#Vibration sensor

Explore tagged Tumblr posts

Text

Unveiling the Power of Vibration Sensor

Two Switching Outputs

Employs pre-alarm and main alarm outputs for enhanced monitoring and response.

Integrated History Memory with Real-Time Clock

Facilitates seamless data monitoring, display, and recording, bolstering operational efficiency.

Scalable Analogue Current Output

Delivers precise measurements of vibration velocity, optimizing performance analysis.

Versatile Analogue Input

Enables monitoring of additional measurements, expanding its utility beyond vibration detection.

A Multifaceted Guardian

Comprehensive Insights

Provides deep insights into machinery performance and environmental conditions.

Proactive Maintenance

Alerts to potential issues before they escalate, ensuring preemptive actions.

Adaptability Across Industries

Reliable tool for diverse sectors, ensuring optimal functioning and strategic maintenance.

Conclusion: Empowering Proactive Decision-Making

The vibration sensor emerges as a cornerstone in monitoring and control, empowering proactive decision-making and safeguarding critical systems. Its advanced features and adaptability make it indispensable across industries, ensuring optimal performance and preemptive maintenance

#Vibration Sensor#Vibration Sensor automation#Vibration Sensor for industrial agricaltural use#Vibration Sensor for factory#Vibration Sensor india#Vibration Sensor buy online

1 note

·

View note

Text

A Guide to Vibration Sensor Cables for Peak Performance

In the dynamic landscape of industrial operations, ensuring the seamless functioning of machinery is paramount. One crucial component that plays a pivotal role in monitoring and maintaining equipment health is the vibration sensor. However, the effectiveness of these sensors heavily relies on the quality and durability of the cables connecting them. In this guide, we explore the key considerations for selecting vibration sensor cables to achieve peak performance in industrial settings.

Understanding Vibration Sensor Cables: These cables are the lifelines of any monitoring system, facilitating the transmission of crucial data from sensors to monitoring equipment. At where precision meets innovation, a comprehensive range of vibration sensor cables is offered to cater to diverse industrial needs.

Quality Materials for Optimal Performance: STI's cables are crafted from high-quality materials, ensuring resilience in the face of harsh industrial environments. With a focus on durability, these cables guarantee reliable signal transmission, minimizing downtime and optimizing operational efficiency.

Shielding Against Interference: Industrial settings often feature electromagnetic interference that can compromise sensor accuracy. STI's vibration sensor cables come equipped with advanced shielding technologies, safeguarding the integrity of data signals against external interference. This results in more accurate readings and enhanced performance.

Temperature and Environmental Considerations: In industrial environments where temperatures can fluctuate drastically, choosing cables that can withstand extreme conditions is imperative. STI's vibration sensor cables are engineered to endure a wide range of temperatures, ensuring consistent performance in diverse climates.

Installation and Maintenance: Ease of installation and maintenance is another crucial aspect considered by www.stiweb.com. With user-friendly designs and robust construction, STI's cables simplify the installation process and reduce the need for frequent maintenance, contributing to overall cost-effectiveness.

In conclusion, selecting the right vibration sensor cablesis paramount for ensuring peak performance in industrial operations. At where innovation meets reliability, the comprehensive range of vibration sensor cables reflects a commitment to excellence in industrial sensor technology. Choose STI for quality cables that stand the test of time, contributing to the longevity and efficiency of your industrial machinery.

0 notes

Text

How to make a factory smart

The term “SMART FACTORY” is becoming more popular, and is often related to industry 4.0. SMART factories are critical to achieving Industry 4.0 expectations. The strategic importance of SMART FACTORY is undeniable, as early adopters have reported operating more efficiently and driving more to the bottom line.

According to Deloitte, in the United States alone, 86% of manufacturers believe that smart factories will be the main drivers of competition by 2025.Furthermore, 83 percent believe that smart factories will transform the way products are made.

This post will discuss what a smart factory is, its benefits, how to get started, and how solutions provided by CIMCON can help with the process.

What is a SMART FACTORY

SMART FACTORY is a networked industrial facility that combines data, collecting results from devices, processes, machines, and apps to generate actionable insights. The SMART FACTORY transformation highlight the importance of connectivity,the need to connect assets and data across a range of systems, platforms, and data structures, some of which were never meant to be connected. Once a facility and its assets are connected with the use of Sensors and Edge Devices, they unleash a flood of information to be translated and acted upon.

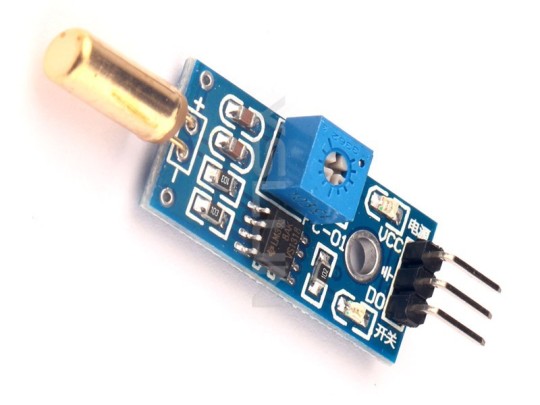

SMART FACTORY Sensors / EDGE devices can be found in a variety of manufacturing environments. CIMCON provides vibration sensor VIBit and the Edge Platform CIM devices. A vibration sensor is a sensitive and calibrated instrument that detects anomalies in the functioning of real-time equipment (motor, pump, etc.). Vibration sensors can provide a warning, allowing the facility to resolve the problem before there is an accidental shutdown. The CIM device can gather data from numerous devices (wired or wireless), using the appropriate protocol and transforming the captured data into a readable format.

Challenges without a SMART FACTORY

In today’s manufacturing industry, organizations are expected to streamline operations, reduce costs, regularly update product formulas, drive supply chain efficiencies, increase employee productivity and maintain business relationships. With expectations so high, the manufacturing industries cannot afford to run into any issues that may interfere with the productivity. But without the implementation of SMART FACTORY, there are some common challenges that may come up with time.

Lengthy implementation period

Costly customization

Inflexibility

Siloed data

Risk of lagging behind new aged technology

The benefit of Smart Factory using CIMCON solutions

Agile production process: SMART FACTORY allows the manufacturer to adapt to changing client needs, budgets, and product quality requirements due to the connectivity of multiple systems, processes, devices, etc., to provide an edge on the delivery of a product.

Enhancing the efficiency and reliability of manufacturing operations: CIM devices and the sensor network will enable the industry to collect data on processes and equipment and provide alerts if there is a deviation. The acquired data is analyzed in near real-time, allowing manufacturers to immediately modify equipment parameters. The analysis of sensor-generated data throughout the manufacturing process aids in identifying trends and scope for improvement. In addition, the likelihood of human error is minimized in production procedures.

Increased visibility into operations on the shop floor: Through IIoT products, SMART FACTORY provides a greater sense of visibility into shop floor operations by providing continuous real-time updates on production operations.

Information safety: In SMART FACTORIES, data priority is necessary. So, the more technologies are involved with sensors and Edge devices, the more secure the factory must be for customers, suppliers and investors.

Predictive maintenance improves uptime: Data regarding the health and performance of equipment is communicated near-real-time to the cloud via IIoT, ensuring advanced planning in maintenance work and boosting machine availability.

Increased worker safety: Sensors are used to communicate information without the physical presence of humans to ensure maximum safety.

Step-by-step instructions for constructing a SMART FACTORY

Establish your goals and needs: To ensure you put your resources in the right places, you must also understand the “WHYs” behind your decision to implement a smart factory.

Get your personnel on board: Legacy systems are still in existence in many production plants, making the deployment of smart technologies difficult. Creating a new solution to replace an existing legacy system may incur costs such as the purchase of a new instrument and the hire of a digitally skilled individual. Because the human workforce is always an important part of the manufacturing process, it must be trained to adapt to changing conditions.

Be cyber secure: In today’s scenario of data-driven technology and usage of increased IIoT devices, data security is a rising concern. Updating security measures should be implemented to provide future-proof security from unwanted threats.

Make a new investment in instruments: To make SMART FACTORY a reality, manufacturing facilities need to invest in IIoT sensors and CIM devices to collect data from legacy machines. IIoT sensors and CIM devices help manufacturing facilities quickly adopt innovative technology for the digital transformation.

Make a new investment in hiring personnel: To adopt the new technology, the manufacturing facility needs to invest in data analysts to turn the data collected into something usable or valuable – one more area to reskill your existing personnel to fulfil the requirement. This is also an area where CIMCON can help provide technical expertise.

Open to change and keep upgrading SMART FACTORY implementation: As you and your staff grow more familiar with innovative technology and its benefits, it will become easier to continue to expand smart technologies to other facility areas. The factory is flexible and responsive and can perform in a dynamic environment.

Implementing smart factory technology with CIMCON’s product and platform

Implementing the SMART FACTORY in any business can be difficult and time-consuming. CIMCON DIGITAL is a company that can provide support for digital transformation in terms of both software and hardware, with vast experience in the development and implementation of automation using various in-house developed products, such as sensors, CIM devices, and so on.

CIMCON devices will address all the issues that will transform the industries and support in converting the factories into smart factories of the future.

Contact us today to begin your smart factory adventure.

#predictive maintenance#iot edge platform#condition monitoring sensors#vibration sensor#digital transformation solutions

0 notes

Text

atrociously sticky adhesive, gone, due to the powers of a heat gun and goo-gone

#all the oils have been stripped from my hands#smart home bullshit#got a pile of tilt/vibration sensors to detect two main things:#did i remember to put the frozen bagels in the oven before i started making coffee?#and: have they picked up the garbage bins yet?#but the fucking things came with so much of the world's most annoying and stubborn adhesive on them for fuck only knows why

35 notes

·

View notes

Text

etho redstone r&d letsplay episode with a sick new redstone contraption [VIBRATING]

#khaos.txt#ITS SO COOL#i love love love how he repurposed the hopper clock timer to be a memory switch#its so smart#cuz most ppl would just think to put a timer/delay on their skulk sensor-activated things (im specifically thinking bdubs's conveyor on hc)#but no!! he figured out a smart way for the redstone to *know* for certain that u're there!!!#every day my respect for this man increases#like he's still finding new and creative ways to use redstone ingame and im just [VIBRATING]#and also? its so simple? like its incredibly simple and compact and just WOAGH

2 notes

·

View notes

Text

https://www.futureelectronics.com/p/semiconductors--analog--sensors--accelerometers/lis2mdltr-stmicroelectronics-5089926

High temperature accelerometers, programmable accelerometer sensors

LIS2MDL Series 3.6V 50 Hz High Performance 3-Axis Digital Magnetic Sensor-LGA-12

#STMicroelectronics#LIS2MDLTR#Sensors#Accelerometer Sensors#high temperature#programmable#wireless accelerometer programming#accelerometer vibration sensor#accelerometer chip#3 axis accelerometers#single axis accelerometer

1 note

·

View note

Text

The Ultimate Guide to Choosing the Right Glue for Your Vibration Sensor

In the dynamic world of industrial technology, selecting the appropriate components for your vibration sensor is crucial for ensuring optimal performance. One often-overlooked aspect is the adhesive used to affix the sensor in place. At STI Web, where precision meets innovation, we understand the significance of choosing the vibration sensor glue for your vibration sensor applications.

Understanding Your Requirements: Before delving into the options available, it's essential to assess your specific needs. Consider factors such as environmental conditions, temperature variations, and the material of the surfaces involved. At STI Web, our range of vibration sensors caters to diverse industries, and we recognize the importance of tailoring adhesive solutions to match these unique requirements.

Options for Vibration Sensor Glue: Epoxy Resin Adhesives: Ideal for demanding environments with extreme temperatures. Provides excellent bonding strength and durability. Resistant to chemicals and moisture, ensuring longevity. Cyanoacrylate Adhesives: Quick-drying and easy to apply. Suitable for applications with minimal stress and temperature variations. Offers reliable adhesion for various surfaces. Silicone Adhesives: Known for flexibility and resistance to environmental factors. Excellent for applications with vibration and movement. Provides a strong, yet flexible bond. Expert Guidance from STI Web:

Navigating the plethora of adhesive options can be challenging. At STI Web, our commitment to excellence extends beyond our cutting-edge sensor technology. Our experts are ready to assist you in choosing the right glue for your vibration sensor, ensuring seamless integration and enhanced performance.

Conclusion: In the realm of vibration sensors, the choice of adhesive is a critical consideration that should not be underestimated. STI Web, with its comprehensive range of products and commitment to customer satisfaction, stands as a reliable partner in helping you make the right decision. For more information on our vibration sensors and adhesive solutions, visit explores the possibilities of precision in motion.

0 notes

Text

The Power of Predictive Maintenance Vibration Analysis Sensors

The integration of vibration sensors marks a significant leap forward in predictive maintenance. Wireless vibration sensors for predictive maintenance allow the seamless process of fault detection, swift responses, precision in analysis, the sophistication of machine learning, downtime reduction strategies, and the ultimate optimization of production efficiency.

For More:

0 notes

Text

Vibration Sensor Market Size, Share, Trends, Outlook, Forecast 2024-2032

According to IMARC Group latest report titled “Vibration Sensor Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032”, offers a comprehensive analysis of the industry, which comprises insights on vibration sensor market forecast. The report also includes competitor and regional analysis, and contemporary advancements in the global market.

The global vibration sensor market size reached US$ 4.5 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 7.4 Billion by 2032, exhibiting a growth rate (CAGR) of 5.4% during 2024-2032.

Request a Free Sample Report: https://www.imarcgroup.com/vibration-sensor-market/requestsample

A vibration sensor, also known as an accelerometer or vibration transducer, is a device designed to detect and measure vibrations in machinery or structures. It converts mechanical vibrations into electrical signals, providing valuable data for monitoring equipment health and identifying potential issues. Vibration sensors are widely used in various industries, including manufacturing, aerospace, automotive, and infrastructure. They help prevent equipment failure, reduce maintenance costs, and enhance overall operational efficiency by detecting abnormal vibrations that may indicate misalignments, imbalance, or wear. The collected data aids in predictive maintenance strategies, ensuring timely intervention and preventing unexpected breakdowns in machinery or structural components.

Market Trends:

The global market is majorly driven by the increasing emphasis on predictive maintenance. In line with this, industries worldwide are increasingly adopting predictive maintenance strategies, leveraging vibration sensors to monitor equipment health. These sensors play a pivotal role in detecting abnormalities in machinery early on, reducing downtime, and optimizing maintenance schedules. Furthermore, the rise of Industry 4.0 and the broader trend of industrial automation contribute significantly to the market's growth. Vibration sensors are integral components of smart manufacturing systems, enabling real-time monitoring and control of machinery. This facilitates data-driven decision-making, improves overall equipment effectiveness, and supports the transition toward more efficient and connected industrial processes. Besides, the expanding use of vibration sensors in diverse applications, including automotive, aerospace, healthcare, and infrastructure, drives market diversification. In the automotive sector, for example, vibration sensors contribute to vehicle safety and performance monitoring. In healthcare, they play a role in medical diagnostics and monitoring equipment. Additionally, rapid technological advancements, particularly in sensor design and data analytics, enhance the capabilities of vibration sensors. Integrated wireless communication and Internet of Things (IoT) connectivity enable seamless data transmission and remote monitoring, fostering the adoption of these sensors across various industries.

View Full Report with TOC & List of Figure: https://www.imarcgroup.com/vibration-sensor-market

Competitive Landscape

The competitive landscape of the industry has also been examined along with the profiles of the key players operating in the market.

Analog Devices Inc.

Bosch Sensortec GmbH (Robert Bosch GmbH)

Dytran Instruments Inc.

Emerson Electric Corp.

FUTEK Advanced Sensor Technology Inc.

Hansford Sensors Ltd.

Honeywell International Inc.

National Instruments Corporation

NXP Semiconductors N.V.

Rockwell Automation

Safran Colibrys SA

SKF

TE Connectivity Ltd.

Texas Instruments Incorporated.

Key Market Segmentation:

Our report has categorized the market based on region, product, technology, material, and end-use industry.

Breakup by Product:

Accelerometers

Velocity Sensors

Non-Contact Displacement Transducers

Others

Breakup by Technology:

Piezoresistive

Strain Gauge

Variable Capacitance

Optical

Others

Breakup by Material:

Doped Silicon

Piezoelectric Ceramics

Quartz

Breakup by End-Use Industry:

Automotive

Healthcare

Aerospace and Defence

Consumer Electronics

Industrial Machinery

Others

Breakup by Region:

North America (United States, Canada)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Asia Pacific (China, Japan, India, Australia, Indonesia, South Korea, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

Key Highlights of the Report:

Market Performance (2018-2023)

Market Outlook (2024-2032)

Porter’s Five Forces Analysis

Market Drivers and Success Factors

SWOT Analysis

Value Chain

Comprehensive Mapping of the Competitive Landscape

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

0 notes

Text

Accelerometer and Vibration Sensor Market

0 notes

Text

Bently Nevada Vibration Sensors Supplier - Your Trusted Source: WOC

Your Trusted Bently Nevada Vibration Sensors Supplier. Contact World of Controls today to procure Bently Nevada vibration sensors. We provide worldwide shipping.

0 notes

Text

Trumen is a technocrat driven organization aimed at providing top-of-the-range and high quality level measurement and process control instruments. Formed by the pioneers who devoted their respective lives in development, design and delivery of solution to the problems faced in the field of level sensing and process measurements. Trumen has a fixed point agenda about “sensing matters”, and each device created at Trumen is thoroughly tested to pass the quality norms set in-house, in order to give the best performance in all operating conditions.

The products designed and manufactured by Trumen confirm to various international quality standards. Instruments having best in class IP-68 certified enclosures, Ex-proof enclosures suitable for hazardous area and gas group IIA, IIB and IIC and PU Epoxy coated enclosures suitable for harsh environment. Trumen also produces instruments with SS enclosures suitable for food and pharma industries and PU enclosures suitable for chemical industries.

Address: 39, Mangal Nagar, Behind Sai Ram Plaza, Near Rajeev Gandhi Circle, AB Road, Indore, Madhya Pradesh 452001

Web: https://trumen.in/

Contact: 0731 497 2065

#Point Level Switches#Level Transmitter#Indicator Controller Transmitter#Level Switch#Level Sensor#Level Indicator#Vibrating Fork Level Sensor#Vibrating Fork Level Switch#Vibrating Rod Point Level Switch#Tuning Fork Point Level Switch#Admittance Point Level Switch#Rotating Paddle Level Switch#Radar Level Transmitter

0 notes

Text

0 notes

Text

Wtf is that shit clipped onto Folinics ears? Are those monitors or headphones?

0 notes

Text

deputy's daughter

words: 1.6k

warnings: 18+ only!, p in v sex, unprotected sex, pull out method, caught

“rafe!” you hiss as he makes his way into your room through his preferred method of the window. “my dad is going to kill you!”

“is he home?” he questions. he didn't see the cop car sitting in your driveway, which is why he scaled the lattice to sneak inside.

“no, but he's gonna be home any minute now!” you keep your voice quiet despite the rest of the house being empty.

“let me kiss you until he gets home then.” rafe says, cupping your cheeks and pulling you into a heated kiss. you know it's never just a kiss with him, but you can't help but open your lips for his adventurous tongue, gripping his shirt to pull him in closer.

rafe smirks against your mouth. he could have texted you asking you to let him, but that would have taken all the fun out of it.

“you have to leave as soon as my dad gets home.” you scold him as rafe lays you back on your bed.

“i know you can’t keep quiet.” rafe chuckles, hand groping at your tits through your thin pajama shirt. thankfully the flood lights above the garage are motion sensored, and with your open window they'll alert you when your dad gets home.

“if only deputy shoupe knew what i was doing to his little angel of a daughter.” rafe chuckles as you send him a glare, tugging at his shirt in a silent plea for him to take it off.

“shut up, cameron. he likes you anyways.” you roll your eyes. now if it was a pogue in your bed, that would be a whole different story.

“mhm.” rafe nods, tugging your shirt up, revealing your bare chest. “im just so charming. all the parents love me.”

“all?” you raise your eyebrows, taking your shirt the rest of the way off, flinging it across the room. “you mean you do this with other girls.”

“not anymore.” rafe shakes his head, mouth dropping to your nipple, tongue flicking over the sensitive bud. “you know they don't compare to that delicious pussy, baby.”

you tsk. “it's a shame you don't have time to eat it then.”

rafe sighs dramatically, like it physically hurts him to not be able to give you head, to let his tongue drag through your folds and slurp up your juices.

“just a quick taste then ill fuck you, promise.” rafe tugs your pajama shorts down, knowing you never wear underwear just for him as he buries his face between your legs, forcing your thighs apart as his greedy mouth explores your pussy.

“delicious, baby.” rafe groans, voice vibrating against your skin. “my favorite meal.” he continues for only a moment longer, flicking his tongue against your entrance before moving up to press a wet kiss to your clit, making you moan out, eyes flickering to your window, making sure you somehow didn't miss the floodlights turning on.

rafe stands up with a lick of his lips, quickly undressing himself until he's just as bare as you are.

“condom?” he asks, forgetting to put one in his pocket, so caught up with getting over to your house on time, even running from his car to your yard, always parking a block away to not cause suspicion.

“fuck, you didn't bring one?” you groan, turning towards your bedside table. you squint in the low light as you scrounge through the drawer, but you know that you used the last one with rafe a week ago.

“just…” you sigh, pressing your forehead into the bed. “just pull out, okay?”

“promise.” rafe nods, eyes on your ass like they have been since you first turned onto your stomach, only half listening to what you're saying, but glad that you're still letting him fuck you.

rafe kneels over your legs before you can move back to your front or rise to your hands and knees. “stay like that.” he hums, gripping his cock and pushing it between your thighs, rubbing the head through your slick.

“fuck, you're so hot.” rafe groans as you reach behind your back, pulling your ass apart to show off both of your holes. “gonna let me play with this one one day?” rafe hums, his tip sliding past your entrance to your other hole, tapping against it.

“maybe.” you smirk. but certainly not today, not when you're already playing on limited time.

rafe slides back down to your cunt, pushing in as he leans forward, covering your body with his own. one hand keeps him held up, stopping from putting his complete weight on you, while the other grips your ass.

“fuck.” rafe groans out, his voice sounding more hoarse than usual. “you feel so good with nothing in between us.”

you moan as well as rafe bottoms out, pushing as far in as your pussy allows. he sits still, allowing you to adjust, to feel every ridge and vein of his cock. he goes from giving you nothing to pounding into you in an instant, the sound of your skin slapping together filling the room.

rafe gives a glance at the window. lights still off. he smirks down at you, your hands now gripping into the bedsheets as he plows into you from behind, using the full force of his hips with every thrust.

“m-more.” you mewl out, body shuddering as rafe manages to go deeper with a tilt of his hips, along with you arching your back and bringing your ass up further into the air.

you let out loud groans with every thrust that's now hitting your sweet spot, pushing your orgasm quickly to the surface.

“fuck baby, you're so tight.” rafe grunts out. “don't know how much longer i can last.”

“re-remember to pull out.” you manage to hum out, even though you wish you could feel him fill you up, you're not on birth control and are already taking a risk with having sex at all.

“ass or tits?” rafe questions.

“ass.” you shake your hips from side to side, making rafe let out a loud curse, pulling out sooner than he'd like to to jack himself off, spilling almost instantly over your ass and back, spreading long ropes of cum along your skin.

rafe is quick to grab a tissue and clean you off, as much as he likes seeing you covered in his cum, he's got other things to focus on.

just as he's about to flip you over to eat you out, the lights outside turn on.

“fuck!” you curse, knowing you have seconds before your dad enters the house. you turn over to look at rafe. you gotta get out.”

“you didn't cum yet.” rafe shakes his head, body covering you again, pressing you back down into the plush mattress. “im not leaving without giving you at least one orgasm.”

“you're gonna be leaving with a bullet in your chest if my dad catches you!” you hiss out.

“itll be worth it.” rafe manages to force his hand underneath you, finding your clit with ease as he rubs his fingers between your folds.

“y/n!” your dads voice calls out. you usually greet him downstairs, staying locked in your room is bound to cause suspicion.

“rafe.” you moan out quietly. “please, stop.” you can barely keep yourself from screaming out as his fingers just move faster, his weight pressing down on you too much to move.

“babygirl?” shoupe calls out, his loud footsteps marching up the stairs.

“i-in my room!” you call out.

“you okay?” he asks, now right outside your door. you have to cover your mouth as rafe flicks your clit. you take a deep breath before answering.

“yeah, fine!” your voice wobbles a little, something you know your dad notices. “just period cramps!”

“can i get you some midol?” he questions, and you know his ear is pressed to the door, listening for any signs that something is amiss as rafe rubs you quicker, refusing to slow down, needing to get an orgasm out of you.

“already took some!” you call out, having to press your face into your mattress as you cum, body shaking as rafe smirks above you, hearing your muffled noises. “i think im just gonna go to bed early.” you say as soon as you recover.

“alright, goodnight sweetheart.”

rafe finally allows you to flip over, lifting himself to lay on his side next to you. you raise your eyebrows and hold your finger to your lips, signaling rafe to be quiet until you hear your father's footsteps move down the hallway.

“rafe, you almost got us caught!” you whisper, giving him a shove on the shoulder, only to be met by a proud smile on his face.

“had to get you off, princess, otherwise it wouldn't be fair.” rafe leans forward to plant a kiss on your lips, feeling the way you melt against him.

“am i forgiven?” he questions.

“yeah, just get out.” you giggle quietly. you think your dad bought your explanation, but you can never be too sure.

rafe dresses quickly, throwing your pajamas onto the bed so you can also get decent.

“gotta give you one more kiss.” he leans over your bed to give you a sweet kiss, lips moving gently against each others.

“okay, now go.” you shoo rafe out, heading to the window now that your legs feel a bit more stable, watching him climb down the lattice. he gives you a wave once his feet hit the concrete, only for his entire body to freeze when the side door opens up, your dad stepping out into the light.

“rafe cameron, im going to kill you!”

taglist: @drewstarkeyslut @forstarkey @f4ll-for-you @dilvcv @drudyslut @jjmaybankswifes-blog @rafescokenostril @jjsmarijuana @seeingstarks @angelofcigs @cece45450 @babygorewhore @vanessa-rafesgirl @michelleisheres-blog @outerbankspov @drewstarkeyswifehoe @cutielando @kamninaries @buckyswhxre @rafeinterlude @bellbottombaby @deeaardiary @rubixgsworld @wearemadeofstardust0 @leighbronk @starkeysheart @pradabambie @tobesolovelysstuff @alexiskirkland @rafestar @brioffthegrid @juniebugg @magicalyoura @cokepewpsii @mysticallystilinski @luvdella @aerangi @folklorsweet @yourenogoodforme @auryyz @mayhem-72 @thestarlithideout @marvelfanfics1recs @rafesgiirl

#rafe smut#rafe cameron smut#obx smut#outer banks smut#rafe fic#rafe fanfic#rafe fanfiction#rafe cameron fic#rafe cameron fanfic#rafe cameron fanfiction#rafe x you#rafe x oc#rafe x reader#rafe x y/n#rafe cameron x you#rafe cameron x oc#rafe cameron x y/n#rafe cameron x reader#rafe drabble#rafe blurb#rafe imagine#rafe one shot#rafe cameron drabble#rafe cameron blurb#rafe cameron one shot#rafe cameron imagine

3K notes

·

View notes