#TensileStrengthTesting

Explore tagged Tumblr posts

Text

🔬Tensile Strength Unleashed: Witness the intricately detailed working of our IIOT Based Tensile Strength Tester put into action to test the Material Resistance against an applied tensile force.

A few highlighting features of this Tensile Strength Tester include:-

📈 - Provides Real-Time Graphs and Multi-Test Reports instantly

🔬 - Can undertake vital tensile tests like Elongation, Compression, Tongue-Tear

⚡- Rapid Service Response

💻 - IIOT 4.0 Enabled

Know More

#TensileStrengthTesting#StrengthinMaterials#TensileTesting#TensileStrength#IIOT#IIOTBased#paramountinstruments#qualitycontrol#testingequipments#textile#qualityassurance#textileindustry#performancetesting

0 notes

Text

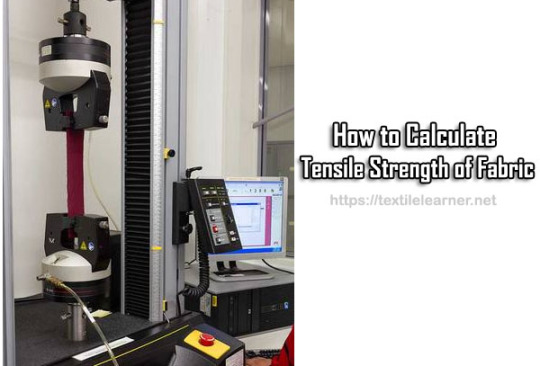

How to Calculate Tensile Strength of Fabric

How to Calculate Tensile Strength of Fabric #tensilestrength #tensilestrengthtest #fabrictensiletest #TensileStrengthofFabric

Different Methods of Fabric Tensile Strength Test Md. Rubel Miah Department of Textile Engineering World University of Bangladesh Email: [email protected] Fabric Tensile Strength Test Fabric tensile strength can be tested using universal tensile strength testing equipment with suitable sample mounting jaws. There are different methods of tensile testing of fabric, which are as follows: Strip…

View On WordPress

0 notes

Text

Tensile Strength Tester (Manually and Elec):

We at industrialshoppingmall offering Tensile Strength Tester@105000/- Rs. For more details visit:https://industrialshoppingmall.com/product/tensile-strength-tester-(manually-and-elec)/141 mail:[email protected], Mobile:9030000071

Tensile Strength Tester (Manually and Elec):

Tensile Strength Tester (Manually and Elec) Specification: A loading Machine, double lever type, with steel scale marked from 0-500 Newtons in 10 Newton division. Maximum loading capacity 5 kN. Automatic Loading system using Lead Shot. Lead shot 15 kg supplied with the machine. Set of weights for weighing lead shot comprising one each for weighing upto 0.5 kN, 1 kN, 1.5 kN & 2.0 kN. One standard Briquette Mould with Base Plate also Supplied.

0 notes

Text

How does a Tensile Tester work?

Tensile Testers are one of the most frequently used testing equipment's in the field of material testing. They play a crucial role in determining the mechanical properties of materials, such as pulling strength, elasticity, and flexibility. Understanding how a tensile tester works is essential for producing precise and trustworthy results, be it in the industrial sector or while performing research in a lab.

In this blog, we will delve deep into the working of the tensile strength tester and will also be covering the key benefits that performing a tensile test using a tensile machine offers.

Starting with the step wise process of how a tensile tester typically works:

1. Preparation of the Specimen - A small sample of the textile material is cut into a specific size and shape suitable for the tensile strength tester.

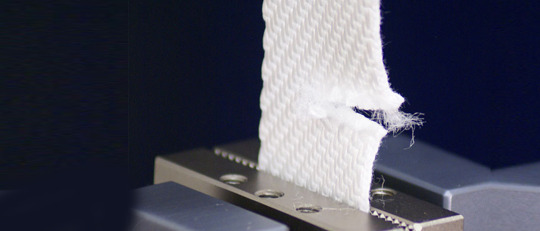

2. Mounting the Specimen - The sample is then mounted between the two jaws or grips of the tensile tester. The jaws are specifically designed to prevent any damage or slippage to the specimen (sample) during the test.

3. Testing the Specimen - A controlled force is applied at a steady rate to the specimen until the material breaks. The tensile tester then measures the amount of force applied and resulting elongation of the specimen.

4. Data Compilation - The data that is collected during the test, including the elongation at break, modulus of elasticity, and the tensile strength can then be used to assess the mechanical properties of the textile material.

5. Examination: The results of the test help to assess the performance and quality of textile material which can be used to make decisions regarding the quality control, material selection, and product design.

Understanding the systematic process of a tensile strength tester’s working can make sure that accurate and reliable measurements are undertaken every time a test is performed.

Benefits of performing a Tensile Test using a Tensile Strength Tester :

Identifying Weaknesses at the Initial Stage: Tensile strength testing can help to identify any flaws or weaknesses in a fabric, such as areas that might be prone to breaking or tearing. By using this information, the production process can be adjusted as needed to increase the fabric's quality.

Improving Quality Control: Tensile strength testers are frequently used for quality control assessments in the textile industry. Testing the tensile strength of a fabric can help manufacturers ensure that the final product meets the required standards of durability and strength, thus increasing customer satisfaction and trust.

Cost Efficiency: Performing the tensile test can help to detect the materials that may be prone to breaking or are less durable, which can in turn lead to cost savings by eliminating the use of such damaged materials in the production process.

Assuring Safety Standards: One of the main reasons for performing the tensile test is to also ensure that the safety of fabrics and garments is ensured for end use. Using the tensile strength equipment, manufacturers can make sure that the fabrics/garments meet the required safety standards and are not prone to breaking or tearing during use.

Developing Suitability for Specific Applications: Testing the tensile strength of fabrics can also help to determine its suitability for specific end use applications like outdoor gear or heavy-duty workwear. Thus, by testing the strength of the fabric, manufacturers can make sure that it holds up under the intended use conditions.

We may assert that assessing the tensile strength of materials is important to assure their durability, quality and safety is up to the mark and is fully perfected for its end-use application.

#paramountinstruments#qualitycontrol#testingequipments#qualityassurance#performancetesting#tensilestrengthtester#tensiletesting#tensilestrength#tensilestructure

0 notes

Text

Putting Materials to Test: A Comprehensive Guide to the Top 6 Tensile Strength Tests

A Tensile Strength Tester is one of the most widely used testing instruments used in the textile industry to ensure premium quality products are manufactured consistently.

Below, we have covered the 6 Key tests that a tensile strength machine performs to ensure product excellence!

1. Elongation Test - This test measures the extent to which a material can stretch before reaching its breaking point. It plays an important role in evaluating the materials’ behavior under tension assessing their suitability for various applications where elongation properties are crucial such as textiles, fabrics, etc.

2. Seam Slippage Test - A Seam Slippage test is used to assess the integrity and strength of a seam or stitched area in a material. It is used to calculate the resistance of the seam to slippage or separation under tension.

3. Breaking Strength Test - The Breaking Strength test is used to measure the maximum force that a material can withstand before it breaks or fractures. The test provides data by evaluating the strength and load-bearing capacity of a material under tension.

4. Compression Test - A Compression test is used to evaluate the behavior of a material under compressive forces or loads. Compression testing involves applying a squashing or crushing force to the material in order to calculate the response.

5. Tongue Tear Test - A Tongue Tear test determines the resistance of a material to rupture or tear along a pre-cut tongue-shaped slit or notch. The test involves employing a tensile force perpendicular to the direction of the slit, that causes the tear to propagate along the material. This test plays a crucial role in assessing the durability and tear strength of materials, specifically those used in applications where tear resistance is vital, such as textiles, fabrics, etc.

6. Puncture Test - The Puncture test measures the ability of a material to withstand piercing or penetration by a sharp object. This test involves employing a controlled force on the material using a specific puncturing tool or probe. It is used to calculate the force that is required to puncture the material and evaluate its puncture resistance.

These tests evaluate and assess the materials on important parameters, thus making the tensile strength tester a quintessential testing equipment for the textile industry.

0 notes

Text

Tensile Strength Tester

A Tensile Strength Tester is a machine used to determine the tensile strength of materials. It is also known as a universal testing machine, because it can test a wide range of materials including metals, plastics, rubber, textiles, paper, and many more.

The tensile strength testing machine works by clamping a sample of the material at both ends and then applying a tensile force to the sample until it breaks. The force required to break the sample is then measured and recorded, providing an indication of the material's tensile strength.

#TensileStrengthTester #TensileTestingMachine #TensileTester #Tensile

0 notes