#The overload relay is wired in series with the motor

Explore tagged Tumblr posts

Text

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelives#Hi-Hi-Tech Automation#DrugFreeIndia#doubleoverload

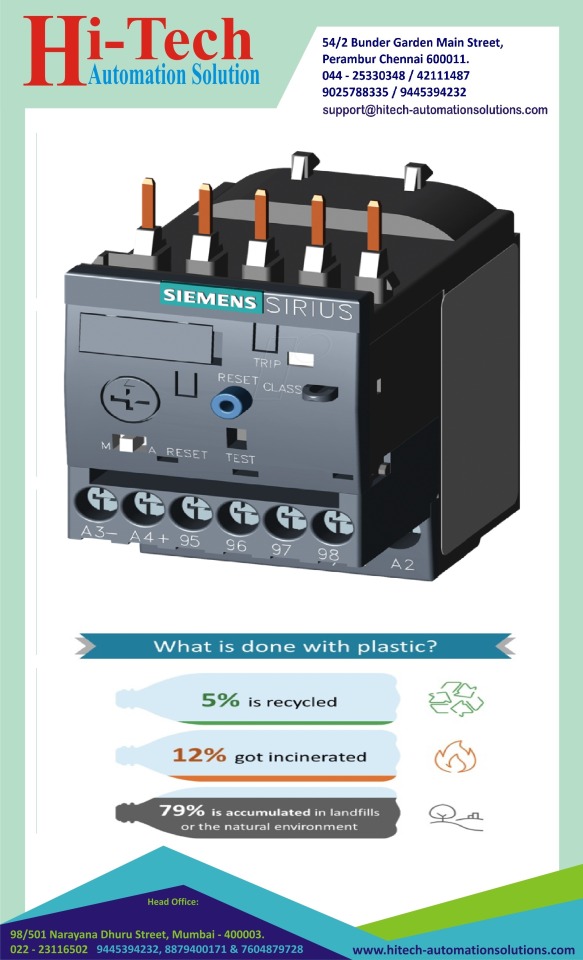

The overload relay is wired in series with the motor, so the current that flows to the motor when the motor is operating also flows through the overload relay. It will trip at a certain level when there is excess current flowing through it. This causes the circuit between the motor and the power source to open.

What is the purpose of overload relay?

Overload relays cut off current to the motor when a high-current situation develops due to a ground fault, short circuit, phase failure, or mechanical jamming. They are an inexpensive way of avoiding downtime for repair or replacement of failed motors from excessive current

How is an overload relay reset?

When set in the H or HAND position the RESET button must be pressed manually to reset the overload relay after a tripping event. On the other hand, when set in A or AUTO position, the overload relay will reset automatically after a tripping event

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelives#Hi-Hi-Tech Automation#DrugFreeIndia#doubleoverload#The overload relay is wired in series with the motor#so the current that flows to the motor when the motor is operating also flows through the overload relay. It will trip at a certain level w#What is the purpose of overload relay?#Overload relays cut off current to the motor when a high-current situation develops due to a ground fault#short circuit#phase failure#or mechanical jamming. They are an inexpensive way of avoiding downtime for repair or replacement of failed motors from excessive current#How is an overload relay reset?#When set in the H or HAND position the RESET button must be pressed manually to reset the overload relay after a tripping event. On the oth#when set in A or AUTO position#the overload relay will reset automatically after a tripping event

0 notes

Text

youtube

Tablet Coating Pan R&D Lab Model

Tablet Coating Pan R&D Lab Model (small coating pan) uses for sugar/film coating onto tablets. All contact parts are made from Stainless Steel 316L, or FDA approved materials for cGMP compliance.

PAN: The Coating Pan is Semi Ellipsoidal size pan with a circular mouth for charging & discharging of tablets, Pan mounted at an inclination of 45 degrees to the horizontal.

DRIVE ASSEMBLY: The tablet coating pan consists of a suitable 3 Phase, 440 V, 1440 RPM TEFC motor with suitable worm reduction gear box and cone pulley arrangement to give three speed output.

HOT AIR BLOWER: The tablet coating pan unit is provided with a hot air blower consisting of suitable 3 Phase 440 V, 2880 RPM TEFC electric motor & centrifugal blower with damper delivering required CFM. The air is heated by means of suitable electric heater to give air at 30 to 90 degrees Heater with thermostat control and flexible hose pipe.

CONTROL PANEL: Unit provided with suitable control panel with starters and push button to actuate the drive and for blower The circuits consist of MCCBs, relays and contractors in series Ample overload protection is provided by the MCCB and the relay Wires coming out of the connections are numbered for easy recognition.

MOUNTING: The motor and gear box is mounted inside sturdy MS frame and the pan mounted on the Gearing housing fitted in the stand. Blower mounted by the side of the stand or placed in remote location if required.

FINISH: All joints argon Arc welded, and all SS Parts polished to suitable finished required of pharmaceutical equipment MS parts painted to smooth finish.

0 notes

Text

Overload Relays: Principle of Operation, Types, and Connection

Overload Relay:

Overload relay is an electrical device designed as the heating prototypes of the electric motor. It breaks up the flow of current when the heat-detecting device in the relay attains a fixed temperature. An overload relay device can be prepared with a heater linked with generally closed connections that unlocks when the heater gets extremely hot.

Principle Of Overload Relay Operation

When excess current is drawn into the motor, it causes an overload. This causes overheating of the motor and may damage the motor. Thus, it is required to protect the engine, circuits, and branch circuit components from overload conditions. Overload relays protect the motor and branch circuit components from an overload. Overload relays monitor the flow of current in the circuit. Suppose the current rises above a specific limit over a particular time. In that case, the overload relay will trip, performing a supplemental contact that suspends the motor control circuit. This leads to the de-energization of the contactor and dismissal of the power to the motor. Without any power, the motor and motor circuit elements do not overheat. Overload relays can be manually or automatically reset, and the motor can be restarted.

Working Of An Overload Relay and connections:

Since the overload relays are wired in with the motor in series circuits, the current also flows through them, and whenever the current overflow, overload relays trip. This opens the circuit between the motor and the power source. The overload relay can be reset manually or automatically after a planned time. After the cause of the overload is identified, you can restart the motor. Connection of an overload relay seems like two opposite question marks or like 'S.'

Types of Overload Relays:

Bimetallic thermal overload relays: Bimetallic thermal overload relays are made up of two metals with different coefficients and thermal expansion properties. A winding is wrapped around the bimetallic strips to carry the current. When overheating occurs due to the excessive current, these bimetallic strips bend to one side, Which activates the trip. As the bimetallic strip heats due to the excessive current, the two metals expand at different rates because of varying coefficient and thermal capacity, causing the strip to bend toward the lower thermal coefficient expansion strip. It actuates a usually closed contactor when the strip turns, causing it to open, stopping the current flow. When the overload relays cool down, and the metal strips have reverted to their regular positions, the circuit resets to restart the motor.

Eutectic thermal overload relays: In these kinds of overload relays, eutectic alloys are used, a blend of metals with different melting and solidification points. They are placed in a tube and connected to a heater winding. When the excessive current flows through them, it heats the alloy. When the alloy is at a specific temperature, it melts into a liquid—activating the trip. Eutectic thermal overload relay can be reset only when the alloy has adequately cooled and returned to solid-state.

Electronic overload relays: These Overload relays measure the current and do not rely on temperature changes. They're also less prone to false tripping, making them more accurate than previously mentioned overload relays. Electronic overload relays provide data like TCU percentage( thermal capacity utilization), FLA percentage (full-load amps), time-to trip, RMS, and ground-fault.Electronic overload relays can also protect motors against phase loss.

0 notes

Text

Fuse Market Shows Increasing In Huge Demand with Top Influencing Key players | Fuji Electric Co.Ltd, Bel Fuse Inc., S&C Electric Company.

Fuse Market can be defined as an electrical safety device which stops the flow of current when there is overload or excess appliance gets connected to the particular circuit. Its main function is to interrupt or break the flow of current by getting a metal strip or metal wire within the fuse and is melted when the current gets overloaded. The major reason for excess current is generally device failure, short circuit and overload. Nowadays hybrid in-plugged technology is being used in electric cars. It has its major applicability in power transformers, electrical appliances, electrical cabling in home, mobile phones, motor starters, laptops, power chargers, cameras, scanners, printers, automobiles, electronic devices and gaming.

Asia-Pacific fuse market is projected to register a highest CAGR of 9.5% in the forecast period of 2019 to 2026.

Get Sample Report at :

https://www.databridgemarketresearch.com/request-a-sample/?dbmr=asia-pacific-fuse-market

Competitive Analysis: Asia Pacific Fuse Market

Few of the major competitors currently working in Asia Pacific Fuse Market are Siemens, Schneider Electric, Eaton, Littelfuse, Blue Sea Systems, PolyTrans, MERSEN, Fuji Electric Co., Ltd, Bel Fuse Inc., S&C Electric Company, Weber South Pacific, ABB, HINODE ELECTRIC CO.,LTD., Pacific Engineering Corporation, Matsuo Electric Co.,Ltd., Eti, DF Electric., Legrand, AEM Inc., Schurter Holding AG., SIBA, Panasonic Corporation and lawsonfuses-india.com.

Key Pointers Covered in the Asia Pacific Fuse Market Trends and Forecast to 2026

Asia Pacific Fuse Market New Sales Volumes

Asia Pacific Fuse Market Replacement Sales Volumes

Asia Pacific Fuse Market Installed Base

Asia Pacific Fuse Market By Brands

Asia Pacific Fuse Market Size

Asia Pacific Fuse Market Procedure Volumes

Asia Pacific Fuse Market Product Price Analysis

Asia Pacific Fuse Market Healthcare Outcomes

Asia Pacific Fuse Market Cost of Care Analysis

Asia Pacific Fuse Market Regulatory Framework and Changes

Asia Pacific Fuse Market Prices and Reimbursement Analysis

Asia Pacific Fuse Market Shares in Different Regions

Recent Developments for Asia Pacific Fuse Market Competitors

Asia Pacific Fuse Market Upcoming Applications

Asia Pacific Fuse Market Innovators Study

Get Detailed TOC:

https://www.databridgemarketresearch.com/toc/?dbmr=asia-pacific-fuse-market

Key Developments in the Market:

In January 2019, SCHURTER Holding AG has launched DG12 which is a compact connector with filter and circuit breaker. DG12 integrates main filters with IEC inlet with a TA35 miniature circuit breaker.

In February 2019, SCHURTER Holding AG has launched TA35: Thermal circuit breaker which will enable the dual function i.e. thermal overcurrent protection and ON/OFF switch. It has the rated current of 0.05 A to 20 A. This will be used majorly in commercial lighting and power distribution.

In February 2019, Weber South Pacific has decided to commission and install in-house temperature rise testing laboratory. This will enable the company to make less product related error and to produce better product.

In November 2018, Easergy P3, has been launched by Schneider Electric which has unparalleled efficiency with medium voltage protection relay. This will strengthen medium voltage equipment protection and control devices segment.

Segmentation: Asia-Pacific Fuse Market

The Asia-Pacific fuse market is segmented into four notable segments which are type, product type, voltage type and industry.

On the basis of type, the market is segmented into AC fuses, DC fuses. In 2019, AC fuses segment is likely to grow at the highest CAGR in the forecast period of 2019 to 2026.

In February 2019, at DistribuTECH 2019 S&C launched VacuFuse Self-Resetting Interrupter, which will eliminate nuisance fuse operations and will save maintenance expenses. The focus of the launch was to increase the reliability.

On the basis of product type, the market is segmented into cartridge type fuses, rewirable fuses, switch type fuses, drop out type fuses, striker type fuses, expulsion type HRC fuses, liquid type HRC fuses, cartridge type HRC fuses, and accessories. The cartridge type fuses is sub-segmented into D-type fuses and link-type fuses. In 2019, cartridge type fuses segment is likely to grow at the highest CAGR in the forecast period of 2019 to 2026.

In February 2019, New series of NHXL battery fuse link 1500V d.c. has been launched by the Eti. It has majorly DC applicability. This is a major step in enhancing the product portfolio specifically in battery fuse.

Inquire Before Buying:

https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=asia-pacific-fuse-market

Research Methodology: Asia Pacific Industrial Services Market

Data collection and base year analysis is done using data collection modules with large sample sizes. The market data is analyzed and forecasted using market statistical and coherent models. Also market share analysis and key trend analysis are the major success factors in the market report. To know more please request an analyst call or can drop down your enquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market, and primary (industry expert) validation.

Apart from this, other data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Company Market Share Analysis, Standards of Measurement, Top to Bottom Analysis and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Key insights in the report:

Complete and distinct analysis of the market drivers and restraints

Key Market players involved in this industry

Detailed analysis of the Market Segmentation

Competitive analysis of the key players involved

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market.

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

Browse Related Report Here:

Quantum Dot Solar Cell Market

Flexible Sensors Market

0 notes

Text

Fuse Market Shows Strong Growth with Leading Players | Littelfuse, Blue Sea Systems, PolyTrans, MERSEN, Fuji Electric Co., Ltd, Bel Fuse Inc., S&C Electric Company.

Fuse Market can be defined as an electrical safety device which stops the flow of current when there is overload or excess appliance gets connected to the particular circuit. Its main function is to interrupt or break the flow of current by getting a metal strip or metal wire within the fuse and is melted when the current gets overloaded. The major reason for excess current is generally device failure, short circuit and overload. Nowadays hybrid in-plugged technology is being used in electric cars. It has its major applicability in power transformers, electrical appliances, electrical cabling in home, mobile phones, motor starters, laptops, power chargers, cameras, scanners, printers, automobiles, electronic devices and gaming.

Asia-Pacific fuse market is projected to register a highest CAGR of 9.5% in the forecast period of 2019 to 2026.

Get Sample Report at :

https://www.databridgemarketresearch.com/request-a-sample/?dbmr=asia-pacific-fuse-market

Competitive Analysis: Asia Pacific Fuse Market

Few of the major competitors currently working in Asia Pacific Fuse Market are Siemens, Schneider Electric, Eaton, Littelfuse, Blue Sea Systems, PolyTrans, MERSEN, Fuji Electric Co., Ltd, Bel Fuse Inc., S&C Electric Company, Weber South Pacific, ABB, HINODE ELECTRIC CO.,LTD., Pacific Engineering Corporation, Matsuo Electric Co.,Ltd., Eti, DF Electric., Legrand, AEM Inc., Schurter Holding AG., SIBA, Panasonic Corporation and lawsonfuses-india.com.

Key Pointers Covered in the Asia Pacific Fuse Market Trends and Forecast to 2026

Asia Pacific Fuse Market New Sales Volumes

Asia Pacific Fuse Market Replacement Sales Volumes

Asia Pacific Fuse Market Installed Base

Asia Pacific Fuse Market By Brands

Asia Pacific Fuse Market Size

Asia Pacific Fuse Market Procedure Volumes

Asia Pacific Fuse Market Product Price Analysis

Asia Pacific Fuse Market Healthcare Outcomes

Asia Pacific Fuse Market Cost of Care Analysis

Asia Pacific Fuse Market Regulatory Framework and Changes

Asia Pacific Fuse Market Prices and Reimbursement Analysis

Asia Pacific Fuse Market Shares in Different Regions

Recent Developments for Asia Pacific Fuse Market Competitors

Asia Pacific Fuse Market Upcoming Applications

Asia Pacific Fuse Market Innovators Study

Get Detailed TOC:

https://www.databridgemarketresearch.com/toc/?dbmr=asia-pacific-fuse-market

Key Developments in the Market:

In January 2019, SCHURTER Holding AG has launched DG12 which is a compact connector with filter and circuit breaker. DG12 integrates main filters with IEC inlet with a TA35 miniature circuit breaker.

In February 2019, SCHURTER Holding AG has launched TA35: Thermal circuit breaker which will enable the dual function i.e. thermal overcurrent protection and ON/OFF switch. It has the rated current of 0.05 A to 20 A. This will be used majorly in commercial lighting and power distribution.

In February 2019, Weber South Pacific has decided to commission and install in-house temperature rise testing laboratory. This will enable the company to make less product related error and to produce better product.

In November 2018, Easergy P3, has been launched by Schneider Electric which has unparalleled efficiency with medium voltage protection relay. This will strengthen medium voltage equipment protection and control devices segment.

Segmentation: Asia-Pacific Fuse Market

The Asia-Pacific fuse market is segmented into four notable segments which are type, product type, voltage type and industry.

On the basis of type, the market is segmented into AC fuses, DC fuses. In 2019, AC fuses segment is likely to grow at the highest CAGR in the forecast period of 2019 to 2026.

In February 2019, at DistribuTECH 2019 S&C launched VacuFuse Self-Resetting Interrupter, which will eliminate nuisance fuse operations and will save maintenance expenses. The focus of the launch was to increase the reliability.

On the basis of product type, the market is segmented into cartridge type fuses, rewirable fuses, switch type fuses, drop out type fuses, striker type fuses, expulsion type HRC fuses, liquid type HRC fuses, cartridge type HRC fuses, and accessories. The cartridge type fuses is sub-segmented into D-type fuses and link-type fuses. In 2019, cartridge type fuses segment is likely to grow at the highest CAGR in the forecast period of 2019 to 2026.

In February 2019, New series of NHXL battery fuse link 1500V d.c. has been launched by the Eti. It has majorly DC applicability. This is a major step in enhancing the product portfolio specifically in battery fuse.

Inquire Before Buying:

https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=asia-pacific-fuse-market

Research Methodology: Asia Pacific Industrial Services Market

Data collection and base year analysis is done using data collection modules with large sample sizes. The market data is analyzed and forecasted using market statistical and coherent models. Also market share analysis and key trend analysis are the major success factors in the market report. To know more please request an analyst call or can drop down your enquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market, and primary (industry expert) validation.

Apart from this, other data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Company Market Share Analysis, Standards of Measurement, Top to Bottom Analysis and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Key insights in the report:

Complete and distinct analysis of the market drivers and restraints

Key Market players involved in this industry

Detailed analysis of the Market Segmentation

Competitive analysis of the key players involved

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market.

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

Browse Related Report Here:

Quantum Dot Solar Cell Market

Flexible Sensors Market

#Fuse Market#Fuse Market share#Fuse Market size#Fuse Market trends#Fuse Market news#Fuse Market report#Fuse Market growth#Fuse Market forecast

0 notes

Text

N1-§8 How To Select The Solid-State Relays?(2)

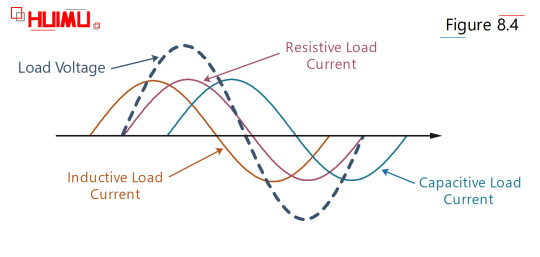

Load Type:

The loads can be divided into three types based on the electrical impedance: Resistive Load Type (or Pure Resistive Load), Inductive Load Type and Capacitive Load Type. There is no pure inductive load and pure capacitive load in the usual electrical appliances, because these two type loads don not do active power. In the series-parallel circuit, if the capacitive reactance is larger than the inductive reactance, the circuit is capacitive load; and vice versa.

Resistive Load:

In a nutshell, a load that operates only by then resistor-type components is called the resistive load. However, some loads have low resistance at low temperatures, which results in a larger startup current. For example, when the electric furnace is just turned on, the current is 1.3-1.4 times larger than the stable current; when the incandescent lamp is turned on, the current is 10 times larger than the steady current. Q1: What are the characteristics of the resistive load (when working)? A1: In the DC circuit, the relationship between current and voltage is in accordance with the fundamental ohm's law, I=U/R; in an AC circuit, the current phase is the same as the phase of the voltage (compared to the power supply). Q2: Which are resistive loads? A2: Heating device that is heated by electric resistance (like resistance furnace, oven, electric water heater, hot oil, etc.), and lamps that rely on resistance wire to emit light (like iodine tungsten lamp, incandescent lamp, etc.).

Inductive Load:

Generally speaking, the inductive load is the load that applies the principle of electromagnetic induction (with inductance parameters), such as high-power electrical products (like refrigerators, air conditioners, etc.). The inductive load will increase the power factor of the circuit, and the current through the inductive load cannot abrupt change. At startup, the inductive load requires a much larger starting current (approximately 3-7 times) than the current required to maintain normal operation. For example, the starting current of an asynchronous motor is 5-7 times the rated value, and the starting current of the DC motor is slightly larger than the starting current of the AC motor; some metal-halide lamps have a turn-on time of up to 10 minutes, and their pulse currents up to 100 times steady state current. Furthermore, when the power is turned on or off, the inductive load will produce a counter-electromotive force (usually 1-2 times the supply voltage), and the counter electromotive force(abbreviated counter EMF or simply CEMF) will be superimposed with the power supply voltage, and the resulting voltage is up to three times the supply voltage. So, when the load type is an inductive load, the output terminal of solid-state relay should connect a varistor with a withstand voltage of 1.6-1.9 times the load voltage. The counter EMF is an indefinite value that varies with L and di/dt, and if the current rate of change (di / dt) is too high, the SSR will be damaged. In practical applications, CEMF can be reduced by series inductance L, and the magnitude of the L inductance depends on the size and cost. Q3: What are the characteristics of the inductive load (when working)? A3: Inductive loads are lagging (current lags voltage). In the DC circuit, the inductive load allows current to flow through and energy to be stored in the inductor, and the current lags behind the voltage. In the AC circuit, the current phase lags behind the voltage phase (compared to the power supply), and the phase can lag a quarter cycle (or 90 degrees) at the maximum. Q4: Which are inductive loads? A4: Lamps that rely on energized gas to emit light (like daylight lamps, high-pressure sodium lamps or HPS lamps, mercury lamps, metal-halide lamps, etc.), and high-power electrical equipment (like motor-based equipment, compressors, relays, etc.).

Capacitive Load:

Generally, a load with a capacitance parameter is called the capacitive load, and the capacitive load will reduce the power factor of the circuit. During charging or discharging, the capacitive load is equivalent to a short circuit because the voltage across the capacitor cannot be changed abruptly. Q5: What are the characteristics of the inductive load (when working)? A5: Capacitive loads are leading (current leads voltage). In the DC circuits, capacitive loads prevent current from flowing, but can store energy. In the AC circuits, the current phase leads the voltage phase (compared to the power supply), and the phase can lead a quarter cycle (or 90 degrees) at the maximum. Q6: Which are inductive loads? A6: Device with a capacitor, such as a compensation capacitor. And power control devices such as switching power supplies, IT equipment and etc.

How to choose Solid-State Relay according to load type?

1) For inductive and capacitive loads, a solid-state relay with a higher dv/dt is recommended, if there is a biggish dv/dt (voltage exponential rise rate) applied to the relay’s output terminal during the AC solid state relay turning on/off. 2) For AC resistive loads and most AC inductive loads, zero-crossing relays are available to extend the life of load and relay, and reduce their own RF interference. 3) As a phase output controller, a random type solid state relay should be used.

*Power Factor:

In electrical engineering, the power factor of an AC power system is defined as the ratio of the real power flowing to the load to the apparent power in the circuit, and is a dimensionless number in the closed interval of -1 to 1. If it is not specified the load power of the general product is the apparent power (includes both active power and reactive power). But the general specification of the inductive load often gives the magnitude of active power. For example, although a fluorescent lamp is labeled 15 to 40 watts (its active power), its ballast consumes approximately 8 watts of power, so 8W should be added to 15~40w to calculate the total power. The inductive portion of the product (i.e. the amount of reactive power) can be calculated from the given power factor.

Input Control Signal:

1) Input Control Voltage: the input control voltage has a wide range of 3~32V. 2) Input Control Current: the input current of DC SSRs and AC single-phase SSRs is generally around 10mA, and the input current of AC three-phase SSRs is generally around 30mA, which also can be customized to be less than 15mA. 3) Control Frequency: the control operating frequency of AC solid state relays generally does not exceed 10HZ, and the DC solid state relay control signal period should be greater than five times the sum of the relay's "on time" and "off time".

Mounting Method:

In many cases, the load power will limit whether the SSR is mounted on the PCB, the panel or the DIN rail.

Ambient Temperature:

When the relay is in the on state, it will withstand the dissipated power of P = V (on-state voltage drops) × I (load current), and the load capacity of the SSR is greatly affected by the ambient temperature and its own temperature. If the ambient temperature is too high, the load capacity of the SSR will inevitably decrease accordingly, moreover, the SSR switch may be out of control, or even be permanently damaged. Therefore, it is necessary to set a certain margin according to the actual working environment, and select the appropriate heat sink size to ensure the heat dissipation conditions. For load currents greater than 5A, a heat sink should be installed. For currents above 100A, the heat sink and fan should be equipped for strong cooling. If the SSR relay is operated at high temperatures (40 ° C ~ 80 ° C) for a long time, the load current can be reduced according to the maximum output current and ambient temperature curve provided by the manufacturer to ensure normal operation, and the load current is usually controlled within 1/2 of the rated value.

* Derating Factor:

The table below shows the recommended derating factor for the rated output current of solid-state relays applied on various loads at room temperature (the overload capability and the load surge current have been considered).

There are two ways to use the derating factor: 1) The rated current value of the solid state relay can be selected according to the derating factor of different environments and different load types. The rated current of the SSR relay is equal to the continuous current value of the load divided by the derating factor. 2) If the solid-state relay has been selected and the load type or environment changes, the load current should be adjusted based on the load curve and the derating factor in certain environment. The adjusted current multiplied by the derating factor must be lower than the rated value of the solid state relay. In addition, when SSRs are run in applications that require more frequent operation, longer life, and more stable reliability performance, the derating factor needs to be further multiplied by 0.6 based on the data in the table. However, the load current should not be lower than the minimum output current of the solid state relay, otherwise the relay will not be switched on or the output state will be abnormal.

0 notes

Text

How to choose automotive wiring harness and connector?

With the increasing popularity of automobiles, the problem of how to choose the wiring harness and connectors has become the doubt of many automakers and buyers.Konnra Electronics is here to help you choose the wiring harness and connectors for your car.

Automotive low voltage wire The 600V withstand voltage is a low-voltage electric wire in the electrical classification, and it has become a low-voltage electric wire for automobiles because it is attached to the characteristics of a car in the automobile field. The wires are also classified into a heat resistant type and a thin type depending on the material thickness of the insulator. A) Construction of the conductor

B) Insulator

In order to prevent the burning of electric wires due to heat generation, a flame retardant is added in advance in the insulator. The flame retardant is also a plastic material, which acts to soften the insulator. At high temperatures, the flame retardant will be released and the insulator will harden. As the car vibrates, cracks appear and the wires are exposed. If you continue driving under such conditions, it is likely to be one of the causes of electrical shorts.

Shielded wires and strands for automobiles:

In recent years, in order to develop high-performance/comfortable, the automotive industry is gradually converting from a switch-control function to an electronic device that automatically senses driving/environmental changes and selects the most suitable state for driving.

To perform such complicated control, what is needed is a precision electronic instrument that can calculate a lot of information in an instant without error. In addition, the sensor is required to sense driving/environmental information by a weak current change, and ON-OFF can be switched rapidly (digital signal) when the current changes.

In this case, if a high-current electric wire is placed together with a high-voltage electric wire (ignition system, electric wave), a high voltage will damage a semiconductor component in a precision electronic instrument, and a sensor circuit affected by the electric wire will flow and be turned ON. The same current as the -OFF signal causes an operation error.

Therefore, in order to avoid the influence of large current and high voltage externality, shielded wires and stranded wires are used on important digital loop wires.

A) Shielded wire

Type and characteristics

We use a shielded metal wire that is wrapped around the wire to reflect electromagnetic waves from the outside as a shielded wire. The following are the types and characteristics of shielded wires:

B) Stranded wire

Effect of stranded wire

We refer to a wire that twists two wires together as a stranded wire or a 2-core wire, which is a method for effectively preventing electromagnetic wave interference. As shown in Fig. 2, the electromagnetic waves generated by the current lines can be cancelled according to the inversion of each ring.

Figure 1 shows the direction of the current generated by the strands under the induction of electromagnetic current.

Figure 2 Cancellation effect of twisted wires

If the current line through which the electromagnetic current flows is parallel to the signal line, the induced current in the same direction will be generated regardless of which line. However, if the power supply line through which the electromagnetic current flows is the same as the twisted line of the signal line, the induced current generated by the signal line is opposite to the direction.

The car wiring harness is the main body of the car circuit, and there is no car circuit without the wire harness. As people's safety, comfort, economy and emissions requirements increase, the wiring harness of the car becomes more and more complicated, but the space for the wire harness is getting smaller and smaller. Therefore, how to improve the overall performance design of automotive wiring harness has become the focus of attention, and automotive wire harness manufacturers no longer simply engage in wire harness design and manufacturing, and the pre-development of automobile host manufacturers has become an inevitable trend. Based on years of experience in wire harness design and manufacturing,Konnra Electronics talks about the general design process and design principles of wire harnesses.

(I) The vehicle circuit design

(1) Power distribution design

Whether the design of the power supply system of the car is reasonable is directly related to the normal operation of the car electric device and the safety of the whole car. Therefore, the starting point of the car wiring harness design in all countries in the world is basically based on safety. The vehicle electrical system consists essentially of three parts.

Battery direct power supply system (generally called normal power or 30 power). The load connected to this part of the power supply is generally a safety component or an important part of the car. The main purpose is to control as little as possible when supplying power to these parts, to ensure that these parts can work normally even if the car does not start up. Go to the site for maintenance, etc. Such as: engine ECU and engine sensor operating power, fuel pump operating power, ABS controller power, diagnostic interface power supply.

Ignition switch controlled power supply system (generally referred to as IG file or smart). This part of the electrical device is basically used only when the engine is running, and the power supply from the generator avoids the possibility of competing for power when charging the battery. Such as: instrument power supply, brake light power supply, airbag power supply, etc.

The power supply of the load (generally referred to as the ACC power supply) is removed when the engine is started. This part of the electrical device generally has a large load and does not have to work when the car is started. Generally a little cigarette lighter power supply, air conditioning power supply, radio and power supply, wiper power supply, etc.

(2) Line protection design

Line protection is to protect the wires and protect the loop electrical components. The protection device mainly has a fuse, a circuit breaker and a fusible link.

a. The principle of selection of fuses

Engine ECU, ABS, etc. have a great impact on the performance and safety of the whole vehicle. In addition, electrical components that are susceptible to interference from other electrical equipment must have a single fuse.

Engine sensors, various types of alarm lights, external lighting, and other electrical components have a greater impact on vehicle performance and safety, but such electrical loads are not sensitive to mutual interference. Therefore, such electrical loads can be combined with each other depending on the situation, and a fuse can be used in common.

The electric load of the general electric device type provided for the purpose of increasing the comfort can be combined with each other according to the situation, and a fuse is used in common.

The fuses are divided into fast-melting and slow-melting. The main component of the fast-acting fuse is a thin tin wire. The chip fuse is widely used because of its simple structure, reliability, vibration resistance and easy detection. The slow-melt fuse is actually a tin alloy piece. The fuses are typically connected in series to an inductive load circuit, such as a motor circuit.

Resistive and inductive loads should avoid using the same fuse as much as possible.

Generally calculate and determine the fuse capacity according to the maximum continuous operating current of the electrical device, according to the empirical formula: fuse rated capacity = maximum operating current of the circuit ÷ 80% (or 70%).

b. Breaker

The biggest feature of circuit breakers is recoverability, but it is costly and less used. Circuit breakers are generally thermo-mechanical devices that utilize different thermal deformations of the two metals to open or close the contacts or self-switch. The new circuit breaker uses PTC solid material as an overcurrent protection component, which is a positive temperature coefficient resistor that is turned off or on depending on the current or temperature. The biggest advantage of this protection element is that it can be switched on automatically after troubleshooting, without manual adjustment and replacement.

c. Fusible line

The characteristic of the fusible link is that when the line passes a huge overload current, the fusible link can be blown for a certain period of time (generally ≤ 5 s), thereby cutting off the power supply and preventing a malignant accident. The fusible link is also composed of a conductor and an insulating layer. The insulating layer is generally a chlorosulfonated polyethylene material, because the insulating layer is thick, so it is seen. It is thicker than the wire of the same specification.

The fusible link is usually connected to the circuit directly led out by the battery. Commonly used cross-sections of fusible links are 0.3mm2, 0.5mm2, 0.75mm2, 1.0mm2, 1.5mm2, and even larger cross-section fusible wires such as 8mm2. The length of the wire segment of the fusible link is divided into three types: (50±5) mm, (100±10) mm, and (150±15) mm.

The fusible link should have an obvious mark. When it is blown, its mark should still exist for easy replacement. The melting characteristics of the fusible link are shown in Table 1.

Table 1 Fuse characteristics of fusible wire

(3) Selection and design of relays

The relay is divided into two types, current type and voltage type. Generally, whether or not to use a relay is determined according to the power of the electric appliance and the bearing capacity of the switch. Commonly used relay devices generally include wipers, horns, defrosting, headlights, fog lamps, fans, blowers, turn signals (flashers), and the like. The relays are divided into 6V, 12V, and 24V. The commonly used relays are rated at 12V.

Technical requirements for the selection of relays: 1 good reliability; 2 stable performance; 3 light weight, small size, long life, small impact on surrounding components; 4 simple structure, good processability, low cost.

(4) Design rules for ground distribution

Engine ECU, ABS, etc. have a great impact on the performance and safety of the whole vehicle, and are easily interfered by other electrical equipment, so the grounding points of these parts must be set separately.

For the airbag system, its grounding point should not only be single, but also to ensure its safety and reliability, it is best to use double grounding. The purpose is that one of the grounding rails fails, and the system can ground the iron through another grounding point to ensure the safe operation of the system.

In order to avoid interference, the radio system must also be grounded separately.

The grounding of the weak signal sensor is preferably independent, and the grounding point is preferably closer to the sensor to ensure the true transmission of the signal.

Other electrical devices can share a common ground point with each other according to specific arrangements. The principle is to tie the iron near, to avoid the excessive length of the wire, causing unnecessary voltage drop.

The battery negative line, engine ground wire, etc. due to the large cross-section of the wire, it is necessary to control the line length and direction, reduce the voltage drop; in order to increase safety, the engine, the body is generally connected to the negative pole of the battery;

Grounding method: First, the iron is passed through the hole joint. This method must be insulated with heat-shrinkable tube at the tail of the joint; the second is to directly lap the iron through the inner short-circuited sheath.

(II), the three-dimensional layout of the harness is designed

This process is mainly to simulate the harness direction and diameter of different areas, consider the sealing and protection of the wiring harness, and simulate the fixing position and fixing mode of the wiring harness, as shown in Figure 1. The main software for 3D wiring is PRO-E, UG and CATIA.

Third, the selection design of the connector

The connector is the core component of the harness, and the performance of the connector directly determines the overall performance of the harness, and plays a decisive role in the stability and safety of the entire vehicle.

(1) Selection principle of selection of connectors

The connector is selected to ensure good contact with the electrical device, the contact resistance is minimized, and the reliability is improved. The connector of the double spring type compression structure is preferred.

The connector is reasonably selected according to the cross-sectional area of the wire and the magnitude of the passing current.

The jacket in the engine compartment is connected to the jacket. Because the temperature and humidity in the cabin are too large and there are many corrosive gases and liquids, it is necessary to choose a waterproof jacket.

If the same sheath is used in the same harness, the color must be different.

Based on the overall coordination of the exterior of the car, a black or dark jacket should be preferred in the engine compartment.

In order to reduce the type and number of sheathing butt joints, it is preferred to use a hybrid type to make the assembly convenient.

For terminal connectors for airbags, ABS, ECUs, etc., which require high performance, gold-plated parts should be preferred to ensure safety and reliability.

The battery connector (battery clip) has a cone inside and a taper of 1:9; the battery clip is made of tin-plated copper, galvanized copper or lead-bismuth alloy.

The currents that can be carried by plugs of different specifications are generally as follows: 1 series, about 10A; 2.2 or 3 series, about 20A; 4.8 series, about 30A; 6.3 series, about 45A; 7.8 or 9.5 series, about 60A.

(II) Performance analysis of raw materials (materials) of connectors

1. Sheath material (plastic parts)

Commonly used materials are mainly PA6, PA66, ABS, PBT, pp, etc., I have summarized their specific performance differences. When designing the plug-in, different materials can be selected according to different needs. Flame-retardant or reinforcing materials can be added to the plastic according to the actual situation to achieve the purpose of strengthening or flame retardant, such as adding glass fiber reinforcement.

2. Terminal material (copper)

The copper used for the connectors is mainly brass and bronze (the hardness of brass is slightly lower than that of bronze), and brass accounts for a large proportion. In addition, different coatings can be selected according to different needs.

Four-wire selection design

(1) Choice of wire type

The wire harness design uses the wire type to focus on the environment and function of the wire harness. For example, the ambient temperature around the engine is high, and there are many corrosive gases and liquids. Therefore, it is necessary to use high temperature, oil, vibration and friction resistant wires; the wires on the trunk lid should maintain its elasticity at low temperatures, so use cold elastic wires to ensure normal operation; the wires on the automatic transmission must be resistant. High temperature and hydraulic oil resistance have good temperature stability; weak signal sensors use shielded wires, such as knock sensor and crank position sensor, ABS wheel speed sensor, etc.; the inner wire has high bending resistance requirements.

Commonly used wires for automotive wiring harnesses usually use stranded copper wires, and the insulation is PVC insulation. The wire harness wire should have the characteristics of temperature resistance, oil resistance, wear resistance, water resistance, corrosion resistance, oxidation resistance and flame retardancy.

The types of wires commonly used in automotive wiring harnesses include Japanese standard (AVSS, etc.), national standard (QVR), German standard (FLRY), and American standard. AVSS (AVS) wire is characterized by thin skin insulation and good flexibility; QVR is characterized by thick insulation, soft and good ductility; German standard wire insulation is thinner and flexible; American standard wire insulation is generally Thermoplastic or thermoset elastomers, as well as processed by irradiation. The appropriate type of wire can be selected according to the needs of the user and different working environments.

(2) Calculating the cross-sectional area of the selected conductor

Calculate the current of the circulating wire according to the power of the electrical device; the electrical equipment that works for a long time can select the wire with the actual current carrying capacity of 60%; for the short-time working electrical equipment, the wire with the actual current carrying capacity of 60%-100% can be selected.

The cross-sectional area of the wire is appropriately changed according to different working environments and temperature.

The cross-sectional area of the wire is appropriately changed according to the direction of the wire and the number of connectors (ie, the magnitude of the voltage drop).

Regarding the calculation of the cross-sectional area of the wire, some experts have concluded some empirical formulas: I=P/UsA=IρL/Ud

Where: I - current; P - power; Us - system voltage; A - wire cross-sectional area; Ud - allow maximum voltage drop loss; ρ - copper resistivity; L - wire length.

Or according to the following empirical formula: I=A×10+8/2

The empirical theoretical value of the allowable current flow and the cross-sectional area of the conductor (more than the calculated value according to the above formula)

Five, the design of the whole vehicle wiring harness seal (rubber parts)

When the automobile wiring harness is through the hole, the rubber member is generally used for the transition to play the functions of wear resistance, waterproofing and sealing. Mainly distributed in the following parts: the interface between the engine and the cab, the interface between the front compartment and the cab (two places on the left and right), the four-door (or back door) and the compartment interface, the inlet of the fuel tank.

Commonly used materials are generally natural rubber, neoprene, silicone rubber, EPDM, and the like.

Characteristics of natural rubber: good elasticity and mechanical strength, excellent flexural resistance, high tear strength and good cold resistance. Disadvantages: The aging resistance is not good, it is not resistant to oil and ozone, and it is flammable.

The characteristics of neoprene: good resistance to ozone, heat aging, oil resistance, flame retardancy and self-extinguishing; but low temperature resistance.

Characteristics of silicone rubber: heat resistance, cold resistance and weather resistance are good; the disadvantage is that it is not resistant to oil. The characteristics of EPDM: weather resistance, ozone resistance, heat resistance, corrosion resistance, acid and alkali resistance, etc., and high strength and high expansion ratio; Disadvantages: poor adhesion, and no natural elasticity Good rubber and poor oil resistance.

In comparison, the comprehensive performance of EPDM is better, so the rubber parts for automotive wiring harnesses are generally selected from EPDM materials.

Sixth, the entire vehicle wiring harness and fixed design

(I) Harness wrapping design

The wire bundle is wrapped out to wear, flame retardant, anti-corrosion, prevent interference, reduce noise, and beautify the appearance. Generally, the following dressing design scheme is formulated according to the working environment and space.

The engine harness has a harsh working environment, so it is completely wrapped with a bellows with high flame retardancy, water resistance and high mechanical strength.

The working environment of the front cabin is also relatively poor. Most of the branches are also wrapped with a flame-retardant bellows, and some branches are wrapped with PVC pipes.

The instrument line has a small working space and a relatively good environment. It can be wrapped or wrapped with tape.

The door line and the ceiling line have a small working space, which can be completely wrapped with tape, and some branches can be wrapped with industrial plastic cloth; the thin top line can be directly glued to the body with a sponge tape.

Since the chassis wire has a large number of contact parts with the vehicle body, it is wrapped with a bellows to prevent wire harness wear.

(II) Performance analysis of raw materials for dressing

1. Bellows

Bellows generally account for about 60% or more in wire bundle dressing. The main feature is that the wear resistance is good, and the high temperature resistance, flame retardancy and heat resistance are good in the high temperature zone. The temperature of the bellows is between -40 and 150 °C. Its material is generally divided into PP and PA2. PA material is superior to PP material in flame retardant and wear resistance; however, PP material is stronger than PA material in bending fatigue resistance.

2. PVC pipe

The function of the PVC pipe is similar to that of the bellows. The PVC pipe has good flexibility and bending resistance, and the PVC pipe is generally closed, so the PVC pipe is mainly used for the branch of the wire harness to make the wire smoothly transition. The heat resistance temperature of the PVC pipe is not high, generally below 80 °C.

3. tape

The tape acts as a bundle, wear, insulation, flame retardant, noise reduction, marking, etc. in the wire bundle, and generally accounts for about 30% in the wrapping material. The wiring harness tape is generally divided into three types: PVC tape, air-laid cloth tape and cloth tape. PVC tape has good wear resistance and flame retardancy; the temperature resistance is around 80 °C, the noise reduction is not good, and the price is relatively cheap. The flannel tape and the cloth tape material are PET. The banding property and the noise reduction of the flannel tape are the best, and the temperature resistance is about 105 °C; the abrasion resistance of the cloth tape is the best, and the temperature resistance is up to 150 °C. The common disadvantage of flannel tape and cloth tape is that it is not flame retardant and expensive.

(III) Harness fixed design

The central electrical box is generally fixed by steel bars, bolts, etc., or directly mounted on the vehicle body by a fixed structure designed by the electrical box itself.

Each wire harness is generally fixed in the body hole with a plastic cable tie, a hook, or the like. Most of the body holes are round holes or elliptical holes, and the diameters are generally 5mm, 6mm, and 7mm.

The sheaths that are butted between the bundles are generally collectively fixed by a sheath bracket and mounted on the vehicle body.

#car connector#car connectors#automotive connector#automobile connector#automotive connectors#automobile connectors#car wire harness#automotive wire harness#automobile wire harness

0 notes

Text

Principle of motor plugging protection

Locked-rotor protection function: when the flow is in a fully automatic judgment motor locked-rotor state or in running state or electrical short circuit state, if the flow is in running state, the controller to set the current limit value in a fixed value, to keep the vehicle driving ability;

If the

motor

is in a pure turn state, the controller will control the flow limit under 10A after 2 seconds, which will protect the motor and battery, and save energy. If the motor is in short circuit, the controller will control the output current under 2A to ensure the safety of the controller and battery. Motor stalling protection to a certain extent, can be understood as overload protection, when the motor load is very big, is less than the load torque, torque motor start to run the motor cannot turn, but at the moment of the motor current is very big, very easy to burn out motor, so set the locked-rotor protection, it refers to the speed of the current and rotating speed of the motor switch contact with logical relationship to realize the trip, is blocked up to do a general overhaul of motor test, to check the performance of the motor. Lacks is the so-called normal three-phase power supply circuit, a phase of the original three-phase equipment will reduce the output power to make it not working or cause an accident. So for some important equipment need to add missing phase protection device. When the circuit power supply is missing, the negative sequence current component will be generated, and the three-phase current is unbalanced or too large, causing the motor to quickly burn down. In order to ensure the safe operation of the motor, which in the case of lack of phase operation timely stop the motor running, to avoid fire accidents caused by motor, general motors is associated with lack of protection device. There are three solutions to the lack of phase protection of motors: 1, 3 relay or contactor coil Y0, monitoring phase 3 phase voltage. Three relay contacts are connected in series and then connected to the motor's contactor coil loop. In this case, if the 3-phase current is normal, the three relays are closed, and the three open contacts are closed. The coil loop of the motor's contactor can work normally. If the power supply is missing, there must be at least one

relay

not absorbing, the coil circuit of the motor contactor is disconnected, the contactor is not able to absorb, or it is forced to disconnect, and it can break phase protection function. 2. There are many special relay protection relay in China. The principle is similar to the above, which can simplify your wiring and occupy the space of the control cabinet. For example, using a thermal relay and a contactor coil, as long as the phase is missing and the current is a big one, it will jump. 3. Using the motor intelligent protector, small size, more function, more than the phase protection, can also have quick break protection, overcurrent protection, start time over long protection, unbalanced current protection, etc.

This article comes from : http://www.relay-protector.com/technical/520.html . Please refer to the source !

0 notes