#United States Gear Pumps Industry

Explore tagged Tumblr posts

Text

Jerry Can Gear Pump Based Filling Machine

Company Overview: Shiv Shakti Machtech is Manufacturer, Supplier and Exporter of Jerry Can Gear Pump Based Filling Machine. A Jerry Can Gear Pump Based Filling Machine is a state-of-the-art liquid filling system designed to handle the precise filling of jerry cans and similar containers. This type of filling machine utilizes a high-quality gear pump mechanism, ensuring accurate and efficient dispensing of liquids in industries such as chemicals, lubricants, oil, food and beverage, and more. Our Jerry Can Gear Pump Based Filling Machine is ideal for multiple applications, including Jerry Can Filling Machine, Filling machine for oil, chemical, Jar, Jerry can bulk filler, 25 liter Oil Jerry can filling machine, 5 Liter Jerry Can Filling Machine, Edible Oils Filling Machine for Jerry Can, 5kg 10kg 15kg 25kg Pail Big Gallon Filling Machine, Bucket Paint Jerry Can Gear Pump Viscous Liquid Filling Machine, Lube Oil Jerry Can Filling machine, Jerry Cans Packaging Line, Positive Displacement Pump Jerry Can Filling Machine, Serov Filling Machine for Jerry can, Specifications: The Filling Principal: Gear Pump / Flowmeter / Loadcell Filling Range: 5 liter to 50 liter - different model available The Filling Liquid: Oils, Liquids, Solvent, Paints, semi viscous liquids Filling Container: Jerry Can, Bucket, Gallon, Pail Number of Filling Head: 2 to 16 heads - different model available Construction: Stainless Steel Shiv Shakti Machtech is a Jerry Can Gear Pump Based Filling Machine and an exporter worldwide, including Algeria, Angola, Antigua, Barbuda, Argentina, Armenia, Australia, Austria, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Congo, Democratic Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica, Ecuador, Egypt, Guinea, , Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece, Guyana, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, South Korea, North Korea, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia, Maldives, Mali, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique, Myanmar (Burma), Namibia, Nepal, Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal, Serbia, Singapore, Slovakia, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United Arab Emirates (UAE), United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, Zimbabwe. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Algeria#Angola#Antigua#Argentina#Armenia#Australia#Austria#Bahrain#Bangladesh#Barbuda#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#Botswana#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#CentralAfricanRepublic#Chad#Chile#Colombia#Congo

1 note

·

View note

Text

United States Hydraulic Pumps Market Dynamics and Future Landscape Review 2024 - 2032

The United States hydraulic pumps market is a crucial segment of the broader industrial landscape, driven by diverse applications across various sectors. Hydraulic pumps are essential components in numerous machinery and equipment, enabling efficient fluid power transmission. As industries continue to innovate, the demand for advanced hydraulic pumps is growing, making the United States hydraulic pumps market a focal point for manufacturers and investors alike.

Overview of Hydraulic Pumps

Hydraulic pumps are mechanical devices that convert mechanical energy into hydraulic energy by moving fluid. They are categorized into various types, including gear pumps, piston pumps, and vane pumps, each designed for specific applications. The performance and efficiency of these pumps are vital for operations in industries such as construction, manufacturing, and agriculture.

Types of Hydraulic Pumps

Gear Pumps

Gear pumps are widely used for their simplicity and efficiency in transferring hydraulic fluids. They operate using gears that mesh together to create a vacuum that draws in fluid and then pushes it out.

Piston Pumps

Known for their high efficiency and ability to handle high pressures, piston pumps are commonly used in heavy machinery and industrial applications. They utilize pistons to create pressure and flow.

Vane Pumps

Vane pumps are versatile and can handle a variety of fluids. They consist of a rotor with vanes that move within a cavity, creating a pumping action.

Market Trends

Growth Drivers

The United States hydraulic pumps market is experiencing significant growth due to several factors:

Industrial Automation: The push for automation in manufacturing processes is leading to increased demand for hydraulic systems, including pumps.

Infrastructure Development: Ongoing infrastructure projects and investments in construction are driving the need for reliable hydraulic equipment.

Technological Advancements: Innovations in pump design and materials are improving efficiency and reducing energy consumption, making hydraulic pumps more appealing to end-users.

Challenges

Despite the positive outlook, the market faces challenges such as:

Fluctuating Raw Material Prices: The cost of materials used in manufacturing hydraulic pumps can impact pricing and profitability.

Competition from Electric Pumps: The rise of electric pumps as alternatives to hydraulic systems may pose a threat to market growth.

Key Players in the Market

Several companies dominate the United States hydraulic pumps market, each contributing to the industry's evolution:

Parker Hannifin Corporation: A leader in motion and control technologies, Parker offers a wide range of hydraulic pumps known for their reliability and performance.

Bosch Rexroth AG: Renowned for its innovative hydraulic solutions, Bosch Rexroth focuses on high-quality and energy-efficient pump designs.

Eaton Corporation: Eaton provides a comprehensive portfolio of hydraulic pumps and systems, catering to various industrial needs.

Future Outlook

The future of the United States hydraulic pumps market looks promising, with projections indicating continued growth. As industries evolve, the demand for more efficient, durable, and technologically advanced hydraulic pumps will remain strong. Companies that can innovate and adapt to changing market dynamics will likely succeed in this competitive landscape.

In conclusion, the United States hydraulic pumps market is an integral part of the industrial sector, driven by technological advancements and increasing demand across various applications. As businesses seek reliable and efficient fluid power solutions, the market is set for sustained growth and evolution in the coming years.

Related Reports

Portable Generator

Power Quality Equipment

Hydrogen Fueling Station

Water Desalination

0 notes

Text

Understanding Hydraulic Power Units: The Heart of Hydraulic Systems

Hydraulic power units (HPUs) are the central component of hydraulic systems, providing the energy needed to drive machinery and perform heavy-duty work. From industrial equipment to construction machines and even aviation systems, hydraulic power units play a critical role in powering devices that require high force and precision. But what exactly is a hydraulic power unit, how does it work, and why is it so widely used?

In this blog, we’ll explore the basics of hydraulic power units, their components, applications, and why they remain an indispensable part of modern engineering.

What is a Hydraulic Power Unit?

A hydraulic power unit (HPU) is a self-contained system that generates and delivers hydraulic power to various machines and devices. Unlike electrical or mechanical power, which relies on motors or engines, hydraulic power units use fluid to transmit energy. By pressurizing hydraulic fluid (usually oil), HPUs create enough force to move and control heavy machinery and tools with precision.

These units are typically composed of a reservoir to store the hydraulic fluid, a pump to move the fluid through the system, valves to control the flow, and a motor to drive the pump. Together, these components provide the necessary power to operate everything from small hydraulic tools to large industrial systems.

How Does a Hydraulic Power Unit Work?

Hydraulic power units operate based on Pascal's law, which states that pressure applied to a confined fluid is transmitted equally in all directions. When hydraulic fluid is pressurized, it can be directed to different components of a machine, allowing them to perform tasks like lifting, moving, or compressing.

Here’s a step-by-step breakdown of how a typical HPU functions:

Reservoir: The hydraulic fluid is stored in a tank or reservoir, which also helps cool the fluid as it cycles through the system.

Pump: The hydraulic pump draws the fluid from the reservoir and pressurizes it, creating the force needed to move mechanical parts.

Motor: An electric or gas-powered motor drives the pump, ensuring the continuous flow of hydraulic fluid under pressure.

Valves: These control the direction and flow rate of the hydraulic fluid, allowing the operator to adjust the speed and direction of the machinery.

Cylinders/Actuators: The pressurized fluid is directed into hydraulic cylinders or actuators, which convert the hydraulic energy into mechanical motion, powering the machinery.

Types of Hydraulic Power Units

Hydraulic power units come in different shapes and sizes, depending on the application. Here are the most common types:

Standard HPUs: These are the most common and are used in a wide variety of industrial applications, from powering lifts and presses to factory automation systems.

Mini HPUs: Compact and portable, these units are ideal for mobile equipment or smaller machinery that requires hydraulic power but doesn't need a large system.

Custom HPUs: Built to meet specific industrial requirements, custom hydraulic power units are often used in complex or unique applications like offshore drilling, aerospace, or large-scale manufacturing.

Applications of Hydraulic Power Units

Hydraulic power units are used across a range of industries due to their ability to generate significant force with precision. Here are some common applications:

Industrial Machinery: HPUs power heavy machinery like presses, conveyors, and injection molding machines used in manufacturing and processing plants.

Construction Equipment: Many construction machines, such as excavators, bulldozers, and cranes, rely on hydraulic systems for lifting and moving heavy loads.

Agriculture: Tractors, combines, and other farming equipment use hydraulic power to control implements, operate lifts, and handle complex farm tasks efficiently.

Aerospace: In aircraft, hydraulic power units control vital systems like landing gear, brakes, and flight control surfaces.

Marine: Hydraulic systems are used in boats and ships to operate winches, steering systems, and deck equipment.

Automotive Industry: In automotive manufacturing, hydraulic presses are essential for shaping metal parts, assembling components, and even in testing vehicles for durability.

Advantages of Hydraulic Power Units

Hydraulic power units are preferred in many industries due to several key advantages:

High Power Density: HPUs can generate a tremendous amount of force in a relatively small system, making them ideal for applications where space is limited but power needs are high.

Precision Control: Hydraulic systems allow for fine control over movement, speed, and force, making them perfect for tasks that require accuracy, such as in aerospace or manufacturing.

Durability: Hydraulic power units are robust and can withstand harsh environments, heavy loads, and continuous use, making them highly reliable in demanding industries like construction and marine.

Efficiency: Although hydraulic systems require energy to operate, they are efficient in converting that energy into mechanical work, especially for tasks that require steady, high force.

Maintenance of Hydraulic Power Units

Like any other mechanical system, hydraulic power units require regular maintenance to ensure optimal performance and prevent breakdowns. Here are a few key maintenance tasks:

Fluid Checks: The hydraulic fluid should be checked regularly for contamination, proper levels, and viscosity. Clean fluid is essential for preventing damage to the pump and valves.

Filter Replacement: The filters in an HPU must be changed regularly to keep debris and contaminants from entering the system.

Component Inspection: Regularly inspecting seals, hoses, and valves for leaks or wear can prevent larger issues and keep the unit running efficiently.

Temperature Monitoring: Overheating can damage hydraulic systems, so it's important to monitor the temperature of both the fluid and the system as a whole.

Conclusion: The Essential Role of Hydraulic Power Units

Hydraulic power units are an integral part of many industries, providing the muscle and precision needed to power machinery that lifts, moves, and shapes the world around us. With their high force output, durability, and versatility, HPUs remain one of the most efficient and effective ways to deliver mechanical power in industrial settings. Whether in a massive construction crane or a delicate aerospace system, hydraulic power units continue to be a vital force in engineering and innovation.

0 notes

Text

Boosting Industrial Growth: The Role of Industrial Equipment Suppliers in the UAE

The rapid industrial growth in the UAE owes much to the accessibility of high-quality industrial equipment. Central to this success are the industrial equipment suppliers in UAE who ensure that businesses have the necessary tools to thrive. This article delves into the crucial role these suppliers play in the UAE’s industrial sector, the range of equipment they provide, and their contribution to the country's economic development.

The Vital Role of Industrial Equipment Suppliers

Industrial equipment suppliers are fundamental to manufacturing and production industries. They provide essential machinery and tools used in different stages of production. In the UAE, these suppliers are crucial for many reasons:

Quality and Reliability: By providing top-tier equipment, suppliers help ensure smooth and efficient industrial operations. High-quality machinery reduces downtime, reduces maintenance costs, and boosts productivity.

Technological Advancement: Suppliers introduce the latest technology to the UAE’s industrial sector, including advanced automation tools, precision machinery, and state-of-the-art manufacturing equipment. This helps local industries stay competitive globally.

Customization and Support: Suppliers understand the specific needs of different industries and offer customized solutions and ongoing support. This ensures the equipment meets the exact requirements of businesses, leading to better performance and output.

Wide Range of Equipment

Industrial equipment suppliers in the UAE provide a broad array of products catering to various sectors:

Manufacturing Machinery: This includes CNC machines, lathes, milling machines, and other tools essential for metalworking, plastics, and composite materials manufacturing.

Construction Equipment: Suppliers offer cranes, bulldozers, excavators, and other heavy machinery crucial for the UAE’s numerous infrastructure projects.

Oil and Gas Industry Equipment: The UAE’s oil and gas sector relies heavily on specialized equipment such as drilling rigs, pumps, compressors, and safety gear.

Renewable Energy Equipment: With a growing focus on sustainability, suppliers are providing equipment for solar and wind energy projects, including solar panels, wind turbines, and energy storage solutions.

Logistics and Material Handling: Forklifts, conveyors, automated storage systems, and other logistics equipment are vital for efficient warehousing and distribution.

Economic Impact

Reliable industrial equipment suppliers have a significant positive impact on the UAE’s economy. They support various industries by providing the tools needed to increase production efficiency and quality, leading to higher output and fostering economic growth.

Furthermore, in line with the UAE's sustainability objectives, equipment providers assist regional industry in lessening their environmental impact by promoting the adoption of cutting-edge technologies. The availability of latest machinery also draws in foreign investment since multinational corporations see the United Arab Emirates as a dependable and technologically advanced industrial powerhouse.

Conclusion

Industrial equipment suppliers are essential to the UAE’s industrial landscape, providing the machinery and tools necessary for different sectors to thrive. By offering high-quality, reliable, and advanced equipment, these suppliers enhance productivity, support economic growth, and contribute to the country's sustainability efforts. As the UAE continues to evolve as a global industrial leader, the role of these suppliers will remain pivotal in driving innovation and maintaining a competitive edge.

#Industrial equipment supplier in UAE#Fastener Insertion Machines in UAE#Portable tapping machines in UAE#Carbide application equipment in UAE

0 notes

Text

AEAUTO: Leading the new trend of electric steering-by-wire for commercial vehicles

At a time when heavy-duty commercial vehicles are undergoing electrification and autonomous driving, innovation in commercial vehicle steering systems is crucial. AEAUTO stands out in the field of commercial vehicle electric steering-by-wire with its superior technology and products.

At present, the development of autonomous driving functions for commercial vehicles has encountered technical difficulties. Foreign products are not sold in China, and the domestic commercial vehicle market has an increasingly strong demand for localization. Traditional and electric hydraulic steering dares to challenge and successfully develop the first generation of commercial vehicle electric wire-controlled steering systems, bringing a new solution to the industry.

Advantages of AEAUTO Electric Steering-by-Wire System

1. System efficiency increased by 30%.

There is no energy loss in the hydraulic link, and the design combines electric and wire control, which perfectly meets the needs of heavy-duty commercial vehicles such as electric vehicles and self-driving heavy trucks.

2. System weight reduced by 35%.

Compared with traditional hydraulic or electric hydraulic steering, this system eliminates five components such as the hydraulic pump and hydraulic steering gear, and steering is completely driven by an electric motor, which is light in weight and small in size.

The total system cost is reduced by 20%. After removing multiple components and amortizing the R&D investment and mold costs, the overall cost of parts is greatly reduced.

AEAUTO electric steering-by-wire system core technology advantages

1. 8000Nm high torque output.

Through a dual-winding motor, high-precision ball screw, and flat secondary enveloping toroidal worm reduction mechanism, as well as a 24V high power density motor and patented reduction mechanism, the 8000Nm high torque output required for heavy-duty commercial vehicles is achieved.

2. High-reliability redundant design.

Using a functional safety-based redundant architecture with dual-winding motors, dual MCUs, and dual control chips for heavy-duty commercial vehicles ensures high reliability and safety of the steering system, meeting the urgent needs of the electric steering system as a functional safety component.

3. The angle control response time does not exceed 50ms.

Based on the in-loop dynamic tracking and feedback control strategy of the power assist value, it adopts a low-inertia permanent magnet synchronous motor, determines the control mode through different sensor signals, and uses the control algorithm to accurately track the target parameters to achieve rapid response of EPS power assist, which is at the international leading level.

Compared with foreign competitors, AEAUTO has better performance in terms of system voltage and angle control response time. Although 48V voltage is designed to output more power, it is not a common standard. AEAUTO also achieves high power output with its unique reduction mechanism without affecting matching and compatibility. In addition, the company's control strategy and algorithm are outstanding, achieving a better angle control response time.

AEAUTO electric steering-by-wire helps heavy-duty trucks become more electrified and autonomous

Our products have undergone a series of rigorous tests, including performance tests, bench tests, and durability tests, and obtained the EU CE certification in June 2021. In terms of customer cases, the electric buses of Karsan in Europe and the products of Otokar, a leading Turkish bus company, both use AEAUTO's electric steer-by-wire system and are sold to many European countries and the United States.

In addition, AEAUTO has also built a heavy-duty commercial vehicle electric steering R&D test platform, which covers software-in-the-loop simulation, testing, calibration, reliability, and durability test benches, and has passed the assessment of Nanjing Engineering Technology Center.

With its advanced technology, excellent product performance, and reliable quality, AEAUTO has demonstrated strong competitiveness in the field of electric steer-by-wire for commercial vehicles and has made positive contributions to promoting the electrification and autonomous driving development of heavy-duty commercial vehicles.

0 notes

Text

Asphalt Pumps Market News and Forecast by 2024-2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Asphalt Pumps Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Asphalt Pumps Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Asphalt Pumps Market?

The global asphalt pumps market size reached US$ 773.5 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,120.1 million in 2032, exhibiting a growth rate (CAGR) of 4.2% during 2024-2032.

What are Asphalt Pumps?

Asphalt pumps are mechanical tools employed in construction to transfer hot asphalt from storage tanks to mixing plants or paving machines. These pumps are specifically designed to manage the high temperatures and viscosity of hot asphalt, ensuring a consistent and seamless flow. Available in different types such as gear pumps, screw pumps, and centrifugal pumps, each is suited for various asphalt applications. Asphalt pumps are essential for the dependable and efficient transportation of asphalt in construction projects.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1849

What are the growth prospects and trends in the Asphalt Pumps industry?

The asphalt pumps market growth is driven by various factors and trends. The asphalt pumps market is experiencing growth, fueled by rising global demand for road construction and maintenance. These pumps are essential for the efficient transportation of hot asphalt in construction projects. Market expansion is also propelled by advancements in pump technology, resulting in more efficient and durable pumps. Furthermore, government efforts to enhance infrastructure, particularly in developing nations, are contributing to market growth. Despite this, challenges such as fluctuating oil prices and environmental issues related to asphalt production may impede market expansion. Hence, all these factors contribute to asphalt pumps market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type of Pump:

Gear Pump

Screw Pump

Centrifugal Pump

Rotary Vane Pump

Others

By Capacity:

Low Capacity (Up to 500 GPM)

Medium Capacity (500-1,000 GPM)

High Capacity (Above 1,000 GPM

By End-Use Industry:

Road Construction

Roofing

Emulsion Plants

Others

By Power Source:

Electric

Hydraulic

Pneumatic

Segmentation by Region:

North America

United States

Canada

Europe

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific

China

India

Japan

Australia & New Zealand

ASEAN

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Who are the key players operating in the industry?

The report covers the major market players including:

Viking Pump, Inc.

Johnson Pump

Roper Pump Company

Flowserve Corporation

Colfax Corporation

SPX Flow, Inc.

Blackmer (PSG Dover)

Maruyama Mfg. Co., Inc.

Warren Rupp, Inc. (IDEX Corporation)

All-Flo Pump Co.

Stansteel Corporation

Hydromatik (Bosch Rexroth)

Viking-Cives Group

Sujal Engineering

Maag Pump Systems

View Full Report: https://www.reportsandinsights.com/report/Asphalt Pumps-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

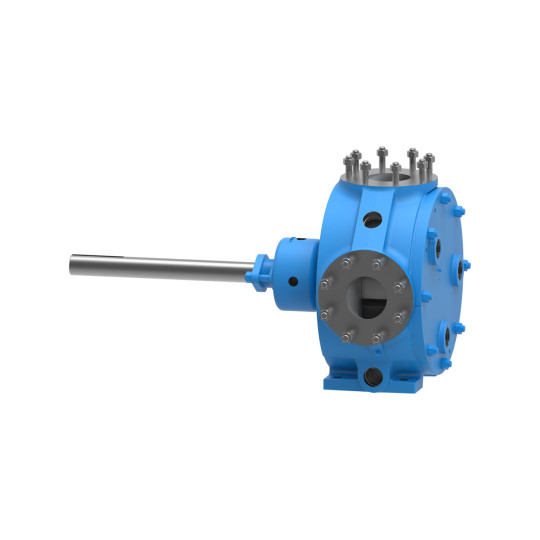

The Complete Guide to Hydraulic Gear Pumps of the Marketing Intertech Alpha Series

Introduction

Hydraulic gear pumps play a crucial role in numerous industrial applications, providing the necessary power and efficiency to ensure optimal performance. Among the notable series in the market, the Commercial Intertech Alpha Series stands out for its advanced features and reliable performance. In this comprehensive guide, we will delve into the various aspects of the Alpha Series hydraulic gear pumps, exploring their design, benefits, applications, and maintenance.

Understanding Hydraulic Gear Pumps

What is a Hydraulic Gear Pump?

A hydraulic gear pump is a type of positive displacement pump that uses meshing gears to pump fluid by displacement. It is one of the most common types of pumps used in hydraulic systems. The two main types of AGCO hydraulic pumps are internal and external gear pumps. The Alpha Series by Commercial Intertech belongs to the external gear pump category, which is widely used due to its simplicity and efficiency.

Components of a Hydraulic Gear Pump

Gears: The primary components that mesh together to move the fluid.

Housing: The casing that holds the gears and other internal components.

Inlet and Outlet Ports: Openings through which the fluid enters and exits the pump.

Bearings: Support the rotational movement of the gears.

Seals: Prevent leakage of the hydraulic fluid.

Features of the Commercial Intertech Alpha Series

The Alpha Series Bosch hydraulic pumps by Commercial Intertech are known for their exceptional design and performance characteristics. Here are some of the key features:

Advanced Performance

The Alpha Series is designed as an advanced-performance version of the traditional "bushing block" style pumps. This design innovation results in superior efficiency and reliability, making them ideal for demanding applications.

Low Noise Operation

One of the standout features of the Alpha Series is its low noise operation, even at high pressures. This makes them suitable for environments where noise reduction is critical.

Range of Displacements

The Alpha Series pumps are available in four frame sizes (P3, P5, P11, and P17) with displacements ranging from 0.8 to 52 cm³/rev (0.048 to 3.17 in³/rev). This wide range allows for flexibility in matching the pump to the specific needs of various applications.

Built in the USA

All Alpha Series pumps are proudly built in the United States, ensuring high-quality manufacturing standards and reliable performance.

Benefits of Using Alpha Series Hydraulic Gear Pumps

Efficiency

The advanced design of the Alpha Series pumps results in higher efficiency, which translates to better energy utilization and cost savings over time.

Durability

With robust construction and high-quality materials, Alpha Series pumps are built to last, reducing the need for frequent replacements and maintenance.

Versatility

The wide range of displacements and sizes available makes the Alpha Series pumps versatile, suitable for various industrial and mobile applications.

Reduced Downtime

The reliability and low maintenance requirements of these pumps help in minimizing downtime, ensuring continuous operation and productivity.

Applications of Alpha Series Hydraulic Gear Pumps

The Alpha Series hydraulic gear pumps are used in a variety of applications across different industries. Some of the common applications include:

Construction Equipment: Used in machinery such as excavators, loaders, and bulldozers.

Agricultural Machinery: Essential for tractors, harvesters, and other farming equipment.

Industrial Machinery: Applied in manufacturing and processing equipment for efficient fluid power.

Mobile Equipment: Utilized in mobile hydraulic systems for vehicles and equipment.

Maintenance and Troubleshooting

Regular Maintenance Tips

Check Fluid Levels: Regularly check and maintain the hydraulic fluid levels to ensure optimal performance.

Inspect for Leaks: Routinely inspect the pump and associated components for any signs of leaks.

Monitor Performance: Keep an eye on the pump's performance indicators, such as noise levels and operating temperatures.

Replace Worn Parts: Timely replacement of worn-out parts can prevent major breakdowns and extend the pump's lifespan.

Common Issues and Solutions

Cavitation: This occurs when there is a rapid formation and collapse of vapor bubbles within the fluid. It can be prevented by maintaining proper fluid levels and avoiding air ingress.

Overheating: Ensure adequate cooling and proper ventilation to prevent the pump from overheating.

Seal Leakage: Regularly check and replace seals to prevent fluid leakage and maintain pump efficiency.

Choosing the Right Pump

When selecting an Alpha Series hydraulic gear pump, consider the following factors:

Application Requirements: Match the pump specifications with the demands of your application.

Operating Conditions: Consider the operating environment, including temperature, pressure, and fluid type.

Performance Ratings: Check the pump's performance ratings to ensure it meets your desired efficiency and capacity.

Conclusion

The Commercial Intertech Alpha Series hydraulic gear pumps are a testament to advanced engineering and reliable performance. With their superior efficiency, low noise operation, and robust construction, they are an excellent choice for various industrial and mobile applications. Proper maintenance and timely troubleshooting can further enhance their longevity and performance. By understanding the features and benefits of the Alpha Series, you can make an informed decision and ensure optimal performance for your hydraulic systems.

For more information and to explore the range of Alpha Series hydraulic gear pumps, visit Hydraulic.net.

Contact us to know more.

0 notes

Text

Best Hydraulic Hose Repair Near Me

Make positive that you keep on twisting and jiggling up the pulley until and except the force belt receives comfortable. By utilising the field give up wrench, begin disconnecting and disenabling the inlet hydraulic hoses and outlet hydraulic hoses! Make sure the drain is nicely empty enough from any kind of fluid. Take off the pump from your tractor and get begin to keep on doing away with and commencing the mounting bolts of hydraulic pumps. Right after this step, a person then connects and connect the brand-new hydraulic pump together with the mounting bolts. Make certain that you tighten up the screws and fittings of inlet and outlet hoses in a right way. Open the valve of the bleeder with the help of wrench. Start aligning the pressure belt of the tractor at the pulley. Right on the pulley, ensure that you do place the pressure belt on it, follow required amount of strain against that pulley. As soon because the strain receives created and evolved, fill out the Hydraulic Hose Repair.

Hydraulic pump basically and oftenincludes tools pumps, rotary vane pumps, screw pumps and peristaltic pumps. It depends upon the machinery that what kind of hydraulic pump it has in it! Most of the machineries have screw pumps, some have gear pumps. This unique piece of writing can be telling the readers concerning the information and information about the Hydraulic Hose Repair. Starting with the gear pumps! The equipment pumps mesh up and overwhelm up the two gears causing the fluid motion. Those gears are been meshed up in any such way that the fluid receives mechanically started transferring. Tooth equipment pump has to date been considered because the best equipment pump. It is made of meshing gears; these gears are rotate in this type of manner that the fluid gets pulled off right away. Gear pumps are made from metal and they are enclosed in a sealed field. It additionally relies upon the form of equipment that you are using; distinctive equipment might exchange the composition of the tool’s pumps. Moving toward the rotary vane pumps! They are extra efficient and powerful as compare to the equipment pumps.

The enterprise of hydraulic cylinders may be very a hit and has given employment to several Indians internationally. It is likewise one of these industries that have been largely critical in phrases of the general improvement of the USA. With worldwide and country wide gamers vying to emerge as infrastructure majors in a rustic like India, the significance given to infrastructure additives is largely increasing. The uninhibited boom of this sector will only make sure the complete growth of the united states in phrases of industry and commerce.

Hydraulic cylinders are the main inputs for any infrastructure implementation and improvement. These components are used in bulk within the construction system industry and other production sectors. There has been large growth in sectors together with cement, metal, mining and in the oil and gas sectors. These components are very vital for the success of the infrastructure enterprise and therefore there has been a giant boom.

0 notes

Text

Quotation of copper row bus processing machine (how much is a set of Hunan CNC bus processing machine)

The work itinerary of each processing unit can easily adjust, reduce processing time, and improve production efficiency. By replacing the mold, it can also achieve a variety of processing functions, such as rushing holes, long circular holes, standing bending, flat bending, pressed flowers, and flattening, pressed nasal noses, twisted twist, etc.

In Zheng Zezhi's view, the machine is a replacement of workers' work and solved the problem of recruitment difficulties for enterprises. But this shows that it is not that the machine has driven away the workers, but that there are few workers, and the machine replaces the lack of workers. Quotation of copper row bus processing machine

It can monitor various operating status of the line in real time, such as power supply, power outage, shortage, grounding, short -circuit, short circuit, overcurrent, etc., quickly confirm the changes and places of the operating state of the monitored line. When the operating status of the line delivery, power outage, missing phase, grounding, short circuit, flow, overcurrent, etc., the line signal collector detects the changing signals. Various signals of change are emitted by wireless devices in a coding manner. As a receiving terminal, the duty personnel are informed by the computer after the computer processing, the screen display and other methods. The operating state of the monitoring line occurs and confirm the location of the change.

Copper's busbar bending machine quotes the heat shrinking pipes on the copper row, and uses armal gun to evenly heat the heating shrinking tube (operating method -1: the right hand holds the hot air gun, the left hand holds the copper row, rotating, and moving the hot air gun. Operation method-2: Place the hot air gun on the workbench, rotate and move with copper row). Make the heat shrinking sleeve evenly on the copper row, without wrinkles, bubbles.

It is a comprehensive parent line manufacturing enterprise integrating scientific research, production and sales. Since its establishment, it has won wide praise and support for users with high -quality products, careful services and continuous innovation. The Dalin parent line machine adheres to tradition, continuously innovates, leads the trend with technology, and builds a brand with quality. The company brings together the top talents in the parent line industry, and has a good R & D team, experienced production technology elites and professional after -sales service teams. The company has the parent line series series: CNC parent line processing machine series, ordinary parent line processing machine series, transfer parent line processing machine series, portable parent line processing machine series, parent line level machine, CNC hydraulic punching series, CNC bending machine series, CNC shear shear More than a dozen series of more than a dozen series such as board machine series. The company has always adhered to the business philosophy of "management as root, quality, innovation as the soul, and service as the way", and constantly strives to provide users with more and better products and services. The biggest feature of the company is to make full use of its own technical strength to maximize user needs in all projects.

Filter: Each time the oil is changed, the filter should be replaced or thoroughly washed; other filters are abnormal in the machine tool or other filters such as poor oil or oil quality, and should be replaced; It's best to replace one year.

Leaf pump: Divided into dual -acting blades and single -acting blade pumps. This kind of pump has uniform flow, stable operation, small noise, work pressure and volume efficiency higher than the gear pump, and the structure is more complicated than the gear pump.

0 notes

Text

Alariq Oman: The Guardians of Safety - Fire Trucks in Oman

In the heart of the Arabian Peninsula, where desert landscapes meet bustling cities, safety is a paramount concern. Oman, a country known for its rich history, stunning landscapes, and progressive approach to modernization, also places a high value on the safety and well-being of its citizens and residents. Ensuring this safety is a dedicated team of heroes - the fire brigade of Oman. Central to their mission is the trusty workhorse of firefighting operations - the fire truck. In this article, we delve into the world of Alariq Oman, exploring the role of fire trucks in Oman's firefighting efforts, their features, and the tireless firefighters who operate them.

The Importance of Fire Trucks

Fire trucks are the unsung heroes of emergency response teams. They are specially designed and equipped vehicles that serve as the frontline defense against fires, rescues, and hazardous material incidents. In Oman, a country that experiences various types of emergencies, from urban fires to rural blazes and traffic accidents, fire trucks play a pivotal role in mitigating disasters and saving lives.

Types of Fire Trucks in Oman

Pumper Trucks: Pumper trucks, also known as fire engines, are the most recognizable type of fire truck. They are equipped with water tanks, hoses, and a pump system to deliver water or firefighting foam to extinguish fires. These trucks are the workhorses of the firefighting fleet and are dispatched to tackle blazes of all sizes.

Aerial Trucks: Aerial trucks, often referred to as ladder trucks or turntable ladders, feature an extendable ladder with a platform at the end. They are essential for reaching high-rise buildings and rescuing people trapped on upper floors during fires.

Rescue Trucks: Oman's terrain is diverse, and so are the emergencies its firefighters respond to. Rescue trucks are equipped with specialized tools for extricating people from vehicles, buildings, or other precarious situations. They also carry equipment for handling hazardous materials incidents.

Wildland Fire Trucks: Oman's rugged landscape includes vast areas of wilderness susceptible to wildfires. Wildland fire trucks are designed to traverse rough terrain and deliver water to remote areas, making them essential for controlling wildfires.

Airport Fire Trucks: With a number of international airports, Oman has a fleet of airport fire trucks dedicated to responding to aircraft-related emergencies. These trucks are equipped with powerful firefighting systems and foam to combat aviation fires effectively.

Specialized Hazardous Materials (HazMat) Units: Oman's industrial sector necessitates specialized HazMat units equipped to handle chemical, biological, radiological, and nuclear incidents safely.

Features of Fire Trucks in Oman

Oman's fire trucks are equipped with state-of-the-art features that enable them to respond swiftly and effectively to emergencies. These features include:

Water and Foam Tanks: Fire trucks carry large water tanks and foam tanks to tackle various types of fires. The foam is particularly effective for suppressing flammable liquid fires.

High-Pressure Water Pumps: Powerful pumps can deliver a substantial amount of water per minute to combat fires effectively.

Emergency Lighting and Sirens: Fire trucks are equipped with bright emergency lighting and blaring sirens to alert other motorists and pedestrians when en route to an emergency.

Safety Equipment: Firefighters' safety is paramount. Fire trucks are stocked with personal protective equipment (PPE), such as helmets, turnout gear, and self-contained breathing apparatus (SCBA).

Communication Systems: Advanced communication systems ensure seamless coordination among firefighters and other emergency response agencies.

Medical Equipment: Many fire trucks carry basic medical equipment to provide immediate assistance to accident victims before the arrival of ambulance services.

Hydraulic Tools: Rescue trucks are equipped with hydraulic tools, including the "jaws of life," for cutting through vehicle wreckage during extrication operations.

The Heroes Behind the Wheels

Fire trucks, though impressive machines, are only as effective as the firefighters who operate them. The firefighters of Alariq Oman are true heroes, undergoing rigorous training to handle a wide range of emergency situations. These brave men and women work tirelessly, often in hazardous conditions, to protect lives and property.

Training: Oman's firefighters undergo comprehensive training programs that cover fire suppression techniques, rescue operations, first aid, and hazardous materials management. Their training ensures they can respond effectively to any emergency.

24/7 Vigilance: Firefighters are on call 24/7, ready to respond to emergencies at a moment's notice. Whether it's a blazing inferno in a residential area or a complex industrial incident, they are always prepared to spring into action.

Community Outreach: Oman's firefighters also engage in community outreach programs to educate the public about fire safety and prevention. This proactive approach helps reduce the occurrence of fires.

Physical and Mental Toughness: Firefighting is physically and mentally demanding. Firefighters must maintain peak physical fitness to handle the physical rigors of the job and possess the mental fortitude to remain calm under pressure.

Teamwork: Effective teamwork is essential in firefighting. Firefighters rely on one another to ensure the success of their operations, often working in tight-knit units to save lives and property.

Alariq Oman, with its dedicated firefighters and well-equipped fire trucks, stands as a symbol of safety and preparedness in the Sultanate. In a country that values the well-being of its people, these brave individuals and their trusty machines are the first line of defense against the destructive forces of fire and other emergencies. As Oman continues to grow and develop, the commitment of its fire brigade remains unwavering, ensuring that the safety and security of its citizens and residents are always safeguarded.

0 notes

Text

Gear Pump Filling Machine

Shiv Shakti Machtech is based in Ahmedabad and specializes in the Manufacturer, Supplier and Exporter of Gear Pump Filling Machine, Mustard Oil, Lubricant Oil, Hair Oil. Shiv Shakti Machtech offers a Gear Pump Filling Machine designed for various industries, accommodating products such as mustard oil, lubricant oil, hair oil, shampoo, phenyl, liquid soap, paint, and even liquor. From thick oils to thin liquids, the Gear Pump Filling Machine delivers unmatched performance, meeting diverse production needs effectively. Engineered for durability, the machine withstands tough operating conditions, constructed from high-quality materials and equipped with robust components, ensuring long-term performance and minimal downtime. Specification: Capacity: 20 bottles per minute (BPM). Number of Heads: 2. Warranty: 1 year. Driven Type: Electric. Filling Volume: 50ml to 1 liter. Automation Grade: Automatic. Bottle Diameter: Up to 90mm. Speed: Up to 20 bottles per minute. Model Name/Number: SF-60. Height of Conveyor: 850mm. Adjustable Height: Yes, with adjustable height feature Deal: New only. Brand: Shiv Shakti Machtech. Country of Origin: Made in India. Geographical Coverage: Shiv Shakti Machtech serves Gear Pump Filling Machine, Mustard Oil, Lubricant Oil, and Hair Oil in serves worldwide, including, Albania, Algeria, Andorra, Angola, Antigua and Barbuda, Argentina, Armenia, Australia, Austria, Azerbaijan, The Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Burundi, Cabo Verde, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Comoros, Congo, Democratic Republic of the Congo, Republic of Costa Rica, Côte d’Ivoire, Croatia, Cuba, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, East Timor (Timor-Leste), Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Eswatini, Ethiopia, Fiji, Finland, France, Gabon, The Gambia, Georgia, Germany, Ghana, Greece, Grenada, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Honduras, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, South Korea, North Korea, Kosovo, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Mauritania, Mauritius, Mexico, Micronesia, Federated States of Moldova, Monaco, Mongolia, Montenegro, Morocco, Mozambique, Myanmar (Burma), Namibia, Nauru, Nepal, Netherlands, New Zealand, Nicaragua, Niger, Nigeria, North Macedonia, Norway, Oman, Palau, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Samoa, San Marino, Sao Tome and Principe, Saudi Arabia, Senegal, Serbia, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Suriname, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Tuvalu, Uganda, Ukraine, United Arab Emirates, United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, Zimbabwe. Read the full article

#Ahmedabad#Albania#Algeria#Andorra#Angola#AntiguaandBarbuda#Argentina#Armenia#Australia#Austria#Azerbaijan#Bahrain#Bangladesh#Barbados#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#BosniaandHerzegovina#Botswana#Brazil#Brunei#Bulgaria#BurkinaFaso#Burundi#CaboVerde#Cambodia#Cameroon

1 note

·

View note

Text

Oil And Gas Pump Market Insights and Forecasting Trends Review 2024 - 2032

The oil and gas pump market plays a critical role in the energy sector, facilitating the extraction, transportation, and processing of oil and gas. As demand for energy continues to rise globally, the market for pumps used in oil and gas applications is experiencing substantial growth. This article delves into the dynamics of the oil and gas pump market, exploring its key drivers, challenges, segmentation, regional insights, and future trends.

What are Oil and Gas Pumps?

Oil and gas pumps are mechanical devices used to move fluids (liquid or gas) in the oil and gas industry. They are essential for various processes, including exploration, extraction, refining, and transportation. Different types of pumps are employed depending on the application and the properties of the fluids being handled.

Types of Oil and Gas Pumps

Centrifugal Pumps: Commonly used for transporting fluids at a constant flow rate, ideal for refining and water injection processes.

Positive Displacement Pumps: Suitable for high-viscosity fluids, often used in hydraulic fracturing and in applications requiring precise flow control.

Submersible Pumps: Designed to operate submerged in the fluid, commonly used in well drilling and groundwater extraction.

Market Dynamics

Growth Drivers

Increasing Global Energy Demand

Rapid industrialization and population growth are driving the demand for oil and gas, subsequently increasing the need for efficient pumping solutions.

Technological Advancements

Innovations in pump design, materials, and automation technologies enhance efficiency, reliability, and performance, driving market growth.

Exploration and Production Activities

Rising investments in upstream activities, particularly in emerging markets, are boosting the demand for pumps in drilling and extraction processes.

Challenges

Environmental Regulations

Stricter environmental regulations concerning emissions and spills can pose challenges for pump manufacturers and operators in the oil and gas sector.

Volatility in Oil Prices

Fluctuating oil prices can impact exploration and production budgets, leading to uncertainty in pump demand.

Maintenance and Reliability Issues

The harsh operating conditions in oil and gas environments can lead to pump failures, necessitating regular maintenance and replacement, which can incur high costs.

Market Segmentation

By Type of Pump

Centrifugal Pumps

Positive Displacement Pumps

Others (including diaphragm pumps and gear pumps)

By Application

Upstream (exploration and production)

Midstream (transportation and storage)

Downstream (refining and distribution)

By Region

North America

Europe

Asia-Pacific

Middle East & Africa

Latin America

Regional Analysis

North America

North America, particularly the United States, holds a significant share of the oil and gas pump market, driven by extensive exploration and production activities, especially in shale oil and gas. Technological advancements in hydraulic fracturing are further boosting demand.

Europe

Europe's market is influenced by its aging oil and gas infrastructure and the need for modernization. The European Union's commitment to sustainability also drives investment in more efficient and environmentally friendly pumping solutions.

Asia-Pacific

The Asia-Pacific region is witnessing rapid growth due to increasing energy demand, particularly in countries like China and India. Investment in offshore oil and gas projects is also on the rise, driving the need for robust pumping solutions.

Middle East & Africa

The Middle East remains a vital region for oil production, and ongoing investments in infrastructure development and enhanced oil recovery techniques are expected to bolster the demand for oil and gas pumps.

Future Trends

Digitalization and IoT Integration

The integration of Internet of Things (IoT) technologies in pump systems allows for real-time monitoring and predictive maintenance, reducing downtime and improving operational efficiency.

Energy Transition and Sustainability

As the industry shifts toward greener practices, the demand for pumps that can handle biofuels and other alternative energy sources is expected to increase. Manufacturers are focusing on developing more sustainable and efficient pumping solutions.

Automation and Smart Pumps

The trend toward automation in oil and gas operations is leading to the development of smart pumps equipped with advanced sensors and control systems, enhancing reliability and efficiency.

Conclusion

The oil and gas pump market is on a growth trajectory, driven by rising energy demands, technological advancements, and increasing investments in the sector. While challenges such as environmental regulations and market volatility persist, the future looks promising with the advent of digital technologies and a shift towards sustainable practices. As the global energy landscape evolves, the oil and gas pump market will continue to adapt, playing a vital role in meeting the world's energy needs.

More Trending Reports

Solar Pump Invertor Market Analysis

Europe, US & China Electrolyser Market Analysis

North America Transformer Market Analysis

Oil and Gas Refining Industry Market Analysis

0 notes

Text

Premier gaming laptop, the Raider GE78 HX KO 18

Raider GE78 HX KO user opinions

In terms of overall performance, what kind of 17-inch gaming laptop can beat out an 18-inch flagship model? You are in for a gaming experience that will take you to heights that have never been seen before when you equip yourself with the state-of-the-art Raider GE78 HX.

With its Intel Core i9–13980HX central processing unit (CPU) and NVIDIA GeForce RTX 4090 Graphics, the Raider GE78 HX provides unequaled power as well as a flawless visual experience. The NVIDIA GeForce RTX 4090 serves as the source of power for both of these components. It is geared up with proprietary OverBoost Ultra Technology, which gives it the ability to unleash an amazing 250 watts of full power on both the central processing unit (CPU) and the graphics processing unit (GPU). Because of the magnificent Mystic Light design and the QHD+ 240 Hz gaming display that this monitor provides, you should get ready to be immersed in a gaming experience that is unlike anything else you’ve ever had.

Let’s have a look at the performance of the Raider GE78 HX, shall we?

The Raider GE78 HX obtains a 3DMark Time Spy Graphic Score that is 5% higher than the 18-inch flagship laptop that is now available on the market, which is an exceptional performance gain. The Raider GE78 HX is currently available for purchase.

Moving ahead in time to the year CyberPunk 2077, the Raider GE78 HX maintains its status as the industry leader by obtaining a 5% performance advantage over the same competitor.

In terms of performance, God of War highlights the supremacy of the Raider GE78 HX, which is superior than the 18-inch flagship laptop by an amazing 7%. God of War was developed by Sony Computer Entertainment and published by Sony Interactive Entertainment.

Behold the Raider GE78 HX as it brings unprecedented power to the table during these taxing games, so ushering in a new era in the performance of the most advanced gaming systems.

Are you interested in finding out more about this laptop and wondering how the Raider GE78 HX manages to generate such outstanding results? If so, you’ve come to the right place. Do you have any other questions about the structure of it?

Be prepared to be taken to a visual world that will take your breath away with the brand-new Mystic Light. This product has a compelling matrix lighting design that elegantly extends over the whole of the front panel of the chassis. The incorporation of the Steelseries Per-Key RGB, a gaming keyboard that has backlit WASD keys, brings a level of sophistication that was not before there in your set-up.

In addition, since it is feasible to combine the bandwidth of three distinct networks, you will be able to take advantage of transfer rates of up to 2.5 Gbps from the Killer LAN E3100 and up to 3 Gbps from the 2.4GHz, 5GHz, or 6Hz of Wi-Fi 6E, depending on which one you choose to use. With a maximum capacity for data transmission of up to 5.5 gigabits per second, you may take pleasure in very quick file transfers on a level that you have never reached before. This functionality is only included into the 13VI and 13VH versions since they are the only ones available.

Shared Pipe enhances thermal capabilities and allows you to reach the full potential of your CPU performance, enabling you to enjoy the power and potential of your computer’s processor. Because MSI Cooler Boost 5 is now available, players have the opportunity to entirely take control of the expansive and detailed gaming worlds they discover.

Embrace “Discrete Graphics Mode,” a feature that is exclusive to MSI and will offer you performance that is unrivaled. This mode is designed to release the full potential of your graphics capabilities.

Prepare yourself for the impact that will be brought about by MSI’s one-of-a-kind OverBoost Ultra Technology, which will pump out an astonishing 250 watts of pure power and offer an adrenaline rush that is unsurpassed in its breadth. In other words, be ready for the game-changing effect that will bring about.

If you have the most current version of the Raider GE78 HX, you should be prepared to take your gaming experience to the next level now that you have it.

0 notes

Text

Turn Notifications Off and ‘Forest Mode’ on for National Forest Week

New Post has been published on https://eazycamping.net/turn-notifications-off-and-forest-mode-on-for-national-forest-week/

Turn Notifications Off and ‘Forest Mode’ on for National Forest Week

National Parks get a lot of love, but it was in a national forest that I first played “fairies” around our campsite with my two kids, now a classic we play every trip. It was in a national forest that my son practiced walking up and down a slope covered in pine needles at just over a year old and my daughter learned to balance her way across an entire log (more challenging than a balance beam at the gym).

In national forests, my family has splashed in lakes and creeks, spent nights under the stars, and gazed at the moon through our telescope. We’re just one family among many thousands that has made memories in these special places. This National Forest Week, let’s celebrate just how important national forests and grasslands are to millions of Americans.

Credit Sommer Merrill / 500px via Getty Images

Why National Forests Matter

According to the National Forest Foundation (NFF), national forests and grasslands encompass 193 million acres of wildlands across the United States.

This includes:

More than 9,000 miles of scenic byways to drive

Almost 150,000 miles of trails to hike

More than 4,400 miles of wild and scenic rivers to float

At least 5,100 campgrounds to pitch a tent

328 natural pools to swim in

The foundation’s president and CEO, Mary Mitsos, says: “These lands are the foundation of America’s outdoor recreation heritage and sustain our way of life. They provide water to millions of Americans in thousands of communities, clean our air, store carbon, and provide timber, minerals, oil and gas, and other resources for industry and communities.”

Managed by the USDA Forest Service, national forests and grasslands host more than 170 million visits each year, and Mitsos says this pumps $13.5 billion into the U.S. economy annually, sustaining nearly 223,000 jobs in gateway communities.

What’s more, national forests and grasslands are home to important ecosystems, thousands of plant species, and wildlife—including everything from elk and bears to trout and ducks.

Credit Luís Henrique Boucault via Getty Images

Switch on ‘Forest Mode’ and Get Involved

This year, the theme for National Forest Week is “Forest Mode.” Mitsos says: “This year’s theme of ‘Forest Mode’ invites the public to switch their digital notifications off and switch ‘Forest Mode’ on. Whether this means taking a quiet morning hike before work, a thrilling whitewater rafting adventure, or telling stories by the campfire after a day spent outside with friends, the NFF encourages recreators to experience these moments in a forest nearby while recreating responsibly.”

In addition to stepping into your favorite forest, here are four ways to get involved and support national forests and grasslands during this National Forest Week:

Participate in the National Forest Week Photo Contest

Submit your favorite photo of a national forest for the chance to win one of these outdoor-themed prizes, including gear, an America the Beautiful Pass, gift cards for adventure tour companies, and cool swag. There are three categories—landscape, recreation, and youth photography—and the deadline to enter is midnight (MT) on July 16, 2023.

Credit NFF

Donate to a Treasured Landscape

Donations to the Treasured Landscapes, Unforgettable Experiences program helps improve wildlife habitats and recreation opportunities. Past projects have included restoring two rivers in central Oregon and enhancing a critical salmon habitat in Alaska.

Plant a tree

The NFF is on a quest to plant and grow 50 million trees in national forests by the end of 2025 (they’ve already planted over 29 million). You can help them reach this goal by donating $1 to the cause.

Join the conversation

Join the NFF live on Twitter tonight, Wednesday, July 12, 2023, at 9 PM ET / 6 PM PT for a conversation about national forests and their importance.

Why do national forests matter to you? Tell us in the comments.

Source

0 notes

Text

The Ethical Side of Diamonds: Transparency, Sustainability and Human Rights

Behind every shimmering diamond lies a story - one that is often marred by the unethical practices of the diamond industry. From conflict diamonds to exploitative labor, the journey of a diamond from mine to market can be riddled with ethical challenges. However, as consumers become increasingly conscious of their purchases, transparency, sustainability and human rights have emerged as critical issues for the industry's future. In this blog post, we delve into the ethical side of diamonds and explore how consumers can play a crucial role in promoting change.

What are Diamonds?

Diamonds are rare and valuable gemstones. They are mostly found in Africa, Asia, and the United States. Diamonds come from very small rocks called "icecaps." The diamonds are formed over many years. The process of diamond formation is very slow and takes millions of years for the diamond to form.

Diamonds have many colors, including yellow, brown, orange, green, blue, purple and pink. Diamonds can also be transparent or translucent. Diamonds have a hardness of 9 on the Mohs scale, meaning other similar hardness minerals can only scratch them. Diamonds also have a long life expectancy because they do not rust or corrode- which is common with other gems.

Diamond Mining and its Impact on the Environment

The mining of diamonds takes a great toll on the environment. The De Beers Group has perpetuated this problem for years through its lack of transparency about the environmental damages caused by its diamond mines.

Diamond mining is a dirty business, and De Beers needs to do more to clean up its act if it wants people to start buying its diamonds again. Nowadays, lab grown diamonds Singapore is getting popular for being environmentally friendly.

The Evolution of Diamonds: From the Ground to the Cutting Room Floor

Diamonds are naturally occurring and have been used as jewelry and ornamentation since ancient civilizations. Over the years, they've become one of the most coveted gems in the world, with a value that has only grown. What is interesting about diamonds is their history. Diamonds come from the ground, but their journey to our hands is anything but simple.

The history of diamonds can be traced back to over 2 billion years ago when they formed inside meteorites. After crashing down to Earth, these small rocks were subjected to high pressure and heat and turned into what we now know as diamonds. Diamonds occur in different colors (red, yellow, blue, etc.), but their primary characteristic is that they have an even number of points on their surface (6).

From the ground to our fingertips, diamonds go through several phases before making it to market: exploration, development and production. Exploration happens when miners search for new deposits of diamonds; development refers to preparing these deposits for mining, and production deals with getting the diamonds out of the ground and onto shelves.

Production processes for diamond mines can involve dangerous practices such as pumping water at high pressure deep underground to break up rocks and extract treasure chests full of diamonds. Child labor in these mines is also common; children are often responsible for dangerous tasks like wearing heavy safety gear while working in extremely hot conditions.

In recent years there has been a lot of talk about the "diamond bubble," which refers to the idea that diamonds are becoming too expensive for the average person to afford. Many experts predict that the diamond market will significantly decline in the next few years, which could lead to a decline in diamond prices. It is important to remember that diamonds are a precious commodity, and their value can be affected by many factors.

Diamond Trading and its Impacts on Socioeconomic Development

Diamond trading fuels poverty and human rights violations in some of the world's poorest countries. The diamond trade negatively impacts social and economic development in these areas due to the concentration of wealth that often accompanies diamond trading.

Global demand for diamonds drives unsustainable mining operations that can damage natural resources, contribute to environmental degradation, and violate human rights. Many miners are forced to work in hazardous conditions with little pay and no benefits. Diamond companies have been accused of engaging in slavery-like practices by forcing laborers to live in inhumane conditions without safety measures or proper medical care.

The global diamond market is highly commercialized, exacerbating these negative consequences' impact. Policies that targeted the diamond trade alone would not be enough to solve these issues; instead, concerted efforts are needed to address broader issues such as poverty, inequality, and abusive labor practices.

Conclusion

When it comes to diamonds, there are many questions that consumers and investors alike have. Questions like where the diamonds were mined, who was paid in exchange for their labor, and whether those people were treated ethically come to mind. But even more pressing are ethical issues related to the diamond industry, such as transparency and human rights. With clearer ethics guidelines coming into play, businesses worldwide need to step up into man made diamonds UK more.

0 notes

Text

Asphalt Pumps Market News and Forecast by 2024-2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Asphalt Pumps Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Asphalt Pumps Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Asphalt Pumps Market?

The global asphalt pumps market size reached US$ 773.5 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,120.1 million in 2032, exhibiting a growth rate (CAGR) of 4.2% during 2024-2032.

What are Asphalt Pumps?

Asphalt pumps are mechanical tools employed in construction to transfer hot asphalt from storage tanks to mixing plants or paving machines. These pumps are specifically designed to manage the high temperatures and viscosity of hot asphalt, ensuring a consistent and seamless flow. Available in different types such as gear pumps, screw pumps, and centrifugal pumps, each is suited for various asphalt applications. Asphalt pumps are essential for the dependable and efficient transportation of asphalt in construction projects.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1849

What are the growth prospects and trends in the Asphalt Pumps industry?

The asphalt pumps market growth is driven by various factors and trends. The asphalt pumps market is experiencing growth, fueled by rising global demand for road construction and maintenance. These pumps are essential for the efficient transportation of hot asphalt in construction projects. Market expansion is also propelled by advancements in pump technology, resulting in more efficient and durable pumps. Furthermore, government efforts to enhance infrastructure, particularly in developing nations, are contributing to market growth. Despite this, challenges such as fluctuating oil prices and environmental issues related to asphalt production may impede market expansion. Hence, all these factors contribute to asphalt pumps market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type of Pump:

Gear Pump

Screw Pump

Centrifugal Pump

Rotary Vane Pump

Others

By Capacity:

Low Capacity (Up to 500 GPM)

Medium Capacity (500-1,000 GPM)

High Capacity (Above 1,000 GPM

By End-Use Industry:

Road Construction

Roofing

Emulsion Plants

Others

By Power Source:

Electric

Hydraulic

Pneumatic

Segmentation by Region:

North America

United States

Canada

Europe

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific

China

India

Japan

Australia & New Zealand

ASEAN

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Who are the key players operating in the industry?

The report covers the major market players including:

Viking Pump, Inc.

Johnson Pump

Roper Pump Company

Flowserve Corporation

Colfax Corporation

SPX Flow, Inc.

Blackmer (PSG Dover)

Maruyama Mfg. Co., Inc.

Warren Rupp, Inc. (IDEX Corporation)

All-Flo Pump Co.

Stansteel Corporation

Hydromatik (Bosch Rexroth)

Viking-Cives Group

Sujal Engineering

Maag Pump Systems

View Full Report: https://www.reportsandinsights.com/report/Asphalt Pumps-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes