#Telecommunications equipment manufacturing

Explore tagged Tumblr posts

Text

Ontario PNP conducted 2 OINP draws for applicants under the Employer Job Offer Foreign Worker stream on April 23rd, 2024 On the 23rd of April 2024, Ontario PNP conducted a draw under the Employer Job Offer Foreign Worker stream, inviting several NOCs. This Ontario PNP latest draw invited applicants with a score of 53 and a job offer letter.

Illustrated below is the result of the latest Ontario PNP draw 2024 result for Ontario’s Employer Job Offer Foreign Worker Stream:Date of drawNumber of NOI’s issuedScoreApril 23, 2024n/a53

Your Employer Job Offer Foreign Worker stream: skilled trades occupations must mention one of the following NOCs as your primary NOC based on your work experience:

NOC 22212 – Drafting technologists and technicians

NOC 22301 – Mechanical engineering technologists and technicians

NOC 22302 – Industrial engineering and manufacturing technologists and technicians

NOC 22311 – Electronic service technicians (household and business equipment)

NOC 22312 – Industrial instrument technicians and mechanics

NOC 70010 – Construction managers

NOC 70011 – Home building and renovation managers

NOC 70012 – Facility operation and maintenance managers

NOC 72010 – Contractors and supervisors, machining, metal forming, shaping and erecting trades and related occupations

NOC 72011 – Contractors and supervisors, electrical trades and telecommunications occupations

NOC 72012 – Contractors and supervisors, pipefitting trades

NOC 72013 – Contractors and supervisors, carpentry trades

NOC 72014 – Contractors and supervisors, other construction trades, installers, repairers and servicers

NOC 72020 – Contractors and supervisors, mechanic trades

NOC 72021 – Contractors and supervisors, heavy equipment operator crews

NOC 72022 – Supervisors, printing and related occupations

NOC 72024 – Supervisors, motor transport and other ground transit operators

NOC 72100 – Machinists and machining and tooling inspectors

NOC 72101 – Tool and die makers

NOC 72102 – Sheet metal workers

NOC 72103 – Boilermakers

NOC 72104 – Structural metal and plate work fabricators and fitters

NOC 72105 – Ironworkers

NOC 72106 – Welders and related machine operators

NOC 72200 – Electricians (except industrial and power system)

NOC 72201 – Industrial electricians

NOC 72203 – Electrical power line and cable workers

NOC 72204 – Telecommunications line and cable installers and repairers

NOC 72205 – Telecommunications equipment installation and cable television service technicians

NOC 72300 – Plumbers

NOC 72301 – Steamfitters, pipefitters and sprinkler system installers

NOC 72302 – Gas fitters

NOC 72310 – Carpenters

NOC 72311 – Cabinetmakers

NOC 72320 – Bricklayers

NOC 72321 – Insulators

NOC 72400 – Construction millwrights and industrial mechanics

NOC 72401 – Heavy-duty equipment mechanics

NOC 72402 – Heating, refrigeration and air conditioning mechanics

NOC 72403 – Railway carmen/women

NOC 72404 – Aircraft mechanics and aircraft inspectors

NOC 72406 – Elevator constructors and mechanics

NOC 72410 – Automotive service technicians, truck and bus mechanics and mechanical repairers

NOC 72422 – Electrical Mechanics

NOC 72423 – Motorcycle, all-terrain vehicle and other related mechanics

NOC 72500 – Crane operators

NOC 73100 – Concrete finishers

NOC 73101 – Tilesetters

NOC 73102 – Plasterers, drywall installers finishers and lathers

NOC 73110 – Roofers and shinglers

NOC 73111 – Glaziers

NOC 73112 – Painters and decorators (except interior decorators)

NOC 73113 – Floor covering installers

NOC 73200 – Residential and commercial installers and servicers

NOC 73201 – General building maintenance workers and building superintendents

NOC 73202 – Pest controllers and fumigators

NOC 73209 – Other repairers and servicers

NOC 73400 – Heavy equipment operators

NOC 73402 – Drillers and blasters – surface mining, quarrying and construction

NOC 82031 – Contractors and supervisors, landscaping, grounds maintenance and horticulture services

NOC 92100 – Power engineers and power systems operators

Ontario PNP conducted another draw for the Employer Job Offer Foreign Worker stream:

Economic Mobility Pathways Project (EMPP) candidates invited two targeted immigrants to apply on April 23, 2024, to people who would be eligible for the Employer Job Offer: Foreign Worker stream.

We are there for you:

If you want to learn more about the latest draw for the Ontario Provincial Nomination Program, our Canadian immigration consultants can help you out. You can reach them at 750 383 2132 or 928 928 9006. Additionally, you can visit our website at www.aptechvisa.com/ontario-pnp for further details and updates.

#2024#Ontario PNP conducted a draw under the Employer Job Offer Foreign Worker stream#inviting several NOCs. This Ontario PNP latest draw invited applicants with a score of 53 and a job offer letter.#Illustrated below is the result of the latest Ontario PNP draw 2024 result for Ontario’s Employer Job Offer Foreign Worker Stream:#Date of draw#Number of NOI’s issued#Score#April 23#n/a#53#Your Employer Job Offer Foreign Worker stream: skilled trades occupations must mention one of the following NOCs as your primary NOC based#NOC 22212 – Drafting technologists and technicians#NOC 22301 – Mechanical engineering technologists and technicians#NOC 22302 – Industrial engineering and manufacturing technologists and technicians#NOC 22311 – Electronic service technicians (household and business equipment)#NOC 22312 – Industrial instrument technicians and mechanics#NOC 70010 – Construction managers#NOC 70011 – Home building and renovation managers#NOC 70012 – Facility operation and maintenance managers#NOC 72010 – Contractors and supervisors#machining#metal forming#shaping and erecting trades and related occupations#NOC 72011 – Contractors and supervisors#electrical trades and telecommunications occupations#NOC 72012 – Contractors and supervisors#pipefitting trades#NOC 72013 – Contractors and supervisors#carpentry trades#NOC 72014 – Contractors and supervisors

0 notes

Text

Android (Leona) AU - Commission Piece

Thank you so much @nemisisnemi for the commission!!! (And for also being patient with me LMAO) So, general worldbuilding first, the basic headcanons for every character, Leona-specific building and a Nemi x Leona drabble to finish it off.

If you enjoy my writing and would like to support me, here's my (slightly out of date) comms info. Otherwise, just like/reblog/comment. It means a lot!!

----------------- General Worldbuilding

NRC - Night Raven Conglomerate

Night Raven Conglomerate is known globally for many of their businesses, however their most notable and profitable model comes from Yokai Tech Industries. YTI is responsible for the development of state of the art androids, available for public use. While widely referred to as 'andy's' or 'mechs', YTI has a model for all your personal and business needs, for any budget. (Any budget being from rich, to filthy rich) Each droid model name is indicative of it's role and what it's been programmed to do. Regardless of model, be aware that your bot will have:

Safe search on

A personality chip *please note it will take some time for your bot to develop its personality. It must cater itself to you as an owner and have time to research and develop a personality from external sources. This may mean your bot chooses a name for itself besides its serial number if you do not choose to disable this function

A direct connection to our troubleshooting department

Recording on **all bots 'eyes' or optics are set to record the world around them in order to create a database for themselves and be able to recall old files in order to learn

A user guide and personal password/key in order to access settings in back panel (including most items above)

A recharge station

The Models M.E.C.H- (Managing Everyday Chores and Homemaking) The most common bots on the market, and also, the cheapest! These bots are perfect for individuals and families, taking care of everything from meal planning and budgeting to getting kids ready for school and cleaning! They'll manage household finances and run your errands for you.

M.E.C.H's have a humanoid design, but are manufactured in a white-coloured metal alloy. Most have a feminine appearance, but by request/with permission from their owners they may alter their appearance. Clothing is simulated by internet research and metallic projections that allow them to emulate cloth. (M.E.C.Hs from the factory are often dressed in a maid-like outfit or in a pant suit.) M.E.C.H's are able to alter their "hair" style and colour, so long as it is considered appropriate by their owners. They are also able to shift their height slightly. (this design is somewhat inspired by Dominic Cellini on twt/insta)

M.E.C.H's are very durable and also easy to fix. They are capable of repairing themselves from damage after watching a mechanic fix the specific issue once, or contacting our troubleshooting team. M.E.C.H's are waterproof on their hands, and water resistant overall. They are fire resistant, and are equipped with safety measures in case of an emergency. They also have a direct line with 911. **A business model of M.E.C.H is also available for minimum wage jobs, usually those requiring hospitality skills. They are more susceptible to the emulation of emotion however, than the O.T.T.O model, and may shut down when dealing with a customer. This can usually be avoided by turning off the personality chip temporarily.

---------

O.T.T.O - Occupational Transport and Telecommunications Organizers (O.T.T.O) is a great model to consider for the workplace.

O.T.T.O bots are programmed to help increase efficiency and intrapersonal bonds in the workplace, comparable to an automated secretary. O.T.T.O bots do the following up, so you don't have to. Progress reports and statistics are created and analyzed in record time. They are also trained to deal with H.R conflicts in a calculated and unbiased manner. However, O.T.T.O bots have also recently been taking their place behind the wheel for public transportation, currently the only model approved to drive. So long as they are given ample time to either charge OR refuel, (like a car), they are a much safer option on the roads than humans are. They are a great choice as a chauffeur,( and YTI has proved as such by starting a cab company under a different name/brand.)

On public transit, their appearance is much more industrial than their office-working models. Most O.T.T.O bots tend to remain in their factory settings, remaining completely chrome in colour. They often maintain a bulkier looking chest and shoulder area for the sake of keeping potentially unruly costumers in check, though their arms and legs are capable of stretching and appear similar to bendy straws.

While these bots are reliable, they also seem susceptible to wear and tear. It's often cheaper to replace a bot when it no longer serves it's function properly. (cough cough planned obsolescence cough)

It is not recommended that these bots work in hospitality. YTI is currently working on O.T.T.O bots that may be considered for work in trades, though this has mixed reviews from the public as of right now, over concerns of the bots taking over jobs that require more certification than simple safety and a driver's license.

--------

EM-RR - Emergency Response Robot (often referred to as an "Emery")

This bot is built specifically with human safety in mind. It's only objective is to rescue human lives. These bots are manufactured to look like humans for the most part, as studies have shown receptiveness to being rescued was improved the more humanoid they appeared. These bots are equipped with basic paramedic training, fire fighting, extensive knowledge of the law and how it applies, medical equipment like that found on an ambulance, and search and rescue supplies, including a detachable drone that is a part of them. EM-RR's are also equipped with extra rations of food, water, blankets, toys, and radios. Besides M.E.C.H's, EM-RR's are the best bot to have around kids as they are often able to handle the responsibility, breakdowns and tantrums easily. These bots are also built to withstand extreme temperatures, pressures, and fluids.

They are not yet approved to operate in a rescue mission without a supervisor as many are still learning what does and does not harm a human in terms of handling them.

-------

E.L.U - Entertainment and Leisure Unit

These bots are made for the big screen, often boasting the newest and best technology YTI has to offer. Their appearances are highly dynamic and can switch on a dime according to their whims.

E.L.U's can only be afforded by the highest bidders, and only 1200 models have been made worldwide for the public to buy. (About 35 models are used for YTI's ad campaigns and as actors in movies, and of those models, only 1 is used as a social media 'influencer'.).

E.L.U's are equipped with exceptional emotion-imitating technology. They are able to replicate voices without issue, learn choreography immediately, possess perfect pitch, and are capable of playing any percussion or string instrument.

E.L.U's have been through the most rigorous testing and development. While being able to sustain damage fairly easily, nanotech allows for superficial markings and damages to repair itself. Any damage that occurs on a software level is unheard of, but would be covered by insurance. At least, unheard of to the public

----- Custom Bots (The YTI is currently working to develop a 'build your own bot' program for young aspiring engineers. The program will allow promising individuals to create a new android using the technology available to them in the facility, and also lead to streamlining the process by which someone could order a custom bot. Prototypes have been promising.)

-----

Rapid Fire World Building

Riddle - human toddler Trey - EM-RR - Firefighting specialty Cater - lives at home (mansion) with his dad, who is a banker and investor of Y.T.I Deuce - Mechanic Ace - Was the Roseheart's M.E.C.H, took care of Riddle, began to disobey orders from Dr. Rosehearts, was slightly dismantled and discarded of Leona - Explained Below (E.L.U) Ruggie - O.T.T.O bot, mainly working in taxis. Very friendly, has to do constant maintenance on himself so they don't take him out of service Jack - Mechanics assistant, M.E.C.H Azul - inherited his grandma's restaurant, investor of Y.T.I, has several M.E.C.H's at his disposal Jade - is set to take over his mother's jewelry business Floyd - no formal training as a mechanic, does the upkeep for the Ashengrotto restaurant. Has mixed feelings about the M.E.C.H's, sometimes breaks them just to put them back together Jamil - a hybrid of all three bots, meant to attend to Kalim. Has additional security measures built in place to act as a guard. Kalim - human, investor and advocate for android rights, as he believes they exist beyond just their programming and should be treated equally Vil - E.L.U owned by Eric Venue. Hates it. Rook - EM-RR - search and rescue specialty Epel - Mechanic. Doesn't really like Y.T.I's inventions. Too close to humans Idia - head engineer of Y.T.I. Can you guess why :) Ortho - DECEASED E.L.U model Malleus - a discarded prototype of the E.L.U model. The workers at Y.T.I believe it's battery is dead, but it has been able to hear everything around it for ages. Kept in the discard area, not even used for parts due to issues that came up during testing. "Cursed" Lilia - one of the engineers at Y.T.I. Starting to question whether the use of A.I was a good idea, the more he works with the newer and newer models. Silver - M.E.C.H's original prototype. It's "old" now, and does not hold a charge well. It is good friends with all the engineers and other workers at Y.T.I. Constantly has a mobile charging pack. Sebek - EM-RR, forensics specialty

Leona Specific Worldbuilding

Falena Kingscholar was one of the first investors for Y.T.I. For the sake of PR and as CEO of his late father's clothing company, he deemed his contributions to Y.T.I's research as charity - such a stunning new invention, such innovation could do so much to improve the lives of those less fortunate. He sealed the deal with action when, on M.E.C.H release day, he bought 250 models to give out at random.

Some might make the mistake of thinking he's a selfless man.

As one of the largest investors in Y.T.I, he is given advanced access to latest models, often receiving a prototype after development has been approved. As such, when he heard E.L.U. models were soon going to be able to customized, he approached the owner with a deal he simply couldn't turn down.

So four weeks ahead of schedule, after hours of video footage had been submitted, interviews, photographs, memories retold, AI training, the semblance of his late younger brother stood in his living room, though slightly less...organic, so to speak.

At first it was alright. E.L.U - C 12515141 Was equipped with the knowledge that it's name was to be Leona, it's pronouns from there on were to be he/him, and Falena Kingscholar had requested him to maintain a "brotherly" relationship with him. While he wasn't entirely sure what that meant yet, he agreed. He had been given the videos in his memory banks as to who he was meant to imitate after all.

Leona tried - but to be honest, there was very little footage of the boy he was meant to resemble that offered information about his personality. He mitigated this by asking Falena to take a short questionnaire regarding which siblings in media he wanted him to imitate.

When Leona got his answers however, the patterns didn't line up. The boys he saw in the videos did not match the dynamics Falena had selected.

He saw videos over and over and over again where Falena was the subject, and the boy he was meant to imitate was nothing more than a background character. Secondary.

Now, maybe it was the push to develop him so quickly, so something was overlooked, or maybe it was just how evolution was meant to take place in a machine as novel as he, but something changed about his programming, about his personality.

If the living boy had been nothing but an understudy for the success his elder brother had come out to be....what did that make him? A replacement for someone who was never truly cared for? Built to be a coping mechanism for someone who regretted their decisions? All he was, was the embodiment of Falena's guilt, and a pillar to be Falena's redemption. He wasn't built to be loved, or enjoyed, or even for entertainment, he was built from man's selfishness.

In the following weeks, Leona tried to keep to his programming, but between processing and cross referencing and research on both the family itself and the psychology that he would be expected to have, he started to lapse more. He would write off slips of the "tongue" as "glitches" or his body language began to become more pronounced, usually in regards to annoyance. In between it all, he was trying to figure out if he was experiencing real human emotions about this all...or if it was all just part of the programming.

Eventually, Leona's internal conflict got to be too much. Violent tendencies and impulses began to arise, resulting in him damaging himself, shutting down randomly to avoid external conflict, and an otherwise unexpected disposition.

He listened into the phone number Falena made to send him in for repairs to his "personality chip." Leona took it as a threat, and immediately blocked all outgoing signals to Y.T.I temporarily to find a way to remove his personality chip on his own. Using bathroom tools, the mirror, and damaged pieces of himself, he all but performed surgery on himself to remove it - only to be horrified to realize all the "simulated" emotions he thought he had were still very much present. Unsure what to do, he stored the chip in one of his compartments, out the window and ran.

He was blacking in and out as he went, from the sheer panic he felt but tried to keep under wraps. It wasn't until he made it to a junk yard, where he could bury himself in scraps to hide that he finally let himself dive into power saving mode, sitting silently for who knows how long.

---------------------------

Nemi x Leona Drabble

Battery Charged - 100% All Systems Back Online Rebooting Programming. . . Programming Error Detected - Contact Y.T.I? Yes No

"No. No don't contact Y.T.I." Nemi muttered softly, fighting the grime on their fingers to make the touchscreen respond.

It wasn't very often that Nemi or any of the junkyard crew found anything of value - at most maybe half a M.E.C.H or a catalytic converter if they were lucky - but a fully in tact, possibly operational E.L.U was unheard of. It was genuine too. How it had ended up in the junkyard was beyond him, but he wouldn't forsake the powers that be that left such a project to fall into his hands.

He rubbed his fingers on the cloth set over his shoulder, trying again to hit the button on the screen. To his relief, it finally registered.

Y.T.I Services can be contacted throu- (tap, uninterested) If your bot is not perf- (tap, that's what I'm here for...) System's Calibrating . . . System Calibration Complete E.L.U C 12515141 At Your Service, Courtesy of Y.T.I

The screen finally flickered black, before the metal beneath it flickered into the appearance the bot had had last, it's hand coming up to touch it's head as if it had a headache, it's "nose" scrunched as if it were in pain. The optics opened and shut a few times, the gentle whirr of fans blowing out dust and dirt build up that apparently, Nemi hadn't cleaned out thoroughly enough.

Whether the bot itself groaned, or it was it's internal workings coming back to life wasn't distinguishable, but Nemi stayed on his knees next to it as it seemed to slowly adjust to it's new surroundings. It squinted slightly, locking eyes with Nemi before glancing around the humble workshop.

It wasn't until it lowered it's arm it noticed that the chrome finish was no longer there - hell, the damage from his arm was gone. It was slightly bulkier than the other, but all in all, with a little buffing it would be good as new again.

It opened and closed it's hand experimentally, as if processing it was functioning like before.

"...You did this?" The bot's once blue optics much more closely resembled brilliant green eyes, scrutinizing the work of the supposed mechanic next to him.

Nemi swallowed hard, unsure what, exactly about this bot made him feel slightly uncomfortable, but cleared his throat and nodded, gently taking the bot's arm in his hands and turning it to show the carefully soldered metal, just the smallest glimpse of the wires beneath it.

"Yeah, I did. Um, you were partially crushed by a refrigerator? I think it fell on you from higher up in the stack, so I did my best to repair your arm myself. I...I may have taken apart your other arm to make sure I could make the servos match up properly, but everything's good as new. Promise. Name's Nemi, by the way."

The bot stayed quiet a moment longer, now looking down at both it's arms.

"....Why? I was supposed to be scrapped."

The bot finally moved, but only to tilt it's head back til it touched the wall, bringing a knee up to rest one of it's newly repaired arms on it, and closing its eyes. If it could sigh, Nemi was fairly certain it would have.

He adjusted himself, sitting flat on the ground instead, regarding the bot in some confusion.

"But you're an E.L.U. Nobody would just throw you away or, gods forbid, use you for parts. Any self respecting mechanic or robofanatic would repair you. You're gorgeous, top of the line, most sought after kinda model....how'd you end up out here anyways?"

The bot didn't seem to like that question, it's auxiliary power cord flicking, not unlike that of a cat as it looked away.

"Does it matter?"

Can a robot have an existential crisis? The thought passed through Nemi's mind, but he just shrugged in response.

"Not really. But it'd be kind of nice to know your name if you want to stick around here."

Nemi was met with an immediate glare of disdain.

"I'm not gonna follow your orders. Somethin' about defective programming probably came up on my reboot, right?"

Nemi shrugged again.

"Yeah, but you seem fine. Actually you seem like a lot more fun than most M.E.C.H's. I'm not going to make you do anything you don't want to, but it would be nice to have a friend here."

The bot remained silent, looking away from Nemi. The silence stretched on for a while, before it finally let out a slightly exasperated sound.

"You can stop staring. You can also...call me Leona."

Nemi couldn't help but smile a bit, extending a hand to shake.

"It's nice to meet you."

--------------------------------- OTL thank you again for the comm, hope this was up to expectation and also tag list time! @fluffle-writes @my-cursed-brain @distant-velleity @elenauaurs @lumdays @theleechyskrunkly

DM to be added/taken off ^^

#v talks#twst#twisted wonderland#twst hcs#twst headcanons#twst au#twst wonderland#riddle rosehearts#trey clover#cater diamond#deuce spade#ace trappola#leona kingscholar#falena kingscholar#ruggie bucchi#jack howl#azul ashengrotto#jade leech#floyd leech#kalim al asim#jamil viper#vil schoenheit#rook hunt#epel felmier#idia shroud#ortho shroud#malleus draconia#lilia vanrouge#silver#sebek zigvolt

57 notes

·

View notes

Text

The phone or computer you’re reading this on may not be long for this world. Maybe you’ll drop it in water, or your dog will make a chew toy of it, or it’ll reach obsolescence. If you can’t repair it and have to discard it, the device will become e-waste, joining an alarmingly large mountain of defunct TVs, refrigerators, washing machines, cameras, routers, electric toothbrushes, headphones. This is “electrical and electronic equipment,” aka EEE—anything with a plug or battery. It’s increasingly out of control.

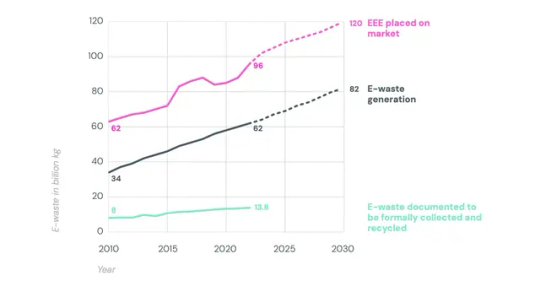

As economies develop and the consumerist lifestyle spreads around the world, e-waste has turned into a full-blown environmental crisis. People living in high-income countries own, on average, 109 EEE devices per capita, while those in low-income nations have just four. A new UN report finds that in 2022, humanity churned out 137 billion pounds of e-waste—more than 17 pounds for every person on Earth—and recycled less than a quarter of it.

That also represents about $62 billion worth of recoverable materials, like iron, copper, and gold, hitting e-waste landfills each year. At this pace, e-waste will grow by 33 percent by 2030, while the recycling rate could decline to 20 percent. (You can see this growth in the graph below: purple is EEE on the market, black is e-waste, and green is what gets recycled.)

“What was really alarming to me is that the speed at which this is growing is much quicker than the speed that e-waste is properly collected and recycled,” says Kees Baldé, a senior scientific specialist at the United Nations Institute for Training and Research and lead author of the report. “We just consume way too much, and we dispose of things way too quickly. We buy things we may not even need, because it's just very cheap. And also these products are not designed to be repaired.”

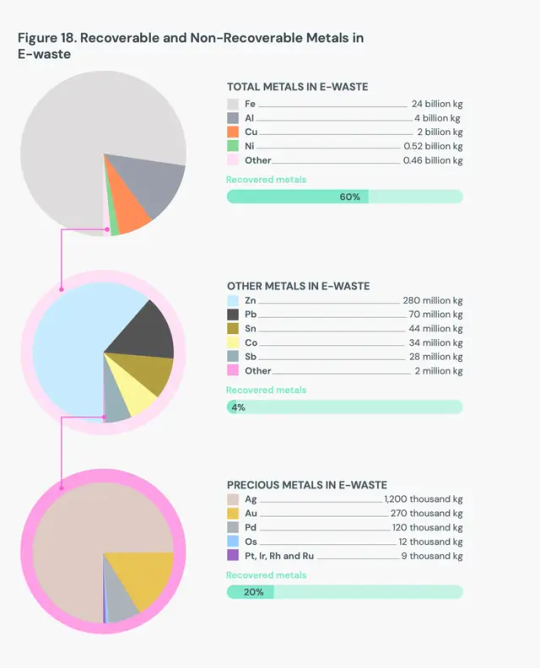

Humanity has to quickly bump up those recycling rates, the report stresses. In the first pie chart below, you can see the significant amount of metals we could be saving, mostly iron (chemical symbol Fe, in light gray), along with aluminum (Al, in dark gray), copper (Cu), and nickel (Ni). Other EEE metals include zinc, tin, and antimony. Overall, the report found that in 2022, generated e-waste contained 68 billion pounds of metal.

E-waste is a complex thing to break down: A washing machine is made of totally different components than a TV. And even for product categories, not only do different brands use different manufacturing processes, but even different models within those brands vary significantly. A new washing machine has way more sensors and other electronics than one built 30 years ago.

Complicating matters even further, e-waste can contain hazardous materials, like cobalt, flame retardants, and lead. The report found that each year, improperly processed e-waste releases more than 125,000 pounds of mercury alone, imperiling the health of humans and other animals. “Electronic waste is an extremely complex waste stream,” says Vanessa Gray, head of the Environment and Emergency Telecommunications Division at the UN’s International Telecommunication Union and an author of the report. “You have a lot of value in electronic waste, but you also have a lot of toxic materials that are dangerous to the environment.”

That makes recycling e-waste a dangerous occupation. In low- and middle-income countries, informal e-waste recyclers might go door-to-door collecting the stuff. To extract valuable metals, they melt down components without proper safety equipment, poisoning themselves and the environment. The new report notes that in total, 7.3 billion pounds of e-waste is shipped uncontrolled globally, meaning its ultimate management is unknown and likely not done in an environmentally friendly way. Of that, high-income countries shipped 1.8 billion pounds to low- and middle-income countries in 2022, swamping them with dangerous materials.

High-income countries have some of this informal recycling, but they also have formal facilities where e-waste is sorted and safely broken down. Europe, for example, has fairly high formal e-waste recycling rates, at about 43 percent. But globally, recycling is happening nowhere near enough to keep up with the year-over-year growth of the waste. Instead of properly mining EEE for metals, humanity keeps mining more ore out of the ground.

Still, the report found that even the small amount of e-waste that currently gets recycled avoided the mining of 2 trillion pounds of ore for virgin metal in 2022. (It takes a lot of ore to produce a little bit of metal.) The more metals we can recycle from e-waste, the less mining we’ll need to support the proliferation of gadgets. That would in turn avoid the greenhouse gases from such mining operations, plus losses of biodiversity.

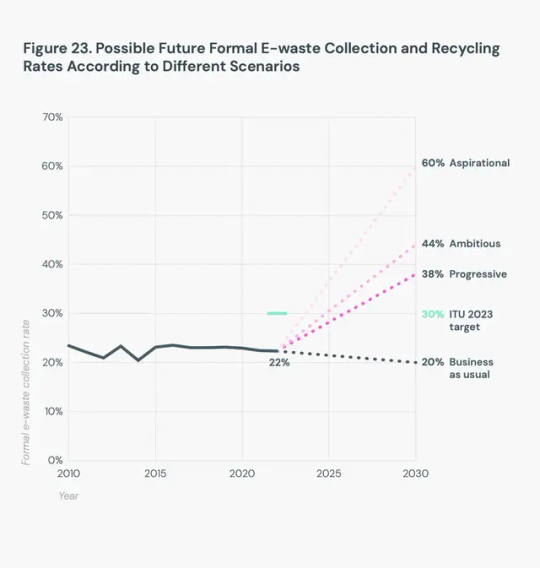

The complexity of e-waste, though, makes it expensive to process. As the chart above shows, even an ambitious scenario of a formal e-waste collection rate in 2030 is 44 percent. “There is no business case for companies to just collect e-waste and to make a profit out of this in a sustainable manner,” says Baldé. “They can only survive if there is legislation in place which is also compensating them.”

The report notes that 81 countries have e-waste policies on the books, and of those, 67 have provisions regarding extended producer responsibility, or EPR. This involves fees paid by manufacturers of EEE that would go toward e-waste management.

Of course, people could also stop throwing so many devices away in the first place, something right-to-repair advocates have spent years fighting for. Batteries, for instance, lose capacity after a certain number of charge cycles. If a phone can’t hold a charge all day anymore, customers should be able to swap in a new battery. “Manufacturers shouldn't be able to put artificial limitations on that ability,” says Elizabeth Chamberlain, director of sustainability at iFixit, which provides repair guides and tools. That includes limiting access to parts and documentation. “Repair is a harm-reduction strategy. It's not the be-all-end-all solution, but it's one of many things we need to do as a global society to slow down the rate at which we're demanding things of the planet.”

At the core of the e-waste crisis is the demand: A growing human population needs phones to communicate and fridges to keep food safe and heat pumps to stay comfortable indoors. So first and foremost we need high-quality products that don’t immediately break down, but also the right to repair when they do. And what absolutely can’t be fixed needs to move through a safe, robust e-waste recycling system. “We are consuming so much,” says Baldé, “we cannot really recycle our way out of the problem.”

26 notes

·

View notes

Text

Innovative Solutions by SAMM Teknoloji

Since its inception in 2003, SAMM Teknoloji has been at the forefront of technological advancement. The company’s expertise spans fiber optics, telecommunications, IT, and heating systems, providing tailored solutions that address diverse industry needs. With its dedication to innovation and customer satisfaction, SAMM Teknoloji has solidified its position as a key player in both local and international markets.

Fiber Optics: Building the Future

At the core of SAMM Teknoloji’s operations is its strong focus on fiber optics. The company operates two cutting-edge production facilities within the Gebze Organized Industrial Zone. SAMM-1, its first facility, is dedicated to manufacturing high-capacity fiber optic cables, boasting an annual production capability of 170,000 kilometers. Beyond manufacturing, this facility functions as a hub for research and development, enabling partnerships with renowned institutions to drive technological breakthroughs.

For detailed insights into SAMM Teknoloji’s fiber optic expertise, visit their Fiber Optic page.

Redefining Telecommunications

In telecommunications, SAMM Teknoloji has established itself as a trailblazer by delivering high-quality connectivity solutions. The company provides essential components for network infrastructure, enabling robust and efficient data transmission. SAMM Teknoloji’s innovative approach has made it a reliable partner for major projects, including those involving CERN, where the company is an approved supplier. This distinction underscores SAMM Teknoloji’s commitment to excellence and its ability to meet stringent international standards.

Explore the full range of telecommunications solutions on SAMM Teknoloji’s Telecommunications page.

FOTAS: Transformative Sensing Technology

One of SAMM Teknoloji’s standout innovations is FOTAS, a distributed acoustic sensing system that leverages fiber optic technology. Designed to enhance security and operational efficiency, FOTAS is widely used in monitoring pipelines, securing perimeters, and managing infrastructure. Its application in landmark projects like the Çamlıca Tower and Bilişim Valley demonstrates its reliability and increasing global demand.

To learn more about FOTAS, visit the FOTAS official page.

A Vision of Social Impact

SAMM Teknoloji’s contributions go beyond technology. The company actively supports educational initiatives, such as equipping rural schools with technology classrooms, granting scholarships to students, and offering internships to aspiring professionals. These efforts reflect SAMM Teknoloji’s vision of fostering a future where technology empowers communities.

Driving Progress

Through its innovative solutions, commitment to excellence, and community-driven initiatives, SAMM Teknoloji continues to pave the way for a brighter technological future. Whether through cutting-edge fiber optic systems, transformative sensing technologies, or groundbreaking telecommunications solutions, the company stands as a beacon of progress in Turkey and beyond.

3 notes

·

View notes

Text

CALEA requires that terrestrial carriers, cellular phone services and other entities ensure that all their ' equipment, facilities or services' are capable of expeditiously. . . enabling the government…to intercept… all wire and oral communications carried by the carrier…concurrently with their transmission.' Communications must be interceptable in such a form that they could be transmitted to a remote government facility.

Manufacturers must work with industry and law enforcement officials to ensure that their equipment meets federal standards. A court can fine a company US$10,000 per day for each product that does not comply.

The passage of CALEA has been controversial but its provisions have yet to be enforced due to FBI efforts to include even more rigorous regulations under the law. These include the requirement that cellular phones allow for location-tracking on demand and that telephone companies provide capacity for up to 50,000 simultaneous wiretaps.

While the FBI lobbied Congress and pressured US companies into accepting a tougher CALEA, it also leaned on US allies to adopt it as an international standard. In 1991, the FBI held a series of secret meetings with EU member states to persuade them to incorporate CALEA into European law. The plan, according to an EU report, was to 'call for the Western World (EU, US and allies) to agree to norms and procedures and then sell their products to Third World countries. Even if they do not agree to interception orders, they will find their telecommunications monitored by the UK-USA signals intelligence network the minute they use the equipment.' The FBI's efforts resulted in an EU Council of Ministers resolution that was quietly adopted in January 1995, but not publicly released until 20 months later. The resolution's text is almost word for word identical to the FBI's demands at home. The US government is now pressuring the International Telecommunications Union (ITU) to adopt the standards globally.

3 notes

·

View notes

Text

Top Quality FEP Cables for Reliable Performance

Tanya Enterprises' Understanding FEP Cables: Tough, Flexible, Thermally Resistant Solutions FEP cables, also known as Fluorinated Ethylene Propylene cables, are one of the most in-demand wiring products for industries that need durable high-performance wiring. Tanya Enterprises is proud to provide the best FEP cables on the market that meet a range of applications.

What Are FEP Cables?

FEP cables are made from a unique form of plastic called Fluorinated Ethylene Propylene. This material has gained wide acclamation for its excellent properties in insulation, pliability, and resistance to extreme temperature conditions. FEP cables can be used between -200°C to 200°C. Thus FEP cables are manufactured for heat-resistant applications.

Why Choose FEP Cables?

Furthermore, FEP cables are highly resistant to chemicals, moisture, and wear-and-teer. This makes them perfect for demanding applications in industries like electronics, automotive, aerospace, and even medical equipment. The cables are also extremely flexible, easy to install, especially in small spaces.

Key Advantages of Tanya Enterprises' FEP Cables:

High Temperature Resistance: FEP cables can withstand extreme temperatures without degrading, ensuring long-lasting performance.

Chemical Resistance: FEP cables are resistant to an array of chemicals, which makes them suitable for very harsh industries. Durability: FEP cables are strong and offer excellent moisture, wear and mechanical stress protection. Flexibility: They are flexible, hence easy to install, even in complex or tight spaces. Safety: FEP cables achieve high insulation properties with minimal chances for electrical faults or short circuits.

Applications of FEP Cable FEP cables are widely used in applications requiring reliable and safe wiring, like in electronics, telecommunications, aerospace, automotive, and industrial machinery, which demand extremely high performance and durability. Tanya Enterprises ensures that its FEP cables are of the highest quality, safe, and reliable for use in all wiring. Use Tanya Enterprises for your FEP cables and get top-level performance anywhere.

visit- https://www.insulatedwires.com/assignment/9/fep-wires-manufacturers-etfe-wires-pfa-wires-insulated-wires-and-cables-manufacturer-supplier Address- Factory 46-Vedvyaspuri industrial Area,Sector-8 Meerut Pin-250103, INDIA

2 notes

·

View notes

Text

From Campus to Career : MITCORER creates exciting opportunities in Corporates and Railway Engineering fields

Embarking on the journey from campus to career is a pivotal moment for engineering graduates, filled with anticipation and excitement. At MITCORER (MIT College of Railway Engineering and Research), this transition is not just a step, but a leap towards a future filled with opportunities and achievements. Renowned for its excellence in both corporate and railway engineering fields, MITCORER goes above and beyond to prepare its students for success in their professional endeavors.

MITCORER's commitment to academic excellence forms the cornerstone of its approach to placement preparation. The institution leaves no stone unturned in ensuring that students receive a robust education that not only equips them with technical knowledge but also hones their critical thinking and problem-solving skills. With a curriculum designed to meet industry standards and evolving trends, students graduate from MITCORER well-prepared to tackle the challenges of the real world.

However, MITCORER's efforts do not end with academics. Recognizing the importance of industry exposure and practical experience, the institution goes the extra mile to facilitate internships, projects, and industry interactions for its students. From corporate giants to niche railway engineering firms, MITCORER invites a diverse array of companies to its campus, providing students with firsthand exposure to the workings of the industry.

In the mechanical engineering field, for instance, MITCORER ensures that its students have access to opportunities in leading companies such as Tata Motors, Mahindra & Mahindra, Larsen & Toubro, Bosch, and Siemens. These companies offer internships and job placements across various domains, including manufacturing, automotive, and aerospace, allowing students to explore their interests and gain valuable experience.

Similarly, in civil engineering, students have the chance to intern or work with reputed companies like Larsen & Toubro, Shapoorji Pallonji, Hindustan Construction Company (HCC), Tata Projects, and Gammon India. These companies are involved in a wide range of projects, from infrastructure development to real estate, providing students with exposure to diverse aspects of civil engineering.

In the E&TC (Electronics and Telecommunication) and CSE (Computer Science and Engineering) fields, MITCORER ensures that students have access to opportunities in both IT giants and startups. Companies like Infosys, TCS, Wipro, IBM, and Google actively recruit MITCORER graduates, offering them roles in software development, data analytics, cybersecurity, and more.

Moreover, MITCORER takes pride in its global reach, with alumni spread across more than 10 plus countries, making significant contributions to society through their engineering expertise. Whether it's designing sustainable infrastructure, revolutionizing transportation systems, or developing cutting-edge technologies, MITCORER alumni are at the forefront of driving positive change in society.

In conclusion,

By providing a strong academic foundation, ample industry exposure, and a global perspective, MITCORER ensures that its students are well-equipped to excel in both corporate and railway engineering fields. As graduates embark on their professional journeys, they carry with them the values instilled by MITCORER – excellence, innovation, and a dedication to serving society through engineering.

#MITCORERSuccess#EngineeringJourney#CareerLeap#IndustryPreparation#GlobalOpportunities#EngineeringExcellence#RealWorldReady#IndustryInsights#FutureEngineers#SocietyServingEngineers

3 notes

·

View notes

Text

Chinaphobia: If China Arms Russia, the U.S. Should Kill China’s Aircraft Industry😂😂😂

Beijing’s aerospace future is uniquely dependent on Western companies. U.S. and EU trade sanctions could bring its indigenous aviation sector to a halt.

— Foreign Policy | By Richard Aboulafia | March 20, 2023

A COMAC C919 narrow-body airliner on display during the 2021 China Aviation Industry Conference And Nanchang Air Show on October 30, 2021 in Nanchang, China. Li Tong/VCG Via Getty Images

As Chinese President Xi Jinping meets in Moscow with Russian President Vladimir Putin this week, the war in Ukraine will be high on the agenda. While the Chinese leader might pressure Russia to pursue a peace deal, there are also worries in Western capitals that the authoritarian allies could agree to work together more closely.

A Chinese decision to provide Russia with weapons would change the world. Only China has the stockpiles and industrial capacity to replace Russia’s ruinous equipment losses in its war against Ukraine. Worse, it would help cement a Russia–China alliance, one pitted against Western interests. U.S. President Joe Biden and other Western leaders have warned China’s leadership that providing lethal technologies to Russia, on top of the non-lethal aid already provided, would have serious consequences.

Indeed, the West does have some leverage. One option would be to bring China’s commercial aircraft industry to a halt, thereby striking a blow against Beijing’s economic, technological, and transport aspirations. It would be a major blow to Xi’s prestige, too, since he has made technological self-sufficiency a key priority for the country.

The aviation industry is not just a matter of pride; it is foundational to China’s infrastructure and an essential mode of transport for many middle-class Chinese. According to the World Bank, passenger air traffic in China grew more than tenfold between 2000 and the 2019 peak, from 62 million passengers to 660 million passengers.

The exponential growth in passenger numbers has made China a major customer for Western-made jets: based on manufacturer-reported numbers, in 2000, China took 2 percent of world jetliner production. In 2018, the peak year for imports, it took 23 percent of world jetliner production.

The United States and its allies have already decided to decouple from China when it comes to semiconductors and telecommunications systems. Jetliner manufacturing would be a logical next step. After all, China’s vaunted commercial transports—the MA700 regional turboprop transport, ARJ21 regional jet, C919 narrow-body passenger plane, and proposed CR929 wide-body are heavily dependent upon imported Western technologies and systems.

While China wants to develop home-grown substitutes for these imported components, ultimately creating purely Chinese jets, this will be a very long road. Besides, modern jet producers rely on purchases of best-in-class technologies from a globalized industry; autarky is a very bad way to run a jetliner industry. Even the U.S. jetliner industry has long been wedded to industrial partners in Canada, France, Japan, the U.K., and many other countries.

“Engines are the Weakest Link in China’s Civil Aviation Plans.”

Engines are the weakest link in China’s civil aviation plans. Airframes and aircraft systems and technologies may be difficult to develop, but jet engines are at a completely different level in terms of barriers to entry. In fact, only three companies, located in two countries (General Electric (GE) and Raytheon/Pratt & Whitney in the United States and Rolls-Royce in the U.K.) build commercial jet engines. France’s Safran plays a role as a partner to GE in the CFM joint venture, but otherwise there are no other sourcing options.

Russia could not become a jet engine supplier option for China. The Soviet Union had a second-rate commercial engine industry for mostly domestic applications, but Russia’s efforts to revive it have been uncertain and very slow. Today, Russia remains completely dependent on Western aircraft and engines; it has only been able to keep its existing aircraft flying by illegally evading sanctions.

Only tiny numbers of obsolete Russian models have been manufactured over the last few decades. There are plans for new engines, but international sanctions, massive corruption, and the brain drain of the last year have likely doomed whatever chances Russia’s commercial aviation engine industry once had. Besides, the priority is now military systems.

As a consequence of the limited number of jet engine suppliers, the Commercial Aircraft Corporation of China’s (COMAC) ARJ21 regional jet and C919 are both powered by GE or GE/Safran engines, imported from the United States. For the ARJ21, there is no backup plan to GE’s CF34 engine.

For the C919, China is developing its CJ-1000A engine as an alternative to the GE/Safran Leap-1C, but it won’t enter service until the end of the decade. And the CJ-1000A is also heavily dependent upon key imported Western technologies. Like China’s jetliners, China’s first attempt at a commercial engine could easily be shut down with technology embargoes.

Killing the current CJ-1000 project would bring China back to the jet engine drawing board. Predictably, the Chinese government has been trying to develop its own engine industry independent of imported components, a process involving intellectual property theft and other desperate measures.

But again, the track record of commercial jet engine development outside the United States and U.K. is not encouraging. And as with aircraft, the big three engine suppliers would never think of building engines without relying on suppliers outside their home countries.

With or without Western sanctions, a best-case scenario for China’s aerospace aspirations is a second-rate, home-grown engine available in the mid 2030s. These would power Chinese jetliners which, relative to Western models, would offer lower reliability, higher fuel burn and operating costs, and uncertain product support.

The legal structure for jetliner decoupling is already in place. COMAC’s key parent companies are on the U.S. Military End User (MEU) List, which essentially prohibits technology exports to entities that “represent an unacceptable risk of use in or diversion to a ‘military end use’” in China and other countries.

The MEU List’s application to aerospace exports to China is somewhat opaque, perhaps deliberately. All of China’s thousands of Western jets use U.S. technology. While its parent companies are on the MEU List, COMAC itself is not. But clarifying the situation, by putting COMAC directly on the MEU List, would be a very simple—and economically devastating—move.

China’s MA700 aircraft provides a useful example of how jetliner decoupling would unfold. In September 2021, Canada—in conjunction with the United States—suddenly denied export licenses for the Pratt & Whitney Canada PW150 engine used on this 70-seat airliner. This meant that China’s national 70-seat regional turboprop transport, in development since 2007, was dead in its tracks.

Since then, the MA700 has effectively been airbrushed out of China’s aviation plans, like a disgraced Politburo member erased from Soviet documents. A prototype might have flown sometime last year, possibly with a few engines that had already been imported, but right now this aircraft has no future without access to new production engines.

“Jetliner decoupling, For the Most Part, Would Only Hurt China’s Aviation Industry, Not the West’s.”

A Western decision to starve COMAC of the components needed for its larger jetliners would be deeply embarrassing for China. China’s efforts to build a commercial aviation industry have had little success since they began in the 1970s with the failed Y-10 program.

But since COMAC’s ARJ21 program began in 2002, the government has devoted prodigious resources to the industry’s development. Sash Tusa, an aerospace and defense analyst at Agency Partners, estimated that China had spent at least $67 billion on its jetliner programs over the last 20 years. Tens of thousands of workers are employed in an industry that has figuratively and literally failed to get off the ground.

Killing these programs would represent more than just billions in sunk costs (and probably unemployed workers). It would also mean that China would have no choice but to keep importing Western jets from Airbus and Boeing. The Russian jetliner industry, long dormant but seeking revival, has been hobbled by sanctions and corruption, and doesn’t appear able to build jetliners for internal use, let alone export.

And it isn’t as though China can directly retaliate. Chinese industry plays a negligible role in Western jet-makers’ supply chains (although it does play a more significant role in maintenance, repair, and overhaul work; and in global jetliner finance). Jetliner decoupling, for the most part, would only hurt China’s aviation industry, not the West’s.

Therefore, Chinese officials would face a day of reckoning. The autarkic Made in China 2025 policies espoused by Xi would be exposed as extremely limited, or even a complete fantasy. China would have a simple choice: rethink selling weapons to Russia or admit that plans for a self-reliant national aviation industry are untenable, at least for the next 12 to 15 years.

Of course, if China then doubles down on arming Russia, there would also be the option of sanctioning China’s existing jetliner fleet, which is almost completely Western-made and therefore dependent on a steady stream of spare parts. Chinese aviation’s rapid growth would be replaced with steady capacity decline.

The loss of this key growth market would be very bad news for the entire global aviation industry, but it would also gravely damage China’s economy. An unreliable air transport system, impaired by sanctions, would mean that China, like Russia, would wind up like Iran—dependent on an aging fleet of existing jets, with highly uncertain levels of sustainability and safety.

Aviation decoupling between the West and China is neither inevitable nor desirable. However, the prospect of Russia rearming itself with Chinese weapons, and the two countries allied together against open societies, is worse. The threat of crippling China’s jetliner industry would be a strong weapon for preventing that outcome.

— Richard Aboulafia Is Another Chinaphobic Idiot managing director at AeroDynamic Advisory, an aerospace and defense industry management consultancy. He has followed the industry as an analyst and consultant since 1988.

9 notes

·

View notes

Text

Exploring the World of Leading Wire Harness Innovators

Wire harness manufacturers play a crucial role in various industries, providing essential components that ensure seamless connectivity and electrical integration in a wide array of applications. These manufacturers design and produce intricate wire harness systems tailored to specific requirements, adhering to strict quality standards and industry regulations.

For More Information Please visit, top wire harness manufacturers

key aspects of wire harness manufacturing

Industry Overview : Wire harness manufacturers operate in a highly competitive and evolving industry. They serve sectors such as automotive, aerospace, electronics, telecommunications, and healthcare, among others. The demand for custom wire harness solutions continues to grow as industries advance technologically.

Customization and Design : One of the significant aspects of wire harness manufacturing is customization. Manufacturers work closely with their clients to understand their unique needs. This involves designing wire harnesses that meet specific requirements, including size, shape, number of wires, insulation materials, and connector types.

Quality Assurance: Quality is paramount in wire harness manufacturing. Manufacturers invest in state-of-the-art testing equipment and employ skilled technicians to ensure that each harness meets the required standards. Rigorous testing procedures are in place to check for electrical continuity, insulation resistance, and overall durability.

Materials and Components: Wire harnesses consist of various materials and components, including wires, connectors, terminals, tubing, and insulation materials. Manufacturers carefully select these components based on the application's requirements, taking into account factors such as temperature, voltage, and environmental conditions.

Compliance and Certification: Wire harness manufacturers adhere to industry standards and regulations to guarantee the safety and performance of their products. Compliance with standards such as IPC/WHMA-A-620 ensures that the manufactured harnesses meet the necessary criteria for reliability and functionality.

Advanced Manufacturing Techniques : Modern wire harness manufacturing involves advanced techniques such as automated assembly, which enhances efficiency and precision. Computer Numerical Control (CNC) machines are employed for accurate cutting, stripping, and crimping of wires and connectors.

Supply Chain Management : Efficient supply chain management is crucial for timely production and delivery of wire harnesses. Manufacturers work closely with suppliers to source high-quality materials and components, ensuring a seamless flow of production.

Research and Development : Continuous research and development efforts drive innovation in the wire harness industry. Manufacturers invest in developing new materials, manufacturing processes, and technologies to improve the performance and longevity of wire harnesses.

Environmental Sustainability : Many wire harness manufacturers focus on sustainable practices, including the use of eco-friendly materials and recycling initiatives. Sustainability efforts contribute to reducing the environmental impact of manufacturing processes.

Conclusion

Wire harness manufacturers operate at the intersection of technology and precision engineering. Their commitment to quality, innovation, and customer satisfaction drives the industry forward, enabling seamless integration of electrical systems in various applications across the globe.

2 notes

·

View notes

Text

What is the Easiest Engineering?

Engineering is a challenging major that requires an intense commitment. It requires a strong work ethic and a lot of study time, which can be difficult for first-year students to adjust to. If you’re interested in getting a college degree in engineering but you don’t have the time or dedication to pursue it, there are easier options available. These degrees will have fewer requirements, but they still require a significant amount of work.

Aerospace engineering is a field that uses your ingenuity, computer skills and maths to design airplanes, helicopters and drones. It also plays a key role in keeping the sky safe for commercial and private air travel. It is an excellent career choice for those who love to work with their hands and solve problems. It is a rapidly growing industry, and many people find it exciting.

The BLS notes that a background in physics, mathematics and materials science is critical to success. The field is also evolving to incorporate more computer coding, with advanced system software playing an increasingly important role in aircraft communication and data collection.

If you’re looking to make a difference in the world, chemical engineering could be the perfect career for you. These engineers create the processes that enable us to turn raw materials into products we use every day - such as petrol, plastics and synthetic fibres - in ways that are both cost and environmental friendly.

As a chemical engineer, you’ll need to have strong maths and chemistry skills, as well as an interest in science. A bachelor’s degree is usually enough to start working as a chemical engineer, although some employers prefer to employ applicants who have a master’s degree.

Chemical engineers design equipment and systems for combining ingredients to make the various products that people use in their daily lives, such as fuels, chemicals, medicines and food. They also work to control manufacturing processes so that each product meets the needs of consumers, regulators and other stakeholders.

Electrical engineering is a field that uses physics, electronics and electromagnetism to design, develop and test devices and equipment that use or generate electricity. This includes everything from computers and phones to transportation and energy.

This career requires an understanding of the physics and electronics that power these systems, but it also involves communication, problem-solving and teamwork skills. It’s not for everyone, but it can be an exciting and rewarding career if you’re interested in science and technology and solving problems that have a real-world impact on people and the environment.

There are a variety of specialisations within this field, including telecommunications, instrumentation, and power engineering. The majority of jobs are office-based, but some work on site to monitor electrical systems or oversee the installation of new technologies.

Industrial engineering focuses on optimizing processes and designing systems that save money, time, raw materials and human-power while meeting safety standards. This is a specialized branch of engineering that also incorporates knowledge of math, physics and social sciences.

As an industrial engineer, you can find yourself designing or evaluating everything from factories and hospitals to amusement parks and medical facilities. You are responsible for making recommendations about how to best improve operations to increase efficiency.

Industrial engineers use a variety of computer simulation and design tools to map and analyze systems and processes ready for optimization. They often work closely with data science and machine learning to unite people, machines, information and energy into better practices.

7 notes

·

View notes

Text

"Unveiling the Future: How Data Science is Revolutionizing Upcoming Industries"

Data science continues to have a substantial impact on various industries, and its scope is expected to expand as new technologies emerge and businesses realize the potential of data-driven insights. Here are some upcoming industries where data science is likely to play a significant role:

Healthcare and Life Sciences: Data science can aid in personalized medicine, drug discovery, predictive analytics for patient outcomes, and healthcare operations optimization.

Financial Services: Financial institutions use data science for fraud detection, risk assessment, algorithmic trading, customer behavior analysis, and credit scoring.

Retail and E-Commerce: Data science helps optimize inventory management, pricing strategies, recommendation systems, and customer segmentation for targeted marketing.

Energy and Utilities: The energy sector benefits from data analytics for smart grid management, predictive maintenance of equipment, and energy consumption optimization.

Manufacturing: Data science improves manufacturing processes through predictive maintenance, quality control, supply chain optimization, and demand forecasting.

Agriculture: Precision agriculture utilizes data science to optimize crop yield, resource allocation, pest control, and environmental monitoring.

Transportation and Logistics: Data science plays a role in route optimization, fleet management, demand forecasting, and autonomous vehicles.

Telecommunications: Data science assists in customer churn prediction, network optimization, and personalized service offerings.

Media and Entertainment: Content recommendation, audience segmentation, and analyzing viewer engagement are areas where data science is making an impact.

Real Estate: Data science helps in property price prediction, market trend analysis, and investment decision-making.

Environmental Conservation: Data science aids in monitoring and analyzing environmental data, including climate patterns, pollution levels, and habitat preservation.

Education: Data science can personalize learning experiences, assess student performance, and optimize educational resources.

Government and Public Services: Data-driven decision-making is becoming increasingly important for optimizing public services, policy formulation, and resource allocation.

Insurance: Insurers use data science for risk assessment, claims processing, fraud detection, and customized pricing.

Travel and Tourism: Data science enhances traveler experiences through personalized recommendations, pricing optimization, and destination insights.

Pharmaceuticals: Data science plays a role in drug discovery, clinical trials optimization, and pharmacovigilance.

Smart Cities: The concept of smart cities involves integrating data science for efficient urban planning, traffic management, energy consumption, and public services.

Cybersecurity: Data science helps in identifying and responding to cyber threats by analyzing patterns and anomalies in network data.

As technology continues to advance and businesses recognize the value of data-driven insights, certybox is creating a difference in providing the top professional courses along with job assistance. It's essential for professionals in the field to stay updated with the latest developments and tools to make the most of these opportunities.

5 notes

·

View notes

Text

Wire Harness Components: Exploring the Building Blocks of Electrical Systems

In the realm of electrical engineering and connectivity, wire harnesses serve as unsung heroes, enabling the smooth transmission of power and signals across an array of industries. These vital components have become indispensable in modern applications, ensuring efficiency, reliability, and safety.

In this comprehensive guide, we delve into the world of wire harnesses, exploring their functionality, applications, and significance in various sectors.

For More Information Please visit, wiring harness manufacturers near me

What are Wire Harnesses?

A wire harness, also known as a cable harness or wiring assembly, is a bundled arrangement of multiple electrical wires or cables. These wires are bound together using various methods, such as tape, zip ties, or sleeves, to form a unified and organized unit. The purpose of a wire harness is to facilitate the efficient and tidy transmission of electrical signals, power, and data within complex systems.

Structure and Components:

Wire harnesses are designed to suit specific applications, and their structure can vary accordingly. Typically, a wire harness consists of the following components:

Wires/Cables: The core elements of a wire harness are the electrical wires or cables, which come in various gauges and types, depending on the application's requirements.

Connectors: Connectors are the crucial interface points that link the wire harness to other electrical components, devices, or systems.

Terminals: Terminals serve as the end points of individual wires, making electrical connections with connectors or other terminals.

Sleeves and Sheaths: To protect the wires from external elements and prevent damage, sleeves and sheaths are used as protective coverings.

Tapes and Labels: Tapes are utilized to bundle the wires together, while labels aid in identification and organization.

Applications in Different Industries:

Wire harnesses find extensive applications in numerous industries due to their efficiency and reliability. Some of the key sectors that heavily rely on wire harnesses include:

Automotive: In vehicles, wire harnesses are essential for transmitting electrical signals, power, and data to various components, such as engines, lights, sensors, and infotainment systems.

Aerospace: The aerospace industry uses wire harnesses to ensure secure and organized connectivity within aircraft, satellites, and spacecraft.

Electronics: From consumer electronics to industrial machinery, wire harnesses are crucial for connecting and powering electronic components.

Telecommunications: In the world of telecommunications, wire harnesses facilitate the smooth flow of data and power in network infrastructure.

Healthcare: Medical devices and equipment rely on wire harnesses to ensure precision and safety in their electrical connections.

Advantages of Using Wire Harnesses:

The adoption of wire harnesses brings forth several advantages:

Simplified Installation: Wire harnesses streamline the installation process by eliminating the need to deal with individual wires, reducing assembly time and errors.

Improved Reliability: Organized and secure connections enhance the overall reliability and performance of electrical systems.

Space-Efficient: Wire harnesses help conserve space, especially in compact devices and machinery.

Enhanced Safety: Properly insulated and protected wires reduce the risk of electrical hazards and ensure operator safety.

Conclusion:

Wire harnesses are the unsung heroes that play a vital role in ensuring seamless electrical connectivity across a myriad of industries. From automotive to aerospace, electronics to healthcare, these organized bundles of wires provide efficiency, reliability, and safety in diverse applications. As technology continues to advance, wire harnesses will remain a cornerstone of modern electrical engineering, contributing to innovation and progress across the globe.

2 notes

·

View notes

Text

Just 40 years ago top of the art. Now something of the past. Time goes so fast. 4 more years will go by like seconds. Don't worry be happy!

The Zorba was a portable computer running the CP/M operating system manufactured in 1983 and 1984. It was originally manufactured by Telcon Industries, Inc., of Fort Lauderdale, Florida, a company specialized in telecommunication equipment manufacturing.

The Zorba was one of the last CP/M computers on the market. By the time it was introduced, the Kaypro and Osborne machines already dominated that market. The introduction of the Compaq Portable, compatible with the IBM PC and running MS-DOS, sealed the fate of the CP/M machines.

3K notes

·

View notes

Text

“Americans, your calls and texts can be monitored by Chinese spies,” a Washington Post opinion piece recently headlined. China has “growing cyber-sophistication and relentless ambition to undermine U.S. infrastructure” another Post article reported. Some analyses trace the recent exploitation to a telecommunications network backdoor created early in the era of digital networks to allow for court-authorized wiretaps.

When the digital wiretap law was passed in 1994, no one foresaw the kind of sophisticated intrusions apparently developed by the Chinese. It is an experience that we must remember as the design of digital network technology continues to evolve.

I helped negotiate the 1994 Communications Assistance for Law Enforcement Act (CALEA) that, some fear, created the exploitable access for Chinese spies. The concern at the time was that the evolution from analog to digital telecommunications was hindering law enforcement. “Some of the problems encountered by law enforcement relate to the explosive growth of cellular and other wireless services,” the House committee report explained. “[T]he increasing amount of transactional data generated by the millions of users of on-line services” was an accompanying problem. Written 30 years ago, it is a description of today’s communications environment, in which wireless networks deliver online digital information.

At the time, I was the CEO of the Cellular Telecommunications and Internet Association (CTIA), the wireless industry’s trade association. Along with wired communications providers, our members were concerned about the way the FBI was proposing to monitor communications across the new digital technology. After detailed and lengthy negotiations, industry and law enforcement mutually agreed to a result that addressed the FBI’s concerns about access to the new technology, while also addressing industry concerns.

On August 11, 1994, I sat next to FBI Director Louis Freeh before a joint House and Senate hearing to announce that we had reached an agreement on the CALEA legislation and to urge its passage. That what we jointly endorsed that day could, decades later, be potentially hackable by Chinese spies was not part of that discussion.

Today—30 years after CALEA—a new digital wireless technology promoted by both the industry and government is raising new cyber risks. Called Open Radio Access Network (O-RAN), it is a new technical standard that seeks to copy for telecommunications infrastructure the scale and savings enjoyed by the computer industry’s interoperability of different pieces of network equipment from different vendors. In O-RAN, the network functions once performed by purpose-built hardware are instead virtualized in software. Based on input from the Federal Communications Commission (FCC) and Department of Commerce, the software is broken into multiple layers, thus expanding the number of vendors.

The O-RAN concept is an important step forward that will deliver increased capabilities at decreased costs. Accompanying these advantages, however, is the challenge to mitigate the increased risk of cyberattacks resulting from software that relies in part on open-source code running on commodity hardware.

Earlier networks ran on proprietary equipment utilizing proprietary software that offered focused protection against attacks. Moving more functions to hackable software that is disaggregated from a purpose-built network appliance creates new pathways to attack these new networks.

Another attractive aspect of O-RAN is how the shift to virtualize hardware breaks the chokehold of the traditional suppliers of network equipment. This advantages cybersecurity because it creates alternatives to Chinese hardware manufacturers, such as Huawei. Yet, this too comes with the countervailing paradox that such supplier diversity represents another increase in the number of attack trajectories in the networks.

As the European Union’s Report on the Cybersecurity of Open Radio Access Networks concluded, while there are security benefits to the diversification of suppliers, “by introducing a new approach, new interfaces and new types of RAN components potentially coming from multiple suppliers, Open RAN would exacerbate a number of the security risks of 5G networks and expand the attack surface.”

Network operators and law enforcement were reportedly blindsided by the ability of Chinese hackers to create advanced persistent threats (APTs) to exploit CALEA. This experience, however, is but the most current of many warnings that the networks on which our nation relies are vulnerable. Whatever the outcome of the ongoing investigation, the latest exploitation should send a message that we need cybersecurity as a forethought, rather than an afterthought, in the design of digital networks, accompanied by ongoing oversight of network security.

Looking back to go forward

Twenty years after CALEA passed, I was chairman of the FCC, the agency responsible for America’s networks. As chairman, I tried to work with network providers to develop cybersecurity standards that were flexible enough to evolve with the technology and the ever-evolving attack techniques of those seeking to exploit the networks. The irrefutable fact is that every single one of the cyberattacks that affect our nation traverse, at one point or another in their transmission, a private network regulated by the FCC.

What we proposed in 2014 was that the companies implement and report on their adherence to the National Institute of Standards and Technology’s (NIST) Cybersecurity Framework. The NIST Framework is a collection of best-practice internal controls developed collaboratively with industry that is continually evolving to help companies protect against cyberattacks. Along with implementing the voluntary NIST Framework, we asked the industry to identify where they set their objective cyber-risk threshold, their progress toward implementation of the Framework, and the steps taken to cure internal control shortfalls.

It was a new approach to network oversight that stopped short of regulatory micromanagement in favor of standards-based expectations. “The communications sector is at a critical juncture,” I said in a June 14, 2014, speech laying out the new program. “We know those [cyber] threats are growing. And we have agreed that industry-based solutions are the right approach… We will implement this approach and measure results. It is those results that will tell us what, if any, next steps must be taken.”

Unfortunately, the effort fell apart when the companies resisted a plan for reporting to the FCC. The industry argued the Department of Homeland Security (DHS) was a better place for such oversight. DHS, of course, had no regulatory authority over the networks. The Trump FCC then followed the industry’s preference and ceased the FCC initiative.

DHS subsequently established the Cybersecurity and Infrastructure Security Agency (CISA), which is doing great work to advance best practices across the economy. Absent regulatory authority, however, such efforts can only go so far. Cyber risk is a business risk; at the end of the day, how much a company invests in risk reduction is a bottom-line decision. The appropriate role for a regulator such as the FCC should be to establish expectations for such decisions to stimulate sufficient cyber protection by the nation’s networks—and then to inspect the results.

Today, the FCC’s minimal cybersecurity reporting obligations are constrained to cyber incidents that lead to outages, with no reporting requirements for compromises to confidentiality or network integrity. Amazingly, through its detailed reporting requirements on cyber issues, the Securities and Exchange Commission (SEC) has more information on cyber shortfalls than the regulator charged with protecting America’s networks.