#Two Track Secondary Packaging System

Explore tagged Tumblr posts

Text

over the last two weeks or so ive played through earthbound two and a half times, and mother 1 three times. replaying both back to back repeatedly has made me realize a lot of things

1.) mother 1 is a LOT more open in what it lets you do, where it lets you go, and when. once you open up the train tracks, you're free to go do the rest of the game in pretty much any order you want. hell, you can make it all the way to R7038xx without ever getting a single melody, which i find to be pretty interesting. not only that, but you dont even need to get most of the party members. strictly speaking, the only one you truly need to get is Loid, and that's just to get rid of the rock on the train tracks. and even then, with the use of an exploit i found out about only a few days ago, you can get rid of him and go fight giygas by yourself, which is pretty funny.

2.) mother 1+2 is like, wicked impressive. nevermind the fact that they crammed earthbound onto the gba, they also packaged it with mother 1 as well, and they're both the full games. it ain't no rayman advance kinda deal either where it's a super botched port, like it's a perfectly valid way to play both games, and some people even prefer the gba version of mother 1 since it makes a couple of quality of life improvements. not to mention, they rebuilt both games from the ground up, it's not like they could emulate snes on gba. (i mean, you can emulate NES apparently, since there's that nes classic line of games for the gba, but... this is cooler.) the sound department could... definitely use some work, and the colors look pretty washed out, but there are patches to fix the colors, and if you're playing the game on a real gameboy, i think the sound is the last thing you'd be concerned about. also, apparently some people took the time to apply the earthbound script to the mother 2 half of mother 1+2, and even reprogrammed the text system to have the original fonts and make it non-monospace, which is SUPER impressive. for my second playthrough of earthbound i played it with the new fantran patch, and it's pretty damn slick.

3.) man, fuck the sword of kings. i realized very recently that i'd never fully committed to the sword of kings grind, and decided that this would finally be the time i claim my birth right as a mother fan and do it. and like, it SUCKS. i mean, to begin, yes it's annoying that it's a 1/128 chance, but it goes deeper than that. the fact that it's only dropped by an enemy that you can potentially never see again, and it's the ONLY item poo can equip as a weapon is pretty fucked up. not to mention, the other enemies that they put in the starman base just absolutely suck, i hate the nuclear power robots so much. they made the grind WAY more painful than it already would have been otherwise. at the very least, i find it to be very gracious that jeff's spy command has the secondary effect of letting you steal whatever item an enemy would have dropped mid battle, just so it doesn't get overwritten by another enemy drop, which by the way YES that can happen, and YES i had it happen to me. it sucks ass. and the worst part is, the sword of kings isn't even that good!! and neither is poo on a gameplay level! you get the guy way later than any other party member, he has all these little catches like not being able to eat american food or equip anything but the kingly items, he gets taken away from you almost immediately after you get him, he just feels really weird. starstorm is pretty cool, but you only get the omega version right before the final area, and you can only use it on the handful of encounters you get there since you can't really use it in the final boss. (i mean technically you can use it in the first phase, if you want to get a biblical reflected beatdown when it hits both pokey and giygas) idk, the guy just isn't all that useful, and it's unfortunate since i really like him on a design level.

i have more words i want to say but honestly i might save them for an entry on my website instead since im very close to the tumblr word limit rn

28 notes

·

View notes

Text

The Step-by-Step Guide to Filing a Trademark With the USPTO

Whether you’re launching a startup, releasing a new product, or building a brand from scratch, securing a trademark is a crucial step in protecting your identity in the marketplace. Filing a trademark with the United States Patent and Trademark Office (USPTO) may seem complicated at first, but with the right approach, it’s a straightforward process.

This guide breaks down each step of the USPTO trademark filing process—so you can move forward with clarity and confidence.

Step 1: Choose a Strong Trademark

Before you file anything, make sure your name, slogan, or logo is distinctive and legally protectable. The USPTO is more likely to approve trademarks that are:

Fanciful or invented (e.g., “Kodak”)

Arbitrary (e.g., “Apple” for computers)

Suggestive (e.g., “Netflix” suggests streaming)

Avoid generic or descriptive terms like “Best Coffee” or “Fast Tech Services”—these are usually rejected unless they’ve gained secondary meaning.

Step 2: Conduct a Comprehensive Trademark Search

Before you spend money on a filing, check to make sure your trademark isn’t already in use or registered. Use the USPTO’s TESS search system to identify:

Exact and similar names

Phonetically or visually similar marks

Conflicts in the same or related classes

If you're unsure how to interpret results, consider hiring a trademark search company or attorney. Catching conflicts now can save you thousands later.

Step 3: Determine Your Filing Basis

The USPTO allows you to file under two main bases:

Use in Commerce (§1(a)) – If you are already using the mark in business

Intent to Use (§1(b)) – If you plan to use the mark in the near future

Choose the one that reflects your current situation. If you file under intent to use, you’ll need to submit a Statement of Use later, once your brand is active.

Step 4: Identify the Correct Class of Goods/Services

Trademarks must be registered in one or more of the 45 international classes (Nice Classification), such as:

Class 25: Clothing

Class 9: Software

Class 35: Advertising and business consulting

Pick the class(es) that best reflect your offerings. Misclassifying your goods/services can delay your application or lead to rejection.

Step 5: Prepare Your Application

You can file your trademark through the USPTO’s TEAS (Trademark Electronic Application System). There are three main forms:

TEAS Plus ($250/class) – Lowest fee, more strict requirements

TEAS Standard ($350/class) – More flexible but higher cost

TEAS Reduced Fee (RF) – Retired in 2020; no longer available

You’ll need to submit:

Owner information (individual or business)

Word mark or logo image (if applicable)

Class of goods/services

Filing basis (use in commerce or intent to use)

Specimen (if already in use) — e.g., screenshot of your website, label, packaging

Signature and fee payment

Step 6: Track Your Application Status

After submission, the USPTO assigns a serial number to your application. A USPTO examining attorney will review it in about 3–4 months. They may:

Approve it for publication

Issue an Office Action (requiring corrections or clarifications)

Reject it based on conflicts or legal grounds

Use the TSDR system (Trademark Status and Document Retrieval) to monitor progress.

Step 7: Respond to Office Actions (If Any)

If the USPTO finds issues, you’ll receive an Office Action. You must respond within 3 months (with a 3-month extension available for a fee).

Responses might include legal arguments, revised specimens, or disclaimers. If you're unsure how to proceed, it's wise to consult a trademark attorney.

Step 8: Publication and Opposition

If your application is approved, it will be published in the USPTO’s Official Gazette. During this 30-day window, third parties can file an opposition if they believe your mark infringes on theirs.

If no one objects (or you overcome the objection), your mark proceeds to registration.

Step 9: Final Registration

For use-in-commerce filings, you’ll receive a registration certificate.

For intent-to-use filings, you must file a Statement of Use before registration is finalized.

Once registered, your trademark is protected nationwide, giving you exclusive rights in your category.

Final Thoughts

Filing a trademark with the USPTO is a strategic step toward building a defensible and recognizable brand. While the process can feel technical, following these steps—or getting help from a trusted trademark search company or attorney—ensures you avoid common mistakes and set your business up for long-term success.

Need help with your application or interpreting your USPTO results? I can walk you through it or connect you with filing professionals.

0 notes

Text

Honda A13 Service Code: What It Means for Your Vehicle's Maintenance

https://autorepairlebanontn.com/?p=3876 Honda A13 Service Code: What It Means for Your Vehicle's Maintenance Wondering what that Honda A13 service code means on your dashboard? You’re not alone. This common maintenance indicator appears in many Honda vehicles to remind owners it’s time for exact routine services. We’ve helped thousands of Honda owners understand these service codes and what they require. The A13 code specifically calls for several important maintenance tasks including an oil change, tire rotation, and replacement of key components. Getting this service done promptly helps maintain your vehicle’s performance and prevents costly repairs down the road. Table of Contents Toggle Understanding the Honda A13 Service CodeWhat the A13 Service Code IncludesOil and Filter ChangeTire RotationTransmission Fluid ChangeWhen to Schedule Your A13 ServiceMileage IntervalsWarning IndicatorsDIY vs. Professional A13 ServiceDIYProfessionalRequired Tools and PartsStep-by-Step ProcessCost of Honda A13 ServiceBreakdown of CostsTotal Estimated CostDealership vs. Independent ShopsBenefits of Regular A13 MaintenanceEngine Oil and Filter ChangeTire RotationTransmission Fluid ChangeOverall Vehicle HealthConclusionFrequently Asked QuestionsWhat does the Honda A13 service code mean?How often should I expect to see the A13 service code?Can I perform the A13 service myself?How much does the Honda A13 service cost?What happens if I ignore the A13 service code?Is it better to get A13 service at a dealership or independent shop?What are the benefits of regular A13 maintenance?How long does the A13 service take to complete? Understanding the Honda A13 Service Code The Honda A13 service code appears on your vehicle’s maintenance minder system when your Honda requires exact maintenance tasks. This code combines two service indicators: the primary maintenance service A (oil change) and the secondary maintenance service 13 (which covers several components). Service A specifically indicates it’s time for an oil change and oil filter replacement. Your engine oil gradually loses its lubricating properties over time, making regular replacement essential for optimal engine performance and longevity. The “13” portion of the code refers to two distinct maintenance tasks. The “1” component signals that your transmission fluid requires replacement. Fresh transmission fluid ensures smooth gear shifting and protects the transmission system from premature wear. The “3” component indicates it’s time to replace your differential fluid, which lubricates the gears in your vehicle’s differential system. Honda designed this coding system to simplify vehicle maintenance scheduling. Instead of tracking multiple service intervals separately, the maintenance minder combines these needs into a single, easy-to-understand code. This approach helps you maintain your vehicle efficiently without overwhelming you with individual service reminders. Many Honda models manufactured after 2006 use this maintenance minder system, including popular vehicles like the Civic, Accord, CR-V, and Pilot. The system calculates service intervals based on your actual driving conditions rather than rigid mileage markers, providing more accurate maintenance timing customized to your exact usage patterns. What the A13 Service Code Includes The Honda A13 service code represents a exact maintenance package that includes three essential services for your Honda vehicle. Each component of this code corresponds to a particular maintenance task that keeps your car running smoothly and efficiently. Oil and Filter Change The “A” portion of the A13 service code indicates it’s time for an engine oil and oil filter change. Fresh oil lubricates your engine components, reducing friction and preventing premature wear. This basic maintenance task helps extend your engine’s lifespan and maintains optimal performance. Honda technicians typically use manufacturer-recommended oil grades specifically formulated for your vehicle’s requirements. Tire Rotation The “1” in the A13 code signifies the need for a tire rotation service. Rotating your tires ensures even wear across all four tires, extending their useful life and saving you money in the long run. This service includes checking tire pressure and inspecting tires for any signs of damage or excessive wear. Proper tire maintenance improves handling, traction, and fuel efficiency while promoting safety on the road. Transmission Fluid Change The “3” component indicates it’s time to change your transmission fluid. Transmission fluid lubricates, cools, and cleans the internal components of your transmission system. Fresh fluid helps prevent overheating and ensures smooth gear shifts. During this service, technicians drain the old fluid completely and replace it with new fluid that meets Honda’s specifications for your particular model. When to Schedule Your A13 Service The A13 service code appears on your Honda’s dashboard when the vehicle’s maintenance minder system determines these exact tasks are due. This timing is based on your vehicle’s mileage and the condition of the monitored components rather than a fixed schedule. Mileage Intervals Honda’s Maintenance Minder system triggers the A13 code at recommended maintenance intervals that vary by model and driving conditions. Most Honda vehicles display this code around every 5,000 to 7,500 miles for oil changes and tire rotations. Transmission fluid replacement intervals are calculated based on your actual driving habits, including factors like stop-and-go traffic, highway driving, or towing. The system’s adaptive nature ensures your vehicle receives maintenance exactly when needed, eliminating unnecessary service visits while protecting your vehicle’s components from premature wear. Warning Indicators Your Honda communicates maintenance needs through dashboard indicators that shouldn’t be ignored. When the A13 code illuminates, it’s accompanied by a wrench symbol or maintenance reminder on your dashboard display. This visual alert serves as an important warning that your vehicle requires attention for exact maintenance tasks. Postponing these services after the indicator appears can result in reduced performance, decreased fuel efficiency, and potential long-term damage to critical components. The warning system is designed to give you adequate time to schedule service before components reach critical condition, helping you maintain your Honda’s reliability and resale value. DIY vs. Professional A13 Service Honda A13 service can be performed either at home or by professional mechanics. When deciding between DIY and professional service, several factors should be considered including cost, time, expertise, and available tools. DIY Performing the A13 service yourself offers important cost savings compared to professional servicing. Many Honda owners with basic mechanical knowledge can complete these maintenance tasks at home. You’ll need to set aside approximately 2-3 hours to complete all three service components (oil change, tire rotation, and transmission fluid replacement). The parts for DIY service typically cost between $50-$100, depending on the quality of oil and transmission fluid selected. DIY service gives you complete control over the quality of parts used and attention to detail during the process. Mechanics often develop a better understanding of their vehicle’s condition by performing maintenance themselves, potentially catching other issues before they become serious problems. Professional Professional Honda A13 service comes with the confidence of trained expertise and proper equipment. Technicians at dealerships and specialized shops have experience with Honda-exact systems and access to manufacturer-exact tools. Most professional services include a warranty, typically 12 months or 12,000 miles, providing peace of mind after the work is completed. The cost for professional A13 service ranges from $100-$180 for the oil change portion alone, with additional charges for tire rotation ($20-$50) and transmission fluid replacement ($80-$150). Though more expensive than DIY, professional service saves you time and eliminates concerns about proper disposal of hazardous materials like used oil and transmission fluid. Required Tools and Parts For DIY A13 service, exact tools and parts are necessary for each component: Oil Change Components: Honda-compatible oil filter (genuine Honda or quality aftermarket) 4-5 quarts of the correct viscosity engine oil (typically 0W-20 for newer models) Oil filter wrench Socket set with appropriate size for drain plug Oil drain pan (minimum 5-quart capacity) Funnel Shop rags or paper towels Disposable gloves Tire Rotation Items: Floor jack rated for your vehicle’s weight Jack stands (minimum 2) Lug wrench or impact wrench Torque wrench Tire pressure gauge Chalk or marker to label tire positions Transmission Fluid Service Materials: 3-4 quarts of Honda-exact automatic transmission fluid (ATF) Transmission pan gasket (if applicable to your model) Drain pan (different from oil pan to avoid contamination) Funnel with filter for transmission fill Ratchet and socket set Honda-exact drain and fill plugs (if needed) Step-by-Step Process The A13 service involves three distinct procedures that can be performed in sequence: Engine Oil and Filter Change: Drive your Honda for 5-10 minutes to warm the oil for better drainage. Park on a level surface, engage the parking brake, and allow the engine to cool slightly. Locate the oil drain plug underneath the vehicle and position your drain pan. Remove the oil filler cap on top of the engine to improve oil flow. Carefully unscrew the drain plug and allow oil to drain completely (about 5-10 minutes). Locate and remove the oil filter using an oil filter wrench. Apply a small amount of new oil to the gasket of the new filter before installation. Hand-tighten the new filter and replace the drain plug to specified torque. Add the recommended amount of new oil through the filler opening. Start the engine and check for leaks, then verify the oil level with the dipstick. Tire Rotation: Check all tire pressures and adjust to specifications found in your owner’s manual. Loosen (but don’t remove) all lug nuts while the vehicle is still on the ground. Jack up the vehicle and secure it with jack stands at appropriate lifting points. Remove the wheels and rotate them according to Honda’s recommended pattern (typically front-to-rear crossover for most models). Reinstall each wheel and hand-tighten the lug nuts in a star pattern. Lower the vehicle and use a torque wrench to tighten lug nuts to specification (usually 80-100 ft-lbs). Recheck tire pressures after rotation. Locate the transmission fluid drain plug while the vehicle is level. Position a drain pan and remove the plug, allowing fluid to drain completely. Replace the drain plug with a new sealing washer if required. Locate the transmission fluid fill hole (typically on the side of the transmission). Use a funnel to add new Honda-exact ATF in small increments. Check the fluid level frequently during filling to avoid overfilling. Start the engine and shift through all gears with the parking brake engaged. Recheck the fluid level and top off if necessary. Verify there are no leaks around drain and fill plugs. Cost of Honda A13 Service The Honda A13 service cost varies based on several factors including your vehicle model, location, and chosen service provider. Understanding the typical price range helps you budget properly for this essential maintenance. Breakdown of Costs Oil and filter replacement typically costs between $103.58 and $181.08. Tire rotation expenses are generally lower than other components of the A13 service but still contribute to the overall cost. Transmission fluid service represents the most important expense, ranging from $140.08 to $502.73 depending on your transmission type and service provider. Total Estimated Cost You can expect to pay approximately $243.66 to $683.81 for a complete Honda A13 service. This price range doesn’t include additional inspections or supplementary services that might be recommended during your appointment. Regional pricing differences and your exact Honda model can influence where your final cost falls within this range. Dealership vs. Independent Shops Honda dealerships provide service with manufacturer-trained technicians who use genuine Honda parts. These services typically come with a 1-year or 12,000-mile warranty, offering peace of mind after your maintenance is complete. Dealership technicians possess specialized knowledge of Honda vehicles and access to the latest technical information. Independent automotive shops often charge less for the same A13 service components compared to dealerships. These shops frequently offer more flexible scheduling options and might use quality aftermarket parts that cost less than OEM components. Many independent mechanics provide comparable expertise at reduced rates, though warranty coverage and parts quality can vary between establishments. Your choice eventually depends on whether you prioritize manufacturer backing and guaranteed parts or cost savings and scheduling convenience. Both options can deliver quality A13 service when you select reputable providers with positive customer reviews. Benefits of Regular A13 Maintenance Engine Oil and Filter Change Regular oil changes maintain your engine’s health by providing essential lubrication to moving components. Fresh oil reduces friction between engine parts, preventing excessive wear and potential overheating issues. Replacing the oil filter ensures only clean oil circulates through your engine, removing harmful contaminants and debris. This combination of fresh oil and a new filter significantly improves overall engine performance, extends engine life, and helps maintain optimal fuel efficiency in your Honda vehicle. Tire Rotation Tire rotation promotes even tread wear across all four tires, extending their useful lifespan considerably. Even wear patterns improve your vehicle’s traction and handling capabilities, especially during challenging weather conditions. Your Honda’s steering response and stability benefit from properly rotated tires, creating a safer driving experience. Properly maintained tires also contribute to better fuel economy, as evenly worn tires create less rolling resistance on the road. Transmission Fluid Change Transmission fluid replacement preserves your automatic transmission’s performance by maintaining proper hydraulic pressure and lubrication. Fresh transmission fluid reduces internal friction and heat buildup, protecting sensitive components from premature wear. Your Honda’s shifting quality remains smooth and responsive with clean transmission fluid, eliminating hesitation or harsh engagement between gears. This maintenance task helps you avoid costly transmission repairs or replacement, which can be among the most expensive vehicle repairs. Overall Vehicle Health Adhering to the A13 service schedule enables early detection of potential issues before they develop into major problems. Regular maintenance appointments create opportunities for mechanics to spot developing concerns with brakes, suspension, and other critical systems. Your Honda’s reliability improves with consistent A13 service completion, reducing the likelihood of unexpected breakdowns. Properly maintained vehicles typically maintain higher resale values, protecting your automotive investment while enjoying improved performance and efficiency during ownership. Conclusion The Honda A13 service code is your vehicle’s way of communicating essential maintenance needs. By addressing this code promptly you’ll extend your Honda’s lifespan while maintaining optimal performance and safety. Whether you choose DIY maintenance or professional service the important thing is not to ignore these indicators. Regular A13 service protects your investment by preventing costly repairs down the road. The combination of oil changes tire rotations and transmission fluid replacement works together to keep your Honda running smoothly for years to come. We recommend establishing a relationship with a trusted service provider or learning the basics of these maintenance tasks yourself. Your Honda will thank you with reliable performance and fewer unexpected issues on the road. Frequently Asked Questions What does the Honda A13 service code mean? The Honda A13 service code is a maintenance indicator that combines multiple service needs. The “A” indicates it’s time for an oil change and filter replacement, the “1” signals transmission fluid replacement, and the “3” indicates differential fluid replacement. This code appears on your dashboard when these maintenance tasks are due based on your driving conditions. How often should I expect to see the A13 service code? You’ll typically see the A13 service code every 5,000 to 7,500 miles for the oil changes and tire rotations. The transmission fluid replacement intervals vary based on your driving habits. Honda’s maintenance minder system calculates these intervals based on your actual driving conditions rather than a fixed schedule. Can I perform the A13 service myself? Yes, you can perform the A13 service yourself if you have the necessary tools and expertise. A DIY approach saves money and gives you control over parts quality. However, professional service offers trained expertise, proper equipment, and often warranties. The choice depends on your mechanical skills and comfort level with vehicle maintenance. How much does the Honda A13 service cost? A complete Honda A13 service typically costs between $244 and $684, depending on your vehicle model, location, and service provider. Oil and filter replacement ranges from $104 to $181, tire rotation is relatively inexpensive, and transmission fluid service—the most significant expense—costs between $140 and $503. What happens if I ignore the A13 service code? Ignoring the A13 service code can lead to reduced vehicle performance, decreased fuel efficiency, and potential long-term damage to critical components. Postponed oil changes can damage your engine, uneven tire wear affects handling and safety, and neglected transmission fluid can cause overheating and gear shifting problems. Regular maintenance prevents costly repairs. Is it better to get A13 service at a dealership or independent shop? Both options have merits. Dealerships offer manufacturer-trained technicians, genuine parts, and warranties, but at higher costs. Independent shops typically provide lower prices and more flexible scheduling while still delivering quality service. Your choice depends on whether you prioritize manufacturer backing or cost savings. What are the benefits of regular A13 maintenance? Regular A13 maintenance improves engine performance, fuel efficiency, and vehicle lifespan. Oil changes reduce friction and prevent overheating, tire rotations ensure even tread wear and better traction, and transmission fluid changes maintain smooth gear shifts. Following the schedule also allows for early detection of potential issues, improving reliability and resale value. How long does the A13 service take to complete? A professional A13 service typically takes 1-2 hours to complete. If you’re doing it yourself, expect to spend 2-3 hours, depending on your experience level and available tools. The oil change takes approximately 30-45 minutes, tire rotation about 30 minutes, and transmission fluid replacement around 1 hour. https://autorepairlebanontn.com/?p=3876 Absolute Auto Repair

0 notes

Text

Print & Apply Labeling Systems Manufacturers in the UK: Leading the Way in Smart Automation

In the fast-paced world of manufacturing, packaging, and logistics, accuracy and efficiency are non-negotiable. One critical piece of technology that ensures smooth operations is the print and apply labeling system. These systems automatically print and apply labels onto products, cartons, or pallets — streamlining workflows and reducing the risk of human error. The UK, with its robust engineering and automation sectors, is home to some of the most innovative manufacturers of these systems.

What Are Print & Apply Labeling Systems?

Print & apply labeling systems are automated solutions that combine two essential functions:

Printing labels (typically with barcodes, product information, or tracking data), and

Applying them directly to items, cartons, or pallets using a variety of application methods like tamp, blow, or wipe.

These systems are widely used in industries such as:

Food and Beverage

Pharmaceuticals

Warehousing and Logistics

E-commerce and Retail

Automotive and Electronics

Why Choose a UK-Based Manufacturer?

The UK boasts a strong heritage in manufacturing and automation technology, with many companies offering state-of-the-art labeling equipment tailored for complex industrial environments. Here's why working with a UK-based manufacturer is advantageous:

1. Innovation & Engineering Excellence

British manufacturers are known for high standards of quality and a commitment to innovation. Most systems are designed to meet global compliance standards such as GS1, CE marking, and FDA guidelines.

2. Custom Solutions

Leading UK manufacturers provide customizable labeling systems that fit into your existing production lines, whether you need corner-wrap labeling, pallet labeling, or high-speed label applications.

3. Reliable After-Sales Support

UK-based firms typically offer prompt service, spare parts availability, and on-site technical support — ensuring minimal downtime.

4. Integration with Smart Systems

Modern print and apply systems come with advanced connectivity features. From ERP integration to remote diagnostics and Industry 4.0 readiness, UK manufacturers are pushing the envelope in intelligent labeling automation.

Top UK Print & Apply Labeling System Manufacturers

Several UK companies are renowned for their world-class labeling technology. While each offers unique strengths, here are a few industry leaders:

ALTech UK – Offers modular systems known for high-performance labeling, suitable for both primary and secondary packaging.

Domino Printing – A global name with UK roots, known for integrated printing and coding solutions including robust labelers.

CLE Labelling Solutions – Specializes in custom-built systems for complex labeling applications across various industries.

LabelPack Automation – Offers scalable and affordable print and apply machines for SMEs and large enterprises alike.

Key Features to Look For in a Labeling System

When choosing a system, consider:

Print resolution & speed

Labeling accuracy

Ease of integration with existing systems

User-friendly interface

Support for various label materials and formats

Conclusion

Investing in a reliable print and apply labeling system is not just about automating your labeling process—it's about ensuring traceability, accuracy, and compliance in a competitive market. UK-based manufacturers continue to lead the way with flexible, innovative, and robust systems tailored to your business needs. Whether you're scaling up production or modernizing your logistics operations, a smart labeling solution from a trusted UK manufacturer can be a game-changer.

0 notes

Text

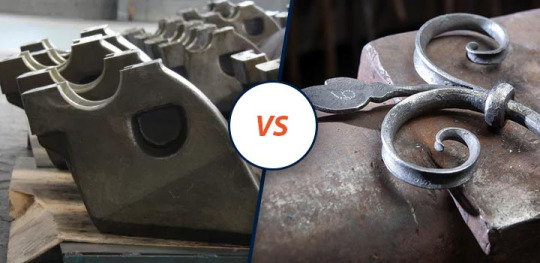

Know The Difference Between Wrought Steel And Cast Steel

Steel is one of the maximum versatile materials in manufacturing, extensively used in industries starting from production to automobile engineering. However, no longer all steel is created equal. Two common sorts, wrought metal and solid metallic, vary of their manufacturing methods, residences, and packages. Understanding the variations among that two paperwork is vital for choosing the right cloth for your unique needs.

1. The Manufacturing Process

The number one distinction among Wrought Steel And Cast Steel lies in how they may be produced. Wrought steel is produced by way of time and again heating and operating the metal via forging, rolling, or extrusion processes. This mechanical process refines the fabric, improves its grain structure, and strengthens the metallic. The non-stop deformation ensures the metallic is free from voids and defects, making it harder and extra ductile.

On the other hand, cast steel is created through pouring molten metal into a mildew in which it solidifies. The casting manner allows for the advent of complex shapes that could be hard or high priced to obtain via forging. While solid steel is commonly less difficult to provide for intricate designs, the rapid cooling at some stage in solidification can result in inner stresses or defects like porosity.

2. Material Properties

Due to the difference of their formation, Wrought Steel and Cast Steel showcase distinct mechanical residences. Wrought metallic is normally stronger, greater ductile, and has better fatigue resistance due to its delicate grain structure. The system of rolling or forging aligns the metal grains, making the cloth able to withstanding high-pressure programs. As a result, wrought steel is frequently selected for structural components wherein power and toughness are crucial.

In comparison, forged steel tends to be extra brittle and less ductile, because it doesn’t undergo the identical mechanical refining manner as wrought steel. However, it has a distinct gain in terms of pliability in design and production. Cast steel may be synthetic into complex shapes without requiring additional machining or meeting, making it ideal for elaborate parts like equipment housings, engine additives, and big business equipment.

3. Applications

The differences in production processes and residences directly influence the applications of wrought and solid steel. Wrought metallic is typically utilized in applications wherein energy and sturdiness are essential, along with in pipelines, girders, shafts, and railroad tracks. These components need to undergo high loads and vicious environmental conditions, and wrought steel’s inherent durability makes it suitable for such uses.

Meanwhile, solid metal is frequently hired in situations that require complicated geometries and shapes. Examples include components like pump housings, engine blocks, and valve bodies. The casting system permits producers to create elements with difficult designs and ranging thicknesses that might be costly or impossible to attain with wrought steel.

4. Cost and Production Efficiency

When it comes to price, there are differences between the two styles of metal. Wrought metal is regularly extra costly to supply because of the tremendous labour and system worried in the rolling and forging procedures. However, its advanced mechanical homes justify the higher price in many applications, especially wherein protection and overall performance are priorities.

In contrast, cast metallic tends to be more price-effective for generating huge or complex shapes. The casting manner lets in for the manufacturing of complex additives with fewer secondary methods, which reduces each hard work and fabric fees. However, the danger of defects and the ability want for submit-casting treatments like warmth remedy or machining can add to the general fee.

5. Conclusion.

And from this view, it becomes possible to understand how important are differences of Wrought Steel And Cast Steel for particular applications. Wrought steel has ductility and elasticity, and has shock resistance, thus, being very good for strength-demanding parts size and flexibility His In contrast with such properties strengthening, melt-iron is poured into Molds in order to produce cast iron. Different shapes and designs are achieved in this way. Although cast iron is often lighter than wrought iron, it also offers the advantage of larger production and more complex geometries Ultimately, a choice must be made between wrought iron and cast iron based on the particular demands of the application.

0 notes

Text

Low-price group buying is not the antidote

If traffic and algorithms make more and HE Tuber more users pay attention to the local life of Douyin and transform it into effective "grass planting", then "low price" is the "lubricant" in this business chain.

Since the second half of last year, Douyin has launched a price war with other platforms, and has begun to issue "9.9 yuan coupons" for group purchases indiscriminately, using low-price strategies to snatch users, and even exaggerated to the point of "the cheaper you get, the cheaper I will be." Two pieces" momentum, not giving up a penny on this matter.

TikTok screenshot

In order to compete for B-side merchants, Douyin has attracted a group of catering merchants with a service rate of 2.5%. The average service rate for various product categories is 3%, and the highest does not exceed 8%. For this reason, other platforms have also begun to lower service rates for catering merchants, and even actively help merchants obtain resources.

Faced with "countermeasures", Douyin can only invest more money to maintain high operating and promotion costs.

Therefore, Douyin’s local life service has a huge revenue, but it is not a very profitable business. For local merchants, although Douyin’s commission is not high, lowering the group purchase price to 50% off or even lower does not create a large profit margin in itself. It is more for the purpose of attracting traffic to the store and can only be regarded as It's advertising at a loss.

But many times, users may go to offline stores to buy group buying coupons. Once the group buying discount ends and the original price is restored, they will not make repurchases. In other words, although Douyin’s traffic is very strong and merchants have spent a lot of time and energy on it, they may not really be able to make money from it.

This also exposed the most critical problem of Douyin in the local life business, which is that Douyin, which has always been focusing on "group purchase packages" as its core operation, has a single way of attracting traffic, has a limited number of stores displayed, and has never been able to establish users' active participation in the platform. The mentality of looking for a store.

Douyin city interface

After all, the core of visiting a store is the "store" rather than the "voucher". If the platform's local life business wants to last for a long time, the platform needs to be able to provide enough store details and establish a relatively reasonable reputation system, so that users will have a clear mind when looking for stores. That is to say, users are accustomed to opening the platform with purpose, looking for suitable stores, and leaving reviews after consumption. Group purchases and discounts are secondary parts.

Only in this way can more high-quality merchants be seen, a positive business cycle can be formed, and business assets can be accumulated.

As long as Douyin cannot solve the mental problems of users, it will not be able to become a leader in the local life track.

The smell of gunpowder smoke continues in the local living market

After Douyin entered the market and caused a stir, the competition in the local lifestyle market has become increasingly fierce.

In addition to Douyin, Xiaohongshu recruits merchants and launches online group buying, and the official local life account "Marmot" has also started operations;

Kuaishou integrates local life business, launches local life mini-programs, and explores differentiated paths;

Even video accounts have begun to layout local life and are testing related services on a small scale.

Compared with the cruel "Thousand Regiments War" around 2015, this time the competitors are no longer inexperienced novices, but domestic Internet giants with strong backgrounds and outstanding advantages in their respective fields.

They have been developing for many years and have mature business models and user accumulation. They all want to take a share of the local life market and look for the second growth curve.

At the same time, the old players in local life, after decades of development, have carried out in-depth market education, established a stable life service empire, and have a complete distribution system, supply resources, after-sales chain, etc.

In addition, in the face of changes in the industry situation, old players have also shifted from passive defense to active offense and taken a series of measures to target new entrants represented by Douyin. Douyin will also face greater pressure.

With players from all parties working together, local life is destined to not be peaceful, and the landscape is also being reshaped. There are well-deserved giant players in front of it, and new forces are also gearing up, and Douyin sandwiched in the middle is really, with sea water on one side and flames on the other.

Douyin naturally wants to win the battle of local life, but the minds of users who come to the store have not yet been cultivated, and merchant resources do not have an advantage. It is not easy for Douyin to break through with its traffic alone.

1 note

·

View note

Text

Elements of Logistics: Building Blocks for Supply Chain Success

To achieve supply chain success, it is crucial to understand the core elements of logistics, which include transportation strategies, warehouse management, and inventory control.

Transportation strategies serve as a pillar of logistics, ensuring the efficient movement of goods from one point to another.

Effective warehouse management and inventory control contribute to minimizing costs and maximizing customer satisfaction.

Understanding the Core Elements of Logistics

Logistics is composed of essential components that serve as the foundation for achieving success in the supply chain. Understanding the core elements of logistics is crucial for effective logistics and supply chain management.

One of the key aspects is the importance of logistics management, which involves the coordination and control of the flow of goods, services, and information. The elements of logistics include inventory management, transportation, warehousing, packaging, and material handling. These elements work together to ensure the smooth and efficient movement of goods from the point of origin to the point of consumption.

Additionally, logistics planning and optimization play a significant role in minimizing costs and maximizing customer satisfaction. Features of logistics management include strategic decision-making, risk management, and performance measurement.

Transportation Strategies: A Pillar of Logistics

Transportation strategies serve as a crucial pillar within the realm of logistics, playing a pivotal role in ensuring the smooth and efficient movement of goods throughout the supply chain.

Effective transportation strategies involve various elements, including route planning and real-time tracking.

Route planning helps optimize the movement of goods by identifying the most efficient routes, considering factors such as distance, traffic, and fuel consumption.

Real-time tracking enables logistics professionals to monitor the progress of shipments, ensuring timely deliveries and allowing for quick response to any unforeseen issues.

In the context of supply chain management, logistics encompasses the entire process of planning, implementing, and controlling the flow of goods from the point of origin to the point of consumption.

To learn more about transportation strategies and their role in logistics, please contact us.

Warehouse Management and Inventory Control

Warehouse management and inventory control are essential components of a successful supply chain. They ensure the efficient storage, organization, and tracking of goods.

In today's dynamic business environment, there are two main types of trade: general trade and modern trade. General trade refers to traditional retail channels, while modern trade includes large supermarkets, hypermarkets, and e-commerce platforms.

Regardless of the trade type, effective warehouse management and inventory control play a crucial role in supply chain management. They enable companies to optimize their stock levels, reduce costs, and meet customer demands efficiently.

Moreover, secondary distribution, which involves the transportation of goods from central warehouses to regional or local distribution centers, requires accurate inventory control and efficient warehouse management to ensure timely and accurate deliveries.

Conclusion

In conclusion, the elements of logistics discussed in this article are crucial building blocks for achieving success in the supply chain. By focusing on key aspects such as transportation, inventory management, warehousing, and information systems, companies can optimize their operations and ensure efficient delivery of goods and services.

Implementing effective logistics strategies can lead to improved customer satisfaction, reduced costs, and increased profitability for businesses. Therefore, understanding and leveraging these elements is essential for supply chain success. Contact us to know more : Mojro Technologies.

#logisticsplanning#logistics and supply chain management#logistics software#logistics#logisticsmanagement

0 notes

Text

The Oldsmobile 442 represents one of the most iconic muscle cars of the 1960s and 1970s. Its unique name immediately conjures images of powerful V8 performance in a iconic package. But what exactly does 442 stand for on these classic Oldsmobiles? The numbers and branding have an important historical meaning tied to the model's origins. This in-depth guide will examine the story behind the 442 name and explain what each digit signifies on this legendary machine. We’ll cover: The origins and creation of the 442 What the 4, 4, and 2represent in the name Engine specs tied to 442 badging Special edition 442 models Decoding 442 identification codes Common myths and misconceptions Understanding the heritage behind the 442 provides deeper appreciation for these iconic performance cars. Read on to learn the complete story behind one of Oldsmobile’s most famous set of numbers! Origins of the Oldsmobile 442 The Oldsmobile 442 made its debut in 1964 as an optional package on the F-85 and Cutlass models. It was the brainchild of Oldsmobile engineer Joe Wolfram, who conceived the 442 as a way to lump all of the division’s performance parts into one package. The name 442 specifically highlighted three key components of the muscle car recipe: 4-barrel carburetor 4-speed manual transmission Dual 2-inch exhausts This powerful drivetrain transformed the midsize F-85 and Cutlass into muscle cars capable of seriously competing against Pontiac, Buick and other brands on the track and strip. The 442 package proved so popular that Oldsmobile decided to spin it off into its own distinct model in 1968. A legend was born that turned the 442 into a performance icon of the era. What Does 4 Stand For in 442? The first 4 in 442 refers to the 4-barrel carburetor that came standard for these high-performance engines. 4-barrel carbs had four separate barrels containing fuel jets and air inlets. This allowed more fuel and air into the engine compared to a simple 1-barrel or 2-barrel carb. The increased airflow resulted in significant horsepower gains. Some quick history on the significance of 4-barrel carbs: More airflow - Four separate barrels and venturis improved airflow over fewer barrels. Multiple primaries - Having two primary and two secondary barrels provided economy during cruising plus max power when stomping the gas. Performance standard - By the 1960s, 4-barrel carbs had become standard equipment for V8 performance engines across brands. The first digit in 442 tells us these Oldsmobiles came armed with serious high-performance 4-barrel carburetion. What Does the Second 4 Stand For? The middle 4 represents the 4-speed manual transmission equipped in all 442 cars. When originally launched, a heavy-duty close-ratio 4-speed manual was mandatory equipment with the 442 package. A 3-speed automatic wasn’t even offered until 1967. The 4-speed stick shift delivered several performance advantages: Quick, precise shifting Kept engines in ideal power band Maximized acceleration Matched revs for quicker shifts Better drivetrain durability under abuse A manual transmission was considered essential for serious performance. The second 4 in 442 tells buyers this Olds packed a beefy 4-speed standard. What Does 2 Represent in Olds 442? The final 2 denotes the dual exhaust system these cars came equipped with. High-performance V8 engines needed free-flowing exhausts to breathe properly and minimize backpressure. Dual exhausts split flow between two pipes rather than one, reducing backpressure substantially compared to a single pipe. Benefits of the dual exhaust in the 442: Increased exhaust flow improved power Separate pipes optimized scavenging Reduced backpressure for smoother flow Signature exhaust note for intimidation The final 2 in 442 confirms these Oldsmobile engines were equipped with a tuned dual exhaust ideal for no-compromise performance.

Oldsmobile 442 Engine Specifications In keeping with its performance pedigree, the 442 always came equipped with serious V8 muscle under the hood. Here are some key specs on the engines: 1964-1967 330 cubic-inch V8 310 to 345 horsepower 10.25:1 compression ratio Hydraulic lifter camshaft 4-barrel carburetor Dual exhaust 1968-1969 400 cubic-inch V8 325 to 350 horsepower 10.5:1 compression Mechanical lifter cam Aluminum intake manifold 4-barrel carb Dual exhaust 1970-1972 455 cubic-inch V8 310 to 370 horsepower 10.5:1 compression High-lift camshaft Aluminum intake 4-barrel carburetor Dual tailpipes These high-winding, high-compression V8s perfectly aligned with the performance image of the 442. Special Edition Oldsmobile 442 Models In addition to the standard 442, Oldsmobile offered several legendary special-edition performance models over the years: 442 W-30 Lightweight body panels Specially tuned engine Unique intake/carb High-lift camshaft Force-air induction Dual exhaust with crossover TH400 automatic transmission Anti-sway bars & suspension kit W-25 Ram Air hood 442 Hurst/Olds Custom graphics and paint Hurst shifter Lightened body panels H.O. 455 V8 engine Force-air induction California custom tripower carb Dual exhaust with H-pipe TH400 automatic transmission Upgraded suspension kit Front and rear spoilers 442 Cutlass Supreme Luxury 442 model Renamed to Cutlass Supreme in 1973 Appointment upgrades Strato bucket seats Custom interior trim Full instrumentation Console Radial tires Woody exterior trim These special editions took 442 performance to even higher levels. How to Decode 442 VIN Numbers Oldsmobile 442 VIN numbers provide a lot of useful information once you know how to decipher them. Here’s how to break down a typical 442 VIN: 3 - Oldsmobile division 42 - 442 model 37 - 3 for Oldsmobile engine, 7 denotes Big Block 455 V8 M - Assembled in Lansing, MI plant 7 - Model year (1977) 151667 - Unit sequential production number So VIN 3R42M7XXXXXX decodes to a 1977 Oldsmobile 442 with a 455 Big Block V8 assembled in Michigan. Easy once you know the key! Common Myths and Misconceptions Given its legendary status, the Oldsmobile 442 is also prone to some common myths and misconceptions: Myth: 442 denotes a 4-speed, 4-barrel carb, 2-exhaust Fact: It actually stood for 4-barrel carb, 4-speed trans, and dual exhaust. Myth: All 442s were red, white, and blue Fact: That color scheme was popular but 442s were produced in many color combinations. Myth: The 442 was the first muscle car Fact:Pontiac GTO, Plymouth Road Runner and others pre-dated the 442 by a few years. Myth: Only V8s came in the 442 Fact: Some early models could be equipped with 6-cylinder engines. Myth: The 442 was built from 1964-1974 Fact: Production actually ended in 1976 in the US, continuing until 1981 in Canada. Make sure to get the real facts on one of Oldsmobile's greatest performance models! Why 442 Branding Was Significant The 442 name brilliantly captured the essence of these cars - optimizing all the essential ingredients for standout V8 performance. It immediately communicated the 442’s performance pedigree with: 4-barrel carb for max airflow feeding the engine 4-on-the floor manual gearbox for quick acceleration Dual exhaust for free-breathing power The logo also looked cool, with a vintage ‘60s vibe. For buyers, seeing 442 badging signaled serious performance capability from Oldsmobile. FAQs What does the 442 stand for on Oldsmobile models? The 442 stands for: 4 - 4-barrel carburetor 4 - 4-speed manual transmission 2 - Dual exhaust This combination optimized high-performance for the engine, drivetrain, and exhaust. What engines came in the Olds 442 muscle car?

Popular V8s included: 330 cubic-inch V8 making 310-345 hp 400 cubic-inch V8 making 325-360 hp 455 cubic-inch Big Block V8 making 310-370 hp The 442 always came with serious V8 muscle. What was the meaning of the W-30 on special edition 442s? W-30 stood for the lightweight Olds performance parts on these models: W - Special engine tuning 3 - TH400 3-speed automatic transmission 0 - Rear axle ratio So W-30 denoted specially optimized drivetrain components. How can I decode the VIN number on an Olds 442? A typical 442 VIN reveals: Make (Oldsmobile) 442 Model Engine Assembly plant Model year Build sequence Knowing positions reveals manufacturing details. Were all 442 models painted red, white and blue? No. While that was a popular scheme, the 442 was produced in many colors over its lifetime ranging from basic white/black to wild neon hues in the 1970s. It came in almost every major color combo. The 442 name tells the story of one of history’s greatest muscle cars. Understanding the heritage behind the logo provides deeper connection to an iconic Oldsmobile performance model. #Wiack #Car #CarInsurance #CarRental #CarPrice #AutoLoans

0 notes

Text

The Oldsmobile 442 represents one of the most iconic muscle cars of the 1960s and 1970s. Its unique name immediately conjures images of powerful V8 performance in a iconic package. But what exactly does 442 stand for on these classic Oldsmobiles? The numbers and branding have an important historical meaning tied to the model's origins. This in-depth guide will examine the story behind the 442 name and explain what each digit signifies on this legendary machine. We’ll cover: The origins and creation of the 442 What the 4, 4, and 2represent in the name Engine specs tied to 442 badging Special edition 442 models Decoding 442 identification codes Common myths and misconceptions Understanding the heritage behind the 442 provides deeper appreciation for these iconic performance cars. Read on to learn the complete story behind one of Oldsmobile’s most famous set of numbers! Origins of the Oldsmobile 442 The Oldsmobile 442 made its debut in 1964 as an optional package on the F-85 and Cutlass models. It was the brainchild of Oldsmobile engineer Joe Wolfram, who conceived the 442 as a way to lump all of the division’s performance parts into one package. The name 442 specifically highlighted three key components of the muscle car recipe: 4-barrel carburetor 4-speed manual transmission Dual 2-inch exhausts This powerful drivetrain transformed the midsize F-85 and Cutlass into muscle cars capable of seriously competing against Pontiac, Buick and other brands on the track and strip. The 442 package proved so popular that Oldsmobile decided to spin it off into its own distinct model in 1968. A legend was born that turned the 442 into a performance icon of the era. What Does 4 Stand For in 442? The first 4 in 442 refers to the 4-barrel carburetor that came standard for these high-performance engines. 4-barrel carbs had four separate barrels containing fuel jets and air inlets. This allowed more fuel and air into the engine compared to a simple 1-barrel or 2-barrel carb. The increased airflow resulted in significant horsepower gains. Some quick history on the significance of 4-barrel carbs: More airflow - Four separate barrels and venturis improved airflow over fewer barrels. Multiple primaries - Having two primary and two secondary barrels provided economy during cruising plus max power when stomping the gas. Performance standard - By the 1960s, 4-barrel carbs had become standard equipment for V8 performance engines across brands. The first digit in 442 tells us these Oldsmobiles came armed with serious high-performance 4-barrel carburetion. What Does the Second 4 Stand For? The middle 4 represents the 4-speed manual transmission equipped in all 442 cars. When originally launched, a heavy-duty close-ratio 4-speed manual was mandatory equipment with the 442 package. A 3-speed automatic wasn’t even offered until 1967. The 4-speed stick shift delivered several performance advantages: Quick, precise shifting Kept engines in ideal power band Maximized acceleration Matched revs for quicker shifts Better drivetrain durability under abuse A manual transmission was considered essential for serious performance. The second 4 in 442 tells buyers this Olds packed a beefy 4-speed standard. What Does 2 Represent in Olds 442? The final 2 denotes the dual exhaust system these cars came equipped with. High-performance V8 engines needed free-flowing exhausts to breathe properly and minimize backpressure. Dual exhausts split flow between two pipes rather than one, reducing backpressure substantially compared to a single pipe. Benefits of the dual exhaust in the 442: Increased exhaust flow improved power Separate pipes optimized scavenging Reduced backpressure for smoother flow Signature exhaust note for intimidation The final 2 in 442 confirms these Oldsmobile engines were equipped with a tuned dual exhaust ideal for no-compromise performance.

Oldsmobile 442 Engine Specifications In keeping with its performance pedigree, the 442 always came equipped with serious V8 muscle under the hood. Here are some key specs on the engines: 1964-1967 330 cubic-inch V8 310 to 345 horsepower 10.25:1 compression ratio Hydraulic lifter camshaft 4-barrel carburetor Dual exhaust 1968-1969 400 cubic-inch V8 325 to 350 horsepower 10.5:1 compression Mechanical lifter cam Aluminum intake manifold 4-barrel carb Dual exhaust 1970-1972 455 cubic-inch V8 310 to 370 horsepower 10.5:1 compression High-lift camshaft Aluminum intake 4-barrel carburetor Dual tailpipes These high-winding, high-compression V8s perfectly aligned with the performance image of the 442. Special Edition Oldsmobile 442 Models In addition to the standard 442, Oldsmobile offered several legendary special-edition performance models over the years: 442 W-30 Lightweight body panels Specially tuned engine Unique intake/carb High-lift camshaft Force-air induction Dual exhaust with crossover TH400 automatic transmission Anti-sway bars & suspension kit W-25 Ram Air hood 442 Hurst/Olds Custom graphics and paint Hurst shifter Lightened body panels H.O. 455 V8 engine Force-air induction California custom tripower carb Dual exhaust with H-pipe TH400 automatic transmission Upgraded suspension kit Front and rear spoilers 442 Cutlass Supreme Luxury 442 model Renamed to Cutlass Supreme in 1973 Appointment upgrades Strato bucket seats Custom interior trim Full instrumentation Console Radial tires Woody exterior trim These special editions took 442 performance to even higher levels. How to Decode 442 VIN Numbers Oldsmobile 442 VIN numbers provide a lot of useful information once you know how to decipher them. Here’s how to break down a typical 442 VIN: 3 - Oldsmobile division 42 - 442 model 37 - 3 for Oldsmobile engine, 7 denotes Big Block 455 V8 M - Assembled in Lansing, MI plant 7 - Model year (1977) 151667 - Unit sequential production number So VIN 3R42M7XXXXXX decodes to a 1977 Oldsmobile 442 with a 455 Big Block V8 assembled in Michigan. Easy once you know the key! Common Myths and Misconceptions Given its legendary status, the Oldsmobile 442 is also prone to some common myths and misconceptions: Myth: 442 denotes a 4-speed, 4-barrel carb, 2-exhaust Fact: It actually stood for 4-barrel carb, 4-speed trans, and dual exhaust. Myth: All 442s were red, white, and blue Fact: That color scheme was popular but 442s were produced in many color combinations. Myth: The 442 was the first muscle car Fact:Pontiac GTO, Plymouth Road Runner and others pre-dated the 442 by a few years. Myth: Only V8s came in the 442 Fact: Some early models could be equipped with 6-cylinder engines. Myth: The 442 was built from 1964-1974 Fact: Production actually ended in 1976 in the US, continuing until 1981 in Canada. Make sure to get the real facts on one of Oldsmobile's greatest performance models! Why 442 Branding Was Significant The 442 name brilliantly captured the essence of these cars - optimizing all the essential ingredients for standout V8 performance. It immediately communicated the 442’s performance pedigree with: 4-barrel carb for max airflow feeding the engine 4-on-the floor manual gearbox for quick acceleration Dual exhaust for free-breathing power The logo also looked cool, with a vintage ‘60s vibe. For buyers, seeing 442 badging signaled serious performance capability from Oldsmobile. FAQs What does the 442 stand for on Oldsmobile models? The 442 stands for: 4 - 4-barrel carburetor 4 - 4-speed manual transmission 2 - Dual exhaust This combination optimized high-performance for the engine, drivetrain, and exhaust. What engines came in the Olds 442 muscle car?

Popular V8s included: 330 cubic-inch V8 making 310-345 hp 400 cubic-inch V8 making 325-360 hp 455 cubic-inch Big Block V8 making 310-370 hp The 442 always came with serious V8 muscle. What was the meaning of the W-30 on special edition 442s? W-30 stood for the lightweight Olds performance parts on these models: W - Special engine tuning 3 - TH400 3-speed automatic transmission 0 - Rear axle ratio So W-30 denoted specially optimized drivetrain components. How can I decode the VIN number on an Olds 442? A typical 442 VIN reveals: Make (Oldsmobile) 442 Model Engine Assembly plant Model year Build sequence Knowing positions reveals manufacturing details. Were all 442 models painted red, white and blue? No. While that was a popular scheme, the 442 was produced in many colors over its lifetime ranging from basic white/black to wild neon hues in the 1970s. It came in almost every major color combo. The 442 name tells the story of one of history’s greatest muscle cars. Understanding the heritage behind the logo provides deeper connection to an iconic Oldsmobile performance model. #Wiack #Car #CarInsurance #CarRental #CarPrice #AutoLoans

0 notes

Text

Below are some potential advantages that a DMS could provide to your business.

Before a product can make it to store shelves, it must pass through a series of rigorous processes, beginning with production and ending with distribution. As soon as manufacturing is complete, the product is shipped to distributors and retailers.

A comprehensive distribution management system (DMS) hones in on the key nodes of the supply chain to optimize the shipping logistics of finished goods. Manufacturing, packaging, inventory management, warehousing, and shipping are all steps in the process.

Distribution management software is essential in India due to the rising complexity of supply chain management and customer service. This strategy of following secondary markets to the point of sale simplifies several channel sales aspects, including stock replenishment, storage expenses, and production scheduling.

Let's take a look at why a Distribution Management System might be useful. Even though the actual number of advantages is almost certainly unlimited, we have created a short list of the most significant ones:

1. Quickly accessible in the present

As a manufacturer of fast-changing consumer goods, you understand how important it is to keep tabs on all of the information flowing through your distribution channels in real-time. Lacking a DMS forces businesses to rely on infrequent, outdated, and costly offline data given by distributors at predetermined periods. Distributors shouldn't do anything that can disrupt their supply chain, including reducing their stock levels, the number of pending orders, the number of returned orders from retailers, etc. Therefore, distribution management software is essential for running an efficient distribution system.

2. Remotely observing

Fast-moving consumer goods (FMCG) companies are rapidly expanding their distribution networks to include virtually every district in India, thanks to the country's robust economic growth. Acquiring accurate data on your product flow from all of your distributors may be challenging due to the challenges connected with enormous numbers, time management, and the geographical isolation of the distributor. If a distributor management system is in place, distributors in cities, rural areas, or anywhere else in the world may have access to the same data.

3. Offering incentives to shops that carry your products is crucial.

Using a DMS would be tremendously helpful because it would streamline and automate so many processes. This program will make a distributor's life easier in many ways, including the automation of product movement of all kinds, system-generated bills, data on late payments, and smart notifications.

4. Arguments should be settled more rapidly.

The DMS's streamlined claims processing is sure to be a hit with your distributors. The DMS allows the company and its distributors to keep a close eye on deliveries and payables by handling things like return policies, damaged receipts, and everything else. In addition, if all claims are submitted electronically using DMS, they can be finalized much more quickly than if they were submitted manually, which would require numerous rounds of changes between the two sides.

5. Smarter Administration of Marketing and Promotion

There isn't a single company that doesn't rely heavily on marketing and incentives. Many companies have significant capital available for such an undertaking. With the help of the Distributor Management System, you will know exactly how each scheme is operating, and there will be no surprises when it comes to billing.

6. Quick Restocking

Stockists, distributors, retailers, and other channels of distribution are all points of contact between FMCG manufacturers and their customers; as such, they must maintain meticulous inventory records. Inventory levels, expiration dates, batch numbers, and return information can all be tracked with DMS. Access to significant updates and replacement parts is expedited through distributor sites.

7. Making a Manufacturing Strategy

Ideally, your ERP system's demand planning module would receive updates from your distribution management system. In doing so, the ERP's production planning engine can consider factors like inventory at warehouses and upcoming orders. Consequently, you will make better use of, and waste less of, your manufacturing resources.

#distribution management software#distribution management system (dms)#distribution management system

0 notes

Text

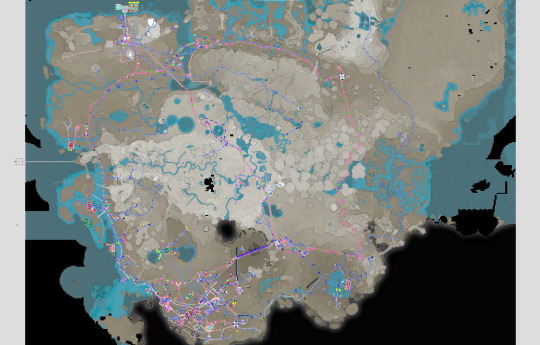

because i'm still rotating this in my head: here's a screenshot of the heart of my nerd kingdom, with major features labeled. this was taken like two weeks ago after i finished the bulk of S.P.I.N.E. rebuilding:

and here's a detail of the map, with the same region, detailing the above view:

you know what i love? when you go to some tourist thingy with a high view and they have something pointing out where various buildings and other noteworthy features are. saw a lot of those in recent trips to fancier cities than mine, but now i have the power to make my own...!

a little bit of writing on what some of these buildings are, behind the cut

Home and Central Storage: base of operations. central storage is at the end of a long supply chain that produces most of the basic materials needed for constructing most everything. after the S.P.I.N.E. rebuild, it also features an integrated train station, just for me, dedicated to receiving my personal train that i drive around to wherever i'm building stuff. mass transit is fun, but you know what's more fun? taking mass transit and using it for the benefit of one person and that one person's individual commute. this is entirely consistent with Satisfactory's whole vibe of taking a pristine alien wilderness and turning it into an industrialized pollution dimension

Space Elevator: for those unfamiliar with the game, the metagame involves producing highly complex parts and then sending them up a space elevator to your space bosses. this makes the Space Elevator a building of primary importance, representing the end destination of the game's most complicated projects. it's visible from anywhere on the map. it's very cool. i love giant space architecture

S.P.I.N.E.: Supply Processing Integrated Network Environment is a demi-megafactory that produces the bulk of basic materials. it has gradually incorporated the functions of once-separate facilities, so it is very dense with machines. the big fat column of conveyor belts it produces lead up into Central Storage

The Barns: secondary production facilities. at present these are used for grinding up local flora and fauna into useful products. in the case of packaged alien protein made from dead animals, the usefulness is in looking at a giant storage bin of processed alien protein and saying "neat."

Old Frame Factory: the first complex multi-level production facility i ever built. the second iteration, actually! its functionality was recreated in the new S.P.I.N.E. which means these machines are currently off. i haven't torn the buildings down yet because I wanna re-use them at some point, kinda like how my city's The Old Spaghetti Factory is built inside a former train depot (you can look at the windows and see currently-used train tracks. it's very cool. trains and spaghetti... two things I love...)

The Petrolpolis: so named because it was the site of my first petroleum processing machines. those have been cleared out and moved further up the production pipeline, but the building was repurposed and dressed up to serve as a big train depot. it's kinda uggo now but it was still one of the first buildings i put effort into making look cool

Petrolpolis Computas: these buildings use petroleum products received at the Petrolpolis, make computers and supercomputers, and then send them down the line, through S.P.I.N.E. and into Central Storage. it's all lines. it's all lines

Director General: a very large factory that builds Assembly Director Systems, complex computers needed by the thousands for the current (and currently final) phase of Space Elevator parts. this factory requires a steady input of numerous processed materials, which is what the Copper and Steel foundries are for, plus bunches of other stuff received from previously mentioned and mysterious, unseen buildings. i got a factory called Cablewerkz on the other side of the map that just makes cables and sends them via train to Director General, which also has its own dedicated train station. this building is broken into two halves, the upper of which sits offset from the bottom, because there is a giant flying alien manta ray that circles over this region constantly, and I did not take his route into account when i started this massive project. by the time i got halfway up, i realized the manta would fly into and through my factory, but i didn't want to start over, so i just kinked the upper half off to the side. so this factory features an integrated train station (wow!) and a dedicated alien patrol route observation deck (wow?). also i produced the needed quantity of Assembly Director Systems dozens upon dozens of hours ago so this whole factory is mothballed

anyway thank you for joining me on this tour

i found the tool that makes a custom map of all your stuff in Satisfactory and i've been staring at it for like 45 minutes. yes every single little pip and line on there is something i placed myself and with intention, but i am in no way immune to the pleasure of seeing familiar things from Very High Up

23 notes

·

View notes

Link

Click here to watch the machine Operation

0 notes

Note

You can't actually think that the average person is as much to blame for climate change as billionaires who erase years of progress with their own personal space race. Right? Tell me how me using paper straws or freezing in the winter/roasting in the summer is going to counter a CEO ordering a forest cut down a day.

Think you're being obtuse lol. That post isn't about the damage the rich do alone. It's about how leftists are using that harm to refuse their own accountability and their own ability to make small changes and in doing so, they are giving up their collective power to make larger changes. Experts have made it clear that it's not just about "billionaires," so you can shut up with that.

The crisis is going to demand LARGE changes from all of us - and yes, some of those changes are going to be uncomfortable. Set your thermostat at 80 in the summer and at 60 in the winter. Bodies adjust and those temperatures are safe for most everyone. In many climates, AC isn't necessary for more than 3 weeks of the year. Including where i live in the Southwest.

Stop using straws altogether and get rid of disposable items at restaurants - it's not hard. And if you're not the few who may need a plastic straw, then stop hiding behind them to avoid your own ability to change. Take the bus, and plan where you live so that you can. Live in a smaller space. Get a bike. Eat less meat and keep red-meat to an absolute minimum. And yes, vote and advocate for people who can make real change and regulations at the top to make changes for US easier to do in our daily lives while also multiplying the impact.

but don't forget that these corporations function toward demand - and they do listen - and they do know change is coming and preparing for it. If you can afford to, start using the power you do have, and you DO HAVE it, and stop hiding behind some convenient wall so that you can think you're exempt from making any changes in your own life - assuming you actually care about the climate crisis at all and aren't just using it to channel pure anger at an "other" (this case the rich or the billionaire class).

Anger is a secondary emotion and I think the way it is discharged, including in your ask, is not helpful to you or the crisis. You're just discharging blame. Accountability is a two-way street, and if you actually do make changes, you will be living YOUR values, which is valuable and it does matter. If the paper straw makes you feel more aligned with your values (and it does make a difference, no matter how small), then that is a good thing.

What you've done with this post is what they love to see. They don't actually care that you or I think they're evil, shortsighted, or whatever. Because you hiding behind that is just allowing yourself to remove yourself from the system (which can't be done btw) and enables you to keep buying the products made by the evil billionaires. It's funny how that works, isn't it? Saying it's all the fault of the billionaires while changing nothing you are doing is what they love to see.

why is it that you all talk about how each individual can create a massive collective action leading to a revolution or whatever, but you don't see how that is true, if not even MORE true, on this subject? Critical Mass bike rides have politically made it possible for cities to invest in more bike infra. Using reusable jars and containers on bulk items at your local coop reduces plastic individually, and also demonstrates a market for less plastic packaging. You might still need to buy certain things in plastic, but the more you buy available in other packaging helps enable even more. Even Target is now selling deodorant tubes made of paper and toothpast sold in aluminium tubes. I get bulk shampoo, conditioner, moisturizer, soap, and cleaning products at my Coop (I in fact now have a plastic free bathroom and nearly plastic free kitchen!).

And like i said, i know my impact is marginal, but it is still an impact. On a personal level, the impacts benefit my mental health, they align with my values, and I find my life more enjoyable. I have a small apartment, but can take the bus or bike everywhere, and I have become more and more a part of a community that shares those values and lifestyles which is enriching. So yes, billionaires are doing a lot of damage, but we live in a society and all play a part. We can work toward holding them accountable and making those changes at the same time we make changes at home. But i have very little respect for people who think they can't make any change or who discharge all their responsibilities on others.