#Thermosetting Plastics Market Analysis

Explore tagged Tumblr posts

Text

Global Thermosetting Plastics Market Is Estimated To Witness High Growth Owing To Increasing Demand For Lightweight and Durable Materials

The global Thermosetting Plastics Market is estimated to be valued at US$ 127,332.15 million in 2022 and is expected to exhibit a CAGR of 4.72% over the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights. A) Market Overview: Thermosetting plastics are a class of materials that are extensively used across various industries due to their excellent thermal and mechanical properties. These plastics are cured and hardened through irreversible chemical reactions, making them harder and more rigid than thermoplastics. The market for thermosetting plastics is driven by the increasing demand for lightweight and durable materials in industries such as automotive, aerospace, electrical and electronics, and construction. Thermosetting plastics find applications in circuit boards, automotive body parts, electrical insulators, adhesives, coatings, and more. These materials provide excellent heat resistance, chemical resistance, and electrical insulation, making them ideal for use in demanding environments. B) Market Key Trends: One key trend in the Thermosetting Plastics Market is the growing demand for eco-friendly materials. With increasing focus on sustainability and environmental concerns, there is a rising preference for bio-based thermosetting plastics over traditional petroleum-based materials. Bio-based thermosetting plastics are derived from renewable resources such as plant oils and starch, reducing the carbon footprint and environmental impact of the manufacturing process. These materials offer similar properties as traditional thermosetting plastics while being more sustainable and recyclable. For example, BASF SE, one of the key players in the market, has developed a range of bio-based epoxy resin systems for various applications. These resins are based on renewable raw materials such as succinic acid derived from plant oil. They provide similar performance and processability as traditional epoxy resins, while reducing the overall environmental impact. C) PEST Analysis: Political: The thermosetting plastics industry is regulated by various government agencies and authorities to ensure product safety and environmental compliance. Regulatory frameworks and standards vary across different regions, influencing the market dynamics and opportunities. Economic: The growing industrialization and increasing GDP of emerging economies such as China, India, and Brazil are driving the demand for thermosetting plastics. These countries have witnessed significant investments in infrastructure development, automotive production, and electronics manufacturing, creating a favorable market landscape for thermosetting plastics. Social: The increasing consumer demand for lightweight and fuel-efficient vehicles, smart devices, and sustainable construction materials is propelling the adoption of thermosetting plastics. These materials offer improved energy efficiency, reduced emissions, and enhanced product performance, aligning with the evolving social preferences. D) Key Takeaways: The global Thermosetting Plastics Market is expected to witness high growth, exhibiting a CAGR of 4.72% over the forecast period, due to increasing demand for lightweight and durable materials. The automotive industry, in particular, is driving the demand for thermosetting plastics due to their weight reduction potential and ability to withstand harsh operating conditions.

Key players operating in the global Thermosetting Plastics Market include Alchemie Ltd., Asahi Kasei Corporation, BASF SE, BUFA GmbH & Co. KG, Celanese Corporation, Covestro AG, Daicel Corporation, DSM, Eastman Chemical Company, INEOS, Kanoria Chembond Pvt. Ltd, Lanxess AG, LG Chem, Mitsubishi Engineering-Plastics Corporation, Nihon Gosei Kako Co. Ltd, Polynt SpA, Satyen Polymers Pvt. Ltd, Showa Denko KK, Solvay, Sumitomo Bakelite Co. Ltd, and U-PICA Company Ltd. These key players are focusing on product innovation, strategic collaborations, and capacity expansions to gain a competitive edge in the market.

#Thermosetting Plastics Market#Advanced Materials#Thermosetting Plastics Market Growth#Thermosetting Plastics Market Analysis#Thermosetting Plastics Market Forecast#Thermosetting Plastics Market Future#Thermosetting Plastics Market Key Players#Thermosetting Plastics Market Overview

0 notes

Text

Europe DAP & DAIP Molding Compounds Market, Outlook and Forecast 2025-2030

Diallyl Phthalate (DAP) and Diallyl Isophthalate (DAIP) molding compounds are specialized thermoset plastics widely recognized for their exceptional electrical insulation properties, mechanical strength, and high resistance to chemicals and heat. These materials are primarily used in electrical and automotive applications, where durability and performance are critical. DAP and DAIP are synthesized through polymerization processes that enhance their stability, making them an ideal choice for precision molding applications.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/285615/europe-dap-daip-molding-compounds-forecast-market-2025-2030-471

Market Size

The Europe DAP & DAIP Molding Compounds market was valued at US$ 156.48 million in 2024 and is projected to reach US$ 225.64 million by 2030, growing at a CAGR of 6.30% during the forecast period from 2024 to 2030. The increasing demand for high-performance thermoset plastics in electrical and automotive industries is a significant factor driving this growth. Germany leads the market, accounting for approximately 35.6% of the total market share due to its strong industrial base and technological advancements.

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

Drivers:

Growing demand for electrical insulation materials in power transmission and distribution.

Expanding automotive sector requiring high-performance thermoset plastics.

Increasing research and development (R&D) investments in advanced composite materials, with €45.8 million dedicated to innovation in 2024.

Enhanced electrical properties, with a reported 38.4% improvement over traditional materials.

Restraints:

High production costs associated with DAP & DAIP materials.

Stringent environmental regulations on thermoset plastic manufacturing.

Availability of alternative materials such as epoxy and phenolic resins.

Opportunities:

Rising adoption of halogen-free flame-retardant materials.

Expansion of manufacturing capabilities across Europe.

Growing emphasis on sustainable and recyclable thermoset plastics.

Challenges:

Fluctuating raw material prices affecting production costs.

Supply chain disruptions impacting material availability.

Limited awareness among end-users about the benefits of DAP & DAIP compounds.

Regional Analysis

Germany dominates the market, contributing 35.6% of the total revenue due to its strong electrical and automotive sectors. The United Kingdom, France, and Italy also play crucial roles, with significant investments in high-performance plastics. Spain, the Netherlands, and Belgium exhibit steady growth, driven by increasing industrial applications of thermoset molding compounds.

Competitor Analysis

The Europe DAP & DAIP Molding Compounds market is highly competitive, with major players investing in technological advancements and expanding their production capabilities. Key companies operating in this market include:

BASF SE

Evonik Industries AG

SABIC

Celanese Corporation

Sumitomo Chemical Co., Ltd.

LANXESS

Solvay S.A.

Toray Industries, Inc.

Covestro AG

Royal DSM

These companies focus on developing innovative formulations to enhance product performance and sustainability.

Market Segmentation (by Application)

This report provides a deep insight into the global DAP & DAIP Molding Compounds market, covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trends, niche market, key market drivers and challenges, SWOT analysis, and value chain analysis.

The analysis helps the reader shape the competition within the industries and develop strategies for the competitive environment to enhance potential profit. Furthermore, it provides a simple framework for evaluating and assessing the position of business organizations. The report structure also focuses on the competitive landscape of the global DAP & DAIP Molding Compounds market. This report introduces in detail the market share, market performance, product situation, operation situation, etc., of the main players, which helps industry professionals identify key competitors and understand the competition pattern of the market.

Market Segmentation (by Type)

General Purpose Grade

High Heat Resistance

Halogen-Free Flame Retardance Grade

Other

Key Company

Maintain this section intact, with no changes or additions.

Geographic Segmentation

Preserve this section as-is, without edits or omissions.

FAQ

What is the current market size of the Europe DAP & DAIP Molding Compounds market?

➣ The market was valued at US$ 156.48 million in 2024 and is projected to reach US$ 225.64 million by 2030, with a CAGR of 6.30%.

Which are the key companies operating in the Europe DAP & DAIP Molding Compounds market?

➣ Key players include BASF SE, Evonik Industries AG, SABIC, Celanese Corporation, Sumitomo Chemical Co., Ltd., LANXESS, Solvay S.A., Toray Industries, Inc., Covestro AG, and Royal DSM.

What are the key growth drivers in the Europe DAP & DAIP Molding Compounds market?

➣ Major drivers include the growing demand for electrical insulation materials, the expanding automotive sector, and increased R&D investments.

Which regions dominate the Europe DAP & DAIP Molding Compounds market?

➣ Germany leads with a 35.6% market share, followed by the United Kingdom, France, Italy, Spain, the Netherlands, and Belgium.

What are the emerging trends in the Europe DAP & DAIP Molding Compounds market?

➣ Emerging trends include the adoption of halogen-free flame-retardant materials, expansion of manufacturing capabilities, and increased focus on sustainable thermoset plastics.

Competitor Analysis

The report also provides analysis of leading market participants including:

Key companies DAP & DAIP Molding Compounds revenues in Europe market, 2019-2024 (Estimated), ($ millions)

Key companies DAP & DAIP Molding Compounds revenues share in Europe market, 2023 (%)

Key companies DAP & DAIP Molding Compounds sales in Europe market, 2019-2024 (Estimated),

Key companies DAP & DAIP Molding Compounds sales share in Europe market, 2023 (%)

Key Points of this Report:

The depth industry chain includes analysis value chain analysis, porter five forces model analysis and cost structure analysis

The report covers Europe and country-wise market of DAP & DAIP Molding Compounds

It describes present situation, historical background and future forecast

Comprehensive data showing DAP & DAIP Molding Compounds capacities, production, consumption, trade statistics, and prices in the recent years are provided

The report indicates a wealth of information on DAP & DAIP Molding Compounds manufacturers

DAP & DAIP Molding Compounds forecast for next five years, including market volumes and prices is also provided

Raw Material Supply and Downstream Consumer Information is also included

Any other user's requirements which is feasible for us

Reasons to Purchase this Report:

Analyzing the outlook of the market with the recent trends and SWOT analysis

Market dynamics scenario, along with growth opportunities of the market in the years to come

Market segmentation analysis including qualitative and quantitative research incorporating the impact of economic and non-economic aspects

Regional and country level analysis integrating the demand and supply forces that are influencing the growth of the market.

Market value (USD Million) and volume (Units Million) data for each segment and sub-segment

Distribution Channel sales Analysis by Value

Competitive landscape involving the market share of major players, along with the new projects and strategies adopted by players in the past five years

Comprehensive company profiles covering the product offerings, key financial information, recent developments, SWOT analysis, and strategies employed by the major market players

1-year analyst support, along with the data support in excel format.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/285615/europe-dap-daip-molding-compounds-forecast-market-2025-2030-471

0 notes

Text

Best Practices in Design for Manufacturing (DFM) for Plastic Parts

Design for Manufacturing (DFM) is a strategic engineering approach that simplifies and optimizes the manufacturing process right from the design stage. When applied to plastic part design, DFM ensures that products are easier, cost-effective, and efficient to manufacture without compromising on quality or performance.

In today's competitive market, the ability to address potential manufacturing challenges early in the design phase is a game-changer. From warping and sink marks to dimensional inaccuracies, DFM principles tackle these issues head-on, streamlining production, reducing costs, and maintaining product reliability.

This blog delves into the essential best practices for DFM in plastic part design. Whether you're an engineer, a designer, or a manufacturer, you'll find valuable insights and advanced strategies to elevate your design game. Here's what you can expect:

How Finite Element Analysis (FEA) predicts stress points to refine designs.

The role of sustainable materials and circular design in modern manufacturing.

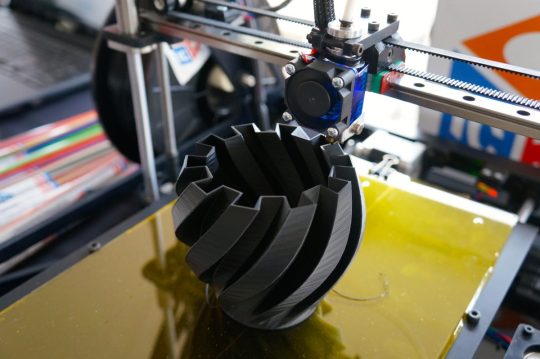

How additive manufacturing (AM) enhances production workflows for better outcomes.

Get ready to explore innovative approaches and actionable insights that go beyond standard practices, giving you the edge in plastic part design.

Advanced Material Selection

Thermoplastics vs. Thermosetting Plastics

Selecting the right material is a fundamental step in DFM. Plastics are categorized into thermoplastics and thermosetting plastics:

Thermoplastics:

These plastics soften when heated and solidify when cooled, making them suitable for processes like injection molding and recycling. Examples include Polypropylene (PP), Polycarbonate (PC), and ABS. They are ideal for applications requiring flexibility and recyclability.

Thermosetting Plastics:

Once cured, these plastics become rigid and heat-resistant, making them excellent for high-stress applications. Examples include epoxies and phenolics.

Advanced Material Blends

To meet complex design requirements, advanced material blends offer enhanced properties:

Glass-Filled Nylon: Provides increased rigidity and durability.

UV-Resistant Polymers: Suitable for outdoor components.

Carbon Fiber-Reinforced Plastics: Achieve superior strength-to-weight ratios. Using custom blends helps optimize designs for specific applications, such as medical devices requiring both strength and biocompatibility.

Sustainable Materials

Eco-friendly material selection is vital for reducing the environmental impact of plastic production:

Biodegradable Plastics: Materials like PLA (Polylactic Acid) offer sustainability without compromising performance.

Recycled Polymers: Incorporating recycled materials reduces production waste and aligns with circular economy goals.

Circular Design Concepts: Ensures parts are designed for reuse and recyclability at the end of their lifecycle.

Material Properties and Applications

DFM optimizes material properties to meet specific part requirements:

Thermal Resistance: For parts exposed to high temperatures.

Chemical Resistance: Critical for medical or industrial applications.

Hygroscopic Behavior: Mitigating moisture absorption in materials like Nylon ensures dimensional stability.

Wall Thickness Optimization

Importance of Uniform Wall Thickness

Consistent wall thickness is a key factor in achieving defect-free plastic parts. It helps:

Improves Material Flow

Consistent wall thickness ensures smooth and uniform material flow during the injection molding process. This helps avoid disruptions, reduces the risk of incomplete filling, and enhances the overall quality of the part.

Minimizes Defects

Uniform walls help minimize common defects such as warping, sink marks, and voids. These issues often arise from uneven cooling or pressure variations, both of which are mitigated with consistent thickness.

Reduces Cycle Time

A uniform wall thickness allows for faster and more predictable cooling, which significantly reduces production cycle times. This efficiency accelerates manufacturing and enhances productivity.

Variable Wall Thickness

In complex designs where uniform thickness isn’t feasible, gradual transitions in wall thickness are essential. Key strategies include:

Avoiding sudden thickness changes to prevent material flow disruptions.

Using ribs and bosses to support structural integrity without adding unnecessary weight.

Advanced Simulations for Wall Thickness

Simulation tools improve wall thickness optimization:

Finite Element Analysis (FEA) helps identify stress concentration points.

Computational Fluid Dynamics (CFD) simulates plastic flow and cooling behaviors.

Draft Angles for Mold Release

Purpose of Draft Angles

Draft angles are critical for ensuring smooth mold release during injection molding. Properly designed draft angles prevent parts from sticking to the mold, reducing production downtime and mold wear.

Recommended Angles

The general recommendations include:

1° to 3°: For smooth surfaces.

3° to 5°: For textured surfaces to account for friction.

Micro-Feature Drafting

For intricate or micro-scale features, smaller draft angles (as low as 0.5°) may be required. These features often appear in:

Medical Device Prototypes

Intricate features with smaller draft angles, sometimes as low as 0.5°, are essential for medical device prototypes. These components often require precise micro-texturing to meet stringent design and performance standards.

Additive Manufacturing for Low-Volume Applications

In low-volume production, especially using additive manufacturing, small draft angles are tested to evaluate their efficiency. This approach is particularly useful for validating designs and ensuring manufacturability before scaling up.

Impact on Automated Assembly

Proper draft design enhances automation processes such as pick-and-place systems and robotic handling. It also ensures precision for operations like insert molding and overmolding.

Rib and Boss Design for Strength and Efficiency

Guidelines for Ribs

Ribs add structural support without increasing wall thickness. DFM best practices for rib design include:

Rib thickness: 60% of the adjacent wall thickness.

Gradual rib transitions to avoid sink marks.

Tapered rib design for better mold release.

Topology Optimization for Rib Placement

Using advanced design software, topology optimization identifies the most efficient rib placements. This reduces:

Overall part weight.

Material usage while maintaining strength.

Boss Design and Cooling Integration

Bosses provide locations for screws or fasteners. Effective boss design ensures:

Adequate wall support to prevent cracking.

Integration with cooling channels to improve heat dissipation during molding.

Undercuts and Complex Features

Challenges in Molding Undercuts

Undercuts add complexity to molds, increasing costs and production time. They often require side-actions, lifters, or collapsible cores for molding.

Solutions for Undercuts

To address undercuts:

Redesign to eliminate unnecessary undercut features.

Utilize collapsible cores or slides for complex designs.

3D-Printed Mold Inserts

For low-volume production or prototyping, 3D-printed mold inserts provide a flexible and cost-effective solution. They allow for:

Testing complex geometries before final production.

Reducing lead times and tooling costs.

Tolerances and Fits

Managing Tight Tolerances

Precision is critical in plastic part design, especially for:

Shrinkage compensation: Accounting for material contraction during cooling.

Managing hygroscopic materials like Nylon to maintain dimensional stability.

Statistical Tolerance Analysis

Using tools like Six Sigma and GD&T (Geometric Dimensioning and Tolerancing) ensures tight tolerances for high-quality production.

Surface Finish and Functional Texturing

Importance of Surface Finish

Surface finish impacts both functionality and aesthetics. Proper finishes:

Improve part appearance.

Enhance functional performance (e.g., reducing friction).

Laser Texturing for Precision

Laser technology offers precise surface texturing, enabling:

Functional designs like self-cleaning surfaces.

Custom finishes for improved medical device prototyping.

Gate and Runner System Design

Hot vs. Cold Runner Systems

Hot Runners: Reduce material waste and cycle time.

Cold Runners: More cost-effective for smaller production runs.

Sequential Valve Gating

This advanced gating technique prevents flow marks and ensures uniform part filling, especially for larger parts.

Assembly Considerations

Integrated Fasteners

Designing integrated fasteners, such as snap fits or living hinges, reduces assembly complexity and costs.

Design for Disassembly

Designing for easy disassembly aligns with sustainability goals, enabling recyclability and reducing waste.

Future Trends in DFM

As the manufacturing landscape evolves, new advancements in technology and materials are redefining how we approach Design for Manufacturing (DFM). These trends promise to further streamline processes, improve sustainability, and enhance product quality.

AI-Driven Design Automation

Artificial Intelligence (AI) is transforming DFM by enabling intelligent design optimization. AI tools analyze massive datasets to identify patterns, predict design flaws, and suggest improvements early in the design phase. Key benefits include:

Automated Design Adjustments: AI-powered software can automatically adjust dimensions, tolerances, and geometries for manufacturability.

Faster Iteration Cycles: Machine learning algorithms reduce the time required for design revisions by predicting potential issues like stress points or material weaknesses.

Sustainable Plastic Innovations

The focus on environmental sustainability has pushed the boundaries of material science. Manufacturers are exploring innovative solutions to reduce waste and environmental impact:

Bio-based Plastics: Materials such as Polylactic Acid (PLA) and PHA are derived from renewable resources, offering biodegradability without compromising performance.

Recycled Plastics: Advanced sorting and recycling technologies are enabling high-quality recycled polymers for use in new designs, promoting a circular economy.

Integration of Additive Manufacturing (AM) for Complex Prototypes

Additive Manufacturing (AM), or 3D printing, continues to revolutionize prototyping and low-volume production. Its applications in DFM include:

Freedom of Design: AM enables the creation of intricate geometries, internal channels, and lightweight structures that are otherwise impossible with traditional manufacturing methods.

Rapid Prototyping: Engineers can produce prototypes within hours, test functionality, and iterate designs quickly.

Hybrid Manufacturing: Combining AM with traditional methods like injection molding allows for greater flexibility and cost-effectiveness. For example, 3D-printed mold inserts can be used for prototyping before committing to costly metal molds.

Enhanced Data-Driven DFM

Digital Twins: Digital twins—virtual replicas of physical products—are becoming central to optimizing manufacturing workflows. They allow real-time simulation and troubleshooting, ensuring smoother transitions from design to production.

IoT Integration: Sensors and IoT-enabled devices provide real-time feedback during manufacturing, helping refine designs for greater accuracy and efficiency.

The future of DFM is exciting, with these advancements poised to redefine efficiency, sustainability, and innovation across industries. Embracing these trends will ensure manufacturers stay competitive in an ever-evolving market.

Conclusion

Design for Manufacturing (DFM) is pivotal in creating cost-effective, high-quality, and reliable plastic parts. By implementing DFM principles early in the design phase, you can avoid common manufacturing challenges such as warping, sink marks, and dimensional inaccuracies while optimizing material use and production efficiency. From selecting the right materials to leveraging advanced technologies like AI, additive manufacturing, and sustainable practices, these strategies empower engineers and manufacturers to innovate while staying competitive in a rapidly evolving market.

At Aprios, we specialize in delivering end-to-end manufacturing solutions tailored to your needs. Our expertise in DFM for plastic part design ensures streamlined production, reduced costs, and superior product quality. Whether you're looking for advanced prototyping, material optimization, or scalable production processes, we’re here to help.

Explore how Aprios can take your project from concept to reality with our custom manufacturing services. We specialize in bringing your designs to life efficiently and sustainably, ensuring streamlined production and superior product quality. Contact us today to learn more about how we can support your manufacturing needs. Let Aprios help you transform your design vision into exceptional, manufacturable products.

#Custom Manufacturing Services#dfm services#design for manufacturing solutions#dfm development services#design for manufacturing services

1 note

·

View note

Text

Japan Thermoset Plastics Market Analysis 2032

Japan thermoset plastics market is expected to observe a CAGR of 5.38% during the forecast period FY2025-FY2032, rising from USD 5,107.88 million in FY2023 to USD 8,204.15 million in FY2032F. The growth of the market can be attributed to the quick development of the utilization of engineering plastics.

By FY2032, the thermoset plastics market in Japan is anticipated to grow due to the application of thermoset plastics market in Japan, driven by the nation’s ongoing development of its bio-based phenolic resins utilizing lignin and the quick development of integrated molding technology for carbon fiber-reinforced plastic. Therefore, it’s predicted that these developments would raise the need for thermoset polymers in several industries including steel, fertilizers, and the automobile industry.

Due to Japan’s stringent waste management and recycling laws, recycling technology and sustainable thermoset polymers are developing. NIPPON STEEL Chemical & Material Co., Ltd. supplies thermoset resin materials to enhance the durability and corrosion resistance of coatings applied to industrial facilities, bridges, and pipelines. This helps increase the demand for thermoset plastics.

For instance, Mitsui Chemicals Inc. and Microwave Chemical Co., Ltd. are developing chemical recycling technology using microwaves. Microwaves, used as household ovens and telecommunications, can directly and selectively transfer energy to materials, making conventional chemical processes more energy efficient. Environmentally friendly technology can reduce CO2 emissions and generate energy from renewable sources.

Saturated polyester resins, epoxy resins, and polyurethane foam manufacturing have increased significantly in the market, indicating a persistent need for these materials. Recent business changes that may affect the direction of thermoset plastic market in the future include advancements in manufacturing technology and the emergence of eco-friendly alternatives.

For instance, Daicel Corporation, specialist in innovative thermoset plastics solutions, is serving several industries including automotive, electronics, construction, and healthcare. Automotive parts, electrical components, building materials, and medical devices employ phenolic resins, epoxy resins, and polyurethane systems. Due to its concentration on these areas, Daicel is a reliable partner for companies looking for high-performance thermoset plastics solutions. It helps to propel innovation and sustainable growth in Japan’s industrial sector.

Thermoset Plastics Revolutionize Vehicle Lightweighting in EVs

Advance development in lightweight electric vehicles (EVs) has surged Japan’s thermoset plastic market. Players in Japan’s thermoset market are collaborating to develop advanced thermoset resin molding, while companies such as Nissei Plastic aim to optimize the injection pressure, which can help manufacturers create parts with tighter tolerances and improved quality. Overall, Japan’s automotive sector shows a bigger trend towards lightweight vehicles and sustainability, which can significantly impact the EV manufacturing while increasing the demand for thermoset plastics.

For instance, Celanese Corporation has launched two new polyamide solutions for electric vehicle powertrain components and battery applications. The Frianyl PA W-series flame-retardant polyamide solutions enable the production of large, thick-walled components for EV batteries. These solutions improve safety, design, and manufacturing efficiency. Applications include battery module housings and electronic box housings. The Frianyl PA W Series solutions have an excellent relative tracking index even after 1,000 hours of aging at 125 degrees Celsius. They offer remarkable long-term color stability, without visible changes to the naked eye or color laboratory measurements.

Wind Energy Industry Fuels Japan Thermoset Plastics Market Size

Wind energy generation promotes sustainability and economic progress by accelerating income creation through sophisticated recycling techniques in the thermoset plastics market. For instance, according to the Japan Wind Power Association (JWPA), by the end of FY2023, Japan’s total installed wind power capacity reached 5,213.4 MW. Due to breakthrough methods in small-molecule assistance, it is now possible to recycle wind turbine blades with up to 100% resin degradation yield for waste composite materials. Furthermore, as Japan and other countries increase their investments in wind power, using carbon fiber composites may generate economic growth while supporting sustainability in the market.

Increasing Utilization of Epoxy in Thermoset Plastics Dominates Japan Thermoset Plastics Market

Epoxy resins are essential thermoset polymers with unique characteristics and can be used in a wide temperature range. Epoxy has the highest contribution in Japan thermoset plastics market due to increasing use of epoxy in electrical components, paintbrush manufacturing, adhesives for structural usage, metal coatings, and high-tension electrical insulators increasing the demand of epoxy in thermoset plastics market in Japan. For instance, DIC’s epoxy resin curing agent, which can withstand temperatures up to 200 degrees Celsius and is recyclable, makes it easier to remold thermoset plastics, which were previously difficult to recycle.

Adoption of Injection Molding Technology in Japan Thermoset Plastics

As per the processing type, injection molding holds dominant market share due to its increasing usage in thermoset plastics leading to chemical crosslinking and hardening of polymer. Thermoset injection molding equipment generally includes a hydraulically driven clamping device for mold closure and an injection device for conveying materials, producing thermoset plastics used in the automobile industry and medical devices. Injection moldings offer advantages such as high production efficiency, intricate design capabilities, and consistent quality, making it a favored option among manufacturers for a wide range of applications.

South Japan Become the Highest Contributor in the Market

In 2024, the southern region of Japan has the highest share in Japan thermoset plastics market, followed by the north region. Japan’s regions are expected to experience a rise in power generation sector which will fuel the advancement of thermoset plastics. Thermoset plastics are successively employed in numerous applications, significantly contributing to the efficiency and reliability of power generation processes. For instance, NIPPON STEEL Chemical & Material Co., Ltd operates manufacturing plants across Japan, including Tokyo, Osaka, and Nagoya. The company continuously develops advanced technology and production capabilities to meet the demand for thermoset plastics.

Download Free Sample Report

Future Market Scenario (FY2025 – FY2032F)

As per Japan thermoset plastic market analysis, the demand for thermoset plastics will significantly increase over the forecast period, owing to rising demand from key End-use industries, including transportation, automotive, marine, aviation, power generation, oil, refinery, and others. Thermoset materials play a crucial role in the rising research and development activities for construction of wind turbine blades, solar panels, and other renewable energy infrastructure. For instance, the expansion of wind power generation capacities has expanded from 6.5 GW in FY2018 to 8.2 GW in FY2021 and solar power capacity has increased from 15.9 GW in FY2018 to 27.9 GW in FY2021. Additionally, thermoset plastics are heavily utilized for tanks, corrosion-resistant pipes, and insulation materials in the oil and refinery industries. As Japan continues to invest in infrastructure development and modernization of its oil and refinery facilities the demand for thermoset materials is expected to rise. Also, thermoset polymers are preferred within the maritime and aviation sectors because of their high strength-to-weight ratio and resistance to corrosion. Japan is predicted to become a maritime and aerospace-focused nation, which will increase demand for thermoset composites in shipbuilding, aircraft interiors, and structural components.

For instance, Daicel Corporation and Polyplastics Co., Ltd. partnered together to innovative thermoset plastic products with improved mechanical strength, flame retardancy, and heat resistance. The collaboration helps strengthen the companies’ competitive positions and differentiation in thermoset plastics market through technological leadership and product innovation, which will enhance their competitive standing in the thermoset plastics industry by means of technological leadership and product innovation.

Similarly, Microwave Chemical Co., Ltd. and Mitsui Chemicals Inc. are creating chemical recycling technology that can lower CO2 emissions and increase the energy efficiency of existing chemical operations using microwaves. The firm is engaged in the chemical recycling of plastics, including thermosetting sheet molding compound, flexible polyurethane foam, and waste from car shredders. Both businesses want to begin demonstration testing shortly following verification testing at a bench facility since early tests have yielded encouraging findings. The objective is to transform difficult plastic waste streams into premium materials that won’t sacrifice quality and are appropriate for delicate applications.

Report Scope

“Japan Thermoset Plastics Market Assessment, Opportunities and Forecast, FY2018-FY2032F”, is a comprehensive report by Markets and Data, that provides an in-depth analysis and qualitative and quantitative assessment of the current state of Japan thermoset plastics market, industry dynamics, and challenges. The report includes market size, segmental shares, growth trends, opportunities, and forecast between FY2025 and FY2032. Additionally, the report profiles the leading players in the industry, mentioning their respective market share, business model, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/japan-thermoset-plastics-market

Latest reports-

Contact

Mr. Vivek Gupta 5741 Cleveland street, Suite 120, VA beach, VA, USA 23462 Tel: +1 (757) 343–3258 Email: [email protected] Website: https://www.marketsandata.com

0 notes

Text

Thermosetting Plastics Market Size, Regional Revenue and Outlook 2025-2037

Research Nester assesses the growth and market size of the global thermosetting plastics market which is anticipated to be on account of the rising demand for bio dependent thermosetting plastic

Research Nester’s recent market research analysis on “Thermosetting Plastics Market: Global Demand Analysis & Opportunity Outlook 2037” delivers a detailed competitors analysis and a detailed overview of the global thermosetting plastics market in terms of market segmentation by type, molding process, end-user industry and by region.

Growing Demand for Bio-Based Thermosetting Plastics to Promote Global Market Share of Thermosetting Plastics Market

Request Free Sample Copy of this Report @ https://www.researchnester.com/sample-request-5892

The global thermosetting plastics market is estimated to grow majorly on account of the increased demand for polyurethane in the automotive industry. Some common uses of thermoset plastics across numerous industries and sectors include water & gas pipelines, medical equipment, storage boxes, and construction machinery parts. Since the thermosetting plastics are flexible and lightweight. Thermoset composites remain stable at all temperatures and in all ambiance. For instance, Bakelite is the most common thermoset plastic that is widely used in kitchenware, jewelry, children's toys, and pipe stems. Bakelite is also used in making switches because of its poor conductivity to electricity and heat. Other than this, epoxy resin is also applied to floors and various other surfaces to add tough coating. The global epoxy resin production stood at almost 3600 thousand tonnes in the year 2022. On the back of the rising utilization of thermoset plastics on various devices, the global thermosetting plastics market is anticipated to grow during the forecasted period. Other than this, the rising growth in the construction industry and rising demand for polyurethane in the automotive industry. Also, the advent of bio-based plastics is likely to showcase growth opportunities for the global thermosetting plastics market during the forecasted period. The properties such as chemical resistance, heat resistance, and structural integrity of the thermoset plastics are also going to augment the growth of the global thermosetting plastics market during the forecasted period.

Some of the major growth factors and challenges that are associated with the growth of the global thermosetting plastics market are:

Growth Drivers:

Rising Demand for Bio-depended Thermosetting Plastics

Surging Utilization of Thermosetting Plastics Making Kitchen Utensils

Challenges:

The rising feedstock crunch and exorbitant cost of thermosetting plastics, stringent government policies, and problems related to manufacturing techniques are some of the major factors anticipated to hamper the global market size of the global thermosetting plastics market.

Request for customization @ https://www.researchnester.com/customized-reports-5892

By type, the global thermosetting plastics market is segmented into unsaturated polyesters, polyurethanes, phenolic, epoxy, amino, alkyd, vinyl, and ester. Out of these, the unsaturated polyesters segment is expected to grow the most during the forecasted period. The growth can be attributed to the outstanding thermal opposition and high creep power of the materials.

By region, the Europe thermosetting plastics market is to generate the highest revenue by the end of 2036. The rising demand for thermosetting plastics can be attributed to the increasing utilization of epoxy for making various appliances.

This report also provides the existing competitive scenario of some of the key players of the global thermosetting plastics market which includes company profiling of Alchemie Ltd., Celanese Corporation, LANXESS, DAICEL CORPORATION, INEOS, BASF SE, Covestro A.G., BUFA GmbH & Co. KG, Daicel Corporation, Eastman Chemical Company, Asahi Kasei Corporation, Mitsui Chemicals, Inc., NIPPON STEEL Chemical & Material Co., Ltd., INOAC Corporation and others.

Access our detailed report @ https://www.researchnester.com/reports/thermosetting-plastics-market/5892

About Research Nester-

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision in order to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

Silicone Sealants Market Technological Advancements and Product Developments

Silicone Sealants Market Growth Strategic Market Overview and Growth Projections

The global silicone sealants market was valued at USD 3.78 billion in 2021 and is projected to reach USD 6.50 billion by 2030, registering a CAGR of 6.2% from 2022 to 2030.

The latest Global Silicone Sealants Market by straits research provides an in-depth analysis of the Silicone Sealants Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global Silicone Sealants Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the Silicone Sealants Market are

3M Company

BASF

B Fuller company

Dow Silicones Corporation

RPM International, Inc.

Henkel AG & Co

DuPont

Wacker Chemie AG

Shin-Etsu Silicones

I. du Pont de Nemours and Company

Get Free Request Sample Report @ https://straitsresearch.com/report/silicone-sealants-market/request-sample

The Silicone Sealants Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global Silicone Sealants Market: Segmentation

The Silicone Sealants Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

By Type

Acetoxy

Amino

Oximinics

Acetic

Others

By Technology

Room temperature vulcanizing (RTV)

Thermoset or Heat cured

Radiation cured

Pressure-sensitive

UV Cured

Others

By Application

Glass

HVAC

Paperboard & Packaging

wood & Furniture

Plastic

Plumbing

Sound Damping

Gasketing

Others

By End-Use Industry

Transportation (Automotive, Aerospace, Marine, Railway and Others)

Building & Construction (Residential Construction, Commercial Construction, Infrastructure and Others)

Electrical & Electronics

Household Appliance

Textile Industry

Healthcare

Packaging

Industrial

Others

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/silicone-sealants-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the Silicone Sealants Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the Silicone Sealants Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the Silicone Sealants Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the Silicone Sealants Market market over the next several years?

How do regulatory and legal frameworks influence the market?

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

0 notes

Text

Wind Turbine Composite Materials Market - Forecast(2024 - 2030)

Wind Turbine Composite Materials Market Overview

Request Sample :

The government across the globe is also investing huge amounts in alternative energy sources such as solar and wind which is further supporting the market growth for composite materials. The increasing focus of governments on offshore wind energy installations is driving the market growth between 2021–2026. However, the high cost of carbon fiber and epoxy resin and recyclability issue of composites will likely hamper the market growth during the forecast period.

COVID-19 Impact

The COVID-19 pandemic has impacted the composite materials industry which has further impacted the wind turbine market. Due to the Covid-19, the manufacturing industry is impacted very badly that further impacted the wind turbine composite materials market. The slowdown in wind turbine installations and lack of raw material supplies, and workforce are impacting the market negatively. The covid-19 impacted every operation such as supply chain, production, sales, and others. However, the companies resumed their operation in 2021, which may positively impact the market.

Report Coverage

The report: “Wind Turbine Composite Materials Market — Forecast (2021–2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the Wind Turbine Composite Materials industry. By Fiber Type: Glass Fiber, Carbon Fiber, Aramid Fiber, and Basalt fiber By Resin Type: Thermoplastic [Polyethylene, Polystyrene, Polyamides, Nylon, Polypropylene, Others], and Thermoset [Epoxy, Polyester, Phenolic Polyamide, and Others] By Technology: Injection Molding, Compression Molding, Pultrusion, Filament Winding, and Layup By Application: Blades, Wind turbine Hub, Rotor, Tower, Nacelle, Cables, Blade Pitch Controller, Propellers, and Others By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, Italy, France, Netherlands, Belgium, Spain, Denmark, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and Rest of the World (the Middle East and Africa)

Inquiry Before Buying :

Key Takeaways

The Asia Pacific region is expected to dominate the market and register the highest CAGR of 12.8% during the forecast period (2021–2026). The presence of leading chemical companies along with rapid growth in the personal care industry is propelling regional growth.

Epoxy resin is one of the widely used resins in wind turbine manufacturing. The segment is expected to register a high growth rate during the forecast period.

The growing installation of wind turbines in developing countries such as Brazil, Mexico, India, and China is creating a positive impact on the usage of wind turbine composite materials.

Figure: Asia Wind Turbine Composite Materials Market Revenue, 2020–2026 (US$ Billion)

For More Details on This Report — Request for Sample

Wind Turbine Composite Materials Market Segment Analysis: By Fiber Type

The glass fiber reinforced plastics segment accounted for the largest share of more than 55% in the wind turbine composite materials market in 2020 and is estimated to grow at a significant rate during the forecast period. Glass fiber offers various properties including high strength, high durability, weather-resistant, and lightweight have boosted its demand in numerous end-use industries. The easy availability and cost-effectiveness of glass fiber reinforced plastics are the key factors propelling the demand for glass fiber composites in wind turbine manufacturing. The carbon fiber segment will register a significant growth rate during the forecast period. Carbon fibers offer various properties such as low thermal expansion, high stiffness, high-temperature tolerance, and high chemical resistance among others.

Schedule A Call:

Wind Turbine Composite Materials Market Segment Analysis: By Resin Type

The thermoset segment accounted for the largest share of more than 70% in the Wind turbine composite materials market in 2020 and is estimated to grow at a significant rate during the forecast period. Thermoset composite is usually based on carbon, glass, and aramid fibers. Epoxy resin is the widely used thermoset type in wind turbine composite materials. Approximately 50% of European wind blades are manufactured from epoxy resin. These resins offer lightweight, and good adhesion compared to other resin types. Generally, they are combined with glass fibers and carbon fibers to manufacture wind blades. The thermoplastic segment is expected to register a significant growth rate during the forecast period. Thermoplastics are less expensive compared to thermoset resin types. They are easily weld-able, non-toxic in nature, and recyclable. These are some of the driving factors supporting the market growth between 2021–2026.

Wind Turbine Composite Materials Market Segment Analysis: By Technology

The Layup segment accounted for the largest share of more than 33% in the wind turbine composite materials market in 2020 and is estimated to grow at a significant rate during the forecast period. Layup is the most common method used for the production of composites. The method is involved in placing layers of composite fiber in a structured order by using a matrix of resin and hardener. This method is widely used for the production of wind blades.

Wind Turbine Composite Materials Market Segment Analysis: By Application

The blades segment accounted for the largest market share of more than 55% of the market in 2020 and is estimated to grow significantly during the forecast period. Turbine blades serve as the most important composite-based part of wind turbines. The growing demand for wind energy is driving manufacturers to develop large wind blades for the high production of wind energy. For the development of large blades, a huge quantity of composite materials is used. Glass fibers and carbon fibers are used for the manufacturing of wind blades.

Wind Turbine Composite Materials Market Segment Analysis — By Geography

The Asia Pacific region held the largest share of more than 45% in the Wind Turbine Composite Materials market in 2020, owing to the rapid growth in the installation of wind turbines. The presence of developing nations such as China and India is driving the market growth. The presence of leading wind turbine manufacturers including Suzlon Energy Limited, and AVIC Huiteng Windpower Equipment Co., Ltd are supporting the region’s growth during the forecast period. The increasing investments by key developers for manufacturing efficient wind turbines are also boosting the market growth during the forecast period. According to the data published by Global Wind Energy Council (GWEC), China installed about 52 gigawatts of new wind power capacity in 2020.

Buy Now :

Wind Turbine Composite Materials Market Drivers

Rising Demand for Renewable Energy Sources

Wind energy is one of the fastest-growing renewable energies globally. Wind power is a clean energy source, and its usage is on the rise worldwide. The U.S. wind energy occupies approximately 38% of total renewable energy produced in 2019. According to the IRENA’s data, wind energy generation is increased from 7.5GW in 1997 to 564GW by 2018. Some ongoing and under-construction wind projects in the U.S. include Traverse Wind Energy Center, Aviator Wind Project, Goodnight Wind Energy Project, Alle-Catt Wind Farm, and Vineyard Wind I among others. According to the Ministry of New and Renewable Energy (MNRE), India has the fourth-highest wind installed capacity in the world with a total installed capacity of 39.25 GW (as of 31st March 2021) and has generated around 60.149 billion Units during 2020–2021. According to the European Commission, the total installed wind energy capacity in Europe reached 210GW and is estimated to reach 350GW, supplying up to 24% of electricity demand

Wind Turbine Composite Materials Market Challenges

Recyclability Issue of Composites

Composite materials are preferred for wind applications because of their durability and superior strength. Proper waste disposal and recycling at the end of the useful life of composite materials are necessary. Many current and future waste management and environmental legislation are making strict regulations on engineering materials to be properly recovered and recycled. The complex material compositions and the cross-linked nature of thermoset resins are making it difficult for recyclability. However, the use of polymers that can be recycled when used with carbon and other niche fibers reduces the composite non-recyclable. This has become a major issue as the landfills are filling up at a faster pace along with the need for going green due to global warming. Biological attack on composite materials may consist of fungal growth or marine fouling

Wind Turbine Composite Materials Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Wind Turbine Composite Materials market. Major players include:

TPI Composites, Inc.

MFG Wind

LM Wind Power

Gamesa Corporation Technology

Vestas Wind Systems A/S

Suzlon Energy Limited

Siemens AG

AVIC Huiteng Windpower Equipment Co., Ltd.

AREVA and others.

Acquisitions/Technology Launches

In May 2021, Hexcel launched a range of HexPly® surface finishing prepregs and semi- prepregs for wind turbine blades and automotive and marine applications.

Relevant Reports

Composite Materials Market — Forecast(2021–2026) Report Code: CMR 0010

High-Temperature Composite Materials Market — Forecast(2021–2026) Report Code: CMR 10087

For more Chemicals and Materials Market reports, please click here

#WindTurbine#CompositeMaterials#RenewableEnergy#SustainableTech#GreenEnergy#MaterialInnovation#CleanEnergySolutions

0 notes

Text

0 notes

Text

Pigment Dispersants Market: Current Analysis and Forecast (2022-2028)

According to a new report published by UnivDatos Markets Insights, the Pigment Dispersants Market was valued at more than USD 38 billion in 2020 and is expected to grow at a CAGR of around 4% from 2022-2028. The analysis has been segmented into Pigment Type (Organic Pigment and Inorganic Pigment); Dispersion Type (Water-based and Solvent-based); Application (Decorative Paints & Coatings, Automotive Paints & Coatings, Industrial Paints & Coatings, Plastic, and Others); and Region/Country.

The pigment dispersants market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the pigment dispersants market. The pigment dispersants market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing market growth. Furthermore, this statistical market research repository examines and estimates the pigment dispersants market at the global and regional levels.

Market Overview

Pigment dispersants are two-component structures, with the anchoring group providing strong adsorption onto the pigment surface. Polymeric chains, which are attached to the anchor group, provide stabilization. Pigment dispersants are used by manufacturers to color a wide range of materials, including paint, coatings, and plastics. Thermoset composites, inks, plastics, textiles, and decorative and industrial applications are some major factors in their uses.

The growing demand for paints and coatings in automotive, construction, and other industries in developing nations positively influences the growth of the market. For instance, according to the National Bureau of Statistics, construction output contributed 25.9% of China's GDP in 2020, up from 6.2% in 2019. This rapid growth in construction activity contributed to the growth of the pigment dispersant market.

Some of the major players operating in the market include BASF SE, King Industries Inc., Dow, Ethox Chemicals LLC., Solvay S.A., The Lubrizol Corporation, Elementis plc, Kao Corporation, Palsgaard, and American Element.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted almost every industry. Also, the companies suffered a huge downfall in revenue due to a halt in production activities and regulations forbidding social gatherings. Furthermore, disruption in raw material supply, liquidity shortage, and labor shortage. These factors affected the market growth during the pandemic.

The global pigment dispersants market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

On the basis of dispersion type, the market is categorized into water-based and solvent-based. Among these, the solvent-based category to hold a significant share of the market in 2020. This is mainly due to the wide range of applications, beneficial properties, and high consumption of these pigments. Moreover, these pigments are highly used in labels and packaging inks, in coatings for wood & metal, and in cosmetic nail lacquers which will boost their market growth during the forecast period.

Based on application, the pigment dispersants market has been classified into decorative paints & coatings, automotive paints & coatings, industrial paints & coatings, plastic, and others. The decorative paints & coatings category is to witness considerable growth during the forecast period. This is mainly due to their demand in the residential, commercial building construction, and automotive sectors.

Pigment Dispersants Market Geographical Segmentation Includes:

North America (United States, Canada, and Rest of North America)

Europe (Germany, United Kingdom, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

This is mainly due to the rapidly growing middle-class population, which fuels the textile and plastic demand. The pigments and dyes market will majorly be concentrated in the Asia Pacific region, mainly due to lenient environmental laws, cheap labor costs, easy availability of low-cost raw materials, and higher market demands. Furthermore, the development of new products and the availability of market players in developing countries are also contributing to the growth of the market in the region. For instance, in 2021, AkzoNobel N.V. and Mercedes-Benz expand their partnership agreement for another 4 years. This means the company will continue to provide vehicle refinish products including automotive and specialty coatings and services in China and a preferred partner in Indonesia.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=32458

The major players targeting the market include

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Pigment Dispersants Market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the pigment dispersants market?

• Which factors are influencing the pigment dispersants market over the forecast period?

• What are the global challenges, threats, and risks in the pigment dispersants market?

• Which factors are propelling and restraining the pigment dispersants market?

• What are the demanding global regions of the pigment dispersants market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

About UnivDatos Market Insights

UnivDatos Market Insights (UMI) is a passionate market research firm and a subsidiary of Universal Data Solutions. We believe in delivering insights through Market Intelligence Reports, Customized Business Research, and Primary Research. Our research studies are spread across topics across the world, we cover markets in over 100 countries using smart research techniques and agile methodologies. We offer in-depth studies, detailed analysis, and customized reports that help shape winning business strategies for our clients.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Powder Coatings Market - Forecast(2024 - 2030)

Powder Coatings Market Overview

The Powder Coatings Market size is forecasted to reach US$18.2 billion by 2027 after growing at a CAGR of 6.1% during the forecast period 2022-2027. Powder coating is a dry finishing process in which free-flowing, thermoplastic or thermoset powder material is applied to a surface, melted and then allowed to dry and harden into a protective coating. Powder coating based on thermoplastic polymers is derived from polyolefins, polyvinyl chloride, polyvinyl fluoride, polyester and so on whereas thermoset-based powder coatings are derived from epoxy, polyester, acrylic, polyurethanes and so on. Powder coating imparts a high-quality, durable finish, that allows for improved efficiency and is eco-friendly. Powder coatings are based on polymer resin systems. The environmental advantages offered by powder coatings compared to liquid coating methods drives the powder coatings market. The pandemic resulted in shortages of raw materials and supply chain disruptions. According to Echemi, a chemical industry B2B website, there were shortages of neopentyl glycol that is used in many of the resins for powder coatings and triglycidyl isocyanurate which is a curing agent used in polyester powder coatings. This resulted in price hikes of over 60% in the Powder Coatings industry.

Powder Coatings Market Report Coverage

The “Powder Coatings Market Report – Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments of the Powder Coatings industry.

By Resin Type: Thermoset (Epoxy, Polyester, Acrylic, Fluoropolymer, Polyurethanes and Others) and Thermoplastic (Polyamide, Polyolefin, Polyethylene, Polyvinyl Chloride, Polypropylene and Others).

By Coating Method: Fluidized Spray, Electrostatic Fluidized Bed, Electrostatic Spray and Others.

By Substrate: Metal (Steel, Aluminum and Others) and Non-Metal (Plastic, Wood, Ceramics, Glass and Others).

By End-Use Industry: Automotive [Two-wheelers (Scooters and Bikes) and Three/Four-wheelers (Passenger Cars, Heavy Commercial Vehicles and Light Commercial Vehicles)], Construction (Outdoor Construction and Indoor Construction), Appliances (Refrigerator, Water Coolers, Vending Machines, Washing Machines, Air Conditioners/Coolers, Electrical Fans, Kitchen Blenders/Mixers, Vacuum Cleaners, Water Heaters, Ovens & Chimneys, LPG Cylinders and Others), Electrical & Electronics (Transformers, Generators, ATM Machines, Industrial/Commercial Systems, Electrical Motor Stators/Rotors, Electric Meters & Connectors, Computer Room Floor System and Others), General Industrial (Industrial Carts & Power Tools, Storage & Racking, Escalators & Elevators, Lockers, Walls & Fittings, Water Pumps, Steel Drums, Pipes & Rebars and Others), Furniture (Outdoor Metal Furniture, Beds & Chairs, Benches and Others), Medical, Transportation & Equipment (Railways, Industrial Transportation, Construction Equipment, Agricultural Equipment, Marine, Aerospace) and Others.

By Geography: North America (the USA, Canada and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Denmark, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and Rest of South America), Rest of the World (the Middle East and Africa)

Request Sample

Key Takeaways

The Asia-Pacific region dominates the powder coatings market on account of the increasing construction activities and the recovering automotive industry. According to Invest India, the construction industry in India is expected to reach $1.4 trillion by 2025.

There are two types of powder coatings, thermoplastic and thermoset. Thermoplastic powders are commonly derived from polyolefins, polyvinyl chloride and polyvinyl fluoride while thermosetting powders are derived from acrylic, epoxy and polyester resins.

Thermoplastic powder coating melts and flows when heat is applied but continues to have the same chemical composition once it cools and solidifies. On the other hand, thermoset powder coatings will not melt when heated after curing.

The major opportunity for this market is developing thin-film coatings.

A detailed analysis of strengths, weaknesses, opportunities and threats will be provided in the powder coatings market report.

Powder Coatings Market Segment Analysis – by Resin Type

The thermoset segment held a dominant Powder Coatings Market share in 2021 and is expected to grow at a CAGR of 7.2% during the forecast period of 2022-2027. In the powder coating process, as the powder heats and melts it flows around the surface of the object and undergoes a chemical change called cross-linking which forms a hard and durable coating. Thermosetting coatings do not re-melt when they are cooled after heat is re-applied. In its powdered state, thermoset material tends to have a much lower molecular weight than other coating materials, usually requiring less heat to melt, making it more energy efficient. Thermoset powders are commonly derived from epoxy, acrylic, polyester and polyurethane groups. The most frequently employed are epoxy and polyester-based resins. Epoxy resin-based thermoset powders form a tough impact-resistant coating that has excellent corrosion resistance, so they are used for internal applications. Polyester-based coatings have the added advantage of being highly UV resistant, making them an ideal choice for outdoor applications. Thus, the thermoset segment is anticipated to dominate the powder coatings market.

Inquiry Before Buying

Powder Coatings Market Segment Analysis – by Application

The construction segment held a dominant Powder Coatings Market share in 2021 and is expected to grow at a CAGR of 8.3% during the forecast period of 2022-2027. Powder coating can be used for metal components such as door frames, railings, window frames, fencing, shelters, storefronts, façade or other areas of buildings. According to WSP, around 25% of the overall construction cost is the façade, with the metal contributing a major part of the cost. Powder coating can prevent corrosion and minimize re-coating as it imparts a long-lasting coating. The powder coat is more resistant to scratching, fading, erosion or other types of damage that can ruin the aesthetic appeal of a building The latest trend in the construction industry is low-emitting products and sustainable buildings. According to the U.S. Green Building Council (USGBC), 1,105 projects have been certified with LEED certification for green buildings in the U.S. in 2021. Powder coatings are solvent and VOC-free and produce less waste than other coating methods, making them a clear choice for green buildings. Thus, the construction industry is expected to dominate the market.

Powder Coatings Market Segment Analysis – by Geography

The Asia-Pacific region held the dominant Powder Coatings Market share up to 60% in 2021 owing to the rising consumption of powder coatings from the automotive, construction and appliances sector. The construction activities in the region rebounded after the initial lockdown in 2020. The government of India has made several investments in construction and infrastructure to aid in development. As per a report by the Indian Construction Equipment Manufacturers Association (ICEMA), the construction equipment industry recorded a 47% growth in the second quarter of FY2021-22. According to a news report in Reuters, in FY22-23, US$529.7 billion will be invested to further drive economic growth across the country. China’s construction sector is expanding rapidly. according to the National Bureau of Statistics, China’s construction output is estimated to be worth approximately US$4.3 trillion in 2021. China plans to invest US$1.43 trillion in key construction projects as part of its 14th five-year plan. As per the National Development and Reform Commission (NDRC), the Shanghai plans call for a total investment of US$38.7 billion over the next three years. The Japanese construction industry is expected to boom as the World Expo will be hosted in Osaka, Japan in 2025. Therefore, this region is set to dominate the Powder Coatings market.

Schedule a Call

Powder Coatings Market Drivers

Environmental Advantages of Using Powder Coatings

Powder coating is the green process of choice for finishing operations. It produces less waste than other finishing processes such as liquid coating. The use of powder coating aids in eliminating waste because, after application, the powder coating overspray can be reclaimed and reused. These types of reclamation practices keep overhead costs low while minimizing environmental impacts. Solvents contain volatile organic compounds (VOCs) which are detrimental to the environment. In liquid coatings, the average VOC content is between 3.5 to 5.5 pounds per gallon, which is approximately one-third to one-half of each gallon of the liquid coating being emitted into the environment during the application process. Since powder coating lines do not require the use of solvents, they do not emit VOCs and can operate with reduced energy, faster curing and lower temperatures. This makes powder coatings highly attractive from an environmental perspective. Innovations in the powder coatings industry strive to make it even better. For instance, in early 2020, Sherwin-Williams General Industrial Coatings division launched the Powdura ECO line made from a resin that uses pre-consumer recycled polyethylene terephthalate (rPET). Thus, the environmental advantages offered by using powder coatings drive the market.

Growing Usage of Powder Coatings in Electric Vehicles

The growth of electric vehicles (EVs) can be attributed to increasing oil prices and growing awareness regarding climate change. According to the International Energy Agency (IEA), in 2021, sales of electric cars (including fully electric and plug-in hybrids) doubled to a new record of 6.6 million. Sales kept rising in 2022 as well, with 2 million electric cars sold worldwide in Q1 2022, up almost 75% compared to Q1 2021. To keep EV motors and batteries operating efficiently, it’s important to maintain an optimum temperature range. Sometimes EV motors can generate operating temperatures that may exceed 200°C. Powder coatings are used to insulate battery boxes and isolate thermal activity. To take advantage of the growing EV market, powder coating manufacturers are launching products that cater to EVs. For instance, in January 2022, Arkema announced high-voltage coating solutions for electric vehicles. The two new polyamide 11 powder coating grades with UL certification were introduced for use in electric vehicle battery systems and other applications. Thus, the growing usage of powder coatings for EVs drives the market.

Powder Coatings Market Challenge

High Initial Investment

The major restraint in the Powder Coatings market is the high initial investment required to set up the powder coating equipment. Liquid coating applications only require a spray gun and a spray area. Comparatively, a powder coating workshop needs a spray gun, spray booth and curing oven. The addition of the curing oven adds significantly to the initial start-up costs for powder coating. The size of the curing oven purchased needs to take into account the maximum part size that can effectively be handled. Larger, thicker and heavier parts require a larger and more powerful oven, which further adds to the overall equipment costs. While metals can be powder coated using electrostatic spray deposition, non-metals require a fluidized bed powder coating application. The need for a fluidized bed also increases the overall equipment costs for the establishment of a complete powder coating facility. This can prove to be a challenge for the powder coatings market.

Buy Now

Powder Coatings Industry Outlook

Product launches, acquisitions and R&D activities are key strategies adopted by players in the Powder Coatings market. The top 10 companies in the Powder Coatings Market are:

PPG Industries

AkzoNobel Powder Coatings

BASF SE

Axalta Coating Systems

The Sherwin Williams Company

Jotun

Valspar Corporation

Nippon Paint Holdings Co. Ltd.

Kansai Nerolac Paints Limited

Tiger Coatings

Recent Developments

In June 2022, Polychem launched a new powder coating collection called the Effects Collection. The collection features powder special effects, such as speckles, translucents, metallics, sparkle translucent, veins, patina effects, river textures, fine textures and dramatic illusion colors, available in a variety of colors.

In May 2022, AkzoNobel Powder Coatings launched a comprehensive range of ready-to-ship powder coatings ranges specifically for the North American market. The range comprises approximately 500 unique powder coatings, with a broad variety of premium quality colors, textures and finishes.

In February 2022, PPG announced that it has entered into an agreement to acquire the powder coatings business of Arsonsisi, an industrial coatings company based in Milan, Italy. The acquisition will enable PPG to expand its powder coatings offering in the Europe, Middle East and Africa (EMEA) region.