#Top Yarn Weaving Machine Manufacturers

Explore tagged Tumblr posts

Text

What Makes a Yarn Weaving Machine Essential in Textile Production?

The success of any manufacturing process, especially textile production, depends largely on the machinery employed in carrying out the task. One of the many machines involved in textile production is the weaving machine. We can say that yarn-weaving machines are very useful and are actually needed in the process of textile production. If you are in search of Yarn Weaving Machine Manufacturers, Dashmesh Jacquard is one of the leading & registered manufacturers, supplier eligible under T.U.F.S. for weaving and allied machinery like looms, jacquards, warping & winding machines.

Read More: What Makes a Yarn Weaving Machine Essential in Textile Production?

#Yarn Weaving Machine Manufacturers#Best Yarn Weaving Machine Manufacturers#Top Yarn Weaving Machine Manufacturers

0 notes

Text

TEXTILE DESIGN IN 2023-24

Overview of top textile importer, exporter countries & manufacturing industries. Textile design is the art of creating designs for woven, knitted, or printed fabrics. It is an integral part of the textile industry, which encompasses the production of fibers, yarns, fabrics, and finished textile products. Textile design is a vast field that encompasses a wide range of techniques and processes, including drawing, painting, printing, weaving, and embroidery. In this article, we will explore the history of textile design, the various techniques used in textile design, and the current trends in the field. History of Textile Design Textile design has a long and rich history that dates back to prehistoric times. The first textiles were made by hand using natural fibers such as flax, cotton, and wool. These fibers were spun into yarn and woven into fabrics using simple looms. Textiles were used for clothing, bedding, and household items such as curtains and tablecloths. Over time, textile design became more complex as new techniques and materials were developed. The introduction of the spinning wheel in the Middle Ages allowed for the production of finer and more even yarns. The invention of the Jacquard loom in the 18th century enabled the production of intricate patterns and designs. The Industrial Revolution in the 19th century brought about significant changes in the textile industry, with the introduction of mechanized production methods. In the 20th century, textile design became an art form in its own right. The development of new synthetic fibers such as nylon and polyester allowed for new possibilities in textile design. The Bauhaus school, founded in Germany in 1919, played a significant role in the development of modern textile design. The school's emphasis on functional design and the use of new materials and techniques had a profound influence on the field. Techniques Used in Textile Design Textile design encompasses a wide range of techniques and processes. Some of the most common techniques used in textile design include: Drawing and Painting: Many textile designs begin as drawings or paintings. Designers use a variety of media, including pencil, pen, ink, and watercolor, to create designs that are then transferred to fabric. Printing: Printing is a common technique used in textile design. Designs are created on paper using a variety of techniques, such as block printing, screen printing, and digital printing. The designs are then transferred onto fabric using heat or pressure. Weaving: Weaving is the process of interlacing two or more sets of yarns or threads at right angles to create a fabric. Weaving can be done by hand on a loom or by machine. Knitting: Knitting is a technique used to create fabrics by interlocking loops of yarn. Knitting can be done by hand or by machine. Embroidery: Embroidery is the art of decorating fabric or other materials with needle and thread. It is often used to add texture and dimension to textile designs. Current Trends in Textile Design Textile design is a constantly evolving field, with new techniques and materials being developed all the time. Some of the current trends in textile design include: Sustainability: The textile industry is one of the most polluting industries in the world, and there is a growing trend towards sustainable textile design. This includes the use of organic and recycled materials, as well as the development of eco-friendly production methods. Digital Printing: Digital printing is a relatively new technique in textile design that allows designers to create complex designs with a high level of detail. It is also more environmentally friendly than traditional printing methods, as it uses less water and produces less waste. 3D Printing: 3D printing is a cutting-edge technology that is being used in textile design to create innovative fabrics with a variety of textures and shapes. Smart Textiles: Smart textiles are fabrics that are designed to be interactive and responsive. Smart Textiles: Smart textiles are fabrics that are designed to be interactive and responsive. They incorporate electronic components such as sensors, actuators, and microcontrollers to enable the fabric to sense and respond to its environment. Smart textiles can be used in a wide range of applications, from fashion to medical devices. For example, smart textiles can be used in clothing to monitor vital signs and adjust temperature, or in bedding to monitor sleep patterns and adjust the bed's firmness. Innovation in Materials: There is a growing trend towards innovation in materials in textile design. Designers are exploring new materials, such as sustainable and bio-based materials, to create fabrics with unique properties. For example, fabrics made from bamboo, soy, or hemp are becoming more popular due to their sustainable and eco-friendly properties. Mixing of Textures and Prints: There is a trend towards mixing different textures and prints in textile design. Designers are using contrasting textures and prints to create bold and visually striking designs. This trend is evident in fashion, where designers are using a combination of textures such as silk and velvet or prints such as stripes and florals to create unique and eye-catching garments. Digital Fabrication: Digital fabrication is the use of digital tools such as computer-aided design (CAD) and 3D printing to create textiles. This technique allows designers to create complex designs with a high degree of precision and accuracy. Digital fabrication is particularly useful for creating one-of-a-kind textiles or small production runs. Collaboration and Interdisciplinary Work: Collaboration and interdisciplinary work are becoming increasingly important in textile design. Designers are working with scientists, engineers, and other professionals to develop new materials and technologies. This collaborative approach is leading to innovative solutions and new possibilities in textile design. Textile design is a dynamic and constantly evolving field. From the early hand-woven textiles to the cutting-edge smart textiles of today, textile design has come a long way. The field encompasses a wide range of techniques and processes, from drawing and painting to digital fabrication and smart textiles. With the growing focus on sustainability and innovation, textile design is poised to continue to evolve and shape the future of fashion, interior design, and other related industries. TOP TEXTIL EXPORTER COUNTRY The textile industry is a global industry, with many countries producing and exporting textiles. The top textile exporting countries in the world are: - China: China is the world's largest exporter of textiles, accounting for around 35% of global textile exports. The country has a strong manufacturing base and is known for its production of cotton, silk, and woolen textiles. - India: India is the second-largest exporter of textiles in the world, with a share of around 12% of global textile exports. The country is known for its production of cotton textiles, including handloom textiles, and is also a significant exporter of silk and woolen textiles. - Bangladesh: Bangladesh is the third-largest exporter of textiles, with a share of around 6% of global textile exports. The country is known for its production of low-cost cotton textiles and is a major supplier to many western clothing brands. - Vietnam: Vietnam is the fourth-largest exporter of textiles, accounting for around 5% of global textile exports. The country has a growing textile industry and is known for its production of cotton and synthetic textiles. - Turkey: Turkey is the fifth-largest exporter of textiles, with a share of around 4% of global textile exports. The country has a well-established textile industry and is known for its production of high-quality cotton textiles and home textiles. Other significant textile exporting countries include Pakistan, Italy, Germany, Indonesia, and the United States. The textile industry plays an important role in the economies of these countries, providing employment opportunities and contributing to the overall economic growth. TOP TEXTILE IMPORTER COUNTRIES The global textile trade is driven by demand from textile importing countries that rely on textile imports to meet their domestic demand. The top textile importing countries in the world are: - United States: The United States is the world's largest textile importer, accounting for around 16% of global textile imports. The country has a significant textile industry but also relies on imports to meet the demand for a wide range of textile products. - Germany: Germany is the second-largest textile importer, with a share of around 9% of global textile imports. The country has a well-established textile industry but also imports a significant amount of textiles to meet the demand for high-quality fabrics. - Japan: Japan is the third-largest textile importer, accounting for around 8% of global textile imports. The country has a significant textile industry but also imports textiles to meet the demand for a wide range of consumer products, including clothing and home textiles. - United Kingdom: The United Kingdom is the fourth-largest textile importer, with a share of around 6% of global textile imports. The country has a significant textile industry but also imports a significant amount of textiles to meet the demand for a wide range of products. - France: France is the fifth-largest textile importer, accounting for around 4% of global textile imports. The country has a significant textile industry but also imports textiles to meet the demand for high-quality fabrics and luxury goods. Other significant textile importing countries include Italy, Spain, Canada, Russia, and China. The textile industry plays an important role in the economies of these countries, providing employment opportunities and contributing to the overall economic growth. TOP TEXTIL MANUFACTURING COMPANY The textile manufacturing industry is a highly competitive industry with many companies vying for market share. The top textile manufacturing companies in the world are: - China National Textile and Apparel Council (CNTAC): CNTAC is the world's largest textile manufacturing company. It is a state-owned enterprise that has a dominant position in the Chinese textile industry. CNTAC operates a large number of textile mills and produces a wide range of textile products, including cotton, silk, wool, and synthetic fabrics. - Indorama Ventures: Indorama Ventures is a global chemical and textile manufacturing company with a presence in more than 30 countries. The company produces a wide range of textile products, including polyester, nylon, and spandex fabrics. - Luthai Textile: Luthai Textile is a leading textile manufacturing company based in China. The company produces a wide range of cotton and polyester fabrics, including high-quality shirting fabrics. - Vardhman Textiles: Vardhman Textiles is one of the largest textile manufacturing companies in India. The company produces a wide range of cotton and synthetic fabrics, including home textiles, garments, and yarns. - Hyosung Corporation: Hyosung Corporation is a South Korean company that produces a wide range of textile products, including polyester, nylon, and spandex fabrics. The company has a significant global presence and operates textile mills in several countries. Other significant textile manufacturing companies include Toray Industries, Inc., Teijin Limited, Milliken & Company, and Arvind Limited. These companies are known for their high-quality textile products, innovative technologies, and sustainable manufacturing practices. TOP 10 BEST DIGITAL TEXTILE DESIGN COMPANIES The textile industry has rapidly adopted digital technologies, leading to the emergence of several digital textile design companies. The top 11 best digital textile design companies are:

- Mahashankh Design: Mahashankh Design is a India-based company that offers world most complex & convertible digital designs services in two format 1. Shared Design : in Shared Design copyright of design will remains to mahashankh design before the payment & After the payment only they have right to use in personal projects. 2. Dedicated Design : in Dedicated Design all rights will be goes to customer after payment . - Spoonflower: Spoonflower is a US-based company that offers digital printing services for custom fabric, wallpaper, and gift wrap designs. The company's platform allows customers to upload their designs and have them printed on a range of fabrics. - Printful: Printful is a Latvian-based company that offers on-demand printing and fulfillment services for custom apparel, home decor, and accessories. The company's platform allows customers to upload their designs and have them printed on a range of products. - Patternbank: Patternbank is a UK-based company that provides trend forecasting and digital textile design services to the fashion and textile industries. The company's platform offers a range of design tools and resources to help designers create unique and innovative designs. - Kornit Digital: Kornit Digital is an Israeli-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints. - Lectra: Lectra is a French-based company that offers software and hardware solutions for the fashion and textile industries. The company's platform includes design software, cutting machines, and automation tools designed to help manufacturers improve their production efficiency. - Epson: Epson is a Japanese-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints. - EFI: EFI is a US-based company that offers software and hardware solutions for the textile industry. The company's platform includes design software, printers, and automation tools designed to help manufacturers improve their production efficiency. - AVA CAD/CAM Group: AVA CAD/CAM Group is a UK-based company that provides digital textile design and print solutions to the fashion and textile industries. The company's platform includes design software, color management tools, and production planning tools designed to help textile manufacturers and designers improve their efficiency. - Mutoh: Mutoh is a Japanese-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints. - HP: HP is a US-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints. These digital textile design companies are known for their innovative solutions and their ability to help designers and manufacturers create unique and high-quality textile products. Read the full article

3 notes

·

View notes

Text

Indonesia Textile Manufacturing Market Size, Growth, and Trends Forecast 2024-2032

Indonesia Textile Manufacturing Market Overview

Base Year: 2023

Historical Years: 2018-2023

Forecast Years: 2024-2032

Market Growth Rate: 5.30% (2024-2032)

Growing demand for apparel, coupled with government support for the textile industry, is driving the expansion of Indonesia's textile manufacturing market. According to the latest report by IMARC Group, Indonesia textile manufacturing market size is projected to exhibit a growth rate (CAGR) of 5.30% during 2024-2032.

Indonesia Textile Manufacturing Industry Trends and Drivers:

The Indonesia textile manufacturing market is expanding rapidly, owing to several interconnected factors. Primarily, the market is driven by cheap labor as well as the wealth of natural resources across the nation. Besides this, the growing demand for clothing and textiles both domestically and abroad is a major driver of market expansion. Meanwhile, Indonesia’s strategic location and strong trade relationships enable it to export textiles to key markets, including the United States, Europe, and Asia. Furthermore, the rising demand for versatile and high-quality fabrics for applications in fashion, home textiles, and technical textiles is thereby bolstering the growth of the Indonesia textile manufacturing market. Additionally, the initiatives of government bodies, such as tax incentives and investment in industrial zones, are fostering the development of the textile industry.

Emerging trends in the Indonesia textile manufacturing market include the adoption of cutting-edge technologies like automation and digital printing to improve production efficiency and product quality. In addition to these factors, the increasing focus on sustainability is also shaping the market, with manufacturers adopting eco-friendly practices, such as the use of organic fibers and water-saving dyeing techniques, to meet global environmental standards. Moreover, the rise of fast fashion and e-commerce is driving demand for quick turnaround times and diversified product offerings. Apart from this, collaborative efforts between local manufacturers and international brands are helping to enhance production capabilities and expand market reach, positioning Indonesia as a competitive player in the global textile industry. Consequently, the convergence of these factors is anticipated to propel the Indonesia textile manufacturing market in the coming years.

Download a sample copy of the Report: https://www.imarcgroup.com/indonesia-textile-manufacturing-market/requestsample

Indonesia Textile Manufacturing Industry Segmentation:

The report has segmented the market into the following categories:

Process Type Insights:

Spinning

Weaving

Knitting

Finishing

Others

Textile Type Insights:

Fiber

Yarn

Fabric

Garments

Others

Equipment and Machinery Insights:

Simple Machines

Automated Machines

Console/Assembly Line Installations

Regional Insights:

Java

Sumatra

Kalimantan

Sulawesi

Others

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape in the market. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Key highlights of the Report:

Market Performance (2018-2023)

Market Outlook (2024-2032)

COVID-19 Impact on the Market

Porter’s Five Forces Analysis

Strategic Recommendations

Historical, Current and Future Market Trends

Market Drivers and Success Factors

SWOT Analysis

Structure of the Market

Value Chain Analysis

Comprehensive Mapping of the Competitive Landscape

Note: If you need specific information that is not currently within the scope of the report, we can provide it to you as a part of the customization.

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

0 notes

Text

Traditional Rugs

Commercial offices and retail stores require a durable floor covering that enhances the aesthetics of the space, is easy to maintain, and helps reduce noise levels. With so many options available today, let us help you narrow it down. In this post, we discuss the best flooring options based on location and by material. These ground mats are durable, they are simple to clean and can be utilized for a lengthy time. One of the most important suppliers of excessive-quality. Its luxurious carpet collections are manufactured for the top end of the industrial & residential market, Buy online right now from the main carpet and flooring retailer on the net. They are manufactured from synthetic fibers, such as silk and wool, which are extra durable than different rugs and are additionally produced from other-thetic fibers - sisal rugs melbourne.

If you are considering a natural look, many natural fiber carpets are durable and carry commercial ratings. A stain-resistant sisal from our sisal collection offers classic sisal constructions, like bouclé or tiger-eye, woven from the most stain-resistant sisal yarns available on the market. It is hard to beat synthetic materials with their overall durability, stain-resistance, range of colors, and design options. Hence, most commercial carpet is made from synthetics like nylon or polypropylene, or a blend of materials. In general, the yarns in a commercial carpet are solution-dyed, colorfast, UV-resistant, and mold and mildew resistant - sisal rugs Adelaide.

The addition of a modern wool rug into any design style is a great way to connect traditional and contemporary décor while offering the warmth and comfort that we expect from wool. This simple update transforms a room and offers an excellent avenue for self-expression, as wool rugs come in an array of colors, patterns, and textures. As a leading source of classic and design-forward wool rugs, we created this guide on modern wool rugs and high-end options from around the world. Traditional rug production methods include hand knotting and hand weaving, a slow but precious process that creates unique, artisan rugs. Modern manufacturing methods like tufting produce rugs and carpets quickly and consistently, supplementing human labor with industrial machines. For more information, please visit our site https://thenaturalflooringcompany.com.au/

0 notes

Text

Knitted Fabric Manufacturers - Response Fabrics • Knitted Fabric Manufacturers - Response Fabrics

Knitted Fabric Manufacturers

Response Fabric specializes in the export, sourcing, and marketing of knitted fabric manufacturers. We have been dealing in cotton fibers, cotton waste, cotton yarn, cotton knitted fabrics much more. The knitted fabric that is produced is flexible and can be readily fabricated into smaller parts. This makes it ideal for hosiery products such as socks, and hats. It is made from 100% cotton hosiery yarn by using circular knitting machines.

Blended Knitted Fabric Latest Price in india

The price of the blended knitted fabric in India is starting from Rs. 480\kg, and more.

Knitted Cotton Fabric Manufacturers & Suppliers in India

Response Fabrics counted among the top manufacturers & suppliers in India for knitted fabric. This offers a broad collection of Knitted Cotton fabric. This guarantee to use the selective, and essential material by our merchants. We have attained expertise in offering these products in creative styles, and designs to enhance the looks of the spaces. Designed using superior quality cotton & other fabrics in a multitude of colors, and shades, these products are sure to win the hearts of everyone.

Knitted Fabric Manufacturers in Surat

For the best Manufacturer & Exporter of Designer Knitted Fabric Manufacturer in surat check the Response Fabrics that is the professional supplier of high quality Designer knitted Fabrics in Delhi. We specialized in supplying quality Fabrics, Leather, Synthetic Suede leather, which is widely used for automotive furniture sofa, footwear, fashion, gloves, sports, equipment, consumer electronics, etc. Response fabrics offer you all types of qualities in Leatherette, manufacturers offer you a wide range of artificial leather that can be used in offices, sofas, chairs, cinema halls, auditoriums, automobiles, jackets and so do we. The primary advantage of artificial leather is that it doesn’t get faded, doesn’t get easily cracked or wrinkled.

Circular Knitted Fabric Manufacturers

This manufacturer of circular knitted fabrics offers the excellent quality of knitted fabrics. These circular knitted fabrics are mainly used for designed home furnishing items, carry bags, and many other things. These products are high on every feature like color, look, design, and finishing. We are having excellent task work, and world class production machinery that aids to manage the urgent order on time. These fabrics are ideal for designing handicrafts items, and home furnishing items. Thisoffers the best suited for making apparel, and accessories.

Response Fabric feels love to bring your satisfied products as per your requirement! If you have made up your mind, it is time to start browning the pictures, and pick the best alternative that suits your choice, and need.

Knitted Pile Fabric Manufacturers

Response Fabric is one of the excellent & premium brands for Knitted Pile Fabric in India. Company has its own fabric weaving factory, and dyeing factory that allows it to control product quality to meet client’s requests. There is a vast stock capacity, we are able to provide fabric cut-length service, and ship out the fabrics in one day. Offering superior spill, and stain resistance coupled with remarkable performance, and durability, extra post-treatment brings you more than just high performing technical fabrics.

Knitted Spandex Fabric Manufacturers

Response Fabrics is the one stop solution for all your wholesale requirements of Knitted Spandex Fabric, and more. We deal in a wide variety of fabrics focusing on timely delivery of your bulk requirements. We are the exclusive dealer in India. We offer short lead times in a wide variety of products ranging from Knitted Spandex Fabric, Upholstery Fabric, rexine, and much more.

READ MORE...Best Fabric Manufacturers In India, Upholstery Fabrics

0 notes

Text

Rapier Loom Machine- All You Need to Know

In the mid-20th century, the textile industry witnessed a transformative leap with the advent of Rapier Loom Machines. Born out of a need for enhanced efficiency and precision in weaving, these machines quickly evolved, embracing mechanical and electronic innovations. This brief exploration traces the concise history that propelled Rapier Loom Machines into the forefront of modern textile manufacturing. Discover accuracy and effectiveness with Weavetech, your reliable textile manufacturing partner. Being one of Gujarat’s top manufacturers of rapier loom machines, we put innovation at the center of your output. With our cutting-edge rapier loom machines, which are built for dependability, speed, and versatility, you may enhance your weaving experience.

What is the Rapier Loom Machine?

A Rapier Loom Machine is a textile weaving device that uses a rapier a thin, flexible rod or tape to insert the weft yarn across the warp threads during fabric production. Renowned for their precision and versatility, these machines have evolved, incorporating electronic controls for enhanced efficiency in the weaving process.Single rapier machines use one rapier for weft insertion, while double rapier machines use two. The dual-rapier system in double-rapier machines offers increased versatility and efficiency, particularly for intricate weaving patterns. The choice depends on the fabric’s complexity and production requirements.

What are the features of the Rapier Loom machine?

Here are some prominent features commonly associated with modern rapier loom machines:

Rapier System: The most distinctive feature of a rapier loom is the use of a rapier or a rigid or flexible rod to carry the weft yarn across the warp threads.

Flexible Rapier: Some rapier looms use a flexible rapier, which is a tape or band that can bend around the loom to carry the weft through the shed.

Rigid Rapier: In contrast, rigid rapiers are straight and do not bend. They move horizontally to insert the weft through the shed.

Shedding Mechanism: Rapier looms employ shedding mechanisms to create an opening (shed) through which the weft can be inserted. Common shedding mechanisms include dobby or cam shedding.

Electronic Jacquard Attachment: High-end rapier looms may have an electronic jacquard attachment for more complex and intricate fabric patterns.

Speed and Efficiency: Rapier looms are known for their high weaving speed and efficiency, making them suitable for large-scale production of fabrics.

Versatility: Rapier looms can be used to weave a variety of fabrics, including plain weaves, twills, and complex patterns. They are versatile and can handle a range of yarn types.

Automatic Functions: Many modern rapier looms are equipped with automatic functions such as automatic warp and weft replenishment, automatic pick finding, and automatic tension control.

Easy Set-Up and Operation: Rapier looms are generally considered easier to set up and operate compared to some other types of looms, making them popular in industrial textile production.

Monitoring and Control Systems: Advanced rapier looms may include monitoring and control systems that help in detecting and correcting weaving defects.

Double Rapier System: Some rapier looms use a double rapier system, where two rapiers work in coordination to insert the weft simultaneously. This can increase the weaving speed and efficiency.

Warp Stop Motion: A warp stop motion system is often integrated into rapier looms to detect and stop the loom in case of warp yarn breakage.

These features collectively contribute to the efficiency, flexibility, and advanced capabilities of modern rapier loom machines in the textile industry. Weavetech, the top manufacturer of Rapier Loom Machines in Gujarat, will help you up your weaving game. Our state-of-the-art machinery guarantees quick, accurate, and adaptable textile production.

What clothes are made by Rapier Loom machine?

Rapier Loom machines produce a variety of fabrics, including cotton, polyester, wool, silk, denim, and more, used for diverse clothing items such as shirts, dresses, jeans, and formalwear.

What is Rapier fabric?

Rapier fabric is woven using a Rapier Loom machine, incorporating diverse materials like cotton, polyester, and silk, to create versatile textiles for clothing and other applications. The evolution of Rapier Loom machines has undeniably left an indelible mark on the textile industry. From the simplicity of single-rapier systems to the enhanced capabilities of double-rapier machines, these looms have redefined efficiency, precision, and versatility in fabric production. The ability to weave a spectrum of fabrics, from everyday cotton to luxurious silk, highlights the adaptability of Rapier Looms in meeting the diverse demands of the fashion world. As technology continues to advance, these machines stand poised at the forefront of innovation, driving the industry forward. In essence, the journey of Rapier Loom machines is not just a story of mechanical ingenuity but a testament to their integral role in shaping the very fabric of our textile landscape.

With Weavetech, the Best Textile Machinery Manufacturer in Gujarat, you can unleash the potential of textile production in the future. Our cutting-edge Rapier Loom Machines guarantee quick and accurate weaving while redefining efficiency. Improve your manufacturing skills by getting in touch with Weavetech right away.

This Blog Originally Posted Here:

https://www.weavetech.com/rapier-loom-machine-all-you-need-to-know/

0 notes

Text

"Weaving Excellence: Madaan Engineering's High-Quality Rapier Loom Machines in India"

In the intricate world of textile manufacturing, the choice of weaving machinery plays a pivotal role in determining the quality and efficiency of the production process. Rapier loom machines, with their advanced technology and versatility, have become a cornerstone in the textile industry. Among the myriad of manufacturers in India, Madaan Engineering has emerged as a prominent player, offering top-notch Rapier Loom Machines that stand out for their quality, performance, and competitive pricing.

Understanding Rapier Loom Machines:

Rapier loom machines are a type of shuttleless weaving machine widely used in the textile industry for their flexibility and ability to handle a variety of fabrics. These machines utilize a rapier, a flexible steel or fiberglass rod, to insert the weft yarn across the warp threads, ensuring precision and speed in the weaving process.

Madaan Engineering's Rapier Loom Machines:

Madaan Engineering, based in Karnal, Haryana, is at the forefront of manufacturing and supplying high-quality Rapier Loom Machines in India. The company's commitment to excellence is evident in its state-of-the-art manufacturing facilities, cutting-edge technology, and a team of skilled professionals dedicated to producing world-class weaving machinery.

Key Features of Madaan Engineering's Rapier Loom Machines:

Innovative Technology: Madaan Engineering incorporates the latest technological advancements in the design and manufacturing of its Rapier Loom Machines. This ensures optimal performance, increased efficiency, and adaptability to diverse textile production requirements.

Sturdy Construction: The robust build of Madaan Engineering's Rapier Loom Machines guarantees durability and longevity, even under demanding operational conditions. The machines are engineered to withstand the rigors of continuous usage, offering reliability to textile manufacturers.

User-Friendly Design: Madaan Engineering prioritizes user convenience in its machine design. The Rapier Loom Machines are easy to operate and maintain, with features that simplify the weaving process. This user-friendly approach enhances productivity and minimizes downtime.

Versatility in Fabric Handling: These Rapier Loom Machines excel in handling a wide range of fabrics, from lightweight to heavy-duty materials. The versatility of the machines makes them suitable for various textile applications, providing manufacturers with flexibility in their production processes.

Competitive Pricing:

Madaan Engineering understands the importance of cost-effectiveness in the competitive textile industry. The company strives to offer Rapier Loom Machines at competitive prices without compromising on quality. This commitment to affordability makes Madaan Engineering a preferred choice among textile manufacturers looking to invest in reliable and efficient weaving machinery.

Customer Satisfaction:

The testimonials from satisfied customers are a testament to the success of Madaan Engineering in delivering high-quality Rapier Loom Machines. Clients appreciate not only the performance and durability of the machines but also the prompt and responsive customer support provided by the company.

Conclusion:

In the dynamic world of textile manufacturing, Madaan Engineering stands as a reliable partner for those seeking excellence in Rapier Loom Machines. The company's commitment to innovation, quality, and competitive pricing has solidified its position among the leading Rapier Looms Manufacturers in India. With a focus on customer satisfaction and a track record of delivering reliable weaving solutions, Madaan Engineering continues to weave success stories for textile manufacturers across the country.

CONTACT US TODAY: +91 - 9812003292, +91-8607603344, +91-9996133347 0180-3551641 [email protected] [email protected] Office / Work Madaan Engineering Works Pvt Ltd. E-67, Old Industrial Area, Near Gole Chakker, Panipat - 132103, Haryana(INDIA) Work - Madaan Agro Industries Kabri Road, Near TDI Bypass, Panipat 132103 Haryana INDIA

#jacquard machine price in india#disc harrow manufacturers in india#jacquard suppliers in panipat#jacquard manufacturers in panipat#electronic jacquard manufacturers in panipat

0 notes

Text

Denim Manufacturing Overview

youtube

Warp yarns for indigo denim textiles must go through many processing stages before they can be woven. These stages are specific to the production of indigo fabrics. The warp yarns are often indigo coloured using a mechanism known as a long-chain or rope range. Multiple ends of yarn are made into a rope or ball warp for this system and then continually coloured. Following dyeing, the dyed ball warp is rebeamed into individual yarns that are equally placed onto section beams. After that, the beams are cut and braided. If the warp yarns are to be slasher or sheet dyed, they will be indigo coloured after being warped into section beams. In most situations, the yarns are cut or sized at the same time. After then, the yarn is weaved. If the warp yarns are to be beam dyed, they are warped onto perforated dye beams rather than made into ropes. Following beam dyeing, the dyed yarn is sliced and weaved. If natural warp yarns are used, the strands will be warped onto section beams before being slashed and woven. After then, the cloth is treated normally. Desizing, preparation, dying (if required), and finishing are all included. Unlike warp yarn, the filler yarn is packaged and supplied directly to the weaving machine, where it is placed into the fabric without any wet processing, but coloured filling yarns are occasionally used to make a distinctive appearing denim.

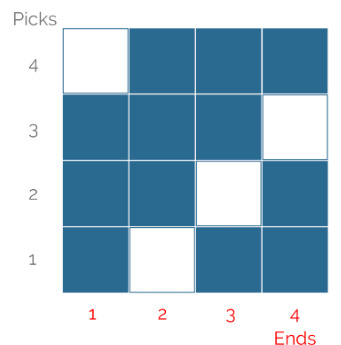

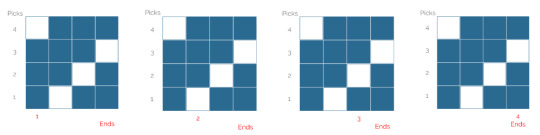

Denim Construction, Weaves, & Weights

youtube

A bottom-weight 14-ounce denim is typically constructed with 55 to 64 warp ends per inch and 38 to 42 filler picks per inch. The number of warp ends per inch is also known as the fabric sley. Of course, the weight is affected by the yarn size, fabric weave pattern, and fabric tightness. The quantity of sizing remaining on the completed cloth is also affected by the weight of the fabric. Other denim textiles and denim look-alikes may have 52 to 70 warp ends per inch and 36 to 52 picks per inch of manufacture.

As a rule, denim is woven as:

3 X 1 twill

2 X 1 twill

2 X 2 twill

3 X 1 broken twill

2 X 2 broken twill

The completed fabric weights range from 3.5 to 16.5 ounces per square yard. Blouses, tops and shirts are commonly made from materials weighing 3.5 to 8 ounces per square yard. Heavyweight denim fabric ranging from 8 to 16.5 ounces per square yard is commonly used for trousers, pants and jackets. Different denim patterns, such as 3 X 1 twill, use numerical notations to indicate what each warp yarn is doing in relation to the filler yarns interlacing with it.

Broken twills

youtube

Broken twills are made by breaking up the twill line at different intervals, preventing it from being straight. Yarns one and two are weaving a 3 X 1 twill, however yarn three is not weaving in a twill sequence, which breaks the fabric's twill line.

Non-Conventional Denim Fabrics

Non-conventional denim fabrics include:

Herringbone weaves

Bedford cords

Seersucker

3 X 1 twill weaves

1 X 3 twill weaves

Plain-weave chambray

Jacquard

Dobby weaves

Reference:

0 notes

Text

Magnificent Look to Your Space by Choosing Top-Notch Flatweave Wool Durry

Normally, the rugs are known for their beauty and the best traditional look. Flat weave rugs are one of the rugs which are commonly used in many countries. These are also affordable options for making your home decoration without any hassle. Flat weave rugs are the flattest rugs, so these do not show the woolen piles. These are the main reasons why the most preferred type of rug. flatweave wool dhurrie exporters India brings you the finest range of rugs that are perfect to have a new look, ineffective, and functional aspects.

Best Colors and Patterns:

Flat weave rugs are 100% woven and provide a flat surface. These are also easy-to-carry properties and are widely used in India. Flat weave rugs are also known for the best patterns and colors. These can be easily moved on either side and made with the finest quality of yarn. The colors of these products also remain intact giving a beautiful look. Rugs In Style is the reliable and top flatweave wool durry manufacturers India for providing the best quality PET dhurries. These are specially made from eco-friendly materials suitable for bringing the classic look. A team of skilled craftsmen is looking to perfect the traditional art of dhurrie weaving with the best technology. Flat weave rugs are woven, so they are not hand-knotted.

Easy Maintenance:

Normally, the Flat weave rugs are quite easier to clean as well as maintain. These rugs do not need any kind of maintenance level to this extent. Flatweave wool Durry can be easily washed as well as cleaned. These do not require any professional cleanings and give an amazing option. It would be quite an efficient option to make it really easy to clean and maintain them. Flatweave wool Durry can be easily vacuumed or washed in machines without any worry of damaging the texture of rugs.

Cost-Effective:

Flat weave rugs is not that much expensive. These are one of the perfect options for people who are looking to decorate their homes with quirky patterns. Rugs In Style assures of bringing the finest quality PET dhurries made from eco-friendly materials. Team of skilled craftsmen is looking to bring the finest quality dhurrie weaving with serving affordability to the extent.

Expert team would also weave unique and intricate designs from the choicest yarns. These quality

flatweave wool durry

are dyed with delightful tones that can easily connoisseurs of interior design. These are also suitable options for making your home to beautiful aspects. You can conveniently get top-notch products for fulfilling the beauty of the room.

0 notes

Text

Warping Machine Manufacturers

A warping machine is a textile apparatus used to prepare yarn for weaving. It arranges yarns from a creel onto a large cylinder called a warper's beam, creating a parallel and evenly tensioned yarn sheet. This process ensures that the yarn will be woven without distortion. Warping machines are essential in producing high quality woven fabrics, streamlining the weaving process. Are you Looking for reliable top warping machine manufacturers in India? Dashmesh Jacquard & Powerloom offers advanced solutions for your textile needs.

#Warping Machine#Warping Machine Manufacturers#Warping Machine Manufacturers in India#Warping Machine Supplier#Warping Machine Supplier in India

0 notes

Text

The Future of Textile Manufacturing: Warping and Beaming Machines Market Analysis and Top Manufacturers for 2030

The Future of Textile Manufacturing: Warping and Beaming Machines Market Analysis and Top Manufacturers for 2030 Table of Contents Introduction Overview of Textile Manufacturing The Importance of Warping and Beaming Machines in Textile Manufacturing Market Analysis and Trends for Warping and Beaming Machines Top Manufacturers of Warping and Beaming Machines Future Developments and Innovations in Warping and Beaming Machines Challenges and Opportunities in the Warping and Beaming Machines Market Advancements in Technology Impacting the Textile Industry Overall Investments and Funding in the Warping and Beaming Machines Industry Future Outlook and Predictions for Warping and Beaming Machines Market Conclusion FAQs The Future of Textile Manufacturing: Warping and Beaming Machines Market Analysis and Top Manufacturers for 2030 The textile manufacturing industry has come a long way over the years, with new technology and machines transforming the way materials are produced. One of the key components of textile manufacturing is the process of warping and beaming, which involves the preparation of materials before they are woven. This process has undergone significant changes and improvements over the years, with the introduction of new technologies and advancements. In this article, we will provide an overview of the textile manufacturing industry, with a focus on the importance of warping and beaming machines. We will analyze the market for these machines, discussing current trends and predictions for the future. We will also highlight the top manufacturers of warping and beaming machines, as well as advancements in technology impacting the broader textile industry. Overview of Textile Manufacturing Textile manufacturing is the process of creating fabrics or other similar materials through the use of weaving, knitting, or crocheting techniques. The industry has been around for thousands of years, with cultures around the world developing unique methods and tools for producing textiles. Today, the textile manufacturing industry is a multi-billion dollar global market, with a strong demand for high-quality and sustainable materials. In textile manufacturing, warping and beaming are crucial steps that come before the actual weaving process. Warping is the process of arranging yarns on a beam in preparation for weaving, while beaming involves winding these yarns onto a larger beam that can then be used in the weaving process. The Importance of Warping and Beaming Machines in Textile Manufacturing Warping and beaming are critical steps in textile manufacturing, and the use of machines has revolutionized how these steps are performed. These machines are designed to increase efficiency, productivity, and precision, allowing textile manufacturers to produce high-quality materials quickly and cost-effectively. Warping and beaming machines come in a variety of types and sizes, depending on the specific needs of the manufacturing process. Some of the key benefits of warping and beaming machines include: - Increased productivity: These machines are designed to be highly efficient, allowing textile manufacturers to produce more materials in less time. - Improved precision: Machines ensure that yarns are arranged and wound onto beams accurately, minimizing errors and waste. - Increased flexibility: Warping and beaming machines can handle a range of different materials and sizes, making them highly versatile. Market Analysis and Trends for Warping and Beaming Machines The market for warping and beaming machines is expected to grow significantly in the coming years, driven by rising demand for high-quality textiles. According to a report by Market Research Future, the global warping and beaming machines market is expected to reach $1,026.1 million by 2023, growing at a CAGR of 6.43% from 2018 to 2023. One of the key trends driving this growth is the increasing adoption of technology in the textile manufacturing industry. Advancements in automation and robotics have made warping and beaming machines more efficient and easier to operate, while also reducing the need for manual labor. Another key trend is the rising demand for sustainable and eco-friendly textiles. Textile manufacturers are increasingly focused on reducing their environmental impact, and warping and beaming machines can help them achieve this by increasing efficiency and reducing waste. Top Manufacturers of Warping and Beaming Machines There are many manufacturers of warping and beaming machines around the world, but some stand out for their quality, reliability, and innovation. Here are some of the top manufacturers of warping and beaming machines: - Karl Mayer: A German company that produces a range of warping machines, including those for producing high-performance fabrics and technical textiles. - Murata Machinery: A Japanese company that makes warping machines for a range of applications, including denim and corduroy fabrics. - Benninger: A Swiss company that produces a range of warping and beaming machines, including those used for wool and blended yarns. - CCI: An American company that specializes in beaming machines for a range of applications, including woven and knitted fabrics. Future Developments and Innovations in Warping and Beaming Machines As technology continues to advance, we can expect to see further developments and innovations in warping and beaming machines. One key area of focus is the use of data analytics and machine learning to improve the efficiency and accuracy of these machines. Additionally, we can expect to see continued investments in automation and robotics, with textile manufacturers looking for ways to reduce labor costs and increase efficiency. There may also be a greater focus on sustainability, with warping and beaming machines designed to reduce waste and minimize environmental impact. Challenges and Opportunities in the Warping and Beaming Machines Market While the future of warping and beaming machines looks bright, there are still some challenges and opportunities to keep in mind. One of the biggest challenges facing manufacturers is the increasing competition from cheaper overseas producers, particularly in Asia. However, there are also opportunities to innovate and differentiate through the use of new technologies and materials. Additionally, as the demand for sustainable and eco-friendly textiles continues to grow, there may be opportunities to create new market niches. Advancements in Technology Impacting the Textile Industry Overall Warping and beaming machines are just one example of the many advancements in technology that are impacting the textile industry overall. Other notable innovations include: - 3D printing: This technology allows textile designers to create complex and intricate shapes, designs, and textures. - Smart fabrics: Fabrics that can sense and respond to changes in their environment, making them ideal for use in wearable technology. - Digital printing: This technology allows textile manufacturers to create highly detailed and vibrant patterns and designs. Investments and Funding in the Warping and Beaming Machines Industry The warping and beaming machines industry has attracted significant investments and funding in recent years, as manufacturers look to stay ahead of the curve and take advantage of new technologies. Some notable investments include: - In 2019, Karl Mayer announced that it would be investing more than €100 million in new technology and research and development over the next five years. - In 2020, Indian textile manufacturer Raymond Ltd. announced that it would be investing Rs 250 crore to upgrade its loom network, including the purchase of new warping machines. Future Outlook and Predictions for Warping and Beaming Machines Market Overall, the outlook for the warping and beaming machines market looks positive. With rising demand for sustainable textiles, increased automation and innovation, and continued investments in research and development, we can expect to see significant growth in the coming years. However, manufacturers will need to keep an eye on emerging trends and technologies to stay ahead of the curve. By staying on top of these developments and investing in the right areas, they can continue to grow and thrive in the highly competitive textile manufacturing market. Conclusion The textile manufacturing industry continues to evolve and innovate, with warping and beaming machines playing a crucial role in this ongoing transformation. As new technologies and materials emerge, we can expect to see further advancements in this area, making the textile manufacturing process more efficient, sustainable, and cost-effective than ever before. FAQs 1. What is a warping machine? A warping machine is a piece of equipment used in the textile manufacturing process to arrange yarns on a beam in preparation for weaving. 2. What is a beaming machine? A beaming machine is a device used to wind yarn onto a larger beam that can be used in the weaving process. 3. What are some of the key benefits of using warping and beaming machines? Some of the key benefits of using these machines include increased productivity, improved precision, and increased flexibility. 4. What are some of the top manufacturers of warping and beaming machines? Some of the top manufacturers include Karl Mayer, Murata Machinery, Benninger, and CCI. 5. What are some of the emerging trends and technologies in the textile manufacturing industry? Emerging trends and technologies include 3D printing, smart fabrics, and digital printing. #BUSINESS Read the full article

0 notes

Text

Discover the Best Handloom Fabric Material in Mumbai with HTC Silk

When it comes to finding the perfect fabric for your next project, nothing beats the elegance and uniqueness of handloom fabric. And if you're in Mumbai, you're in luck! HTC Silk, the renowned online wholesale importer of fine fabrics, brings you the best handloom fabric material in Mumbai! Our collection boasts a wide range of handloom fabrics, each with its own distinct texture and design. In this blog post, we'll take you on a journey through the fascinating world of handloom fabric material in Mumbai - from its rich history to the various styles available today. So, grab a cup of chai and get ready to explore!

Peek Into History

Handloom fabric material has a long and rich history in India, dating back centuries. The art of handloom weaving has been passed down from generation to generation and is now a celebrated craft that is deeply ingrained in Indian culture. Mumbai, in particular, has a thriving handloom industry, with many weavers and artisans creating unique and beautiful pieces of fabric.

At HTC Silk, we understand the importance of supporting local artisans and preserving traditional crafts. That's why we source our handloom fabric material directly from Mumbai weavers, ensuring we offer only the highest quality products. Our handloom fabrics come in a range of materials, including cotton, silk, and viscose, and are available in a variety of vibrant colors and intricate designs. Additionally, if you are looking for a reliable viscose fabric wholesaler in Mumbai, you now know the answer!

Handloom Heirlooms!

Not only are handloom fabrics beautiful, they also offer a range of benefits. Handloom fabric material is generally more durable than machine-made fabrics, as the yarn is tightly woven by hand. This means that handloom fabrics are less likely to tear or wear out over time. Additionally, handloom fabrics are usually made using natural fibers, which are breathable and hypoallergenic, making them ideal for sensitive skin.

Also, did you know? Mumbaians are notoriously famous since way before for their bargaining tactics to buy silk velvet fabrics on wholesale price!

Global Trend

Handloom fabrics have gained popularity in the fashion industry in recent years, as people become more conscious of sustainable and eco-friendly fashion choices. The beauty of handloom fabric lies in its uniqueness, as each piece is handcrafted and no two pieces are exactly alike. This uniqueness is highly valued by consumers who seek to stand out with one-of-a-kind pieces. Handloom fabrics also offer a wide range of designs and patterns, from traditional to contemporary, making them versatile for different fashion styles.

The trend has been noticed not just in India but all around the world, with designers and fashion houses incorporating handloom fabrics into their collections. This has also helped in promoting the rich cultural heritage of handloom fabrics and the skilled artisans who create them.

Handloom and HTC

HTC Silk's handloom fabric stands out in the market for its exceptional quality and durability. Our handloom fabrics are meticulously crafted by skilled artisans, ensuring a unique and beautiful texture that cannot be replicated by machines. We use only the finest materials, sourced from reputable suppliers, to create fabrics that are soft, comfortable, and long-lasting. Our handloom fabrics are perfect for a variety of applications, from clothing to home décor, and are sure to impress even the most discerning customers.

In addition to our handloom fabric material, we also offer a wide range of other fabrics, including the best silk fabrics material near me. Our silk fabrics are sourced from the finest manufacturers in India and are available in a variety of weights, finishes, and colors. We also offer viscose fabric, which is a lightweight and breathable material that is perfect for summer clothing. As a top viscose fabric wholesaler in Mumbai, we are committed to offering only the highest quality products to our customers.

Conclusion

HTC Silk is the ultimate destination for anyone looking for the finest handloom fabric material in Mumbai. We take pride in our unwavering commitment to quality, sustainability, and affordability, making us the go-to choice for discerning fashion designers, textile artists, and anyone in need of exquisite fabrics for their next project. So why not let your creativity flow and explore our collection today? We guarantee that you'll be inspired to create something truly unique and beautiful!

You can follow us on our social media handles to know about our products and offers. For more information about fabric types and pricing, you can visit our website or call: +91 9820510025 or mail: [email protected].

#viscose fabric wholesaler in mumbai#top quality net fabric design online#georgette silk fabric importer in india#handloom fabric material in mumbai

0 notes

Text

Are you looking for an Ashford rigid heddle loom?

You know your desire to weave but must still prepare to invest in a shaft loom. Using your beautiful yarn and an Ashford rigid heddle loom, you may weave stunning cloth for your use or to decorate your home. This rigid heddle loom is inexpensive, portable, and simple to use. The package comes with everything. Warping is fast and simple to do. The inflexible heddle is an excellent way to learn how to weave by hand and is also very adaptable. Produce exquisite and one-of-a-kind apparel and household goods. Create gorgeous designs with pick-up sticks or weave distinctive fabrics using colour and texture. The loom can also be used to weave wall hangings and tapestries — contact yarn hub.

Searching for Yarn Australia?

If you’re seeking yarn Australia, get in touch with yarnhub. A beautiful, smooth, textural yarn that will give your textile projects personality. This yarn’s texture and appeal come from how the wool is twisted into small loops. It is wonderful for strong heddle weaving with the 5dpi reed and lovely for knitting. The fabric is cosy and somewhat thin, and it weaves up rapidly. Thick gauges yield good results when machine knitting. We provide top-notch loom supplies, dyes, and hand-dyed yarns. Our range of hand-dyed, distinctive colours of YarnHub signature yarns will stimulate your creativity. Be open-minded. Let your creativity soar as you browse YarnHub’s online store. YarnHub offers a huge variety of top-notch yarn for your textile research.

Are you trying to get cheap cotton yarn in Australia?

Cheap cotton yarn in Australia is made from unwashed cotton formerly in a paddock. Cleaner and simpler don’t exist! Use natural colours or cellulose dyes to colour it. We offer top-notch yarns that have been hand-dyed, dyed, and loom materials. Our selection of hand-dyed, eye-catching yarns from YarnHub will inspire your creativity. Keep an open mind. Browse YarnHub’s online store and let your imagination soar. For your textile study, YarnHub offers a vast selection of excellent yarn.

Have you been hunting for recycled crochet yarn?

It’s a lovely compliment to your creative endeavours to use recycled crochet yarn made from waste textile manufacturing and leftover fabric. This eco-friendly yarn is perfect for weaving, making baskets, macramé, crocheting, knitting, producing rugs, and other textile projects. Fit for use in basketry, mixed media, and weaving. Recycled linen may be uneven in certain spots; thus when used for crocheting or knitting, it functions best when combined with a finer strand of linen, cotton, hemp, or anything comparable.

0 notes

Text

Printed Fabric Manufacturers for Upholstery - Response Fabrics

Printed Fabric Manufacturers for Upholstery

If you want to get the best Printed fabric manufacturers for upholstery in India then Response Fabrics is one of the top well renowned manufacturers of a broad assortment of Printed fabric, Artificial Leather Fabric, Upholstery Fabric, Mesh Fabric, Blackout Fabric, etc. The offered fabrics are woven at the well-developed manufacturing unit by making use of premium quality yarns, and threads in compliance with defined quality standards. The production department is well-furnished with ultra-modern machines, tools, and equipment to weave these fabrics.

Upholstery Fabric Manufacturers & Suppliers in India

Response Fabrics has the best solution for the best selective variety of upholstery fabric that is a delight to those who wear it as well as those who touch, and see it. The collection of upholstery fabric online gives the best look altogether. The threads used in our cotton fabrics are durable, and fade resistant. This brings great joy for all the customers who buy cheap upholstery fabric from our online store & enjoy different benefits from these.

Upholstery Fabrics are made from a soft feel, high-strength, fire-retardant vinyl fabric, we don’t compromise with the comfort, and elegance, but without the price tag you’d expect. The Responsive Fabric Upholstery Fabric is extremely easy to wipe down, delivering true comfort.

Printed Holland Velvet Upholstery Fabric

Response Fabrics are a leading Manufacturer & Supplier of a wide range of single tone micro velvet fabric, two tone velvet fabric, printed velvet fabric, micro velvet fabric, red velvet fabric, digital printed velvet fabric. We have constructed a wide, and well functional infrastructural unit that plays an important role in the growth of our company. We offer these products at reasonable rates, and deliver these within the promised time-frame.

Purchase Premium-Quality printed upholstery fabric

We, at Response Fabrics, aim to make the best premium-quality printed upholstery fabric available at pocket-friendly prices. All our products go through various quality checks before they are sent out. We know that investing in furniture is a big-deal that’s why all of our products are made with utmost care, and expert specialization. Our range of affordable Upholstery fabric is sure to spruce your home, and furniture up.

Printed Cotton Fabric Manufacturers

This manufacturer of fabrics offers the excellent quality of printed cotton fabrics. These cotton printed fabrics are mainly used for designed home furnishing items, carry bags, and many other things. These products are high on every feature like color, look, design, and finishing. We are having excellent task work, and world class production machinery that aids to manage the urgent order on time. These fabrics are ideal for designing handicrafts items, and home furnishing items. Thisoffers the best suited for making apparel, and accessories.

Response Fabric feels love to bring your satisfied products as per your requirement! If you have made up your mind, it is time to start browning the pictures, and pick the best alternative that suits your choice, and need.

Printed Fabric Manufacturers in Surat

For the best Manufacturer & Exporter of Printed Fabric Manufacturer in Surat check the Response Fabrics that is the Professional Supplier of High Quality Designer printed Fabrics in Surat. We specialized in supplying quality printed Fabrics, Leather, Synthetic Suede leather, which is widely used for automotive furniture sofa, footwear, fashion, gloves, sports, equipment, consumer electronics, etc. Response fabrics offer you all types of qualities in Leatherette, manufacturers offer you a wide range of artificial leather that can be used in offices, sofas, chairs, cinema halls, auditoriums, automobiles, jackets and so do we.

Custom Print Fabric India

Response Fabric offers the best creative custom print fabric that is one of the finest on demand fabric printing companies in India. We offer digital printing on all fabrics, and can do digital printing on all knitted, woven, and felt fabrics like cotton, linen, polyester, rayon, wool, etc. At responsive fabrics, we provide aesthetic, and cost-efficient solutions to all textile needs.

cotton printed fabric wholesale price

The price of cotton printed fabric wholesale is starting from Rs. 70\Meter, and goes on.

printed cotton fabric manufacturers in ahmedabad

Response Fabrics brings the best printed cotton fabric manufacturers in Ahmedabad with a wide range of printed designs. These are made from certified fabric sourced from vendors of high repute after doing a diligent quality testing as per international standards. These products are attractive in colors, mesmerizing patterns, and quality fabric.

READ MORE...Home - Response Fabrics

#Printed Fabric Manufacturers for Upholstery#Upholstery Fabric Manufacturers & Suppliers in India#Printed Holland Velvet Upholstery Fabric

0 notes

Text

Textiles: Agriculture, industry, couture, and exploitation

You guys may not know this, but I’m a fan of the fashion world, I have a deep respect for handcrafted clothing. The skill needed to make clothes is incredible, I’m a bit rusty with a needle and thread myself, but a few of my friends are spectacularly skilled with a sewing machine and a needle. Envy aside, this is actually a very good skill to learn, the decline of this knowledge has been beneficial to those who work in the fast fashion sector and nobody else. Clothing is an essential part of culture and I think that essential aspect is part of why I really dislike fast fashion as well as haute couture. Generally speaking the fashion industry does some pretty shitty things to workers and markets to those who don’t see anything bigger at stake than how they look, which is awful for a culture that’s as consumption obsessed as that of the US.

It all has to start somewhere, mostly from seeds, as long as you pretend that synthetic fabrics don’t exist for a moment (that deserves a post of its own when I move onto the topic of fossil fuels and their obsolescence), most clothes are made from cotton yarn, which is woven into fabric, which is then cut into various shapes and made into whatever clothing item is being manufactured, yeah? Well, there’s a problem with cotton even into the modern day and that’s the energy cost for processing and water cost for growing when you look at the water cost alone and combine it with the fact that in needs to be processed, transported, woven, and cut that comes out to be a lot of fossil fuels and even more water consumed. Roughly 20,000 litres of water (5,283 gallons) is used to produce 1 kilogram of cotton (2.2 pounds). High water cost combined with pesticide, herbicide, and fungicide use make cotton a nightmare for groundwater pollution, agricultural runoff, and soil depletion. There is a better source of fiber than cotton which uses less water and produces more than cotton does, hemp, the industrial variety of hemp is easy to grow and could be replacing half of all textiles very soon. Industrial hemp uses less than a third of cotton and produces, to read more about this hemp click here.

Now onto the textile industry and how it feeds into both fast fashion and couture. As we’ve established, cloth is incredibly important when talking about fashion and clothing. It’s sometimes a selling point, if you want clothes that are easy to take care of, or want something that’s luxurious but is dry-clean only (I don’t know why people would do that to themselves, but that’s besides the point). The top textile manufacturer right now is Arvind Limited which deals in cotton fabrics, cotton is still king it seems, but it’s an India based company. I can’t seem to find who they supply to, although their financial reports are public access, I cannot find who they sell their fabrics to. I am willing to bet it’s mostly to fast fashion companies and some premier brands. That information is out of my hands however, but I can say they’re making bank as a 3rd party distributor with cheap labour on the ground floor. I’m afraid I cannot give detailed accounts of whom they ship to, but speculation will have to do for now.

A little break from serious topics to discuss couture, haute couture, and handmade clothing, I swear we’ll move onto the topic of exploitation of workers after this. Couture is essentially custom fitted clothing, haute couture is luxury custom fitted clothing, and handmade clothes are self explanatory. The only one out of the three that I don’t have a problem with is handmade clothing because it’s made to be warn more than once and is pragmatic, the couture however, is basically what you see at the Met Gala, to be worn once and never again. I think you see the problem as much as I do, a waste of resources and idolization of others based on appearance. Now, I may be misunderstanding or biased, but clothes are supposed to be worn multiple times. In this respect, couture is no better than fast fashion.

Now onto the final topic of an already lengthy post, exploitation of workers in textiles. From the farmers who grow the fiber, to the cloth makers, to the ones operating the sewing machines in sweatshops, all of these people are being exploited by different organizations. The farmers are exploited via the seed industry as well as pesticide, herbicide, and fertilizer industries because they’re viewed as essential in the production of clothing fibers and food crops. For the manufactures of the cloth, they’re being exploited by whomever runs the factory for processing and weaving the fibers, same goes for sweatshop workers. It’s like this anywhere you go in the textile industry, even “high end” fashion is infamous for seasonal crunch times and overworking designers, photographers, and models. It may not be the same as meager wages in a sweatshop, but nobody should be under extreme stress over something that will go away from public vision in a month’s time. We need to rethink what we wear, me included. Instead of throwing clothes away, we should learn how to resize and repair. We’ll get to that point eventually, but until then we have to be more conscious about the things we take for granted and their social & ecological impact.

That was all for today, this post was 2 days late, but I work a lot now and it’s hard to keep up with any social media, especially when I’m essentially writing essays. So have a good one and stay safe babes.

This has been @punkofsunshine, out.

#solarpunk#solarpunk movement#fast fashion#haute couture#couture#sweatshop#farming#agriculture#modern agriculture#hemp#fashion#exploitation#punkofsunshine#textiles#latepost

67 notes

·

View notes

Text

What to Contemplate Prior to Purchasing a Rug On the internet Or Instore