#UV Tape Market

Explore tagged Tumblr posts

Text

UV Tapes Market Illumination: Shedding Light on the Pinnacle of UV Tape Manufacturing

The UV tapes market has emerged as a pivotal player in the adhesive solutions sector, witnessing a steady ascent in demand across various industries. UV tapes, short for ultraviolet tapes, are adhesive materials that cure and bond rapidly when exposed to ultraviolet light. This unique characteristic makes them indispensable in a range of applications, driving their adoption in sectors such as electronics, automotive, healthcare, and more.

Market Dynamics:

The UV tapes market is experiencing robust growth due to several factors. One key driver is the increasing demand for miniaturized electronic devices, such as smartphones, tablets, and wearable gadgets. UV tapes play a crucial role in these applications by providing reliable and precise bonding in the assembly of electronic components. The growing trend of compact and lightweight designs in consumer electronics amplifies the need for high-performance UV tapes.

Moreover, the automotive industry has also become a significant consumer of UV tapes. With the rising focus on lightweight materials for enhanced fuel efficiency and the increasing use of electronic components in vehicles, UV tapes contribute to efficient bonding in the assembly of automotive parts. Their ability to withstand harsh environmental conditions and temperature variations makes them an ideal choice for automotive applications.

Another contributing factor to the UV tapes market's growth is the expanding healthcare sector. UV tapes find applications in medical devices, diagnostics, and wearable health technologies. The medical industry demands adhesives that are biocompatible, and UV tapes meet this requirement while providing reliable bonding in medical device manufacturing.

Technological Advancements:

The UV tapes market is also benefiting from continuous technological advancements. Manufacturers are investing in research and development to enhance the performance characteristics of UV tapes. Improved adhesion strength, faster curing times, and compatibility with a broader range of substrates are some of the areas where innovation is taking place. These advancements not only expand the application scope of UV tapes but also contribute to the overall efficiency of manufacturing processes.

Environmental Sustainability:

Environmental concerns and the push for sustainable practices are influencing the UV tapes market. Manufacturers are increasingly focusing on developing UV tapes that are environmentally friendly and comply with regulations. Water-based formulations and tapes with reduced volatile organic compound (VOC) emissions are gaining traction, aligning with the global shift towards eco-friendly products.

Challenges and Opportunities:

While the UV tapes market is on a growth trajectory, it is not without its challenges. The high initial cost of UV curing equipment can be a barrier to entry for some manufacturers. Additionally, educating end-users about the benefits of UV tapes and dispelling misconceptions is crucial for widespread adoption.

However, these challenges also present opportunities for market players. Offering cost-effective UV curing solutions, conducting targeted marketing campaigns, and collaborating with end-users to understand specific application needs can help companies overcome these hurdles and establish a strong foothold in the market.

Conclusion:

In conclusion, the UV tapes market is witnessing steady expansion driven by the demand for miniaturized electronic devices, the growth of the automotive industry, and the increasing adoption of UV tapes in healthcare applications. Technological advancements, a focus on environmental sustainability, and strategic approaches to address challenges are shaping the future of this market. As industries continue to seek efficient and reliable bonding solutions, the UV tapes market is poised for further growth and innovation in the coming years.

#UV Tapes Market Share#UV Tapes Market Growth#UV Tapes Market Demand#UV Tapes Market Trend#UV Tapes Market Analysis

0 notes

Text

UV Tapes Market Dynamics: From UV-Curing to High-Performance Adhesive Solutions

UV tapes, also known as ultraviolet tapes, are specialized adhesive tapes that are designed to cure quickly when exposed to ultraviolet (UV) light. These tapes find applications in various industries where precise and rapid bonding or fixation is required. UV tapes are widely used in electronics, semiconductor manufacturing, automotive, healthcare, and aerospace sectors, among others. They offer several advantages, including high bond strength, fast curing times, and the ability to work with delicate or heat-sensitive materials.

The market overview and scope of UV tapes are significant, as they cater to a diverse range of industries. UV tapes are used in applications such as component assembly, LCD and OLED screen manufacturing, printed circuit board (PCB) fabrication, and medical device assembly, to name a few. They are particularly valued in the electronics industry for their ability to create strong, reliable bonds on intricate components.

Growth in the UV tapes market industry has been notable in recent years. This growth can be attributed to the increasing demand for smaller and more complex electronic devices, which require precise bonding solutions. Additionally, the automotive sector's push towards lightweight and energy-efficient vehicles has created a need for UV tapes in bonding lightweight materials and components.

The UV tapes market has become a crucial part of the broader adhesive tape industry. Manufacturers in this sector are continually innovating to develop UV tapes with enhanced properties, such as improved adhesion, flexibility, and resistance to environmental factors. This innovation is driven by the growing demand for UV tapes across various industries, and it reflects the industry's commitment to meeting evolving customer needs.

Trends in the UV tapes market indicate a shift towards sustainable and environmentally friendly products. Manufacturers are exploring UV tapes that are free from harmful chemicals and have minimal environmental impact. Additionally, the adoption of automation and robotics in manufacturing processes is driving the demand for UV tapes with features like high-speed curing to optimize production efficiency.

In conclusion, the UV tapes market is witnessing substantial growth due to their widespread applications across diverse industries. As technology continues to advance and industries seek efficient and reliable bonding solutions, the UV tapes market is expected to evolve further, with a focus on innovation and sustainability. This market is poised to play a pivotal role in meeting the evolving needs of various industries in the coming years.

0 notes

Text

I haven’t been excited by a new toy in a while, but MGA’s new Miniverse got my attention.

These are available everywhere, including Amazon: https://amzn.to/3GGeEIt

However, that’s not always a good thing. It’s not always a positive aspect of a toy that catches my eye.

The big “what???” of these is that they’re marketed to kids age 8 and up, and contain UV resin.

Now..... Resin is

well it’s

...

It’s not for kids.

Allergies to uncured resin are common (both 2-part epoxy and UV resins) and can be severe.

There are lots of warnings in the packaging. I didn’t read them.

You should wear gloves and a respirator when working with any resin, even in a well ventilated area. There aren’t many proper respirators that fit kids....

Froggy on YouTube was too afraid to open her resin and instead used tinted Mod Podge which worked just as well.

I, however, am old and experienced with both types of resin (though no expert), unafraid of the possible reaction I could endure (I’m familiar with resin allergy and how it can be, so a good test subject) so I figured I’d give these a look to see just how bad an idea they might be for kids.

I did NOT wear gloves or a respirator while working on these kits in the name of science.

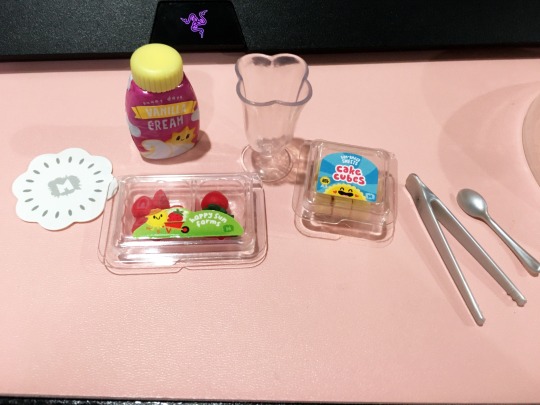

My first order was 3x of the Diner balls (there are 3x of the Cafe ones on the way).

I wanted a blueberry cheesecake.

None of my three were any type of cheesecake. I got this strawberry and cake parfait, choco-hazelnut spread and strawberry toast, and key lime pie.

First warning on this one: When I opened the little plastic bag that contained the “vanilla cream”, it smelled of UV resin and left my finger sticky. Some resin must have gotten on the outside of the bottle before it was bagged. It did make me itch at the time, which I was like “oh no....” but I’ll get back to that. One of the other balls had the same experience, but not all three.

The positives: Wow this is cute. There are screened veins on the strawberries, the whole berries have painted leaves, and the cake cubes are textured. These are very nice little minis, if a little under-detailed and obviously plastic.

Excellent for doll houses.

Every tiny bottle of resin has a big DO NOT EAT THIS sticker on it with information if you peel it off and unfold it.

The negatives: resin

You get tools, but they’re insufficient. I’ll address that later, also.

The little fruit and cake packages are difficult to open and I tossed my cake cubes across the desk. I am clumsy.

The resin bottle is VERY difficult to open. While this is good to prevent leaks (presumably), it did result in me and various tools being covered in resin trying to get it open.

Most of these items are a good scale for 1/6th dolls (Mini Me is a Live Action Beauty and the Beast Belle head on a curvy Barbie body). That bread is kind of big, those are bulk peanut butter, and that’s a LOT of vanilla cream.

Speaking of the bread...

I am NEVER opening this. Never. It’s too cute as it is. There is a TINY. BREAD. TAB.

Never.

That freed up one kit’s stuff to mix with the others.

These limes are transparent like they’ve been baked.

The whipped cream tube opens and there are all of these dollops inside, but I’m not the only one that thought they looked like little garlic! With a little toasty-colored dry brushing they could also be meringues.

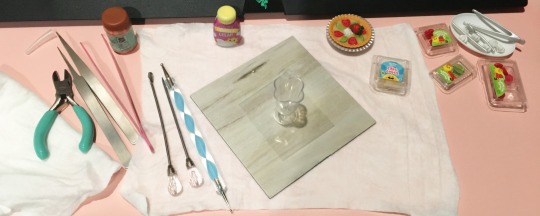

Anyway, this was my “I’ve done this before.” set up. I didn’t tape down my tape (that’s a vinyl flooring sample, it’s an excellent base for working on UV resin), but it was fine for this small project.

I like to work on baby wipes because the damp, rough texture stops things from rolling or sliding around (it’s especially handy if you’re playing with glitter) and I keep another on hand to wipe my tools or my fingers as needed with the container nearby because I do go through a lot of wipes. Negative to baby wipes is that they’re prone to dropping strings everywhere.

Back to the tools.

You don’t want to touch uncured resin. The tools that come with these kits are playscale. Imagine trying to dig the key lime pie goo out of this jar with that tiny knife (though that set comes with a spoon). You’re going to be covered in resin.

There’s only about 1/3 of the jar full.

I used my normal resin doing spoon which is long and still had to stop to wipe my fingers a few times because I am clumsy.

The same with the tweezers.

These longer ones are much safer.

Each of these three kits has a different texture of resin. This is the “Nutella” which is thick and spreadable. I was using it as chocolate sauce since I didn’t want to use the bread. The vanilla cream was runny, and the key lime pie goo was in the middle.

I was doing this at 5 am in the winter so there was no sun. I used my nail lamp, so I can’t say whether these would set properly in the sun.

Having experience with UV resin, I did the key lime pie in two layers, curing the lower layer of just lime goo first so that the pieces wouldn’t get pushed too deep into said goo, then adding a second, thinner layer to set the fruit into.

I got this all over myself even with my longer, more appropriate tools.

Because the deco is plastic you can’t hit the resin with a flame to get rid of bubbles. Sometimes you can get them to pop if you blow on it hard and fast (POOF!) but I didn’t bother.

Obviously I switched mine up and made a strawberry limeade pie instead, using some of the Nutella to make a chocolate dipped strawberry on top.

As for the parfait, I am disappointed that the cake cubes on the bottom are obscured by the resin. It is very runny, ran down and around and covered them right up.

I also did this one in layers. I was wondering if the white resin would be able to cure because sometimes opaque tinted UV resin, especially white, can’t cure and you end up with a thin, cured crust and then that can be easily broken and uncured resin comes out everywhere.

This white resin cured fine. It’s not opaque.

I’m wishing I’d skipped the whipped cream on the parfait because the bright white of the whipped cream makes the transparency of the vanilla cream resin more obvious.

And this is what I’m left with!

If I hadn’t put the big strawberry on the key lime pie, it all would have fit into the pie crust container.

I cured the mostly empty insides of the vanilla cream and key lime goo containers but not the Nutella because I might come back and use that some day.

Whipped cream bits are back into the can.

I didn’t want to have empty fruit packaging so I pulled out some polyclay canes and refilled them.

Final thoughts

If you were to do these kits as intended, you’d be throwing away most of them. There was a TON of plastic bags inside, three layers of plastic outside, the pie crust and fruit containers and resin bottles/jars would be empty, there are many, many papers inside telling how to use the resin and warnings and the checklist and MGA’s usual “Give us your toy ideas for free!” flyer they include in everything these days.

I didn’t put them in the pictures but each kit does come with a small table that can snap into the ball to use as a dust-free display, and a doily or place mat depending on what you’re making.

I DID get resin all over my fingers. The resin DOES smell, but not as strong as my usual UV resin and it doesn’t sting my nose like my usual UV resin. If I were allergic, I’d be in pretty bad shape right now. As it is, I just feel kind of gross even though I’ve gotten as much off of my hands as I can.

Washing your hands won’t get this off, you need rubbing alcohol, which is where baby wipes come in handy.

Are these for kids 8+?

no

I mean, it depends on the kid. I’ve seen kids that can outcook adults.

Giving this to me at that age or even as a teen would be a mistake. It would end up in my hair, up my nose, on the dog, in my mom’s purse somehow.... I am clumsy.

It depends on the kid, but in general, no. There are very few respirators that properly fit children.

This is for teens and adults who already know how to handle UV resin.

145 notes

·

View notes

Text

Everything You Need to Know About PVC Tape and Bijli Tape for Electrical Insulation

When it comes to electrical work, choosing the right type of tape is essential for safety, efficiency, and long-lasting results. PVC tape, commonly known in India as Bijli tape, is a staple for electricians and DIY enthusiasts alike. Made of polyvinyl chloride (PVC), these tapes provide essential insulation, protection, and durability in various electrical applications. In this blog, we’ll explore what PVC tape and Bijli tape are, their benefits, and why selecting high-quality products from reliable PVC tape manufacturers is crucial. We’ll also discuss the versatility and types of PVC tape rolls available in the market.

What is Bijli Tape?

"Bijli tape" is a colloquial term used in India for PVC electrical insulation tape. Popularly known as Bijli tapes, these are essentially PVC tapes specifically tailored for the Indian market and are widely used by electricians across the country. These tapes are crucial for ensuring secure, insulated, and damage-free electrical connections in various environments, including homes, offices, and industrial settings.

Key Benefits of Using PVC and Bijli Tape

PVC tape and Bijli tapes are essential for any electrical project due to their unique features and advantages:

High Insulation: PVC tape rolls are designed to provide superior electrical insulation. They help prevent electrical shorts, shocks, and potential fires.

Flexibility and Stretchability: PVC tapes are known for their flexibility, which makes them easy to use even around tight corners and bends.

Durability: PVC tapes are highly resistant to wear, abrasion, and moisture. This makes them a long-lasting solution for electrical insulation.

Temperature and Flame Resistance: Good-quality PVC and Bijli tapes are designed to withstand varying temperatures and are often flame retardant, adding an extra layer of safety to electrical setups.

Versatile Application: Available in different colors, PVC tape rolls can be used to identify wires, mark circuits, and create easy-to-recognize electrical systems.

Choosing High-Quality PVC Tape Manufacturers

With the market flooded with PVC and Bijli tapes, it’s essential to choose reliable and reputable PVC tape manufacturers to ensure quality and durability. Here are some factors to consider:

Material Quality: High-quality PVC tape is made from durable polyvinyl chloride with a strong adhesive that lasts for a long time without peeling.

Adhesion Strength: Look for PVC tape that adheres well to various surfaces, including metal, plastic, and rubber.

Thermal and Electrical Insulation Properties: Manufacturers should provide product details, including resistance to heat, voltage rating, and insulation thickness.

Certifications and Standards: Choose manufacturers who comply with safety and quality standards, ensuring their products are certified and meet industry benchmarks.

Some well-known PVC tape manufacturers offer a wide range of products, including specialized electric tape rolls designed for various applications, from industrial machinery to household wiring.

Types of PVC Tape Rolls and Applications

There are several types of PVC tape rolls available, each designed for specific applications. Here’s a look at some common types:

Standard PVC Electrical Tape Rolls: These are general-purpose tapes commonly used for insulating electrical wires. They are often available in various colors to help differentiate between wires.

High-Voltage PVC Tape Rolls: Used in heavy-duty industrial applications, high-voltage PVC tapes provide enhanced insulation and protection in high-voltage environments.

Weather-Resistant PVC Tapes: Designed for outdoor applications, these tapes are UV-resistant and moisture-resistant, making them ideal for use in harsh weather conditions.

Flame-Retardant PVC Tapes: Often used in environments where safety is paramount, flame-retardant PVC tapes minimize the risk of fire in case of electrical faults.

Bijli Tape: Specifically popular in India, Bijli tapes are widely used in household and commercial electrical projects for their reliability and insulation quality.

How to Use PVC Tape Effectively

Using PVC tape effectively can extend the life of your electrical work and ensure safety. Here are some best practices:

Clean the Surface: Ensure the surface is dry and clean before applying the tape to guarantee strong adhesion.

Apply with Tension: Stretch the tape slightly as you wrap it around wires to ensure a secure fit without any gaps.

Layering: For additional protection, especially in high-voltage applications, consider layering PVC tape by wrapping it multiple times around the wires.

Color Coding: Use different colors of PVC tape to organize wires, mark phases, or distinguish between circuits.

PVC and Bijli Tape in Electrical Safety

When dealing with electricity, safety is paramount. Using high-quality PVC tape rolls is an essential part of securing electrical connections and avoiding hazards. PVC tapes, particularly those sourced from reputable manufacturers, are tested to ensure they withstand the electrical and thermal demands of modern electrical systems. Insufficient or low-quality insulation can lead to short circuits, fire hazards, or electric shocks, making the choice of PVC and Bijli tape an important safety decision.

Conclusion

PVC tape and Bijli tapes are essential tools in the electrician’s toolkit, providing insulation, protection, and durability for a wide range of applications. From general-purpose electric tape rolls to weather-resistant and flame-retardant variants, choosing the right tape is crucial for ensuring safe and long-lasting electrical setups. By sourcing your PVC tape rolls from trusted manufacturers, you can ensure high quality, better insulation, and a longer lifespan for your electrical work.

#electrical insulation tape#pvc electrical tape#pvc tape manufacturers in delhi#pvc insulation tape in delhi#pvc tape#pvc insulation tape#pvc electrical insulation tape#pvc tape roll#bijli electrical tape#insulation tape roll#bijli tapes#bijli tape

0 notes

Text

https://www.databridgemarketresearch.com/reports/global-non-uv-dicing-tape-market

0 notes

Text

BOPP Films Manufacturers in India

Introduction

Biaxially Oriented Polypropylene (BOPP) films are an essential material in the packaging industry, known for their exceptional strength, clarity, and moisture resistance. As the demand for flexible packaging continues to rise across various sectors—including food, beverages, textiles, and consumer goods—India has emerged as a significant player in the global BOPP film manufacturing landscape. This article explores the key manufacturers in India, the applications of BOPP films, and the market dynamics shaping this industry.

Understanding BOPP Films

BOPP films are produced by stretching polypropylene film in both the machine and transverse directions, resulting in a product that exhibits enhanced mechanical properties and barrier characteristics. The benefits of BOPP films include:

Lightweight and Strong: BOPP films offer excellent tensile strength while being lightweight, making them ideal for packaging solutions.

Moisture and Gas Barrier: Their low permeability helps protect products from moisture, gases, and UV light, extending shelf life.

Clarity and Printability: The high clarity of BOPP films allows for vibrant printing and visibility, enhancing product appeal on retail shelves.

Cost-Effectiveness: BOPP films provide a cost-efficient solution for packaging, reducing material usage without compromising performance.

Key Applications of BOPP Films

BOPP films are utilized across various industries, including:

Food Packaging: Widely used for snack foods, confectioneries, and ready-to-eat meals due to their barrier properties.

Labels and Tapes: BOPP is commonly used in the production of self-adhesive labels and packaging tapes.

Textile and Garment Packaging: BOPP films are preferred for packaging textiles because of their durability and aesthetics.

Industrial Uses: The films are also utilized in industrial packaging, providing reliable protection for goods during transportation.

Market Trends and Challenges

The BOPP film market in India is experiencing significant growth, driven by several trends:

Sustainability Focus: With increasing environmental concerns, manufacturers are investing in sustainable practices and developing biodegradable or recyclable film options.

Technological Advancements: Innovations in production technology are enabling manufacturers to enhance film properties, catering to specialized applications.

Rising E-commerce Sector: The boom in e-commerce is driving demand for efficient packaging solutions, boosting the growth of BOPP films.

Challenges

Despite the growth opportunities, the industry faces challenges such as:

Raw Material Price Volatility: Fluctuations in the prices of polypropylene can impact production costs.

Regulatory Compliance: Adhering to stringent packaging regulations and standards can be challenging for manufacturers.

Intense Competition: The growing number of players in the market leads to increased competition, impacting profit margins.

Conclusion

The BOPP film manufacturing sector in India is poised for robust growth, driven by the expanding packaging industry and evolving consumer preferences. With several leading manufacturers committed to innovation and sustainability, India is set to strengthen its position as a key player in the global BOPP film market. For businesses seeking reliable packaging solutions, partnering with established BOPP film manufacturers in India will be essential to leverage the benefits of this versatile material.

0 notes

Text

Masterbatch Market In-Depth Analysis and Forecast 2024 - 2030

The global masterbatch market size is expected to reach USD 9.65 billion by 2030 to expand at a CAGR of 6.3% from 2024 to 2030 as per the new report by Grand View Research, Inc. Increasing replacement of metal with plastic is projected to fuel the market growth. In addition, rising demand from the European region is expected to propel the demand over the forecast period.

In terms of revenue, black masterbatch was the largest type segment in 2022 and the trend is anticipated to continue over the forecast period. The increasing need for improving the surface appearance of plastic components in automotive and transportation, building and construction, and consumer goods is expected to contribute to the growth. Additive masterbatch is being widely used on account of various properties it imparts to plastics such as antistatic, antifoaming, antioxidant, antimicrobial, thermo-stabilizer, barrier properties, metal deactivators, anti-block, flame retardant, UV stabilizer, oxygen scavenger, and abrasion resistance. The growth of the packaging sector, especially plastic packaging, is anticipated to drive the demand.

These are used in various end-use industries, such as packaging, building and construction, consumer goods, automotive and transportation, and agriculture, as it imparts useful functional properties such as smooth surface finish and desired hardness. The increasing spending capability of customers toward purchasing attractively packaged consumer goods is expected to trigger the need for various plastic componentss to improve the appearance and other properties. These factors together are anticipated to boost the market demand over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Masterbatch Market

Detailed Segmentation:

Market Concentration & Characteristics

The market is fragmented in nature. The masterbatch is primarily used in the polymer industry for coloring and enhancing the properties of plastics. The global polymer industry is experiencing significant growth, driven by increased demand in various sectors such as packaging, automotive, construction, and consumer goods.

Type Insights

The black type dominated the market with a revenue share of 28.48% in 2023. This high share is attributed to the growth in demand for black masterbatch and the high demand for tires, PVC containers, and other products for application in the automotive and transportation, building and construction, agriculture, and packaging industries. The growing need for agricultural products such as drip irrigation tubing and tape, greenhouse films, shade cloth, and geomembranes is also projected to boost market growth over the forecast period.

Carrier Polymer Insights

The polypropylene (PP) carrier polymer segment dominated the market with a revenue share of 26.68% in 2023. It is attributed to the demand for polypropylene as a carrier polymer is projected to increase owing to its excellent mechanical strength and flexibility offered by it. Polypropylene also enhances the quality of surfaces. It is lightweight and, therefore, is used to replace metal components in the automotive industry. All these factors are expected to fuel the growth of the polypropylene segment in the forecast period.

End-use Insights

The packaging masterbatch end-use segment dominated the market with a revenue share of 26.91% in 2023. Its high share is attributable to the packaging industry, which includes retail, industrial, and consumer packaging, which further includes flexible and rigid options. A rise in the number of city inhabitants who require packaged goods is resulting in an increased demand for packaging. Consumers need packaging that is convenient, sustainable, flexible, offers protection, and is easily traceable. As plastic packing fulfills all these needs, its demand is expected to grow, which is, in turn, projected to result in the growing demand for the product. There is immense growth potential for the packaging industry in emerging economies such as India and China.

Regional Insights

Asia Pacific dominated the market with a revenue share of 30.42% in 2023, owing to the presence of several end-use industries, including automotive and transportation, packaging, building and construction, and consumer goods. The growth of these industries is expected to fuel the demand for the product over the next eight years.

Browse through Grand View Research's Paints, Coatings & Printing Inks Industry Research Reports.

• The global oil and gas corrosion protection market size was valued at 9.78 USD billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 2.4% from 2024 to 2030.

• The global technical textile chemicals market size was valued at USD 8.93 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.8% from 2024 to 2030.

Key Companies & Market Share Insights

The market is fragmented, with several global and regional players. Key players in the market comply with the regulatory policies and are engaged in research & development activities to develop innovative products. For instance, Hubron International became a corporate member of The Graphene Council, the world’s largest community for graphene researchers, developers, producers, academics, and scientists. Since Hubron International is involved in masterbatch/compounding of graphene materials and has technologies available for the processing of 2D materials, the growing usage of 2D materials in the thermoplastic arena for providing lightweight products is expected to strengthen Hublon International’s position in the masterbatch market. Most key industry players are integrated across the value chain, posing entry barriers for new market players. Some prominent players in the global masterbatch market include:

• In November 2023, The investment firm Koinos Capital, headquartered in Milan, established the Impact Formulators Group by merging the operations of two Italian companies specializing in masterbatch and additives manufacturing, namely Masterbatch S.r.l. and Ultrabatch S.r.l.

• In November 2023, TER Chemicals and Momentive have mutually agreed to extend their current distribution agreement for high-performance additives in polymer modification. This expansion encompasses all European countries, with the exception of Iberia and the UK. The portfolio offered includes multifunctional masterbatches, anti-block agents, light diffusers, crosslinkers, and coupling agents. These products aim to provide customers with effective solutions to enhance the performance of their products and address various processing challenges.

Key Masterbatch Companies:

• A. Schulman, Inc.

• Ampacet Corporation

• Cabot Corporation

• Clariant AG

• Global Colors Group

• Hubron International Ltd.

• Penn Color, Inc.

• Plastiblends India Ltd.

• PolyOne Corporation

• Tosaf Group

Masterbatch Market Segmentation

Grand View Research has segmented the global masterbatch market report based on type, carrier polymer, end-use, and region:

Masterbatch Type Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• White

• Black

• Color

• Additive

• Filler

• Biodegradable

Masterbatch Carrier Polymer Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• Polypropylene (PP)

• Polyethylene (PE)

o Low-Density Polyethylene

o High-Density Polyethylene

• Polyvinyl Chloride (PVC)

• Polyethylene Terephthalate (PET)

• PUR

• PS

• Biodegradable Plastics

• Other Carrier Polymers

Masterbatch End-Use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• Packaging

• Building & Construction

• Consumer Goods

• Automotive & Transportation

• Agriculture

• Other End-Uses

Masterbatch Regional Outlook (Volume, Kilotons; Revenue, USD Billion, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o U.K.

o France

o Italy

o Spain

o Benelux

o Poland

• Asia Pacific

o China

o India

o Japan

o South Korea

o Taiwan

o Australia & New Zealand

o Indonesia

• Central & South America

o Brazil

o Argentina

o Chile

• Middle East & Africa

o Iran

o Saudi Arabia

o South Africa

Order a free sample PDF of the Masterbatch Market Intelligence Study, published by Grand View Research.

Recent Developments

• In June 2023, Ampacet announced the launch of PET UVA, a masterbatch that offers protection to the packaging contents from harmful UV light, thereby keeping the food fresher, extending product shelf life, and limiting waste. The company also offers UVA in PP and PE.

• In June 2023, Ampacet unveiled the introduction of a new additive - AA Scavenger 0846, designed particularly for restricting the acetaldehyde levels in both PET and rPET bottles. This product launch was aimed at supporting the sustainability efforts of the company in the packaging industry by encouraging the use of recycled materials and reducing waste.

• In April 2023, Penn, Color, Inc. announced the commencement of its world-class facility in Rayong Province, Thailand in order to expand its manufacturing capabilities. The objective of this new plant was to enable the company to deliver high-quality colorant & additive masterbatches across the Asia-Pacific market.

0 notes

Text

Branded Custom Marquees: Why Are They A Must-Have For Events?

Outdoor events hold a special allure, whether it is a carnival, trade show, market stall, or corporate event. Branded custom marquees offer style and flexibility and create a memorable experience. These events are crowded spaces where every business vies for attention.

But with a custom-made printed marquee or gazebo, you can draw in potential clients and seamlessly stand out from the crowd.

Branded custom marquees do just that. They not only shield from the elements but also serve as potent marketing tools. In this guide, Star Outdoor explores marquee benefits, styles, and accessories, making your event planning flawless. To know why this is a must-have for any event, keep reading.

Understand What Branded Custom Marquees Are

Branded marquees, also known as pop-up marquees and gazebos, make a big impact. They’re not just for promotion; they’re community protectors and passion promoters. With branded marquees, you’ll shine bright in any crowd while staying sheltered.

Tailored to your needs, they flaunt your logo and colours boldly. These custom marquees don’t just sit there; they grab attention, making your brand unforgettable. Whether shielding from sun or rain, they’re more than just tents; they’re your brand’s voice in a sea of noise.

Crafted to fit your brand’s unique style, incorporating your logo, colours, and messaging.

Grabs attention with bold branding, ensuring your message stands out and sticks.

Adaptable for any occasion, whether it’s a corporate gathering or an outdoor festival.

How Many Types Of Branded Custom Marquees Are Available?

Custom marquees come in various styles and sizes to match different event needs. From classic pop-up tents to inflatable domes, there’s a marquee for every occasion.

Custom-made Classic 32 marques or gazebos feature a reinforced aluminium frame and a durable polyester canopy with hot-taped seams for water resistance. Double-lined corners reduce wear and tear. Boast a UVE ARPANSA rating of 99%.

Get set up in minutes with easy clips and Velcro attachments. Adjust the height with five levels to fit your needs. Choose between wheeled or handled carry bags for convenience.

Stand out with expertly designed marquees and high-resolution printing options. They’re built to attract attention and draw crowds.

Branded custom marquees are made with top-quality materials and high-grade manufacturing. Quick repairs can be made easily as spare parts are readily available.

Pick between Classic 32 or Deluxe 40 sizes and accessories. They’re tailored to suit your needs.

Now That You Know The Features, Let’s Talk About The Benefits Of Branded Custom Marquees For Events

1). It Upraises Your Stall’s Professionalism

A printed gazebo or marquees boosts your stall’s professionalism. Customers notice the effort you put in. They want top-quality products from businesses. It shows your brand is valuable, and you’re building a name for it. This dedication shines through in your products and leaves a good impression on customers.

2). Help To Craft Brand Recognition

Your brand’s identity matters. Marketers know it’s key to success. Your logo and colours spark emotions in people. They represent your brand’s beliefs. They tell customers what you’re about. It’s a chance for new customers to get to know you. Building awareness is vital. Especially when you’re aiming for new customers. Marketers agree branding is crucial for success.

3). It Gives You Advertising All Around During The Event.

Your logo doesn’t have to sit at the top of the tent; it can be on all sides. This way, people can easily spot it from any angle. Even if they’re on the opposite side, they’ll still know your stall offers something they might like.

4). Maximize Your Brand’s Reach With Innovative Product Or Service Promotions

Crafting a standout promotion for your brand ranks high in consumer engagement. Whether vending lemonade or home goods, captivating passersby is key. A branded custom marquee serves as your stage. It beckons, enticing curious minds to pause and delve into your offerings. It’s the ultimate billboard for your business, broadcasting your essence to the world.

5). Get New Opportunities To Expand Your Customer Base

Every business wants new customers. What if you could grab their attention with your brand’s logo on a branded custom marquee? Choose fonts and colours wisely to make sure your brand stands out to everyone.

What Makes A Star Outdoor Branded Custom Marquee A Must-Have?

Step into the spotlight with Star Outdoor’s custom marquees. More than mere shelters, they’re an expression of your brand essence.

Crafted from premium materials, our marquees boast unrivalled durability and visual allure, as well as shelter from the sun and rain. Perfect for outdoor events, school carnivals, or market stalls, they offer protection with panache.

Designed for maximum brand exposure, our marquees feature strategically placed logos and graphics, expertly handled by our in-house graphics team. Built to last, they promise longevity and seamless usability.

What sets us apart? We specialise in creating marquees that command attention. Our design experts will help your brand shine, adhering to your style guide every step of the way.

Attachments like Rain Gutters and Awnings boost protection against water and wind, adding extra peace of mind.

Available in Classic 32 or Deluxe 40 sizes, our marquees cater to every need and budget. Need spare parts? We’ve got you covered with LED lighting for round-the-clock functionality.

Overall, It May Be Said…

Whether you’re throwing a corporate bash, trade show, or outdoor festival, investing in a personalised marquee is a surefire way to make your event shine. Go with Star Outdoor for top-notch quality, endless customisation options, and unbeatable customer service.

We’re here to help you make a splash at events. Our large product range will ensure your brand is amplified to your audience. Whether you require perfectly branded with UPF 50+ sun-protective marquees, flags, an interactive inflatable, stylish umbrellas, or, bespoke deckchairs, we have everything you need in one place.

Let us assist you in elevating your brand, highlighting your passion, and ensuring the safety of your community. For more information, head to our latest event and promotional equipment on our website today.

0 notes

Text

Top Insulation Tape Manufacturers: A Comparative Review

Insulation tape is a vital component in electrical work, ensuring safety and stability in wiring and circuit installations. It protects wires from external elements such as moisture, heat, and electrical currents, making it an indispensable tool for electricians and industries alike. With so many insulation tape manufacturers on the market, choosing the right brand can be a daunting task. This blog aims to provide a comparative review of some of the top manufacturers, focusing on key factors such as durability, safety standards, and product variety. We will also take a look at the innovations from companies like Asio Electricals, which not only excel in insulation tape but also as a circuit breakers manufacturer.

Why is Insulation Tape Important?

Before diving into the review, it’s essential to understand why insulation tape plays such a critical role in electrical work. Its primary function is to insulate electrical wires, preventing the risk of short circuits, electric shocks, and fires. The tape must be durable, flame-retardant, and resistant to wear and tear, making the choice of manufacturer crucial.

1. 3M: A Global Leader in Electrical Solutions

When discussing insulation tape manufacturers, one of the first names that comes to mind is 3M. Known for its wide range of industrial and consumer products, 3M offers high-quality insulation tapes designed for various electrical applications.

Product Range: 3M offers a variety of insulation tapes, including general-purpose vinyl electrical tapes, high-temperature tapes, and rubber splicing tapes. Their tapes are highly regarded for their durability and resistance to UV rays, which makes them suitable for both indoor and outdoor applications.

Safety Standards: 3M ensures that all their tapes meet global safety standards, making them a preferred choice for industrial electricians. Their tapes are flame-retardant, providing an extra layer of safety in wiring installations.

While 3M tapes are among the most expensive on the market, their proven track record of reliability justifies the investment. They are a solid choice for large-scale industrial projects.

2. Asio Electricals: Excellence in Innovation

Asio Electricals has quickly gained recognition in the market for its range of electrical products, including insulation tapes. Though Asio is primarily known as a circuit breakers manufacturer, their insulation tapes have been making waves due to their affordability and high quality.

Product Range: Asio’s insulation tapes are designed to meet the needs of both professional electricians and DIY enthusiasts. Their products are known for their flexibility, which allows for easier wrapping around cables, ensuring a tighter, more secure fit.

Affordability: What sets Asio apart from competitors like 3M is its affordability without compromising on quality. This makes Asio tapes an excellent choice for smaller electrical projects where cost efficiency is a priority.

Innovation: Asio is committed to staying ahead of industry trends by continually innovating its products. Their focus on high safety standards, combined with their reputation as a reliable circuit breaker manufacturer, makes them a trusted brand in the electrical sector.

3. Nitto Denko: Durability and Specialisation

Nitto Denko is another renowned name in the field of insulation tape manufacturers. This Japan-based company offers specialized tapes that cater to niche industries, such as automotive and electronics.

Product Range: Nitto Denko’s tapes are designed for more specific applications, such as high-temperature environments, making them ideal for use in automotive wiring or industrial machinery.

Specialisation: Nitto Denko is a leader when it comes to specialized tapes that go beyond traditional insulation needs. They offer options that provide not only electrical insulation but also heat resistance and chemical protection.

Price Point: Due to their specialised nature, Nitto Denko products are often priced higher than competitors like Asio Electricals. However, for highly specific use cases, their durability and performance are unmatched.

4. Tesa: The All-Rounder

Tesa is a European brand that produces a wide range of tapes for various industries, including electrical, automotive, and industrial. Known for its adhesive technologies, Tesa offers versatile insulation tapes suitable for different environments.

Product Range: Tesa’s insulation tapes are known for their versatility. They offer tapes that provide excellent adhesion even in low-temperature conditions, making them ideal for outdoor applications.

Durability: Tesa tapes are built to last, withstanding both heat and moisture, making them suitable for long-term electrical installations.

Tesa’s products are priced competitively, offering a good balance between performance and cost, making them a popular choice in the European market.

5. Anchor by Panasonic: Affordable and Reliable

Anchor by Panasonic is well-known in India for producing affordable yet reliable electrical products. Their insulation tapes are designed with the Indian market in mind, focusing on delivering durability at a low price point.

Product Range: Anchor offers general-purpose insulation tapes that are perfect for small to medium-scale electrical projects. While they may not offer the advanced features of tapes from brands like Nitto Denko, they are highly reliable for basic insulation needs.

Affordability: Anchor is one of the most budget-friendly options on the market, making it a go-to choice for everyday electrical repairs and installations in India.

Conclusion: Which Manufacturer Should You Choose?

When it comes to choosing the right insulation tape manufacturers, your decision will largely depend on the scope and specific needs of your project. For large-scale industrial projects, brands like 3M and Nitto Denko provide the durability and specialized features required to meet demanding standards. If you’re looking for cost-effective yet reliable insulation tapes, Asio Electricals is an excellent choice, especially when you factor in their innovation in other electrical products like circuit breakers.

For those seeking a balance between performance and cost, Tesa offers a versatile range of tapes suitable for both indoor and outdoor use. Meanwhile, Anchor by Panasonic provides an affordable solution for basic electrical needs.

Ultimately, the right insulation tape should provide long-lasting protection, be easy to apply, and meet the specific demands of your project. With brands like Asio Electricals continuing to innovate, finding a reliable and affordable option has never been easier.

Also Read:

Exploring Global Markets for Wire and Cable Manufacturers

The Importance of an Electric Switch Manufacturing Company

Originally published at https://asioworld.blogspot.com

0 notes

Text

Why OPP Tape is the Preferred Choice for Packaging in Malaysia

Packaging plays a critical role in product protection, storage, and transportation. In Malaysia, where industries like manufacturing, logistics, and retail are rapidly expanding, businesses are constantly seeking efficient, cost-effective, and durable packaging solutions. Among the variety of packaging materials available, OPP (Oriented Polypropylene) tape stands out as the preferred choice. This article explores the reasons behind the widespread use of OPP tape in Malaysia’s packaging industry.

1. Superior Adhesive Strength

OPP tape is renowned for its excellent adhesive properties. It is designed to stick firmly to a variety of surfaces, including cardboard, plastic, and metal. This makes it ideal for securing packages of all sizes, from small parcels to large boxes. In Malaysia, where e-commerce is booming and delivery services are essential, the adhesive strength of OPP tape ensures that packages remain sealed throughout the shipping process. Its reliability reduces the risk of tampering or damage during transit, a key consideration for businesses looking to maintain customer satisfaction.

2. Cost-Effective Solution

One of the primary reasons OPP tape is preferred in Malaysia is its affordability. Compared to other packaging tapes, such as PVC or cloth tape, OPP tape is more economical while still providing the necessary strength and durability. For businesses that handle high volumes of packaging daily, such as manufacturing and retail companies, using OPP tape significantly lowers packaging costs without compromising on quality. This cost-effectiveness is a critical factor in Malaysia’s competitive market, where companies are constantly seeking ways to optimize their operations.

3. Durability and Weather Resistance

Malaysia's tropical climate, characterized by high humidity and frequent rain, presents unique challenges for packaging materials. OPP tape is highly resistant to environmental factors such as moisture, temperature changes, and UV light. This makes it a durable solution for long-term storage and shipping. Even in humid conditions, OPP tape maintains its adhesive properties and does not peel off easily, ensuring that packages remain securely sealed. Its weather resistance makes it a reliable choice for both indoor and outdoor packaging applications.

4. Versatility and Customization

OPP tape is incredibly versatile, catering to various industries and packaging needs. It is available in different widths, thicknesses, and adhesive strengths, allowing businesses to choose the most suitable type for their specific requirements. Additionally, OPP tape can be easily customized with branding or product information, enhancing the overall appearance of the packaging. This feature is particularly valuable for businesses in Malaysia looking to improve brand visibility and customer recognition. Customized OPP tape serves as both a functional packaging tool and a marketing asset.

5. Eco-Friendly Option

Sustainability is becoming increasingly important in the global and Malaysian packaging industries. Many businesses are now seeking environmentally friendly packaging solutions. OPP tape is a more eco-friendly option compared to traditional packaging tapes made from non-recyclable materials. It is made from polypropylene, a type of plastic that is recyclable. As companies in Malaysia work towards reducing their environmental footprint, the use of OPP tape aligns with their sustainability goals, contributing to greener packaging practices.

6. Ease of Use and Application

OPP tape is user-friendly and easy to apply, making it a convenient choice for businesses that require quick and efficient packaging. It can be easily dispensed using a hand-held tape dispenser or machine, ensuring fast application without causing delays in the packaging process. This ease of use is especially beneficial for businesses in Malaysia with high packaging demands, such as e-commerce companies and logistics providers. The ability to apply OPP tape quickly and securely enhances operational efficiency and reduces labor costs.

Conclusion

In Malaysia’s fast-paced industrial landscape, OPP tape has become the preferred choice for packaging due to its superior adhesive strength, cost-effectiveness, durability, and versatility. Its ability to withstand the country’s tropical climate, combined with its eco-friendly properties and ease of use, makes it an ideal solution for businesses of all sizes. As the demand for efficient and reliable packaging continues to grow, OPP tape remains a trusted and valuable tool for ensuring products are safely packaged and delivered to customers across Malaysia.

0 notes

Text

Adhesives for Flexible Packaging Industry | Chemline Global

Chemline manufactures wide range of Hotmelt Adhesive under the Brand Name of “QUIKLOCK” in form of Granules, Bricks and Pillows for different applicaons. The products have been designed to be Odour Free with Good Thermal Stability and reducing charring characteriscs. These are special grades suitable for extreme Climac Condions.

LAMINATION ADHESIVES

Chemline manufactures full range of Solvent free & Solvent Based Polyurethane Adhesives under the brand name CHEMIFLEX, which are successfully running on machines like Nordmeccanica, Expert, Pelican, Futura, Kohli, Narendra etc.

HOTMELT & WATER BASED PRESSURE SENSITIVE ADHESIVES

Chemline manufactures wide range of Pressure Sensitive Adhesives suitable for application in BOPP Packaging Tapes, Holographic Labels, Stickers, Label stocks, Protective Films, Envelope Flaps and other Allied uses.

With more than 28 years of experience in Global Supplies, is one of the unique Indian Companies Chemline manufacturing wide range of Adhesives & Coatings for Flexible Packaging Industry. It has proven its leadership in number of segments in Indian and Overseas Market, which includes PU Lamination Adhesives (Solvent Less & Solvent Based), Water based Adhesives, Water Based Heat Seal Coating UV Coatings, Top Coats, Hot-Melt for Side Sealing of WPP Bags, Waxes for WAD Application among others.

0 notes

Text

UV Tapes Market Insights: Enhancing Bonding Performance with Ultraviolet Technology

UV tapes, short for Ultraviolet (UV) tapes, are specialized adhesive tapes that are designed to cure or bond when exposed to ultraviolet light. These tapes find diverse applications across various industries due to their unique properties and capabilities. In this comprehensive overview, we will delve into the definition, market overview, growth factors, industry applications, and emerging trends within the UV tapes market.

Definition: UV tapes are adhesive materials that exhibit photochemical reactions when subjected to UV light. These tapes are formulated with UV-sensitive compounds that allow them to bond or cure rapidly when exposed to UV radiation. This property makes UV tapes an ideal choice for applications requiring quick and precise bonding, such as electronics assembly, automotive manufacturing, and medical device production.

Market Overview: The UV tapes market has witnessed significant growth in recent years, driven by the increasing demand for advanced bonding solutions in various industries. UV tapes offer several advantages, including fast curing times, high bond strength, and the ability to bond dissimilar materials, which have contributed to their popularity in the market. Key players in the UV tapes market are continuously innovating to expand their product portfolios and cater to the evolving needs of industries.

Market Growth: The UV tapes market growth can be attributed to several factors. Firstly, the electronics industry relies heavily on UV tapes for applications such as semiconductor packaging, LCD assembly, and circuit board bonding. As consumer electronics continue to evolve, the demand for smaller, more efficient, and reliable electronic components has surged, driving the adoption of UV tapes.

Additionally, the automotive sector has embraced UV tapes for various applications, including interior trim bonding and glass installation. The automotive industry's pursuit of lightweight materials and improved safety standards has further fueled the demand for UV tapes.

Industry Applications: UV tapes have found applications in a wide range of industries, including electronics, automotive, medical, aerospace, and packaging. In the electronics industry, they are used for bonding delicate components, while the medical field relies on UV tapes for securing medical devices and instruments. The aerospace sector benefits from UV tapes for their lightweight properties and resistance to harsh environmental conditions.

Trends: The UV tapes market is constantly evolving, and several trends are shaping its future. One notable trend is the development of UV tapes with enhanced sustainability, as industries are increasingly focused on reducing their environmental footprint. Manufacturers are also working on UV tapes with improved thermal and chemical resistance to expand their utility in demanding applications.

In conclusion, UV tapes represent a versatile and essential component in various industries, offering rapid bonding and curing capabilities. As industries continue to advance and demand more efficient and reliable bonding solutions, the UV tapes market is expected to witness sustained growth and innovation in the coming years.

0 notes

Text

Adhesive Tape Films Market Size, Share, Forecast Report by 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Adhesive Tape Films Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Adhesive Tape Films Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Adhesive Tape Films Market?

The global adhesive tape films market was valued at US$ 14.7 Billion in 2023 and is expected to register a CAGR of 4.1% over the forecast period and reach US$ 21.1 Bn in 2032.

What are Adhesive Tape Films?

Adhesive tape films are multifunctional materials widely utilized across various industries, from manufacturing to everyday consumer products. These films comprise a thin layer of adhesive-coated material that adheres securely to numerous surfaces while remaining flexible and durable. Typically crafted from polymers such as polyethylene, polypropylene, or polyester, adhesive tape films can be tailored to possess specific characteristics, including moisture resistance, UV stability, and heat resistance, making them ideal for applications like packaging, insulation, electrical work, and automotive uses. Their easy application and ability to conform to irregular shapes make them crucial in both professional and DIY projects, enhancing efficiency and reliability across multiple sectors.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2466

What are the growth prospects and trends in the Adhesive Tape Films industry?

The adhesive tape films market growth is driven by various factors and trends. The adhesive tape films market is experiencing substantial growth, driven by rising demand for versatile bonding solutions across diverse industries such as automotive, electronics, packaging, and construction. These films provide unique features, including moisture resistance, heat resistance, and electrical insulation, making them suitable for various applications. The surge in e-commerce and the need for effective packaging solutions further stimulate market expansion, as businesses seek reliable products to ensure safe delivery. Moreover, advancements in manufacturing technologies and the introduction of innovative adhesive formulations are enhancing product performance and broadening their applications. With a growing emphasis on sustainability, the market is also shifting toward eco-friendly and recyclable adhesive tape films, aligning with global initiatives to reduce environmental impact. Overall, the adhesive tape films market is well-positioned for continued growth, driven by changing consumer preferences and technological innovations. Hence, all these factors contribute to adhesive tape films market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Transparent

Colored

By Backing Material Type

Polyethylene (PE) Films

Polypropylene (PP) Films

Polyvinyl Chloride (PVC) Films

Polyester (PET) Films

Others

By Adhesive Type

Rubber-Based Adhesives

Acrylic Adhesives

Silicone Adhesives

Others

By End Use

Packaging

Automotive

Electronics

Construction

Healthcare

Paper & Printing

Others

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

Benelux

Nordic

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

3M Company

Taghleef Industries

Nitto Denko Corporation

PAC Adhesive Products (Suzhou) Co., Ltd.

Berry Global Inc.

YANGFENG TAPE AND ADHESIVE PRODUCTS, LTD.

LINTEC Corporation

Shurtape Technologies, LLC

FROMM Holding GmbH Co. KG

USG Corporation

Henkel AG Co. KGaA

Tes tape group

Avery Dennison Corporation

View Full Report: https://www.reportsandinsights.com/report/Adhesive Tape Films-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Automotive Protection Tapes Films Market Insights and Long-Term Growth Predictions 2024 - 2032

The automotive industry is undergoing significant transformations, with advancements in technology and increasing consumer demands for vehicle longevity and aesthetics. One critical component contributing to these needs is the automotive protection tapes and films market. This article explores the current landscape, market dynamics, and future trends of automotive protection tapes and films.

Understanding Automotive Protection Tapes and Films

The automotive protection tapes and films market is on an upward trajectory, driven by increasing vehicle ownership, growing awareness, and technological advancements. As consumer preferences evolve and the industry adapts,

What Are Automotive Protection Tapes and Films?

Automotive protection tapes and films are specialized materials designed to shield vehicles from various forms of damage. These products typically consist of polyurethane or vinyl and are applied to different parts of the vehicle to protect against scratches, chips, environmental damage, and UV rays.

Types of Protection Tapes and Films

Clear Bra Films: These transparent films are applied over the vehicle’s paintwork to provide an invisible layer of protection.

Vinyl Wraps: Used for aesthetic purposes, these wraps can change the vehicle's color while offering some degree of protection.

Surface Protection Tapes: These tapes are utilized in high-wear areas such as door edges and bumpers to prevent scratches and scuffs.

Paint Protection Films (PPF): These films are specifically designed to guard against stone chips, abrasions, and other damages while enhancing the vehicle's appearance.

Market Overview

Key Market Drivers

Rising Vehicle Ownership: The increasing number of vehicles on the road has heightened the demand for protective solutions.

Growing Awareness: Consumers are becoming more aware of the benefits of using protective films and tapes to maintain vehicle aesthetics and resale value.

Technological Advancements: Innovations in materials and application methods have enhanced the performance and durability of protection films and tapes.

Regional Insights

The market for automotive protection tapes and films varies significantly across regions:

North America: Dominates the market due to a high number of luxury vehicle sales and an increased focus on vehicle maintenance.

Europe: Witnesses steady growth driven by stringent regulations regarding vehicle emissions and aesthetics.

Asia-Pacific: Expected to experience the highest growth rate, fueled by rapid urbanization and an increase in disposable income.

Competitive Landscape

Key Players

The automotive protection tapes and films market is characterized by the presence of several key players, including:

3M Company: Known for its innovative solutions and extensive product portfolio.

Avery Dennison: A leader in materials science, providing high-performance protective films.

SunTek: Specializes in PPF and offers a variety of products for automotive applications.

Strategies for Success

Product Innovation: Continuous R&D efforts to develop more advanced and durable films.

Partnerships: Collaborations with automotive manufacturers and dealerships to expand market reach.

Sustainability Initiatives: Increasing focus on eco-friendly materials and production processes to meet consumer demand for sustainable products.

Future Trends

Emerging Technologies

The automotive protection tapes and films market is poised for transformation with the emergence of new technologies. Innovations such as self-healing films and advanced adhesion systems are expected to enhance the functionality and longevity of protective solutions.

Market Challenges

Despite its growth prospects, the market faces challenges, including:

Price Sensitivity: Consumers may hesitate to invest in premium protection products, especially in price-sensitive regions.

Competition from Alternatives: The availability of cheaper alternatives may pose a threat to established players.

Conclusion

The market is expected to witness significant innovations and growth opportunities in the coming years. Understanding market dynamics and consumer needs will be crucial for stakeholders aiming to succeed in this competitive landscape.

#Automotive Protection Tapes Films Market Size#Automotive Protection Tapes Films Market Trend#Automotive Protection Tapes Films Market Growth

0 notes

Text

The Rise of Double-Sided PET Tape in China: A Comprehensive Overview

The Rise of Double-Sided PET Tape in China: A Comprehensive Overview Double-sided PET (Polyethylene Terephthalate) tape has become an essential component in various industries due to its versatility, durability, and strong adhesive properties. In China, the production and application of double-sided PET tape have seen significant growth, driven by advancements in manufacturing technologies and increasing demand across multiple sectors. This article explores the rise of double-sided PET tape in China, its applications, benefits, and the key players in the market.Get more news about double sided pet tape in china,you can vist our website!

Applications of Double-Sided PET Tape Double-sided PET tape is widely used in several industries, including electronics, automotive, construction, and packaging. Its strong adhesive properties make it ideal for bonding and mounting applications. In the electronics industry, double-sided PET tape is used for securing components, such as LCD screens, batteries, and circuit boards. Its high-temperature resistance and excellent electrical insulation properties make it suitable for these applications.

In the automotive industry, double-sided PET tape is used for attaching trim, emblems, and other components to vehicles. Its durability and resistance to environmental factors, such as heat, moisture, and UV radiation, ensure long-lasting performance. In the construction industry, double-sided PET tape is used for bonding materials, such as glass, metal, and plastic, providing a strong and reliable hold.

The packaging industry also benefits from double-sided PET tape, as it is used for sealing boxes, securing labels, and reinforcing packaging materials. Its strong adhesive properties ensure that packages remain securely closed during transit, reducing the risk of damage.

Benefits of Double-Sided PET Tape One of the primary benefits of double-sided PET tape is its strong adhesive properties. It provides a reliable bond between surfaces, ensuring that components remain securely attached. Additionally, double-sided PET tape is resistant to high temperatures, making it suitable for applications that involve exposure to heat. Its excellent electrical insulation properties make it ideal for use in electronic devices, where it helps prevent short circuits and other electrical issues.

Double-sided PET tape is also highly durable, with resistance to environmental factors, such as moisture, UV radiation, and chemicals. This durability ensures that the tape maintains its adhesive properties and performance over time, even in harsh conditions. Furthermore, double-sided PET tape is easy to apply, with a simple peel-and-stick process that requires no additional tools or equipment.

Key Players in the Chinese Market Several companies in China are leading the production and distribution of double-sided PET tape. These companies leverage advanced manufacturing technologies and high-quality materials to produce reliable and efficient adhesive solutions. Some of the key players in the Chinese market include:

Conclusion The rise of double-sided PET tape in China is a testament to the country’s advancements in manufacturing technologies and the increasing demand for high-quality adhesive solutions across various industries. With its strong adhesive properties, durability, and versatility, double-sided PET tape has become an indispensable component in electronics, automotive, construction, and packaging applications. As key players in the Chinese market continue to innovate and expand their product offerings, the future of double-sided PET tape looks promising, with continued growth and development on the horizon.

0 notes