#TechnicalCeramics

Explore tagged Tumblr posts

Text

What's The Differences Between Alumina Ceramic And Zirconia Ceramic

Alumina is a very common technical ceramic material. Zirconia is also widely used in machinery industries. As an advanced ceramics manufacturer, we'd like to introduce the differences between alumina ceramic and zirconia ceramic.

In terms of performance: 1.The density of zirconia ceramics is twice that of alumina ceramics, the bulk density of zirconia is 6.05g/cm3, while that of alumina is only 3.7g/cm3. So zirconia has better compressive properties in comparison. 2.The toughness of zirconia ceramics is 4 times that of alumina ceramics. The toughness of the zirconia ceramic is excellent, which overcomes the inherent brittleness of the ceramic itself, has higher wear resistance, and greatly extends the service life of the product. 3.Zirconia parts with higher surface finish. After grinding and processing of two materials, zirconia has a higher surface finish, and the roughness can reach about Ra0.02. The surface is mirror-like, very smooth, and has a smaller coefficient of friction. But alumina roughness is about Ra0.2~Ra0.4. 4.Zirconia ceramics have excellent thermal insulation, and its thermal conductivity is less than one-tenth of the thermal conductivity of other ceramics. In terms of price: The price of alumina is lower than that of zirconia. One of the reasons is the cost of the raw material, another reason is the high processing cost of zirconia ceramics. In terms of applications: 1.Alumina ceramic could withstand higher temperature, application in industry furnace. 2.As the wear resistance for zirconia is much better, it is frequently used as mortar and pestles, grinding jars and grinding media, bearing balls and ceramic parts in valves and pumps. 3.Zirconia has better corrosion resistance. Zirconia could survive longer in highly corrosive environment and is considered better material in chemistry laboratories. So Zirconia ceramics are suitable for applications in high-load, high-strength, and chemically corrosive environments, while alumina ceramics are suitable for applications with low loads, high temperatures, and heat dissipation. Read the full article

0 notes

Photo

RSiC kiln furniture FOR high temperature technical ceramics RSiC plates, beams, tubes, saggers, nozzles, supports & customized shapes. Contact LENGSTECH for prices www.lengstech.com [email protected] WA+86 13930552202 #LENGSTech #kilnfurniture #kilnshelves #rsic #recrystalizedsiliconcarbide #rsicplate #rsicbeam #supports #kilncar #technicalceramics #advancedceramics #hightemperatureceramics #alumina #zirconia #ceramicfoam #ceramicfilter #refractoryceramics https://www.instagram.com/p/CJI_cPJhm5i/?igshid=5tbp97mecyfb

#lengstech#kilnfurniture#kilnshelves#rsic#recrystalizedsiliconcarbide#rsicplate#rsicbeam#supports#kilncar#technicalceramics#advancedceramics#hightemperatureceramics#alumina#zirconia#ceramicfoam#ceramicfilter#refractoryceramics

0 notes

Link

0 notes

Photo

settling back in after two weeks of intensive relaxation @watershedceramics residency. unpacking all the experiences and information, interactions and conversations. looking forward to the future of clay. #ceramics #watershed #maine #residentartist #ceramicproduction #handbuilt #lowfire #doublerainbow #ceramicresidency #latergram #technicalceramics #lowfiresoda #drobnock #skyporn #claypeople thanks to all of you that were there to experience it all with me. let us do it again soon. (at Watershed Center for the Ceramic Arts) https://www.instagram.com/p/BzYbqEvgsdf/?igshid=10k4huul61rij

#ceramics#watershed#maine#residentartist#ceramicproduction#handbuilt#lowfire#doublerainbow#ceramicresidency#latergram#technicalceramics#lowfiresoda#drobnock#skyporn#claypeople

0 notes

Text

Technical Ceramics Market Report by Opportunities, Key Companies and Growth Factors Forecast to 2025

Felton, 3 December 2019 - Technical Ceramics Market size is expected to value at USD 134.58 billion by 2024, during the forecast period. The market is subject to witness a substantial growth due to cost-effectiveness associated with the use of advanced ceramics products and longer life cycle, and growing competition in the market. Growing demand of the advanced ceramics or technical ceramics in the automotive sector is one of the key factor propelling the market growth in recent years.

Request a PDF Sample @ https://www.millioninsights.com/industry-reports/technical-ceramics-market-size/request-sample

The adoption of the technical ceramics mainly in the developing countries along with expansion of the automobile industry in the region owing to the recent economicgrowth are spiraling the market demand for the technical ceramics industry over the forecast period. The adoption of the technical ceramics as an alternative to the plastics and metals in automotive and healthcare market segment is attributing to the advancement of the market. Globally, the market is predicted to grow at high CAGR in forecast period, providing numerous opportunity for market players to invest for research and development in the technical ceramics market.

The growing awareness about the benefits offered with the use of the technical ceramics over the conventional products are driving the demand for the technical ceramic market in coming years. The advantage associated with the use of the technical ceramics are bio-degradability, durability, reliability, and superior tensile strength. Most of technical ceramics are eco-friendly in nature in comparison with conventional materials, and stringent governmental regulation to limit environmental hazards with use of traditional materials such as plastics is fueling the growth of the technical ceramics during the forecast period. The application of technical ceramics has found its way in the electronic andelectrical industry as well. Growing use of the electronic devices by consumers will further push market demand of technical ceramics.

Excessive adoption of the coated machinery materials, along with shifting inclination towards technical coatings by consumers and recent developments in various deposition processes, are opening numerous potential opportunities for the technical ceramics industry in coming years. Some of the critical factors associated with market limitation are numerous governmental regulations in regards to the environmental impact and growing competition from other types of materials.

The technical ceramics are also referred as engineering ceramics or industrial ceramics or advanced ceramics. Technicalceramics are considered as highly-sophisticated ceramicsconsisting of distinctive characteristics such as mechanical, electrical, thermal and bio-chemical that are suitable for various industrial applications.

The technical ceramics market is divided into regional market segment such as North America, Europe, Asia-Pacific, Latin America and Africa. North America has shown major growth in recent years owing to the use in the environmental and medical sectors and growing emphasis on research for new product development. Asia-Pacific region is predicted to hold major market share in the technical ceramics industry with massive growth in forecast period.

Countries such as India, China and Singapore are leading the Asia-Pacific’s market with growing competition in manufacturing, reduced costs, rising economic growth in the region, and constant demand in the end-user industries.The key players in the technical ceramics market are Kyocera Co., CeramTec Co., Morgan Advanced Materials Inc., McDanel Co., and Saint-Gobain Ceramic Materials.

Market Segment:

Material Outlook (Revenue, USD Million; 2013 - 2024)

• Alumina ceramics

• Titanate ceramics

• Zirconate ceramics

• Ferrite ceramics

• Aluminum nitride

• Silicon carbide

• Silicon nitride

Product Outlook (Revenue, USD Million; 2013 - 2024)

• Monolithic ceramics,

• Ceramic coatings

• Ceramic Matrix Composites

For More Technical Insights, Download Brochure @ https://www.millioninsights.com/industry-reports/technical-ceramics-market-size

0 notes

Text

Technical ceramics market size is expected to value at USD 134.58 billion by 2024, during the forecast period.

The global technical ceramics market size is expected to value at USD 134.58 billion by 2024, during the forecast period. The market is subject to witness a substantial growth due to cost-effectiveness associated with the use of advanced ceramics products and longer life cycle, and growing competition in the market. Growing demand of the advanced ceramics or technical ceramics in the automotive sector is one of the key factor propelling the market growth in recent years.

The adoption of the technical ceramics mainly in the developing countries along with expansion of the automobile industry in the region owing to the recent economicgrowth are spiraling the market demand for the technical ceramics industry over the forecast period. The adoption of the technical ceramics as an alternative to the plastics and metals in automotive and healthcare market segment is attributing to the advancement of the market. Globally, the market is predicted to grow at high CAGR in forecast period, providing numerous opportunity for market players to invest for research and development in the technical ceramics market.

For more information visit at : https://www.millioninsights.com/industry-reports/technical-ceramics-market-size

The growing awareness about the benefits offered with the use of the technical ceramics over the conventional products are driving the demand for the technical ceramic market in coming years. The advantage associated with the use of the technical ceramics are bio-degradability, durability, reliability, and superior tensile strength. Most of technical ceramics are eco-friendly in nature in comparison with conventional materials, and stringent governmental regulation to limit environmental hazards with use of traditional materials such as plastics is fueling the growth of the technical ceramics during the forecast period. The application of technical ceramics has found its way in the electronic andelectrical industry as well. Growing use of the electronic devices by consumers will further push market demand of technical ceramics.

Excessive adoption of the coated machinery materials, along with shifting inclination towards technical coatings by consumers and recent developments in various deposition processes, are opening numerous potential opportunities for the technical ceramics industry in coming years. Some of the critical factors associated with market limitation are numerous governmental regulations in regards to the environmental impact and growing competition from other types of materials.

To get free sample report Visit at : https://www.millioninsights.com/industry-reports/technical-ceramics-market-size/request-sample

The technical ceramics are also referred as engineering ceramics or industrial ceramics or advanced ceramics. Technicalceramics are considered as highly-sophisticated ceramicsconsisting of distinctive characteristics such as mechanical, electrical, thermal and bio-chemical that are suitable for various industrial applications.

0 notes

Text

Technical Ceramics Market Vendor Landscape, Volume Share By Region 2024

17 Oct 2018 - The Global Technical Ceramics Market size is expected to value at USD 134.58 billion by 2024, during the forecast period. The market is subject to witness a substantial growth due to cost-effectiveness associated with the use of advanced ceramics products and longer life cycle, and growing competition in the market. Growing demand of the advanced ceramics or technical ceramics in the automotive sector is one of the key factor propelling the market growth in recent years.

The adoption of the technical ceramics mainly in the developing countries along with expansion of the automobile industry in the region owing to the recent economicgrowth are spiraling the market demand for the technical ceramics industry over the forecast period. The adoption of the technical ceramics as an alternative to the plastics and metals in automotive and healthcare market segment is attributing to the advancement of the market. Globally, the market is predicted to grow at high CAGR in forecast period, providing numerous opportunity for market players to invest for research and development in the technical ceramics market.

The growing awareness about the benefits offered with the use of the technical ceramics over the conventional products are driving the demand for the technical ceramic market in coming years. The advantage associated with the use of the technical ceramics are bio-degradability, durability, reliability, and superior tensile strength. Most of technical ceramics are eco-friendly in nature in comparison with conventional materials, and stringent governmental regulation to limit environmental hazards with use of traditional materials such as plastics is fueling the growth of the technical ceramics during the forecast period. The application of technical ceramics has found its way in the electronic andelectrical industry as well. Growing use of the electronic devices by consumers will further push market demand of technical ceramics.

Request Sample Copy of this Market Research @ https://www.millioninsights.com/industry-reports/technical-ceramics-market-size/request-sample

Excessive adoption of the coated machinery materials, along with shifting inclination towards technical coatings by consumers and recent developments in various deposition processes, are opening numerous potential opportunities for the technical ceramics industry in coming years. Some of the critical factors associated with market limitation are numerous governmental regulations in regards to the environmental impact and growing competition from other types of materials.

The technical ceramics are also referred as engineering ceramics or industrial ceramics or advanced ceramics. Technicalceramics are considered as highly-sophisticated ceramicsconsisting of distinctive characteristics such as mechanical, electrical, thermal and bio-chemical that are suitable for various industrial applications.

The highly-specific properties associated with technical ceramics are further boosted and optimized to meet the required technical requirements during the industrial applications. Combination of the mechanical, bio-chemical, electrical and thermal properties to design and create advanced set of components that are capable of performing required set of the task with high accuracy makes it an ideal alternative to the traditional materials similar to metal and plastic in the respective field of application. Technical ceramics are capable of overcoming technical challenges remain unsolvedwith the use of traditional materials.

Browse Full Research Report @ https://www.millioninsights.com/industry-reports/technical-ceramics-market-size

Few of the highly advanced properties associated with the technical ceramics are wear resistance, high temperature resistance, erosion resistance,and bio-compatibility. The distinct characteristics of the technical ceramics makes it an ideal choiceforvarious industry application such as automobile sector, electrical industries, healthcare sector, power & energy industries and mechanical engineering.

The technical ceramics market is divided into regional market segment such as North America, Europe, Asia-Pacific, Latin America and Africa. North America has shown major growth in recent years owing to the use in the environmental and medical sectors and growing emphasis on research for new product development. Asia-Pacific region is predicted to hold major market share in the technical ceramics industry with massive growth in forecast period.

Countries such as India, China and Singapore are leading the Asia-Pacific’s market with growing competition in manufacturing, reduced costs, rising economic growth in the region, and constant demand in the end-user industries.The key players in the technical ceramics market are Kyocera Co., CeramTec Co., Morgan Advanced Materials Inc., McDanel Co., and Saint-Gobain Ceramic Materials.

See More Reports of this Category by Million Insights @ https://www.millioninsights.com/industry/chemicals-and-materials

#Technical Ceramics Market#Technical Ceramics Industry#Technical Ceramics Market Growth#Technical Ceramics Market Analysis#Technical Ceramics Market Size#Technical Ceramics Market Share#Technical Ceramics Market Report#Technical Ceramics Market Research#Technical Ceramics Industry Outlook#Technical Ceramics Market Segmentation#Technical Ceramics Industry Trends#Technical Ceramics Market Forecast#Technical Ceramics Industry Overview

0 notes

Text

Technical Ceramics Market 2018: Key Players, Development and Opportunities by Forecast to 2023

Technical Ceramics are used in a wide range of end-use industry application owing to their excellent properties such as chemical & heat resistance and mechanical stresses among others. It is extensively used in applications such as medical devices, transport equipments, sports equipments, armour material, circuit carriers and others. The rising growth pharmaceutical and automotive industry across the globe is substantially affecting the growth of the technical ceramics market.

The Global Technical Ceramics Market is being driven by a range of application in various end-use industries such as automotive, energy & power, pharmaceuticals, military & defense and other. Moreover, it is estimated that the electrical and electronics industry is set to witness the highest growth due to the growing consumption in applications such as core materials, circuit carriers, and ceramic substrates in the forecast period, 2017-2023.

Market Segmentation The Global Technical Ceramics Market is segmented into product type, material, and end-user. On the basis of the product type, the market is segregated into monolithic ceramics, ceramic matrix composites, ceramic coatings and others. The market by material is segmented into oxide and non-oxide. The market by end user industry is further categorized into electronics & semiconductor, automotive, energy & power, pharmaceuticals, military & defense and others.

Market Scenario The electrical and electronic segment followed by the automotive end-user segment are anticipated to observe a higher CAGR during the forecast period. The properties such as corrosion resistance, heat resistance makes the use of technical ceramics in applications such as sensors in cars, circuit carries and other electronics components.

Get Sample of Report @ https://www.marketresearchfuture.com/sample_request/5359

Competitive Analysis Some of the prominent players operating in the Global Technical Ceramics Market CeramTec GmbH (Germany), Kyocera Corporation (Japan), Morgan Advanced Materials (U.K), Saint-Gobain Ceramic Materials (U.S.), McDanel Advanced Ceramic Technologies (U.S.), 3M Company (U.S.), Rauschert Steinbach GmbH (Germany), Dyson Technical Ceramics Limited (U.K), Superior Technical Ceramics (U.S.), and NGK Spark Plug Co., Ltd. (Japan) among others.

Regional Analysis The Global Technical Ceramics Market is spanned across five key regions: Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa. Among these, Asia Pacific holds a major share of the market and is expected to be the fastest growing region at a considerably higher CAGR. The presence of the most populated countries of the world such as India and China has augmented the demand for various sectors such as the electronics and automotive among others, which, in turn, is anticipated to fuel the demand for technical ceramics in the region. Moreover, the growing demand for energy has augmented the power sector industry, mainly in India and China which in turn is expected to positively affect the growth of the market.

The European region is estimated to witness a significant growth in the countries owing to the burgeoning pharmaceutical and automobile industry. The increasing use of technical ceramics owing to its enhanced strength, chemical and heat stability among others has increased the adoption rate in the region. Moreover, the growing application in the environmental engineering coupled with the increase government participation in the conservation of environment is further burgeoning the usage of the product in this region.

The North American Technical Ceramics Market is mainly driven by the U.S. and Canada. The presence of the developed end-user industries such as automotive and electronics coupled with the increasing adoption rate is contributing significantly to the growth of the market. Moreover, the growing investment in energy and defense sector is further expected to add fuel to the growth of the market.

Get Complete Report @ https://www.marketresearchfuture.com/reports/technical-ceramics-market-5359

About Market Research Future: At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact: Market Research Future +1 646 845 9312 Email: [email protected]

0 notes

Text

The History of Technical Ceramics

The story of advanced ceramics is an interesting story of how the creation of technical ceramics and the discovery of the potential for various uses of technical ceramics can influence the development of many different industries that use advanced ceramics in their everyday operations. What’s more, it is an account of how further refinement of a certain material can lead to technical ceramics being used for numerous interesting and unusual purposes. So, let’s see about the beginning of advanced ceramics and witness how long technical ceramics manufacturers have come from the early days. What is the history of technical ceramics? The history of technical ceramics can be divided into three distinct periods, and it all begins with earthenware. It was several thousand years ago that humans first learned to make earthenware vessels through kneading and forming clay. However, the first major breakthroughs concerning ceramics were made in China. Ceramics in China It was in China that the first advancements in working with ceramics were made, as well as the various uses for earthenware porcelian and vessels. For example, the method called "Chaishao", where clay vessels were fired at temperatures that ranged from 1,000 to 1,400℃ while surrounded by piles of wood was invented in China. Electrical technology The invention of the electric light bulb by Thomas Edison, as well as the invention of the telephone by Alexander Graham Bell, noted the beginning of a new era – the era of electricity. Up to that point, ceramics were only used as vessels. However, ceramics would get a completely new role. Their insulative capabilities made them a far better alternative to paper or wood, as well as the fact that they were far less affected by environmental factors such as humidity and temperature. This made ceramics extremely reliable. Since then, ceramics became widespread as insulators in many different areas, from household products to power lines, and it is technician ceramics that allowed people to easily use electricity. Electro-ceramics The inventions of the radio, the television, as well as the transistor in the 20th century marked the beginning of electronics. This entire era relied on technical ceramics from the very beginning and the vacuum tubes that employed ceramic materials. Since then, technical ceramics have been used in many different ways in the electronics industry, the two most notable being: Wireless equipment – Only technical ceramics are able to provide high-signal output due to their properties. Semiconductors – The core component of electronics, semiconductors would not be possible without technical ceramics. Technical ceramics have also managed to reduce the size of inductors and capacitors. What’s more, technical ceramics are constantly evolving, and can now even boast incredible magnetic and dielectric properties. It is this possibility for improvement that makes technical ceramics one of the most versatile and future-proof materials today. Who is the leading technical ceramics manufacturer in the China? At Innovacera, we are familiar with the history of technical ceramics, and we know just how far the entire industry has come since the beginning. We are always looking for ways to advance our manufacturing process and keep in track with all the advancements in the technical ceramics industry. We have more than 25 years of experience in the industry, and we are prepared to design and manufacture advanced ceramics for your needs. Dial 0086-592-5589730 or contact us at [email protected], and let us know what we can do for you and your business. Read the full article

0 notes

Photo

RSIC grinded plates with holes dia 4mm 150*150*3mm customized drawings available contact us for prices #lengstech #rsic #resic #recrystalizedsiliconcarbide #siliconcarbide #sicplate #grindedplate #hightemperatureceramics #technicalceramics #advancedceramics #refractorymaterial #industrialceramics #kilnshelves #loadingbatts #kiln #kilnfurniture https://www.instagram.com/p/B9EmG9dAs7I/?igshid=1s07e58k3su34

#lengstech#rsic#resic#recrystalizedsiliconcarbide#siliconcarbide#sicplate#grindedplate#hightemperatureceramics#technicalceramics#advancedceramics#refractorymaterial#industrialceramics#kilnshelves#loadingbatts#kiln#kilnfurniture

0 notes

Text

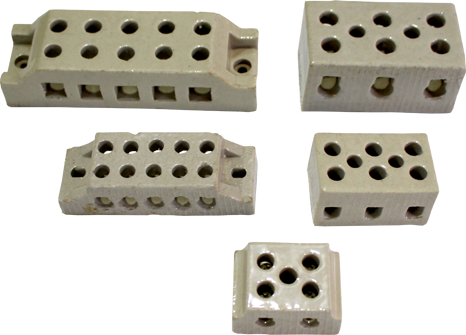

Zircovit's best porcelain Electric connector

Zircovit is Widely known for its Technical Ceramic and one of the their products is Electrical Connectors.

electrical connectors is to prevent people from being electrically shocked accidentally if they come into contact with good conductors.

And Zircovit keeps it available in 3 types of porcelain electrical connectors and are maintenance free

0 notes

Photo

handbuilding with colored porcelain has been a new challenge that kept me busy over the deep winter. figuring out how to glaze it and sort out all the kinky bits regarding the handbuilding process is my spring assignment. seconds and one-offs coming soon. im planning on offering them to off-set the cost of the learning curve. stay tuned. #blackporcelain #coloredclay #handbuilt #porcelain #drobnock #ceramics #tableware #stuffaboutthings #negativespace #thedecorativearts #sculpture #mugsarentjustformondays #cup #mug #coffee #tea #teaware #lowfireiscooler #technicalceramics #nobodyisperfect #prototype #juniatarivervalley #pennsylvania (at Mount Union, Pennsylvania) https://www.instagram.com/p/Bv2PQ-wAOr9/?utm_source=ig_tumblr_share&igshid=1wgvnp6honh0l

#blackporcelain#coloredclay#handbuilt#porcelain#drobnock#ceramics#tableware#stuffaboutthings#negativespace#thedecorativearts#sculpture#mugsarentjustformondays#cup#mug#coffee#tea#teaware#lowfireiscooler#technicalceramics#nobodyisperfect#prototype#juniatarivervalley#pennsylvania

0 notes

Text

Technical Ceramics Market Overview includes Specifications, Definition, Classification and Applications Forecast to 2025

Felton, 2 March 2019 - Technical Ceramics Market size is expected to value at USD 134.58 billion by 2024, during the forecast period. The market is subject to witness a substantial growth due to cost-effectiveness associated with the use of advanced ceramics products and longer life cycle, and growing competition in the market. Growing demand of the advanced ceramics or technical ceramics in the automotive sector is one of the key factor propelling the market growth in recent years.

Request a PDF Sample @ https://www.millioninsights.com/industry-reports/technical-ceramics-market-size/request-sample

The adoption of the technical ceramics mainly in the developing countries along with expansion of the automobile industry in the region owing to the recent economicgrowth are spiraling the market demand for the technical ceramics industry over the forecast period. The adoption of the technical ceramics as an alternative to the plastics and metals in automotive and healthcare market segment is attributing to the advancement of the market. Globally, the market is predicted to grow at high CAGR in forecast period, providing numerous opportunity for market players to invest for research and development in the technical ceramics market.

The growing awareness about the benefits offered with the use of the technical ceramics over the conventional products are driving the demand for the technical ceramic market in coming years. The advantage associated with the use of the technical ceramics are bio-degradability, durability, reliability, and superior tensile strength. Most of technical ceramics are eco-friendly in nature in comparison with conventional materials, and stringent governmental regulation to limit environmental hazards with use of traditional materials such as plastics is fueling the growth of the technical ceramics during the forecast period. The application of technical ceramics has found its way in the electronic andelectrical industry as well. Growing use of the electronic devices by consumers will further push market demand of technical ceramics.

Excessive adoption of the coated machinery materials, along with shifting inclination towards technical coatings by consumers and recent developments in various deposition processes, are opening numerous potential opportunities for the technical ceramics industry in coming years. Some of the critical factors associated with market limitation are numerous governmental regulations in regards to the environmental impact and growing competition from other types of materials.

The technical ceramics are also referred as engineering ceramics or industrial ceramics or advanced ceramics. Technicalceramics are considered as highly-sophisticated ceramicsconsisting of distinctive characteristics such as mechanical, electrical, thermal and bio-chemical that are suitable for various industrial applications.

The technical ceramics market is divided into regional market segment such as North America, Europe, Asia-Pacific, Latin America and Africa. North America has shown major growth in recent years owing to the use in the environmental and medical sectors and growing emphasis on research for new product development. Asia-Pacific region is predicted to hold major market share in the technical ceramics industry with massive growth in forecast period.

Countries such as India, China and Singapore are leading the Asia-Pacific’s market with growing competition in manufacturing, reduced costs, rising economic growth in the region, and constant demand in the end-user industries.The key players in the technical ceramics market are Kyocera Co., CeramTec Co., Morgan Advanced Materials Inc., McDanel Co., and Saint-Gobain Ceramic Materials.

Market Segment:

Material Outlook (Revenue, USD Million; 2013 - 2024)

• Alumina ceramics

• Titanate ceramics

• Zirconate ceramics

• Ferrite ceramics

• Aluminum nitride

• Silicon carbide

• Silicon nitride

Product Outlook (Revenue, USD Million; 2013 - 2024)

• Monolithic ceramics,

• Ceramic coatings

• Ceramic Matrix Composites

For More Technical Insights, Download Brochure @ https://www.millioninsights.com/industry-reports/technical-ceramics-market-size

0 notes

Text

How to solve the problem of fragile ceramic parts?

As we all know, advanced ceramics are special materials with a variety of physical properties. As structural ceramics and functional ceramics apply in machinery, electronics, chemical industry, metallurgy, energy, aerospace, and many other fields. But ceramics have an obvious disadvantage-fragility. The main reason is that the toughness of most ceramics is low, which leads to an increase in brittleness. There is a ceramic - zirconia with high toughness. It is formed by thousands of unit cells to form crystals. It then undergoes high-temperature phase transformation to form microcrystalline ceramics so that the ceramics have excellent wear resistance and drop resistance and high-temperature resistance. ZrO2 ceramic products are white. When the ceramic contains other impurities, the ceramic is grey or yellow. Commonly used molding processes are injection and dry press. They are usually made into crucibles, mobile phone cases, ceramic shafts, abrasive materials, refractory materials, etc. It is believed that in the near future, the excellent characteristics of zirconia ceramics will be widely used in more fields. Read the full article

0 notes

Text

How to solve the problem of fragile ceramic parts?

As we all know, advanced ceramics are special material with a variety of physical properties. They as structural ceramics and functional ceramics apply in machinery, electronics, chemical industry, metallurgy, energy, aerospace and many other fields. But ceramics have an obvious disadvantage-fragility. The main reason is that the toughness of most ceramics is low, which leads to an increase in brittleness. There is a ceramic - zirconia with high toughness. It is formed by thousands of unit cells to form crystals. It then undergoes high-temperature phase transformation to form microcrystalline ceramics so that the ceramics have excellent wear resistance and drop resistance and high-temperature resistance. ZrO2 ceramic products are white. When the ceramic contains other impurities, the ceramic is grey or yellow. Commonly used moulding processes are injection and dry press. They are usually made into crucibles, mobile phone cases, ceramic shafts, abrasive materials, refractory materials, etc. It is believed that in the near future, the excellent characteristics of zirconia ceramics will be widely used in more fields. Read the full article

0 notes

Photo

RSIC grinded plates with holes dia 4mm 150*150*3mm contact us for prices #lengstech #rsic #resic #recrystalizedsiliconcarbide #siliconcarbide #sicplate #grindedplate #hightemperatureceramics #technicalceramics #advancedceramics #refractorymaterial #industrialceramics #kilnshelves #loadingbatts #kiln #kilnfurniture https://www.instagram.com/p/B9EmBACAGYh/?igshid=tcfy6lx6wjzu

#lengstech#rsic#resic#recrystalizedsiliconcarbide#siliconcarbide#sicplate#grindedplate#hightemperatureceramics#technicalceramics#advancedceramics#refractorymaterial#industrialceramics#kilnshelves#loadingbatts#kiln#kilnfurniture

0 notes