#United States Gear Pumps Market Demand

Explore tagged Tumblr posts

Text

United States Hydraulic Pumps Market Dynamics and Future Landscape Review 2024 - 2032

The United States hydraulic pumps market is a crucial segment of the broader industrial landscape, driven by diverse applications across various sectors. Hydraulic pumps are essential components in numerous machinery and equipment, enabling efficient fluid power transmission. As industries continue to innovate, the demand for advanced hydraulic pumps is growing, making the United States hydraulic pumps market a focal point for manufacturers and investors alike.

Overview of Hydraulic Pumps

Hydraulic pumps are mechanical devices that convert mechanical energy into hydraulic energy by moving fluid. They are categorized into various types, including gear pumps, piston pumps, and vane pumps, each designed for specific applications. The performance and efficiency of these pumps are vital for operations in industries such as construction, manufacturing, and agriculture.

Types of Hydraulic Pumps

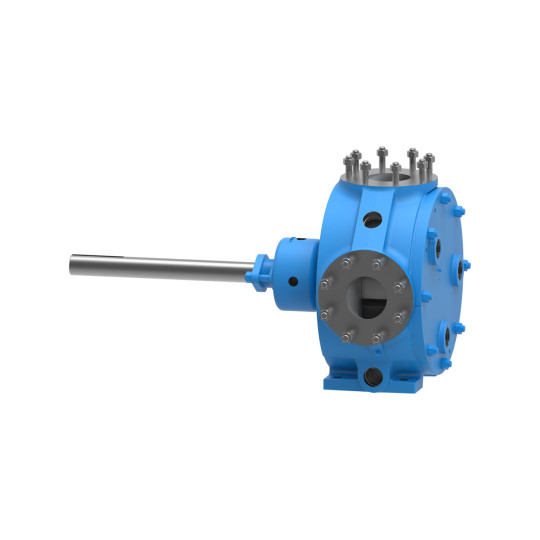

Gear Pumps

Gear pumps are widely used for their simplicity and efficiency in transferring hydraulic fluids. They operate using gears that mesh together to create a vacuum that draws in fluid and then pushes it out.

Piston Pumps

Known for their high efficiency and ability to handle high pressures, piston pumps are commonly used in heavy machinery and industrial applications. They utilize pistons to create pressure and flow.

Vane Pumps

Vane pumps are versatile and can handle a variety of fluids. They consist of a rotor with vanes that move within a cavity, creating a pumping action.

Market Trends

Growth Drivers

The United States hydraulic pumps market is experiencing significant growth due to several factors:

Industrial Automation: The push for automation in manufacturing processes is leading to increased demand for hydraulic systems, including pumps.

Infrastructure Development: Ongoing infrastructure projects and investments in construction are driving the need for reliable hydraulic equipment.

Technological Advancements: Innovations in pump design and materials are improving efficiency and reducing energy consumption, making hydraulic pumps more appealing to end-users.

Challenges

Despite the positive outlook, the market faces challenges such as:

Fluctuating Raw Material Prices: The cost of materials used in manufacturing hydraulic pumps can impact pricing and profitability.

Competition from Electric Pumps: The rise of electric pumps as alternatives to hydraulic systems may pose a threat to market growth.

Key Players in the Market

Several companies dominate the United States hydraulic pumps market, each contributing to the industry's evolution:

Parker Hannifin Corporation: A leader in motion and control technologies, Parker offers a wide range of hydraulic pumps known for their reliability and performance.

Bosch Rexroth AG: Renowned for its innovative hydraulic solutions, Bosch Rexroth focuses on high-quality and energy-efficient pump designs.

Eaton Corporation: Eaton provides a comprehensive portfolio of hydraulic pumps and systems, catering to various industrial needs.

Future Outlook

The future of the United States hydraulic pumps market looks promising, with projections indicating continued growth. As industries evolve, the demand for more efficient, durable, and technologically advanced hydraulic pumps will remain strong. Companies that can innovate and adapt to changing market dynamics will likely succeed in this competitive landscape.

In conclusion, the United States hydraulic pumps market is an integral part of the industrial sector, driven by technological advancements and increasing demand across various applications. As businesses seek reliable and efficient fluid power solutions, the market is set for sustained growth and evolution in the coming years.

Related Reports

Portable Generator

Power Quality Equipment

Hydrogen Fueling Station

Water Desalination

0 notes

Text

AEAUTO: Leading the new trend of electric steering-by-wire for commercial vehicles

At a time when heavy-duty commercial vehicles are undergoing electrification and autonomous driving, innovation in commercial vehicle steering systems is crucial. AEAUTO stands out in the field of commercial vehicle electric steering-by-wire with its superior technology and products.

At present, the development of autonomous driving functions for commercial vehicles has encountered technical difficulties. Foreign products are not sold in China, and the domestic commercial vehicle market has an increasingly strong demand for localization. Traditional and electric hydraulic steering dares to challenge and successfully develop the first generation of commercial vehicle electric wire-controlled steering systems, bringing a new solution to the industry.

Advantages of AEAUTO Electric Steering-by-Wire System

1. System efficiency increased by 30%.

There is no energy loss in the hydraulic link, and the design combines electric and wire control, which perfectly meets the needs of heavy-duty commercial vehicles such as electric vehicles and self-driving heavy trucks.

2. System weight reduced by 35%.

Compared with traditional hydraulic or electric hydraulic steering, this system eliminates five components such as the hydraulic pump and hydraulic steering gear, and steering is completely driven by an electric motor, which is light in weight and small in size.

The total system cost is reduced by 20%. After removing multiple components and amortizing the R&D investment and mold costs, the overall cost of parts is greatly reduced.

AEAUTO electric steering-by-wire system core technology advantages

1. 8000Nm high torque output.

Through a dual-winding motor, high-precision ball screw, and flat secondary enveloping toroidal worm reduction mechanism, as well as a 24V high power density motor and patented reduction mechanism, the 8000Nm high torque output required for heavy-duty commercial vehicles is achieved.

2. High-reliability redundant design.

Using a functional safety-based redundant architecture with dual-winding motors, dual MCUs, and dual control chips for heavy-duty commercial vehicles ensures high reliability and safety of the steering system, meeting the urgent needs of the electric steering system as a functional safety component.

3. The angle control response time does not exceed 50ms.

Based on the in-loop dynamic tracking and feedback control strategy of the power assist value, it adopts a low-inertia permanent magnet synchronous motor, determines the control mode through different sensor signals, and uses the control algorithm to accurately track the target parameters to achieve rapid response of EPS power assist, which is at the international leading level.

Compared with foreign competitors, AEAUTO has better performance in terms of system voltage and angle control response time. Although 48V voltage is designed to output more power, it is not a common standard. AEAUTO also achieves high power output with its unique reduction mechanism without affecting matching and compatibility. In addition, the company's control strategy and algorithm are outstanding, achieving a better angle control response time.

AEAUTO electric steering-by-wire helps heavy-duty trucks become more electrified and autonomous

Our products have undergone a series of rigorous tests, including performance tests, bench tests, and durability tests, and obtained the EU CE certification in June 2021. In terms of customer cases, the electric buses of Karsan in Europe and the products of Otokar, a leading Turkish bus company, both use AEAUTO's electric steer-by-wire system and are sold to many European countries and the United States.

In addition, AEAUTO has also built a heavy-duty commercial vehicle electric steering R&D test platform, which covers software-in-the-loop simulation, testing, calibration, reliability, and durability test benches, and has passed the assessment of Nanjing Engineering Technology Center.

With its advanced technology, excellent product performance, and reliable quality, AEAUTO has demonstrated strong competitiveness in the field of electric steer-by-wire for commercial vehicles and has made positive contributions to promoting the electrification and autonomous driving development of heavy-duty commercial vehicles.

0 notes

Text

Asphalt Pumps Market News and Forecast by 2024-2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Asphalt Pumps Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Asphalt Pumps Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Asphalt Pumps Market?

The global asphalt pumps market size reached US$ 773.5 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,120.1 million in 2032, exhibiting a growth rate (CAGR) of 4.2% during 2024-2032.

What are Asphalt Pumps?

Asphalt pumps are mechanical tools employed in construction to transfer hot asphalt from storage tanks to mixing plants or paving machines. These pumps are specifically designed to manage the high temperatures and viscosity of hot asphalt, ensuring a consistent and seamless flow. Available in different types such as gear pumps, screw pumps, and centrifugal pumps, each is suited for various asphalt applications. Asphalt pumps are essential for the dependable and efficient transportation of asphalt in construction projects.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1849

What are the growth prospects and trends in the Asphalt Pumps industry?

The asphalt pumps market growth is driven by various factors and trends. The asphalt pumps market is experiencing growth, fueled by rising global demand for road construction and maintenance. These pumps are essential for the efficient transportation of hot asphalt in construction projects. Market expansion is also propelled by advancements in pump technology, resulting in more efficient and durable pumps. Furthermore, government efforts to enhance infrastructure, particularly in developing nations, are contributing to market growth. Despite this, challenges such as fluctuating oil prices and environmental issues related to asphalt production may impede market expansion. Hence, all these factors contribute to asphalt pumps market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type of Pump:

Gear Pump

Screw Pump

Centrifugal Pump

Rotary Vane Pump

Others

By Capacity:

Low Capacity (Up to 500 GPM)

Medium Capacity (500-1,000 GPM)

High Capacity (Above 1,000 GPM

By End-Use Industry:

Road Construction

Roofing

Emulsion Plants

Others

By Power Source:

Electric

Hydraulic

Pneumatic

Segmentation by Region:

North America

United States

Canada

Europe

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific

China

India

Japan

Australia & New Zealand

ASEAN

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Who are the key players operating in the industry?

The report covers the major market players including:

Viking Pump, Inc.

Johnson Pump

Roper Pump Company

Flowserve Corporation

Colfax Corporation

SPX Flow, Inc.

Blackmer (PSG Dover)

Maruyama Mfg. Co., Inc.

Warren Rupp, Inc. (IDEX Corporation)

All-Flo Pump Co.

Stansteel Corporation

Hydromatik (Bosch Rexroth)

Viking-Cives Group

Sujal Engineering

Maag Pump Systems

View Full Report: https://www.reportsandinsights.com/report/Asphalt Pumps-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

The Complete Guide to Hydraulic Gear Pumps of the Marketing Intertech Alpha Series

Introduction

Hydraulic gear pumps play a crucial role in numerous industrial applications, providing the necessary power and efficiency to ensure optimal performance. Among the notable series in the market, the Commercial Intertech Alpha Series stands out for its advanced features and reliable performance. In this comprehensive guide, we will delve into the various aspects of the Alpha Series hydraulic gear pumps, exploring their design, benefits, applications, and maintenance.

Understanding Hydraulic Gear Pumps

What is a Hydraulic Gear Pump?

A hydraulic gear pump is a type of positive displacement pump that uses meshing gears to pump fluid by displacement. It is one of the most common types of pumps used in hydraulic systems. The two main types of AGCO hydraulic pumps are internal and external gear pumps. The Alpha Series by Commercial Intertech belongs to the external gear pump category, which is widely used due to its simplicity and efficiency.

Components of a Hydraulic Gear Pump

Gears: The primary components that mesh together to move the fluid.

Housing: The casing that holds the gears and other internal components.

Inlet and Outlet Ports: Openings through which the fluid enters and exits the pump.

Bearings: Support the rotational movement of the gears.

Seals: Prevent leakage of the hydraulic fluid.

Features of the Commercial Intertech Alpha Series

The Alpha Series Bosch hydraulic pumps by Commercial Intertech are known for their exceptional design and performance characteristics. Here are some of the key features:

Advanced Performance

The Alpha Series is designed as an advanced-performance version of the traditional "bushing block" style pumps. This design innovation results in superior efficiency and reliability, making them ideal for demanding applications.

Low Noise Operation

One of the standout features of the Alpha Series is its low noise operation, even at high pressures. This makes them suitable for environments where noise reduction is critical.

Range of Displacements

The Alpha Series pumps are available in four frame sizes (P3, P5, P11, and P17) with displacements ranging from 0.8 to 52 cm³/rev (0.048 to 3.17 in³/rev). This wide range allows for flexibility in matching the pump to the specific needs of various applications.

Built in the USA

All Alpha Series pumps are proudly built in the United States, ensuring high-quality manufacturing standards and reliable performance.

Benefits of Using Alpha Series Hydraulic Gear Pumps

Efficiency

The advanced design of the Alpha Series pumps results in higher efficiency, which translates to better energy utilization and cost savings over time.

Durability

With robust construction and high-quality materials, Alpha Series pumps are built to last, reducing the need for frequent replacements and maintenance.

Versatility

The wide range of displacements and sizes available makes the Alpha Series pumps versatile, suitable for various industrial and mobile applications.

Reduced Downtime

The reliability and low maintenance requirements of these pumps help in minimizing downtime, ensuring continuous operation and productivity.

Applications of Alpha Series Hydraulic Gear Pumps

The Alpha Series hydraulic gear pumps are used in a variety of applications across different industries. Some of the common applications include:

Construction Equipment: Used in machinery such as excavators, loaders, and bulldozers.

Agricultural Machinery: Essential for tractors, harvesters, and other farming equipment.

Industrial Machinery: Applied in manufacturing and processing equipment for efficient fluid power.

Mobile Equipment: Utilized in mobile hydraulic systems for vehicles and equipment.

Maintenance and Troubleshooting

Regular Maintenance Tips

Check Fluid Levels: Regularly check and maintain the hydraulic fluid levels to ensure optimal performance.

Inspect for Leaks: Routinely inspect the pump and associated components for any signs of leaks.

Monitor Performance: Keep an eye on the pump's performance indicators, such as noise levels and operating temperatures.

Replace Worn Parts: Timely replacement of worn-out parts can prevent major breakdowns and extend the pump's lifespan.

Common Issues and Solutions

Cavitation: This occurs when there is a rapid formation and collapse of vapor bubbles within the fluid. It can be prevented by maintaining proper fluid levels and avoiding air ingress.

Overheating: Ensure adequate cooling and proper ventilation to prevent the pump from overheating.

Seal Leakage: Regularly check and replace seals to prevent fluid leakage and maintain pump efficiency.

Choosing the Right Pump

When selecting an Alpha Series hydraulic gear pump, consider the following factors:

Application Requirements: Match the pump specifications with the demands of your application.

Operating Conditions: Consider the operating environment, including temperature, pressure, and fluid type.

Performance Ratings: Check the pump's performance ratings to ensure it meets your desired efficiency and capacity.

Conclusion

The Commercial Intertech Alpha Series hydraulic gear pumps are a testament to advanced engineering and reliable performance. With their superior efficiency, low noise operation, and robust construction, they are an excellent choice for various industrial and mobile applications. Proper maintenance and timely troubleshooting can further enhance their longevity and performance. By understanding the features and benefits of the Alpha Series, you can make an informed decision and ensure optimal performance for your hydraulic systems.

For more information and to explore the range of Alpha Series hydraulic gear pumps, visit Hydraulic.net.

Contact us to know more.

0 notes

Text

Powering Up Productivity: An Insightful Analysis of the Hydraulic Pumps Market and its Wide Range of Applications

Hydraulic pumps are mechanical devices that convert mechanical power into hydraulic energy by forcing fluids through a series of chambers or gears. They are used in a variety of applications, including construction equipment, agricultural machinery, aerospace, and marine applications. The Hydraulic Pumps Market is driven by the growing demand for high-quality hydraulic pumps in industries such as oil and gas, automotive, and mining, among others. The market is also driven by the increasing demand for energy-efficient and eco-friendly hydraulic pumps that are designed to reduce energy consumption and emissions.

The Asia Pacific region is expected to be the largest market for hydraulic pumps, driven by the growing demand for construction equipment, industrial machinery, and agriculture equipment in countries such as China, India, and Japan. North America and Europe are also significant markets, driven by the presence of established industries such as automotive and aerospace. Additionally, the growing demand for renewable energy sources such as wind and solar power is expected to drive the demand for hydraulic pumps in the coming years.

Request For The Sample Copy of The Report @ https://www.persistencemarketresearch.com/samples/28042

Some of the key players in the Hydraulic Pumps Market include Eaton Corporation, Parker Hannifin Corporation, Bosch Rexroth AG, Kawasaki Heavy Industries Ltd., and Danfoss A/S, among others. These companies are focusing on product innovation, development, and customization to meet the specific requirements of different industries. They are also focusing on expanding their global presence through strategic partnerships and collaborations, mergers and acquisitions, and new product launches, to increase their market share and revenue growth.

About us: –

Persistence Market Research is a U.S.-based full-service market intelligence firm specializing in syndicated research, custom research, and consulting services. Persistence Market Research boasts market research expertise across the Healthcare, Chemicals and Materials, Technology and Media, Energy and Mining, Food and Beverages, Semiconductors and Electronics, Consumer Goods, and Shipping and Transportation industries. The company draws from its multi-disciplinary capabilities and high-pedigree team of analysts to share data that precisely corresponds to clients’ business needs.

Contact Us:

Persistence Market Research Address – 305 Broadway, 7th Floor, New York City, NY 10007 United States U.S. Ph. – +1-646-568-7751 USA-Canada Toll-free – +1 800-961-0353 Sales – [email protected]

0 notes

Text

United States Gear Pumps Market 2021: Report Focusing on Opportunities, Top Players, Revenue, Market Driving Factors, & Challenges

4 January 2019 - The United States Gear Pumps Market witnessed a positive CAGR growth in the prescribed period. An external gear pump is a positive displacement type of pump mainly used for transfer and metering of liquids. A gear pump comes with dual gears existing side by side or adjacent to each other. Technically, a gear pump is a precision machine with an enormous tight grip and tolerances and is much capable of working in high differential pressures. It helps in generating flow with enormous power to overcome the induced pressure by the pump. Therefore, a gear pump is a type of permanent displacement pump creating a vacuum at inlet. From the commercial aspect, a gear pump finds major application in construction, agricultural equipment, and movable machineries.

Driving factors responsible for the growth of United States Gear Pumps Market includes price effectiveness of gear pumps over other types coupled with low maintenance costs. Also, gear pumps have an integral valve preference and accessories that enhances the flexibility of using a gear pump as compared to other types. Further, gear pump manufacturers emphasize on e-commerce and a more efficient sales platform to expand their presence in larger geographies by collaborating with regional and international players in order to boost their sales. However, green initiatives coupled with inclination towards renewable energy is anticipated in hindering the market growth during the assessment period.

View Full Report with TOC @ https://www.millioninsights.com/industry-reports/united-states-gear-pumps-market

Product segmentation for the United States Gear Pumps Market includes external gear pumps and internal gear pumps. End-use segmentation for the United States Gear Pumps Industry includes mining & metallurgy, construction, material handling, automotive & transportation and chemicals & petrochemicals.

Geographical segmentation for the United States Gear Pumps Market includes The West, New England, The South, The Middle Atlantic, The Mid-West and The Southwest. The key players in the United States Gear Pumps Market include Viking Pump, Oilgear, Gardner Denver, Commercial Shearing, Danfoss, Hayward Tyler and Moog.

Market Segment:

This report studies sales (consumption) of Gear Pumps in USA market, focuses on the top players, with sales, price, revenue and market share for each player in USA, covering

• Bosch Rexroth

• Parker

• Viking Pump, Inc.

• Kawasaki

• Eaton

• Liquiflo

• Roper Pumps

• Commercial Shearing

• Hayward Tyler

• Haight

• Moog

• ASADA

• Linde Hydraulics(Weichai)

Split by product types, with sales, revenue, price, market share and growth rate of each type, can be divided into

• Internal Gear Pumps

• External Gear Pumps

• Aluminium Body Gear Pumps

• Cast Iron Gear Pumps

Request Sample Copy of This Report @ https://www.millioninsights.com/industry-reports/united-states-gear-pumps-market/request-sample

#United States Gear Pumps Market Growth#United States Gear Pumps Market Demand#United States Gear Pumps Market Share#United States Gear Pumps Market Size#United States Gear Pumps Market Forecast#United States Gear Pumps Industry

0 notes

Text

Which is approximately the amount of powder metallurgy parts

Which is approximately the amount of powder metallurgy parts automotive market 32000t, 37%, an increase of 28%; power tools market grew 29%. Thus, making enterprises in under the pressure of rising costs and can not be conducted effectively, forcing the level of corporate earnings declining. With the vigorous development of China's auto industry, boron powder led to the rapid development of parts and components market. China has become the world's second largest automobile consumer and third largest car producer, the largest potential auto market.5% to about 88000t.25 times the total demand.4567 million and 4.The great potential of chinese powder metallurgy technology market.The current Chinese auto parts enterprises not only face the fierce impact of multinational and domestic enterprises homogeneous competition, as well as the cost of raw materials and downstream extrusion host and distributors to continuously improve product quality standards. According to the China General Machinery Parts Association Powder Metallurgy Branch Report, 2006 China's production of powder metallurgy parts and products increased by 17. According to the China Association of Automobile Manufacturers statistics, first half of 2007, China's total vehicle production and sales were 4. The foreign key of powder forged connecting rod mainstream, such as: the U.Face the current difficulties, and actively cultivate their core competitiveness will become the company needed to solve problems.

Most of the domestic automobile engine used forged steel connecting rod connecting rod and rod casting fatigue secondary to reach 50 million or more weeks is very difficult, because the rod Wholesale Flock Machine of the work are not part of the word by cutting tendons, manganese powder small defects of the connecting rod greater impact on fatigue life. Visible, high value-added powder metallurgy parts is gradually transferred to the automotive sector. Such as: link is an important engine parts, drawing on many models are set to introduce a connecting rod fatigue test load, and requested that the fatigue load cycles to reach 500 million or more.S. These components, the main core technology, powder metallurgy technology is. The lower value-added agricultural industry for powder metallurgy parts is almost reduced by half.5 million tons of steel powder, powder metallurgy products if China's consumption per vehicle to reach the European level, car ownership coupled with the replacement of powder metallurgy parts, then steel powder alone would require nearly 10 million tons of powder metallurgy is currently 1. At the same time, China's long-term lack of powder metallurgy industry due to the number of larger and higher value-added parts needs, there is no opportunity for the powder metallurgy industry to play its unique advantage to provide a good opportunity.36% and 23.The future of China's auto products market potential of powder metallurgy parts will show a growth spurt. And most of China's auto parts business situation is the low level of specialization, product development ability.

We know automotive parts and components in the core, higher value-added are: the engine's intake and exhaust valves, engine connecting rods, transmission gears in cone synchronizer rings and the main oil pump driven gear and so on. Statistics of product categories including iron copper powder metallurgy parts, oil-bearing and friction materials. Therefore, in order to develop their own core competencies, it is imperative to seek the development of powder metallurgy technology activities, as a breakthrough point to enhance the domestic parts already weak competitiveness. Therefore, in the mid-1990s for the automotive and motorcycle industry, powder metallurgy parts by mass almost doubled in 10 years. If calculated according to annual production of 500 million vehicles, China's annual auto parts with about 2. European average per vehicle is the use of powder metallurgy products, 14kg, Japan, 16kg, 19. According to statistics, the developed countries the amount of automobile manufacturing powder metallurgy products, the vast majority of its total powder metallurgy products, such as the United States accounted for 90%, Europe 80%, while China is still less than 40%. General Motors Buick sedan, BMW Germany BMW, GNKSintermetals manufactured and even link to a tensile strength of 1041MPa.In recent years, China's auto industry has maintained rapid development.3738 million, an increase of 22.5kg United States has reached over the next few years may reach 22kg, metal powder supplier while China is the average amount of powder metallurgy parts per vehicle, but only about 5kg. Enterprises do not have the vast majority of parts capabilities of product development, product development, rely mainly on OEM, replacement of the vehicle difficult to adapt to the requirements of their core businesses less competitive.3%

1 note

·

View note

Text

Get Your Pool Supplies

Get Your Pool Supplies

Swimming pools are pleasing peaceful locations for pleasuring as well as unwinding, yet it's always crucial to keep your swimming pools in exceptional states. There are a variety of cleanliness and protective measures that can help you keep your swimming pools A-one. You need correct tools and also instrumentation for proper treatment and upkeep of your swimming pools.

There are a variety of devices that you need in your swimming pool upkeep, usually you are either not knowledgeable about these devices or you do not know exactly how to utilize them. You can understand about your swimming pool upkeep equipment by going thru a great deal of swimming pool upkeep stuff offered online. There are various websites providing quantities of details and suggestions on your pool upkeep as well as swimming pool products.

You swimming pool products consist of a vast selection of equipments, tools, as well as tools for your swimming pool maintenance. Swimming pool supplies include pool filters, filter grids, saltwater chlorinators, swimming pool calculators, swimming pool pumps, cartridges, pool motors, pool heaters, swimming pool timers, freeze guards, mixes of pump and also filter, lights, valves, pool covers and also many others. Swimming pool supplies likewise include the devices that also create a component of swimming pool are ladders, linings, diving boards, slides etc

. Correct swimming pool maintenance plays essential role in maintaining your pool fresh and hygienic. You can utilize usual disinfectants or an oxidizing representatives, like chlorine to prevent the growth raw material in the water. This substantially reduces the filter lots. You can additionally utilize different kinds of decontaminators, such as chlorine, bromine, ozone as well as UV light. Nevertheless, you additionally require to maintain proper pH balance and also alkalinity level of pool water; you require to maintain your swimming pool water risk-free for swimming by maintaining correct balance of your pool water chemistry. Deep sea chlorinators as well as swimming pool calculators can aid you do this job.

Your pool pumps are tool in flowing your pool water thru filets as well as therefore help maintaining swimming pool water tidy. You must get your swimming pools geared up with top quality reliable pool pumps and also filters. The pool pumps and filters function jointly to keep your water clean and clear. Swimming pool pumps as well as filters are available in numerous sizes for your pools. You can purchase the full pump as well as filter system or simply the pump or filter individually to collection your demands. Pool filters are readily available in three different varieties including D.E., Sand, and Cartridge.

Your swimming pool heaters are remarkable devices to keep your swimming pools warm. Pool heating units are offered in finer patterns, which are much more trusted, energy effective, as well as challenging. Some of the pool heaters are even outfitted with merged pool timers and freeze guards. Skimmers are used to eliminate insects leaves, as well as sprigs from the pool water surface. A skimmer appears like a large badminton noise. Your pool are called for to be skimmed daily. It assists protecting against foreign materials from jamming the water filters. Quality skimmers are constantly required for your pool.

Pool covers are one of the most essential items that help to protect pools when they are not in use. They aid covering your pool as well as shield your swimming pools from dirt and also particles. They likewise avoid youngsters, visitors, pet dogs, etc from accidentally falling into swimming pools. Some of the readily available pool cover supplies include domes, soar reels, winter months filters, solar blankets and so on

. You merge materials may additionally include swimming pool devices, toys, video games, floats, etc. You can acquire swimming pool materials both online along with offline. There are a number of stores marketing "swimming pool devices" online, however you must pick a dependable as well as real on-line store.

#pool service#pool builders#pool cleaning service#pool heater#pool installation#pool renovation#pool repair#pool resurfacing#pool decks#pool covers#pool cleaners#swimming pool

2 notes

·

View notes

Text

Oil And Gas Pump Market Insights and Forecasting Trends Review 2024 - 2032

The oil and gas pump market plays a critical role in the energy sector, facilitating the extraction, transportation, and processing of oil and gas. As demand for energy continues to rise globally, the market for pumps used in oil and gas applications is experiencing substantial growth. This article delves into the dynamics of the oil and gas pump market, exploring its key drivers, challenges, segmentation, regional insights, and future trends.

What are Oil and Gas Pumps?

Oil and gas pumps are mechanical devices used to move fluids (liquid or gas) in the oil and gas industry. They are essential for various processes, including exploration, extraction, refining, and transportation. Different types of pumps are employed depending on the application and the properties of the fluids being handled.

Types of Oil and Gas Pumps

Centrifugal Pumps: Commonly used for transporting fluids at a constant flow rate, ideal for refining and water injection processes.

Positive Displacement Pumps: Suitable for high-viscosity fluids, often used in hydraulic fracturing and in applications requiring precise flow control.

Submersible Pumps: Designed to operate submerged in the fluid, commonly used in well drilling and groundwater extraction.

Market Dynamics

Growth Drivers

Increasing Global Energy Demand

Rapid industrialization and population growth are driving the demand for oil and gas, subsequently increasing the need for efficient pumping solutions.

Technological Advancements

Innovations in pump design, materials, and automation technologies enhance efficiency, reliability, and performance, driving market growth.

Exploration and Production Activities

Rising investments in upstream activities, particularly in emerging markets, are boosting the demand for pumps in drilling and extraction processes.

Challenges

Environmental Regulations

Stricter environmental regulations concerning emissions and spills can pose challenges for pump manufacturers and operators in the oil and gas sector.

Volatility in Oil Prices

Fluctuating oil prices can impact exploration and production budgets, leading to uncertainty in pump demand.

Maintenance and Reliability Issues

The harsh operating conditions in oil and gas environments can lead to pump failures, necessitating regular maintenance and replacement, which can incur high costs.

Market Segmentation

By Type of Pump

Centrifugal Pumps

Positive Displacement Pumps

Others (including diaphragm pumps and gear pumps)

By Application

Upstream (exploration and production)

Midstream (transportation and storage)

Downstream (refining and distribution)

By Region

North America

Europe

Asia-Pacific

Middle East & Africa

Latin America

Regional Analysis

North America

North America, particularly the United States, holds a significant share of the oil and gas pump market, driven by extensive exploration and production activities, especially in shale oil and gas. Technological advancements in hydraulic fracturing are further boosting demand.

Europe

Europe's market is influenced by its aging oil and gas infrastructure and the need for modernization. The European Union's commitment to sustainability also drives investment in more efficient and environmentally friendly pumping solutions.

Asia-Pacific

The Asia-Pacific region is witnessing rapid growth due to increasing energy demand, particularly in countries like China and India. Investment in offshore oil and gas projects is also on the rise, driving the need for robust pumping solutions.

Middle East & Africa

The Middle East remains a vital region for oil production, and ongoing investments in infrastructure development and enhanced oil recovery techniques are expected to bolster the demand for oil and gas pumps.

Future Trends

Digitalization and IoT Integration

The integration of Internet of Things (IoT) technologies in pump systems allows for real-time monitoring and predictive maintenance, reducing downtime and improving operational efficiency.

Energy Transition and Sustainability

As the industry shifts toward greener practices, the demand for pumps that can handle biofuels and other alternative energy sources is expected to increase. Manufacturers are focusing on developing more sustainable and efficient pumping solutions.

Automation and Smart Pumps

The trend toward automation in oil and gas operations is leading to the development of smart pumps equipped with advanced sensors and control systems, enhancing reliability and efficiency.

Conclusion

The oil and gas pump market is on a growth trajectory, driven by rising energy demands, technological advancements, and increasing investments in the sector. While challenges such as environmental regulations and market volatility persist, the future looks promising with the advent of digital technologies and a shift towards sustainable practices. As the global energy landscape evolves, the oil and gas pump market will continue to adapt, playing a vital role in meeting the world's energy needs.

More Trending Reports

Solar Pump Invertor Market Analysis

Europe, US & China Electrolyser Market Analysis

North America Transformer Market Analysis

Oil and Gas Refining Industry Market Analysis

0 notes

Text

Transmission Repair Market - Forecast 2022 - 2027

Transmission Repair Market Overview

The Transmission Repair Market is forecast to reach $292.1 million by 2026, growing at a CAGR of 3.9% from 2021 to 2026. Transmissions play a major role in a vehicle’s operation, hence the significant growth in automotive production is set to impact the market growth rate. The significant adoption of periodic maintenance services for the power transmission systems in vehicles in order to increase the vehicle age is set to boost the market growth rate during the forecast period 2021-2026. The hybrid Transmission Market primarily is driven by the growing demand of hybrid electric vehicles. The hybrid electric vehicles provide several benefits such as low harmful gases emission, less usage of gasoline, and others. The increasing prices of gasoline and global warming are driving the use of electrified vehicles. Moreover, governments of different countries are also promoting the use of electric vehicles, by providing relaxation in taxes, which is going to boost hybrid transmission for both transmission general repair and transmission overhaul market. Additionally, companies such as BAE Systems, BorgWarner Inc., Continental, Delphi, DENSO are working on improving the efficiency and reducing the cost of hybrid and internal combustion engine transmission systems which is going to boost the hybrid transmission market.

Report Coverage

The report: “Transmission repair Market – Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Transmission repair market.

By Repair Type: Transmission general repair, Transmission overhaul By Vehicle Type: Passenger car, light and heavy commercial vehicles By Vehicle Fuel Type: Electric Vehicle, Hybrid Vehicle, Diesel Vehicles, Petrol Vehicles and Others By Component: Fly wheel, Clutch plate, oil pump, axle, gear, pressure plate, fluid, O-ring, gasket and seal, transmission filter By Geography: North America (U.S, Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, South Korea and Others), South America(Brazil, Argentina and others), and RoW (Middle East and Africa).

Request Sample

Key Takeaways

Transmission general type is analysed to dominate the market in 2020, majorly attributed to the increasing adoption of periodic maintenance of the vehicles. North America is analysed to dominate the market owing to the rising sales of the passenger as well as commercial vehicles in the region. The significant growth in the average miles driven by a vehicle is set to be the key driving factor for the transmission repair market

Transmission Repair Market Segment Analysis - By Repair type

Transmission general repair dominates the market in 2020 with 79.2% share, owing to the rising adoption of periodic maintenance to increase the life cycle of the vehicle. As the periodic transmission repairs increase the vehicle age and also fuel efficiency, the users tend to opt for transmission general repair thereby contributing to the growth of the market.

Inquiry Before Buying

Transmission Repair Market Segment Analysis - By Vehicle Type

Passenger cars is analysed to hold highest market share in 2020 at 68.4%. As stated by OICA, the number of passenger cars accounted for 67.2 million units whereas the commercial vehicles accounted for 24.6 million units. Adding to this, the growing production plants for passenger cars is also set to escalate the market growth rate. In January 2020, Toyota has announced to invest $700M in the expansion of its production plant in US. In September 2019, Toyota Motor Corporation has announced to expand its facility in Brazil with an investment of $190M to increase the production. The increasing demand of fuel efficient and eco-friendly vehicles is boosting the hybrid transmission market. As more complex transmission is widely used in electric vehicle, which is going to provide huge growth to transmission repair market.

Transmission Repair Market Segment Analysis - Geography

APAC is the dominant region in 2020 with a market share of 35.9% owing to the high production base in the region, followed by North America and Europe. The large market share is majorly attributed to the presence of large production bases in China and India. In March 2020, China Association of Automobile Manufactures has announced that vehicle production and sales volume reached 3.47 million and 3.67 million units. It has also stated that the commercial vehicles have declined than that of passenger vehicles. In December 2019, Morris Garages, a British automobile brand has announced its plans to invest $ 429.25 million. In 2019 According International Energy Agency (IEA), China held the major share 45% of global electric vehicle market, which is increasing rapidly and going to provide huge growth to hybrid transmission market. Additionally, in countries such as India, Japan and others, the demand of electrified vehicles is increasing, which will boost the transmission repair market.

Schedule a Call

Transmission Repair Market Drivers Large Vehicle Parc

The automotive production has significantly risen in the past few years owing to the rising economic standards and affordability in many nations. As stated by OICA the commercial vehicles production has risen by 2% in 2019 compared to 2018 before a decline in 2020 due to Covid-19. Hence the growing vehicular production in various countries is significantly impacting on the transmission repair market.

Increasing Demand of Electric vehicle

The increasing demand of electric vehicles is going to boost hybrid transmission market. The demand of electric vehicles is increasing day by day, as electric vehicles offer several benefits such as low harmful gases emission, low maintenance cost and others. The electric vehicles manufacturers are going to use hybrid transmission widely in hybrid electric vehicles (HEV). The hybrid transmission uses a combination of electric motor and combustion engine substantially, which reduces the vehicle's fuel consumption, which is going to boost the hybrid transmission market.

Buy Now Transmission Repair Market Challenges

Increasing adoption of Electric vehicles

The significantly rising developments impacting the increasing production of the electric vehicles due to its demand is set to hamper the market growth rate during the forecast period. The electric vehicles fundamentally shatter the maintenance industry owing to their high efficiency and features. In November 2019, Volkswagen announced the expansion of the electric vehicle manufacturing plant with an investment of $800M in US.

Transmission Repair Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Transmission repair market. Transmission repair driver market is expected to be dominated by major companies such as Allison Transmission, ZF, BorgWarner, Schaeffler, AAMCO, and Continental among others.

Acquisitions/Technology Launches/Partnerships

In March 2020, ZF Friedrichshafen AG and Wolong Electric Group Co Ltd has announced joint venture on Electric components, which is going to increase the features of hybrid transmission and going to boost hybrid transmission market. In July, 2019, Schaeffler has announced its partnership with TruckOn, Continental’s digital booking platform for commercial vehicle repairs and services.

#Transmission Repair Market#Transmission Repair Market Size#Transmission Repair Market Share#Transmission Repair Market Analysis

0 notes

Text

Asphalt Pumps Market News and Forecast by 2024-2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Asphalt Pumps Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Asphalt Pumps Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Asphalt Pumps Market?

The global asphalt pumps market size reached US$ 773.5 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,120.1 million in 2032, exhibiting a growth rate (CAGR) of 4.2% during 2024-2032.

What are Asphalt Pumps?

Asphalt pumps are mechanical tools employed in construction to transfer hot asphalt from storage tanks to mixing plants or paving machines. These pumps are specifically designed to manage the high temperatures and viscosity of hot asphalt, ensuring a consistent and seamless flow. Available in different types such as gear pumps, screw pumps, and centrifugal pumps, each is suited for various asphalt applications. Asphalt pumps are essential for the dependable and efficient transportation of asphalt in construction projects.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1849

What are the growth prospects and trends in the Asphalt Pumps industry?

The asphalt pumps market growth is driven by various factors and trends. The asphalt pumps market is experiencing growth, fueled by rising global demand for road construction and maintenance. These pumps are essential for the efficient transportation of hot asphalt in construction projects. Market expansion is also propelled by advancements in pump technology, resulting in more efficient and durable pumps. Furthermore, government efforts to enhance infrastructure, particularly in developing nations, are contributing to market growth. Despite this, challenges such as fluctuating oil prices and environmental issues related to asphalt production may impede market expansion. Hence, all these factors contribute to asphalt pumps market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type of Pump:

Gear Pump

Screw Pump

Centrifugal Pump

Rotary Vane Pump

Others

By Capacity:

Low Capacity (Up to 500 GPM)

Medium Capacity (500-1,000 GPM)

High Capacity (Above 1,000 GPM

By End-Use Industry:

Road Construction

Roofing

Emulsion Plants

Others

By Power Source:

Electric

Hydraulic

Pneumatic

Segmentation by Region:

North America

United States

Canada

Europe

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific

China

India

Japan

Australia & New Zealand

ASEAN

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Who are the key players operating in the industry?

The report covers the major market players including:

Viking Pump, Inc.

Johnson Pump

Roper Pump Company

Flowserve Corporation

Colfax Corporation

SPX Flow, Inc.

Blackmer (PSG Dover)

Maruyama Mfg. Co., Inc.

Warren Rupp, Inc. (IDEX Corporation)

All-Flo Pump Co.

Stansteel Corporation

Hydromatik (Bosch Rexroth)

Viking-Cives Group

Sujal Engineering

Maag Pump Systems

View Full Report: https://www.reportsandinsights.com/report/Asphalt Pumps-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Present situation and Prospect of dry screw vacuum pump

At present, the development of various vacuum pumps is more and more affected by vacuum applications. The general vacuum system can not meet the requirements of clean and oil-free corrosion resistance. Therefore, in recent years, the market demand of dry vacuum pumps is very large, and the vacuum products have been updated. A large number of oil-free vacuum systems have been replaced by oil-free and clean vacuum systems. Almost every large vacuum company abroad produces various types of dry vacuum pumps. Screw vacuum pump is a non-contact dry pump. It is an ideal pump in the early 1990s. It occupies the market with its advantages of wide pumping speed range, simple and compact structure, no friction of air extraction chamber components, long service life, low energy consumption and no oil pollution. However, most of its manufacturing technology is mastered by foreign countries. China is still in its infancy, and the market has great demand for dry pumps At present, the development of various vacuum pumps is more and more affected by vacuum applications. The general vacuum system can not meet the requirements of clean and oil-free corrosion resistance. Therefore, in recent years, the market demand of dry vacuum pumps is very large, and the vacuum products have been updated. A large number of oil-free vacuum systems have been replaced by oil-free and clean vacuum systems. Almost every large vacuum company abroad produces various types of dry vacuum pumps. Screw vacuum pump is a non-contact dry pump. It is an ideal pump in the early 1990s. It occupies the market with its advantages of wide pumping speed range, simple and compact structure, no friction of air extraction chamber components, long service life, low energy consumption and no oil pollution. However, most of its manufacturing technology is mastered by foreign countries. China is still in its infancy, and the market has great demand for dry pumps Present situation of dry vacuum pump Due to its superior performance, dry screw vacuum pump has become the preferred vacuum equipment in microelectronics, semiconductor, pharmaceutical, precision processing and other industries in Europe, America and Japan. On the basis of screw compressor, Japan has long developed the multi head rotor profile of vacuum pump and put it into the market. Several German vacuum equipment companies have also gradually developed equal pitch and variable pitch rotor profiles, and have done a lot of research on rotor and body cooling. Key technical problems of screw pump: Structure of dry screw pump: The structure of screw vacuum pump is mainly composed of screw rotor, shell, cooling circulation and sealing materials. The transmission shaft is connected with the driving rotor and drives the driven rotor to rotate through the synchronous gear. A cooling water channel is opened on the shell to cool the temperature of the rotor and exhaust port. The synchronous gear and bearing are lubricated with oil. The interior of the bearing and housing is sealed by seals to achieve the effect of oil-free. The structure of dry screw vacuum pump is similar to that of oil-free screw compressor in sealing and lubrication. Generally, mechanical seals are used at the exhaust end of vacuum pumps, and double lip seals are commonly used at the inlet side. In terms of transmission mode, at present, the common is direct connected motor, which is connected with rotor by coupling, and very few are driven by belt or chain. Due to no internal compression process, the exhaust temperature of equal pitch screw pump is very high (about 110 ℃). If the cooling effect is not good, it will cause deformation of rotor and casing and affect the sobbing effect. Therefore, cooling the casing is an essential link, and water cooling is a common method. Cooling water is supplied to the outer side of the bearing in the casing body to cool the casing and then the rotor. Laibao company applies water cooling inside the rotor to increase the service life of the rotor and achieve good cooling effect. However, this kind of structural design (two-stage type) requires certain technical and processing level support. Sometimes the cooling effect cannot be achieved by water cooling, so the cooling gas (mostly nitrogen) is usually passed near the rotor at the exhaust end. Now the mainstream screw vacuum pump abroad adopts this method. This method has several advantages: it can cool the casing of the rotor and reduce the exhaust temperature; Second, when the gas contains particles, it can prevent particle deposition or chemical reaction from causing explosion. Overview of dry vacuum pumps produced by domestic and foreign companies (1) KDP and SDV series screw vacuum pumps of Taher company. Taher acquired Kenny vacuum. Kenny is a professional manufacturer of vacuum equipment in the United States with a long history. It is also in a world position in the manufacturing of screw vacuum pump. KDP series is a vacuum pump with equal pitch rotor, and SDV is a variable pitch screw pump. Both are water-cooling systems, and air cooling systems can be selected. SDV is an improvement based on KDP. The variable pitch screw pump can realize the internal compression of gas, reduce the exhaust temperature, and save 30% energy compared with the same pitch. Niflon coating is adopted on the rotor, i.e. the layer is Ni and the second layer is PFA. Even if the PFA is worn, the Ni layer can achieve corrosion protection, and kalrez perfluorinated rubber sealing ring is adopted. SDV series is the screw vacuum pump mainly promoted by Kenny company. (2) The srewtine series screw oil-free compression vacuum pump officially launched by LeiBao company in Germany at the end of 2002 is a dry pump specially designed for industrial applications (non semiconductor applications). It is a new design and is specially used to solve the difficult vacuum problems in industrial applications. Such as dust, tar, etc. The pump also adopts variable pitch rotor with internal compression process. There is no internal valve in the pump cavity, so it has strong resistance to dust and tar. The screw of the pump adopts internal hollow cooling, which can reduce the rotor temperature and thermal deformation, so the service life of the screw is prolonged. (3) Cobran series screw pump of Germany puxu company is a vacuum pump for manufacturing process, which is especially suitable for various process flows in chemical and pharmaceutical industries. Puxu is one of the suppliers of vacuum pumps, blowers and compressors in the world. The quality of vacuum pumps is high. Compared with other manufacturers, puxu has a high market share in Europe and the price is expensive. (4) VSA / VSB series of Richler, Germany. VSA is an equal pitch rotor with good market evaluation and stable performance. VSB Series event pitch rotor design (non-linear tooth shape design), like other companies, changes the power consumption and exhaust temperature of the pump through internal compression. Without two-stage compression and intermediate cooling, a single stage can achieve very high vacuum. The sealing element is improved. The static sealing element is preferably PTFE or the sealing element added with PTFE. The dynamic sealing element uses double sealing lips on the suction side of the vacuum pump, and a simple sealing ring with gas overflow prevention is used on the exhaust side of the vacuum pump to prevent solid substances from entering the pump. (5) Japanese manufacturers. Screw vacuum pumps are widely used in Japan, and are widely used in semiconductor and LCD industries. Yoshimura soldiers of Dahuang Co., Ltd. applied for patents on single head first-class screw rotors for a long time and made in-depth research on rotors. Hitachi also made research on screw pump in the early stage. 3. Research prospect: The domestic research of dry screw vacuum pump is still in the initial stage, and many technical problems have not been solved. For example, the rotor coating anti-corrosion technology, reducing the temperature of the exhaust port and increasing the utilization rate of the rotor area are still very difficult. When extracting some active gas, due to the high exhaust temperature, it also needs to be considered in the design. When used in the occasion where the volume needs to be controlled, how to reduce noise should also become the research direction, However, its superior performance determines that it will dominate the vacuum equipment industry, just like the dominant position of screw compressor in the industry.

Dry Screw Vacuum Pumps Used In Fruit Freeze Drying Industry

0 notes

Text

Global Diesel Cars Market Insight Growth Analysis on Volume, Revenue and Forecast to 2021–2028

Market Overview

The most recently published Diesel Cars Market report provides a critical assessment of key growth dynamics, emerging pathways, investment trends in key regional markets, and the competitive landscape in various regions and key players’ strategies. The study also offers insights into the proportion and size of various segments of the Diesel Cars market. The report presents the market analysis based on several factors. Various exploration techniques such as qualitative and quantitative analysis have been used to accurately provide data. To better understand customers, he uses effective graphic presentation techniques such as charts, graphs, tables, and images. Buy Any 3 And Pay For Only 2 Hurry Up To Grab This Exciting Discount...! Offer Valid Till 31st March 2021.

Get Free Sample PDF @ https://ordientmarketresearch.com/sample-request/automotive-transportation/world-diesel-cars-market/OMR4829 The report covers a wide range of areas for a better global market experience as well as industry trends and forecasts. The report covers market models based on product types, application regions, and key vendors. In this report, variables influencing the market such as drivers, controls, and store openings have been carefully described. The review of market models, reviews, and numbers has been done on both a large scale and a micro level. It also gives a general overview of the strategies that the main competitors have received within the company. Other important variables that influence market trends regionally and globally were taken into account. These influencing factors are the socio-political situation, environmental conditions, demographics, legal organizations, and the competitive environment in the region. Market Scope The research report is committed to giving its readers an unbiased point of view of the global Diesel Cars market. Thus, along with statistics, it includes opinions and recommendation of market experts. This allows the readers to acquire a holistic view of the global market and the segments therein. The research report includes the study of the market segments on the basis of type, application, and region. This helps in identifying segment-specific drivers, restraints, threats, and opportunities. Browse Full Premium Report @ https://ordientmarketresearch.com/automotive-transportation/world-diesel-cars-market/OMR4829 Segmental Analysis The report has classified the global Diesel Cars industry into segments including product type and application. Every segment is evaluated based on growth rate and share. Besides, the analysts have studied the potential regions that may prove rewarding for the Diesel Cars manufacturers in the coming years. The regional analysis includes reliable predictions on value and volume, thereby helping market players to gain deep insights into the overall Diesel Cars industry. By Type <2.0L 2.0-3.0L >3.0L By Application Passenger Vehicle Commercial Vehicle Regions covered in Diesel Cars market report are: North America United States Canada Europe Germany France U.K. Italy Russia Nordic Rest of Europe Asia-Pacific China Japan South Korea Southeast Asia India Australia Rest of Asia-Pacific Latin America Mexico Brazil Middle East & Africa Turkey Saudi Arabia UAE Rest of Middle East & Africa To Enquire About Discount Visit @ https://ordientmarketresearch.com/check-discount/automotive-transportation/world-diesel-cars-market/OMR4829 Global Diesel Cars Market Report provide in-depth information about the Leading Competitors involved in this report: Volkswagen Daimler PSA Renault GM FCA Group Ford Hyundai Jaguar Land Rover BMW Honda FAW Group Toyota Volvo Reasons To Buy Diesel Cars Market Report(Key Points): 1.The report provides important statistics on the market status of the Diesel Cars Devices manufacturers and is a valuable guidance and guidance tool for companies and individuals interested in the industry. 2.The report provides a basic overview of the industry including definition, applications, and manufacturing technology. 3.The report includes the company profile, product specifications, capacity, production value, and market share for major vendors for 2021-2030. 4.The overall market is then further subdivided by company, country, and application/type for the competitive landscape analysis. 5.The report estimates Diesel Cars Devices industry market development trends for 2021-2030. 6.An analysis of the upstream raw materials, the downstream demand and the current market dynamics is also carried out. Browse More Reports: https://neighborwebsj.com/uncategorized/4947614/baby-bedding-market-worldwide-latest-industry-trends-trades-supply-demand-future-prospects-by-2030-get-flat-20-off-on-this-report/ https://neighborwebsj.com/uncategorized/4947615/air-source-heat-pumps-market-industry-analysis-and-forecast-2021-2030-get-flat-20-off-on-this-report/ https://neighborwebsj.com/uncategorized/4947617/motorcycle-gear-market-2021-technology-development-key-manufacturers-forecast-based-on-major-drivers-and-trends-up-to-2030-get-flat-20-off-on-this-report/ https://neighborwebsj.com/uncategorized/4947619/frozen-meat-market-by-manufacturers-types-regions-and-application-research-report-forecast-to-2030-get-flat-20-off-on-this-report/ https://neighborwebsj.com/uncategorized/4947734/wedding-ring-market-size-share-growth-revenue-trends-competitive-landscape-forecast-report-get-flat-20-off-on-this-report/ Contact Us Mangesh Mahajan Head of Business Development Phone: +91-7385620197 Email: [email protected] Web: https://ordientmarketresearch.com/

0 notes

Text

Global Black Start Generator Market was valued at US$ XX Bn in 2019 and is expected to reach US$ XX Bn by 2027, at a CAGR of XX % during a forecast period. Global Black Start Generator Market, By TypeA black start generator is a power generation unit, which offers the power plants with the initial power backup during a blackout without depending on an external electric source. Black start generators have a nominal power output of 20 MW commonly and they deliver a fast start up to the main turbine generators. They are widely used in hydro, thermal and nuclear power plants. Increasing manufacturing industries across the globe and growing construction & reconstruction of power plants owing to retiring by regulatory bodies are the main driving factors for black start generators market. The growing its usage in many applications, increasing competitive market and demand of black start generators in the oil & gas industries also expected to boost the growth in the global Black start generators market. Furthermore, Black start generators necessitate regular maintenance and testing to confirm they function during a blackout. This is resulting in high operation and maintenance costs for the generator, which is limiting the growth in the global black start generator market. The objective of the report is to present a comprehensive assessment of the global black start generator market and contains considerate insights, facts, historical data, industry-validated market data and projections with appropriate set of traditions and methodology. The report also helps in understanding dynamics, structure by analysing the market segments by material, type, end-user and region and, project the global market size. The report also provides a clear representation of competitive analysis of key players by product, price, financial position, product portfolio, growth strategies, and regional presence in the global black start generator market. The report also provides PEST analysis, PORTER’s analysis, SWOT analysis to address the question of shareholders in arranging the efforts and investment in the near future to a particular market segment. Diesel type generators are projected to dominate the black start generator market during the forecast period. Diesel generators have some advantages such as quick response time, easy fuel sourcing and storage, and extensive running life are expected to drive the demand for segment. The gas and hybrid generator market for black start is extremely restricted owing to exertion is fuel sourcing and shorter running life. Diesel generators are extensively used at most Coal, Gas and Oil fired power plants and practically all nuclear power plants in the United States requires an emergency backup power source for the station's supplementary needs. These auxiliaries contain critical pumps, fans, hydraulic units, battery chargers, turning gear motors for steam turbines and much more. In big Power Plants, there is generally at least one emergency diesel generator set per unit. These diesel generators are started automatically when an under-voltage relay is started, generally owing to a disastrous station service transfer when a producing unit is stumbled offline. Geographically, Asia Pacific is expected to witnessing significant growth in the global black start generator market. The growth in the market is attributed to the huge growth of power generation and IT & telecom sectors and new and practical policy reforms to support the growth of manufacturing sector in developing economies such as India and China. Increasing foreign direct investment in the developing countries in this region is expected to increase the growth in the black start generator market. Many of the countries in the Asia-Pacific are in the developing phase and absence of suitable power grid, leading to a large number of blackouts. This gap between power demand and supply and poor power grid when coupled with the progression of manufacturing industries and the construction of new power plants is estimated to drive the black start generator ma

0 notes

Text

Demolition Jackhammer Market Analysis, Revenue, Price, Share, Growth Rate, Forecast 2030

Demolition Jackhammer Market: Introduction

Jackhammer is powerful tool that used to demolish concrete, break hard rock, tear up asphalt, etc. It is also known as Demolition Jackhammer, which is an electro-mechanical or pneumatic tool that combines a hammer directly with a chisel. The demolition jackhammer just convert energy to impact. Piston, chisel, rod pin, through bolt, side bolt, front cover, ring bush, accumulator diaphragm, etc. are the parts of Demolition jackhammer.

There are three type of Demolition jackhammer available in market i.e. Pneumatic, hydraulic and electric. Pneumatic jackhammer drive by internal hammer mechanism using air pressure whereas in hydraulic jackhammers piston and a pump is used to create a drive with high oil pressure. It is an extremely efficient technique of transferring energy, as oil does not compress. An electrical jackhammers work on a gear mechanism in which electric motor is used to transform rotary power to hammer for its up-and-down action.

The mostly used demolition hammer is rotary hammers which is commonly practice by the worker at renovating a residence, small facilities and etc. Demolition jackhammer is find application in rock-drilling, used to demolish or break the pavement, rock and concrete at construction site, roads, tunnels, railway tracks and excavation. Larger jackhammer are used in construction machinery, they are usually used to break up rock, concrete and pavement. Demolition is an important as improper demolition can increase costs, present serious safety hazards and hazards compromise the structural integrity.

Get Brochure of the Report @ https://www.tmrresearch.com/sample/sample?flag=B&rep_id=7021

Demolition Jackhammer Market: Dynamics

Driver- The increasing construction activity is a major driver for Demolition jackhammer market. There is increase in construction of roads, railway tracks and tunnels also the infrastructure upgrade initiative and rise of smart city mega-projects in which Demolition jackhammer is used owing to its advantages such as durability, quiet operation, outstanding operator comfort, and low maintenance. The demand for improving the transportation has also been growing globally, because of which there is an increase in demand for jack hammers in construction industries.

Furthermore, increase in mining and quarry activity as demand for metal and mineral commodities is expanding globally. Jack hammers have common mining application such as development of benches in open pit mine, Underground mines face development, which is the major factor that boosts the growth Demolition Jackhammer market.

Restraints- Rise in government regulations for mining operations and construction activity may hamper the market growth of Demolition Jackhammer. For instance, governments of many countries, such as China, U.S have implemented stringent regulations and charges for mining operations.

COVID-19 Impact- Owing to slowdown in construction activities in account of imposed restrictions in wake of COVID-19 pandemic, the demolition jackhammers market is expected to witness a dip in sales of new equipment as per subdued investments and procurement by the stakeholders. The rental sales is however expected to witness to grow at a steady pace during the current and the upcoming years

Demolition Jackhammer Market: Segmentation

The global Demolition Jackhammer market can be segmented on the basis of type and application.

On the basis of Type, Global Demolition Jackhammer market is segmented into:

Pneumatic

Electric

Hydraulic

On the basis of Application, the Global Demolition Jackhammer market is segmented into

Mining

Construction

Tunnelling

Well drilling

To get Incredible Discounts on this Report, Click Here @ https://www.tmrresearch.com/sample/sample?flag=D&rep_id=7021

Demolition Jackhammer Market: Regional Outlook

In terms of regional markets, the developing nations have undertaken the onus of growth as compared to the developed regional markets. Asia pacific is identified to be leading market of the Demolition Jackhammer market followed by Europe and Latin America. In Asia pacific, the country such as China, India are spending more on construction activity as demand of roads, railways etc. are increasing due to increasing population which significantly driving the demolition jackhammer market in Asia pacific region.

In Latin America, the countries such as Mexico, Chile, Brazil, Peru have high mining activity and also infrastructure development which also boosting the Demolition Jackhammer demand, result in increasing market in Latin America.

Also, African countries such as Ghana, Namibia, Burkina Faso, etc. are the major contributor in mining activities of various precious metals which significantly increasing Demolition Jackhammer market.

Demolition Jackhammer Market: Key Participant

Some of the key players in the global Demolition Jackhammer Market are listed below:

M. P. Tools

Zhejiang Hangbo Power Tools Co., LTD

Yongkang Xulang Industry and Trade Co., Ltd.

XtremepowerUS

HiKOKI Power Tools

Robert Bosch Tool Corporation

Jinhua Jujie Electric Machine CO., LTD

Kennametal Inc.

Makita Corporation

KORA Attachments Co., LTD

The research report on the Demolition Jackhammer Market presents a comprehensive assessment, and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. The Demolition Jackhammer Market report also contains projections using a suitable set of assumptions and methodologies. The report provides analysis and information according to market segments such as geography, vehicle type, and sales channel.

Request For TOC @ https://www.tmrresearch.com/sample/sample?flag=T&rep_id=7021

About TMR Research:

TMR Research is a premier provider of customized market research and consulting services to business entities keen on succeeding in today’s supercharged economic climate. Armed with an experienced, dedicated, and dynamic team of analysts, we are redefining the way our clients’ conduct business by providing them with authoritative and trusted research studies in tune with the latest methodologies and market trends.

Contact:

TMR Research, 3739 Balboa St # 1097, San Francisco, CA 94121 United States

Tel: +1-415-520-1050

0 notes

Text