#Tcardsoftware

Explore tagged Tumblr posts

Text

Cellular Manufacturing: A Lean Approach to Production Process

For more details read our article : https://www.linkedin.com/pulse/cellular-manufacturing-lean-approach-production-juixf/

#tcard#tcardsystem#tcardsoftware#cellularmanufacturing#cellularlayout#leanmanufacturing#singlepieceflow#standardizedwork#kanbansystem#jit#kaizen#continuousimprovement#pokayoke

0 notes

Text

7 Insightful Questions for your Next Gemba Walk

Gemba questions can deepen the understanding of leaders through direct observations of operations and having conversations with frontline employees.

Read More on: https://www.linkedin.com/pulse/7-insightful-questions-your-next-gemba-walk-pg6fc/?trackingId=TSe5OXuUBuvgViqu6J4vLw%3D%3D

#gembawalk#gembawalkquestions#gemba#gembakaizen#leaderstandardwork#leanmanagement#leandailymanagementsystem#ldms#dailymanagementsystem#digitalgembaboard#virtualgembawalk#gotogemba#gembalean#leangembawalk#leangemba#gembaboardexamples#gembaaudit#tcardsoftware#tcardsystem#kanban#kanbanboard#digitaltcards#leantransitionsolutions#lts

0 notes

Text

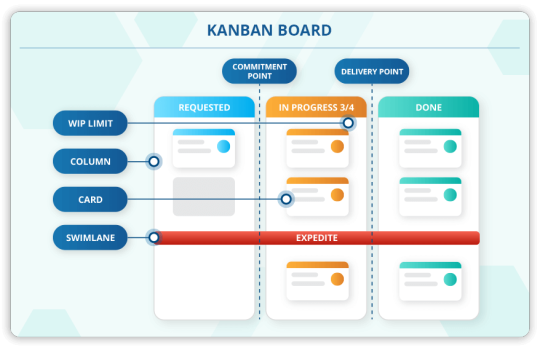

Kanban System Explained

Kanban boards enhance workflow visibility, enabling efficient bottleneck detection, progress tracking, and task prioritisation.

Read More: https://tcard.leantransitionsolutions.com/tcard-kanban-boards

#KanbanBoards#Kanbanboard#tcardkanbanboards#KanbanSystem#virtualkanbanboard#kanbanworkflowmanagement#kanbanflow#kanbantool#kanbanboardexample#kanbanprojectmanagement#kanbanboardfree#kanbancard#kanbanboardonline#kanbanview#kanbanchart#tcard#tcardsystem#tcardsoftware#Digitaltcardsoftware#Lean#lts#Industry4.0#Leantransitionsolution

0 notes

Text

How to Create a Good Digital Work Instruction?

Read More: https://tcard.leantransitionsolutions.com/manufacturing-tcard-software

#Manufacturing#TCardsoftware#Production#Visualise#Tcard#Track#task#Kanban#visualtcardsoftware#Tcardsystem#Visualiseproductionplans#DigitalWorkInstruction#DashboardviewofProductionPlan#WorkOrderManagement#StreamlineShiftManagement#WorkflowOptimisation#Employeeshiftmanagement#InteractiveGuides#SimplifyingTasks#EmployeeTraining#QualityControl#ErrorReduction#LeanManufacturing#PaperlessWorkflows#DigitalTransformation#TaskAutomation#KnowledgeManagement#ContinuousImprovement#ProcessOptimization#OverallEquipmentEffectiveness

0 notes

Text

7 questions to ask on your next Gemba Walk

During a Gemba walk, leaders can better understand operational processes by asking thoughtful questions, allowing them to make informed decisions.

Read More: https://tcard.leantransitionsolutions.com/software-blogs-details/questions-to-ask-on-your-next-Gemba-Walk

#tcard#tcardsystem#tcardsoftware#Gemba#gembawalk#continuousimprovement#gembakaizen#gotogemba#gembalean#gembameeting#gembaconcepts#gembaprocess#gembavisit#problemidentification#problemsolving#gembaaudit#gembaapproach#gembamanagement#efficiency#production#workplace#optimisation#observations#visualmanagement#performancemonitoring#employeemorale#employeeparticipation#workflowanalysis#improvementstrategies#continuouslearning

1 note

·

View note

Text

Streamlining Operations and Boosting Profits: A Case Study on How Flannery Plant Hire Optimised Workflow with Digital Plant Hire Tcards

How LTS Digital Plant Hire TCards helped Flannery Plant Hire to overcome their workflow challenges?

Read More: https://tcard.leantransitionsolutions.com/Flannery-Plant-Hire-Optimised-Workflow-with-Digital-Plant-Hire-tcards

#tcard#tcards#tcardsoftware#tcardsystem#StreamliningOperations#BoostingProfits#FlanneryPlantHire#DigitalPlantHireTcards#FlannerysProgresswithDigitalTcards#tcardsdirectonline#webtcard#tcardholder#ParentChildRelationship#LocationSpecificDashboards#DepotTransferFunctionality#DragandDropFeature#InstantAssetBreakdownIndication#virtualtcardsystem#teecardsystem#planthireTcard#lts#leantransitionsolutions

0 notes

Text

Top Reasons why Teams Abandon their Visuals

Clear objectives, design optimisation, comprehensive training, visual board maintenance, and addressing technological limitations prevent visual abandonment.

Read More: https://tcard.leantransitionsolutions.com/software-blogs-details/top-reasons-why-teams-abandon-their-visuals

#lts#leantransitionsolutions#tcard#tcards#tcardsoftware#tcardsystem#teamwork#gembawalks#huddleboard#teammeeting#5s#visualaids#teamhuddle#visualcues#huddlemeetings#Visualcommunication#Visualstorytelling#visualmanagement#storytellingwithdata#Visualperception#visualappeal#crossfunctionally#visualneglect#Compatibilityissues#Visualfeedback#Visualmessage#visualcomplexity#Visualconsistency#Visualaccessibility#visualsignals

0 notes

Text

How to implement Visual Management in your organisation?

Visual management helps teams to comprehend information quickly, pinpoint improvement areas, and enhance productivity by streamlining overall processes.

Read More: https://tcard.leantransitionsolutions.com/software-blogs-details/how-to-implement-visual-management-in-your-organisation

#lts#lean#leantransitionsolutions#tcard#Tcardsoftware#tcardsystem#DigitalTCard#visualmanagement#visualcontrol#andon#5s#5sboards#5ssystem#kanban#kamishibaiboards#huddleboards#kanbanboard#kanbansystem#thehuddleboard#visualmanagementtechniques#visualmanagementtools#visualmanagementboard#visualmanagementsystem#leanvisualmanagementboard#visualworkflowmanagement#visualmanagementinleanmanufacturing#principlesofvisualmanagement#typesofvisualmanagement#benefitsofvisualmanagement

0 notes

Text

Cellular Manufacturing: A Lean approach to Production Process

Cellular manufacturing reduces waste and increases productivity by eliminating non-value-added activities like excess inventory, transportation, and waiting time.

Read More: https://tcard.leantransitionsolutions.com/software-blogs-details/cellular-manufacturing-lean-approach-to-production-process

#lts#lean#leantransitionsolutions#tcard#Tcardsoftware#tcardsystem#DigitalTCard#cellularmanufacturing#leanmanufacturing#leanproduction#justintime#grouptechnology#manufacturingcells#onepieceflow#flowmanufacturing#productionefficiency#wastereduction#workforcedevelopment#qualitycontrol#customersatisfaction#productivity#competitiveadvantage#businessgrowth#industry40#digitalmanufacturing#smartmanufacturing#automation

0 notes