#TitaniumHeating

Explore tagged Tumblr posts

Text

The muffle heating technique empowers orthopaedic implant manufacturers, providing precise temperature control and ensuring uniform Titanium heating. By carefully controlling atmospheric conditions, oxide formation is prevented, safeguarding the integrity of Titanium.

Explore how this correct heating method enhances mechanical properties, elevating strength and fatigue resistance to unparalleled levels. Additionally, this technique minimises thermal gradients within the Titanium, mitigating the risk of thermal stress-induced deformations and also enhances the microstructural properties, resulting in superior mechanical performance. Experience the precision of tailored heating protocols, designed to meet the demands of orthopaedic implant manufacturing while ensuring consistent quality and reliability.

For more information on optimal titanium heating practices, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumHeating#MuffleFurnace#UniformHeating#HomogeneousStructure#AlphaCaseFree#ImprovedMechanicalProperties#HorizonTitanium#StrongerTogether

0 notes

Video

youtube

Titanium is highly resistant to corrosion, making it an ideal materialfor marine structures like offshore oil rigs, ship hulls, and coastal structures. Titanium can withstand the harsh saltwater environment and has a long lifespan, reducing maintenance costs.

1 note

·

View note

Text

Heating Titanium is crucial for ensuring top-notch quality products. However, conventional methods can sometimes lead to undesirable outcomes. When Titanium is heated in open air or subjected to induction heating, it reacts with atmospheric gases, risking compromised quality. Moreover, with induction heating, only the outer surface receives adequate heat, leaving the inner layers insufficiently heated. This imbalance can lead to titanium failure, often resulting in cracking.

Stay tuned for our upcoming post, where we'll dive into the correct techniques for heating Titanium, ensuring optimal performance and durability.

#KnowYourTitanium#Titanium#TitaniumHeating#OpenAirHeating#InductionHeating#AlphaCaseFormation#UnevenHeating#SurfaceContamination#InhomogeneousMicrostructure#DiminishedMechanicalProperties#HorizonTitanium#StrongerTogether

0 notes

Text

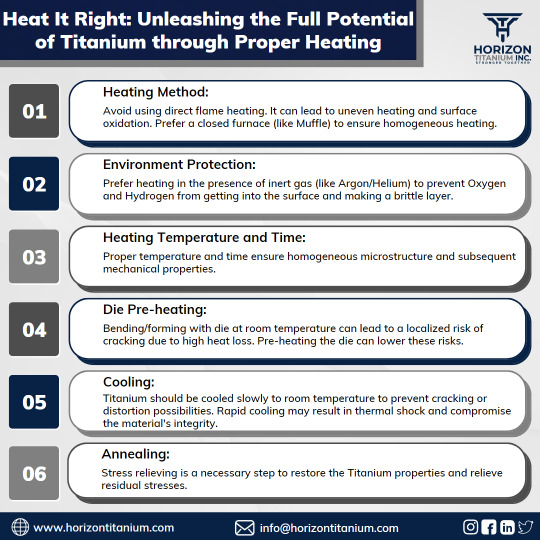

Heat It Right: Unleashing the Full Potential of Titanium through Proper Heating

Unlocking the full potential of titanium hinges on one crucial factor: proper heating. In our article, "Heat It Right: Unleashing the Full Potential of Titanium through Proper Heating," we delve into the essential techniques that can make all the difference. Learn the ins and outs of temperature control, expert tips, and best practices to optimize your titanium heating endeavors. Whether you're in medical, aerospace, manufacturing, or any industry reliant on titanium, this concise guide will empower you to achieve remarkable results. Discover the importance of heating titanium correctly and unlock its extraordinary capabilities.

For more information, feel free to reach out to us at [email protected].

#KnowYourTitanium#Titanium#TitaniumHeating#HeatTreatment#TitaniumMetallurgy#MedicalIndustry#AerospaceEngineering#HorizonTitanium#StrongerTogether

0 notes

Photo

When titanium is heated in the open air, it reacts strongly with the gases around it. This reaction forms different substances like titanium oxide, titanium nitride, and titanium hydride on the surface and just beneath it. These substances are hard and brittle, which means they can easily crack when exposed to high levels of stress. The problem arises because the core of the titanium and its surface have different properties. This creates a stress-raising effect on the surface, preventing the stress from being evenly distributed throughout the titanium. As a result, the titanium can crack and break apart. To know about the right way to heat the titanium and achieve optimum results, You can write to us at [email protected]

#KnowYourTitanium#TitaniumPlate#TitaniumHeating#TitaniumOpenAirHeating#TitaniumCrack#TitaniumBending#AtmosphereGases#TitaniumReaction#TiO2#TiN#TiH2#LowerFractureToughness#TitaniumImplantBending#TitaniumOrthopaedic#TitaniumImplants#MedicalImplants#HorizonTitanium#StrongerTogether

0 notes