#Transparent Pouches Manufacturer

Explore tagged Tumblr posts

Text

F-Flute: A Game-Changer in Retail Packaging

In the bustling aisles of today’s consumer-driven market, where choices abound and attention spans are fleeting, the role of packaging in product presentation is very important. Amidst the visual chaos, a well-designed and distinctive package can be the key to standing out, capturing attention, and conveying brand identity. As e-commerce continues its meteoric rise, the significance of retail packaging has reached new heights. It’s not just a protective shell; it’s the first interaction between the consumer and the product, shaping a lasting impression. Thus, the quality of packaging is very important as it not only protects the product but also plays a crucial role in shaping the overall customer experience.

Today, we are going to learn about Flutes used in packaging. Packman Packaging, the leading manufacturer of corrugated boxes in India, tells us how F-Flute is making waves in the world of retail packaging.

Corrugated material comes in different flute sizes, like A to F, for various packaging needs. Flutes strengthen the cardboard, separating layers and acting as insulation. Bigger flutes offer more strength, while smaller ones enhance structure and printing for retail packaging...

Read Here: https://www.packman.co.in/blog/f-flute-corrugated-box-retail-packaging/

#buy corrugated boxes#packman packaging#buy courier bags online#corrugated box manufacturers#corrugated boxes#buy corrugated boxes online#corrugated box wholesalers#tamper proof courier bags#packmanpackaging#corrugated box suppliers#Gaurav Jalan#Packman Packaging#high-quality bubble sheets#5 ply corrugated boxes#Get PAN India Delivery#Discounts on Bulk orders#Discounts on Bulk Orders.#Transparent Pouches with Zip Lock#Custom Printed Stand Up Pouches#Oval Window Stand Up Pouches.#Silver Standup Pouches with Zip Lock#Stand Up Pouches with Nozzle for Handwash#Ketchup and for Food Paste packaging.

0 notes

Text

Top PVC Tray Manufacturer

Looking for a reliable PVC tray manufacturer? Look no further than Bigfalcon Group! We offer top-quality PVC trays that are perfect for your business needs. Check out our wide range of options online and choose the best one for you. For more details, call us at 9137559944.

#glossy photo paper#a4 size photo paper#kodak photo paper#aadhar pvc card#premium lamination pouch#lamination pouch a4 size#sticker photo paper#PVC Tray Manufacturer#Transparent sticker sheet#Sticker photo paper

0 notes

Text

Spout Pouch Wholesale - A Trending Liquid Packaging in the Market

A stand up pouches and spout pouches are now being trending and growing popular in a packaging market. Buy spout pouches online in bulk or wholesale from Gujarat Shopee in different shapes and sizes starting from 10 MM to 20 MM with a capacity of 250 ML, 500 ML, 750 ML, and 1000 ML.

#spout pouch#spout pouches#buy spout pouch#spout pouch online#spout pouch wholesale#spout pouch suppliers#spout pouch packaging#spout pouch manufacturers#transparent spout pouch#spout pouch price#silver spout pouch

0 notes

Link

Buy zip lock bags online in India at best price from Gujarat Shopee. We offer transparent zip lock bags in wholesale or bulk that can help you to maintain the freshness of product and keep them safe. These zip lock storage bags are available in different sizes and colors.

#zip lock bags#zip lock bags wholesale#transparent zip lock bags#buy zip lock bags online#zip lock pouch#zip lock storage bags#ziplock freezer bags#zip lock bags manufacturers#zip lock bags suppliers

0 notes

Text

Tankiste Cold Weather Gear

This is an impression of a French tank crewman in winter gear. One may see this uniform on tankiste during the cold winter months. While the standard infantry soldier may wear the iconic sheepskin jerkin, the tankiste instead had to rely on their black leather coat during the winter season. This tankiste wears the Toile de Tente Modèle 1897 modifié 1914 as extra waterproofing. This variant of the tent had loops that would allow for two lengths of hemp cordage to be passed through the waist and neck area to allow the tent to be worn as a poncho. Waterproofing the tent was done using paraffin and alcohol thinner.

Knitted items would be issued throughout the entire war, created by French citizens at the homefront and quality checked by the French Red Cross. They would be passed onto the army Quarter-Master where they would be received in as standard issue winter gear. The Red Cross had pamphlets distributed to the civilian population which featured several patterns of knitted gear from blankets, shirts, and scarves, to fingerless mittens and comfort items like tobacco pouches. The knitted garments pictured here are 1917 Red Cross pattern examples. The first display photo shows a standard grey and blue knitted cap, worn at the rear lines or when resting. The knitted cap beside this is intended to be worn under the helmet at the frontline. Below these is a knitted helmet or balaclava. These would be worn below the nose or at the chin, and had tails or capes at the front and back that would fit under the uniform to secure the balaclava in place and provide extra insulation. Below this is a pair of knitted wristlets, to be worn under the tunic providing some hand and arm insulation.

To the right is the standard French Army folding lantern. Specifically, it is the Lanterne de Campement Monjardet Modèle 1910 with its Ersatz Lamp Cover. Many models exist of this pattern and design slightly varies between manufacturers. All examples would be accepted into the army as a regulation item. These would be issued to Corporals to provide necessary lighting at night. Tankiste would also be provided with an electric lamp for their tanks, and the tankiste could also purchase an electric flashlight to give light inside the tank when performing maintenance duties. The candlelit Monjardet lamp folds into a triangular lamp with a hanging handle at the top and a holding handle on the back. The candle is pinned to the bottom panel by a spike and the rear panel is reflective which directs more light outward towards the front. Transparent mica is used as the clear shielding and can be slid out and replaced when it eventually gets damaged from the heat. Holes in the side panels allow for air to pass through and a small vent is placed at the top panel to disperse smoke. Overall, these lanterns were well liked with the troops as its design provided decent light coverage at night while being very compact when stowed.

Below this is a smoking pipe, lighter, and tobacco case. Nothing much to be said here - many smoked as a pastime during this period. The lighter is a commercial 'trench art' lighter, not created by the soldiers themselves but made to look like the examples that were created in the trenches. This style of 'trench art' item was popular among the civilian population and soldiers alike. It resembles an artillery shell with the cap closed, and removing the cap shows the petrol lighter ignition piece. The brass ignition piece can be removed which reveals cotton balls that absorb the liquid fuel. Beside this is a French 32 card manille deck. Manille was a very popular card game among the French at the time period. A tax stamp is placed on the Ace of Clubs which was a common sight on French playing cards. To the right of this is a board game called Solitaire. It consists of a wooden board with 36 removable pegs where the objective of the game is to clear the board of all but one of the pieces by jumping, horizontally or vertically, over an adjacent piece and removing it from the board. These types of time wasting and socializing games were available to soldiers in military bazaars. A light blue wool pocket was provided for this Solitaire example.

#history#tanks#renault ft#technology#world war one#uniforms#reenactor#reenacting#reenactment#reenactors

4 notes

·

View notes

Text

The Benefits of Using PET Film for Flexible Packaging Solutions

In today’s fast-paced consumer market, packaging is no longer just about protection. It is a critical component of branding, sustainability, and functionality. As industries seek innovative materials to meet evolving demands, PET film (polyethylene terephthalate) has emerged as a frontrunner in flexible packaging solutions. It is known for its versatility and transforms how businesses approach packaging design. If paired with a reliable polyester film supplier like Garware, companies can unlock unparalleled durability, aesthetics, and environmental responsibility advantages. Let’s explore the revolutionizing flexible packaging.

1. What is PET Film?

It is a lightweight, transparent polyester film renowned for its exceptional mechanical and chemical properties. Derived from polyethylene terephthalate, the same material used in plastic bottles, PET film is engineered to offer high tensile strength, clarity, and resistance to moisture, heat, and chemicals. These attributes make it ideal for applications ranging from food packaging to electronics, where reliability and visual appeal are paramount.

2. Key Benefits of PET Film in Flexible Packaging

1. Superior Durability and Strength: The high tensile strength ensures packaging remains intact during transportation, storage, and handling. Unlike traditional materials, it resists punctures and tears, making it perfect for heavy-duty applications like industrial product wraps or reusable pouches. This durability extends shelf life by safeguarding contents from physical damage.

2. Exceptional Clarity and Aesthetic Appeal: First impressions matter, and PET film delivers glass-like transparency that showcases products vividly. Its glossy finish enhances print quality, allowing brands to create eye-catching designs for labels, laminates, and shrink sleeves. Whether used for snack packaging or luxury cosmetics, it elevates brand visibility.

3. Advanced Barrier Properties: PET film acts as a robust barrier against moisture, oxygen, UV rays, and contaminants. This is crucial for perishable goods like pharmaceuticals and fresh food, where maintaining product integrity is essential. By preventing spoilage and preserving flavour, this film reduces waste and boosts consumer trust.

4. Lightweight and Cost-Effective: Despite its strength, PET film is remarkably lightweight, lowering shipping costs and carbon footprints. Its efficiency in material usage translates to savings without compromising performance - a win-win for budget-conscious and eco-aware businesses.

5. Sustainability and Recyclability: As industries pivot toward circular economies, PET film stands out for its recyclability. Many PET films are compatible with existing recycling systems, aligning with global sustainability goals. Innovations like biodegradable variants further cement its role in eco-friendly packaging.

3. Choosing the Right Polyester Film Supplier

The benefits of PET film can only be fully realized when sourced from a trusted polyester film supplier. Factors like manufacturing expertise, quality certifications, and technical support are critical. A reputable supplier ensures consistent material performance, compliance with safety standards (e.g., FDA, ISO), and tailored solutions for specific needs.

4. Why Partner with Garware Hi-Tech Films?

Innovation-driven: They invest in R&D to create films that meet evolving market demands, such as high-barrier coatings for extended shelf life.

Sustainability Commitment: Their eco-conscious production processes and recyclable films support brands in achieving sustainability targets.

Global Standards: With certifications like ISO 9001 and FSSC 22000, they guarantee quality and safety across industries, from food to electronics.

By collaborating with Garware Hi-Tech Films, businesses gain access to PET films that balance performance, aesthetics, and environmental responsibility - key drivers in today’s competitive landscape.

Conclusion

PET film is reshaping flexible packaging with its unmatched durability, clarity, and eco-friendly potential. To maximize these benefits, partnering with an industry leader like Garware is essential. As a forward-thinking polyester film supplier, Garware empowers brands to innovate while meeting sustainability goals.

Ready to elevate your packaging strategy? Explore Garware’s PET film solutions and discover how their expertise can transform your products’ protection, presentation, and planetary impact.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description The Waterproof Mobile Pouch Cover is completely sealed with locking mechanism to save all your precious belongings from dust, rain, water, snow and more. It comes with a neck strap to securely hold the pouch to your body and crystal clear windows on both front and back side makes it perfect for taking pictures, videos and surfing. Back side is fully transparent, so no issues with camera for bigger phones. HOW IS IT BETTER? IDEAL FOR UNDERWATER PHOTOS & VIDEOS Capture underwater photos and videos. A perfect Waterproof mobile pouch cover for underwater photography. Compatible with devices up to 100 mm x 165 mm (clear window 70 mm X 135 mm); Comes with a neck strap for convenient carrying. 100 FEET IPX8 CERTIFIED WATERPROOF IPX8 certificated waterproof, keeping your phone safe, sound and dry under extreme conditions. (Kindly note: The water pressure under certain water depth might affect the operation of touchscreen, please take photos by volume button in this case.) Offers waterproof / snowproof / dirtproof protection for your device while maintaining full touch screen functionality TOUCH FRIENDLY Crystal clear windows on both front and back sides makes it perfect for taking pictures, videos and checking emails; Back side is fully transparent, so no issues with camera for bigger phones. Safety Test Before Using Before using the Waterproof Mobile Pouch Case Cover with your phone, just test it with a dry tissue inside, lock the pouch and put it in a bowl of water for a while. This will help you identify manufacturing defects, if any. UNIVERSAL - XL 2021 Model This pouch fits all smartphones up to 7" screen size. It also doubles up as waterproof dry bag / wallet, to store credit card / passport / cash etc. for beach, fishing, diving and water park activities UNIVERSAL SIZE WATERPROOF CASE: This pouch fits all smartphones; It also doubles up as waterproof dry bag / wallet, to store credit card / [passport / cash etc. for beach, fishing, diving and water park activities. TOUCH FRIENDLY: Crystal clear windows on both front and back sides makes it perfect for taking pictures, videos and checking emails; Back side is fully transparent, so no issues with camera for bigger phones. 100 FEET IPX8 CERTIFIED WATERPROOF: Offers waterproof / snowproof / dirtproof protection for your device while maintaining full touch screen functionality IDEAL FOR UNDERWATER PHOTOS & VIDEOS: Compatible with devices up

to 100 mm x 175 mm (clear window 70 mm X 135 mm); Comes with a neck strap for convenient carrying. SECURE SNAP & LOCK: Features a simple snap and lock access, easy to keep out water, snow, dust, sand, and dirt [ad_2]

0 notes

Text

Dairy Container Market Insights Challenges in the Supply Chain and Raw Material Sourcing

The dairy container market is witnessing rapid transformation due to evolving consumer demands, regulatory requirements, and technological innovations. As sustainability becomes a top priority, manufacturers are focusing on recyclable and biodegradable materials. Additionally, the demand for smart packaging and extended shelf-life solutions is shaping the industry's future. This article explores the latest insights into the dairy container market and its growth trajectory.

The Shift Towards Sustainable Packaging Solutions

Sustainability is a driving force in the dairy container market. Companies are adopting recyclable plastics, plant-based packaging, and reusable containers to minimize environmental impact. Consumers are increasingly preferring brands that offer eco-friendly packaging, pushing the industry toward greener alternatives. Regulatory frameworks supporting sustainability initiatives further accelerate this trend.

Role of Technological Advancements in Packaging

Innovation in packaging technology is reshaping the dairy container market. Modified atmosphere packaging (MAP), aseptic packaging, and vacuum-sealed solutions help extend product shelf life and ensure food safety. Additionally, nanotechnology in packaging enhances barrier properties, reducing spoilage and contamination risks. These advancements improve product quality and distribution efficiency.

Changing Consumer Preferences and Their Impact

Modern consumers seek convenience, safety, and sustainability in dairy packaging. Single-serve portions, resealable containers, and easy-to-use designs are gaining popularity. Additionally, rising health awareness has increased demand for transparent labeling, allowing consumers to make informed decisions about ingredients, nutritional value, and sourcing.

Innovations in Lightweight and Durable Packaging

Lightweight yet durable packaging solutions are gaining traction as they reduce transportation costs and environmental footprint. Companies are developing thin-walled plastic containers, flexible pouches, and reinforced paperboard cartons to optimize efficiency. These solutions enhance sustainability while maintaining the structural integrity of dairy products.

Growth Opportunities in Emerging Markets

Emerging economies present significant opportunities for dairy container manufacturers. Increasing disposable income, urbanization, and changing dietary habits are driving demand for dairy products. Countries in Asia-Pacific, Latin America, and Africa are witnessing a surge in dairy consumption, creating growth prospects for packaging companies looking to expand their presence in these regions.

The Impact of Regulations on Packaging Standards

Government regulations play a critical role in shaping the dairy container market. Policies related to plastic waste reduction, food safety, and labeling standards impact packaging materials and designs. Companies must comply with stringent regulations while ensuring that their packaging solutions meet industry and consumer expectations.

Smart Packaging and Digital Labeling Trends

The rise of smart packaging technologies is transforming the dairy industry. QR codes, NFC tags, and RFID tracking enhance traceability, allowing consumers to access real-time product information. Time-temperature indicators also ensure product freshness, boosting consumer confidence in dairy products. These technologies enhance brand transparency and engagement.

Challenges in the Supply Chain and Raw Material Sourcing

Supply chain disruptions and fluctuating raw material prices pose challenges for dairy container manufacturers. Shortages of sustainable materials and transportation inefficiencies impact production costs. Companies must adopt resilient supply chain strategies, invest in alternative materials, and optimize logistics to maintain competitiveness in the market.

The Future of Customization and Brand Differentiation

Customization is becoming a key strategy for dairy brands looking to differentiate themselves in a competitive market. Digital printing allows brands to create personalized packaging designs, seasonal variations, and interactive elements. Unique branding strategies help companies build customer loyalty and stand out in crowded retail spaces.

Future Growth Potential and Industry Forecast

The dairy container market is poised for continued growth, driven by sustainability efforts, technological advancements, and evolving consumer expectations. Companies that invest in eco-friendly solutions, smart packaging, and efficient logistics will gain a competitive edge. The industry's future will be shaped by innovation, regulatory compliance, and global market expansion.

Conclusion

The dairy container market is undergoing significant changes as manufacturers adapt to sustainability trends, technological innovations, and consumer preferences. The shift towards eco-friendly materials, smart packaging, and extended shelf-life solutions is transforming the industry. Companies that embrace these developments will be well-positioned to thrive in the evolving dairy packaging landscape.

#Dairy Container Market#Dairy Container Market trends#Dairy Container#Dairy milk Container#Dairy Container services#milk Container

0 notes

Text

Vacuum Leak Tester A Vital Tool for Perfect Packaging Integrity

In the highly competitive packaging industry, maintaining airtight seals is crucial—not only to protect product quality but also to ensure consumer safety and regulatory compliance. Even the smallest leak can compromise a product, leading to spoilage, contamination, or loss of consumer trust. To effectively address this challenge, manufacturers rely on a powerful quality control tool—the Vacuum Leak Tester. This essential instrument ensures packaging integrity by quickly detecting leaks, thereby safeguarding products, maintaining brand reputation, and ensuring customer satisfaction.

What is a Vacuum Leak Tester?

A Vacuum Leak Tester is a specialized device used to detect leaks or defects in sealed packages efficiently and accurately. The tester operates by placing the packaged product inside a transparent vacuum chamber and evacuating the air to create a vacuum. If the packaging has any leaks, escaping air or contents will become visible as bubbles during this process. This method allows manufacturers to swiftly identify any defects, ensuring only well-sealed packages leave the production line.

Vacuum leak testers are versatile, capable of testing a variety of packaging types, such as bottles, flexible pouches, cans, blister packs, and other sealed containers.

Why Vacuum Leak Testing is Critical

1. Ensuring Product Safety and Freshness

Industries such as food and beverages, pharmaceuticals, cosmetics, and medical devices heavily depend on airtight packaging to maintain product safety and freshness. Even minor leaks can result in contamination, spoilage, or reduced product effectiveness. For instance, leaks in food packaging can lead to spoilage due to oxygen or moisture ingress, while pharmaceuticals risk contamination or potency loss. Regular vacuum leak testing ensures products remain uncontaminated, fresh, and effective until they reach consumers.

2. Compliance with Industry Regulations

Strict regulatory standards set by organizations like the FDA, ISO, and ASTM govern packaging integrity, particularly in sensitive industries like pharmaceuticals and food production. Non-compliance can result in costly recalls, legal penalties, and severe damage to brand reputation. Vacuum leak testers provide manufacturers with tangible evidence of compliance, making it easier to consistently meet these stringent regulatory requirements and protect their business.

3. Cost Efficiency and Waste Reduction

Undetected packaging leaks can cause significant financial losses due to product spoilage, customer complaints, and recalls. By integrating vacuum leak testing into the packaging process, manufacturers can identify and rectify defective packages early, reducing waste, saving costs, and enhancing overall production efficiency.

Key Benefits of Using Vacuum Leak Testers

Rapid and Precise Leak Detection

Vacuum leak testers offer quick, accurate results, enabling manufacturers to promptly detect and resolve packaging issues. This rapid detection minimizes downtime, maintains high production efficiency, and ensures consistently high packaging standards.

Non-Destructive Testing Method

Unlike some inspection methods that destroy packaging during testing, vacuum leak testing is non-destructive. Tested packages remain undamaged and saleable, significantly reducing waste and production costs.

Versatility Across Packaging Types

Vacuum leak testers can evaluate a wide range of packaging formats, from flexible pouches to rigid containers and bottles. This versatility makes them indispensable for manufacturers managing multiple product lines, ensuring consistent packaging integrity across diverse products.

Enhanced Consumer Trust

Regular vacuum leak testing demonstrates a manufacturer's commitment to product quality, safety, and consumer satisfaction. Consumers who trust that their products are reliably sealed and safe are more likely to remain loyal, strengthening brand reputation and market position.

Why Choose Pacorr Vacuum Leak Testers?

Pacorr Testing Instruments is globally recognized for providing advanced, reliable Vacuum Leak Testers. Here's why Pacorr’s testers are preferred by industries worldwide:

High Accuracy: Pacorr Vacuum Leak Testers deliver precise and reliable results, swiftly detecting even the smallest leaks.

User-Friendly Design: Pacorr testers feature intuitive controls, clear visibility through transparent chambers, and automated processes, making leak testing straightforward and efficient.

Durability and Robustness: Constructed from high-quality materials, Pacorr testers are built to withstand demanding industrial conditions, ensuring long-term durability and consistent performance.

Regulatory Compliance: Pacorr Vacuum Leak Testers comply with international standards, simplifying adherence to stringent regulatory requirements.

Comprehensive Customer Support: Pacorr offers extensive technical support, training, and calibration services, ensuring customers maximize the value of their testing equipment.

Industry Applications

Food and Beverage Industry

Vacuum leak testers help maintain product freshness by detecting leaks in food packaging, preventing spoilage and contamination. For beverages, they ensure containers retain carbonation and prevent contamination.

Pharmaceutical Industry

Vacuum leak testing is essential in pharmaceuticals to maintain medication potency, safety, and compliance with strict regulatory standards. Reliable leak detection protects consumer health and reduces recall risks.

Cosmetics Industry

Leak testing in cosmetics packaging prevents contamination and maintains product integrity, which is essential for a premium brand image and customer satisfaction.

Medical Devices and Healthcare

Airtight packaging is critical for medical devices to ensure sterility and patient safety. Vacuum leak testers confirm packaging integrity, ensuring regulatory compliance and safeguarding patient health.

Conclusion

Incorporating a Vacuum Leak Tester Price into your packaging quality control processes is crucial for ensuring product safety, regulatory compliance, cost efficiency, and consumer trust. Pacorr’s advanced vacuum leak testers offer unmatched accuracy, durability, and ease of use, enabling manufacturers to consistently deliver secure, high-quality packaging.

0 notes

Text

Transparent Pouches Manufacturer | Plastic Pouch | Solos Polymers

We are one of the leading Transparent Pouches Manufacturer & Supplier, who offers high transparent pouches in various shapes and sizes. Contact Us Now.

#TransparentStandUpPouches#TransparentPouchesSupplier#TransparentPouches#TransparentPouchesManufacturer

0 notes

Text

Baby Drink Market – Industry Trends and Forecast to 2028 Size: Growth, Share, Value, Trends, and Analysis

"Baby Drink Market Size And Forecast by 2028

According to Data Bridge Market Research The baby drink market is expected to witness market growth at a rate of 9.0% in the forecast period of 2021 to 2028 and is expected to reach USD 107.39 billion by 2028. Data Bridge Market Research report on baby drink market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecast period while providing their impacts on the market’s growth. The increase in the middle class population is escalating the growth of baby drink market.

Our comprehensive Baby Drink Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://www.databridgemarketresearch.com/reports/global-baby-drinks-market

**Segments**

- **Product Type** - Infant Formula - Baby Juice - Baby Electrolyte - Others

- **Distribution Channel** - Supermarkets/Hypermarkets - Convenience Stores - Online Retail - Others

- **Packaging Type** - Bottles - Cartons - Pouches - Others

- **Age Group** - 0-6 Months - 6-12 Months - 12-24 Months - 24 Months and Above

The baby drink market is segmented based on product type, distribution channel, packaging type, and age group. The product type segment includes infant formula, baby juice, baby electrolyte, and others. Infant formula dominates this segment due to its essential nutrients catering to the needs of babies. Baby juice and electrolyte segments are witnessing growth due to the rising demand for healthier alternatives. The market is also segmented by distribution channels such as supermarkets/hypermarkets, convenience stores, online retail, and others. With the increasing trend of online shopping, the online retail segment is showing significant growth. In terms of packaging type, bottles, cartons, and pouches are commonly used to package baby drinks. The age group segmentation includes categories like 0-6 months, 6-12 months, 12-24 months, and 24 months and above, catering to the specific nutritional requirements of babies at different developmental stages.

**Market Players**

- Nestle S.A. - Mead Johnson & Company, LLC - Abbott - Danone - Reckitt Benckiser Group plc - Beingmate - Hain Celestial - The Kraft Heinz Company - Hero Group - FrieslandCampina

The key players in the global baby drink market include Nestle S.A., Mead Johnson & Company, LLC, Abbott, Danone, Reckitt Benckiser Group plc, Beingmate, Hain Celestial, The Kraft Heinz Company, Hero Group, and FrieslandCampina. These companies are actively involved in product innovation, strategic partnerships, and mergers and acquisitions to maintain their market position and meet the evolving consumer demands. Nestle S.A. and Danone are among the prominent players, offering a wide range of baby drinks with a strong global presence. Abbott and Mead Johnson focus on infant formula products, ensuring high quality and safety standards. With increasing competition, market players are investing in research and development to introduce new flavors, organic options, and convenient packaging solutions to attract consumers and enhance brand loyalty.

https://www.databridgemarketresearch.com/reports/global-baby-drinks-market The global baby drink market is poised for significant growth in the coming years as parents increasingly prioritize the health and nutrition of their infants. One emerging trend in the market is the growing demand for organic and natural baby drinks due to concerns about artificial ingredients and additives. Manufacturers are responding to this trend by introducing organic options and highlighting the use of natural ingredients in their products. This shift towards cleaner labels and transparent sourcing is resonating with health-conscious consumers and driving growth in the organic baby drink segment.

Another key trend shaping the baby drink market is the emphasis on convenience and on-the-go consumption. Busy lifestyles and the need for portable options have led to the popularity of baby drinks in handy pouch packaging. Pouches offer convenience, ease of use, and portability, making them a preferred choice for parents looking for convenient options that fit into their busy schedules. As a result, manufacturers are increasingly investing in innovative packaging solutions to enhance the convenience and functionality of their products, driving growth in the pouch packaging segment.

Furthermore, personalized nutrition is becoming a prominent trend in the baby drink market, with parents seeking customized solutions to meet their child's specific dietary needs and preferences. Manufacturers are leveraging technology and data-driven insights to offer personalized recommendations and customized products tailored to individual requirements. This personalization trend is expected to gain traction in the coming years, offering opportunities for brands to engage with consumers on a more personalized level and build brand loyalty through tailored offerings.

Moreover, the digitalization of retail channels is reshaping the distribution landscape of the baby drink market. E-commerce platforms are becoming increasingly popular for purchasing baby drinks, offering a convenient shopping experience, a wide range of products, and home delivery options. The online retail segment is witnessing rapid growth as consumers embrace the convenience of shopping online, especially amidst the COVID-19 pandemic, which has accelerated the shift towards online shopping across various industries. This digital transformation is creating new opportunities for market players to expand their reach, engage with a broader audience, and enhance the overall shopping experience for consumers.

In conclusion, the global baby drink market is experiencing a shift towards organic and natural products, convenience-driven packaging solutions, personalized nutrition offerings, and digitalized distribution channels. These trends are reshaping the market landscape, presenting opportunities for innovation, differentiation, and growth for manufacturers and retailers in the baby drinks sector. By staying abreast of these evolving trends and consumer preferences, companies can position themselves for success in this competitive and dynamic market.**Segments**

Global Baby Drink market, By Product (Baby Formula, Baby Juice, Baby Electrolyte), Application (36 months), Distribution Channel (Supermarket and Hypermarket, Pharmacies and Medical Stores, Specialty Stores, Hard Discounter Stores, Online, Others), Country (U.S., Canada, Mexico, Germany, Sweden, Poland, Denmark, Italy, U.K., France, Spain, Netherland, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, New Zealand, Vietnam, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Brazil, Argentina, Rest of South America, UAE, Saudi Arabia, Oman, Qatar, Kuwait, South Africa, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

- Baby Formula: - Suitable for infants with essential nutrients. - Baby Juice: - Provides a healthier alternative with natural ingredients. - Baby Electrolyte: - Offers hydration and replenishment for babies. - Application: - Catering to different age groups for specific nutritional needs. - Distribution Channel: - Various channels ensuring accessibility for consumers.

**Market Players**

The major players covered in the baby drink market report are Nestle, The Kraft Heinz Company, Mead Johnson & Company, LLC., Danone S.A., Beingmate Group Co., Ltd., CAMPBELL SOUP COMPANY., Abbott, Arla Foods amba, D. Sign Softech Private Limited, Hain Celestial, Dana Dairy, FrieslandCampina, HIPP, ORHEI-VIT, Freed Foods, Inc., Holle baby food AG, Nature's One, Organix Brands Limited, NANNYcare Ltd., among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA), and South America separately. DBMR analysts understand competitive strengths and provide a competitive analysis for each competitor separately.

The global baby drink market is witnessing significant growth driven by consumer preferences for healthier options and convenient solutions for infant nutrition. The inclusion of organic and natural ingredients in baby drinks is gaining traction as consumers become more conscious of what they feed their infants. Manufacturers are responding to this trend by introducing organic variants and emphasizing clean labels to meet the increasing demand for transparent sourcing practices. The market for baby drinks segmented by age groups ensures that products cater to the specific nutritional requirements of infants at different developmental stages, providing a tailored approach to infant nutrition.

A key trend in the baby drink market is the focus on convenience and on-the-go consumption, leading to the popularity of pouch packaging due to its ease of use and portability. This packaging solution aligns with the busy lifestyles of parents, offering a convenient option for feeding infants while on the move. Manufacturers are investing in innovative packaging designs to enhance functionality and appeal to consumers looking for practical solutions that fit their daily routines. Personalized nutrition is emerging as a prominent trend, with parents seeking customized products that address their child's individual dietary preferences and needs, driving manufacturers to offer tailored solutions through technological advancements.

The digitalization of retail channels is reshaping the distribution landscape of the baby drink market, with e-commerce platforms gaining prominence as consumers opt for the convenience of online shopping. The online retail segment is experiencing rapid growth, further accelerated by the shift towards digital platforms during the COVID-19 pandemic. This transformation provides opportunities for market players to expand their reach, engage with a wider audience, and enhance the overall shopping experience for consumers. By staying abreast of these trends and consumer preferences, companies can capitalize on the evolving market dynamics and drive innovation in the baby drink sector to meet the demands of health-conscious parents globally.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies in Baby Drink Market : https://www.databridgemarketresearch.com/reports/global-baby-drinks-market/companies

Key Questions Answered by the Global Baby Drink Market Report:

What is the current state of the Baby Drink Market, and how has it evolved?

What are the key drivers behind the growth of the Baby Drink Market?

What challenges and barriers do businesses in the Baby Drink Market face?

How are technological innovations impacting the Baby Drink Market?

What emerging trends and opportunities should businesses be aware of in the Baby Drink Market?

Browse More Reports:

https://www.databridgemarketresearch.com/reports/global-industrial-cloud-platform-market-for-automation-markethttps://www.databridgemarketresearch.com/reports/global-wireless-ev-charging-markethttps://www.databridgemarketresearch.com/reports/global-automotive-light-vehicle-sensors-markethttps://www.databridgemarketresearch.com/reports/global-image-guided-radiation-therapy-markethttps://www.databridgemarketresearch.com/reports/global-gelcoat-market

Data Bridge Market Research:

☎ Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 982

✉ Email: [email protected]"

#Baby Drink Market – Industry Trends and Forecast to 2028 Size: Growth#Share#Value#Trends#and Analysis

0 notes

Text

Find the Perfect Courier Bag at Euphoria Packaging Private Limited

Rapidly growing packaging industry, versatility, security, and sustainability are key factors driving demand. Euphoria Packaging Private Limited has established itself as a leading manufacturer by offering a wide array of products designed to meet the evolving needs of modern businesses. From eco-friendly courier bags to specialized bank deposit bags, Euphoria Packaging is setting new standards in functionality and innovation.

Euphoria Packaging Private Limited Founded in 2012 with a focus to serve the need of the packing industry Euphoria Packaging Private Limited is reckoned as the dominant Manufacturer firm of best quality.

Euphoria Packaging, Courier Bag Manufacturer, Air Bubble Roll, Eco-Friendly Courier Bags, Plastic Draw Strings, Peel and Seal Bags, Poly Bubble Mailer with Document Pouch, Clear Wicketed Mailers, Suffocation Warning Bags, Bank Deposit / Gold Loan Bags. Sequentially Numbered Bags, LDPE Bubble Envelope, Printed Tamper Proof Bags, Wicket Bags, Poly Bubble Mailers, Poly Mailer Bags, LDPE Courier Flap Bags, LDPE Reclosable Plastic Bag, Plastic Cash Packaging Envelope, Plain Plastic Mail Envelope, Tamper Evident Envelope, Online Courier Bag, Security Envelope, Plastic A4 Size Envelope, LDPE Security Courier Bags, Printed Courier Bag, Tamper Proof Security Bags, Plain Tear Resistant Courier Bags, LDPE Tamper VOID Envelope, Plain LDPE Bubble Envelope, Tamper Proof Courier Bags, E Commerce Courier Bag.

Here’s an overview of some of the key products that define the company’s exceptional product lineup:

1. Eco-Friendly Courier Bags

Euphoria Packaging prioritizes sustainability by offering eco-friendly courier bags made from biodegradable and recyclable materials. These bags are designed to minimize environmental impact without compromising on durability or security. Ideal for e-commerce businesses looking to reduce their carbon footprint, these bags offer a perfect blend of strength and responsibility.

2. Air Bubble Rolls

For industries dealing with fragile products, air bubble rolls are a must-have. Euphoria Packaging provides high-quality bubble rolls that offer superior protection during transit, ensuring that delicate items reach their destination intact. Lightweight and easy to use, these rolls provide a reliable solution for minimizing damage.

3. Peel and Seal Bags

4. Poly Bubble Mailers with Document Pouches

Poly bubble mailers with integrated document pouches are an innovative solution for safely shipping items while keeping accompanying paperwork secure and accessible. These mailers offer added protection with built-in cushioning and a separate compartment for documents, making them ideal for industries requiring detailed shipping information.

5. Clear Wicketed Mailers

Efficiency in packaging operations is essential for high-volume businesses. Clear wicketed mailers streamline the packing process, allowing for quick and organized packaging. Their transparent design ensures easy identification of contents, making them a go-to choice for industries that prioritize productivity.

6. Suffocation Warning Bags

Safety and compliance are critical in packaging. Euphoria’s suffocation warning bags meet industry safety standards while maintaining product visibility. These bags are ideal for retail packaging, providing a clear view of the product while ensuring that users are aware of safety precautions.

7. Bank Deposit and Gold Loan Bags

Specialized security solutions are a hallmark of Euphoria Packaging’s offerings. Bank deposit and gold loan bags are designed to protect sensitive items with tamper-evident features and high-strength materials. These bags offer peace of mind to financial institutions and businesses handling valuable or confidential items.

Innovating for a Sustainable Future

Euphoria Packaging continues to push the boundaries of innovation by offering versatile, secure, and environmentally friendly packaging solutions. Whether it’s protecting delicate items with air bubble rolls or providing eco-conscious courier bags, the company remains committed to meeting the evolving needs of its clients.

For businesses looking to enhance efficiency, security, and sustainability, Euphoria Packaging offers the perfect combination of quality and reliability.

Factory Address: Euphoria Packaging Private Limited Survey №396 Paiki-4, Block-A/3, GSL Nova Compound, Sarkhej Bavla Highway, Moraiya Village, Gujarat — 382213. Ahmedabad, India

Corporate Address: 305 Omkar The Summit, Off western express highway, Vile Parle (East), Mumbai- 400057 Maharashtra, India

Meesho & Other Product : +91–8652780000 || [email protected]

Flipkart & Other Product : +91–8652860000 || [email protected]

0 notes

Text

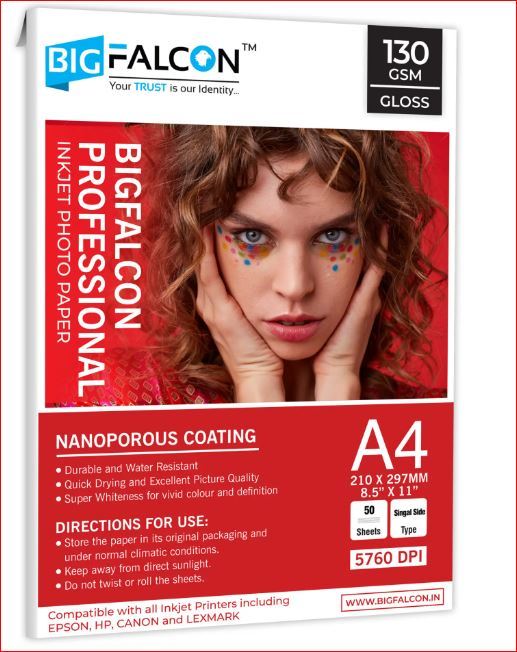

Bigfalcon Digi Print A4size Photo Paper For Your Extreme Needs

A4 size photo paper is nowadays highly practiced for digital printing, and one need to know its features to get all kind of benefits. It is developed to exceed studio standards, and Bigfalcon offers excellent beauty and seamless, realistic output. Premium resin-coated waterproof paper instantly dries and prints the image or picture without signs of fading.

A4 Size Photo Paper

Compatible paper

The photo paper is perfectly suited to most desktops and large-format printers. In addition to this, you will get experienced of uninterrupted services that makes you’re buying this kind of printing machine highly make sense and choice.

High grade realistic result

A4size photo paper is always recommended for providing printouts of your copy with higher resolution and clarity of picture. You will be amazed to see the amount of durability and flexibility it offers to your printing experience.

Buying an A4size photo paper will indeed give you all types of printing benefits as you can scan and take screenshots to work effectively engaged with your official work successfully. A4 size photo paper is recommended simply because it is the perfect size to get photos and images as per the requirements of your business brochures, fliers and visiting or business cards. A4 size usually gives you the best size to render more appealing images and turn them into virtual business objectives in a professional manner.

High-grade realistic image you can generate with A4 size photo paper. Bigfalcon inkjet paper comes in different variants and provides a premium and affordable range of photo paper for casual project deliberation.

Photograph lasts for a long time

The fade-resistant feature of photo paper is meant to protect photographs from gases and light and keep important memories protected for years. Your appealing and eye-catching photos look, and texture brings the photos class and excellence. Excellent paper and affordable cost are some of the pros of A4size photo paper extensively practiced for creating a new benchmark in printing services.

In conclusion

A4size photo paper is generally practiced and preferred for businesses as they work on and try to make their business logo appealing and captivate visitors or customers' attention. With that, A4size photo paper is highly preferred and worth a lot. Try to bring your images and photos real and trendiest.

#Glossy Photo Paper#Kodak Photo Paper#A4 Size Photo Paper#Waterproof photo paper#Lamination Pouch A4 Size#PVC Tray Manufacturer#Transparent sticker sheet#Sticker photo paper#Premium Lamination Pouch#Aadhar Pvc Card

0 notes

Text

Spout Pouches - The Most Convenient Flexible Packaging

In recent times the spout pouch is the most effective flexible packaging solution in the market. Buy spout pouches online in bulk or wholesale that can be best for all types of liquid products, be it ketchup, sauces, soup, oil, juice, and even hand wash have transferred from traditional packaging methods to the more contemporary, and more stylish, spout pouch.

#spout pouch#spout pouches#buy spout pouch#spout pouch online#spout pouch wholesale#Spout Pouch Suppliers#spout pouch packaging#spout pouch manufacturers#transparent spout pouch#spout pouch price#silver spout pouch#20 mm side spout silver pouch

0 notes

Text

Diverse Packaging Methods for a Sustainable and Secure Future

In the rapidly growing packaging industry, versatility, security, and sustainability are key factors driving demand. Euphoria Packaging Private Limited has established itself as a leading manufacturer by offering a wide array of products designed to meet the evolving needs of modern businesses. From eco-friendly courier bags to specialized bank deposit bags, Euphoria Packaging is setting new standards in functionality and innovation.

Here’s an overview of some of the key products that define the company’s exceptional product lineup:

1. Eco-Friendly Courier Bags

Euphoria Packaging prioritizes sustainability by offering eco-friendly courier bags made from biodegradable and recyclable materials. These bags are designed to minimize environmental impact without compromising on durability or security. Ideal for e-commerce businesses looking to reduce their carbon footprint, these bags offer a perfect blend of strength and responsibility.

2. Air Bubble Rolls

For industries dealing with fragile products, air bubble rolls are a must-have. Euphoria Packaging provides high-quality bubble rolls that offer superior protection during transit, ensuring that delicate items reach their destination intact. Lightweight and easy to use, these rolls provide a reliable solution for minimizing damage.

3. Peel and Seal Bags

Security and convenience come together in Euphoria’s peel and seal bags. These bags feature a strong adhesive strip that ensures packages remain securely sealed throughout their journey. The peel-and-seal mechanism saves time and eliminates the need for additional sealing materials, making it a preferred choice for businesses in retail and logistics.

4. Poly Bubble Mailers with Document Pouches

5. Clear Wicketed Mailers

Efficiency in packaging operations is essential for high-volume businesses. Clear wicketed mailers streamline the packing process, allowing for quick and organized packaging. Their transparent design ensures easy identification of contents, making them a go-to choice for industries that prioritize productivity.

6. Suffocation Warning Bags

Safety and compliance are critical in packaging. Euphoria’s suffocation warning bags meet industry safety standards while maintaining product visibility. These bags are ideal for retail packaging, providing a clear view of the product while ensuring that users are aware of safety precautions.

7. Bank Deposit and Gold Loan Bags

Specialized security solutions are a hallmark of Euphoria Packaging’s offerings. Bank deposit and gold loan bags are designed to protect sensitive items with tamper-evident features and high-strength materials. These bags offer peace of mind to financial institutions and businesses handling valuable or confidential items.

Innovating for a Sustainable Future

Euphoria Packaging continues to push the boundaries of innovation by offering versatile, secure, and environmentally friendly packaging solutions. Whether it’s protecting delicate items with air bubble rolls or providing eco-conscious courier bags, the company remains committed to meeting the evolving needs of its clients.

For businesses looking to enhance efficiency, security, and sustainability, Euphoria Packaging offers the perfect combination of quality and reliability.

Euphoria Packaging Private Limited Founded in 2012 with a focus to serve the need of the packing industry Euphoria Packaging Private Limited is reckoned as the dominant Manufacturer firm of best quality.

Euphoria Packaging, Courier Bag Manufacturer, Air Bubble Roll, Eco-Friendly Courier Bags, Plastic Draw Strings, Peel and Seal Bags, Poly Bubble Mailer with Document Pouch, Clear Wicketed Mailers, Suffocation Warning Bags, Bank Deposit / Gold Loan Bags.

Sequentially Numbered Bags, LDPE Bubble Envelope, Printed Tamper Proof Bags, Wicket Bags, Poly Bubble Mailers, Poly Mailer Bags, LDPE Courier Flap Bags, LDPE Reclosable Plastic Bag, Plastic Cash Packaging Envelope, Plain Plastic Mail Envelope, Tamper Evident Envelope, Online Courier Bag, Security Envelope, Plastic A4 Size Envelope, LDPE Security Courier Bags, Printed Courier Bag, Tamper Proof Security Bags, Plain Tear Resistant Courier Bags, LDPE Tamper VOID Envelope, Plain LDPE Bubble Envelope, Tamper Proof Courier Bags, E Commerce Courier Bag,

Factory Address: 305, Omkar The Summit, Level 3, Nr Western Express Highway, Vileparle (East) — Mumbai 400 057.

PHONE : 8652880000

EMAIL : [email protected]

0 notes

Text

Snack Bag Market Share Analysis: Key Trends, Growth Drivers, and Competitive Landscape for 2024-2030

The snack bag market has witnessed steady growth due to increasing demand for on-the-go food packaging solutions. Consumers are leaning toward convenience, sustainability, and innovative packaging designs that enhance shelf appeal and functionality. This article delves into the market share distribution, key players, trends, and the factors influencing growth in this industry.

Market Overview and Growth Drivers

The global snack bag market is expanding, driven by changing consumer lifestyles, urbanization, and the rising popularity of packaged snacks. With the increasing demand for single-serving portions and resealable packaging, manufacturers are investing in new materials and designs to meet customer preferences.

Key Growth Factors:

Convenience and Portability: Consumers seek easy-to-carry snack bags suitable for travel, work, and school.

Sustainable Packaging Demand: Growing environmental awareness is pushing brands toward biodegradable and recyclable materials.

E-Commerce Influence: The surge in online snack sales has increased the need for durable, lightweight, and visually appealing packaging.

Innovative Packaging Technologies: Advancements such as vacuum-sealed pouches, resealable zippers, and smart packaging are gaining traction.

Branding and Marketing Strategies: Companies leverage packaging as a crucial branding tool, emphasizing attractive designs and product transparency.

Market Share by Region

North America: The region dominates the market due to high snack consumption and demand for sustainable packaging.

Europe: Sustainability regulations and eco-friendly innovations drive growth in this market.

Asia-Pacific: Rapid urbanization and a growing middle-class population contribute to the expansion of snack packaging solutions.

Latin America & Middle East: Increasing disposable income and demand for western snack brands fuel market penetration.

Competitive Landscape

The snack bag market features key players, including:

Amcor Plc

Mondi Group

Sealed Air Corporation

Berry Global Inc.

Smurfit Kappa Group

These companies focus on material innovation, cost efficiency, and sustainable solutions to strengthen their market position.

Future Trends and Opportunities

Edible Packaging: Companies are exploring dissolvable and edible snack bags for an eco-friendly approach.

AI-Driven Customization: Smart packaging solutions featuring QR codes and AI-based personalization are gaining traction.

Biodegradable Alternatives: The market is expected to witness increased adoption of plant-based and compostable packaging solutions.

Conclusion

The snack bag market continues to grow, fueled by evolving consumer preferences and packaging innovations. Companies investing in sustainable materials, functional designs, and digital branding will gain a competitive edge in the dynamic market landscape.

0 notes