logistics Policy (NLP).

Looking back, we can confidently assert that 2023 has been a good year for India’s logistics sector. From the increased focus on supply chain sustainability to extensive experimentation with drone deliveries, here are the top trends that defined logistics this year.

1. Greener transportation and supply chain

The amount of greenhouse gases generated by India’s transportation sector has nearly tripled since the 1990s, accounting for over 14% of our total energy emissions. The problem is quite severe if we take into account the massive carbon footprint left by India’s booming supply chain.

In 2022, there was a rise in awareness around cleaner and greener logistics practices, with a nudge on electrifying India’s cargo transportation. Logistics and transportation startups unveiled their fleet of electric (EV) and clean energy vehicles. At Blowhorn, we converted 30% of our fleet to clean fuels and took the pledge of running 100% of our fleet on clean energy by 2025.

In addition, other green practices like solar-powered warehousing, eco-friendly packaging and paperless invoicing were also adopted widely.

2. Third party logistics

The concept of third-party logistics (3PL) took off in India only a few years back. In 2022, India’s 3PL market reached a staggering $58.4 Bn in valuation, with a projected annual growth of 7.42%.By 2027, the market is estimated to reach more than $83.53 Bn.

The 3PL market is primarily driven by manufacturing, FMCG, retail and eCommerce sectors — all of which experienced commendable growth this year. Keeping in mind the needs of the modern Indian entrepreneur, 3PL service providers are also improving their operational speed with the incorporation of technology.

In the coming days, development of infrastructures like logistics parks, dedicated freight corridors, free trade warehousing zones, and container freight stations are expected to improve the efficiency of the Indian 3PL market.

3. Higher investment in technology

With higher investment technology seeping into eCommerce, retail, education, hospitality, finance, and all other sectors, why should logistics be left behind? With increasing market demand for superfast delivery, Indian logistics startups invested more on modern technology to boost their operations.

Experts believe that India is headed towards a technological revolution in logistics. Tech like Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT) are optimally benefitting the supply chain in terms of seamless management, improved route planning, warehouse automation, digital payments and much more.

At Blowhorn, we are already speeding up our deliveries with AI-powered route optimization software. Our automated warehouse management system helps in seamless handling of stored inventory and order dispatch, while we offer a real-time tracking system for all our orders. We have also adopted novel technologies like geo-fencing to reduce the menace of fake delivery attempts.

4. LaaS (Logistics as a Service)

We are well-acquainted with Software as a Service (SaaS) companies. This year saw the emergence of companies following a similar model in fulfillment, offering Logistics as a Service (LaaS). Ideally, this presents a plug and play model for your business’s logistics needs, which you can avail via a simple integration with your 3PL partner.

Blowhorn has set the ball rolling for LaaS in India, offering end-to-end logistics solutions with warehousing, transportation and hyperlocal delivery.

5. Greater supply chain transparency

With rising consumer concerns, logistics stakeholders worked towards improving supply chain visibility and transparency in 2023. Companies are striving to become more transparent with regards to the sustainability of their supply chains. Globally, 2023 saw more companies offering insights on their labor practices, job creation, sourcing methods and compliance with regulatory requirements — in a bid to enhance their brand image among the conscious modern consumer.

6. Blockchain in last mile logistics

While AI is helping to improve speed and efficiency, blockchain has been deemed as a viable solution for more transparency and visibility in last mile logistics. In India and abroad, companies have started incorporating blockchain to optimize the last mile deliveries. The technology has found best use in high value inventory tracking, secure invoicing and payments, fraud detection, improved supply chain transparency, dispute resolution and creating a fair freight marketplace.

With the launch of Open Network for Digital Commerce (ONDC) by the Indian government, there is hope that we will witness further adoption of blockchain in the digital commerce and logistics space. In fact, ONDC itself is a blockchain-based protocol which aims to create a fair and transparent marketplace for small and medium-sized businesses across India. With Blowhorn being one of the early participants of ONDC, we too are waiting and watching the best use case for blockchain in our fulfillment services in the near future to help our customers.

7. Micro-fulfillment > Traditional Warehousing

2022 saw a rise in demand for same day delivery, which is quite difficult to fulfill if your inventory is stocked in a warehouse far away from the customer's location. The longer the delivery distance, the more the delivery time — a simple thumb rule to keep in mind.

This is why top in 2023 opted for micro ecommerce-fulfillment centers or micro-warehouses. The concept of micro-warehousing follows a just-in-time inventory management approach, with goods never staying here for more than a day. The limited inventory is stocked in a network of collocated storehouses at high-demand pincodes. Not only does the process help in reducing a brand’s capital spend on inventory, but it also improves efficiency and decreases resource wastage.

Much before the pandemic, we launched India’s first micro-warehouses or micro-fulfillment centers as an experiment in 2018. Now we maintain an expansive network of micro-warehouses across 28 cities of India. Read this article to find out why more eCommerce startups are choosing micro-fulfillment in 2023-24.

8. Automation in shipping

When it comes to automation in shipping, the process works on a predefined pathway involving packaging, warehousing, material handling and security. In India, the adoption of automation in logistics and shipping has been steadily increasing since the pandemic.

In 2023, 3PL fulfillment companies like Blowhorn incorporated automated solutions to boost efficiency by** reducing overhead costs** and time, streamlining the supply chain and minimizing the chances of manual errors.

9. Extensive focus on hyperlocal logistics

2023 saw a high growth in the hyperlocal space with the emergence of newer players in the quick commerce sector. Meanwhile, eCommerce giants and existing logistics players focused more on faster deliveries to not miss out on their customer needs.

Improved internet penetration led to the growth of fast fulfillment in suburbs and rural belts, thus creating a need for hyperlocal elements like dark stores, micro-ecommerce fulfillment centers along with local delivery jobs.

At Blowhorn, we have developed a platform-agnostic technology to be able to integrate with a wide range of businesses ranging from D2C, marketplaces and omni channel players. Our hyperlocal strategy is defined by AI-based dynamic route planning, real-time order clubbing, automated warehousing, blockchain and even drone deliveries. We are aiming to build a sustainable hyperlocal delivery system to tackle small profit margins, high overhead costs and ever-evolving consumer expectations.

10. Experimentation with Drone Deliveries

Delivery by drones is not new. The idea has been widely explored by logistics providers across India but is yet to be adopted at scale. The idea of mapping a three-dimensional delivery route via drones holds immense potential and has excited the Indian government authorities as well. Jyotiraditya Scindia, the Union Minister for Civil Aviation, has stated the administration’s objective to turn India into a major drone hub by 2030.

Leading logistics players like Blowhorn and others are already chalking out the blueprint to make drone delivery an everyday reality. Gartner predicts that by 2026, more than one million drones will be carrying out retail deliveries, up from 20,000 today. Last year, the Indian government also released the draft of The Drone Rules, 2021, aiming to liberalize drone delivery while fulfilling the safety regulations. Autonomous last-mile delivery via these mini flying machines will significantly determine the growth trajectory of Indian logistics in the upcoming future.

2 notes

·

View notes

Text

Japan Smart Warehousing Market Analysis 2031

Japan smart warehousing market is projected to witness a CAGR of 11.35% during the forecast period FY2025-FY2032, growing from USD 1.87 billion in FY2024 to USD 4.42 billion in FY2032. The market is experiencing growth due to several interrelated factors, such as technological advances, including automation integration, robotics technology, operational efficiency, increasing labor costs, and improved stock management.

The rise of e-commerce and consumer expectations for fast delivery have fuelled the rising demand for efficient logistics and supply chain management prompting companies to adopt advanced warehousing solutions. The Japanese aging labor is urgent to solve labor shortages and maintain productivity automatically. Government initiatives promoting smart technology and sustainable practices drive investment in smart storage infrastructure. In addition, companies are increasingly focusing on data analytics to optimize inventory levels and streamline operations, further supporting market growth. The combination of these factors is driving the expansion of Japan’s smart warehouse industry, positioning it as a key component of the future supply chain ecosystem as companies strive to adapt to the rapidly changing retail environment.

In October 2023, Zebra Technologies Corp. announced that Ebematsu Shoji, a cooking utensil trading company, has deployed Zebra’s MC20 handheld terminals resulting in a daily reduction of 23 hours in warehouse travel time and a 30% decrease in shipping errors. The MC20, a lightweight and durable Android-based device, allows staff to access real-time information, directly enhancing operational efficiency in warehousing, picking, shipping inspection, and inventory management. This implementation, supported by Sofu Systems, aligns with the growing trend of workflow automation in Asia-Pacific warehousing market as 70% of the industry executives plan to adopt such technologies by 2024. By facilitating digitalization and improving productivity, Zebra’s solutions significantly contribute to the growth of Japan smart warehousing market ultimately enhancing customer satisfaction and profitability.

E-commerce to Fuel Smart Warehousing Market Growth

The growth of e-commerce in Japan is a major reason for the growth of the smart warehousing market. Online retail continues to gain popularity, and businesses are challenged to meet customer demands for faster and more efficient delivery services. This enhances the need for advanced decision-making in the farm warehouse, addresses the increase in control, and optimizes preliminary management. Intellectual warehouses such as automation, robot engineering, and data analysts can optimize activities, reduce processing time, and increase accuracy in order. The shift to omnichannel retail requires flexible, responsive warehousing systems that accommodate diverse distribution needs. E-commerce continues to evolve, and businesses are increasingly investing in smart warehouses to strengthen their competitive advantage and meet high consumer expectations, driving the growth of the market.

In April 2023, Kyoto University and IBM Japan developed a medical data and AI platform on Google Cloud to enhance data utilization at Kyoto University’s Graduate School of Medicine and its affiliated hospitals. This platform includes a data lake and data warehouse that facilitates the collection and storage of structured and unstructured medical data, improving accessibility and scalability. Currently aiding clinical research, particularly in diagnosing rare diseases, the platform is set to expand its capabilities by incorporating more data types and developing a comprehensive data catalog compliant with global standards such as HL7 FHIR. This initiative supports research and education and aims to extend its services to other hospitals and organizations, contributing to the growth of Japan’s smart warehousing market by streamlining healthcare data management and fostering innovation through AI applications.

Technology and Automation to Drive Market Growth

Technological advancements contribute to the growth of the smart warehousing market in Japan, which considerably increases operational and precision efficiency. Innovations such as automation, robotics, and artificial intelligence transform traditional warehouse methods. Automated guided vehicles and drones optimize the movement of goods. Advanced inventory management systems use data analytics to optimize stock levels and reduce waste and machine learning algorithms predict demand trends to enable more proactive inventory management. These technologies minimize human error and reduce labor costs and increase throughput allowing companies to complete large orders more quickly. As businesses strive to remain competitive in a rapidly changing market, the adoption of smart warehouse technologies is essential to accelerate investment and development in this sector, improving productivity and shaping the future of warehousing in Japan.

In October 2024, Tecsys Inc. launched its Elite 24.2 software release, enhancing supply chain performance through advanced data science and technology tools. Key features include a Dynamic Picking Control Tower for real-time warehouse monitoring, the personalized My Top 5 business intelligence dashboard for focused management, AI-assisted Item Master Data Cleansing for improved data accuracy and Electronic Shelf Labels for better inventory tracking in healthcare settings. These innovations enable organizations to turn complex data into actionable insights, driving operational efficiency and responsiveness. This focus on data-driven solutions supports the growth of the smart warehousing market by improving automation, accuracy, and decision-making, essential for navigating the complexities of modern supply chains.

Cloud Segment to Dominate Smart Warehousing Market Share

Cloud segments dominate the share of Japan smart warehousing market to provide more advantages than conventional local solutions. Cloud systems provide unprecedented flexibility and scalability so that companies can easily adjust resources to meet the fluctuations of demand and seasonal peaks. This is important in the rapidly changing environment of electronic commerce. These systems enable real-time access to data facilitating better decision-making and enhanced collaboration between supply chain partners. Cloud solutions reduce the need for large upfront investments in hardware and infrastructure, resulting in lower operational costs. It provides seamless integration with advanced technologies, such as IoT, AI, and machine learning, necessary to optimize the warehouses. As businesses prioritize efficiency and flexibility in their logistics processes, their ability to deliver innovative, adaptable, and cost-effective warehousing solutions to cloud industries positions for substantial growth in the logistics market.

In October 2024, Yusen Logistics selected Manhattan Active Warehouse Management for its new 1,191,000 square foot distribution center in Northampton, the United Kingdom, set to open in January 2026. This partnership highlights Yusen’s commitment to enhancing performance through advanced automation and cloud-native technology. Manhattan’s solution, built from API microservices, offers scalability and agility, enabling real-time distribution planning and improved operational decisions. This implementation will foster growth in the smart warehousing market by driving efficiency, reducing operational costs, and integrating warehouse management with transportation and labor systems, ultimately creating a unified supply chain experience that meets the dynamic challenges of modern logistics.

Central Japan to Dominate the Smart Warehousing Market Share

The central region, especially the Kanto region, dominates the smart warehousing market due to its strategic advantages and economic vitality. The region has an extensive transportation network, including highways and railways, facilitating efficient logistics and delivery to meet the needs of the rapidly growing e-commerce sector. The presence of large cities, such as Tokyo and Yokohama, is driving innovation with many technology companies pushing automation, robotics, and data analytics in warehousing solutions. The region’s high population density also creates demand for fast and efficient order fulfillment, encouraging companies to adopt smart warehousing technologies. Combination of factors, such as excellent infrastructure, rich technical ecosystem, and strong consumer demand, along with the position of Tuba region, poses central Japan as a leader in Japan smart warehousing market, which leads to further investment and growth in this sector.

In October 2024, JD Logistics plans to double its overseas warehouse capacity by 2025 as a part of its global supply chain strategy to meet the rising demand for cross-border logistics. The expansion includes increasing its network of bonded and direct-mail warehouses, aiming to provide international express delivery services to around 80 countries and regions by year-end. This growth supports the smart warehousing market by leveraging advanced supply chain technology and enhancing efficiency, enabling faster delivery and improved inventory management, which are crucial for meeting the demands for global e-commerce.

Download Free Sample Report

Future Market Scenario (FY2025 – FY2032F)

Increasing adoption of robotics, AI, and IoT will enhance operational efficiency and accuracy. Automated picking systems, such as drones for inventory management and smart tracking solutions, are expected to rise.

The surge in e-commerce will drive the need for strategically located smart warehouses that can facilitate faster last-mile deliveries. Micro-fulfilment centers may emerge in urban areas to meet consumer demand efficiently.

There will be a strong emphasis on sustainability with warehouses adopting eco-friendly practices such as energy-efficient systems, solar power, and waste reduction initiatives. This will appeal to environmentally conscious consumers and businesses.

Advanced data analytics and AI will enable predictive analytics for inventory management, optimizing the supply chain operations. Businesses will leverage big data to accurately forecast demand, streamline operations, and reduce costs.

Report Scope

“Japan Smart Warehousing Market Assessment, Opportunities and Forecast, FY2018-FY2032F”, is a comprehensive report by Markets and Data, providing in-depth analysis and qualitative and quantitative assessment of the current state of Japan smart warehousing market, industry dynamics, and challenges. The report includes market size, segmental shares, growth trends, opportunities, and forecast between FY2024 and FY2032. Additionally, the report profiles the leading players in the industry, mentioning their respective market share, business models, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/japan-smart-warehousing-market

Latest reports-

Contact

Mr. Vivek Gupta 5741 Cleveland street, Suite 120, VA beach, VA, USA 23462 Tel: +1 (757) 343–3258 Email: [email protected] Website: https://www.marketsandata.com

0 notes

Text

The Future of Supply Chain Management in Melbourne

In a world where businesses strive for efficiency and innovation, supply chain management stands as a cornerstone for operational success. Melbourne, a hub of commerce and logistics, is witnessing a transformative shift in how supply chains operate. With technological advancements and changing consumer expectations, the future of supply chain management Melbourne is both exciting and dynamic.

The integration of artificial intelligence (AI), real-time tracking, and data analytics is reshaping the logistics landscape. These advancements not only streamline operations but also create opportunities for businesses to gain a competitive edge in Melbourne’s fast-paced market. Let’s explore how supply chain management is evolving and the benefits it brings to businesses.

1. Enhanced Efficiency Through AI and Automation

The future of supply chain management lies in automation and AI. From inventory management to demand forecasting, these technologies enable businesses to predict trends and optimize resources. For example, AI-powered algorithms analyze data to forecast product demand accurately, helping companies in Melbourne reduce waste and improve inventory turnover.

Automated processes also minimize human error, ensuring that shipments are delivered on time and costs are kept in check. This shift towards smart logistics makes Melbourne an ideal location for businesses seeking efficiency and innovation in their supply chain strategies.

2. Real-Time Visibility and Tracking

Transparency is crucial in supply chain management, and Melbourne businesses are leveraging technology to achieve it. Real-time tracking systems provide end-to-end visibility, allowing companies to monitor shipments, anticipate delays, and address issues proactively. This enhanced visibility not only improves customer satisfaction but also builds trust among stakeholders.

In the competitive Melbourne market, businesses that offer reliable delivery and transparent processes will thrive. Real-time tracking systems are becoming a standard, ensuring that supply chains remain agile and responsive to changing demands.

3. Sustainable Practices for a Greener Future

Sustainability is no longer a buzzword; it’s a necessity. Melbourne’s businesses are adopting eco-friendly practices in their supply chain operations to align with consumer expectations and regulatory requirements. From using renewable energy sources in warehouses to optimizing delivery routes to reduce carbon emissions, sustainability is shaping the future of supply chain management.

By embracing green logistics, businesses not only contribute to environmental conservation but also enhance their brand reputation. This forward-thinking approach is particularly relevant in a city like Melbourne, known for its commitment to sustainability.

4. Adapting to E-Commerce Growth

The rise of e-commerce has significantly impacted supply chain management. Melbourne’s logistics providers are adapting to the surge in online shopping by investing in last-mile delivery solutions and flexible warehousing. These innovations ensure that products reach consumers quickly and efficiently, meeting the high expectations of modern shoppers.

For businesses in Melbourne, optimizing supply chains to handle e-commerce demands is essential for staying competitive. This includes implementing technology-driven solutions that enhance speed, accuracy, and customer satisfaction.

5. Leveraging Data Analytics for Strategic Insights

Data is the backbone of modern supply chain management. Businesses in Melbourne are harnessing the power of data analytics to gain insights into their operations, identify inefficiencies, and make informed decisions. Predictive analytics helps companies anticipate disruptions, while performance metrics provide a clear picture of supply chain health.

The ability to analyze and act on data is a game-changer, enabling businesses to stay ahead in Melbourne’s dynamic market. By leveraging data-driven strategies, companies can achieve greater operational efficiency and customer satisfaction.

Conclusion: Embrace the Future of Supply Chain Management

The evolution of supply chain management in Melbourne is a testament to the city’s commitment to innovation and excellence. By adopting cutting-edge technologies, sustainable practices, and customer-centric strategies, businesses can unlock new opportunities and drive growth.

If your business is ready to stay ahead in the game, it’s time to embrace the future of supply chain management Melbourne. Invest in modern solutions, partner with forward-thinking logistics providers, and position your company for long-term success in this ever-evolving landscape.

0 notes

Text

#Warehouse Automation Market#Warehouse Automation Market share#Warehouse Automation Market Trends#Warehouse Automation Market Size#Warehouse Automation Market Analysis#Warehouse Automation Market Demand

0 notes

Text

The Rise of Artificial Intelligence in Business Operations

Artificial Intelligence (AI) is revolutionizing the way businesses operate, with applications across industries that span from automating customer service to predictive analytics for decision-making. As AI technology continues to evolve, companies are discovering new opportunities to streamline operations, reduce costs, and enhance customer experiences.

AI in Customer Service

AI has greatly impacted customer service, with AI-powered chatbots and virtual assistants becoming an integral part of business operations. These tools can handle customer queries 24/7, providing quick responses and support. This has not only enhanced customer satisfaction but also allowed businesses to reduce costs associated with hiring human agents. The ability of AI systems to learn from previous interactions and offer personalized recommendations has further improved the customer experience.

For instance, businesses like Amazon and Sephora use AI chatbots to handle customer inquiries. These bots can answer common questions, guide users through product searches, and even resolve issues without the need for human intervention. This efficiency ensures that customers have a seamless experience, whether they’re making a purchase or seeking support.

Data Analytics and Predictive Insights

Data is often referred to as the new oil, and businesses are increasingly turning to AI for analyzing vast amounts of data to uncover insights that can shape strategy. AI-powered analytics tools can process complex datasets quickly, providing businesses with real-time insights into customer behavior, market trends, and operational inefficiencies.

AI systems are used to predict consumer behavior by analyzing historical data and identifying patterns that would otherwise go unnoticed. For instance, retailers can use AI to predict when certain products will experience a surge in demand, allowing them to stock up in advance and avoid stockouts. Similarly, in the financial industry, AI can analyze market trends to forecast stock price movements or identify potential investment opportunities.

Automation in Operations

Automation powered by AI is another transformative application. By using AI, companies can automate repetitive tasks such as data entry, inventory management, and quality control. In manufacturing, for instance, robots powered by AI can perform intricate assembly tasks more efficiently and accurately than human workers. This reduces human error, increases production speeds, and lowers costs.

AI-driven automation also improves workflow efficiency. In industries like logistics, AI-powered systems can optimize delivery routes, manage warehouse inventory, and even predict demand spikes, making supply chains more responsive and efficient.

AI in Decision Making

AI is also helping businesses make more informed and accurate decisions. In human resources, for example, AI algorithms can assess candidates’ resumes, match skills to job descriptions, and even predict a candidate’s potential success at a company. Similarly, in the healthcare industry, AI can analyze patient data to recommend treatment plans or diagnose conditions, reducing human error and improving patient outcomes.

As AI continues to improve, its ability to perform complex tasks will expand, and businesses will need to incorporate AI into their operations to stay competitive. The future of AI in business is vast and evolving, with new applications emerging every day.

0 notes

Text

Global AI In Logistics Market Overview 2024: Size, Growth Rate, and Segments

The ai in logistics global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

AI In Logistics Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size - The ai in logistics market size has grown exponentially in recent years. It will grow from $12.21 billion in 2023 to $18.01 billion in 2024 at a compound annual growth rate (CAGR) of 47.5%. The growth in the historic period can be attributed to increasing complexity in supply chain networks, rising demand for real-time logistics solutions, advancements in ai and machine learning technologies, growing e-commerce sector, need for efficiency and cost optimization in logistics operations.

The ai in logistics market size is expected to see exponential growth in the next few years. It will grow to $83.26 billion in 2028 at a compound annual growth rate (CAGR) of 46.6%. The growth in the forecast period can be attributed to expansion of autonomous vehicles and drones in logistics, rising demand for predictive analytics in supply chain management, growth of smart warehouses and fulfillment centers, integration of blockchain technology for transparent and secure transactions, increasing focus on sustainability and green logistics. Major trends in the forecast period include adoption of ai-powered route optimization for delivery fleets, development of ai chatbots for customer service and support, emergence of predictive maintenance solutions for logistics assets, utilization of ai for demand forecasting and inventory management, implementation of ai-enabled risk management systems for supply chain resilience.

Order your report now for swift delivery @ https://www.thebusinessresearchcompany.com/report/ai-in-logistics-global-market-report

Scope Of AI In Logistics Market The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

AI In Logistics Market Overview

Market Drivers - The rising growth of the e-commerce sector is expected to propel the growth of the AI in logistics market going forward. E-commerce refers to the buying and selling of goods or services over the internet and the transfer of data and funds to complete the transactions. The adoption of AI in logistics helps e-commerce businesses streamline their operations and improve efficiency, leading to benefits such as route optimization, supply chain optimization, and personalized shopping recommendations. For instance, in September 2022, according to the International Trade Administration, a US-based department of commerce, consumer e-commerce now made up 30% of the UK's overall retail sector (up from 20% in 2020), with an annual e-commerce revenue of more than $120 billion. Further, in 2021, 82% of people in the UK will have made at least one online purchase. Therefore, the rising growth of the e-commerce sector is driving the growth of the AI in logistics market.

Market Trends - Major companies operating in the AI in logistics market are focusing on introducing technologically advanced solutions, such as AI-powered supply chain management and orchestration solutions, to increase their profitability in the market. AI-powered supply chain management and orchestration solutions leverage artificial intelligence to streamline and optimize various aspects of the supply chain. For instance, in December 2023, Blue Yonder, an India-based digital supply chain management solutions company, launched Blue Yonder Orchestrator, a new generative AI tool that simplifies supply chain management and orchestration. This new feature combines large language models (LLMs), cloud data, and prompt engineering to recommend supply chain decisions. This AI-powered solution gives business users instant access to advice, forecasts, and intelligent decisions, so they can make the best choices possible and have a positive impact on their supply chain. With so many professionals finding it difficult to retain institutional knowledge in today's supply chain environment, Blue Yonder Orchestrator can be a useful supply chain assistant that helps businesses enhance intuition by leveraging the value of data to make decisions more quickly and effectively.

The ai in logistics market covered in this report is segmented –

1) By Offering: Software, Services 2) By Technology: Machine Learning, Natural Language Processing, Context Awareness Computing, Computer Vision 3) By Application: Self-driving Vehicles And Forklifts, Planning And Forecasting, Machine And Human Collaboration, Automation Of Ordering And Processing 4) By Industry Vertical: Automotive, Food And Beverages, Manufacturing , Healthcare, Retail

Get an inside scoop of the ai in logistics market, Request now for Sample Report @ https://www.thebusinessresearchcompany.com/sample.aspx?id=13568&type=smp

Regional Insights - North America was the largest region in the AI in logistics market in 2023. Asia-Pacific is expected to be the fastest-growing region in the forecast period. The regions covered in the ai in logistics market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies - Major companies operating in the ai in logistics market report are Amazon.com Inc, Alphabet Inc., Microsoft Corporation, DHL International GmbH, United Parcel Service, Inc., FedEx Corporation, CEVA Logistics AG, Intel Corporation, IBM Corporation, Oracle Corporation, Kuehne + Nagel International AG, NVIDIA Corporation, XPO Logistics, Inc., Zebra Technologies, HAVI , Infor, Echo Global Logistics, Symbotic , C3 AI, Turvo Inc., project44 Inc., Wise Systems, Inc., Covariant , Cognitivescale Inc., Slync.io Inc., Transportation Applied Intelligence LLC

Table of Contents 1. Executive Summary 2. AI In Logistics Market Report Structure 3. AI In Logistics Market Trends And Strategies 4. AI In Logistics Market – Macro Economic Scenario 5. AI In Logistics Market Size And Growth ….. 27. AI In Logistics Market Competitor Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis 30. Appendix

Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected]

Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

How to Train Your Team Effectively on Using an eCommerce Order Management System?

Modern retail operations depend heavily on an efficient ecommerce order management system (OMS). A Statista report projects that the size of the global eCommerce market will reach $7. 4 trillion by 2025, highlighting how crucial effective order management is to maintaining competitiveness.

An OMS is necessary to increase productivity, streamline processes, and provide better customer service. Alongside this, offering proper training to your staff is as important to effectively get the best out of an OMS.

The Need for an eCommerce Order Management System

If you want to streamline your operations, you must incorporate an eCommerce order management system into your operations. Reasons include:

Omnichannel Order Processing: Orders from multiple channels are integrated into a single platform through centralized control.

Enhanced Productivity: Automating monotonous tasks lowers error rates and manual labour.

Real-Time Data: Offers the most recent sales and inventory data to help with decision-making.

Customer Experience: Guarantees accurate tracking and prompt order fulfillment.

eCommerce Order Management System Training: Best Practices

To effectively train your team on an ecommerce and warehouse management software, follow these best practices:

Start with the Basics: Introduce the core functionalities and how they interact with other systems. Make sure everyone understands the fundamental components.

Hands-On Training: Conduct practical sessions where team members can engage with the system in real-world scenarios. This helps them become familiar with its functionalities.

Create Detailed Documentation: Provide comprehensive user manuals and quick reference guides. These resources are invaluable for troubleshooting and daily tasks.

Offer Ongoing Support: Training should be continuous. Provide access to a help desk or support team to address any emerging questions or issues.

Monitor and Evaluate: Regularly assess your team’s proficiency. Use feedback to refine training methods and address any knowledge gaps.

Gain Comprehensive Training with Canary7 Ultimate WMS Knowledge Resource

At Canary7, we’re dedicated to helping you and your team excel with our ecommerce order management system and warehouse management software. Our extensive knowledge resources are designed to maximize your system use.

Here’s what Canary7 Ultimate WMS Knowledge Resource offers:

WMS User Guides: Our guides provide step-by-step instructions for our warehouse management software, ensuring ease of use.

WMS API Manuals: Detailed API integration instructions help you customize the system to your needs, offering a unique level of integration.

WMS Insightful Blogs: Stay updated with practical tips and industry trends through our blogs, crafted by warehousing professionals for ongoing learning.

WMS Case Studies: Our case studies showcase real-world successes with our system, offering valuable insights into practical applications and benefits.

Conclusion

You must receive effective training to get the most out of an eCommerce order management system and improve your company’s operations. The extensive resources and support offered by Canary7 guarantee that your team is ready to use the system effectively. Explore Canary7’s offerings and see how our tools can transform your order management processes.

For more information on how Canary7 can enhance your eCommerce order management, visit our website today!

0 notes

Text

The Importance of Data Engineering in Today’s Data-Driven World

In today’s fast-paced, technology-driven world, data has emerged as a critical asset for businesses across all sectors. It serves as the foundation for strategic decisions, drives innovation, and shapes competitive advantage. However, extracting meaningful insights from data requires more than just access to information; it necessitates well-designed systems and processes for efficient data management and analysis. This is where data engineering steps in. A vital aspect of data science and analytics, data engineering is responsible for building, optimizing, and maintaining the systems that collect, store, and process data, ensuring it is accessible and actionable for organizations.

Let's explore how Data Engineering is important in today's world:

1. What is Data Engineering

2. Why is Data Engineering Important

3. Key Components of Data Engineering

4. Trends in Data Engineering

5. The Future of Data Engineering

Let’s examine each one in detail below.

What is Data Engineering?

Data engineering involves creating systems that help collect, store, and process data effectively.It involves creating data pipelines that transport data from its source to storage and analysis systems, implementing ETL processes (Extract, Transform, Load), and maintaining data management systems to ensure data is accessible and secure. It enables organizations to make better use of their data resources for data-driven decision-making.

Why is Data Engineering Important?

Supports Data-Driven Decision-Making: In a competitive world, decisions need to be based on facts and insights. Data engineering ensures that clean, reliable, and up-to-date data is available to decision-makers. From forecasting market trends to optimizing operations, data engineering helps businesses stay ahead.

Manages Big Data Effectively: Big data engineering focuses on handling large and complex datasets, making it possible to process and analyze them efficiently. Industries like finance, healthcare, and e-commerce rely heavily on big data solutions to deliver better results.

Enables Modern Technologies: Technologies like machine learning, artificial intelligence, and predictive analytics depend on well-prepared data. Without a solid modern data infrastructure, these advanced technologies cannot function effectively. Data engineering ensures these systems have the data they need to perform accurately.

Key Components of Data Engineering:

Data Pipelines: Data pipelines move data automatically between systems.They take data from one source, change it into a useful format, and then store it or prepare it for analysis.

ETL Processes: ETL (Extract, Transform, Load) processes are crucial in preparing raw data for analysis. They clean, organize, and format data, ensuring it is ready for use.

Data Management Systems:

These systems keep data organized and make it easy to access. Examples of these systems are databases, data warehouses, and data lakes.

Data Engineering Tools: From tools like Apache Kafka for real-time data streaming to cloud platforms like AWS and Azure, data engineering tools are essential for managing large-scale data workflows.

Trends in Data Engineering:

The field of data engineering is changing quickly, and many trends are shaping its future:

Cloud-Based Infrastructure: More businesses are moving to the cloud for scalable and flexible data storage.

Real-Time Data Processing: The need for instant insights is driving the adoption of real-time data systems.

Automation in ETL: Automating repetitive ETL tasks is becoming a standard practice to improve efficiency.

Focus on Data Security: With increasing concerns about data privacy, data engineering emphasizes building secure systems.

Sustainability: Energy-efficient systems are gaining popularity as companies look for greener solutions.

The Future of Data Engineering:

The future of data engineering looks bright. As data grows in size and complexity, more skilled data engineers will be needed.Innovations in artificial intelligence and machine learning will further integrate with data engineering, making it a critical part of technological progress. Additionally, advancements in data engineering tools and methods will continue to simplify and enhance workflows.

Conclusion:

Data engineering is the backbone of contemporary data management and analytics. It provides the essential infrastructure and frameworks that allow organizations to efficiently process and manage large volumes of data. By focusing on data quality, scalability, and system performance, data engineers ensure that businesses can unlock the full potential of their data, empowering them to make informed decisions and drive innovation in an increasingly data-driven world.

Tudip Technologies has been a pioneering force in the tech industry for over a decade, specializing in AI-driven solutions. Our innovative solutions leverage GenAI capabilities to enhance real-time decision-making, identify opportunities, and minimize costs through seamless processes and maintenance.

If you're interested in learning more about the Data Engineering related courses offered by Tudip Learning please visit: https://tudiplearning.com/course/essentials-of-data-engineering/.

#Data engineering trends#Importance of data engineering#Data-driven decision-making#Big data engineering#Modern data infrastructure#Data pipelines#ETL processes#Data engineering tools#Future of data engineering#Data Engineering

1 note

·

View note

Text

Inventory Management Process: A Comprehensive Guide

Inventory management is the backbone of efficient business operations. A well-structured inventory management process ensures that the right products are in the right place at the right time, minimizing costs and maximizing customer satisfaction. This article dives deep into the essentials of inventory management, its key components, and how businesses can optimize the process for long-term success.

What is Inventory Management?

Inventory management refers to the process of ordering, storing, using, and selling a company’s inventory. It includes managing raw materials, components, and finished goods, as well as warehousing and processing such items.

Steps in the Inventory Management Process

Demand Forecasting Accurate forecasting helps businesses predict future inventory needs based on historical data and market trends.

Inventory Planning Involves setting optimal stock levels and deciding on reordering thresholds to prevent overstocking or stockouts.

Procurement Purchasing the required stock from suppliers, ensuring quality and timely delivery.

Storage and Organization Efficient storage solutions, like categorization and barcoding, improve inventory management process with accessibility and tracking.

Inventory Tracking Using tools like RFID tags or barcode scanners to monitor stock levels in real time.

Order Fulfillment Ensuring that customer orders are picked, packed, and shipped accurately and promptly.

Inventory Audits and Reconciliation Regular audits help identify discrepancies between physical stock and recorded data.

Benefits of a Streamlined Inventory Management Process

Reduced Costs: Avoid overstocking or understocking.

Improved Efficiency: Automated systems save time and reduce manual errors.

Enhanced Customer Satisfaction: Timely order fulfillment builds trust.

Data-Driven Decisions: Analytics provide insights into buying patterns and trends.

Tools and Technologies for Inventory Management

Inventory Management Software: Platforms like Zoho Inventory and QuickBooks automate stock tracking.

Barcode Scanners: Simplify the process of tracking stock.

RFID Technology: Provides real-time updates on inventory movement.

Cloud-Based Systems: Enable remote inventory management across multiple locations.

Common Challenges in Inventory Management

Overstocking or understocking.

Inaccurate data entry.

Inefficient warehouse organization.

Difficulty in tracking fast-moving or perishable items.

FAQs:

Q1: What is the purpose of inventory management? Inventory management ensures optimal stock levels, reduces costs, and enhances customer satisfaction.

Q2: How can technology improve the inventory management process? Tools like RFID and barcode scanners enhance accuracy, reduce errors, and offer real-time insights.

Q3: What are the key metrics in inventory management? Key metrics include inventory turnover, order accuracy, and stock-to-sales ratio.

Conclusion:

A robust inventory management process is indispensable for businesses striving to stay competitive. With the integration of advanced tools and strategic planning, businesses can enhance efficiency and profitability. Start optimizing your inventory today to unlock growth potential.

0 notes

Text

Optimizing Logistics Efficiency with AI and Automation in Supply Chain Management

In the fast-paced world of supply chain management, the need for speed, accuracy, and cost-efficiency has never been greater. Logistics operations, in particular, are critical to ensuring that products are delivered on time, in full, and at the lowest possible cost. As businesses continue to face increasing consumer demands, rising operational costs, and complex supply chain challenges, integrating artificial intelligence (AI) and automation has become essential for optimizing logistics efficiency. These cutting-edge technologies enable companies to streamline their processes, improve decision-making, and enhance customer satisfaction, all while reducing costs and minimizing human error logistic institute in kochi

This blog explores how AI and automation are transforming logistics operations and driving efficiency in supply chain management.

1. AI in Supply Chain Management: Revolutionizing Decision-Making

Artificial intelligence has emerged as a key driver in transforming logistics and supply chain management. By leveraging AI, companies can automate decision-making, optimize processes, and gain insights from vast amounts of data. Here’s how AI is playing a pivotal role:

Predictive Analytics: One of the most powerful applications of AI is predictive analytics. By analyzing historical data, customer behavior, market trends, and other relevant factors, AI algorithms can forecast demand, inventory levels, and potential supply chain disruptions. This predictive capability enables businesses to make informed decisions, ensuring that inventory levels are optimized and deliveries are made on time, minimizing the risk of stockouts or overstocking.

Route Optimization: AI is highly effective in optimizing transportation routes. By analyzing real-time data such as traffic patterns, weather conditions, and road closures, AI can identify the most efficient routes for delivery trucks. This not only reduces transportation costs by minimizing fuel consumption and vehicle wear and tear but also ensures timely deliveries. AI-powered route optimization tools help logistics companies make data-driven decisions about delivery schedules, improving both operational efficiency and customer satisfaction.

Demand Forecasting: AI can forecast future demand patterns by analyzing historical data and external factors. This allows logistics companies to proactively adjust their inventory management strategies, ensuring that the right products are in the right place at the right time. Demand forecasting helps companies avoid delays, reduce the need for expedited shipments, and optimize warehousing.

2. Automation: Streamlining Logistics Processes

Automation is another key element in the optimization of logistics efficiency. By automating repetitive tasks, logistics companies can significantly reduce human error, improve throughput, and lower operational costs. Here’s how automation is being applied:

Automated Warehouses: One of the most notable innovations in logistics automation is the use of robots in warehouses. Automated guided vehicles (AGVs), robotic picking systems, and conveyor belts can transport goods, sort inventory, and handle packaging without the need for human intervention. These robots work around the clock, improving warehouse productivity, reducing labor costs, and minimizing the risk of errors.

Inventory Management Automation: Traditional inventory management systems often rely on manual checks, which can be time-consuming and prone to human error. Automation eliminates these issues by using barcode scanning, RFID technology, and AI-powered systems to track inventory in real time. Automated inventory management systems provide companies with accurate and up-to-date information, reducing the need for stocktaking and enabling more precise reordering.

Self-Driving Vehicles and Drones: The advent of autonomous vehicles and drones is set to revolutionize last-mile delivery. Self-driving trucks can transport goods from distribution centers to urban hubs, while drones can deliver packages directly to customers’ doorsteps. These technologies not only reduce the reliance on human labor but also cut down on transportation costs and improve delivery speed. While widespread adoption is still on the horizon, the potential for automation in the last mile is immense.

3. AI and Automation Integration: A Holistic Approach to Logistics Efficiency

The true power of AI and automation lies in their integration. When combined, these technologies work together to create a seamless and highly efficient logistics operation. Here’s how this integration works:

Real-Time Monitoring and Adaptation: By integrating AI and automation, logistics companies can monitor operations in real time and make adjustments on the fly. For instance, if a delivery truck encounters unexpected traffic delays, AI can reroute the vehicle to minimize disruptions, while automated systems in the warehouse can continue processing incoming orders without delay. This integration helps streamline logistics processes and ensures that operations remain efficient, even in the face of unexpected challenges.

End-to-End Automation: Combining AI with automation allows for end-to-end automation of logistics operations, from order fulfillment to delivery. AI can manage inventory levels, optimize warehouse layouts, and predict demand, while automation handles physical tasks such as picking, packing, and shipping. This end-to-end automation reduces the need for manual intervention, improves operational speed, and lowers costs.

Enhanced Customer Experience: The integration of AI and automation also enhances the customer experience by providing faster, more accurate deliveries. AI enables logistics companies to predict delivery windows with greater accuracy, while automation speeds up the process of picking, packing, and shipping orders. This leads to improved on-time performance and higher customer satisfaction.

4. Cost Reduction through AI and Automation