#VacuumArcWelding

Explore tagged Tumblr posts

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

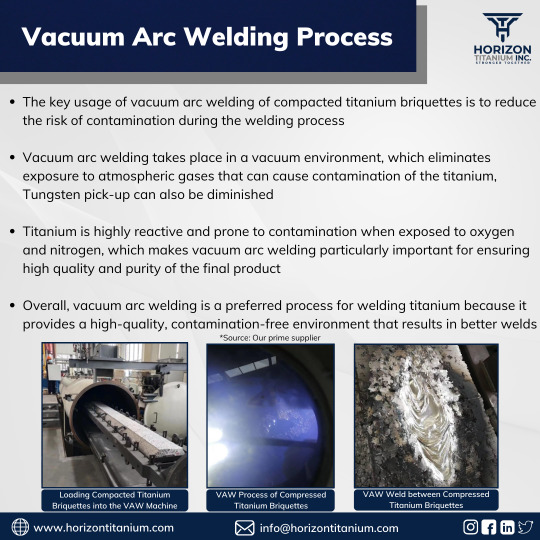

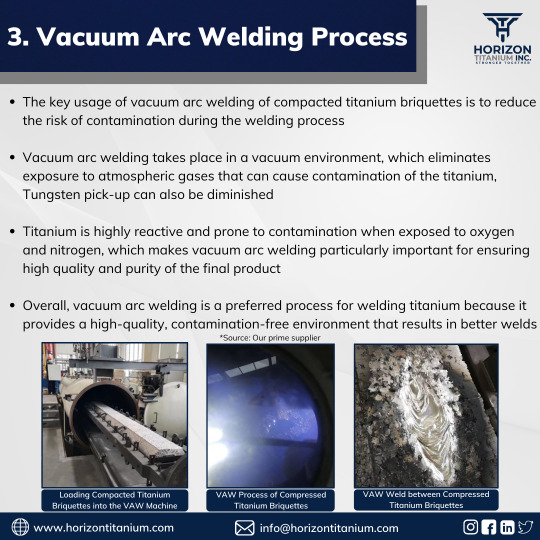

Let's delve into the third major step of our Titanium bar manufacturing process: Creating the Titanium electrode using Vacuum Arc Welding.

Distinguishing Process Parameters

Vacuum environment Consumable electrode

Distinguishing Electrode Weld Quality

Free of Tungsten inclusion High purity High weld strength Low hydrogen content

Please stay tuned as we progress on this journey, offering you an in-depth look into our production process. We are excited to share every crucial phase of crafting high-quality Titanium bars tailored for medical applications.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#MasterAlloysBriquette#VacuumArcWelding#WeldingArc#TitaniumElectrode#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Precision meets perfection!

Discover the finest Medical Titanium round bars that set new standards in quality and performance. Our Medical Titanium bars are produced with the best manufacturing expertise and adhere to stringent quality parameters, ensuring excellence in every bar we deliver.

If you are looking for high-precision Titanium materials, you can email us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#MedicalTitaniumRoundBars#QualityTitanium#Ti6Al4VELI#ELI#Gr23#ASTMF136#ISO5832_3#h9Tolerance#LustrousFinish#SpongeGrade0#VacuumArcWelding#3VAR#Microstructure#UniformDimensions#ChamferedBars#Traceability#OptimumHardness#HigherFatigueStrength#HigherFractureToughness#MedicalImplants#OrthopaedicImplants#MedicalDevices#Orthopaedic#TitaniumImplants#HorizonTitanium#StrongerTogether

0 notes

Photo

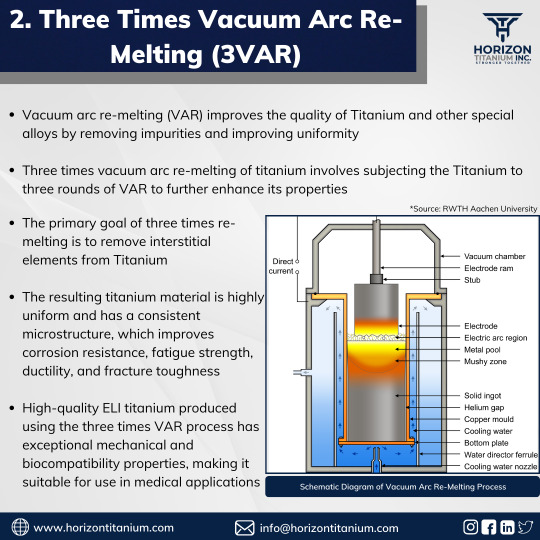

The Vacuum Arc Welding technique is used to join briquettes (compressed titanium sponge and alloying components) to make an input raw material ingot for the Vacuum Arc Re-melting process. Vacuum Arc Welding should be chosen over Plasma Arc Welding, especially for ELI-grade production for medical applications.

#KnowYourTitanium#Titanium#VacuumArcWelding#PlasmaArcWelding#Briquettes#BetterProperties#MechnicalProperties#Metallurgy#FatigueStrength#FractureToughness#HighQuality#TungstenPickUp#Oxygen#Nitrogen#ContaminationFree#QualityWeld#HorizonTitanium#StrongerTogether

0 notes

Photo

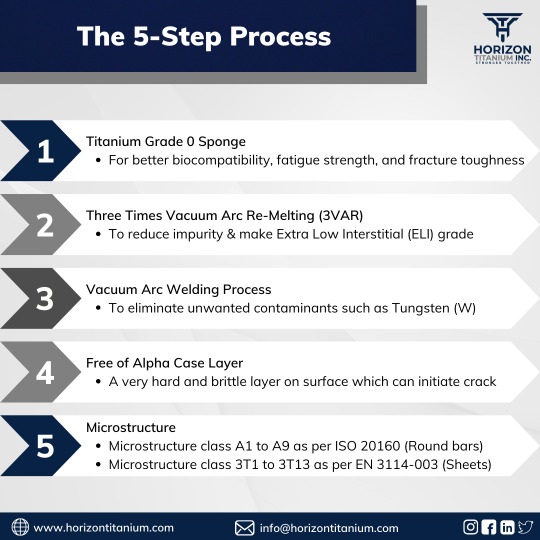

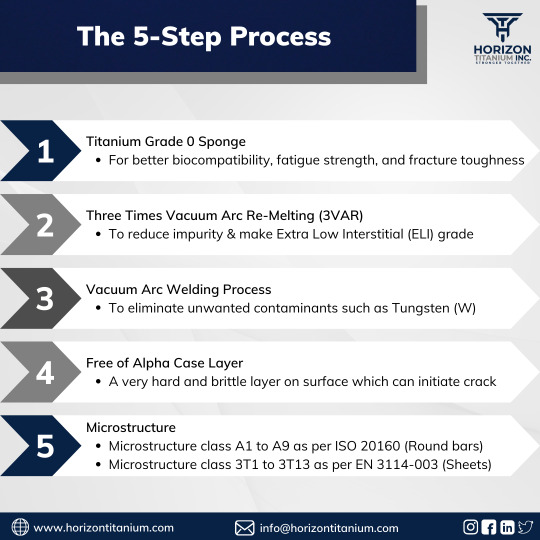

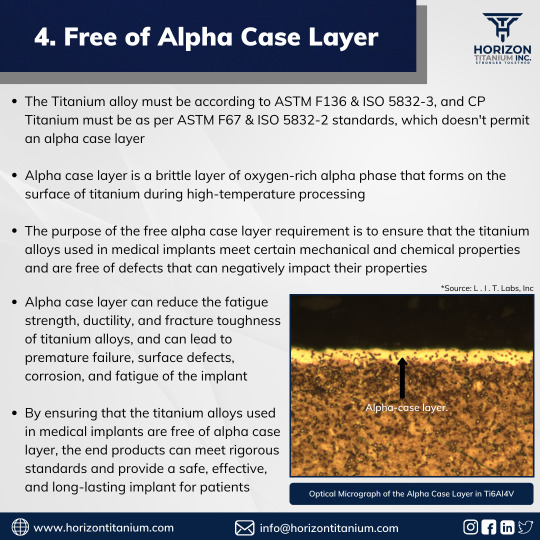

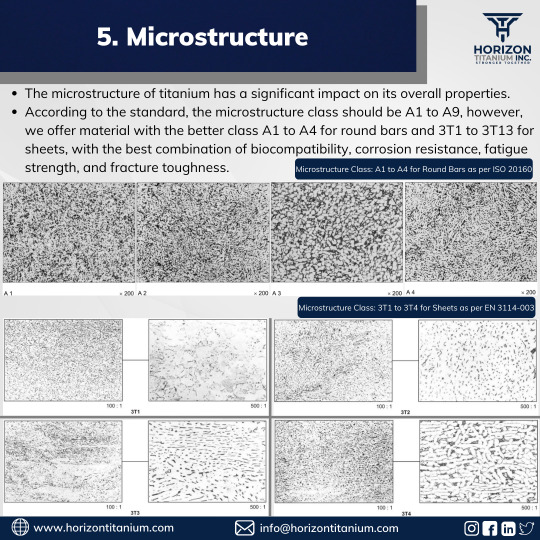

We have identified the five steps to consider when purchasing the right Titanium for medical applications. For more information on Titanium for medical applications, you can write to us at [email protected]

#KnowYourTitanium#The5StepProcess#TitaniumSponge#Sponge0#ThreeTimeVacuumRemelting#VacuumArcWelding#FreeAlphaCaseLayer#Microstructure#Biocompatibility#FatigueStrength#FractureToughness#ELI#OrthopaedicImplants#MedicalImplants#HorizonTitanium#StrongerTogether

0 notes

Photo

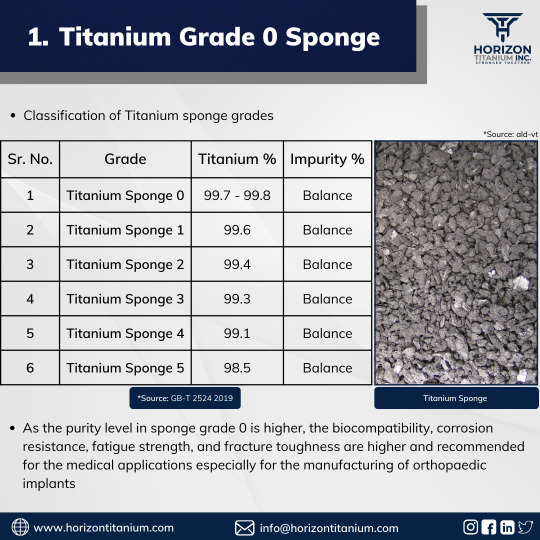

At Horizon Titanium, we understand how important it is to purchase high-quality medical grade titanium for implant manufacturing purposes. That's why we want to share some expert tips with you to help you make the right purchase decision without compromising on quality. We believe that when it comes to medical applications, quality should never be compromised, and we are here to help ensure that your purchase meets the highest standards. If you have any questions or need more information on titanium for medical applications, please reach out to us at [email protected]. We would be more than happy to assist you in any way we can.

#KnowYourTitanium#TitaniumSponge#SpongeGrade0#VacuumArcReMelting#3VAR#VacuumArcWelding#FreeAlphaCaseLayer#Microstructure#HighQualityTitanium#MedicalApplications#TitaniumRoundbars#TitaniumSheets#FatigueStrength#FractureToughness#CorrosionResistance#Biocompatibility#ExpertTips#OrthopaedicImplants#MedicalImplants#HorizonTitanium#StrongerTogether

0 notes