#Urethane cement flooring

Explore tagged Tumblr posts

Link

If you have any querry related to any flooring or you want best floor installation in Florida and Georgia, you can contact us via calling at 844-443-2844.

#brewery flooring#Brewery flooring GA#Brewery flooring FL#commercial flooring#concrete polishing#urethane cement floors#urethane cement flooring

1 note

·

View note

Text

#epoxycoating#CommercialFlooring#epoxyflooring#resinousflooring#CommercialKitchen#epoxy flooring#commercial flooring#epoxy flooring contractors#epoxy floor contractors#urethane cement flooring

0 notes

Text

Urethane Flooring System

How to Apply Urethane Cement Floor Coating System!

#https://www.extremeepoxycoatings.com/urethane-cement-floor-coating/#Urethane Flooring System#Urethane Cement Flooring#Epoxy Flooring Installation#Epoxy Flooring#Epoxy Floor Coatings#How To Install Epoxy Floors#Epoxy Floor Installation#Epoxy Flooring Installation Cost#What Is Epoxy Flooring#Epoxy Flooring Designs#Epoxy Flooring Near Me#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

0 notes

Text

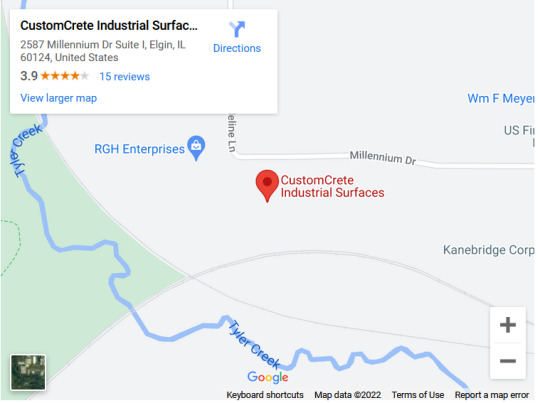

Business Name: CustomCrete Industrial Surfaces

Street Address: 2587 Millennium Dr. Suite I

City: Elgin

State: Illinois (IL)

Zip Code: 60124

Country: United States

Business Phone: (847) 651-9699

Business Email: [email protected]

Website: https://customcrete.net/

Facebook: https://www.facebook.com/CustomCrete.net/

Yelp: https://www.yelp.com/biz/customcrete-elgin

Business Description: CustomCrete offers commercial flooring solutions, including urethane cement, polished concrete, and epoxy systems. We are proud to serve the Elgin area and have been doing so for over 15 years. Let our team revive the look of your industrial floors with a new floor coating system today. Learn more about our services online.

CustomCrete serves a variety of industries, including automotive, manufacturing, healthcare, and more. We are proud to be the go-to choice for flooring solutions, including urethane cement, epoxy systems, and more. Check out our Concrete coatings and polishing services online today.

CustomCrete is proud to work with business owners throughout the Elgin area for their concrete flooring needs. We specialize in high-quality concrete flooring finishes to give our commercial customers the best look and durability for their business. Check out our flooring solutions online today.

Google My Business CID URL: https://www.google.com/maps?cid=4844776868018773114

Business Hours: Sunday Closed Monday 7AM–5PM Tuesday 7AM–5PM Wednesday 7AM–5PM Thursday 7AM–5PM Friday 7AM–5PM Saturday Closed

Payment Methods: Cash Cheque Debit Card Visa Master Card American Express Discover

Services: Polished Concrete, Epoxy, Urethane Cement, Concrete Sealing, Concrete Grinding

Keywords: floor coating near me, floor coatings near me, floor coating companies near me, epoxy coating for concrete, epoxy concrete floor coatings, concrete epoxy floor coatings, commercial epoxy floor coating, commercial epoxy flooring, commercial kitchen epoxy floor coatings, high performance concrete coatings, concrete repair coatings, cement coat, urethane floor coating, polyurea concrete coatings

Business/Company Establishment Year: 2006

Location:

Service Areas:

2 notes

·

View notes

Text

The Most Effective method To Install Hardwood Floor On Concrete Surfaces

There are sure factors to introduce a hardwood floor yourself that you should recall.

Stage One

Significant Level Finished Floors

Hardwood floors may cause a stature distinction on occasion. The last statures are in the 2 ¼ range whenever you have nailed the hardwood made floor. This makes a hindrance for the outside entryway sections and fixed articles. When ¾ inch wood is utilized over the sleepers it raises the tallness normally. This is the motivation behind why new development ought to be arranged

Stage Two

Use Plywood on cement

While introducing hardwood floors attempt to do ¾ inch hardwood on concrete, the most ideal route is to put pressed wood sub floor joining it to a section. Use clasp to hang on.

Stage Three

Drifting sub floors expect compressed wood to be affixed to concrete

Utilize coasting sub floors while utilizing ¾ inch strong hardwood on cement. Coasting sub floors are made of two layers of ½ inch pressed wood introduced inverse each other. It might cover creases and be in a bad way together.

Stage Four

Compressed wood ought to be adhered to concrete

Aside from utilizing gliding sub floors to stick the compressed wood to the solid, you can likewise utilize urethane glue. This is to accomplish kerfs cuts on the posterior with a roundabout saw to improve its flexing properties.

Tips And Suggestions

Aside from the above you can likewise introduce hardwood floors with designed hardwood floors which fundamentally skim over the sub floor. They are stuck to the solid not nailed. Anyway you should counsel a maker before you start the establishment interaction of your wood floor.

External Links:-

Website

Wordpress

Jigsy

1 note

·

View note

Text

Tracking Roller Assembly with Web Guiding System Price, Use, Specification & Application

KEW is one of the leading manufacturer, supplier, and exporter of Tracking Roller Assembly With Web Guiding System.

It consists of two rectangular steel tubing frames. One is stationary, the other is movable. it is supported in a nyalguide sliding block and arcuate bar system and has ab idler roller at either end.

Our Tracking Roller Assembly with Web Guiding System for various industries running with accurate performance.

Technical Specifications of Tracking Roller Assembly:

Electronic of the film Photocell sensor for edge

Electronic 0 5 HP AC Motor

Electrical Panel Board to Operate the complete Unit

Hydraulic Cylinder Adjuster Oil Pipe

Speed of Unit 250/min

Variation of the film Winding is 0.5

Hydro-Pneumatic Web Aligner Unit

0.5 H.P. Motor

Air Pipe 5 Mtr.

Oil Pipe 5 Mtr.

Sensor 1 pcs

Adjuster 1 pcs.

Air Filter 1 pcs.

Oil Filter 1 pcs.

Hydraulic Cylinder size 6 stock 1 pcs

The web can be fed over the TRA in A ‘U’ shaped path, reversing its direction of travel, or through the TRA in a ‘Z’ configuration, maintaining the same direction of travel. It is insensitive to attitude and can even be mounted upside down.

Solidly supported on all four corners by nylaguide bearings, it is not subject to deflections caused by cantilever stresses.

Radial bearings are sealed, and linear bearings are self – cleaning and self – lubricated.

Standard adapter bases consist of a stationary floor mounted frame or plate, a four-unit, standard nylaguide bearing and support system, and a moving frame of the plate.

A heavy-duty servo cylinder is nested between the frames and the nylaguide bearings. The servo cylinder moves the upper adapter base plate back and forth in response to hydraulic signals from the power unit.

The TRA is designed so that it swings in an arc laterally, pivoting about an imaginary pivot point located exactly in the plane of the entering web path.

The servo cylinder swings the other end of the frame, moving the outgoing web laterally back into the desired web path.

It can be installed successfully on lines handling fragile materials such as parchment paper, thin metal foil, or saturated paper even.

Standard Features of Tracking Roller Assembly:Tracking Roller Assembly(TRA) with

Web Guiding System

Frame with the

Web Aligner System

is the best way to guide the web path for proper winding.

This System allows the perfect winding of the web by guiding the web with the help of Linear Bearings or Nyla Guide Bearings to ensure perfect tracking. The Bearings are high quality imported to ensure the working maintenance-free.

The Tracking Roller Unit is generally mounted on Rotogravure, Lamination Machine, etc. Also Manufacturer of

Rewind Trolley with Web Guiding System

It consists of two rectangular steel tubing frames. One is stationary, the other is movable. it is supported in a nyalguide sliding block and arcuate bar system and has ab idler roller at either end.

The web can be fed over the TRA in A ‘U’ shaped path, reversing its direction of travel, or through the TRA in a ‘Z’ configuration, maintaining the same direction of travel.

It is insensitive to attitude and can even be mounted upside down. Solidly supported on all four corners by nylaguide bearings, it is not subject to deflections caused by cantilever stresses.

Radial bearings are sealed, and linear bearings are self-cleaning and self-lubricated. The unit, therefore, requires no maintenance.

Our Other Varieties of Tracking Roller Assemblies:

Tracking Roller Assembly

Tracking Roller Assembly with Web Guiding System

Pivot Tracking Assembly

Web Guiding System With Tracking Frame

Applications of Track Rollers:Track rollers find application in a wide range of use cases, such as robotic welders, assembly and paint line conveying systems, automated storage and retrieval systems, and fracking equipment.

Some of the typical industries which employ track rollers include:

Architectural

Automotive assembly

Cement and concrete plants applications of Track Rollers

Fiberglass manufacturing

Food and beverage production

Foundries and mills

Medical

Metal processing

Mining

Pharmaceutical

Pulp and paper

Sand and gravel

Scientific research

Shipbuilding

Wood products

Track rollers are available to suit the needs of special applications:

All stainless construction for corrosion resistance

High temp construction for up to 325 °F max (continuous) with high temp seals and lubricants

Non-metallic treads that are non-marking and non-sparking, available in nylon and urethane

The above are available with Plain Concentric Stud, Flanged Concentric Stud, and V-Grooved Concentric Stud

Other Related Keywords:

Web Guiding

Web Guiding Unit

Web Guiding System

Web Guiding Equipment

Tracking Roller AssemblyWeb Guide Control System

Web Guiding System Manufacturers

Hydraulic Web Guide Control System

1 note

·

View note

Text

Concrete Acid Stain Colors Photos: 11 Thing You're Forgetting To Do

The stain is acid based, so consider precautions for that.Don gloves and rubber boots when dealing with it.

Crystal clear sealers can insert Visible depth and gloss though defending constructions from have on. Use colored sealers to determine places, like your pool deck or youngsters’s Enjoy area, to combine your home into its purely natural environment and also to signal the excellent amount of maintenance foreseeable future purchasers can anticipate in the course of your home

How to construct a Retractable Cover Handle the shade by creating your individual retractable Cover. Open it up to produce a shady retreat or close it to Enable the sun in.

In case you have Earlier experienced carpet you will have to clear away the tac strips which will probably leave holes in the concrete, these needs to be stuffed and sanded down. We developed an eight inch border throughout the entire room and used a vinyl concrete to resurface the border because of the massive holes the tac strips still left powering.

A craftsman that has experience in acid stained concrete floors is commonly a good candidate to apply his / her skill to acid staining concrete countertops. The Decorative Concrete Institute gives know-how and instruction in acid staining, in addition to Bob Harris Guides.

The amazing mottled or variegated search is similar to acid staining but in case of LastiSeal, it is possible to Make a choice from 37 different colors!

youtube

five. Mix many bottles of the same shade of acid stain with each other within a 5 gallon bucket, various batches could Provide you with distinctive final results in your concrete floor, patio, or driveway.

Surecrete’s SureStain acid concrete stain can be employed indoors and outside. Coloration versions may occur as a result of discrepancies in cement, aggregates and ways of application. See the acid stain color chart under. An excellent item for staining concrete with earth tone coloured floor stains.

(like in the image down below) Knowledgeable installers can seal the concrete with epoxy and urethane sealers for surfaces that will get a wide range of foot traffic.

I chose the Apparent a Thane in Satin for our floors. There continues to be a sheen, nonetheless it’s delicate. It’s a little bit more slippery than I hoped, but person do They give the impression of being astounding!

Your current previous concrete ought to be fantastic to stain, so long as it is not contaminated with glue, paint, oil, grease, sealers, waxes, or anything that will stop the stain from soaking to the pores of your concrete. The only way to check to view if your previous concrete is sealed is by pouring slightly water onto the concrete.

3. Normally do samples on the concrete floor before you go on and obtain all the acid stain. Most businesses have sample bottles they'll offer you, and for The main reason mentioned in tip #2, you won't understand what the stain will seem like on your concrete till you are doing a sample with your concrete.

Observe: Never use the stain in direct sun; watch for a cloudy day or use it if the concrete is in shade. The stain will dry a lot more swiftly while in the Sunshine and won't Provide you A great deal time for you to blend your strokes.

Use color to produce your terrace and entry paving an extension of your property. Define your outdoor eating location, children’s Perform garden and pool space While using the fascinating colors and textures you could generate with sealers. SureCrete offers custom-coloration mixing and can match merchandise to the palette of significant paint producers.

2 notes

·

View notes

Text

20 Myths About Coating Concrete Roof Tiles: Busted

Other than aesthetic motives, evidently a concrete coating is not essential for this tricky and sturdy combination of cement, h2o, sand and gravel, which isn't known to rust after it hardens.

Even so, it can be recommended to help make an indication on a sample of the actual area on which the stain is going to be utilized if you want to ascertain the suitability and the color it can give just after software.

We suggest this kit to people that love the practical experience and satisfaction of staining their homes all by by themselves.

On 1 of the demonstrates you had a gentlemand repairing an outside concrete porch. It acually looked like it was marbelized when he was completed. I want to learn how to try this plus the materia… go through additional

With SUNDEK, You should utilize an acrylic finish to offer your concrete surface a fresh new new look that’s long lasting and straightforward to maintain.

This Stone Tone Concrete Stain is uniquely formulated with chemical compounds that proficiently bond metallic ions with the lime factors within the concrete surface area to deliver out many different long-lasting colors.

Thank you for all of your help. It is good to be aware of that this provider is right here for folks like myself, who need to have answers speedy and they are undecided who to refer to.

youtube

Subscribe Unsubscribe × You are actually on Behr's e-mail list and opted in to acquire the most recent news from Behr. You are actually opted away from Behr email messages. We are sorry to see you go! Sign on to have most popular discounts and most current information.

Pour epoxy and urethane sealers on concrete floors just after about 28 days, once they have completely cured. On the other hand, driveways may need to cure for 6 months right before sealing. A sealing Expert will help guide you in the course of a session.

Several coats will keep dampness from entering and assist reduce h2o injury. This is very significant if you intend to put carpet, hardwood, or other flooring along with the concrete.

By continuing to employ This website you consent to using cookies on your own gadget as explained within our cookie plan Unless of course you might have disabled them.

So that you can have the most effective and durable outcomes, it can be advisable to carefully clean the concrete surface. It is because cleansing the surface area opens up pores for straightforward penetration and for much better binding with the concrete features.

As more US suppliers merge or are acquired, a lot more companies’ proprietors are removed from An important part of the company – The shopper. At Chemline our founder and operator still runs our enterprise.

As soon as their jobs are accomplished, the users log in for their accounts and entire a brief cost survey.

2 notes

·

View notes

Text

The Evolution Of Decorative Concrete Patio Paint

As a neighborhood decorative concrete resurfacing corporation in Houston, TX, we believe that there are additional Positive aspects in overlays Vs pavers, pure stone, and various costlier flooring treatment plans.

You gained’t get NextDay supply on this buy since your cart consists of product(s) that aren’t “NextDay suitable”.

For those whore unfamiliar with Operating with concrete, take into consideration investing a little bit more for an experienced that appreciates how to prepare and resurface with concrete.

The Marshalls Fairstone Sawn Versuro variety of decorative pavers is definitely an ethically sourced, fantastic-grained Indian sandstone. The smooth surface established by the brushed, sandblasted finish of those pavers creates a exquisite, classy and modern contact to any yard paving.

Concrete can also be cast into exclusive and in-depth designs utilizing urethane variety liner. These initiatives could be noticed close to the United States and the globe, usually on sound/retaining walls, setting up exteriors, and bridges.

It’s as simple as using them out and resetting them, that may be an attractive top quality for all those in the DIY. Also, if pavers are adequately installed with a fantastic foundation, there shouldn’t be major concerns with location or heaving.

Stamped concrete can be a appealing end to concrete locations, even so with time and have on the color dyes fade and also the floor looks patchy and unpresentable.

Of course. The primary reason is because the faces from the actions have to be completed and also the tops. This takes beyond regular time, ability, and products. An elevated patio provides the identical circumstance: the exposed edges all must be concluded.

Ethical sourcing: Being an Moral Trading Initiative member, we aim to adhere to the highest moral criteria. If you select an item with the Fairstone mark, this means we’ve taken each and every acceptable precaution to make certain child labour hasn't been applied.

Listed here at Walmart.com, we are devoted to safeguarding your privateness. Your e-mail deal with will never be marketed or dispersed into a 3rd party for any explanation. Make sure you have a minute to critique our Privacy Policy

As a consequence of our determination to shopper gratification, and our commitment to putting in superior quality concrete patios, Biondo Cement is happy to announce that we now present 3d designs with every single free of charge patio estimate.

youtube

This feature is additionally ideal for inside concrete floors. In such a case a just one colour/ stain software with a sealing coat is utilized in lieu of the more elaborate remedy alternatives. Don’t intellect the jargon, your contractor need to be able to clarify all the things to you.

Please be aware that the owner of This great site will not be A CONTRACTOR. If you would like an estimate to your job, remember to Get hold of among our member contractors by clicking in this article.

We use cookies that can help give you the best knowledge on our Internet site. In the event you continue without changing your settings, we are going to presume you are pleased to get all cookies on the web site. On the other hand, you could study our Cookie Coverage listed here.

1 note

·

View note

Text

Decorative Epoxy Floors: Know Your Options

Are you looking for a beautiful floor that not only looks good but also meets the needs of your facility? If so, you may be considering decorative epoxy flooring systems. There are numerous advantages to using a resinous decorative flooring system. Because epoxy and Urethane Flooring systems are extremely durable, they can withstand harsh chemicals as well as heavy traffic, machinery, and equipment. They also come in a variety of decorative styles, allowing you to tailor them to your specific needs and aesthetic preferences. You can also apply different finishes to make them shinier and last longer. So, let's look at some of the most popular types of decorative floors available. Read our blog about, Decorative Epoxy Floors: Know Your Options

1 note

·

View note

Text

🍕🍔🥗The color for this week’s #TBT Restaurant Kitchen flooring projects is #SherwinWilliams #TileRed. Visit our website to learn more about restaurant kitchen flooring.

#UrethaneCement#commercialflooring#epoxy flooring#commercial flooring#epoxy flooring contractors#epoxy flooring contractors nj#epoxyflooring#epoxy floor contractors#epoxy floor#urethane cement flooring

0 notes

Text

extremeepoxycoatings.com

Urethane Cement Floor Coating

When it comes to flooring solutions for your office, resin-coated concrete floors are among the best possibilities, especially if you work in a strictly regulated industry like food production or pharmaceuticals. Using a material like urethane cement for a floor coating or epoxy to cover concrete floors creates a surface that is extremely durable, long-lasting, and easy to maintain and will satisfy your flooring needs with long-term durability. The important question is which type of coating is appropriate for your floor. Urethane cement and epoxy coatings are the two most popular and widely used alternatives for resinous flooring systems, and each has pros and cons and industrial applications of its own!

Urethane Cement – A Glimpse

Urethane cement comes into existence through the direct combination of polymer urethane with cement and aggregates concrete to create a mixture, therefore having the ability to create, and develop resistance to moisture, thermal shock, and chemicals. Also, it has a smooth surface for easy cleaning, has a coating for cement flooring, and can be directly or indirectly applied to the concrete floor!

Urethane Cement Floor Coating System

This urethane flooring system is with no spaces in its range and the thickness is 1/8″-1/4″ (3-6mm) depending on the way it was applied and the area of application. Urethane cement flooring was initially created specifically for the food and beverage sector, though it is now as common to find in commercial and industrial environments because of the heavy machinery used in these places. It can withstand excessive foot traffic. At the time, no other flooring option could stand up to the daily high-pressure, temperature-variable washdowns of this specific commercial establishment. It is created for heavy-duty environments and its the ideal solution to withstand thermal shocks, abrasion, and chemical exposure it is well suited for several places or areas including production spaces. And is used to create gum rubbers, rigid foams, and elastomers. This is primarily used to improve the floor’s functionality i. e durability, chemical resistance, longevity, etc, and to improve the floor’s aesthetics. Same benefits as epoxy flooring!

Industrial Application of the Urethane Cement Floor Coatings

It is used in mortar for plastering, masonry work, pointing, etc. It is also useful in making joints for drains and pipes. It is suitable for water fighting of a structure. Urethane is very efficient in concrete for layering floors, and roofs and constructing lintels, stairs, pillars, etc. It is also used as a hard surface for protection of exposed surfaces of structures against the destructive agents of the weather and certain organic and Inorganic chemicals and thermal cycling. It is also used for precast pipes manufacturing, piles, fencing, post, etc. Mostly used for the construction of important engineering structures. Such as bridges, culverts (dams), tunnels, lighthouses, etc. Also, it is mainly used in the preparation of foundations, watertight floors, footpaths, etc, and most importantly, it is employed for the construction of wells, water tanks, tennis courts, lamp posts, telephone cabins, roads, etc!

Benefits of Urethane Cement Floor Coating

Extreme temperatures can be withstood by urethane cement flooring

Chemical and Moisture Resistance of Urethane Cement

Flooring Made with Urethane Cement Offers Maximum Durability

Protection

Easy Maintenance and Cleaning

At extremeepoxycoatings.com, we have extensive knowledge in the installation of concrete coating, including urethane cement floors, having been in the business for many years. We provide our clients with the most modern floor covering systems. We constantly educate ourselves on the newest concrete flooring systems, and application techniques. Our reputation speaks for We will provide a suitable flooring system or Concrete floor that is resistant to moisture, thermal shock, and chemicals and is low maintenance. We take great pride in our dedication to providing top-notch goods, unrivaled craftsmanship, and unbeatable warranties!

#https://www.extremeepoxycoatings.com/urethane-cement-floor-coating/#https://www.extremeepoxycoatings.com/#Urethane Flooring System#Urethane Cement Flooring#Epoxy Flooring Installation#Epoxy Flooring#Epoxy Floor Coatings#How To Install Epoxy Floors#Epoxy Floor Installation#Epoxy Flooring Installation Cost#What Is Epoxy Flooring#Epoxy Flooring Designs#Epoxy Flooring Near Me#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

1 note

·

View note

Video

instagram

Resinous flooring systems offer better moisture resistant, chemical resistant, and bacteria-resistant properties than their tile alternatives. In this instance, we are providing a moisture resistant urethane cement flooring system loaded with decorative colored quartz for our client to facilitate their health standards and maintenance requirements. #concrete #concreteflooring #epoxy #epoxyflooring #terrazzo #terrazzoflooring #contractor #contractors #contractorsofinsta #construction #constructionlife #architecture #architecturelovers #architecturephotography #design #interiordesign #flooringideas #flooring #commercialflooring #industrial #industrialflooring #flooringcontractor #industrialdesign #miami #miamibeach #doral #fortlauderdale #westpalmbeach #orlando #commercialrealestate (at Deerfield Beach, Florida) https://www.instagram.com/p/B0yTSy2g3Mq/?igshid=c3pyudnmya7x

#concrete#concreteflooring#epoxy#epoxyflooring#terrazzo#terrazzoflooring#contractor#contractors#contractorsofinsta#construction#constructionlife#architecture#architecturelovers#architecturephotography#design#interiordesign#flooringideas#flooring#commercialflooring#industrial#industrialflooring#flooringcontractor#industrialdesign#miami#miamibeach#doral#fortlauderdale#westpalmbeach#orlando#commercialrealestate

1 note

·

View note

Text

Epoxy floors LA gives Reliable Solution for floor coatings

Epoxy ESD flooring surfaces, also called (electrostatic dissipative) ESD flooring finishes, could be the most affordable answer, for your electronic devices production premises, analyze and assembly areas, and nice and clean spaces. Resin based methods are applied at 20-90 mils, and can include both smooth ESD epoxy films, as well as ESD urethane flooring surfaces examples and pictures given at https://www.epoxyfloorsla.com/. They are applied as slim roll on ESD floor coatings, which are effectively suitable for pallet jacks, and light-weight traffic; or fuller screed-employed solutions for greatly destroyed large and cement or regular visitors.

Epoxy floors LA ground coatings have many unique positive aspects:

Over other dissipative conductive flooring surfaces options, such as vinyl, carpets and rugs and tiles, and silicone flooring surfaces

- Expense Effectiveness (very low existence period expense)

- An easy task to maintain; never ever requirements waxing.

- Improved longevity.

- Effortless substantial-tech appearance; simple to clear

- Hi there-gloss or satin finish is offered.

- Chemical substance resistant.

Because of reasonably very low installation cost, and lower upkeep costs (in no way requirements waxing), resinous anti- stationary flooring surfaces provides an exceptional return on investment.

A word of care about ESD covering firms; most firms are simply distributors of your components, and never really carry out the installment. Ever since the ESD flooring surfaces resources are simply just like the applicator, you take a risk about the result at this site https://www.epoxyfloorsla.com. Quite often, the distributor will not be trained in installing of these products, which limits their knowledge in recommending the appropriate ESD layer system products. The fitness of the definite, current floors and removing essential, such as fasten/adhesives; thickness essential, targeted traffic conditions; problem, thickness and spacing of the temperature and joint parts, slab humidity situation, time period of the job.

When comparing resinous ESD epoxy covering applicators is sourcing an installment service provider with a minimum of 10 years of expertise. For remodeling tasks, they can need expertise and gear for removing of ceramic tile adhesive, and carpets and rugs fasten removing. Ensure that applicator should give a convert-essential set up, using their very own manufacturing facility trained organization crews, without the need of depending on unbiased subcontractors. With the finishing of the installation, the conductive flooring surfaces will probably be evaluated and certified for conformity. Due to the hardness and sturdiness of epoxy and urethane, this kind of ESD flooring fails to give a strong finish, along with vinyl and rubberized, or carpeting. Nevertheless, contra- fixed mats can be utilized, in locations where employees represent long intervals.

With all the current above advantages to supply, ESD specifies ought to have a shut have a look at epoxy ESD flooring, which offers one of the most long lasting, long-lasting, cost-effective finishes off for electronic devices producing flooring surfaces.

For more Information visit https://www.epoxyfloorsla.com/

Contact Us:

Los Angeles Epoxy Floors

Address: 427 San Pedro St #15, Los Angeles, CA 90013, USA

Phone: +1-213-905-4174

Email: [email protected]

1 note

·

View note

Photo

The Concrete Makeover

We are experts in most decorative concrete flooring systems, including concrete overlays such as micro topping, stained concrete and urethane cement slurry.We install floors for warehouses, commercial and retail settings. We do residential as well including garage floor epoxy, basements, pool decks.

Address: 70 John St, Clark, NJ 07066, USA Phone: 732-259-5932 Website: http://www.theconcretemakeover.com

#Epoxy Flooring#Warehouse Flooring#Self Leveling Concrete#Commercial Epoxy Floors#Concrete Polishing

1 note

·

View note

Photo

Flashlight, 1981 Steel painted with polyurethane enamel 38 ft. 6 in. (11.7 m) high x 10 ft. 6 in. (3.2 m) diameter University of Nevada, Las Vegas

Screwarch, 1983 Aluminum painted with polyurethane enamel 12 ft. 8 in. x 21 ft. 6 in. x 7 ft. 10 in. (3.9 x 6.6 x 2.4 m) Museum Boymans-van Beuningen, Rotterdam, the Netherlands Cross Section of a Toothbrush with Paste, in a Cup, on a Sink: Portrait of Coosje's Thinking, 1983 Steel and cast iron painted with polyurethane enamel 19 ft. 8 in. x 9 ft. 2 in. x 7 in. (6 x 2.8 x 0.2 m) Haus Esters, Krefeld, Germany

Stake Hitch, 1984 Stake: steel, aluminum, epoxy, painted with polyurethane enamel rope: polyurethane foam, plastic materials, fiber-reinforced plastic; painted with latex Total height: 53 ft. 6 in. (16.3 m) stake with knot, upper floor: 13 ft. 6 in. x 18 ft. 2 in. x 14 ft. 7 in. (4.1 x 5.5 x 4.5 m) stake, lower floor: 12 ft. 10 in. x 5 ft. x 3 ft. (3.9 x 1.5 x 0.9 m) rope, knot to ceiling: 40 ft. (12.2 m) high x 20 in. (0.5 m) diameter Dallas Museum of Art, Dallas, Texas

Balancing Tools, 1984 Steel painted with polyurethane enamel 26 ft. 3 in. x 29 ft. 6 in. x 19 ft. 10 in. (8 x 9 x 6.1 m) Vitra International AG, Weil am Rhein, Germany Dropped Bowl with Scattered Slices and Peels, 1990 Steel, reinforced concrete, fiber-reinforced plastic; painted with polyurethane enamel; stainless steel Seventeen parts (eight bowl fragments, four peels, five orange sections), in an area approximately 16 ft. 9 in. x 91 ft. x 105 ft. (5.1 x 27.7 x 32 m) Metro-Dade Open Space Park, Miami, Florida Bicyclette Ensevelie (Buried Bicycle), 1990 Steel, aluminum, fiber-reinforced plastic; painted with polyurethane enamel Four parts, in an area approximately 150 ft. 11 in. x 71 ft. 2 in. (46 x 21.7 m) wheel: 9 ft. 2 in. x 53 ft. 4 in. x 10 ft. 4 in. (2.8 x 16.3 x 3.2 m) handlebar and bell: 23 ft. 8 in. x 20 ft. 5 in. x 15 ft. 7 in. (7.2 x 6.2 x 4.7 m) seat: 11 ft. 4 in. x 23 ft. 9 in. x 13 ft. 7 in. (3.5 x 7.2 x 4.1 m) pedal: 16 ft. 4 in. x 20 ft. 1 in. x 6 ft. 11 in. (5.0 x 6.1 x 2.1 m) Parc de La Villette, Paris

Binoculars, 1991 Steel frame. Exterior: concrete and cement plaster painted with elastomeric paint. Interior: gypsum plaster 45 x 44 x 18 ft. (13.7 x 13.4 x 5.5 m) Central component of a building designed by Frank O. Gehry and Associates, 340 Main Street, Venice, California Saw, Sawing, 1996 Steel, epoxy resin, fiber-reinforced plastic, urethane and polyvinylchloride foams; painted with polyester gelcoat 50 ft. 8 in. x 4 ft. 9 in. x 40 ft. (15.4 x 1.5 x 12.2 m) Tokyo International Exhibition Center, Big Sight, Tokyo Flying Pins, 2000 Steel, fiber-reinforced plastic, foam, epoxy; painted with polyester gelcoat and polyurethane enamel Ten pins, each: 24 ft. 7 in. (7.5 m) high x 7 ft. 7 in. (2.3 m) widest diameter in an area approximately 123 ft. (37.5 m) long x 65 ft. 7 in. (20 m) wide partially buried pins: #1: 18 ft. 5 in. (5.6 m) high; #2: 13 ft. 2 in. (4 m) high combined pins: #3a/b: 26 ft. 7 in. (8.1 m) high; #5a/b/c: 28 ft. 7 in. (8.7 m) high individual pins: #4: 21 ft. 8 in. (6.6 m) high; #6: 20 ft. 8 in. (6.3 m) high; #7: 17 ft. 9 in. (5.4 m) high ball: 9 ft. 2 in. (2.8 m) high x 21 ft. 12 in. (6.7 m) diameter Intersection of John F. Kennedylaan and Fellenoord Avenues, Eindhoven, the Netherlands

2 notes

·

View notes