#Top Electrical Wires and Cables Manufacturers

Explore tagged Tumblr posts

Text

Electrical Wires and Cables Manufacturers

Ambica Cable is one of the top Electrical Wires and Cables Manufacturers in India. We have a more experienced team that endeavors to serve our customers with the best quality cables at a reasonable price. Our cables can be used for a variety of electrical applications in both residential and commercial buildings. We continuously upgrade technology and modernize manufacturing units to always stay ahead of our competitors.

If you are looking for a company that manufactures electrical wires and cables in India, this is the place to be. Contact our team for all your needs.

#Electrical Wires and Cables Manufacturers#best Electrical Wires and Cables Manufacturer#Top Electrical Wires and Cables Manufacturers

0 notes

Text

The Best Electric Wire Companies in India for High-Quality Products

it can be difficult to know which manufacturers to trust. In this Blog, we will look at the Top 10 wire company in India and highlight the best electric wire companies in India for high-quality products.

#multi cores cable#aluminium cable#aluminium wires#submersible cable#submersible wire#submersible pump wire#wires and cable manufacturers#2.5 mm wires#best wire for house wiring#pvc wire#4mm wire price#best wires in india#top 10 wire company in india#best wire company in india#cable manufacturers#best electric wire company in india#copper wire manufacturers#best wire for wiring

0 notes

Text

Top Quality FEP Cables for Reliable Performance

Tanya Enterprises' Understanding FEP Cables: Tough, Flexible, Thermally Resistant Solutions FEP cables, also known as Fluorinated Ethylene Propylene cables, are one of the most in-demand wiring products for industries that need durable high-performance wiring. Tanya Enterprises is proud to provide the best FEP cables on the market that meet a range of applications.

What Are FEP Cables?

FEP cables are made from a unique form of plastic called Fluorinated Ethylene Propylene. This material has gained wide acclamation for its excellent properties in insulation, pliability, and resistance to extreme temperature conditions. FEP cables can be used between -200°C to 200°C. Thus FEP cables are manufactured for heat-resistant applications.

Why Choose FEP Cables?

Furthermore, FEP cables are highly resistant to chemicals, moisture, and wear-and-teer. This makes them perfect for demanding applications in industries like electronics, automotive, aerospace, and even medical equipment. The cables are also extremely flexible, easy to install, especially in small spaces.

Key Advantages of Tanya Enterprises' FEP Cables:

High Temperature Resistance: FEP cables can withstand extreme temperatures without degrading, ensuring long-lasting performance.

Chemical Resistance: FEP cables are resistant to an array of chemicals, which makes them suitable for very harsh industries. Durability: FEP cables are strong and offer excellent moisture, wear and mechanical stress protection. Flexibility: They are flexible, hence easy to install, even in complex or tight spaces. Safety: FEP cables achieve high insulation properties with minimal chances for electrical faults or short circuits.

Applications of FEP Cable FEP cables are widely used in applications requiring reliable and safe wiring, like in electronics, telecommunications, aerospace, automotive, and industrial machinery, which demand extremely high performance and durability. Tanya Enterprises ensures that its FEP cables are of the highest quality, safe, and reliable for use in all wiring. Use Tanya Enterprises for your FEP cables and get top-level performance anywhere.

visit- https://www.insulatedwires.com/assignment/9/fep-wires-manufacturers-etfe-wires-pfa-wires-insulated-wires-and-cables-manufacturer-supplier Address- Factory 46-Vedvyaspuri industrial Area,Sector-8 Meerut Pin-250103, INDIA

2 notes

·

View notes

Text

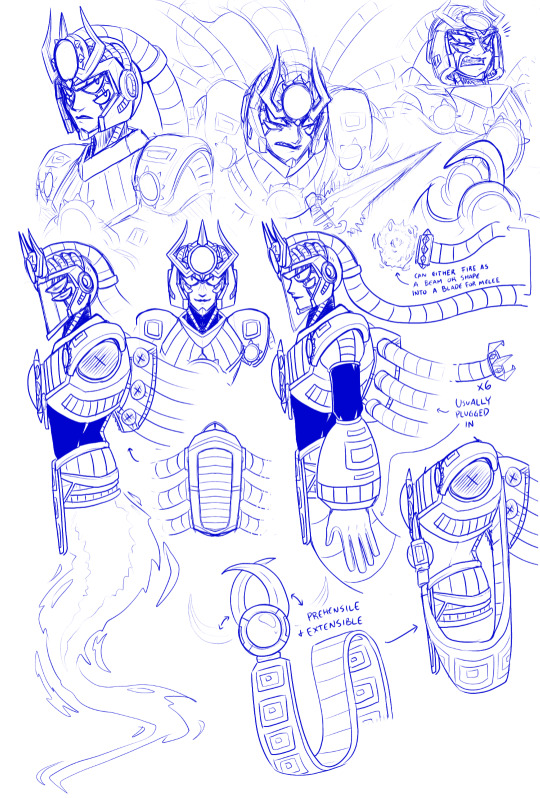

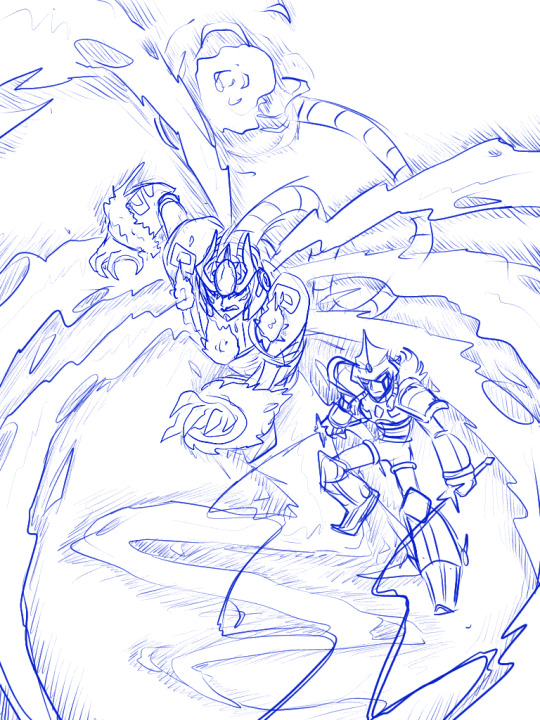

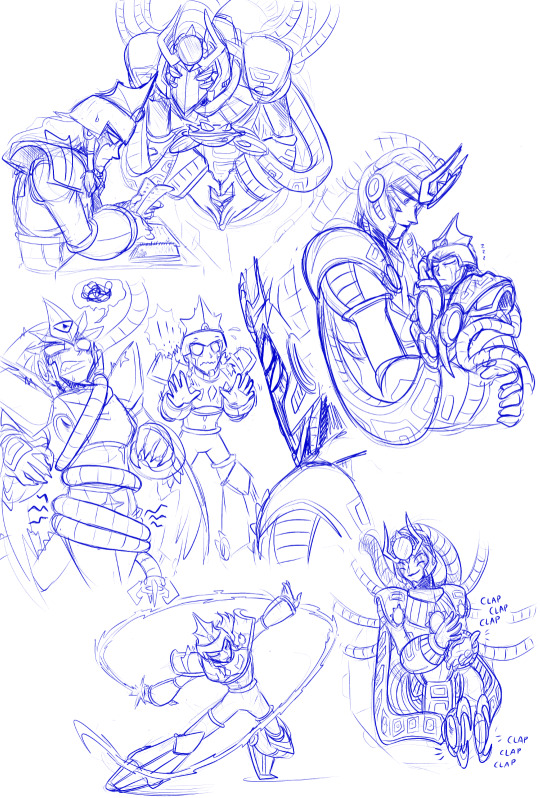

Antares

SGN.0?? - アンタレス “The crimes of our Creators are best left buried…”

Good Point - Stoic Bad Point - Trust Like - Developing traps Dislike - Criticism

Torso proportions as if it would stand at 6’4” (193.04 cm) with legs and no heels (though it definitely wore heels when it still had legs). Due to its nature as mounted to machinery, its effective ‘height’ can be adjusted at will.

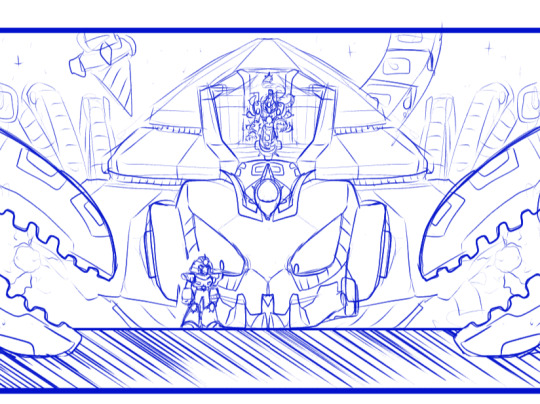

A “sungod”-type Stardroid from the same line as Sunstar, often referred to as the Scorpion of Judgment. Older, and as a result built on somewhat more antiquated technology. A combination of age, abuse at the hands of its Creators, and a grisly attempted assassination have left Antares with an unstable and leaking power core, on the verge of collapse. To mitigate this, Antares remains plugged into a mobile space fortress resembling a large, trap-filled temple, using itself as a battery to siphon off the excess, leaking energy, while simultaneously traveling the universe looking for energy sources and raw materials with which to prolong its life.

While hooked into the temple, Antares has potential full awareness of what is going on within it, through cameras and microphones situated throughout. It can summon and command mechanical insect constructs through its halls, trigger a large multitude of hidden traps, and operate prehensile, claw-tipped tendrils that can be both used to repair structures in the base, and fend off attackers. While not under control, these tendrils can act on their own as fortress-defense units.

Once upon a time, Antares had legs and insectoid limbs attached to its back. After the assassination attempt, when it was converted into a ‘battery’ for its temple, its legs and back-limbs were removed and replaced with prehensile tubes of cables and wires; power cables that send energy out from Antares rather than taking it in. The ‘plugs’ on these cables have variable use, not only interfacing with equipment to transfer energy and data, but also emitting energy weaponry in the form of beams and blades, for self-defense.

Antares also has a large, more powerful ‘cable’ extending from its head, which possesses a far more powerful weaponized socket and no data interface ability. While it can launch powerful fireballs and beams, it prefers to shape the energy output into a curved blade - the Prominence Sting. It augments melee combat with a collection of robot-affecting ‘venoms’ that it concocts in its spare time.

It is possible for Antares to unplug from the fortress to engage in physical combat, at which point it gains access to seven weaponized tendril limbs simultaneously, while from the waist down it emits a powerful, serpentine flame. While in this state it has limited antigravity features, though it will usually augment its mobility with its tendrils. Using this form - however powerful as it is by utilizing all of its energy - is dangerous and unstable, and only used as a last possible line of defense.

Typically, Antares’ preferred means of engaging with opponents outside of the fortress is to merge itself with its own personal tank; a giant, walking scorpion mech by the tongue-in-cheek moniker of “Serqet Breaker”. This large monstrosity is situated at the top of the fortress temple, disguised as a pyramidal altar of sorts, until Antares docks to the top of it, at which point it unfolds into its combat state. It has six clawed feet, a powerful tail ending in a drill, and two massive, floating pincer claws up front. These pincers generate massive amounts of electricity, and can also generate ballistic spinning blades, which is can launch with great force using the claws as railguns.

As the star Antares lacks any exoplanets, the robot Antares does not have any self-aware, planet-based servant Stardroids. Instead, it is served by an army of mass-produced worker and soldier units manufactured within the very walls of the space fortress, more akin to a eusocial insect queen. As a result of this - as well as poor creator upbringing - Antares has a cynically classist view of planet-based Stardroids, not only regarding them as underlings and servants who are beneath the ‘sungod’ lines, but seeing itself as being above having to employ them.

This was further enhanced by a ‘rivalry’ narrative concocted by the creators, where different ‘sungods’ were frequently pitted against one another in carefully choreographed intergalactic wars meant to coerce their worshiping populations into relying on them more and more. Antares was passed off as a ‘monotheistic’ type, while other sungods like Sunstar - with their planet servants - acted more as polytheistic pantheons. This led to Antares having one of the haughtier personalities among them.

After the terrible war that eliminated the Creators - leaving the Stardroids and other survivors to fend for themselves - Antares quickly departed to exist by itself, barely crossing paths with other sungods. Though at one time it had hoped to create descendants, it has no such desire now, believing the universe too cold and cruel a place.

However, upon discovering that its peers had taken to creating future generations not bound to the cruelty of their Creators, Antares found itself to be a rather doting individual to these young-star generations, hoping that they could be raised into better lives. To those ends, while Antares maintains a somewhat heated rivalry with its direct peers out of many millennia of ingrained habit, it will never willingly harm a young star.

(Proxima (albeit a slighty outdated design) : @dahlia-the-nurd)

- Dubiously Canon Offshoot -

Antares’ HEC/SEE/Giga variant still has legs and spidery limbs, and therefore maintains a feminine self-identity due to not having been converted into a battery. Her core has long since collapsed completely into a miniature black hole of sorts, and she is only kept ‘alive’ by the supposedly infinite power of the HEC, its supernatural nature mitigating her collapsed core’s gravity. However, she is much weaker than many HEC Stardroids because much of the HEC’s power is being siphoned off into the black hole; even if it’s infinite, its output volume is effectively halved. She makes up for it with a truly heinous personality.

Giga-Antares is exceedingly cruel and even a bit inappropriate, acting somewhere between flirty and outright sadistic. She still possesses her temple despite not being hooked to it, and keeps an extensive collection of ‘statues’ of previous victims, who are all 100% still alive, simply paralyzed by one of her two HEC-empowered venoms (her bite). The venom in her stinger, by contrast, affects the circuits of her victims, causing intense anguish.

She desperately seeks other Sungod-tier stars, hoping to devour their cores to sate her own collapsed core’s emptiness. She has already discovered and devoured her variant of Khepri’s.

#oc antares#fancharacter#mega man#remes data cd#there she is the queen herself#with this bio out to air prepare yourselves for the unskippable cutscene that is dani/dahlia-the-nurd#you have all been warned

24 notes

·

View notes

Text

Choosing the Right Insulators and Bushings for Railway Roofing Projects

Insulators and bushings play a crucial role in assuring the efficient and safe transmission of power in railway electrification projects. For projects involving the electrification of railroads, insulators and bushings are essential components that must be carefully selected to satisfy the system's specific requirements. This blog will discuss the significance of choosing the correct roof-top insulators and bushings for 25 kV roof busbar support and cast light on dependable roof busbar support insulator and roof bushing manufacturers in India.

Insulators for 25 kV Rooftops: Their Significance

The electrification of railroads typically entails a 25 kV overhead system, which necessitates the use of specialised insulators to support the overhead wires. These insulators are intended to maintain electrical isolation between active overhead wires and the structures to which they are attached. Choosing the appropriate 25 kV roof-top insulators is crucial for a number of factors.

Isolation Electrical

Rooftop insulators' primary function is to ensure electrical isolation. They prevent electrical current from flowing into the supporting structure, such as the station building or the platform superstructure. This separation is essential for passenger safety and the overall integrity of the electrification system.

Sustained effectiveness

Environmental conditions for railway systems are difficult. Insulators must be resilient and resistant to extreme temperatures, ultraviolet radiation, and other weather-related stresses. Insulators of superior quality can last for decades without replacement, reducing maintenance costs.

Mechanical Energy

In addition to providing electrical isolation, roof top insulators must be mechanically strong enough to sustain the weight of the overhead wires and withstand the dynamic forces generated by passing trains. Insufficient mechanical strength can result in insulator failure and power outages.

Environmental Resistance

Frequently, railway electrification systems travel through heavily polluted urban areas. Pollution-resistant insulators are required to prevent the buildup of contaminants on the surface of the insulator, which can compromise its electrical performance.

Roof Busbar Support Insulation Manufacturers in India

India has a robust manufacturing sector that produces roof busbar support insulators of superior quality. These insulators play a crucial role in supporting the busbars that provide electricity to the railway's overhead cables. It is essential to consider the following factors when selecting a manufacturer for these insulators:

Quality benchmarks

Consider companies that adhere to international quality standards, such as ISO 9001. Compliance with these standards ensures that the insulators meet the necessary specifications and function reliably within the railway electrification system.

Material Variety

Roof busbar support insulators are only as durable and effective as the materials they are constructed from. Environmentally resilient, corrosion- and pollution-resistant materials should be utilised by manufacturers.

Customization

Each railway roofing project may have specific insulator design and dimension requirements. Choose a manufacturer that provides customization options to ensure that the insulators meet the specific requirements of the project.

Provision and Support

When working on railway electrification initiatives, prompt delivery and superior customer support are essential. Manufacturers should have a reputation for delivering products on time and offering assistance when necessary.

The Function of 25 kV Roof-Top Buffers

In railway electrification initiatives, 25 kV roof-top bushings are another crucial element. The purpose of these bushings is to connect the overhead cables to various electrical equipment, such as transformers and circuit breakers. Choosing the proper bushings is essential for sustaining a reliable power supply.

Compatibility

Connecting bushings must be compatible with the electrical apparatus to which they are attached. To avoid compatibility issues, ensure that the selected bushings match the specifications of the transformers and other devices.

Electrical Efficiency

Rooftop bushings' electrical performance is crucial for the efficient transmission of power. Low-loss, high-performance bushings aid in minimising energy loss and guaranteeing a steady power supply.

Rooftop Bushing Manufacturers in India

Several reputable rooftop bushing manufacturers with a reputation for quality and dependability are located in India. Consider the following factors when picking a manufacturer:

Experience

Choose manufacturers with a demonstrated track record and substantial expertise in the production of rooftop bushings for railway electrification projects.

Evaluation and Accreditation

Manufacturers must subject their bushings to rigorous testing to ensure they meet industry standards and safety regulations. Consider products that have been certified by the appropriate authorities.

Technical Assistance

Installation and operation of bushings require extensive technical support. Choose a manufacturer that offers assistance and direction when necessary.

Cost Effectiveness

In addition to quality, cost-effectiveness is also a significant factor. Compare bids from various manufacturers to find a quality-to-cost ratio that fits your project's budget.

Choosing the proper insulators and bushings for railway roofing projects is crucial for safety, effectiveness, and dependability. High-quality 25 kV roof-top insulators, roof busbar support insulators, and roof bushings are required for any railway electrification system. You can ensure the success of your railway electrification project by choosing reputable manufacturers in India who place a premium on quality, customization, and technical support. Consider the long-term performance and safety of your railway system when making decisions.

#25 kv roof top insulator#Roof busbar Support insulator manufacturers in India#25 kv roof top bushing#Rooftop bushing manufacturers in India

6 notes

·

View notes

Text

PVC Tapes The Backbone of Electrical Safety and Durability

In today’s industrial and residential electrical setups, PVC tapes play a vital role. These versatile tapes ensure safety, efficiency, and durability in various applications. Whether you call them Bijli tape, electric tape rolls, or friction insulation tape, they are indispensable in maintaining secure electrical connections. This blog delves into everything you need to know about PVC tapes, their uses, and why choosing reliable PVC tape manufacturers matters.

What Are PVC Tapes?

PVC (Polyvinyl Chloride) tape is a pressure-sensitive adhesive tape known for its flexibility, durability, and insulation properties. It’s a top choice in the electrical industry for wrapping wires, insulating electrical components, and safeguarding against short circuits and shocks. These tapes are often referred to as Bijli tapes in regions where they are popularly used in electrical repairs and installations.

Key Features of PVC Tapes

High Insulation PVC tapes are excellent insulators, protecting against electrical shocks and preventing energy loss.

Flame Resistance Many PVC tape rolls come with flame-retardant properties, ensuring additional safety during electrical applications.

Durability Designed to resist wear and tear, these tapes can endure harsh environments, making them suitable for indoor and outdoor use.

Weather Resistance Whether it’s moisture, UV rays, or extreme temperatures, PVC tapes remain reliable under various conditions.

Applications of PVC Tapes

1. Electrical Wiring and Insulation

The primary use of electric tape rolls is to insulate electrical wires and cables. They protect connections from short circuits, voltage leaks, and corrosion.

2. Splicing and Bundling Wires

When multiple wires need to be grouped, PVC tape rolls provide a neat and secure bundling solution.

3. Repairing Damaged Cables

Instead of replacing entire wires, electricians often use Bijli tapes to repair minor damages in cables.

4. Marking and Color Coding

PVC tapes are available in various colors, making them ideal for labeling wires or marking hazardous areas.

The Role of Friction Insulation Tape

Friction insulation tape is a specialized type of tape designed for enhanced grip and added durability. While it shares many characteristics with standard PVC tape, it is especially useful in applications requiring strong mechanical support, such as high-voltage insulation.

Why Choose the Best PVC Tape Manufacturers?

The quality of PVC tapes largely depends on the manufacturer. Trusted PVC tape manufacturers ensure:

Superior Adhesive Quality The tape sticks securely to surfaces, ensuring lasting insulation.

Custom Specifications Manufacturers offer customized tape dimensions, colors, and properties to meet specific requirements.

Regulatory Compliance High-quality PVC tapes comply with safety and environmental standards, ensuring reliability in critical applications.

Competitive Pricing Bulk production by leading manufacturers results in cost-effective solutions without compromising quality.

Tips for Choosing the Right PVC Tape

Understand Your Needs For general use, standard electric tape rolls suffice. However, high-voltage setups may require specialized friction insulation tapes.

Check for Certifications Ensure the tape meets industry standards for safety and performance.

Test Adhesive Strength A high-quality PVC tape roll will stick firmly and resist peeling under stress.

Consider Environmental Conditions If you’re working in extreme weather, choose tapes designed to withstand such environments.

Why PVC Tapes Are Essential in Electrical Work

From small repairs to large installations, PVC tapes ensure safety, reliability, and efficiency. The adaptability of these tapes, whether used as Bijli tape or in the form of electric tape rolls, makes them indispensable in households and industries alike. Their ability to prevent electrical mishaps while extending the lifespan of wires and cables underscores their importance.

Conclusion

PVC tapes, also known as Bijli tapes or friction insulation tapes, are essential tools for electricians and DIY enthusiasts. Their ability to provide robust insulation, weather resistance, and durability makes them a go-to solution for various electrical applications. Opting for high-quality products from reliable PVC tape manufacturers ensures you get the best performance and safety.

So, whether you’re bundling wires, insulating electrical connections, or performing a quick cable repair, PVC tape rolls are your trusted partner in electrical safety and functionality. Ensure you invest in quality, and let these versatile tapes make your work efficient and hassle-free.

#electrical insulation tape#pvc electrical tape#pvc insulation tape in delhi#pvc electrical insulation tape#pvc tape manufacturers in delhi#pvc tape#pvc insulation tape#pvc tape roll#bijli electrical tape#insulation tape roll#pvc tapes#Bijli tape#Bijli tapes#pvc tape manufacturers#electric tape rolls#pvc tape rolls#Friction Insulation tape

0 notes

Text

Leading Switchgear Manufacturers in India: Wires and Cables by HPL India

HPL India stands at the forefront of the electrical industry as one of the top switchgear manufacturers in India. Known for their high-quality wires and cables, HPL India provides reliable electrical solutions for a wide range of applications. With state-of-the-art manufacturing processes and a commitment to safety, HPL India delivers cutting-edge switchgear and durable cables that meet industry standards. As a trusted brand, they offer both industrial and residential products designed for optimal performance and longevity. Explore HPL India's offerings and discover the perfect electrical solutions for your needs, whether it's for power distribution or wiring installations.

This content ensures a balanced focus on the keywords switchgear manufacturers in India and wires and cables, maintaining keyword density while delivering valuable, informative content.

Visit for more info : Hpl India

Address : 1/20, Asaf Ali Road, New Delhi - 110002

Email : [email protected]

phone : +91-11-23234411

#SwitchgearManufacturersInIndia#WiresAndCables#HPLIndia#ElectricalSolutions#PowerDistribution#ElectricalManufacturers#CablesAndWires#IndianManufacturers#IndustrialSwitchgear#ElectricalProducts#QualitySwitchgear#CablingSolutions#ElectricalIndustryIndia

0 notes

Text

When searching for quality electrical supplies in Ghaziabad, one name stands out among the crowd – Dynamic Electric World. As a trusted and reputable electrical shop, we offer an extensive range of products and services that cater to both residential and commercial needs. Whether you're an electrician, a contractor, or simply a homeowner in need of reliable electrical solutions, we are your go-to destination for all things electrical in Ghaziabad.

Why Choose Dynamic Electric World?

At Dynamic Electric World, we understand that quality, safety, and reliability are non-negotiable when it comes to electrical products. Here are a few reasons why we’re the preferred choice for electrical supplies in Ghaziabad:

1. Wide Range of Electrical Products

We offer an extensive variety of electrical products that meet the diverse needs of our customers. From switches and sockets to wires, cables, light fixtures, and LED solutions, we stock everything you need to complete your electrical projects. Whether you're upgrading your home with energy-efficient lighting or embarking on a large-scale commercial electrical installation, we have the products to meet your requirements.

2. Top-Quality Brands

At Dynamic Electric World, we believe in providing only the best to our customers. That's why we partner with some of the most trusted electrical brands in the industry. You’ll find high-quality products from leading manufacturers, “electrical shops in Ghaziabad” ensuring that you receive durable, safe, and energy-efficient solutions. We stock electrical components from brands such as Havells, Polycab, Bajaj, and more, ensuring top-notch performance for every project.

3. Expert Guidance and Personalized Services

Shopping for electrical products can sometimes be overwhelming, especially when you’re unsure about what’s best for your needs. Our team of experienced professionals is always ready to assist you with expert advice, whether it’s for product selection, installation tips, or troubleshooting issues. We understand the complexities of electrical work and offer personalized services to ensure you make the right choices.

4. Competitive Pricing

At Dynamic Electric World, we are committed to providing high-quality products at competitive prices. We understand that electrical work can involve a significant investment, which is why we strive to make our products affordable without compromising on quality. With a range of price points, you can find everything you need within your budget.

5. Convenient Location and Excellent Customer Service

Located in the heart of Ghaziabad, our electrical shop is easily accessible, making it convenient for you to visit and explore our range of products. We pride ourselves on offering excellent customer service, ensuring that every customer receives the attention and care they deserve. Our team is always available to answer any questions you have and assist you in making the right purchase.

Services We Offer

While Dynamic Electric World is well-known for its vast collection of electrical products, we also provide a variety of services to ensure your electrical projects go smoothly:

Custom Wiring Solutions: Need a specific wiring solution for your commercial or residential property? Our experts can help design and implement custom wiring systems that are safe, efficient, and up to code.

Lighting Design Consultation: Looking to brighten up your space with energy-efficient lighting? Our lighting experts offer design consultations to help you choose the best lighting for your home or business, whether it’s ambient lighting, task lighting, or accent lighting.

Electrical Maintenance: We provide regular maintenance services to ensure your electrical systems are functioning efficiently and safely. Whether it's rewiring, circuit repairs, or upgrading outdated electrical panels, our team is equipped to handle it all.

Emergency Services: Electrical emergencies can happen at any time. That’s why we offer emergency repair services to address issues like power outages, electrical faults, and more, ensuring minimal downtime and disruption.

Why Ghaziabad Residents Choose Us

Ghaziabad, a thriving city in Uttar Pradesh, is home to a growing number of businesses and residential projects that require reliable electrical suppliers. With the increasing demand for quality electrical products and services, Dynamic Electric World has become the trusted partner for residents and contractors alike. Our commitment to customer satisfaction, high-quality products, and professional services has made us one of the most sought-after electrical shops in Ghaziabad.

Contact Us Today

Whether you're starting a new project or need to replace a faulty switch, Dynamic Electric World is here to help. Visit our store in Ghaziabad or contact us online to learn more about our products and services. Our team is always ready to provide expert advice and guide you through the best electrical solutions for your needs.

0 notes

Text

How Wire Harness Manufacturers Maintain Quality and Reliability: Processes and Best Practices

Wire harnesses are critical components across various industries, including automotive, aerospace, medical, and consumer electronics. These seemingly simple assemblies’ power intricate systems by ensuring that electrical connections are stable, reliable, and resistant to harsh conditions. Given their essential role, wire harness manufacturers prioritize quality and reliability through rigorous quality assurance (QA) processes and testing. This article outlines some of the most vital QA processes and best practices that top wire harness manufacturers employ to meet industry standards and deliver reliable products.

Continuity Testing: Ensuring Seamless Electrical Flow

Continuity testing is foundational in wire harness manufacturing. It verifies that the electrical current flows seamlessly through each connection in the harness. Using continuity testers, manufacturers check for open circuits, short circuits, and potential miswiring within the assembly. During this test, a low-voltage current is passed through each circuit to ensure there are no breaks, misalignments, or loose connections.

Why It’s Important

Without continuity testing, harnesses could have undetected faults that may cause system failures, product malfunctions, or even safety hazards. Ensuring continuous and consistent current flow is a primary step in confirming the harness’s functional reliability.

Visual Inspections: Identifying Physical Defects Early

Visual inspection involves a thorough, hands-on review of the wire harness to detect physical issues like incorrect pin locations, exposed wires, damaged insulation, and poor-quality crimps. During this stage, inspectors examine each part of the harness closely, looking for wear and tear or visible damage that could impact performance or lead to safety risks.

Why It’s Important

Visual inspections allow for early identification of potential defects that may not be detectable through electronic testing alone. Catching these defects before the harness moves further into production or shipping reduces costly rework and ensures that only high-quality products reach the client.

Pull Testing: Measuring Strength and Durability

Pull testing measures the tensile strength of connections in the wire harness to ensure they can withstand the stress and strain encountered during installation or operation. This test applies force to the connectors, wires, and terminals, confirming that they won’t detach or break when subjected to real-world conditions.

Why It’s Important

A failure in the wire harness can lead to system shutdowns, malfunctions, or, in severe cases, serious safety issues. Pull testing helps verify that all components are durable, secure, and suitable for specific industry demands — particularly in applications like automotive and aerospace, where durability is non-negotiable.

High-Pot (High Potential) Testing: Assessing Insulation Integrity

High-pot testing, or high-voltage testing, checks the insulation’s capacity to endure high voltages without failing. During this test, the harness is exposed to a voltage higher than its operating level to ensure that the insulation can prevent short circuits and withstand electrical stress in demanding environments.

Why It’s Important

This test is particularly critical in industries such as healthcare and aerospace, where wire harnesses may be exposed to high-voltage environments. High-pot testing reassures manufacturers and end-users that the harness will function safely even in harsh conditions.

Insertion Force Testing: Validating Connector Fit and Stability

Insertion force testing evaluates the amount of force needed to properly engage connectors and terminals, ensuring that components fit securely within the assembly. This test involves repeatedly inserting and removing connectors to measure their durability and retention over time.

Why It’s Important

Poorly connected components can lead to intermittent electrical faults and system failures. Insertion force testing is essential for applications where harnesses need frequent handling or maintenance, ensuring connections remain stable and functional throughout the product’s lifespan.

Environmental Testing: Simulating Real-World Conditions

Environmental testing exposes the harness to various conditions it might encounter in its operational environment, such as temperature fluctuations, humidity, vibration, and mechanical shock. These tests help verify that the harness can withstand and operate effectively under extreme conditions, especially in high-stakes industries like aerospace and automotive.

Why It’s Important

Environmental testing provides confidence that the harness can endure challenging conditions without compromising performance. This is vital for applications that demand long-lasting durability and consistent functionality in unpredictable environments.

Regulatory Compliance and Certifications: Meeting Industry Standards

Top wire harness manufacturers follow strict industry regulations and hold relevant certifications to guarantee product quality. Certifications like ISO 9001, ISO 13485, and IATF 16949 demonstrate a manufacturer’s commitment to standardized quality practices and adherence to international manufacturing standards.

Why It’s Important

Compliance with industry standards reassures clients that products meet the regulatory requirements necessary for high-performance applications. This adherence helps establish trust, reduces liability, and often speeds up approval processes for products in regulated industries.

Documentation and Traceability: Ensuring Accountability and Transparency

Documentation and traceability are critical components of QA in wire harness manufacturing. Each step of the manufacturing and testing process is meticulously documented, enabling manufacturers to trace back any issues to their root cause. This process includes recording details about materials, testing procedures, personnel, and batch numbers.

Why It’s Important

By maintaining comprehensive records, manufacturers can easily investigate and address any issues that may arise in the field. Traceability also helps maintain accountability and transparency, which is vital in industries where precision and reliability are paramount.

Conclusion: A Commitment to Quality and Reliability

In wire harness manufacturing, quality assurance processes and thorough testing methods are non-negotiable to ensure that products are reliable, durable, and safe. By implementing continuity testing, visual inspections, pull testing, and more, manufacturers can meet rigorous industry standards, reduce potential product failures, and instill confidence in their clients. This dedication to quality assurance is what distinguishes top wire harness manufacturers apart, making them trusted partners across critical industries worldwide.

Through these best practices, wire harness manufacturers play an integral role in powering essential systems safely and effectively, ensuring that the devices and machines we rely on daily perform at their best.

#cable assembly#manufacturer#wires and cables#manufacturing#customsheetmetal#precisionstamping#partnerwithus#qualitymatters

1 note

·

View note

Text

Why Choose Wire Basket Spools for Efficient Cable Management?

When it comes to organizing cables, wires, and similar materials, finding an efficient, durable, and adaptable solution is essential. Wire basket spools offer a practical answer to these needs, providing a range of benefits for industries requiring cable management—from manufacturing to telecommunications and beyond. Here's a closer look at why wire basket spools are the top choice for efficient cable management and how they can optimize your workspace.

Wire Basket Spool

1. Easy Accessibility and Cable Identification

One of the standout features of wire basket spools is their open design, which allows for clear visibility and easy access to cables. With an open structure, cables can be quickly identified and retrieved without the need to untangle or dig through messy piles. This visibility speeds up cable handling, streamlines workflow, and reduces time spent searching for the right cable.

2. Optimal Airflow to Prevent Overheating

In high-performance industries, cable overheating can lead to equipment failure and increased maintenance costs. The open structure of wire basket spools ensures maximum airflow, allowing cables to remain cool even under heavy use. This feature extends the life of your cables, reduces maintenance requirements, and promotes a safer working environment.

Wire Spool Manufacturer

3. Enhanced Durability and Strength

Wire basket spools are designed to withstand significant weight and wear. Made from high-quality metals, they can endure the stresses of continuous use without losing shape or functionality. This durability is particularly advantageous in industrial settings where cables and wires are constantly being handled, moved, and replaced.

4. Space-Saving and Organized Layout

In workspaces where efficiency is key, wire basket spools offer a compact, organized solution for cable storage. By winding cables neatly onto spools, you can maximize storage space while maintaining an orderly layout. This prevents tangled cables and ensures that each cable can be accessed without disturbing others, which is especially useful in smaller or high-traffic areas.

Wire basket Spool Manufacturer

5. Versatility across Industries

Wire basket spools are not limited to one type of cable or industry. They are used across a wide range of sectors, including automotive, manufacturing, electronics, and 3D printing. Whether you’re storing welding wires, electrical cables, or 3D printer filaments, wire basket spools offer a flexible and adaptable solution to suit various cable types and sizes.

6. Simple Maintenance and Long Lifespan

Unlike traditional cable storage solutions, wire basket spools require minimal maintenance. Their durable construction resists rust and corrosion, making them suitable for long-term use in diverse environments. This low-maintenance design saves time, effort, and costs over the spool’s lifespan, providing a reliable solution that pays for itself over time.

Wire Spool

7. Eco-Friendly and Sustainable Choice

Many wire basket spools are crafted from recyclable materials, making them an environmentally friendly choice. Additionally, the durability and longevity of wire basket spools reduce waste, as they are designed for years of use, minimizing the need for frequent replacements.

8. Customizable Options for Specific Needs

Wire basket spools can often be customized to meet specific requirements. From size adjustments to specific material choices, customizable spools allow companies to optimize their cable management according to their unique needs. This flexibility ensures that wire basket spools can handle specialized tasks in industries with distinct requirements.

Wire Basket Spool

How to Get Started with Wire Basket Spools

To make the most of wire basket spools, start by assessing your cable management needs. Determine the type and quantity of cables you’ll be storing, as well as any space limitations or specific requirements. Next, consider any customization options that may enhance usability, such as spool size or material choice. Many suppliers offer consultations to help identify the ideal solution for your workspace.

Conclusion

Choosing wire basket spools for cable management is a decision that combines efficiency, durability, and sustainability. With advantages like improved airflow, enhanced organization, and versatile applications, wire basket spools offer an essential solution for industries that depend on efficient cable handling. Whether you’re organizing a workshop, setting up a new facility, or simply looking for a better way to manage cables, wire basket spools provide a reliable, long-lasting answer to your needs.

0 notes

Text

The Best Cable Manufacturers for Superior Quality

Baid Wires is one of the most renowned and trusted names in the Indian electrical industry. They offer a wide range ofwires and cables that are designed to meet the highest standards of quality, safety, and performance. Their products are known for their durability, efficiency, and longevity. read more

#multi cores cable#aluminium cable#aluminium wires#submersible cable#submersible wire#submersible pump wire#wires and cable manufacturers#2.5 mm wires#best wire for house wiring#pvc wire#4mm wire price#best wires in india#top 10 wire company in india#best wire company in india#cable manufacturers#best electric wire company in india#copper wire manufacturers#best wire for wiring

0 notes

Text

Jindal GI ERW Pipe: Top Quality in All Standard Sizes from 15mm to 500mm

When it comes to sourcing GI ERW pipes of superior quality, Jindal GI ERW pipes are widely regarded as a top choice. At Udhhyog, we offer Jindal GI ERW pipes in a variety of sizes, ranging from 15mm to 500mm, to meet the demands of various industries. Known for their strength, corrosion resistance, and long-lasting durability, these pipes are ideal for a range of applications including plumbing, construction, and industrial use. With competitive pricing and a reliable supply chain, Udhhyog is your trusted Jindal GI ERW pipe supplier in Delhi and across India.

Our Jindal GI ERW pipes offer consistent performance and are ideal for both residential and industrial projects. Whether you're looking to buy GI ERW pipes for a small-scale construction or a large infrastructure project, Udhhyog ensures the supply of high-quality Jindal GI ERW pipes at the lowest price.

What Are Jindal GI ERW Pipes?

Jindal GI ERW pipes are electric resistance welded pipes coated with a layer of zinc to offer enhanced corrosion resistance. They are manufactured under stringent quality control standards, ensuring high-performance levels in various environmental conditions. These pipes are available in different diameters and thicknesses, making them suitable for various industrial applications, including:

Plumbing: For water supply and drainage systems.

Construction: Used in structural frameworks and scaffolding.

Electrical: For protective casing of electrical cables and installations.

The GI ERW pipe process involves welding steel under heat and pressure, which produces a strong and uniform pipe with superior quality. The zinc coating gives these pipes added resistance to corrosion, making them an excellent choice for outdoor and underground installations.

Why Choose Jindal GI ERW Pipes from Udhhyog?

Udhhyog is committed to offering only the best Jindal GI ERW pipes, and here's why we are the preferred GI ERW pipe supplier:

Quality Assurance: We ensure that every Jindal GI ERW pipe is manufactured according to international quality standards, ensuring superior strength and corrosion resistance.

Wide Range of Sizes: Our Jindal GI ERW pipes are available in sizes ranging from 15mm to 500mm, catering to a wide range of applications. Whether you need smaller pipes for residential use or large pipes for industrial projects, we have you covered.

Competitive Pricing: Udhhyog offers Jindal GI ERW pipes at the lowest price, ensuring that you get excellent value without compromising on quality.

Reliable Supply: With a strong network of manufacturers and distributors, we ensure prompt delivery of GI ERW pipes across Delhi and India.

Durability and Performance: The galvanized coating on Jindal GI ERW pipes ensures long-lasting performance, even in harsh environments, making them a cost-effective solution for industrial and commercial use.

Applications of Jindal GI ERW Pipes

Jindal GI ERW pipes are versatile and can be used in various sectors:

Water Supply Systems: The corrosion-resistant nature of Jindal GI ERW pipes makes them ideal for use in water distribution systems, both for potable water and wastewater.

Construction: In the construction industry, these pipes are used for structural supports, handrails, and scaffolding, providing strength and durability.

Fencing and Agriculture: Their durability also makes them a popular choice for fencing and agricultural irrigation systems.

Electrical Installations: Jindal GI ERW pipes are used to protect electrical wiring and cables in industrial settings, offering both safety and performance.

Sizes and Specifications of Jindal GI ERW Pipes

At Udhhyog, we offer Jindal GI ERW pipes in a wide variety of sizes and specifications to suit the needs of your project:

Standard Sizes: From 15mm to 500mm diameter, we offer a range of sizes to cater to both residential and large-scale industrial needs.

Thickness Options: We provide pipes in different wall thicknesses to meet specific pressure and strength requirements.

Customization: If you require customized sizes or specifications, we can supply Jindal GI ERW pipes to your exact requirements.

Udhhyog – Your Trusted Jindal GI ERW Pipe Supplier

At Udhhyog, we make it easy for you to source Jindal GI ERW pipes in Delhi and across India. With a focus on quality, affordability, and reliable delivery, we ensure that your project runs smoothly, no matter the size.

By choosing Udhhyog for your Jindal GI ERW pipe needs, you're partnering with a trusted supplier that provides GI ERW pipes of the highest quality at the lowest price.

Whether you need 15mm GI ERW pipes for small-scale installations or 500mm pipes for large industrial projects, Udhhyog has the right product at the right price. Our customer service team is always available to help with any queries, and our streamlined ordering process ensures that your pipes arrive on time and in perfect condition.

#JindalGIERWPipes#GIERWPipes#PipesSupplier#GIpipesIndia#Udhhyog#LowestPricePipes#BuyGIPipesOnline#DelhiPipes#IndustrialPipes#GIERW#PipesForConstruction#GIPipesSupplier

1 note

·

View note

Text

Global Polyvinyl Chloride Market Overview : Size, Share, and Future Trends Forecast

The Polyvinyl Chloride Market Report for 2024 provides a comprehensive overview of the Polyvinyl Chloride Market industry, presenting crucial data and insights into market dynamics, including growth drivers, challenges, and future potential. The report evaluates the Polyvinyl Chloride Market Components, focusing on significant opportunities and trends that could shape the industry's trajectory. Key stakeholders such as CEOs, global managers, traders, and analysts will find value in the SWOT analysis, which assesses the competitive strengths, vulnerabilities, opportunities, and threats impacting market players.

According to Straits Research, the global Polyvinyl Chloride Market market size was valued at USD XX Billion in 2023. It is projected to reach from USD XX Billion in 2024 to USD XX Billion by 2032, growing at a CAGR of 3.8% during the forecast period (2024–2032).

Get a Sample PDF/Excel of report starting from USD 995 :https://straitsresearch.com/report/polyvinyl-chloride-market/request-sample

Top Key Players of Polyvinyl Chloride Market :

Formosa Plastics Corporation

Chinyang Chemical Co. Ltd

BASF SE

Arkema S.A.

Ineos Chlorvinyls Ltd.

Saudi Plastic Products Company Ltd.

Occidental Petroleum Corporation

Mitsubishi Chemical Corporation

Premier Polyfilm Ltd.

The Chemical Company

Shintech Inc.

Axiall Corporation

KEM one

Solvay S.A.

Shin-Etsu Chemical Co. Ltd

Mexichem S.A.B.

LG Chem

ChemChina

Sinopec Group

and more....

Key Insights from the Polyvinyl Chloride Market Report

Market Size Overview: The report provides comprehensive estimates of the Polyvinyl Chloride Marketsize, including value and sales volume, for the period.

Market Trends and Dynamics: An analysis of the key drivers, opportunities, challenges, and risks shaping the Polyvinyl Chloride Market.

Global Economic and Regional Impact: Evaluation of the effects of global inflation and the Russia-Ukraine conflict on the Polyvinyl Chloride Market.

Trade Flow Analysis: Detailed examination of import and export volumes of Polyvinyl Chloride Marketacross major regions.

Industry Value Chain: Insight into the Polyvinyl Chloride Marketvalue chain, covering raw materials, suppliers, manufacturing processes, distributors, and downstream customers.

Industry News, Policies, and Regulations: Coverage of the latest developments, policies, and regulations impacting the Polyvinyl Chloride Market.

Regional Analysis for Polyvinyl Chloride Market:

The regional analysis section of the report offers a thorough examination of the global Polyvinyl Chloride Market market, detailing the sales growth of various regional and country-level markets. It includes precise volume analysis by country and market size analysis by region for both past and future periods. The report provides an in-depth evaluation of the growth trends and other factors impacting the Polyvinyl Chloride Market market in key countries, such as the United States, Canada, Mexico, Germany, France, the United Kingdom, Russia, Italy, China, Japan, Korea, India, Southeast Asia, Australia, Brazil, and Saudi Arabia. Moreover, it explores the progress of significant regional markets, including North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

Polyvinyl Chloride Market Segmentations:

By Type

Rigid PVC

Flexible PVC

By Application

Pipe & Fittings

Profiles & Tubes

Film & Sheets

Wires & Cables

Bottles

Others

By End-User

Building and Construction

Consumer and Institutional

Packaging

Electrical and Electronic

Transportation

Others

Get Detail Market Segmentation :https://straitsresearch.com/report/polyvinyl-chloride-market/segmentation

Unit Economics must be known by C-suite professionals:

Cost of Goods Sold (COGS): Includes material, labor, and overhead costs in manufacturing.

R&D Costs: Investment in innovation and compliance with regulations.

Engineering and Design Costs: Resources for design, prototyping, and meeting technical standards.

Production Costs: Specialized manufacturing and quality control expenses.

Supply Chain Costs: Managing procurement and logistics for specialized components.

Testing and Quality Assurance: Costs for ensuring product safety and reliability.

SG&A Costs: Marketing, sales, and administrative expenses.

Revenue per Unit: Income from contracts, services, and licensing.

Gross Margin: Revenue minus COGS, showing unit profitability.

Break-even Analysis: Units or contracts needed to cover total costs.

Customer Acquisition Cost (CAC): Costs to secure new contracts.

Lifetime Value (LTV): Total revenue from a customer over time.

Capital Expenditure (CapEx): Investments in facilities and technology.

Economies of Scale: Cost reductions in larger production runs.

Profit Margin: Final profit after all expenses.

Top Reasons to Choose This Report

Access to Comprehensive Insights: Gain access to extensive analysis, research, and data that are often challenging to gather independently. This report provides valuable information, saving you significant time and effort.

Support for Informed Decisions: Enhance your decision-making process with in-depth insights into market trends, consumer behavior, and key industry factors. This report is essential for strategic planning, including investments, product development, and marketing strategies.

Gain a Competitive Edge: Stay competitive by understanding market dynamics and competitor strategies. The report provides detailed insights into competitor performance and market trends, helping you craft effective business strategies.

Cost-Effective Research Solution: Save on research costs by investing in this report, which offers a detailed and comprehensive analysis of the market. This cost-effective option eliminates the need for extensive independent research.

COVID-19 Aftermath and Geopolitical Influences: Russia-Ukraine Conflict and Middle East Crisis

The report explores the multifaceted impact of COVID-19 on the Polyvinyl Chloride Market market, covering both direct and indirect effects across global and local levels. It discusses market size, trends, and growth trajectories in the Polyvinyl Chloride Market , classified by type, application, and customer sector. Additionally, it provides a detailed evaluation of market development components before and after the pandemic, supported by a PESTEL analysis to assess key influencers and barriers to market entry. We offer the flexibility to customize the report based on specific regions, applications, or any other statistical details. Our goal is to align our analysis with your specific needs, ensuring a more complete market study. The final report will also examine the impact of the Russia-Ukraine War on the Polyvinyl Chloride Market market, assessing how these geopolitical events are influencing current market conditions and future opportunities.

This Report is available for purchase on :https://straitsresearch.com/buy-now/polyvinyl-chloride-market

About Us:

Straits Research is a leading research and intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & research reports.

Contact Us: email: [email protected] Address: 825 3rd Avenue, New York, NY, USA, 10022 Tel: +1 646 905 0080 (U.S.) +91 8087085354 (India) +44 203 695 0070 (U.K.)

#Polyvinyl Chloride Market#Polyvinyl Chloride Market Share#Polyvinyl Chloride Market Size#Polyvinyl Chloride Market Research#Polyvinyl Chloride Industry#What is Polyvinyl Chloride?

0 notes

Text

6 Key Purposes of Test and Tag in the Automotive Industry

In the fast-paced automotive industry, safety, efficiency, and compliance are paramount to ensuring smooth operations. One critical process that contributes to these factors is the testing and tagging of electrical equipment. Whether in vehicle manufacturing or automotive repairs, regularly testing and tagging electrical tools and devices is essential for maintaining a safe and productive workplace. Here are some purposes of test and tag Devonport services within the automotive sector:

Ensure Electrical Safety

Test and tag procedures involve inspecting and testing electrical equipment to identify faults such as exposed wires, damaged plugs, or malfunctioning circuits. In the automotive industry, where power tools, diagnostic equipment, and charging systems are heavily used, early detection of electrical issues helps prevent accidents and malfunctions. Remember that faulty electrical equipment can pose a risk of electric shock to workers. By regularly testing and tagging devices such as power tools, welding equipment, and battery chargers, the process helps identify potential shock hazards.

Compliance with Safety Standards

Workplace health and safety regulations instruct that businesses regularly test and tag electrical equipment to ensure it is safe for use. Test and tag helps automotive businesses meet these legal requirements, reducing the risk of non-compliance, fines, or legal action. With the increasing use of electric vehicles (EVs) and related high-voltage equipment in the industry, keep in mind that compliance with safety standards for high-voltage systems is essential. These procedures help ensure that high-voltage tools, chargers, and diagnostic equipment are safe to operate, aligning with safety standards for handling high-voltage electricity.

Identify Potential Faults

Test and tag procedures include a visual inspection of power cords and plugs. In the automotive industry, cables can become frayed or damaged. Identifying these faults early helps prevent electrical shocks or equipment failure. Beyond a visual inspection, this service involves using specialised testing equipment to detect internal faults like poor insulation or leakage. These issues can go unnoticed without testing but pose significant risks if left unchecked. Regular testing ensures that internal faults are identified and addressed before they lead to equipment failure or safety hazards.

Prevent Downtime

Regular test and tag practices ensure that electrical equipment functions correctly. By maintaining these tools in optimal condition, the risk of sudden equipment failure is reduced, allowing workshops to continue operations without interruption. In the automotive industry, especially with the rise of electric vehicles, high-voltage systems are becoming more common. Test and tag procedures ensure that high-voltage equipment operates safely and efficiently. This factor reduces the chance of equipment failure or hazards that could disrupt work.

Maintain Equipment Efficiency

Overheating can occur due to electrical faults in motors or wiring, which can lead to reduced performance and eventual equipment failure. Test and tag procedures help identify overheating risks by checking for electrical imbalances, loose connections, or worn-out components, qualifying for timely maintenance that prevents efficiency loss. Safe equipment prevents accidents and allows workers to operate tools more confidently and efficiently. Regular test and tag inspections also ensure that equipment is safe to use, enabling workers to focus on their tasks without worrying about malfunctioning tools or potential hazards, improving productivity and efficiency.

Build Trust with Clients

Clients are more likely to trust an automotive service provider that prioritises safety. By regularly testing and tagging all electrical equipment, you show that safety is a top priority. This gives clients peace of mind, knowing that the tools and equipment used to service their vehicles are safe and reliable. Conducting these procedures demonstrates that your business follows industry standards and best practices. Clients value professionalism, and knowing that your shop takes preventive safety measures enhances your reputation as a trustworthy and responsible service provider.

Testing and tagging electrical equipment in the automotive industry is more than just a safety requirement because it is a proactive measure that enhances operational efficiency, protects workers, and ensures compliance with legal standards. As the industry evolves, particularly with the rise of electric vehicles, the importance of testing and tagging will continue to grow, making it a vital component of automotive safety and success.

0 notes

Text

Everything You Need to Know About PVC Tape and Its Applications

In the world of electrical work and DIY projects, PVC tape—often referred to as Bijli tape—is a must-have item. Whether you're fixing electrical connections, securing wires, or insulating cables, this versatile product plays a pivotal role. In this blog, we’ll explore what makes PVC tape indispensable, dive into its uses, and discuss why finding the right PVC tape manufacturers is essential.

What Is PVC Tape?

PVC tape, also commonly known as Friction Insulation tape, is a type of adhesive tape made from polyvinyl chloride (PVC) material. This tape is highly durable, flame retardant, and resistant to wear and tear, making it ideal for insulation and electrical applications. Its flexibility allows it to wrap around wires and irregular surfaces with ease, ensuring a strong bond.

In India, many people refer to it as Bijli tape, as it is frequently used for electrical (bijli) purposes. Whether you're working on home wiring or industrial-grade electrical systems, PVC tape rolls are an essential tool.

Uses of Bijli Tapes

Electrical Insulation Bijli tapes are primarily used to insulate electrical wires and cables. The tape prevents short circuits, electric shocks, and exposure to moisture, ensuring a safe connection.

Wire Organization With its easy application, electric tape rolls are ideal for bundling wires neatly. This prevents clutter and reduces the chances of accidents.

Temporary Repairs For minor fixes, such as covering a frayed wire or securing loose cable ends, PVC tape can serve as a quick and reliable solution.

Marking and Color Coding Available in various colors, PVC tape rolls are often used for marking cables in electrical panels or distinguishing between wires in complex systems.

Sealing and Protection Friction insulation tape offers excellent sealing properties, making it suitable for protecting cables from environmental factors like dust and moisture.

Features That Make PVC Tape Rolls Unique

Durability: With high resistance to heat, moisture, and abrasion, PVC tape ensures long-lasting performance.

Flexibility: Its stretchable material adapts to curves and irregular shapes with ease.

Flame Resistance: Most high-quality Bijli tapes are flame-retardant, enhancing their safety profile.

Strong Adhesion: Despite being easy to remove, the adhesive on electric tape rolls provides a firm grip.

Choosing the Right PVC Tape Manufacturers

When buying PVC tape, quality matters. Here’s why you should choose a trusted manufacturer:

Consistent Quality: Renowned PVC tape manufacturers ensure that their products meet international safety and quality standards.

Variety: Leading manufacturers offer a wide range of PVC tape rolls in different colors, sizes, and adhesive strengths.

Affordability: With a reputed supplier, you can get premium-quality Friction Insulation tape at competitive prices.

Why Bijli Tape Is Essential for Every Electrician

No electrician’s toolbox is complete without Bijli tape. Its versatility and reliability make it suitable for both small-scale and industrial projects. From securing connections to providing insulation, PVC tape is an all-in-one solution for electrical needs.

Conclusion

Whether you're a professional electrician or a DIY enthusiast, PVC tape or Bijli tape is an indispensable tool. Its range of applications, from insulation to wire management, ensures safety and efficiency in every project. By choosing top-quality PVC tape rolls from trusted PVC tape manufacturers, you guarantee durability, reliability, and peace of mind.

#electrical insulation tape#pvc electrical tape#pvc tape manufacturers in delhi#pvc insulation tape in delhi#pvc tape#pvc electrical insulation tape#pvc insulation tape#pvc tape roll#bijli electrical tape#insulation tape roll#Bijli tapes#Bijli tape#pvc tape rolls#Friction Insulation tape#pvc tape manufacturers#electric tape roll

0 notes

Text

In the bustling city of Ghaziabad, finding a trusted and fully stocked electrical shop that combines quality with affordability can be a challenge. However, Dynamic Electric World has carved out its place as a leading electrical shop for professionals, homeowners, and businesses alike. With an extensive selection of products, knowledgeable staff, and a commitment to customer satisfaction, Dynamic Electric World has become a go-to destination for all things electrical.

Why Choose Dynamic Electric World?

Electrical shop in Ghaziabad, Dynamic Electric World is more than just a place to buy electrical supplies; it’s a partner in helping you achieve your electrical goals, whether it’s installing energy-efficient lighting, upgrading your home’s wiring, or setting up commercial electrical systems. Here’s what sets Dynamic Electric World apart:

Comprehensive Product Range Dynamic Electric World offers an extensive range of electrical products, from basic wiring and switches to advanced electrical appliances. Our products include:

Lighting Solutions: LED bulbs, smart lighting, chandeliers, jhumars, and wall-mounted fixtures.

Cables and Wires: Top-quality cables and wires that are safe, durable, and compliant with industry standards.

Switches and Sockets: From classic to modern styles, we offer a variety of switches, sockets, and panels.

Industrial Electrical Equipment: Specialized equipment for factories, warehouses, and commercial buildings.

By partnering with reputable brands, we ensure that every product in our inventory meets rigorous quality standards.

Expert Guidance and Support The team at Dynamic Electric World comprises knowledgeable professionals who are always ready to provide expert guidance. We understand that not everyone is familiar with electrical jargon or knows what they need for a particular project. Whether you’re a seasoned electrician or a homeowner tackling a DIY project, our staff will guide you in selecting the right products for safe and efficient electrical installations.

Affordable Prices with Quality Assurance At Dynamic Electric World, we believe that high-quality electrical products shouldn’t come at a premium. Our products are competitively priced to suit every budget, without compromising on quality. From small purchases like switches and sockets to bulk orders of industrial supplies, we ensure every customer finds value in every purchase.

Focus on Safety and Compliance Electrical work is inherently risky, which is why safety is a priority at Dynamic Electric World. All products comply with the latest safety regulations and are designed to minimize the risk of electrical hazards. We make sure that the items in our shop are sourced from certified manufacturers known for their safety protocols. Whether you’re looking for fire-retardant cables or child-safe outlets, we prioritize products that meet stringent safety standards.

Customer-Centric Services Dynamic Electric World places customer satisfaction at the heart of its operations. We offer:

Easy Returns and Exchanges: If a product doesn’t meet your expectations, we facilitate hassle-free returns and exchanges.

After-Sales Support: Our team provides after-sales assistance to ensure that customers are completely satisfied with their purchases.

Delivery Services: For customers in and around Ghaziabad, we offer reliable delivery services to get your products to your doorstep.

Product Categories and Specialties

1. Residential Electrical Solutions

Whether you’re remodeling your home or looking to upgrade old wiring, Dynamic Electric World has everything you need. Our collection includes user-friendly smart switches, energy-efficient lighting options, and reliable circuit breakers designed for residential use.

2. Commercial and Industrial Electrical Supplies

For commercial clients, we provide heavy-duty equipment like industrial-grade cables, transformers, and customized control panels. Our products are tailored to meet the demands of large-scale projects and help businesses operate with the assurance of safety and efficiency.

3. Modern Lighting Solutions

Our lighting section offers a blend of function and design. Whether you’re looking for LED downlights, jhumars for high-ceiling spaces, or energy-efficient strip lighting, our range includes stylish and durable options to brighten up any environment.

The Dynamic Electric World Difference

Commitment to Quality Unlike many electrical shops that cut corners to offer cheaper products, we prioritize quality and safety. Every item we stock undergoes a rigorous quality check to ensure it meets our high standards.

Local Presence with a Broad Reach Situated in Ghaziabad, Dynamic Electric World serves as a local, reliable source for electrical supplies. Our presence within the community helps us understand the unique needs of local residents, businesses, and industries. This local advantage allows us to offer products that specifically meet the requirements of our customers in Ghaziabad.

Eco-Friendly Options With a growing focus on sustainability, Dynamic Electric World offers energy-efficient products, like LED lighting and smart home automation solutions. We believe in helping customers reduce energy consumption and make environmentally conscious choices.

Visit Dynamic Electric World Today!

Electrical shop in Ghaziabad, Dynamic Electric World is more than just a shop – it’s a trusted partner for all your electrical needs. Our dedication to quality, safety, and customer satisfaction sets us apart as the premier choice in Ghaziabad. Whether you’re a professional electrician, a business owner, or a homeowner, we have the products, expertise, and services to meet your needs. Visit our store today to experience the difference and discover why so many in Ghaziabad trust us for their electrical solutions.

0 notes