#Thermal conductive pads

Explore tagged Tumblr posts

Text

Upgrade your cooling system with the ultimate thermally-conductive interface pads from E Control Devices. Our ultra-lightweight pad offers superior thermal performance and a low thermal impedance, letting you keep your electronics cool with minimal heat dissipation - trust the power of E Control Devices!

0 notes

Text

Liftoff!!! Europa Clipper is Away! 🛰️

NASA’s Europa Clipper has embarked on its long voyage to Jupiter, where it will investigate Europa, a moon with an enormous subsurface ocean that may have conditions to support life. The spacecraft launched at 12:06 p.m. EDT Monday aboard a SpaceX Falcon Heavy rocket from Launch Pad 39A at NASA’s Kennedy Space Center in Florida.

The largest spacecraft NASA ever built for a mission headed to another planet, Europa Clipper also is the first NASA mission dedicated to studying an ocean world beyond Earth. The spacecraft will travel 1.8 billion miles (2.9 billion kilometers) on a trajectory that will leverage the power of gravity assists, first to Mars in four months and then back to Earth for another gravity assist flyby in 2026. After it begins orbiting Jupiter in April 2030, the spacecraft will fly past Europa 49 times.

In 2031, the spacecraft will begin conducting its science-dedicated flybys of Europa. Coming as close as 16 miles (25 kilometers) to the surface, Europa Clipper is equipped with nine science instruments and a gravity experiment, including an ice-penetrating radar, cameras, and a thermal instrument to look for areas of warmer ice and any recent eruptions of water. As the most sophisticated suite of science instruments NASA has ever sent to Jupiter, they will work in concert to learn more about the moon’s icy shell, thin atmosphere, and deep interior.

Read more:

12 notes

·

View notes

Text

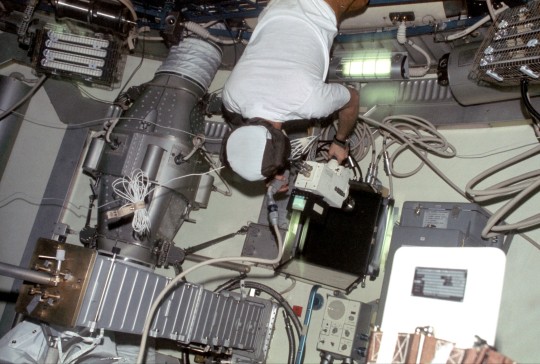

Skylab Missions: Skylab 3

*

"These three men are the prime crewmen for the Skylab 3 mission. Pictured in the one-G trainer Multiple Docking Adapter (MDA) at the Johnson Space Center (JSC) are, left to right, scientist-astronaut Owen K. Garriott, science pilot; and astronauts Jack R. Lousma and Alan L. Bean, pilot and commander, respectively."

Mission Duration: July 28 - September 25, 1973

Time Duration: 58 days, 15 hours, 39 minutes, 42 seconds

"The Skylab 3 mission started out as routine, but was not without in-flight high drama of its own. Shortly after docking and entering the Orbital Workshop (OWS), all three crew members experienced motion sickness, delaying the activation of OWS on-board equipment.

A more serious concern was raised on Mission Day-5 (MD-5). An apparent failure of two of the four thruster quadrants of the Command Service Module (CSM) reaction control system was detected.

Not only could an actual failure like this create an early end to the mission, it also could conceivably render the CSM incapable of supporting a safe return of the astronauts to Earth.

Launch crews at the Kennedy Space Center were placed on a 24-hour per-day, seven day per-week work schedule to prepare the Skylab 4 Saturn IB launch vehicle for flight in case an early launch was needed for a rescue operation."

The Skylab 4 Saturn IB (CSM-118/SA-208) launch vehicle is rolled to Launch Complex 39, Pad B.

"A decision was made to continue the mission, and although the Skylab 4 launch vehicle had been rushed to flight-readiness, the CSM performed flawlessly during re-entry operations.

On August 6, 1973 astronauts Garriott and Lousma performed a spacewalk which lasted 6 hours, 31 minutes. During this spacewalk, the astronauts were able to extend an external twin-pole thermal shield to replace the parasol thermal shield installed by the Skylab 2 crew. They also retrieved and replaced film from solar telescopes housed outside the OWS.

A second spacewalk by astronauts Garriott and Lousma was conducted on August 24, 1973. This one lasted 4 hours, 31 minutes. During this spacewalk, the astronauts retrieved and replaced film from solar telescopes housed outside the OWS and installed a cable for a new rate gyro package. They also performed some maintenance activities.

The third and final spacewalk of the mission was conducted on September 22, 1973. This one was conducted by astronauts Bean and Garriott and lasted 2 hours, 41 minutes. During this spacewalk, the astronauts retrieved and replaced film from solar telescopes housed outside the OWS and performed maintenance activities on other external experiment packages.

Scientific experiments, including the observation of unanticipated dynamic solar activity, continued for much of the 59-day mission. The crew participated in classroom-oriented educational demonstrations regarding weightlessness.

The Skylab 3 crew set a new manned space flight endurance record. Their in-flight health fared markedly better than the Skylab 2 crew, with the exception of the amount of bone calcium loss.

A significant demonstration of long-term space flight and the long-term viability of the OWS was successfully achieved."

* Due to a NASA management error, crewed Skylab mission patches were designed in conflict with the official mission numbering scheme.

An interesting side note, the wives created their version of the patch. I've covered the NSFW bits just so the Tumblr staff doesn't mark my blog as NSFW.

"The main feature on the second Skylab crew patch was Leonardo da Vinci's universal man, slightly retouched to make it 'G-rated'! Without their husbands knowledge, the astronaut wives also had a patch made which was a joke version of the official crew patch. The universal man figure had been replaced by a 'universal woman'. Instead of the astronauts names; Bean, Garriott and Lousma, their wives first names were shown: Sue, Helen-Mary and Gratia. The crew first became aware of the wives patch when they found stickers of them in their lockers on board Skylab."

source, source

NASA ID: S72-51123, S73-28714, 72-HC-90, SL3-108-1288, SL3-109-1345, S74-15583, SL3-111-1505, S73-34369, SL3-117-2109

#Skylab III#Skylab 3#SL-3#SLM-2#NASA#Apollo Program#Apollo Applications Program#Skylab Orbital Workshop#Skylab OWS#Skylab#Space Station#July#September#1973#Saturn IB#CSM-118#SA-208#rocket#rollout#Kennedy Space Center#KSC#Florida#my post

114 notes

·

View notes

Text

Liftoff! NASA’s Europa Clipper Sails Toward Ocean Moon of Jupiter

The massive spacecraft heads for Europa to search for signs of whether the ocean thought to exist beneath the moon’s icy shell could support life.

NASA’s Europa Clipper has embarked on its long voyage to Jupiter, where it will investigate Europa, a moon with an enormous subsurface ocean that may have conditions to support life. The spacecraft launched at 12:06 p.m. EDT Monday aboard a SpaceX Falcon Heavy rocket from Launch Pad 39A at NASA’s Kennedy Space Center in Florida.

The largest spacecraft NASA ever built for a mission headed to another planet, Europa Clipper also is the first NASA mission dedicated to studying an ocean world beyond Earth. The spacecraft will travel 1.8 billion miles (2.9 billion kilometers) on a trajectory that will leverage the power of gravity assists, first to Mars in four months and then back to Earth for another gravity assist flyby in 2026. After it begins orbiting Jupiter in April 2030, the spacecraft will fly past Europa 49 times.

“Congratulations to our Europa Clipper team for beginning the first journey to an ocean world beyond Earth,” said NASA Administrator Bill Nelson. “NASA leads the world in exploration and discovery, and the Europa Clipper mission is no different. By exploring the unknown, Europa Clipper will help us better understand whether there is the potential for life not just within our solar system, but among the billions of moons and planets beyond our Sun.”

Approximately five minutes after liftoff, the rocket’s second stage fired up and the payload fairing, or the rocket’s nose cone, opened to reveal Europa Clipper. About an hour after launch, the spacecraft separated from the rocket. Ground controllers received a signal soon after, and two-way communication was established at 1:13 p.m. with NASA’s Deep Space Network facility in Canberra, Australia. Mission teams celebrated as initial telemetry reports showed Europa Clipper is in good health and operating as expected.

“We could not be more excited for the incredible and unprecedented science NASA’s Europa Clipper mission will deliver in the generations to come,” said Nicky Fox, associate administrator, Science Mission Directorate at NASA Headquarters in Washington. “Everything in NASA science is interconnected, and Europa Clipper’s scientific discoveries will build upon the legacy that our other missions exploring Jupiter — including Juno, Galileo, and Voyager — created in our search for habitable worlds beyond our home planet.”

The main goal of the mission is to determine whether Europa has conditions that could support life. Europa is about the size of our own Moon, but its interior is different. Information from NASA’s Galileo mission in the 1990s showed strong evidence that under Europa’s ice lies an enormous, salty ocean with more water than all of Earth’s oceans combined. Scientists also have found evidence that Europa may host organic compounds and energy sources under its surface.

If the mission determines Europa is habitable, it may mean there are more habitable worlds in our solar system and beyond than imagined.

“We’re ecstatic to send Europa Clipper on its way to explore a potentially habitable ocean world, thanks to our colleagues and partners who’ve worked so hard to get us to this day,” said Laurie Leshin, director, NASA’s Jet Propulsion Laboratory in Southern California. “Europa Clipper will undoubtedly deliver mind-blowing science. While always bittersweet to send something we’ve labored over for years off on its long journey, we know this remarkable team and spacecraft will expand our knowledge of our solar system and inspire future exploration.”

In 2031, the spacecraft will begin conducting its science-dedicated flybys of Europa. Coming as close as 16 miles (25 kilometers) to the surface, Europa Clipper is equipped with nine science instruments and a gravity experiment, including an ice-penetrating radar, cameras, and a thermal instrument to look for areas of warmer ice and any recent eruptions of water. As the most sophisticated suite of science instruments NASA has ever sent to Jupiter, they will work in concert to learn more about the moon’s icy shell, thin atmosphere, and deep interior.

To power those instruments in the faint sunlight that reaches Jupiter, Europa Clipper also carries the largest solar arrays NASA has ever used for an interplanetary mission. With arrays extended, the spacecraft spans 100 feet (30.5 meters) from end to end. With propellant loaded, it weighs about 13,000 pounds (5,900 kilograms).

In all, more than 4,000 people have contributed to Europa Clipper mission since it was formally approved in 2015.

“As Europa Clipper embarks on its journey, I��ll be thinking about the countless hours of dedication, innovation, and teamwork that made this moment possible,” said Jordan Evans, project manager, NASA JPL. “This launch isn’t just the next chapter in our exploration of the solar system; it’s a leap toward uncovering the mysteries of another ocean world, driven by our shared curiosity and continued search to answer the question, ‘are we alone?’”

More About Europa Clipper

Europa Clipper’s three main science objectives are to determine the thickness of the moon’s icy shell and its interactions with the ocean below, to investigate its composition, and to characterize its geology. The mission’s detailed exploration of Europa will help scientists better understand the astrobiological potential for habitable worlds beyond our planet.

Managed by Caltech in Pasadena, California, NASA JPL leads the development of the Europa Clipper mission in partnership with the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, for NASA’s Science Mission Directorate in Washington. The main spacecraft body was designed by APL in collaboration with NASA JPL and NASA’s Goddard Space Flight Center in Greenbelt, Maryland, NASA’s Marshall Space Flight Center in Huntsville, Alabama, and NASA’s Langley Research Center in Hampton, Virginia. The Planetary Missions Program Office at Marshall executes program management of the Europa Clipper mission.

NASA’s Launch Services Program, based at NASA Kennedy, managed the launch service for the Europa Clipper spacecraft.

8 notes

·

View notes

Note

#fun fact: we can accidentally cook you in the mri machine#it is very much A Thing

why does this sound like a thing that could just happen at any time. like it isn't _that_ uncommon.

...tell me more?

:cackles and rubs hands: welcome to the wonderful world of what can go wrong during an mri scan.

You have the obvious - someone walks in with an oxygen tank, which promptly flies into the machine, explodes, and kills everyone, then the resultant fire causes the MRI machine to dump helium into the room with the patient and potentially kills everyone all over again, while also destroying your million-pound Big Chungus. I am only being mildly hyperbolic.

But radiofrequency burns are far more common.

They occur because we zap you with a bunch of radiofrequency pulses, which wobble your atoms in a certain way, causing variations within the magnetic alignment of these atoms, thus helping us to gain insight into the density of different tissues within your body by measuring how quickly these atoms relax back to their 'normal' alignment. You can read more on that here!

But as for burns, the important thing is that these pulses cause 'excitation' - they give energy to your atoms! And this is specifically thermal energy.

Your body temp will often go up by about a degree in an MRI machine - which isn't especially dangerous. But in certain circumstances (such as: if you're in direct contact with the radiofrequency-generating coil or the bore of the machine, or with any conductive metal (nose studs, etc), or even, in certain cases, if your skin is in direct contact with itself and thus increasing the heating effect in that particular spot) it can absolutely cause the cooking of soft tissue.

We combat this in numerous ways.

The first and most obvious is: we strip you down to make sure you're not wearing any graphic tees with tiny bits of metal in the design, or leggings with the same (you would be surprised how much clothing contains enough conductive material to result in an RF burn!). We take out all your piercings and so forth. We pop you in one of our special gowns.

Other than that, we position you on the bed so that you won't touch the sides of the machine as you enter. This is, unfortunately, why some larger patients cannot safely use the MRI machine - as well as concerns about the upper capacity of bed weight.

We then put a well-padded coil over you, and - if you're going to be in the machine for a long time - ensure you're lying stretched out without like, arms folded over your chest or whatnot.

All of these things greatly reduce your chance of suffering an RF burn! However, they do still happen - and most of the time, unfortunately, patients do not notice until after the scan is complete, at which point we can only treat the injury rather than preventing it. Still, be aware of your body during an MRI scan, and use your buzzer/etc. to contact the controllers if you start to feel significant heat build up!

...Let's just not talk about how we can pop your organs with Ultrasound. No need to go into that. Nope. Nosiree.

#long blergh of words because I am too lazy to hunt pics xxxx#but heeheeeehehe#it's true#we do cook people but usually only a little!!!!

9 notes

·

View notes

Text

Thermal Interface Materials | Thermal Management Solutions - Techni3

Thermal Interface Materials

What are Thermal Interface Materials?

Successful thermal management of high-power electronic components (single chips, multi-chip modules, integrated circuits, etc.) with high heat dissipation ratings requires careful design engineering. The most important goal in electronic cooling is to maintain junction temperature from rising above prescribed levels. Junction temperature is good predictor of the useful life of the component. Thermal interface materials bridge the interface between hot components and a chassis or heat sink assembly. Heat transfer is increased, and components are kept cooler. An example is a gap filler pad transferring heat between two or more solid surfaces.

How do they work?

Materials formulated in the lab are manufactured and inserted between parts to enhance the thermal coupling. Most applications involve dissipating heat. When two surfaces are interfaced, rough surfaces create insulating air gaps between them. These gaps create thermal barriers to heat transfer due to the low thermal conductivity of air. Heat will transfer and be removed more rapidly because of the presence of an engineered material that has significantly higher thermal conductivity than the air in the interface. Thus, the material helps minimize the resistance of heat flow into, through, and out of an interface.

What are Common Uses?

● Gap Filler Pads – These materials can offer a unique combination of extremely high thermal conductivity and softness. The combined features reduce mechanical stress while maintaining thermal performance. Several offerings are free of silicone, an ideal situation for some applications, Some feature no oil bleed. An example is a gap filler pad transferring heat in a densely packed PCB.

● Dispensable Gap Fillers – Examples include liquid putty gap fillers, thermal pastes, gels, and greases. They are generally non-electrically conductive. Putty is used for filling in gaps that are present between irregular or unusual surfaces or those that do not touch one another. A popular application ofliquid gap fillers is handheld gaming systems. Fragile components, design density, and high operating temperatures are common issues to be resolved.

● Phase Change – Components within servers and computers of all types achieve increased processing speeds and overall functionality and reliability improvements with phase change materials. They take advantage of latent heat of fusion to absorb heat, but they change phase only once to allow for the material to fill up all nooks and crevices. Screen-printable formulations deliver the reliability and performance of a phase change material with the low-cost handling of thermal grease.

● Automation Support – Through advancements in robotic motion control, users can now automate the application of all forms of thermal interface materials. These pioneering applications add speed, reliability, and rapid ROI to any application process while lowering overall costs.

● Electrically Insulating -Electrical isolation can be a critical design consideration in numerous applications. Electrically insulating products offer solutions whenever reliability, cut-through resistance, and thermal conductivity are critical factors. Military and aerospace applications are examples.

● Thermally Conductive PCB -Thermal management can be designed directly into PCBs. Design teams can desire systems which eliminate costly, secondary thermal management components, seeking to drastically reduce system size.

0 notes

Text

Aluminum pcb vs fr4 pcb board

FR4 board is a code name for the grade of flame-retardant material. It represents a material specification that the resin material must be able to extinguish by itself after burning. It is not a material name, but a material grade. Therefore, there are many types of FR-4 grade materials used for pcb, but most of them are composite materials made of so-called Tera-Function epoxy resin, Filler and glass fiber.

FR-4 PCB board, according to different uses, industry insider generally call them: FR-4 Epoxy Glass Cloth, insulating board, epoxy board, epoxy resin board, brominated epoxy resin board, FR-4 , Fiberglass board, fiberglass board, FR-4 reinforcement board, FPC reinforcement board, flexible circuit board reinforcement board, FR-4 epoxy resin board, flame-retardant insulation board, FR-4 laminated board, epoxy board , FR-4 light board, FR-4 fiberglass board, epoxy glass cloth board, epoxy glass cloth laminate, circuit board drilling pad etc.

Main technical features and applications of FR-4 board: stable electrical insulation performance, good flatness, smooth surface, no pits, thickness tolerance standards, suitable for high-performance electronic insulation requirements products, such as FPC reinforcement board, PCB drilling pad, glass fiber meson, potentiometer carbon film printed glass fiber board, precision star gear (wafer grinding), precision test plate, electrical (electrical) equipment insulation support spacer, insulation backing plate, transformer insulation plate, motor insulation, grinding gear, electronic switch insulation board, etc.

The aluminum pcb board is a metal-based copper-clad laminate with good heat dissipation function. Generally, a single-sided aluminum PCB is composed of a three-layer structure, which is a circuit layer (copper foil), an insulating layer and a metal base layer. For high-end use, it is also designed as a double-sided board, and the structure is circuit layer, insulating layer, aluminum base, insulating layer, and circuit layer. Very few applications are multi-layer boards, which can be formed by bonding ordinary multi-layer boards with insulating layers and aluminum bases.

Compared with traditional FR-4 PCB, aluminum pcb circuit boards have the following advantages:

Good thermal conductivity. The metal layer of the aluminum pcb board can quickly dissipate heat, transfer the heat of the device, minimize the thermal resistance, and have good thermal conductivity.

More environmentally friendly. Aluminum-based pcb boards do not contain substances harmful to human health and the environment, and are more environmentally friendly than FR-4 circuit boards.

High durability. FR-4 pcb may be warped, bent, cracked etc during production and transportation; ceramic substrates are also more fragile. Aluminum pcb circuit boards make up for the shortcomings of FR-4 boards and ceramic substrates, have longer durability, and avoid board cracks caused by production and transportation.

Higher performance. The circuit layer of the aluminum-based PCB board is etched to form the circuit. Compared with the traditional FR-4 pcb board, under the same line width, thickness, etc., the current carried by the aluminum pcb is higher than that of the FR-4 pcb board.

0 notes

Text

Heltec 3S-20S Universal Lithium Battery pack Low Temperature Heating Module

This heating module supports battery packs ranging from 3S (3 cells in series) to 20S (20 cells in series), making it versatile across various applications, from consumer electronics to industrial and outdoor tools. It uses a thermally conductive pad and intelligent heating circuitry to warm the battery pack without adding significant bulk or weight. The module also includes safeguards against overheating, enhancing the reliability and longevity of both the battery and the device it powers.

This system is ideal for e-bikes, drones, or solar-powered systems used in cold environments. By ensuring battery stability in subzero temperatures, the Heltec heating module enables reliable power output, extended battery life, and improved device performance, making it a valuable addition for anyone using lithium-powered devices in challenging climates.

Contact

+𝟭 𝟳𝟳𝟵-𝟳𝟳𝟬-𝟯𝟭𝟬𝟵

1585 Beverly CT, Unit 121, Auror

0 notes

Text

ASUS TUF Gaming A2 SSD With PCIe NVMe And SATA Storage

ASUS launched the TUF Gaming A2 SSD enclosure today for gamers seeking reliable and speedy storage. The enclosure transfers data at 20 Gbps over USB-C 3.2 Gen 2×2, twice as fast as the TUF Gaming A1. The TUF Gaming A2‘s IP68 water and dust protection and US MIL-STD-810H durability protect the SSD in most environments.

The silicone-rubber shell protects the SSD while traveling. An effective thermal management system guarantees exceptional cooling to guarantee consistent performance, and the Q-Latch mechanism makes it simple and tool-free to install SSDs. TUF Gaming A2 is ideal for anyone wishing to keep a large collection of games because it works well with PCs, Macs, mobile devices, and the newest gaming consoles.

Exceptional SSD performance

With USB 3.2 Gen 2×2 connectivity that can supply up to 20Gbps of bandwidth, the TUF Gaming A2 triple the data transfer capabilities of its predecessor, the TUF Gaming A1. Even though the newest AAA games frequently weigh more than 100GB, it only takes 90 seconds1 to move a whole game from the SSD to a popular gaming platform like ROG Ally or a console.

The cutting-edge Q-Latch makes it simple to install or remove the NVMe M.2 SSD without the need for specialized tools. Screws are not required because the latch design uses a straightforward locking mechanism to secure the drive. The TUF Gaming A2 also has SATA and PCIe NVMe connectors, supports a variety of 2242/2260/2280 SSD form factors, and has a 4TB storage capacity.

Rugged and ready for anything

A series of tests, including drops from a height of 1.22 meters, are performed on the TUF Gaming A2. It boasts IP68 water and dust protection and complies with the strict U.S. MIL-STD-810H specifications. The TUF Gaming A2’s premium silicone-rubber shell helps to guarantee steady performance in any condition by absorbing shocks and withstanding high temperatures.

In addition to protecting against dust, rain, and UV rays, it also shields data from electrical disruptions and static. Additionally, the ribbed pattern facilitates easy gripping while moving. Finally, with a K-value of 3, the highly conductive interior thermal pad can efficiently disperse the heat produced by the SSD to avoid overheating and guarantee stability over the long run.

Play and create across multiple platforms

TUF Gaming A2 is compatible with the newest game consoles, including the Xbox, PlayStation 5, and ROG Ally, as well as Windows 11, macOS, and mobile devices.

What distinguishes the TUF Gaming A2 SSD Enclosure?

Outstanding Durability and Build Quality

The TUF Gaming A2 SSD Enclosure’s tough, military-grade durability is one of its distinguishing characteristics. Because of its durable construction, the enclosure is appropriate for those who require dependable storage while on the go. Among the crucial elements of its construction quality are:

Shock Resistance: The TUF Gaming A2’s frame resists shocks, minimizing impact and drop damage.

ASUS created the TUF Gaming A2 container to MIL-STD-810H requirements to resist harsh conditions without compromising functionality.

Weatherproof: The housing resists moisture and dust, so consumers can use it outside.

Lightning-Quick Data Transfer Rates

Beyond durability, the TUF Gaming A2 SSD Enclosure boasts amazing speed to go along with its tough exterior. It supports 10 Gbps data transfer using USB 3.2 Gen 2×1. Speed makes it ideal for data backup, gaming, and content creation. When transferring massive files, installing games, or browsing media libraries, users can anticipate blazing-fast speed.

Widespread NVMe and SATA SSD compatibility

The TUF Gaming A2 SSD Enclosure gives consumers the option to use a range of drives by supporting both NVMe and SATA SSDs in M.2 form factors. This extensive interoperability means that users can adapt the enclosure based on their preferred storage solutions and demands. The TUF Gaming A2 easily supports a variety of storage types, whether you’re installing a new drive or reusing an existing one.

Easy-to-use Interface and Tool-Free Setup

With its tool-free installation function, ASUS has made the TUF Gaming A2 SSD Enclosure exceptionally user-friendly. The container can be opened, the SSD inserted, and closed without tools or screws. Due to its user-friendly design, the TUF Gaming A2 is an economical alternative for quickly and easily increasing storage capacity.

Due to its lightweight and tiny size, the enclosure can fit nicely in a pocket or bag for on-the-go storage.

Improved Control of Heat

Controlling heat is one of the most important features of external SSD enclosures. The TUF Gaming A2 SSD Enclosure from ASUS features sophisticated thermal management to keep the drive cool even when performing demanding tasks. The following characteristics enhance thermal performance:

The enclosure incorporates thermal pads to disperse heat and maintain appropriate temperatures for longer operation.

Aluminum Alloy Body: Heat dissipation reduces overheating and ensures steady operation.

A fashionable, gaming-focused aesthetic

The TUF Gaming A2 SSD Enclosure has a military-inspired design with aggressive lines and a matte finish, in keeping with the rough style of the TUF Gaming series. Its durability and small size give useful value for consumers who require performance on the road, and its branding and design components make it an ideal addition to any gaming setup.

Read more on Govindhtech.com

#TUFGaming#ASUSTUFGaming#GamingA2#SSD#PCIeNVMe#SATAStorage#GamingA2SSD#News#Technews#Technology#Technologynews#Technologytrends#Govindhtech

0 notes

Text

Swati Innovatives: Your Most Trusted Copper Powder Manufacturer in India

Copper powder plays a crucial role in many aspects of modern life, integrated into various products from electronics to automotive components. Its exceptional properties make it indispensable across multiple industries. At Swati Innovatives, we don’t just view copper powder as a material—we see it as a transformative force. As one of the leading copper powder suppliers in India, we take pride in being more than just a supplier; we are a partner committed to enhancing your success. Our dedication to mastering the art of copper powder production has established us as a premier manufacturer in India.

Recent Blogs

Understanding the Properties and Benefits of Cuprous

Read More

Understanding the Properties and Benefits of Cuprous

Read More Why Our Copper Powder Stands Out Among Copper Powder Suppliers in India Copper powder is distinguished by several unique characteristics that make it an essential raw material across various sectors. Here’s what sets our copper powder apart:

High Electrical Conductivity: Copper powder’s excellent electrical conductivity is crucial for the electronics industry, particularly in applications such as printed circuit boards and conductive ink circuits.

Thermal Conductivity: Essential for heat management, copper powder is used in developing heat sinks and automotive components to effectively dissipate heat.

Malleability and Ductility: Copper’s malleability and ductility allow for easy shaping into intricate designs and complex geometries, providing flexibility in product development.

Corrosion Resistance: Naturally corrosion-resistant, our copper powders are durable and reliable in harsh conditions, ensuring longevity in various applications.

Antimicrobial Properties: With a focus on health and safety, our copper powder is ideal for creating surfaces with antimicrobial properties, suitable for healthcare and sanitation applications.

Our Journey as a Leading Copper Powder Manufacturer in India At Swati Innovatives, we have perfected our manufacturing processes to provide copper powder that meets the highest standards of quality and performance. Our journey of innovation and commitment has established us as a leading copper powder manufacturer in India.

Our Cutting-Edge Processes as a Copper Powder Supplier in India We utilize advanced technologies and methodologies to produce high-quality copper powders. Our processes include:

Atomisation: This technique involves spraying molten copper through a high-pressure nozzle to create fine droplets or particles, resulting in a powder with excellent purity and flowability.

Electrolytic Deposition: This method produces pure, fine copper powders ideal for electronic and chemical industries, ensuring high performance due to its purity.

Mechanical Milling: For customized solutions, mechanical milling is used to grind copper into fine powders with specific particle sizes, meeting tailored blending needs.

Applications of Copper Powder: Transforming Industries Copper powder’s versatility makes it crucial in various industries. Here are some key applications:

Electrical and Electronics Industry: Copper powder is vital for electronic components such as conductive inks and electrical contacts, integral to modern technology.

Powder Metallurgy: Used in the pressing and sintering of metal powders, copper enhances the strength and durability of components with complex geometries.

Chemical Industry: Copper powder acts as a catalyst in chemical reactions, improving efficiency and innovation in chemical synthesis and pharmaceutical production.

Coatings and Paints: Provides a metallic sheen and antimicrobial properties, suitable for aesthetic and hygiene-focused applications in coatings and paints.

Automotive Industry: Enhances performance and safety in friction materials like brake pads and clutch discs through its thermal conductivity and wear resistance.

Aerospace Industry: Ideal for weight-sensitive applications due to its light weight, excellent electrical and thermal conductivity support aerospace innovations.

Welding and Brazing: Serves as a filler metal for strong, durable joints in welding and brazing applications, crucial for electronics and machinery.

Art and Decorative Applications: Adds color and metallic sheen to artistic works, allowing for creative expression in sculptures, paintings, and decorative coatings.

Purity in Filtration and Separation: Effective in removing impurities from gases and liquids, contributing to cleaner, safer processes.

Additive Manufacturing (3D Printing): Enables the creation of complex parts with high precision, essential for industries like aerospace, automotive, and electronics.

Sustainability at the Core: How We Uphold Our Role as Responsible Copper Powder Suppliers in India At Swati Innovatives, sustainability is a key focus. Our commitment extends to reducing environmental impact through recyclable materials and energy-efficient manufacturing practices.

Recycling Copper Powder: We champion the recycling of copper powder, reducing the need for raw material extraction and promoting sustainable practices.

Energy-Efficient Manufacturing: Our production processes are designed to minimize waste and energy use, aligning with global sustainability goals.

Our Promise of Excellence as a Copper Powder Manufacturer in India Quality is the cornerstone of our operations. We ensure that our copper powder meets the highest performance and reliability standards through rigorous quality control.

Stringent Testing: Raw materials undergo rigorous testing, and regular checks during production ensure that our copper powder meets all specifications.

Meeting Global Standards: We adhere to international quality standards, ensuring that our copper powder performs optimally across various industries.

Partnering with You Every Step of the Way as Your Copper Powder Supplier Swati Innovatives is dedicated to building long-term relationships with our clients. We offer expert guidance and support to help you select the right copper powder for your needs.

Partner with us today to experience the transformative power of copper powder. Contact us to learn more about our products and how we can help you achieve your goals. Together, let’s unlock the full potential of copper powder for a brighter, more innovative future.

For more information or to discuss your requirements, call us at +9199789 06802 +9193741 77467 or , or email us at [email protected] Our team is ready to assist you with expert advice and tailored solutions.

0 notes

Text

Best Thermal conductive pads in India

In order to deal with the heat concerns of electrical batteries, cars, and electricity electronics, thermally conductive pads are a direct cooling approach that might absorb heat throughout the battery module. Electric cars need heat technology because overheating harms insulation, magnets, and bearings as well as motor additives and coatings. The performance and safety of electric cars will thus be considerably improved by having proper temperature management. Considered one of the major problems with electric vehicles is thermal control.

0 notes

Text

Electrosurgical Instruments

Electrosurgical instruments are vital tools in modern medical procedures, playing a critical role in surgeries across various medical disciplines. These instruments use high-frequency electrical currents to cut, coagulate, desiccate, or fulgurate tissue. The ability to precisely control bleeding and tissue manipulation makes electrosurgical instruments indispensable in today's operating rooms, allowing for more efficient surgeries with reduced blood loss and quicker recovery times for patients.

Types of Electrosurgical Instruments

There are several key categories of electrosurgical instruments, each designed to fulfill specific surgical needs:

Electrosurgery Forceps

These are commonly used for grasping and manipulating tissues during surgery. Electrosurgical forceps apply electrical energy to coagulate tissues, sealing blood vessels and minimizing bleeding. The forceps can either be monopolar or bipolar, with bipolar forceps being more precise as the current flows between the two tips of the instrument, reducing the risk of damaging surrounding tissues.

Sealers and Scissors

Sealers are used to coagulate blood vessels, while scissors simultaneously cut and seal tissues during surgical procedures. The dual functionality of these instruments enhances the efficiency of operations, particularly in minimally invasive surgeries such as laparoscopic procedures. The thermal energy generated at the tips ensures that bleeding is kept to a minimum, offering clear visibility for the surgeon.

Electrosurgery Cables

These cables transmit electrical energy from the electrosurgical generator to the instrument itself. They are designed to handle high-frequency currents while maintaining safety standards to avoid accidental burns or electric shocks. Cables must be robust, durable, and compatible with various electrosurgical devices to ensure seamless functionality during procedures.

Diathermy Pencils

Diathermy pencils are handheld devices that allow surgeons to cut or coagulate tissues with high precision. Equipped with a fine tip, these pencils deliver controlled electrical currents directly to the target tissue. They are especially useful in delicate surgeries where precise cutting or coagulation is essential, such as in neurosurgery or cardiovascular procedures.

Diathermy Electrodes

Electrodes are crucial components of electrosurgical systems. They are the conductive elements that make contact with the patient's tissue to deliver the required energy. Diathermy electrodes come in different shapes and sizes, depending on the type of surgery being performed. These instruments help in both cutting and coagulating tissue, reducing the need for traditional surgical tools like scalpels.

Diathermy Patient Plates

Also known as grounding pads or return electrodes, diathermy patient plates are critical for patient safety during monopolar electrosurgical procedures. They help to complete the electrical circuit by safely channeling the electrical current back to the generator, ensuring that the current does not cause unintended harm to the patient. Proper placement and monitoring of these plates are crucial to prevent burns or injuries.

Benefits of Electrosurgical Instruments

Electrosurgical instruments offer numerous advantages over traditional surgical tools. The most significant benefit is their ability to minimize blood loss during surgery. By using electrical currents to coagulate tissue and seal blood vessels, surgeons can perform procedures with greater accuracy and less interruption. This results in shorter operating times and reduced risks of complications. Additionally, electrosurgical instruments allow for less invasive procedures, leading to faster recovery times and less post-operative pain for patients.

Another notable advantage is the reduced risk of infection. Since electrosurgical tools can often perform multiple functions—such as cutting and coagulating simultaneously—they reduce the number of instruments that come into contact with the patient, decreasing the likelihood of contamination.

Conclusion

Electrosurgical instruments are essential to modern surgery, offering precision, efficiency, and enhanced safety for both patients and healthcare professionals. With ongoing advancements in technology, these instruments continue to evolve, contributing to more successful outcomes in various surgical fields.

0 notes

Text

Jinan EMI Shielding Technology CO., LTD established in 2003 is a high-tech enterprise majoring in the research and development of EMI Shielding Materials, EMI Gaskets, EMI Shielding Room Products, pyramidal microwave absorber and Thermal Management Products.

#RFID NFC ferrite absorber Jinan#China#Berrylium copper Finger stock gasket Jinan#copper foil adhesive tape Jinan#conductive adhesive tape Jinan

0 notes

Text

The Role of Reflow Ovens in Modern Electronics Manufacturing

The Role of Reflow Ovens in Modern Electronics Manufacturing Reflow ovens are essential machines in the electronics manufacturing industry, primarily used for reflow soldering surface mount electronic components to printed circuit boards (PCBs). This article explores the various types of reflow ovens, their working principles, and their significance in the manufacturing process.Get more news about Reflow Oven,you can vist our website!

Types of Reflow Ovens There are several types of reflow ovens, each with unique features and benefits:

Infrared Reflow Ovens: These ovens use ceramic infrared heaters to transfer heat to the PCBs through radiation. They are efficient but require careful control to avoid overheating components. Convection Reflow Ovens: These ovens heat air in chambers and use that air to transfer heat to the PCBs through convection and conduction. They offer more accurate temperature control compared to infrared ovens. Infrared Convection Ovens: These combine infrared and convection heating methods, providing a balance between efficiency and temperature control. Vapour Phase Ovens: These ovens use the phase transition of a heat transfer liquid to emit thermal energy, ensuring high energy efficiency and oxygen-free soldering. Pressure Curing Ovens: Also known as autoclaves, these ovens minimize voiding and improve adhesion strength in bonding processes by increasing pressure during the curing process. Working Principles Reflow ovens operate through a series of temperature-controlled zones, each serving a specific purpose in the soldering process:

Preheat Zone: The PCBs are gradually heated to a temperature that activates the flux in the solder paste, removing any oxides from the component leads and pads. Soak Zone: The temperature is held steady to ensure uniform heating of the entire PCB, allowing the solder paste to reach a consistent temperature. Reflow Zone: The temperature is increased to melt the solder paste, forming a strong electrical connection between the components and the PCB. Cooling Zone: The PCBs are gradually cooled to solidify the solder joints, ensuring a reliable and durable connection. Significance in Manufacturing Reflow ovens play a crucial role in modern electronics manufacturing for several reasons:

Precision and Consistency: Reflow ovens provide precise temperature control, ensuring consistent soldering quality across all PCBs. Efficiency: These ovens can handle large volumes of PCBs, making them ideal for mass production settings. Versatility: Reflow ovens can be used for various applications, from prototyping to high-volume manufacturing. Quality Control: The ability to program specific temperature profiles ensures optimal soldering results, reducing the risk of defects. Conclusion Reflow ovens are indispensable tools in the electronics manufacturing industry, offering precision, efficiency, and versatility. By understanding the different types of reflow ovens and their working principles, manufacturers can optimize their soldering processes and achieve high-quality results.

0 notes

Text

Electrolube TBS Thermal Management System: A Comprehensive Solution for Heat Dissipation

In today’s high-tech world, electronic devices and systems are becoming more compact and powerful. This evolution brings a significant challenge: managing heat generated by these systems. Uncontrolled heat can reduce performance, compromise safety, and shorten the lifespan of electronic components. To address this issue, thermal management solutions are essential. One such solution is the Electrolube TBS Thermal Management System. Renowned for its efficiency and versatility, this system is designed to offer superior heat dissipation in a wide range of applications.

Understanding the Importance of Thermal Management

Thermal management is critical in various industries, from consumer electronics to automotive and aerospace. As electronic devices become smaller, the heat generated in confined spaces increases. Without an effective thermal management system, excessive heat can cause circuits to fail, devices to overheat, and overall performance to degrade. The Electrolube TBS Thermal Management System offers a reliable solution to these problems, ensuring electronic devices can operate efficiently even under high-temperature conditions.

Features of Electrolube TBS Thermal Management System

The Electrolube TBS Thermal Management System is designed with advanced technology to meet the demanding needs of modern electronics. Some of its notable features include:

High Thermal Conductivity: One of the standout features of the Electrolube TBS system is its high thermal conductivity, which enables efficient heat transfer from critical components to heat sinks or other cooling systems. This ensures that the temperature remains within safe operating limits.

Flexibility and Versatility: The TBS system is highly versatile and can be used in various applications, from small-scale consumer devices to large industrial machines. Whether it’s for a smartphone or a data center, this system adapts seamlessly to different thermal management needs.

Durability and Reliability: Designed for long-term use, the Electrolube TBS Thermal Management System is highly durable. It can withstand extreme temperatures, making it suitable for industries like aerospace and automotive, where conditions can be harsh.

Easy Application: The TBS system is user-friendly and easy to apply, reducing installation time and effort. It comes in different forms, such as pastes and pads, providing flexibility in how it’s applied to different devices.

Applications of Electrolube TBS Thermal Management System

The Electrolube TBS Thermal Management System is used in a wide range of industries, addressing the thermal management needs of various electronic systems. Its broad applicability stems from its adaptability and superior heat dissipation capabilities.

Automotive Industry: Modern vehicles are equipped with a multitude of electronic systems, from navigation to infotainment and safety features. These systems generate significant heat, and effective thermal management is crucial to ensure their reliability and longevity. The Electrolube TBS system is used in automotive applications to maintain optimal operating temperatures and prevent overheating.

Consumer Electronics: With the increasing demand for faster, more powerful devices, heat management has become a pressing concern in the consumer electronics sector. Smartphones, laptops, and tablets generate heat that needs to be controlled to ensure consistent performance. The Electrolube TBS Thermal Management System plays a key role in managing the thermal performance of these devices, keeping them cool even during intensive use.

Aerospace Industry: In aerospace, where components are exposed to extreme environmental conditions, the Electrolube TBS system offers a robust solution. It ensures that electronic systems remain functional in high-temperature environments, contributing to the overall safety and reliability of aerospace technologies.

Industrial Machines: High-power industrial machines, such as servers and data centers, require advanced thermal management to function effectively. The Electrolube TBS Thermal Management System is employed to keep these systems running smoothly, minimizing the risk of overheating and potential system failures.

Benefits of Electrolube TBS Thermal Management System

The Electrolube TBS Thermal Management System offers numerous benefits, making it a preferred choice for businesses and engineers dealing with heat management challenges.

Improved Performance: By effectively dissipating heat, the Electrolube TBS system ensures that electronic components operate at their optimal performance levels. This results in improved overall device performance and longer operational life.

Enhanced Safety: Uncontrolled heat can lead to overheating, which can be dangerous, especially in high-power applications. The Electrolube TBS system reduces the risk of overheating, enhancing the safety of electronic systems.

Longer Component Lifespan: Heat is one of the leading causes of wear and tear in electronic components. By controlling temperature, the Electrolube TBS Thermal Management System helps extend the lifespan of components, saving businesses time and money on replacements.

Cost-Effective Solution: Implementing a thermal management system can significantly reduce maintenance and repair costs over time. The long-term durability and reliability of the Electrolube TBS system contribute to cost savings for businesses in the long run.

Conclusion

As electronic devices continue to evolve, so does the need for efficient thermal management solutions. The Electrolube TBS Thermal Management System provides a reliable, high-performance option for controlling heat in various applications, from consumer electronics to industrial machines. With its high thermal conductivity, versatility, and ease of application, this system offers a comprehensive solution to one of the biggest challenges faced by engineers and businesses today. Whether you’re working in the automotive, aerospace, or electronics industry, the Electrolube TBS Thermal Management System is a critical tool in ensuring the safe, efficient, and long-lasting operation of electronic devices.

1 note

·

View note

Text

Understanding Annular Rings in PCB Design | Lion Circuits

In the world of printed circuit board (PCB) design, every detail counts, and one such detail that plays a critical role is the concept of annular rings. These features are essential for ensuring reliable electrical connections and maintaining the integrity of the PCB during the manufacturing process. At Lion Circuits, we recognize the importance of understanding annular rings and their implications for effective PCB design.

What Are Annular Rings?

Annular rings refer to the circular band of copper that surrounds a plated-through hole on a PCB. Essentially, when a hole is drilled into the board and subsequently plated, the copper forms a ring around the hole. This ring is critical because it provides a conductive pathway between the pad and the plated hole, ensuring that electrical signals can pass through without interruption.

Importance of Annular Rings

Electrical Connectivity: The primary purpose of annular rings is to establish a reliable connection between the PCB’s pads and the through-hole components. If the annular ring is too small or improperly formed, it can lead to weak or intermittent connections, which can cause circuit failures.

Mechanical Strength: Annular rings contribute to the mechanical stability of the PCB. A well-formed ring ensures that components are securely anchored to the board, reducing the risk of damage due to thermal expansion or mechanical stress.

Manufacturing Tolerance: During the PCB fabrication process, various factors can affect the integrity of annular rings, such as drilling tolerances and plating processes. Understanding how to design effective annular rings can help mitigate issues during manufacturing, leading to higher yield rates.

Designing Effective Annular Rings

When designing PCBs, it’s crucial to consider the size and dimensions of the annular rings. Here are some guidelines to follow:

Minimum Ring Width: Aim for a minimum width of 0.2 mm for the annular ring to ensure a strong connection. However, this may vary based on specific manufacturing capabilities.

Drill Hole Size: The size of the drill hole impacts the annular ring width. When designing, make sure to account for the drill size and how it will affect the resulting annular ring.

Layer Count: In multilayer PCBs, consider how the annular rings will interface between layers. Proper alignment is crucial for maintaining electrical integrity across layers.

Conclusion

Understanding annular rings is fundamental for anyone involved in PCB design and manufacturing. These features play a vital role in ensuring electrical connectivity, mechanical strength, and overall reliability of the PCB. At Lion Circuits, we emphasize the importance of precise design practices, helping you create high-quality PCBs that meet your specifications. By paying close attention to details like annular rings, you can enhance the performance and longevity of your electronic devices. If you're looking for expert guidance on PCB design or manufacturing, reach out to us today!

0 notes